Rock Wool, Stone Wool, Mineral Wool, & Slag Wool Insulation

Identification

Rock Wool, Stone Wool, Mineral Wool, & Slag Wool Insulation

Identification

Natural and man-made stone or vitreous fibers

- POST a QUESTION or COMMENT about Rock Wool mineral fiber insulation

Here we discuss the properties, appearance, health hazards, and possible asbestos content in mineral wool insulation.

This mineral wool or "rock wool" insulation article illustrates and describes mineral wool or "rock wool" and slag wool insulation materials. Our page top photo shows what this insulation may look like in place in a building attic.

Rock wool or "rockwool" insulation is also called mineral wool and slag wool though there can be differences among the components of these insulations.

We describe old house or "antique" mineral wool insulation as well as modern mineral wool insulating products still used in buildings.

This document assists building buyers, owners or inspectors who need to identify insulation in buildings by simple visual inspection.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Mineral wool or "rock wool" or "slag wool" building insulation properties

Mineral wool insulation, developed in the 1850's and patented in 1875 in the U.S., also called rock wool or in some texts slag wool insulation, remained in popular use in the U.S. up to the 1950's.

Photograph above provided courtesy of Carson Dunlop Associates, a Toronto home inspection & education firm.

Mineral (or "Rock") wool is still in use today in some new construction, in manufactured housing, and in special applications such as the insulation of low-slope roofed cathedral ceilings and scissors-truss roofs.

Article Contents

- WHAT is MINERAL WOOL, ROCK WOOL, SLAG WOOL INSULATION?

- DEFINITION of MINERAL WOOL or MINERAL FIBER vs FIBERGLASS

- DIFFERENT PROPERTIES of MINERAL WOOL, STONE WOOL vs FIBERGLASS

- AIRBORNE FIBER HAZARD from MINERAL WOOL INSULATION?

- INSTALLATION PROCEDURES - avoid settling in spray-applied mineral wool

- R-VALUE of MINERAL WOOL

- R-VALUE DETERIORATION?

- ROCK WOOL / MINERAL WOOL / STONE WOOL INSULATION PRODUCING COMPANIES & more identification photos

- ROCKWOOL TRADEMARK ISSUES

- HISTORY & RESEARCH about MINERAL WOOL / STONE WOOL INSULATION

...

What is Mineral Wool or Rock Wool or Slag Wool Insulation?

Mineral wool is produced by melting rock and slag using coke as a fuel.

The molten minerals are spun into fine fibers using high-velocity spinning rotor and a stream or air or steam.

A binder is applied to the fibers that are then collected on a wire mesh conveyer.

The mineral wool fibers are then cut or granulated and packaged for shipment or they are further cured with additional binder so that the resulting fiber blanket can be cut into insulating batts and in some products, combined with a vapor barrier or facing.

In our photograph of white mineral wool insulation shown here in the attic of a Canadian home, the insulation was delivered and installed in a chopped or "granulated" form that was simply poured and raked level between the floor joists of an attic.

Below: While mineral wool insulation may be white, gray, black or even pink, it most-often looks like either the photos just below.

See all of the MINERAL WOOL IDENTIFICATION, APPEARANCE VARIATIONS in our separate photo guide to the different versions, colors, and textures of mineral wool, rock wool, or slag wool insulation.

Above: Johns Manville Spintex insulation.

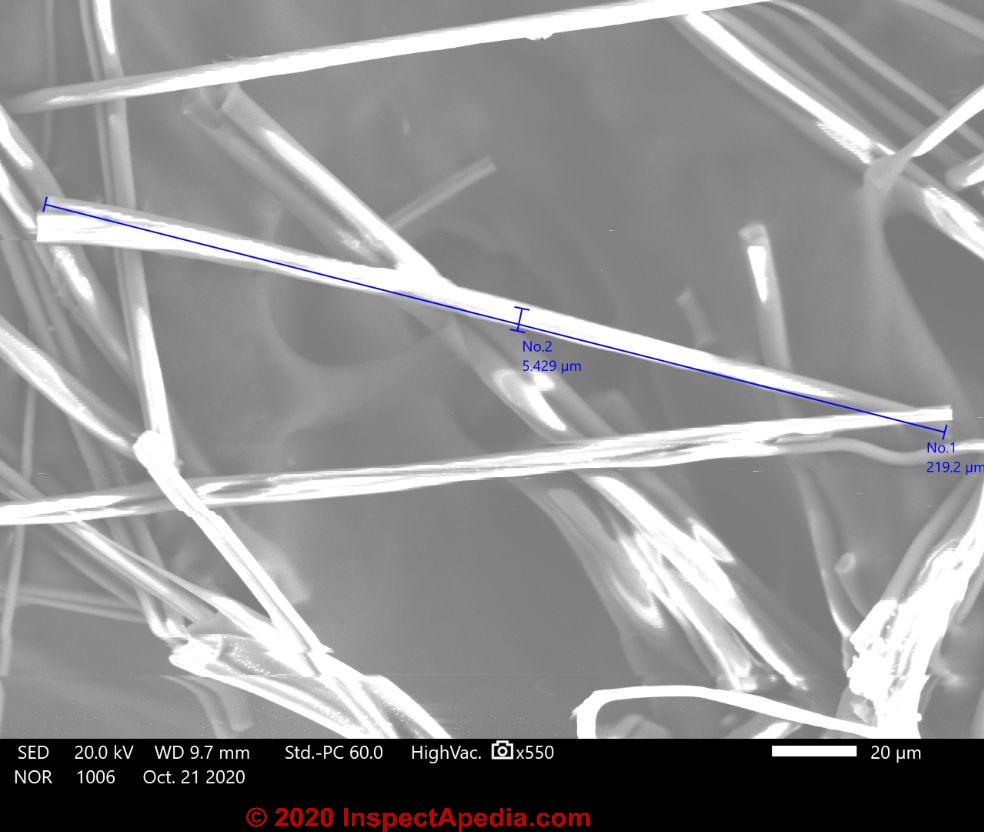

SEM Images of Slag Wool & Where to Find Slag Wool Testing in Poland

I am providing an image of Slag Wool (examined in our lab in Poland) from our Scanning Electron Microscope - SEM including EDX spectra starting from rockwool morphology (attached).

