Determine the Age of a Building

Determine the Age of a Building

Age of building components, public records,

& visual clues

Home Page & Article Index

- POST a QUESTION or COMMENT about how to determine the age of a building or home or its components & systems

How to find the age of a building:

How old is my house?

This article series provides a photo guide to determining the age of a building by examination of the architectural style of construction or the building materials and components that were used in the structure.

Here we list some helpful clues to answer the question "how old is the house?" and we provide photographs of key visual clues useful for determining the age of a building.

The age of a building can be determined quite accurately by documentation, but when documents are not readily available, visual clues such as those available during a professional home inspection can still determine when a house was built by examining its components, building materials, even nails, fasteners, and types of saw cuts on lumber.

Our page top photo shows the 1840 Justin Morrill Smith Historic house in Vermont.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

List of Visual & Documentary Clues to Building Age

How to determine the age of a building - Building component age: construction materials, methods, including hardware, saw cuts, and other details can help determine when a building was constructed or when it was modified.

How to determine the age of a building - Building component age: construction materials, methods, including hardware, saw cuts, and other details can help determine when a building was constructed or when it was modified.

Visual & Other Clues Tell Us Building Age or the Age of its Components & Systems.

[Click to enlarge any image]

Visual clues pointed out by a home inspector or available to any careful building inspector can help indicate the age of a building.

Article series contents

- AGE of a BUILDING

- AGE of HEATERS, BOILERS, FURNACES

- ANTIQUE FLUSH TOILETS

- BUILDING RECORDS

- CHIMNEYS & FIREPLACES, Age, Types

- DOOR HARDWARE AGE

- ELECTRICAL COMPONENTS, AGE, TYPES

- ELECTRICAL PANEL AGE - decode the data tag serial number

- FOUNDATION MATERIALS, Age, Types

- FRAMING MATERIALS, Age, Type

- FRAMING METHODS, AGE, TYPES

- HOPPUS MEASURER

- HEATER, BOILER, FURNACE Age

- HOME CONSTRUCTION CATALOGS 1950

- INSULATION MATERIALS, Age, Types

- KIT HOMES, Aladdin, Sears, Wards, Others

- NAILS & HARDWARE, Age, Types

- OLD ELECTRICAL WIRING TYPES

- OLD HOUSE MYSTERIES & SOLUTIONS - what's that strange thing?

- PLUMBING MATERIALS & FIXTURE AGE

- ROOFING MATERIAL AGE vs BUILDING AGE

- WINDOW HARDWARE AGE

- WATER HEATER AGE & MANUALS

Clues to building age include these examples which we expand and detail in text and articles below.

- Architectural style, decorations, trim, building components - our introductory material is

at ARCHITECTURE, STYLE, & BUILDING AGE.

For detailed guides, see the detailed architectural building component identification articles listed under:

ARCHITECTURE & BUILDING COMPONENT ID - BUILD YOUR DREAM HOME - details of modest home construction in the U.S. in the 1950's, how-to text, drawings, materials lists, materials prices

- Building material types (shiplap siding, cement asbestos shingle siding, aluminum siding, vinyl siding, plywood vs. tongue and groove sheathing, even types of brick.

See SIDING MATERIAL & AGE

and

See FLOORING MATERIALS, AGE, TYPES, etc (listed below).

and

See OLD HOUSE MYSTERIES & SOLUTIONS for an example of re-use of industrial materials as building roof sheathing. - CELOTEX CemestO BOARD HOMES 1940s

- CHIMNEYS & FIREPLACEs, AGE, TYPES chimney construction, type of mortar used, materials;

also see CHIMNNEY ARCHITECTURAL STYLES - PHOTO GUIDE - DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- ELECTRICAL COMPONENTS, AGE, TYPES electrical wiring, different wire types and generations of wire, fuses, circuit breakers, panels, etc.

- ELECTRICAL PANEL AGE - decoding the data tag in an electrical panel serial number

- OLD HOUSE ELECTRICAL SYSTEMS describes older generations of electrical wiring

- FLOOR TILE HISTORY & INGREDIENTS - history of asphalt floor tile, vinyl-asbestos floor tile, dates, ingredients, manufacture

- FLOORING MATERIALS, AGE, TYPES wide board wood, strip flooring, pre-finished flooring, vinyl flooring, ceramic tile floors, vinyl-asbestos tile floors, "linoleum", carpeting, etc.

- FOUNDATION MATERIALS, Age, Types, such as use of brick, stone, wood, concrete block, poured concrete

- FRAMING MATERIALS, AGE, TYPES, lumber width and edge finish of wood boards in various uses, interior trim, and

- FRAMING METHODS, AGE, TYPES, Construction and framing methods such as post and beam, presence or absence of a ridge board, balloon framing or platform framing

- FRAMING AGE, SIZE, SPACING, TYPES logs, hewn timbers, full-sized dimensional lumber, modern dimensional lumber, trusses, web trusses, panelized construction, etc.

- HEATING EQUIPMENT AGE, TYPES, such as mechanical systems and plumbing materials; presence of gas piping, style of fireplace

- HOPPUS MEASURER - early carpentry & construction measurement guides & tools, history, photos, & excerpts from Hoppus's Measurer

- INSULATION MATERIALS, AGE, TYPES when did builders first no insulation, or use brick, corn cobs, newspaper, mineral wool, rock wool, vermiculite, fiberglass, chopped fiberglass, cellulose, foam board and spray foam insulating products?

- NAILS, AGE & HISTORY Construction fasteners, nails, screws, the use of treenails or pegs in post and beam framing, and fasteners such as roofing nails and screws used, hardware: window and door hardware, hinges, doorknobs, door pulls, latches

- DRYWALL, FIBERBOARD, PLASTER INTERIORS what did we use on building walls before drywall and paneling? Ages and eras of plaster, plasterboard, wood lath, metal lath, etc.

- PLUMBING MATERIALS & FIXTURES, AGE, TYPES such as lead and clay pipes, orangeburg pipe, cast iron, galvanized iron, PVC and ABS plastics

- ROOFING MATERIALS, AGE, TYPES, asphalt shingles, stone roofs, slate roofs, tile roofs, wood shingle and shake roofs, built up roofing ("tar and gravel roofs"), modified bitumen roofs, EPDM and other membrane roof coverings

- SAW & AXE CUTS, TOOL MARKS, AGE, hand hewn adze marks or even the type of saw cut marks on framing lumber

- SEARS KIT HOUSES and also LOG HOME GUIDE for examples of pre-cut and kit homes.

- SIDING MATERIALS, Age, Types

- WINDOWS & DOORS, Age, Types

- And many similar details are available to the careful eye.

Keep in mind that even when we can identify specific types of building materials and building methods, precise dating of the time of construction of a building remains difficult: old building materials were often re-used, so beams, siding, and other components may appear in a building built later than when the materials were first made.

Also, in the U.S. various states had machines for making cut nails, screws, and sawmills at different times. For example, New York State was industrialized earlier than some western or southern states, so machine-made nails appear earlier in New York than elsewhere.

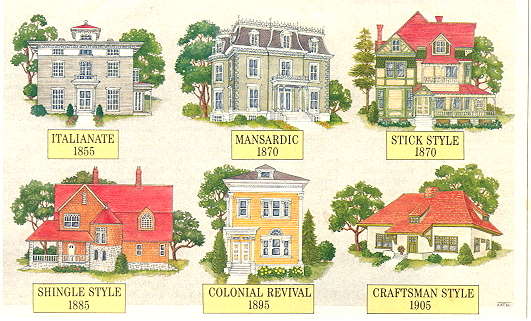

Photo Examples of Architecture & Style Providing Typical Dates of Construction

While building architectural styles such as "Victorian" continue to be built into the present, the combination of a recognizable architectural style with an inspection of the building materials which have been used provide considerable information about the age of a home as well as its history of changes and additions.

See ARCHITECTURE, STYLE, & BUILDING AGE for photographs of buildings in North America and Europe demonstrating various architectural styles and dates.

Guide to Using Building Records to Help Determine the Age of a Building

This article explains and list examples of source of public records that can help determine the age of a building.

Because the office where building records are held will vary by name and municipal authority, the exact name and location of building records in your community will vary from those examples shown here.

Sources of public records to assist in determining the age of a building

- As suggested by reader Kathy Bohon, call your county Recorder of Deeds and inquire when the property was placed on the tax rolls. The date of construction can be 1-3 years prior or in some cases, much earlier if records are incomplete.

- Local town, county, or even state or provincial (in Canada) tax records may indicate the original date of construction of a building

- Historical records containing real estate listings include indications of building age

- Census records can indicate that a building was present at a particular address at the time the census was taken.

- Papers found in the building itself, its archives, will often indicate when the building was present.

- Notes and annotations written on the building itself may indicate dates of its age or modification. When we renovated a neo-victorian house in Poughkeepsie, New York we found, on removing aluminum siding, that the siding installers had written their names and the year that the siding was installed (1960).