Hopefully I will add slag wool photo and spectra in future.

As for the possibility of sending slag samples to Poland I would be grateful and share the analytical results on forum.

Usually we have limited rights to publish the projects and results due policy of company :) - Alexsandra, EETP, Poland

See these separate articles if you want to compare your insulation that might be mineral wool with

...

Definitions of Mineral Wool, Mineral Fiber vs. Fiberglass

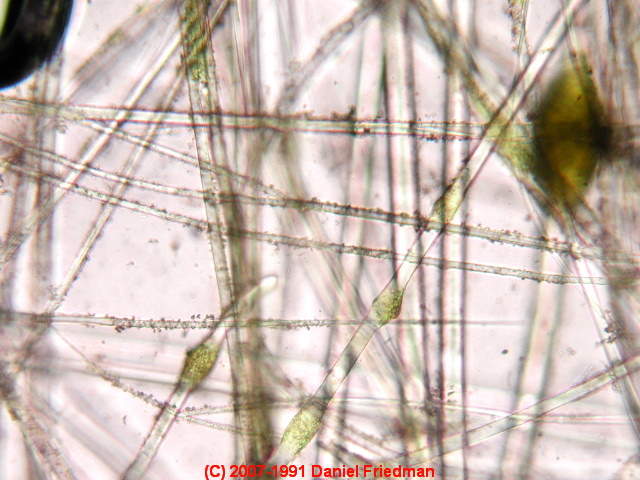

Below we show a much-magnified image of mineral wool insulation showing the characteristic glassy globules or spheres found in the product. In this image we're looking at mineral wool magnified about 30x in a stereo microscope.

According to the US EPA,

The term "mineral wool" can be used to describe any fibrous glassy substance made from minerals or mineral products.

For the purpose of this study, mineral wool has been defined to include only those fibers made primarily from natural rock or metallurgical slag.

Below we show mineral wool fibers as seen under our lab microscope, magnified about 400x.

Shown above: photographs of Gold Bond™ brand mineral wool insulation in a 1960's Haddonfield New Jersey Home, viewed first under the stereo microscope and then (immediately above) at 400x. You can see the gold colored resin binder that gave this insulation its product name - Gold Bond.

...

What's the Difference between mineral fiber insulation, mineral wool or stone wool & fiberglass?

Mineral fiber insulation includes two insulation groups: stone wool insulation (insulation made from rock and slag) and fiberglass insulation (glass fiber insulation).

Adding a bit of confusion, stone wool insulation manufacturers may call their product "rock wool", "Rockwool", "mineral wool" or even "mineral fiber". Rock wool and stone wool are essentially the same, as we will explain on this page.

Click to enlarge any image]

- Mineral wool insulation

like that shown in our photograph, includes only stone wool insulation (insulation made from rock and slag).

Mineral wool insulation will not contain any fiberglass.

Therefore, properly, the term mineral wool insulation is a proper subset of mineral fiber insulation.

Some stone wool insulation products have an oil added to the product to reduce dust - a feature not found in fiberglass insulation.

- Fiberglass,

in its most broad use, refers to a reinforced plastic made from glass fibers embedded in a resin matrix, or to a textile woven from glass fibers or filaments.

Fiberglass insulation is comprised principally of glass fibers bound together in a loose matrix by small amounts of resin.

Glass fibers, as in fiberglass insulation, are a flexible but still fragile fiber made by fusing sand with soda, lime and other ingredients.

Because glass (including the glass fibres that comprise fiberglass insulation) uses a base of sand, a granular rock fragment comprised principally of siliceous and other rocks (the beach), that defines glass as a mineral fiber.

Our photograph below shows modern fiberglass insulation fragments under the microscope at about 1000x. The yellow-green material is a resin binder.

To remind us of sand as the principal ingredient of glass, I include below my photograph of sand at Woodend Beach, Christchurch, New Zealand.

Watch out: the use of "stone wool" in the literature and product names used by some manufacturers can be a bit confusing. For example CertainTeed's Insulsafe® Sp Premium Blowing Wool is described by the company as "blowing wool" that is a fiberglass product.

From the company that invented Premium Blowing Wool -

InsulSafe SP is a fiberglass blowing insulation used in residential and commercial construction as a thermal and sound absorbing insulation. It is designed for pneumatic installation in open (attic) and closed (sidewalls/floor) construction cavities.

It may be used in retrofit applications. - source: InsulSafe SP product description retrieved 2018/0608, original source: https://www.certainteed.com/building-insulation/products/insulsafe-sp-premium-blowing-wool/

Comparison Table: Fiberglass vs Stone Wool Insulation |

||

| Feature | Fiberglass | Mineral Wool |

| Classification | Mineral Fiber glass made from sand, a mineral | Mineral Fiber made from melted rock May contain recycled steel (slag) |

| Ingredients | Glass fibers bound in a loose matrix by resin. 20-30% recycled content |

Mineral fibers made from basaltic rock & slag (from steel production) melted at 3000°F May contain recycled glass May have oil added to reduce dust Up to 70% recycled content |

| Cost / sq.ft. (loose fill) | $0.281 | $0.501 Typically 25-45% more costly than fiberglass |

| Density | 0.5 to 1.0 pounds per cubic foot4 12.2 kg/m3 in 3 1/2" batts8 |

1.7 pounds per cubic foot4 44.2 kg/m3 in 3" batts8 |

| Dimensional stability / rigidity | Lower than mineral wool | Greater than fiberglass |

| Fire Resistance | Lower fire resistance than mineral wool Meets building codes/standards |

Greater fire resistance than fiberglass Greater density improves fire resistance Meets building codes/standards |

| Installation in walls, ceilings | Requires stapled facing or wire support Cut with box knife |

Friction fit, self-supporting Cut with serrated knife |

| Loose fill | Widely available | Available, less widely than fiberglass |

| Melting point | 1,200°F | 2,000°F |

| Mold resistance | Equivalentt2 | Equivalent2 |

| Rigidity | Lower than rock wool | Higher than fiberglass, easier to install & cut batts |

| R-Value | 2.2 to 2.7 per inch | 3.0 and 3.3 per inch |

| Sound isolation - STC rating | Sound Reduction 4-10 dB depending on installation details STC improves by 4-10 points over an empty cavity.9 Equivalent according to CertainTeed3 |

Sound Reduction typically 10 dB in common stud wall STC 42-555 6 8 Equivalent according to CertainTeed3 |

| Thermal Resistance | Greater than rock wool due to lower density, lower conductivity | |

| Transportation | Lower density, compressed, 3x more batts transported per unit volume | Higher density, fewer batts transported per unit volume |

| Water resistance | Hydrophylic, takes up water, easily becomes soggy | Hydrophobic, resists taking-up water |

| Weight | .68 the weight of mineral wool per unit volume | 1.46 heavier than fiberglass per unit volume |

Notes to the table above

- The terms Mineral Wool, Rock Wool, Rockwool, Stone Wool, and Slag Wool all refer to mineral-fibre insulation of various mixes and properties. In general Rock wool or stone wool use stone as their primary ingredient with an inclusion of some slag wool while slag wool insulation uses slag wool (made from blast furnace slag) as its primary ingredient with an inclusion of some stone or rock wool, typically basalt.

- FIBERGLASS vs STONEWOOL, FACTS YOU SHOULD KNOW BEFORE YOU INSULATE [PDF] CertainTeed Corporation, 20 Moores Rd. Malvern PA 19355 USA Website: certainteed.com - retrieved 2018/06/08, CertainTeed Corporation, original source: https://www.certainteed.com/resources/30-45-073.pdf

OPINION: this brochure appears to be written from a "pro-fiberglass" point of view and may be incomplete - editor. - See FIBERGLASS INSULATION MOLD

- National Research Council of Canada (NRC) Report. [citation details needed]

- U.S. Department of Energy

- MINERAL WOOL STC TYPICAL SOUND BARRIER ASSEMBLIES [PDF] Johns Manville Corporation, Building Insulation Division P.O. Box 5108 | Denver, CO 80217-5108 USA Website: www.JM.com Tel: 1-800-654-3103 | retrieved 2018/06/08, original source: https://www.jm.com/content/dam/jm/global/en/ building-insulation/Files/BI%20Data%20Sheets/ BI%20Canada/BID_CAN_6MineralWoolSTC.pdf

- SOUND ATTENUATION FIRE BATT INSULATION / MINERAL WOOL, [PDF] Owens Corning, retrieved 2018/06/08, original source: http://www2.owenscorning.com/around/sound/commercial_acoustics/soundatt.pdf

- ACOUSTICAL ASSEMBLIES, [PDF] U.S. Gypsum Corp., retrieved 2018/06/08, original source: http://www.usg.com/content/dam/ USG_Marketing_Communications/united_states /product_promotional_materials/finished_assets/ acoustical-assemblies-en-SA200.pdf

- ROXUL AFB® ACOUSTICAL FIRE BATTS [PDF] retrieved 2018/06/08, original source: https://www.pharosproject.net/uploads/ files/sources/583/1375800155.pdf

- SOUND ATTENUATION BATTS [PDF], Owens Corning, retrieved 2018/06/08, original source: https://www2.owenscorning.com/around/ sound/commercial_acoustics/pdf/ SoundAttenuationBatt.PDF

- Research cited at References or Citations

- Our independent research 2018/06/08

...

Airborne particle characteristics of Rock Wool / Stone Wool Insulation

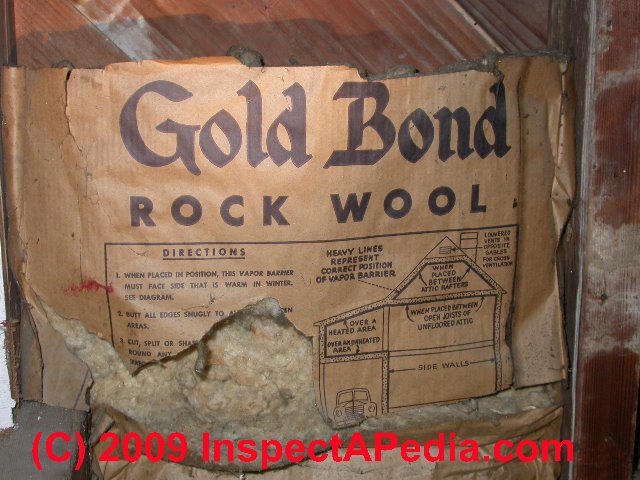

Question: Gold Bond Wool Rock Insulation

(May 3, 2012) Gold Bond Rock Wool said:

I've started removing fiberboard from the walls of an old porch-turned-bathroom and found the same Gold Bond Wool Rock as in your photos. Regarding the disintegration factor you mentioned, the product in my walls is very loose.