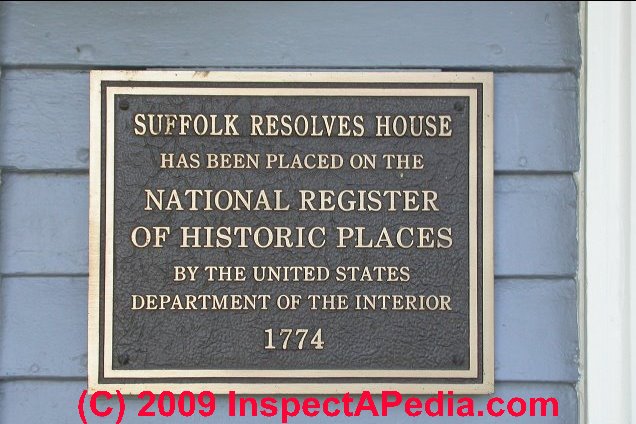

- Historic homes that are in a national, state, or local historic register may include a plaque (photo above left of the Suffolk Reserves House of 1774) as well as extensive documentation in local historical records.

The Suffolk Resolves house (located in Milton, Massachusetts and placed in the National Register of Historic Places in 1973) whose plaque is shown above documents the Suffolk resolves, a statement of colonial animosity, signed 9 September 1774 and ultimately leading to the United States Declaration of Independence from Great Britain in 1776. Such a home is of course well preserved and documented.

Some examples of conditions that confuse dating the age of a home include

- The original home may have been substantially modified, renovated, or a large addition may have been built abutting or even overlaying the original structure.

- The home may have been brought to its present site from another location.

- The home may have been built on the site of an earlier structure of which no components remain, or sometimes, portions of the foundation of the original structure may be in place but nothing else, for example after a major fire.

Readers are welcome to Contact Us by email to suggest other locations of records that help document the age of a building and the date of its original construction.

Chimneys & Fireplaces as Indicators of Building Age

Here is a photograph of an unlined single wythe brick chimney on an 1856 home in New York State.

The location, size, shape, building materials, and use of chimneys on buildings offer good details aiding in estimating the age of a building.

These details can also indicate where additional safety inspections or perhaps repairs or updating are needed for safe use of a chimney, fireplace, building heating system, or wood stove.

CHIMNEY MATERIALS vary among none (a hole in a roof), brick, stone, masonry block, metal flues, insulated metal chimney flues, and wood-framed metal flues on buildings.

Three different colonial era homes were common in America.

- Early homes of one room included a chimney at one end.

- Second were homes that had a chimney at either end, consisting of two rooms with (or without) an entry between them.

- The third group used a central chimney placed between the two rooms and provided a fireplace in each room. Earliest of these homes were only one-room deep; later they grew to two rooms deep. -- Isham.

Building Age from Dates on Chimney Components

Look for product names and / or dates cast into masonry or metal chimney components. Especially if the component is likely to be original to the building, the date and history of that part can set an "earliest likely" date for the home.

Look for product names and / or dates cast into masonry or metal chimney components. Especially if the component is likely to be original to the building, the date and history of that part can set an "earliest likely" date for the home.

For example, the Richardson & Boynton Co. cast iron chimney cleanout door shown here was observed at a Vassar College home (79 Raymond Ave.) in Poughkeepsie, New York.

It isn't likely that this chimney cleanout door was manufactured before the year cast into its cover: 1888. Richardson & Boynton Co. was a manufacturer of heating equipment and hardware, particularly boilers, furnaces, and stoves.

The company was founded in Brooklyn New York in 1837 and was one of the largest employers in Red Hook Brooklin from about 1850 until the company moved to Dover, New Jersey in 1896. So we know this chimney cleanout was made in Brooklyn and found its way north to Poughkeepsie.

[Historical details of Richardson & Boynton Co. are at various sources including this website: http://maggieblanck.com/BrooklynRedHook/RichardsonBoynton.html - Ed.]

Research excerpt from the company's trade catalog:

"Perfect" hot water warm air heaters for hard and soft coal, wood, gas, and oil ; late 1800's and early 1900's cover design and typeset ; cooking and french ranges ; steam-vapor and hot water boilers ; "R&B" ; laundry water heaters and stoves ; air conditioning units ; warm air heating systems ; radiators ; "Blue Streak" ; "Blue Comet" ; "Newport Magazine Feed" ; sectional and hot blast smokeless boiler series ; vapor-vacuum-pressure heating systems ; "Baltimore" fire-place heaters ;

Details about this very chimney cleanout as well as about inspecting the condition of chimneys, flues, fireplaces, woodstoves are

and

at CHIMNEY INSPECTION DIAGNOSIS REPAIR

Doors & Door Hardware as Indicators of Building Age

Details about doors and examples of how they can help determine the age of a building are

at DOOR HARDWARE AGE

Electrical Components as Indicators of Building Age

Here is a photograph of an obsolete 30-Amp electrical meter and fuse panel, ca 1935.

While varying somewhat by area of the country in the U.S., Latin America, Europe, and other areas, there are recognizable generations of electrical wiring such as

KNOB & TUBE, greenfield, armored cable

or "BX WIRING" wiring using a metallic shield or "armored cable),

or "NM/ NMC WIRING, and other electrical wiring materials (copper, tinned copper, aluminum, copper-plated aluminum), and also, easily recognized generations of electrical meters and electrical service panels.

In a series of detailed articles listed

at ELECTRICAL COMPONENTS, AGE, TYPES we illustrate various of these materials and products and we provide information about their safety or about the need to inspect or perhaps replace or upgrade certain problem equipment.

Flooring Materials as Indicators of Building Age

Please see our full-text articles on types and eras of use of various building flooring materials found in the articles listed under:

FLOORING MATERIALS, AGE, TYPES

Abbreviated comments on some flooring types are also found just below. In some cases, floor covering such as carpets and tiles have been in use for thousands of years.

If we comment on these materials it is to identify certain modern variations such as ceramic bath or wall tiles that are purchased pre-glued to a mesh backer to speed tile placement. But in general we focus on flooring materials that have special properties, ability to date the era of their use, or environmental concerns.

Various types of flooring and the inspection, diagnosis, and repair of flooring defects are discussed

at FLOOR TYPES & DEFECTS.

Types of building flooring that contain asbestos, a health and environmental concern, are discussed in detail at ASBESTOS FLOOR TILE IDENTIFICATION.

List & History of Resilient Floor Coverings Used in buildings

Resilient floor coverings include organic flooring materials such as asphalt tile, cork tile, linoleum, rubber flooring, vinyl tile, vinyl sheet flooring.

See

- CORK FLOORING

- FLOOR TILE / SHEET FLOORING PHOTO GUIDES

- FLOORING MATERIALS, AGE, TYPES

- HISTORY & INGREDIENTS of FLOORING

- LINOLEUM & OTHER SHEET FLOORING

- LINOLEUM & SHEET FLOORING FAQs

- RESILIENT SHEET FLOORING ID GUIDE

- RESILIENT VINYL or CORK FLOOR

- SELF-STICK TILES, ASBESTOS

- SHEET FLOORING, VINYL ASBESTOS

- SHEET FLOORING INSPECT / TEST

- WHITE SHIELD® BACKING ASBESTOS in FLOORING

Asphalt Tile Flooring as an Indicator of Building Age - 1920 - 1960 (est)

In 1920 asphalt roofing manufacturers, who had been using asphalt and fiber binders to make asphalt roofing shingles for some time, tried to develop a rigid product that could be a substitute for (more costly) slate roofing.

The material did not perform acceptably as a roof covering, but it led to the development of asphalt floor tiles.

Asphalt floor tiles are 9" square (or other sized) tiles which used asphalt as the main binding material. the original asphalt tiles were produced only in dark colors because asphalt was a main ingredient.

Rosato indicates that the first publicized asphalt tile installation was in 1920 in New York City's Western Union office.

The product was very successful and by 1936 over four million square yards of asphalt floor tiles were being sold annually. By 1940, 5% of floor coverings sold in the U.S. were asphalt tile. -- Rosato

If you encounter black or very dark asphalt floor tiles they are probably very high in asbestos fibers. We discuss floor tiles as an asbestos fiber source in buildings in more detail

at ASBESTOS FLOOR TILE IDENTIFICATION.

Cork Flooring Tiles as an Indicator of Building Age -

Cork floor tiles were considered a warm, quiet, but less durable resilient floor covering than some of its competitors.

It was sold often for use in residential dens, family rooms, or other warm, low-traffic areas, and it may have been popular (research needed) for use in areas where workers had to spend long periods standing - where it would have competed with rubber floor coverings. In 1952 cork flooring sales made up 2% of total floor tile sales. -- Rosato p88.

See CORK FLOORING

Vinyl Asbestos Floor Tiles as an Indicator of Building Age - 1930 - 1976 (est)

Vinyl floor tiles, including vinyl-asbestos floor tiles and homogenous vinyl floor tiles (non-asbestos product) are almost as old as asphalt floor tiles. By the early 1950's in the U.S. vinyl tile floor products were more popular than asphalt-based flooring. The reason is pretty obvious.

Asphalt-based flooring as it was originally produced used heavy asphalt products which meant that the floor tiles could be made in dark colors only.