I had trouble removing a section without it coming off the paper and falling apart in my hands.

Since that piece was on the floor and to the open ground to daylight, I would think that particles eventually escaped plus the elements over time (heat in southern climate and/or lack of ventilation) created the deterioration.

Ants had made a colony in the insulation and the paper is frail, I am removing it.

Reply: rock wool is not an asbestos product

No Mike, rock wool is not an asbestos product, at least not as generally would be found in a residential building.

Patent research does, however, disclose some mineral wool or "rock wool" insulation products that were indeed combined with asbestos for special applications.

Details are at ASBESTOS IN MINERAL WOOL / STONE WOOL

Our photo above shows the original branding of Gold Bond™ Rock Wool, insulation observed in a 1920's home built in Poughkeepsie, NY. Because it is more dense (about 1.2 pounds /cubic foot) than some other insulating materials such as fiberglass (about 1/2 pound per cubic foot), some writers point out that rockwool is less likely to become airborne.

This is a confusing view unless supported by more specific data. Most air movement in buildings is upwards and outwards through the building attic.

We have identified some conditions in which air moves down from building attics into the occupied space, such as when a whole house fan is inadequately vented to the outdoors (and the attic is both pressurized and its dust stirred up by the fan).

A fiberglass batt provides less total volume of small particles to be stirred by an attic fan than does granular insulation such as vermiculite, rockwool, blown-in cellulose, or even chopped fiberglass (used in blown-in installations).

We'd also need to consider the average particle size and weight when evaluating the ease with which a material becomes airborne. So particle density or density of an insulation material per cubic foot is not the whole story.

...

How to Avoid Moisture & Settling Problems when Spray Applying Mineral Wool, Rock Wool, Slag Wool Insulation

Because these mineral fiber insulation products are often applied by spraying as a wet slurry onto building surfaces or into building cavities, they should not be covered by a vapor retarder barrier until the insulation has dried.

We recommend using a long-probe moisture meter such as models made by Delmhorst™ to assure that the rock wool sprayed into building cavities has dried to ambient indoor humidity before the wall or ceiling is covered with a vapor retarder or enclosed.

Mineral wool insulation is used by some manufactured home and possibly some mobile home manufacturers. Because these structures are later transported to their ultimate building site the insulation is exposed to vibration that can cause settling of the insulation within building cavities.

Wet-process blown-in mineral wool insulation thickness can decrease by up to 16% in this case, according to Graves and Yarborough.

What the study did not examine, and which may be still more important, would be the development of gaps at the tops or sides of vertical wall sections if settlement moves the wall cavity insulation. - "An Evaluation of the Settling of Loose-Fill Rock Wool Insulation in the Attics of Two Manufactured Home Units", ASTM, Graves RS, Yarbrough DW, January 1990.

A review of patent disclosures shows that some mineral wool insulation products added cellulose, flax, or other products to reduce settlement when this material was installed in walls.

On 2017-10-17 by Van - will adding cellulose cause a packing problem in the original rock wool insulation?

I think I may have wool insulation in my attic. It is white and fluffy. I do not have enough. What would be the best type of insulation to put on top of it?

I was thinking cellulose however someone said that may not be a good choice. It would pack it down.

On 2017-10-17 by (mod) - are there settling or packing issues when adding loose-fill cellulose on top of Rock Wool insulation?

Mineral wool loose-fill can be covered over by fiberglass batts, chopped fiberglass, or cellulose. There is no specific settling/packing issue that arises when placing loose fill cellulose over existing insulation.

- Lea, Daniel. "Cellulose: Building insulation with high recovered content, low embodied energy." In Green Building Materials 96 Conference. 1996.

Excerpts:

Cellulose has been regarded as a relatively low technology product, but today's cellulose insulation and installation technology is actually highly sophisticated. Light density cellulose insulation is an example of this sophistication. In the 1980s 2.6 pounds per cubic foot was a typical settled density for cellulose.

Today conventional cellulose products with settled densities of 1.5 to 1.7 pcf are common. Several producers offer material for attic installation that uses adhesive and a small amount of water to limit settling. These products are marketed under various brand names, and are sometimes referred to as “stabilized cellulose."

Stabilized cellulose may have a settled density as low as 1.3 pcf. Traditionally “open blow” installation of any insulation has been a dusty process, and cellulose has been regarded as especially dusty. Now low-dust cellulose for blown installation is available.

This material produces virtually no visible dust during installation, resulting in a much cleaner job and more pleasant working conditions for installers. Wet-spray cellulose, which is installed in wall cavities and covered by sheet rock, is one of the fastest-growing insulation products in new construction.

This material is much more effective in preventing air infiltration than insulation batts, as the Colorado study demonstrated, and it is not subject to settling.

Settling is the subject of much misconception. All loose-fill insulation settles to some extent. Sellers of other insulation materials occasionally attempt to mislead consumers by stating that the R-Value of cellulose insulation decreases as the material settles.

It does, but under federal law and in accordance with the accepted industry standard, cellulose insulation R-values and coverage data are always stated at settled density.

Far from being “cheated” out of R-Value as the insulation settles, home owners with cellulose systems actually benefit from bonus R-Value until the material reaches settled density.

Really? OPINION: if insulation in walls settles to leave a gap at the top of each wall stud cavity where there is no insulation at all, I would hardly call that an improvement in the wall's R-value. The author's discussion above makes sense for insulation loosely-filled into a horizontal area such as an attic floor. - Editor.

...

What is the insulating R-value of mineral wool?

Mineral wool is a good insulating material and has a better "R" value and more sound-reduction ability per inch than some fiberglass. Rock Wool insulating Batts have an R value of about 3.14 to 4.00 per inch.

Blown-in rock wool or mineral wool insulation such as that shown in our attic photos above on this page, has an R value of about 3.10-4.00 per inch.

Other sources we researched indicated that slag wool loose-fill insulation had an R value of about R-2 to R 3.3 and one source claimed an R value of 4.1 per inch for rock wool. [Home Energy Magazine Online, July/August 1997]

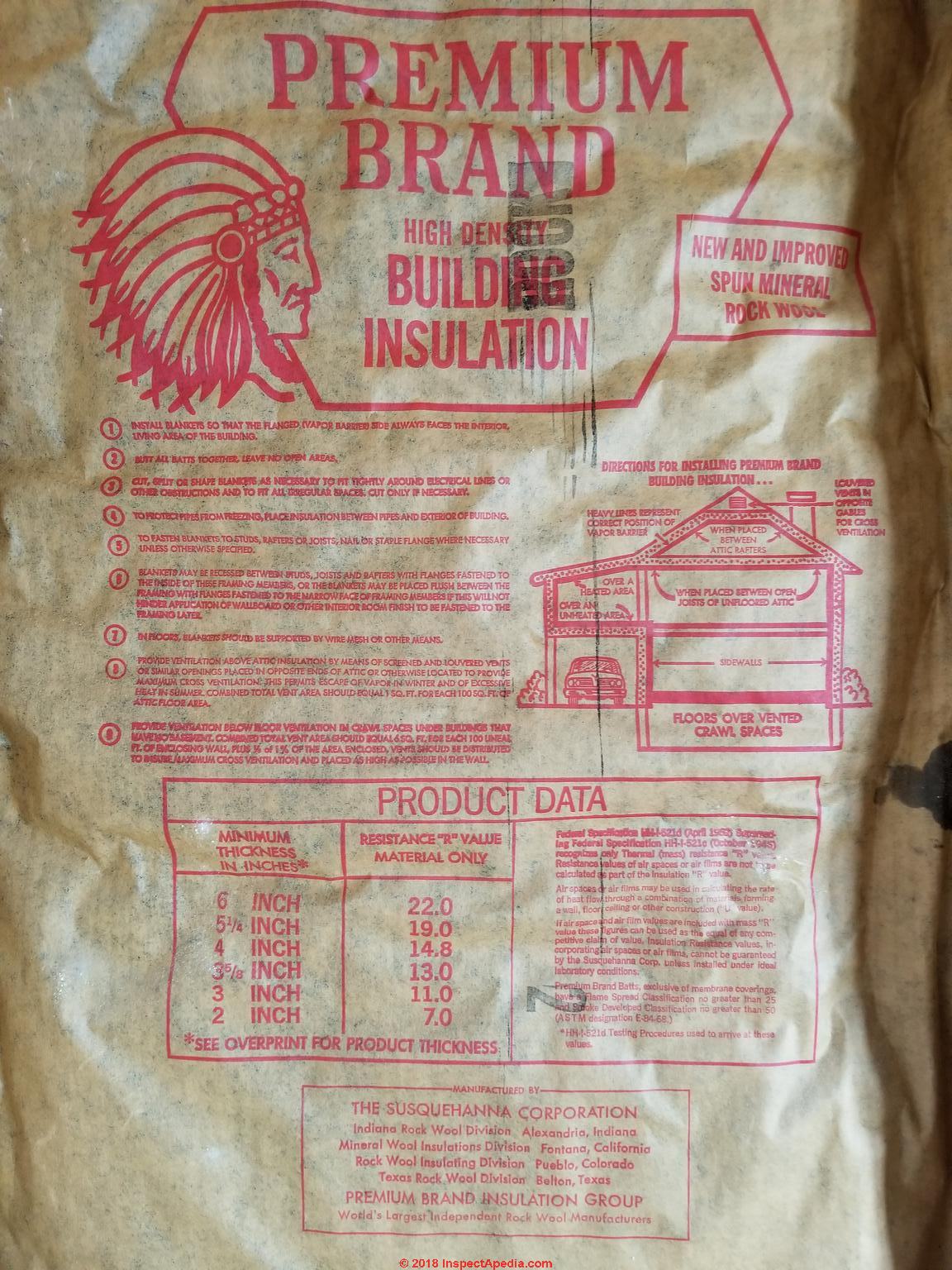

In the Indiana Rock Wool R-values table shown here, you'll see that two-inches of that mineral wool product was rated at R 7 and six-inches at R-22. That compares with typical low-density fiberglass insulation that is about R-19 for six-inches.

Bottom line: a safe rough estimate is to assume mineral wool made of rock or slag has an R value of about 3.35 per inch in batt form and an R value of about 2.25 in loose fill installations.

To compare insulating material R-values see our table

...

Does the R-value of mineral fiber insulation deteriorate with age?

Rock wool does not lose its R-value over time except insofar as the loose fill insulation may become compacted or unevenly distributed due to disturbance or settle over time

Rock wool does not deteriorate in R-value except, as would be the case with any loose fill insulation, if it is disturbed so as to no longer be uniformly distributed, or if it is packed by being compressed from storing items on top of it or walking on it or something similar.

However in vertical applications such as wall cavities, there were problems with rock wool settling. If settlement leaves voids at the top or sides of an insulated wall cavity, that'd certainly reduce its effectiveness.

I don't have data on the time-rate of settlement of mineral wool insulation - something that will be interesting to research. I have read of efforts to mix other fibres in with mineral wool to reduce the settlement problem.