Soon after asphalt-asbestos floor tiles were marketed manufacturers heard from their buyers that consumers wanted lighter floor tiles and tiles of varying color and pattern.

Organic resin vinyl increased in popularity for this reason, but slowly. By 1952, the production of vinyl plastic floor tile sales in the U.S. was about half the volume of asphalt floor tiles, selling 35 million square yards.

Microphotographs of vinyl-asbestos floor tiles can be seen at our article

at ASBESTOS FLOOR TILE IDENTIFICATION. -- Rosato

Sheet Flooring Materials That Indicate Age of a Building

Here is a photograph of an early (pre-vinyl) continuous floor covering, ca 1900, in an 1840 historic Vermont house.

Note the fabric backing of the flooring material. This article explains various common flooring materials (rough wood, finished wood, parquet, carpeting, linocrusta, sheet vinyl, and other items as they assist in determining The age of a building or other building.

See RESILIENT SHEET FLOORING ID GUIDE -

and see SHEET FLOORING INSPECT / TEST

Linoleum Sheet Flooring As an Indicator of Building Age - 1890 - 1960 (est)

According to Rosato, "The original resilient floor coverings were developed during the latter part of the Nineteenth Century by Frederick Walton. The original covering was linoleum for use as a floor decking on British naval ships."

The composition of the original products included asphaltic binders to which an asbestos filler was added by mixing on a rubber mill.

List of Non-Resilient Floor Coverings Used in buildings

Non-resilient floor coverings used in buildings that can assist in determining the age of a structure include bamboo, brick, concrete, stone, and a wide variety of wood products.

See NON-RESILIENT FLOORING as well as the following:

- CERAMIC TILE FLOOR, WALL

- ENGINEERED WOOD & LAMINATES

- LAMINATE PLASTIC FLOOR

- STONE, GRANITE, MARBLE, AGGLOMERATE

- TILE FLOOR INSTALL on CONCRETE

- WOOD FLOOR AGE TYPES HISTORY

- WOOD FLOOR ENGINEERED & SOLID

- WOOD FLOOR ENGINEERED, REPAIRS

Determining the Age of buildings Using Laminate Flooring Products

Contemporary snap-together flooring products that resemble wood or other surfaces, but are made of plastic, and other pre-finished and ready-to-assemble wood flooring products are a much more modern product.

Sadly the laminate floor shown at left was ruined by a building flood. Pressure from expanding materials absorbed both the original free space around the floor perimeter and added enough force to buckle the flooring up at the center of the room.

Pergo™ laminate flooring, for example, was developed by Pergo AB, a Swedish company founded around 1890 as a vinegar manufacturer.

Product development for Pergo laminate flooring began in 1977 and was first brought to the market in 1984. Pergo laminate flooring was first sold in the U.S. in 1994.

See

Foundation Materials as Indicators of Building Age

Foundation materials commonly used for buildings include:

- Wood, beams set on grade or on flat stone set on or close to ground level

- Stone, natural found on site or brought to the building site

- Brick, less commonly used below grade, more often used from grade-level up, set on stone below grade.

- "Cinder blocks" or concrete blocks

- Poured concrete

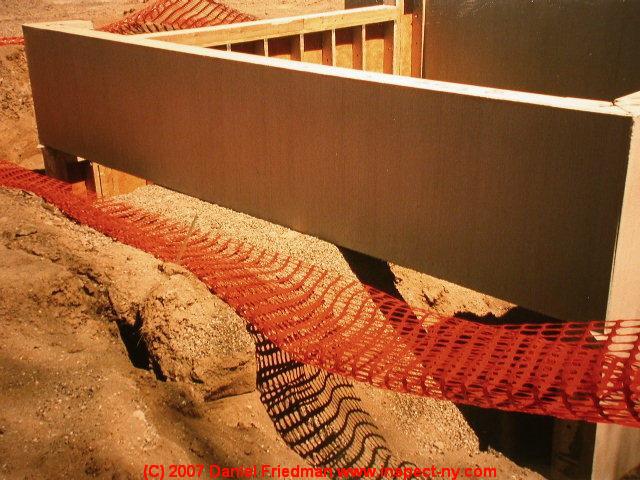

- Pre-fabricated concrete foundation sections assembled onsite (photo at left)

- Wood, treated lumber, treated plywood on treated wood or on concrete studs

In evaluating the probable age of a home when inspecting its foundation, we consider the foundation materials and style of workmanship.

A photograph of a buckling, damaged stone foundation on an 1864 structure in Rhinebeck, NY is shown at left.

A building's foundation materials and style of construction, stone, wood, brick, masonry block (at least two different generations), and poured concrete (various generations and methods including hand-built and by machine and pumper truck) can give considerable information about the foundation age.

On occasion we'll find a very old structure which has been moved and re-set on a new concrete or concrete block foundation, adding more historical information to the home.

All of the common building foundation materials, how they fail, how they are inspected, are discussed

at FOUNDATION DAMAGE REPAIR GUIDE.

Reader Comment: rock-faced or patterned concrete block foundation age

The foundation material below the house in the middle of the main structure is limestone with mortar. The outside is rock faced block with "rope(?) joints" (Photo shown here)

The foundation material below the house in the middle of the main structure is limestone with mortar. The outside is rock faced block with "rope(?) joints" (Photo shown here)

[Click to enlarge any image]

The main house is all on crawlspace, with only the kitchen having a root cellar below it. - by private email 2020/07/11

Moderator Comment: first use of decorative or faced concrete block foundations & walls in the U.S.

RE: " The outside is rock faced block with "rope(?) joints" (pic) "

Those look like form-cast concrete blocks - if so that's a later foundation material, possibly 1920s to 1960s.

I'd look for evidence the foundation was repaired, rebuilt, modified.

Reader Comment: Rock-faced block foundations dating in the 1880s?

In this region, there are numerous houses with rock faced block foundations known to have been built in the 1880s.

Just pulled a lock off of the basement door. Looked up the mark; Russell & Erwin. Dates to between 1846 & 1851. Looked like it has been there forever, having even dropped 3/4 of an inch from its keeper, just like the door it came off has!

Who knows when the core structure of this place was built!

Moderator reply:

All of the formed faced or decorative-pattern concrete block homes I've inspected were newer.

But I'm puzzled about how the home foundations you cite could date between 1846 & 1851.

Perhaps citing some research we can understand the early history of use of concrete block foundations and decorative-stone-faced concrete blocks in North America and elsewhere.

[Click to enlarge any image]

The earliest patent I've found for finished stone faced concrete block is Ransome, Patent No. 405800, in 1889.

A second earliest patent I found for finished block faces was by Wight in 1906 though of course there would have been versions before his patent, and my search was not exhaustive.

From sources I've read, the first widespread-use of hollow-core concrete blocks date from about 1890. Ransome's decorative-faced concrete blocks date from 1889; in the U.S. - Harmon S. Palmer didn't patent his concrete block production machine design until 1900.

The product was a tremendous success, such that within 5 years of that patent there were many companies producing such blocks. Some of my early research in New York included talking with (now deceased) Henry G. Page (Poughkeepsie) who started a construction business after WWI by making his own concrete blocks.

Henry's blocks were a topic of some discussion among inspectors because his hand-mixed portland cement was sometimes a bit light on the portland, and the blocks, after a few decades, were rather crumbly. Henry and other block manufacturers used a hand-casting machine - it was very labor intensive.

His blocks were set up on the family farm property on Rte. 55 - now a pit, partly dug by soil he used for his block-concrete mix.

Portland cement, critical in the fabrication of concrete blocks, dates from 1824 in England (Joseph Aspdin). So concrete blocks could pre-date the sources I've found to date.

Research on the History of Concrete Blocks & Finished-Face Concrete Block Walls & Foundations

- Fenner, Miner E. "Concrete construction." U.S. Patent 901,798, issued October 20, 1908.

- Koski, John A. "How Concrete Block Are Made." Masonry Construction, October 1992, pp.374-377.

- Mattson, Albin F. "Tunnel-lining of reinforced concrete blocks." U.S. Patent 830,345, issued September 4, 1906.

- Mueller, John. "Mold construction for concrete walls." U.S. Patent 936,798, issued October 12, 1909.

- Palmer, Harmon S, CONCRETE WALL for BUILDINGS [PDF] U.S. Patent 674,874, issued May 28, 1901.

This patent was applied for 1900-03-21 - Ransome, E.L., FINISHING CONCRETE AND ARTIFICIAL STONE SURFACES US Patent No. 405800, June 25, 1889, illustrated above on this page.

Excerpt:

MIy invention relates to the treatment of wall and other surfaces made of concrete; and it consists in giving these surfaces a close imitation to natural stone by first placing projections upon the inner surfaces of the molds or cribos, to form corresponding re cesses in the surfaces of the concrete for the imitation joining, either with or without bor ders, and Subsequently, when the mold is removed, in finishing off said joints or borders by floating in cement or in any of the well known ways, and finally removing the pro jecting surfaces of the wall between such joints and borders either roughly or regularly, SO as to imitate the Various finishes of natural Stone. - Rice, Harmon Howard, and William M. Torrance. The Manufacture of Concrete Blocks and Their Use in Building Construction. New York: Engineering News, 1905.