Special thanks to our content-contributors including

- Lawrence Transue is a Pennsylvania building scientist and consultant, a certified ASHI home inspector, a Licensed Pesticide Applicator, a BPI Building Analyst & Envelope Professional, with 18 Years of Home Inspection Experience. He can be reached by Telephone: 610.417.0763, by Email: lawrence@lawrencetransue.com as well as at his WEBSITE and at FACEBOOK.

...

Rock Wool / Mineral Wool Insulation Producers

In the U.S. there were between 80 and 90 mineral wool manufacturers in the 1950's. By 1980 in the United States mineral wool manufacturers included these facilities. Current rockwool producers in the list below are shown in bold face.

In the U.S. there were between 80 and 90 mineral wool manufacturers in the 1950's. By 1980 in the United States mineral wool manufacturers included these facilities. Current rockwool producers in the list below are shown in bold face.

Watch out: as you will read in some of the "mineral wool" insulation product descriptions found below, the distinction between fiberglass insulation and mineral wool insulation is blurred by some manufacturers who label their product as "mineral fiber" insulation but in product details explain that their "mineral fiber" is glass fibers (yes glass is made from sand which is a mineral).

Those insulations could also be called "fiberglass" and are not "true" or "traditional" mineral wool fiber products such as others described on this page.

Photo: an excerpt from American Rockwool's Premium Plus™ photographs.

Notice that this insulation is pink and may be mistaken for some fiberglass products. Source: http://americanrockwool.com/rockwool-premium-plus.htm retrieved 2018/06/08.

- Acoustimac, 4420 E. Adamo Dr., Ste. 203-204, Tampa FL 33605 USA, Rockboard® 40/60/80,

Roxul Mineral-rockwool ® 60 Acoustic Insulation, Roxul Comfortboard, fire-resistant mineral wool panels, multi-purpose board insulation & acoustic insulation. Tel: 888-827-1266, Website: https://www.acoustimac.com/

ROXUL AFB® is a lightweight, semi-rigid batt insulation specifically designed for steel stud interior wall and floor applications.

This stone wool-based insulation is made from natural stone and recycled content.

ROXUL AFB® ACOUSTICAL FIRE BATTS [PDF] retrieved 2018/06/08, original source: https://www.pharosproject.net/uploads/ files/sources/583/1375800155.pdf - American Rockwool, Corporate Office

1316 Village Creek Drive, Suite 600

Plano, Texas 75093 USA, Corporate Office

1316 Village Creek Drive, Suite 600

Plano, Texas 75093 USA, Tel: 1 (877) 247-5970, Website: Amerrock.com

[Shown in our photo above] Rockwool Premium Plus™ Insulation is a high quality mineral fiber insulation manufactured in a granular form using sustainable products and recycled materials. - Carney Insulation Conwed Corporation Mankato Red Wing Missouri

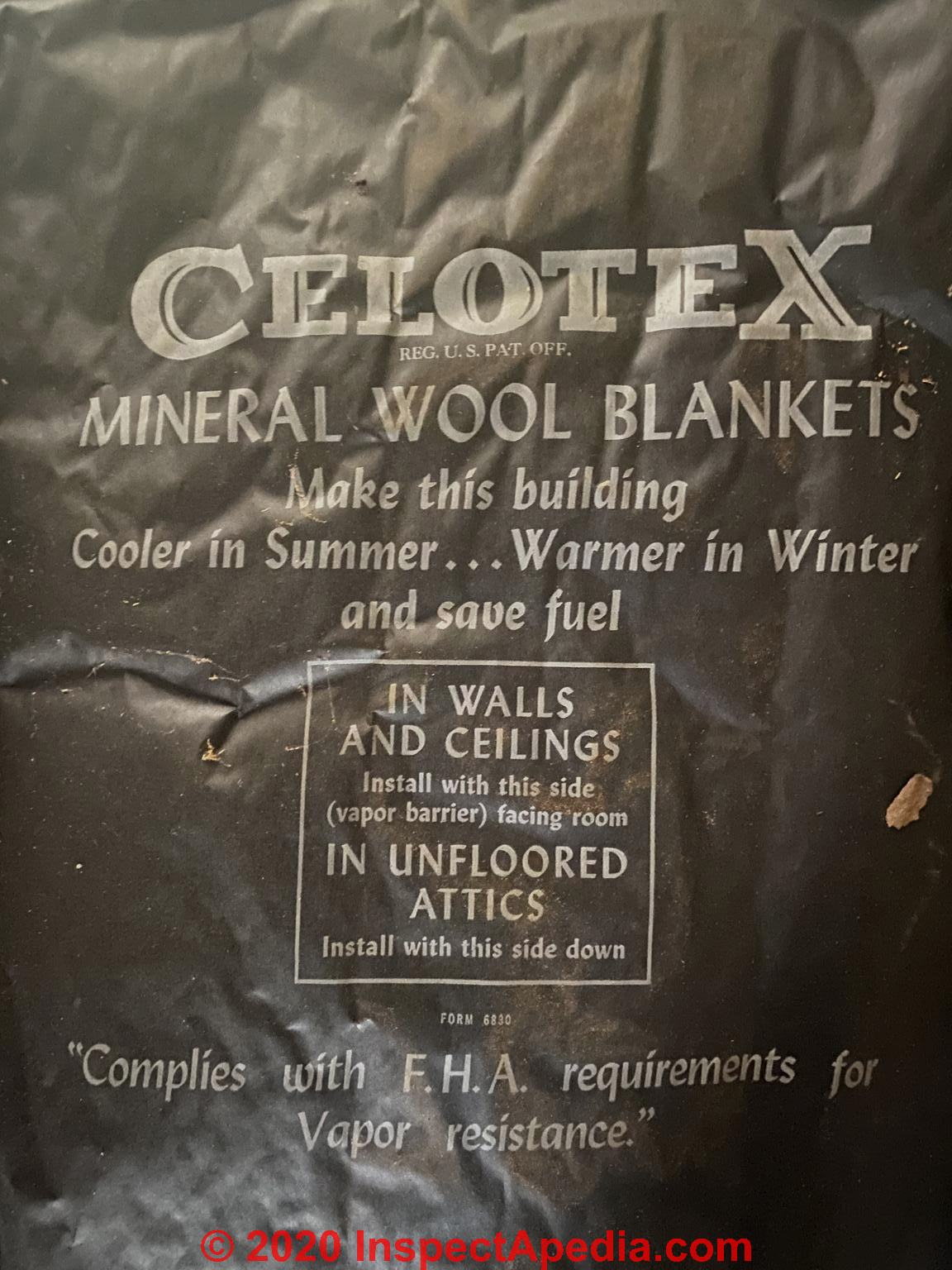

- Celotex

Rockwool Manufacturing Company - photo above of labeling printed on black kraft paper facing used on Celotex insulating mineral wool blankets courtesy of reader Luke, discussed

at CELOTEX HISTORY & PRODUCTS - Eagle-Richer Corporation Rockwool Industries Joplin Cameron New Jersey

- Forty Eight Insulations Aurora Indiana

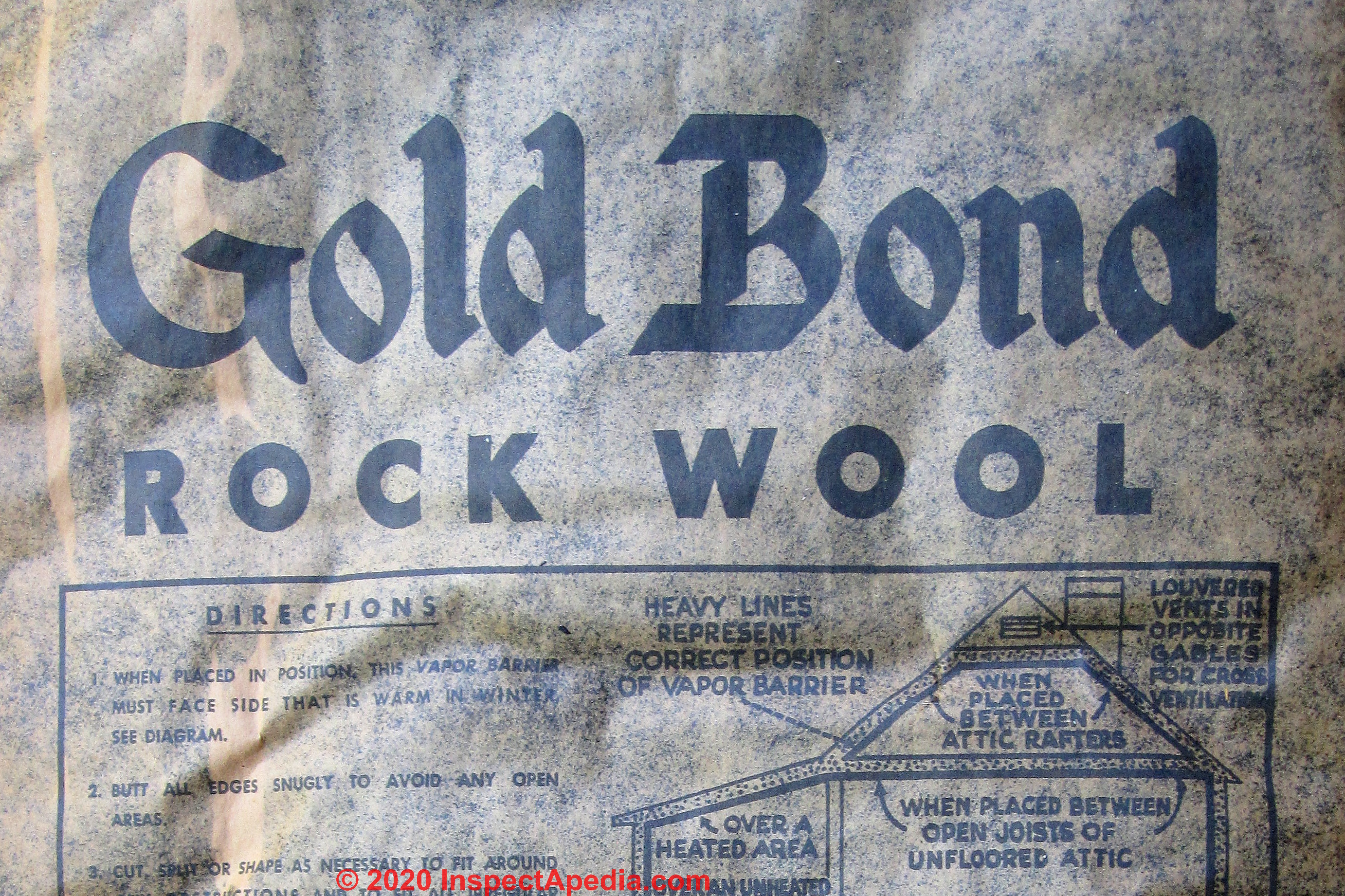

- Gold Bond Rock Wool Insulation - photo above from a 1970's home in Haddonfield New Jersey. Some Gold Bond products contained asbestos.

Gold Bond was a subsidiary of Nataion Gypsum. Both Gold Bond and National Gypsum filed for bankruptcy in 1990, establishing an asbestos settlement trust fund of $370 million to handle asbestos claims. - Guardian Industries

Above and below: photos of JM Ful-Thik Rock Wool Insulation, provided courtesy of home inspector Lawrence Transue.