- Seamans, Edward W. MOLD for CONCRETE BLOCKS [PDF] U.S. Patent 720,536, issued February 10, 1903.

[Below: Seaman's patent for concrete block forming molds]

- Schierhom, Carolyn. "Producing Structural Lightweight Concrete Block." Concrete Journal, February 1996, pp. 92-94, 96, 98, 100-101.

- Sicklesteel, Frank Abram, and Charles Wesley Ballard. "Mold for concrete blocks." U.S. Patent 737,032, issued August 25, 1903.

- Tubesing, William F. "Machine for making concrete blocks." U.S. Patent 868,730, issued October 22, 1907.

- Yeaple, Judith Anne. "Building Blocks Grow Up." Popular Science, June 1991, pp. 80-82. 108.

- Wight, George C., and Theodore V. Galassi. FINISHING the FACES of CONCRETE BLOCKS U.S. Patent 837,165, issued November 27, 1906.

Excerpt:

Our invention relates to the construction of concrete blocks and producing upon the surface of such blocks a representation of a granite finish.

Framing Materials as Indicators of Building Age

- Logs, various sizes, chopped, dried, assembled at the building site

- Hand hewn beams, chopped and then sized with an adze and axe. Adze cuts and axe cuts are normally visible in the rough surface of hand hewn wood structural beams.

- Full-sized 2"x4" (or larger 2 x n") wood framing materials

- Modern wood framing wall studs 2x4's (3.5" x 1/5") and larger members (x" deep by 1.5" thick)

- Glulam beams; large timbers are built-up of laminated wood strips

- Tongue and groove wood subflooring, wall sheathing, roof sheathing

- Plywood subfloors, wall sheathing, roof sheathing

- Oriented-strand board subflooring, wall sheathing, roof sheathing -

see OSB

Here is a photograph of post and beam framing with joint number markings.

The observation of framing materials, framing markings, and framing styles provides considerable information about the probable age of a house.

We discuss framing materials and styles here as an aid to house age determination.

Also see our article

on SAW CUTS & TOOL MARKS

Log framing and both modern and antique log construction are discussed

Antique and modern trusses are distinguished and modern laminated beams and I-truss beams and wood joists are discussed.

Framing Methods as Indicators of Building Age

Common wood structure framing methods include the techniques described below, arranged alphabetically, not by age.

For the full text articles on this topic please see

Below we provide abbreviated discussion taken from the full-text articles listed above.

Arkansas framing system: 2x6 wall studs are spaced 24' on center, a spacing that permitted installation of more wall insulation volume than provide by conventional 2x4 wall studs.

The Arkansas building framing method became popular in North America following the 1970's arab oil embargo and addressed concern for high energy costs.

Balloon Framing Construction Method Description

For full details see our full text article

at FRAMING METHODS, AGE, TYPES and BALLOON FRAMING

Tall wall studs run from the sill plate atop the foundation wall to the top plate below the building rafters. Wall studs and first floor joists rest on the building sill plates (flat wood members set atop the building foundation). The wall studs extend from the first floor sill to a height sufficient to frame both the first and second floor walls.

First floor joists and second floor joists are framed by nailing to these tall wall studs at the appropriate heights. Rafters attach to the top plate of the building walls. Ceiling joists for the top floor are nailed to the sides of the balloon-framed wall studs just as the floor joists were nailed below.

Glulam Beam Construction, Description, History

(In process, contributions invited). For full details see our full text article

at FRAMING METHODS, AGE, TYPES and Glulam Beams

Log Home Construction Methods Defined & Described

For full details see our full text article

at FRAMING METHODS, AGE, TYPES and Log Home Construction

(1640 - est U.S.): solid logs usually felled and prepared at or close to the building site, set on ground level, on flat stones on ground, or on a stone foundation, corners joined using various notch and overlap methods. See Log Home Guide.

Modular Construction Methods Defined & Described

For full details see our full text article

at FRAMING METHODS, AGE, TYPES and Modular Construction

Modular construction (1910 - present) was first provided on a large scale with Sears Kit homes that were distributed from about 1910 to 194o0 -

see HOW to IDENTIFY SEARS & OTHER KIT HOMES

Some modern modular homes built in the U.S. during the 1950's post war building boom originally enjoyed a less than stellar reputation several decades ago, having the reputation of flimsy construction.

That is no longer the case. Since at least the 1980's a modular home is constructed in a factory of one or more sections which are carried to the building site on a trailer (photo above left) and lifted by a crane to be set upon a foundation which has been prepared ahead of time.

Modular homes can be quite large, involving four or quite a few more individual sections which are lifted and "set" into place at the site (photo at left)

Some manufacturers provide custom architectural services and can deliver unique, but factory-built homes in sections.

Nails, Screws & Similar Hardware as Indicators of Building Age

Details about nails and similar hardware and examples of how they can help determine the age of a building are

at NAILS & HARDWARE, Age, Types

OSB - Oriented Strand Board Used in Building Construction, History, Description, Identification

For full details see our full text article

at FRAMING METHODS, AGE, TYPES and OSB

Panelized Building Construction Defined & Described

For full details see our full text article

at FRAMING METHODS, AGE, TYPES

Panelized construction: floor and wall panels constructed in a factory are delivered to and assembled at the building site.

Panels may be conventionally-framed stud walls in modular sections or structural panels may be constructed of a sandwich of OSB (oriented strand board), plywood, or wafer board on either side of solid foam board insulation.

Panelized construction makes use of wall, floor, ceiling or roof "panels" which have been framed off-site and brought to the site by truck. Panels are lifted into place by crane and fastened together on a foundation, and possibly a framed-in floor which have been prepared before the panels arrive.

Some framing panels make use of special materials, such as plywood and foam roof panels for insulated cathedral ceilings.

(In process, contributions invited).

Plank House or Box Construction Method Defined & Described

For full details see our full text article

at FRAMING METHODS, AGE, TYPES

and PLANK HOUSES

1880 - 1920 estimated, with some plank house construction continuing up to possibly 1950. Plank houses were constructed entirely of sawn planks and without the use of larger dimensioned 2x lumber.

Some of the plank houses we've inspected were made from scraps or salvaged lumber such as a home in Dutchess County New York that was constructed from packing crate wood. Larger collections of plank houses were built as company housing in the mining or railroad industries.

(In process, contributions invited).

Platform Framing Construction Method Defined & Described

For full details see our full text article

at FRAMING METHODS, AGE, TYPES

and PLATFORM FRAMING

The platform frame construction method, also called western construction is the most-common residential wood structure framing method in North America. A floor is constructed atop of the building foundation, forming the first "platform", using the platform as a working surface.

Plywood Used in Building Construction, History, Description, Identification

For full details see our full text article

at FRAMING METHODS, AGE, TYPES

and PLYWOOD.

Also see FIRE RETARDANT PLYWOOD.

Plywood (1905 - present as a construction material in North America) is sheet material made of thin veneers of wood that are laid with wood grains in alternating direction, glued, heated, and pressed together. Interior plywood is generally glued with urea formaldehyde based glues; exterior plywood and marine plywood use phenolic formaldehyde glues and are water resistant.

The cross-grain construction combined with glue produces a strong, uniform material that is used for both enclosure and for structural stiffness in frame construction of building walls and roofs.

The properties of plywood, including its tolerance to weather exposure (marine plywood) depend on the glues and finishes used. Both softwood and hardwoods are used in plywoods, and fine wood veneer finishes are also available (for furniture use).

Also see Oriented-strand board subflooring, wall sheathing, roof sheathing -

Post & Beam Construction Method Defined & Described

Photo above: half timbered home in Norway, photographed by the author in 2008.

For full details see our full text article

at FRAMING METHODS, AGE, TYPES

Post and beam construction (1700 - est. in North America): (timber framing) uses horizontal and vertical timbers that are connected (joined) using mortise and tenon joints pinned with wood pegs (treenails).

Timber frame construction initially used hand hewn beams, later manually or mechanically sawn beams cut by a pit saw.; Later timber frame beams were sawn in mills using circular saws.

Timber framing using post and beam construction with mortise and tenon joint connections was used in Europe for at least 500 years before it was first employed in North America.

By 1650 a typical timber frame building used multiple bents and girt beams, may have been more than one story tall, and included an exterior made of horsehair-reinforced cement stuccoed over hand-split lath. Our photo (above) shows an 18th century Norwegian timber frame building using brick infill and stucco to complete the wall enclosure.

Welded Wire Sandwich Framing Panelized Construction

Welded-wire sandwich framing panels: polystyrene or polyurethane foam core insulation is surrounded by a welded-wire space frame.\

For full details see our full text article

at FRAMING METHODS, AGE, TYPES and Welded Wire Sandwich Framing

Wood Framing Spacing & Framing Member Actual Dimensions can indicate building age

For full details see our full text article

at FRAMING AGE, SIZE, SPACING, TYPES

- non-standard wood framing spacings, typically in post and beam or hewn beam frame construction

- 14" spaced wooden stud framing - early balloon framing

- 24" spaced wood stud and wood rafter framing, based on a 24" module - all framing, wall studs, floor joists, roof rafters are spaced 24 inches on center. See Arkansas framing above.

- 16" spaced wooden wall stud and wooden roof rafter or wood roof joist framing

Heating Equipment as Indicators of Building Age

Indoor heating methods by historic periods or years:

See AGE of HEATERS, BOILERS, FURNACES - describing the determination of age & properties of heating equipment, boilers, furnaces by decoding data tags. Where there are special safety or maintenance concerns for certain systems we cite those as well.

- Central fireplaces, no chimneys

- Indoor fireplaces, chimney in building or on exterior building wall

- Free-standing wood-burning stoves, the Franklin Stove

- Coal burning free-standing stoves;

- Kerosene stoves

- Coal fired octopus furnaces and steam boilers

See OCTOPUS FURNACES - Oil burners: different types of oil burners, coal conversions, low speed, high speed, high efficiency

- Oil-fired furnaces, hydronic (hot water) boilers, steam boilers

See STEAM BOILERS

HOT WATER BOILERS - Gas-fired furnaces, boilers, steam boilers

- Electric furnaces and heating boilers

- Geothermal hot water heating systems (e.g. in Iceland)

- Heat pumps -

see AGE of AIR CONDITIONERS & HEAT PUMPS - how to read data tags to decode the age

Above we show a photograph of an "octopus heating furnace", originally coal fired, usually by now (if still in use) converted to natural gas fuel.

These octopus furnaces, also called "gravity heating systems" provided heat by natural convection, hot air rising into the building from the top of the furnace where it was delivered to the building first floor through a wood or iron grate, or perhaps delivered through metal ducts.

The original installation usually supplied heat to a home through a central grate in the first floor of the building from where warm air might rise to upper floors.

Later versions or modified original systems

added ducts to individual rooms, sometimes still only on the first floor of the building.

These furnaces are the ancestor of modern forced hot air heating systems.

This article series describes the properties, installation, troubleshooting & repair of all types of heating systems and heating system fuel types

(coal, oil, gas, wood, solar, electricity) as an aid in determining the age of a home or other building.

Also see WATER HEATER AGE & MANUALS

Insulation Materials as Indicators of Building Age

Insulation materials used in buildings includes:

- Nothing - no insulation - solid log walls, solid stone walls, providing thermal mass. Chinking or other methods used to reduce air leakage were the principal energy savings or comfort detail applied; adobe and concrete construction.

Also see ADOBE CONSTRUCTION. - Air - open cavities in wood framed walls; a small 1" air gap is also found in older structural brick walls; the air gap in brick walls was intended to avoid transmission of moisture from outside the building to its interior.

- Silage or corncobs used as wall insulation

- Paper, newspaper, rags used as wall insulation

- Brick, masonry, as wall cavity fillers to block air leaks and provide thermal mass -

see BRICK LINED WALLS as building insulation - Cotton building insulation batts -

see COTTON BUILDING INSULATION - Perlite building insulation -

see PERLITE BUILDING INSULATION - Asbestos used as insulation in buildings, generally on heating pipes (corrugated asbestos paper lengths wrapped around pipes, asbestos paste at elbows and on boiler exteriors, asbestos paper on heating duct exteriors); asbestos was not normally used as a fill material for the insulation of building cavities though we have encountered it in rare cases.

See ASBESTOS INSULATION - Rock wool or mineral wool used as building wall or ceiling insulation -

see ROCK WOOL INSULATION - Paper or foil air and heat reflective barriers used as ceiling or wall insulation in buildings

- Fiberglass batts used as building insulation - s

See FIBERGLASS INSULATION - Chopped, fire-retardant cellulose (newsprint) building insulation -

see CELLULOSE INSULATION - Chopped fiberglass building insulation

- UFFI urea formaldehyde foam insulation used as building insulation -

see FOAM SPRAY INSULATION - Foam board building insulation products: styrofoam board insulation & other foam insulating board products, paper faced and foil faced insulating boards -

see FOAM BOARD INSULATION - Insulated building panels, a wood "sandwich" of solid foam board and plywood, used primarily on building roofs

- Icynene® foam building insulation

See ICYNENE FOAM SPRAY INSULATION - Latex foam building insulation and other foam insulation products

See FOAM SPRAY INSULATION TYPES

Photo above: rock wool, or "mineral wool" in an older New York home. Note the vertical saw kerf marks (from a pit saw) on the roof sheathing boards - a clue to the age of this building.

See INSULATION IDENTIFICATION GUIDE for a catalog of building insulation materials and how to identify them.

At INSULATION MATERIAL IDENTIFICATION GUIDE we discuss various types of insulation materials (none, air gaps) and for example:

- ASBESTOS INSULATION & FIRE BARRIERS insulation and fire barriers,

- BRICK LINED WALLS

- CELLULOSE INSULATION

- COTTON INSULATION corn or corn husks, hay bales (including hay bale or straw construction),

- straw,

- newspaper,

- ROCK WOOL insulation or mineral wool,

- FIBERGLASS insulation of various colors (brands), types (batts, chopped, etc),

- PERLITE building insulation,

- UFFI and other more modern FOAM BOARD and

- FOAM SPRAY insulation materials, and the use of radiant barriers) and their common eras of usage as an aid to determining the age and history of a building.

- Health and environmental concerns and insulation effectiveness are also addressed such

- as MOLD in fiberglass insulation

- and FIBERGLASS FRAGMENTS in AIR from various sources in buildings.

See INSULATION MATERIAL IDENTIFICATION GUIDE for a catalog of building insulation materials and how to identify them.

Our photo at left shows a pre-1900 brick wall lining used as insulation and as a wind or draft block. Brick nogging can determine the probable age for the home.

Houses built between 1810 and 1900, or perhaps earlier may have brick-lined walls. I have found brick nogging in the walls of a 1790 Poughkeepsie NY home.

Bricks lining the walls of a home is an indicator of when it was built.

See BRICK LINED WALLS for a detailed, illustrated article about the use, detection, and inspection of brick lined walls in older homes were we describe and explain the reasons for and concerns with brick wall lining or "insulation" sometimes called nogging.

Nails and Hardware as Indicators of Building Age

A close observation of the type of fasteners used in a building is one of the most popular means of estimating its age.

Hand wrought nails, machine cut nails, modern round "wire" nails and other details offer considerable information about the time of original construction of a building as well as of the time of modifications to the structure.

Other framing material & hardware details can assist in determining building age. An examination of nails and fasteners and other building hardware is a complimentary effort useful in determining the age of a building and its components.

Nails, Screws & Similar Hardware as Indicators of Building Age

Details about nails and similar hardware and examples of how they can help determine the age of a building are

at NAILS & HARDWARE, AGE, TYPES

Also see SAW & AXE CUTS, TOOL MARKS, AGE for additional building age clues likely to be available when examining building framing materials.

Window Latches, Fasteners, Tracks, Window Weights, and Window Components as Indicators of Building Age

The window latch shown in our photo (above left) dates from the 1840 Justin Morrill Smith Historic house in Vermont.

Details & photo examples of window hardware and age determination details are also found

Door Hardware: latches, knobs, hinges, construction details as an indicator of building age

Above is door hardware from the Suffolk Reserves house dating from 1774.

Notice in both the door hardware photo above and that shown below that unlike contemporary passage door locksets, the knob setback distance from the door edge is considerably greater.

The photos shows the door lock hardware and the folding-down interior turn knob and key opening. On the other side of this door was a small keyhole and a white ceramic door knob.

Details about door hardware age and photo examples of door knobs, latches, hinges, and other details are

Plaster & Drywall & Other Interior Wall Coverings as Indicators of Building Age

Please see DRYWALL, FIBERBOARD, PLASTER INTERIORS where we describe and discuss the identification and history of older interior building surface materials such plaster and lath, Beaverboard, and Drywall - materials that were used to form the (usually) non-structural surface of building interior ceilings and walls.

Readers should see SHEATHING HOMASOTE & OTHER BOARD for a discussion of exterior wall sheathing fiberboard products such as Homasote® and Celotex® insulating roof, wall, and foundation board products.

A quick review and description of these materials is provided just below.

History of Plaster, Plasterboard, Drywall, Wood Lath, Metal Lath

Photograph of hand-split wood lath and plaster wall, from the wall-cavity side. Ca 1800.

There are several generations of plaster and lath, plaster board, and drywall which have been used in buildings.

We name and illustrate these and discuss their periods of use below as an aid in finding out how old a building is and tracing its history. Examples:

- Mud used as a plaster over split wood lath or woven wood lath

- Horsehair mixed with plaster or cement for building exterior wall covering

- Other versions of plaster/lath are described

at DRYWALL, FIBERBOARD, PLASTER INTERIORS

History of the Use of Wood and other Wall Paneling in North America

Wooden wall paneling - tongue and groove pine and other woods

in process

Wall paneling in 4' x 8' sheets

in process

Early colonial paneling is described by Isham.

History of Beaver Board & Upson Board Wall Coverings in North America

Details about Beaver-board and Upson Board, a wood fiber product used as an inexpensive interior wall covering and draft blocker from about 1903 are provided

at

Our photographs (below) show this product from it's back or wall cavity side.

On the exposed side this wood fiberboard product was usually painted and its joints covered with wood lath or other trim. In some applications it was covered with wallpaper. In some homes it was later covered with drywall to provide a more fire-resistant surface.

BEAVERBOARD takes its name from the Beaver N.Y. and the Beaver Board Companies that produced this product until that firm was purchased by Certain Teed Prod cuts in 1928. Beaver Board was produced by the Beaver Wood Fibre Company Limited, in Thorold, Ontario.

Beaver board's competition was from Upson Processed board (John Upson, Upson Company, Lockport, NY) which was produced beginning in 1910. As late as the 1950's Upson Board was used in prefabricated houses and exterior building sheathing and in recreational vehicles.

Upson purchased the Beaver Board plant from CertainTeed in 1955. Upson began its decline in the 1970's and closed in 1984, opening later that year as Niagara Fiberboard.

Guide to Plumbing Materials & Fixtures as Indicators of Building Age

Please see AGE of PLUMBING MATERIALS & FIXTURES for our detailed article on determining the age and life expectancy of plumbing components.

Photograph of an active gaslight found in a 1900 home in New York.

Often old gas lines have been disconnected entirely and sometimes they have been re-used to route electrical wiring to new light fixtures or to gaslight fixtures which have been converted to electric.

Don't assume that an old gas fixture or valve on a wall or found in a fireplace are inactive. We turned-on and lit this fixture which gave a bright surprise to everyone.

Watch out for "live gas" connections to supposedly abandoned gas piping and don't trust "... yeah that was disconnected years ago" unless you can see both ends of a section of abandoned gas piping in a building.

Also see AGE of HEATERS, BOILERS, FURNACES

Also see WATER HEATER AGE & MANUALS

Chart of Dates When Different Types of Plumbing Were Used in Homes

Plumbing fixtures and piping materials offer considerable age in dating a building, including easy clues such as the presence of a date of manufacture stamped into many toilet tanks to the periods of use of types of water supply piping (lead, galvanized steel, black iron pipe, copper, plastic piping) and building drain piping (lead, cast iron, copper, plastic, clay).

Often on older buildings multiple types of piping will be present as repairs and changes have been made in the building plumbing system.

Chart of plumbing types and years of use courtesy of Carson Dunlop Associates, a Toronto home inspection, education, & report writing tool company [ carsondunlop.com ].

Please see AGE of PLUMBING MATERIALS & FIXTURES for our detailed article on determining the age and life expectancy of plumbing components.

Roofing Materials as Indicators of Building Age

History and Dates of Use of Various Roofing Materials

This ROOFING MATERIALS, AGE, TYPES article explains the eras of use of different types of roofing materials as an aid to understanding the history and age of buildings.

If you are trying to determine the age and condition of a particular roof covering, find our article series for your particular roof covering material by using the on-page search function or start

at ROOFING - home

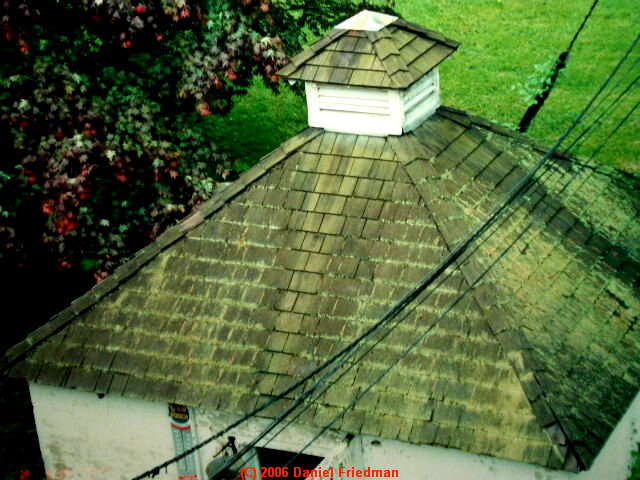

The wood shingle roof shown in the photo above is on a building in Key West, Florida, adjacent to the Hemingway house, viewed from the Key West tower.

Notice the absence of lichens on the wood shingles in the roof area below the metal-flashed rooftop tower?

Wood shingle roofing has been in use for hundreds of years in the U.S. and Europe.

But an inspection of interior and exterior roofing details can indicate the probable age of a wood roof (which can last up to 40 years) as well as the roofing history of the building, the number and types of roofing layers, and related house-age-determination details.

Cement Board & Fiber Cement Building Products

Asbestos-Cement Board & Fiberboard Products

Exterior Siding & Roofing Using Asbestos Cement included asbestos cement shingles, asbestos cement siding, corrugated asbestos-cement roofing.

See ASBESTOS CEMENT ROOFING MATERIALS

and ASBESTOS CEMENT & FIBER CEMENT SIDING

Other fiber cement materials used in construction included

Also see ASBESTOS IDENTIFICATION IN BUILDINGS and

see SIDING MATERIALS, AGE, TYPES

Modern Cement Board & Fiber Cement Products

Cement board is a non-structural building sheathing material which in its contemporary form is made from Portland cement covered with a reinforced fiberglass mesh fabric. Cement board is used as a tile backer or a backer board for stucco applications on buildings.

Current producers include Custom Building Products (WonderBoard™) and US Gypsum (Durock™).

Panels made of a mixture of cement and wood fibers are produced for building siding by James Hardi (Hardi-panel and Cemplank™), and CertainTeed (Weatherboard™).

See details of modern (non-asbestos) fiber cement roofing and siding at

at FIBER CEMENT ROOFING - home

and

at FIBER CEMENT SIDING - home

(Contributions invited - CONTACT us)

Saw Cuts, Tool Marks as Indicators of Building Age

Photo: adze marks on a beam in a barn in RedHook New York, photographed by the author.

Generations of types of saws used in cutting beams, and similar details are readily available on many buildings and offer both clues to building age and wonderful aesthetic detail.

Details at SAW & AXE CUTS, TOOL MARKS, AGE show clues such as hand hewn adze marks or even the type of saw cut marks on framing lumber, in rough chronological order.

There we illustrate different types of saw and tool cut marks in wood: adze cuts, hand sawn pit saw marks, mechanically-operated pit saw marks, circular saw marks, and unmarked, planed modern dimensional lumber.

An excerpt from that article is our photo above and this explanation:

An understanding of how hand-hewn beams were cut, for example, can permit the careful observer to not only recognize the type and age of building framing, but even to understand just where the worker was standing when a blow from a tool was delivered to a building framing member.

Adze cuts to hew a rectangular beam out of a round log were made in two steps: an adze, a hoe-like cutting tool with wooden offset handle was used to make a series of cuts along the round up-facing surface of a log.

Kit Homes can Give Building Age

Sears & Other Kit Houses as Indicators of Building Age

For details, photographs, books, and references on how to identify Sears Kit Homes

see SEARS KIT HOMES: How to identify Sears catalog kit houses photos and tips for identifying these interesting homes.

See details at

- AGE of a BUILDING, HOW to DETERMINE for references on identifying and determining the age of buildings

- ALADDIN KIT HOUSES

- BRICK LINED WALL CAVITIES - determining the age of older homes by bricks in wall cavities.

- BUILD YOUR DREAM HOME 1950 guide to building a modest home, from site selection through finish painting

- HOME CONSTRUCTION CATALOGS 1950

- KIT HOMES, Aladdin, Sears, Wards, Others

- LEAK DIAGNOSIS & CURE in LOG HOMES if you are reading our log home article series

- SEARS KIT HOME IDENTIFICATION

For information about the age, history, and use of pre-cut lumber in wood-frame construction,

see PRE-CUT LUMBER CONSTRUCTION & LEAVITTOWN

A photograph of stencil numbers on wood framing shown here confirms that this building was a Sears Kit House whose model and probable age we can determine.

Other kit homes were sold by Montgomery Ward and by a few other manufacturers

including copies of some of the popular Sears and Roebuck houses that continued to be sold after Sears had

discontinued their production.

This article series describes & explains types of kit homes including kit houses and log home kits which, in the latter instance

continue to be improved and sold.

Siding Materials as Indicators of Building Age

Please see our detailed article on types of siding and how siding materials are inspected, installed, diagnosed, repaired,

at SIDING & SHEATHING IDENTIFICATION - Photo Guide

Asphalt siding such as that shown in the photo of an extension on the rear of the Coolidge Hotel in White River Junction, Vermont, was the "aluminum siding" of the 1930's and 1940's in the United States.

That is, it was a popular "no maintenance" siding material sold often as a cover-up product for older siding in poor condition. (Aluminum siding and then vinyl siding were sold both for that purpose and also as exterior wall cladding for new construction as well).

See SIDING ASPHALT SHINGLE or SHEET.

Asphalt siding material was made in two common versions, one much like asphalt roof shingles and the other (as in this photo) was comprised of an asphalt coating laminated to hardboard siding material.

Commonly made to look like brick, it also appears in faux-stone versions (not to be mistaken for "perma stone" which has been sold since the 1960's as an exterior wall covering.

It would be rare to find asphalt-based exterior siding material as original wall cladding on a building; usually it was applied over wood clapboards which in turn were badly in need of paint or repair.

History and Dates of Use of Various Building Exterior Siding Materials

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home - includes early wall sheathing products like Beaverboard, Upsonboard, Sackett board etc. -some of these products were also used as exterior wall sheathing.

- SIDING, ASBESTOS FIBER CEMENT - Asbestos fiber & asbestos cement shingle siding: whose popularity declined with the rise in popularity of aluminum siding in the U.S. in the 1950's. This article series provides fiber cement and asbestos cement siding (and roofing) identification, photos, replacement materials, safety recommendations, disposal issues

- SIDING, ALUMINUM - [web article] also see this (ALUMINUM SIDING PHOTO, from a 1960's aluminum siding job, showing siding installed over peeling painted clapboard, siding backer board details).

Aluminum & steel building siding - popular in the U.S. 1940's - 1970's. Because of the large amounts of energy used to produce aluminum siding and increasing raw materials costs, aluminum siding declined in popularity in the U.S. in the 1970's.

Aluminum siding, produced from aluminum coil stock and painted in a wide variety of colors, provided a durable exterior building cladding that resisted rust and rot.

Watch out: some versions of aluminum siding included a paint coating that weathered, chalked, and even washed off entirely, leaving a bare aluminum surface.

With careful surface preparation and selection of a paint recommended by its manufacturer for aluminum siding, it is possible to re-paint weathered aluminum siding - of course we then have converted a "no maintenance" material into one that will require occasional repainting. - SIDING ASPHALT SHINGLE or SHEET - Asphalt shingle siding

See SIDING ASPHALT SHINGLE or SHEET for details

as well as this ASPHALT SIDING [image file] taken at the Coolidge Hotel, White River Junction, VT.

Asphalt siding: materials similar to asphalt roof shingles, used as building siding, designed to resemble brick, wood, or other materials, popular from ca 1930 - 1955.

- Brick building exteriors: structural brick walls & brick veneers

- Composite wood siding - Masonite, Woodruf, and other brands - see hardboard siding

- Hardboard building siding:

see SIDING HARDBOARD IDENTIFICATION & CLAIMS Boise Cascade, Georgia Pacific, Masonite, etc: siding failures, inspections, class actions - PERMA-STONE EXTERIORS - faux stone building exteriors that look like a stone veneer or stone wall

- SIDING EIFS & STUCCO building wall cladding installation defects, leaks, damage, class actions - links list; here's an example PHOTO of EIFS

- SIDING STEEL

- STONE VENEER WALLS - appearing on modern buildings

- LOG HOME CONSTRUCTION GUIDE

vs. SLAB LOG CABIN SIDING - are discussed

Also see ANTIQUE & OLD LOG CABINS

and VERTICAL LOG WALLS on CABINS & HOMES - PAINT FAILURE DIAGNOSIS - extensive library of how-to articles on diagnosing and preventing paint problems on buildings and in art conservation

- Plaster/cement horsehair lath siding

- Sawn clapboard siding -

see SIDING WOOD, FAILURES OVER FOAM BOARD and also

see PAINT FAILURES - SIDING STEEL - Steel building siding was sold based on advantages similar to aluminum siding (see Aluminum siding)

but with disadvantages of heavier weight, more difficult to install (harder to cut and trim), and vulnerable to rust. Steel siding was never as popular in North America as aluminum nor its later replacement - vinyl. - Stucco siding on building exteriors: Horsehair mixed with plaster or cement for building exterior wall covering, also

see SIDING EIFS STUCCO.

and STUCCO OVER FOAM INSULATION - choices of insulation and support for stucco over foam insulation over masonry walls - Synthetic stucco siding, EIFS wall cladding -

see SIDING EIFS & STUCCO - VAPOR BARRIERS - Vapor barriers: history of use of housewrap and vapor barriers; vapor barrier types:

see VAPOR BARRIERS - SIDING VINYL - PVC based vinyl siding was introduced in the U.S. in the 1950's and 60's, began to overtake aluminum siding for building exterior wall coverings in the 1970's and by the 1980's was the dominant exterior siding material on residential structures in the U.S. for both new construction and for remodeling.

The cost of covering a building exterior with vinyl siding was competitive with a properly executed exterior paint job, and the result more durable. Our Vinyl Siding articles include reviews & comments about moisture & vapor barriers. Vinyl siding is popular in part because it is lightweight and easy to work with, easy to cut, trim, and install.

Watch out: early vinyl siding suffered from weathering, cracking, impact damage, and buckling from heating. While modern vinyl siding products are very durable, impact and dent and weather resistant, the material will still buckle if it is not properly installed (nailed too tightly to the building).

Also see - Wood shingle siding: see SIDING WOOD, FAILURES OVER FOAM BOARD and also

see PAINT FAILURES

Details of how this material deteriorates and examples of its variations are discussed below along with other exterior siding materials and their common dates of use.

Windows & Doors & Interior Hardware as Indicators of Building Age

Please see our windows and doors articles

at WINDOWS & DOORS, Age, Types and also

see WINDOW HARDWARE AGE

At left is a photograph of an 1840 window latch on a historic landmark property, the Justin Smith Morrill Homestead in Strafford, Vermont.

This articles cited above explain how we can use details about the construction and materials of use in windows and doors as clues to building age, including window style, size, placement, construction,

and hardware, as well as door style and hardware.

For example, in addition to antique window hardware, take a look at the window glass type, window dimensions (and regularity of dimensions of similar windows in the same building), and the construction of window sashes with or without through-cut muntins.

Notice too how the window is held in an open position: by a removable peg, by sash weights, by window springs, or in the case of renovated antique windows where sash weights were eliminated, the presence of compression tracks that hold window sashes in place.

Building Age Determination Research & References

- Be sure to scroll through the page above where we list building features and materials alphabetically

- See also additional page endReferences or Citations

- Association for Preservation Technology International, 3085 Stevenson Drive, Suite 200, Springfield, IL 62703 USA Tel: 217-529-9039 Fax: 217-529-9120 Email: info@apti.org , Website: https://www.apti.org/

- Building Technology Heritage Library (Web: https://archive.org/details/buildingtechnologyheritagelibrary ) , produced by the Association for Preservation Technology, is a superb resource for old building researchers, owners, or restorers. website: https://archive.org/details/buildingtechnologyheritagelibrary

This library offers large collection of books (over 8000 in July of 2016), catalogs and other documents that are provided free to the public in a variety of electronic forms such as in PDF format or as .epub documents.

The collection includes documents that are rarely found in other libraries nor in other online collections for preservationists.

Excerpt:

The Building Technology Heritage Library (BTHL) is primarily a collection of American and Canadian, pre-1964 architectural trade catalogs, house plan books and technical building guides.

Trade catalogs are an important primary source to document past design and construction practices. These materials can aid in the preservation and conservation of older structures as well as other research goals. About the Building Technology Heritage Library,

The BTHL contains materials from various private and institutional collections. These materials are rarely available in most architectural and professional libraries.

See: COLT HOUSES [PDF, 109 MB] (1954), containing house plans produced by W.H. Colt & Son, Ltd., Bethersden Nr. Ashford, Kent. In 1954,

Colt timber houses, manufactured by Colt at the company's factory in the Kentish Weald had been sold since 1930.

The company described their homes as: "... they must not be considered as resembling ordinary "prefabs."

When erected, each house has an individual character and there is no feeling of mass production or standardisation."

Special thanks to Mike Jackson, FAIA American architect and InspectApedia reader for suggesting this superb resource. Mr. Jackson can be contacted by email at arch419@aol.com - Bullock, Orin M. Jr., The Restoration Manual . Norwalk, CT.: Silvermine Publishers, 1966.

- Flaharty, David, PRESERVING HISTORIC ORNAMENTAL PLASTER (Updated) [PDF] (1990) [Updated, color version]

- Flaharty, David, PRESERVING HISTORIC ORNAMENTAL PLASTER [PDF] (1990) [Original version]

- Grimmer, Anne E. & Paul K. Williams, The PRESERVATION & REPAIR of HISTORIC CLAY TILE ROOFS [PDF] (1992), U.S. National Park Service, Preservation Brief No. 29, retrieved 2022/10/08, original source: https://www.nps.gov/tps/how-to-preserve/briefs/30-clay-tile-roofs.htm

- Grimmer, Anne E., Jo Ellen Hensley, Liz Petrella, Audrey T. Tepper, ILLUSTRATED GUIDELINES on SUSTAINABILITY for REHABIITATING HISTORIC BUILDINGS [PDF] (2011) U.S. Department of the Interior, National Park Service, Standards for Rehabilitation, retrieved 2022/09/2, original source: https://portal.ct.gov/-/media/DECD/Historic-Preservation/03_Technical_Assistance_Research/guidelines-sustainability.pdf

- Grimmer, Anne E., The PRESERVATION & REPAIR of HISTORIC STUCCO [PDF], National Park Service Preservation Brief No. 22., retrieved 2018/06/18, original source: https://www.nps.gov/tps/how-to-preserve/briefs/22-stucco.htm

- Grimmer, Anne E. DANGERS OF ABRASIVE CLEANING TO HISTORIC BUILDINGS [PDF] (1979) [Department of the Interior], Heritage Conservation and Recreation Service [Office of Archeology and Historic Preservation], Technical Preservation Services Division, 1979.

- Grimmer, Anne E., THE SECRETARY OF THE INTERIOR’S STANDARDS FOR

THE TREATMENT OF HISTORIC PROPERTIES WITH GUIDELINES FOR PRESERVING, REHABILITATING, RESTORING & RECONSTRUCTING HISTORIC BUILDINGS [PDF] (2017) U.S. Department of the Interior National Park Service Technical Preservation Services Washington, D.C - retrieved 2022/10/08, original source: https://www.nps.gov/tps/standards/treatment-guidelines-2017.pdf

Excerpts:

The Standards address four treatments: preservation, rehabilitation, restoration, and reconstruction.

...

The Secretary of the Interior’s Standards for the Treatment of Historic Properties are regulatory only for projects receiving Historic Preservation Fund grant assistance and other federally-assisted projects. Otherwise, these Guidelines are intended to provide general guidance for work on any historic building. - HAND BOOK of HOLLOW TILE CONSTRUCTION [PDF] Hollow Building Tile Association (Chicago 1922)

- Howard, Hugh. How Old Is This House? . New York: Noonday Press, 1989.

- Howe, Barbara J., Dolores A. Fleming, Emory L. Kemp, and Ruth Ann Overbeck. Houses and Homes: Exploring Their History . Nashville, TN.: American Association for State and Local History, 1987.

- HUD, U.S. Department of Housing and Urban Development. Rehabilitation Guidelines, volume 111. Washington, D.C.: U.S. Department of Housing and Urban Development, 1980-84.

- Isham, Norman, Morrison, "An Example of Colonial Paneling", The Metropolitan Museum of Art Bulletin, Vol. 6, No. 5 (May, 1911), pp. 112-116, available by JSTOR.

- Jandl, H . Ward, REHABILITATING INTERIORS IN HISTORIC BUILDINGS: IDENTIFYING AND PRESERVING CHARACTER-DEFINING ELEMENTS [PDF] (1988) Preservation Brief No. 18

Excerpt:

While the exterior of a building may be its most prominent visible aspect, or its "public face," its interior can be even more important in conveying the building's history and development over time.

Rehabilitation within the context of the Secretary of the Interior's Standards for Rehabilitation calls for the preservation of exterior and interior portions or features of the building that are significant to its historic, architectural and cultural values. - Jennings, Jan, and Herbert Gottfried. American Vernacular Interior Architecture 1870–1940. New York: Van Nostrand Reinhold Company, 1988.

- Johnson, Ed. Old House Woodwork Restoration: How to Restore Doors, Windows, Walls, Stairs and Decorative Trim to Their Original Beauty. Englewood Cliffs, New Jersey: Prentice-Hall, Inc., 1983.

- Kitchen, Judith L., Caring For Your Old House . Washington, D.C.: The Preservation Press, 1991.

- Levine, Jeffrey, THE REPAIR, REPLACEMENT and MAINTENANCE of HISTORIC SLATE ROOFS [PDF] (1992), U.S. National Park Service, Preservation Brief No. 29, retrieved 2022/10/08, original source: https://www.nps.gov/tps/how-to-preserve/briefs/29-slate-roofs.htm

- MacDonald, Mary Lee, REPAIRING HISTORIC FLAT PLASTER WALLS & CEILINGS [PDF] U.S. National Park Service, Technical Preservation Services, retrieved 2018/06/17, original source: https://www.nps.gov/tps/how-to-preserve/briefs/21-flat-plaster.htm

- Mack, Robert C., FAIA & Anne E. Grimmer, ASSESSING CLEANING AND WATER-REPELLENT TREATMENTS FOR HISTORIC MASONRY BUILDINGS [PDF] (2000) U.S. National Park Service, Technical Preservation Services, retrieved 2022/10/02 original source: https://www.nps.gov/tps/how-to-preserve/briefs/1-cleaning-water-repellent.htm

- Mack, Roberty C., FAIA & John P. Speweik, REPOINTING MORTAR JOINTS IN HISTORIC MASONRY BUILDINGS [PDF] (1998) U.S. National Park Service, Technical Preservation Services, retrieved 2022/10/02 original source: https://www.nps.gov/tps/how-to-preserve/briefs/2-repoint-mortar-joints.htm

- McDonald, Travic C., Jr., UNDERSTANDING OLD BUILDINGS - the PROCESS of ARCHITECTURAL INVESTIGATION [PDF] (1994) Preservation Briefs No. 35, U.S. National Park Service - retrieved 2022/10/08, original source: https://www.nps.gov/tps/how-to-preserve/briefs/35-architectural-investigation.htm

Excerpts:

Whether as a home owner making sympathetic repairs, a craftsman or contractor replacing damaged or missing features, or a conservator reconstituting wood or restoring decorative finishes, some type of investigative skill was used to recognize and solve an architectural question or explain a difficult aspect of the work itself. ...

This Preservation Brief thus addresses the often complex investigative process in broad, easy-to-understand terminology.

The logical sequence of planning, investigation and analysis presented in this Brief is applicable to all buildings, geographic locations, periods, and construction types.

It is neither a "how to" nor an exhaustive study on techniques or methodologies; rather, it serves to underscore the need for meticulous planning prior to work on our irreplaceable cultural resources.

Sections: Historical research, documentation, inventory, stabilization, investigators & investigative skills, Architectural Evidence: Studying the Fabric of the Historic Building, Looking More Closely at Historic Building Materials and Features, Conducting the Architectural Investigation, After Architectural Investigation: Weighing the Evidence, Keeping a Responsible Record for Future Investigators - Myers, John H. & Gary L. Hume (Rev) ALUMINUM AND VINYL SIDING ON HISTORIC BUILDINGS [PDF] ] (1984) U.S. National Park Service, Technical Preservation Services, retrieved 2022/10/02, original source: https://www.nps.gov/tps/how-to-preserve/briefs/8-aluminum-vinyl-siding.htm

- Myers, John H., THE REPAIR OF HISTORIC WOODEN WINDOWS, [PDF] U.S. National Park Servivce, Technical Preservation Services, Preservation Brief No. 9, retrieved 2017/12/07, original source: www.nps.gov/tps/how-to-preserve/briefs/9-wooden-windows.htm

- Nelson, Lee H., FAIA, ARCHITECTURAL CHARACTER—IDENTIFYING THE VISUAL ASPECTS OF HISTORIC BUILDINGS AS AN AID TO PRESERVING THEIR CHARACTER [PDF]

U.S. National Park Service, Preservation Briefs No. 17, September 1988, retrieved 202/10/02, original source: https://www.nps.gov/tps/how-to-preserve/briefs/17-architectural-character.htm

Excerpt:

Every old building is unique, with its own identity and its own distinctive character.

Character refers to all those visual aspects and physical features that comprise the appearance of every historic building.

Character-defining elements include the overall shape of the building, its materials, craftsmanship, decorative details, interior spaces and features, as well as the various aspects of its site and environment.

The purpose of this Brief is to help the owner or the architect identify those features or elements that give the building its visual character and that should be taken into account in order to preserve them to the maximum extent possible. - NPS, Preservation Briefs, U.S. National Park Service, U.S. Department of the Interior, website: https://www.nps.gov/tps/how-to-preserve/briefs.htm

Website excerpt:

Preservation Briefs provide information on preserving, rehabilitating, and restoring historic buildings. These NPS Publications help historic building owners recognize and resolve common problems prior to work.

The briefs are especially useful to Historic Preservation Tax Incentives Program applicants because they recommend methods and approaches for rehabilitating historic buildings that are consistent with their historic character. - NPS, Preservation Tech Notes, U.S. National Park Service, U.S. Department of the Interior, website: https://www.nps.gov/tps/how-to-preserve/tech-notes.htm

Website excerpt:

Preservation Tech Notes provide practical information on traditional practices and innovative techniques for successfully maintaining and preserving cultural resources. - NPS, INAPPROPRIATE PORCH ALTERATIONS [PDF] ITS #9, U.S. National Park Service, Technical Preservation Services, "Interpreting The Secretary of the Interior’s Standards for Rehabilitation", - retrieved 2022/10/02, original source: https://www.nps.gov/tps/standards/applying-rehabilitation/its-bulletins/ITS09-Porch-Alterations.pdf

- NPS, The Secretary of the Interior's Standards for Rehabilitation and Guidelines for Rehabilitating Historic Buildings. Washington, D.C.: Preservation Assistance Division, National Park Service, U.S. Department of the Interior, rev. 1983.