- Johns-Manville Corporation (also a producer of asbestos products)

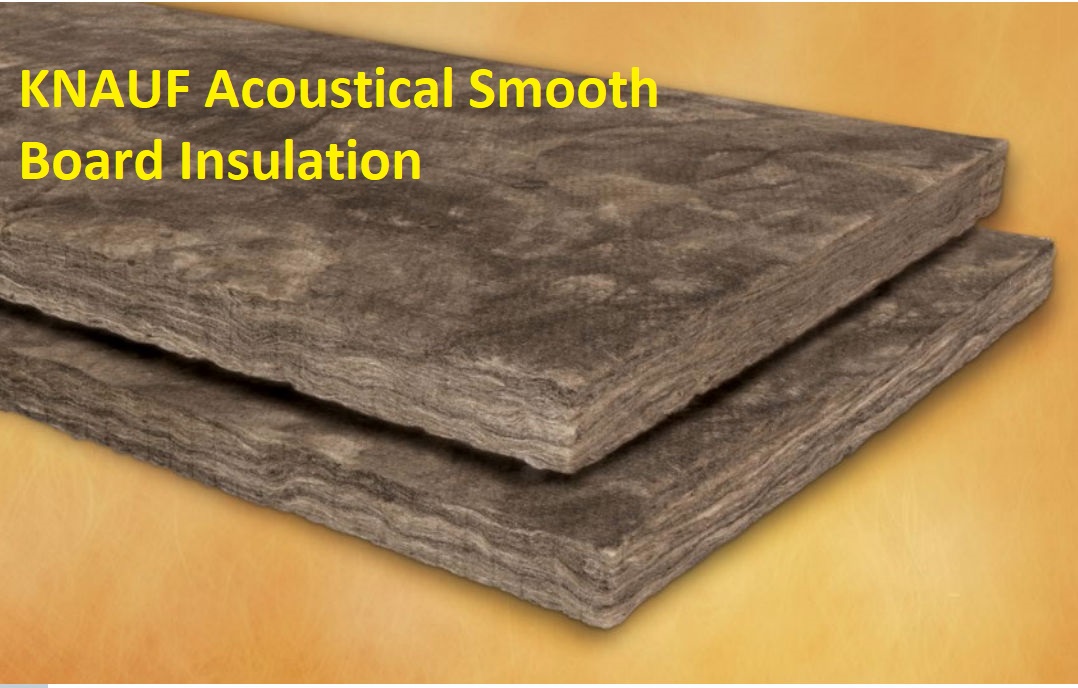

Below: Knauf Greenguard formaldehyde-free mineral wool insulation.

- Knauf Insulation, Knauf Insulation, One Knauf Drive, Shelbyville, IN 46176, USA, Tel: 317-398-4434 Email: info.us@knaufinsulation.com Sales Tel: 800-825-4434 ext. 8576 Website: http://www.knaufinsulation.us/

ACOUSTICAL SMOOTH BOARD Sound Insulation [PDF] retrieved 2019/01/05, original source: http://www.fabsrv.com/wp-content/uploads/2015/08/knauf-acoustical-smooth-board.pdf

Excerpt:

Knauf Insulation Acoustical Smooth Board is a 6.0 PCF thermal and acoustical insulation product made from inorganic glass fibers preformed into boards with ECOSE® Technology. The board is smooth on one side with precision cut tolerances

ECOBATT THERMAL ACOUSTICAL INSULATION [PDF] - retrieved 2018/06/08, original source: http://www.knaufinsulation.us/sites/us.knaufinsulation.com/files/BI-BT-DS_8-17_0.pdf

GREENGUARD IAQ Certified Insulation [PDF] (2010) retrieved 2019/01/05, original source: https://www.knaufinsulation.us/sites/us.knaufinsulation.com/files/content/featured/2010_09_16_KnaufInsulation_CaseStudy.pdf

Above: Knauf Smooth Board sound insulation batts. The color of this and many fiber insulation products is an artifact of the particular binder chosen by the manufacturer.

- L. C. Cassidy and Son

- Owens Corning Sound Attenuation Fire Batts, SOUND ATTENUATION FIRE BATT INSULATION / MINERAL WOOL, [PDF] Owens Corning, retrieved 2018/06/08, original source: http://www2.owenscorning.com/around/sound/commercial_acoustics/soundatt.pdf

Excerpt: Sound Attenuation Fire Batts/Mineral Wool (MW) are made of inorganic fibers derived from basalt, a volcanic rock. The fibers are bonded and formed into flexible batts. The product is manufactured in thicknesses from 1" to 6", and comes in standard metal frame widths.

SOUND ATTENUATION BATTS [PDF], Owens Corning, retrieved 2018/06/08, original source: https://www2.owenscorning.com/around/ sound/commercial_acoustics/pdf/ SoundAttenuationBatt.PDF

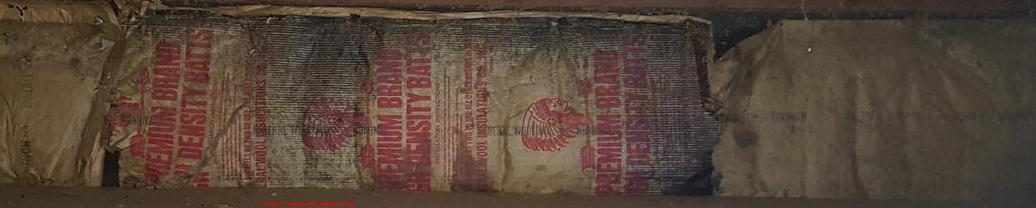

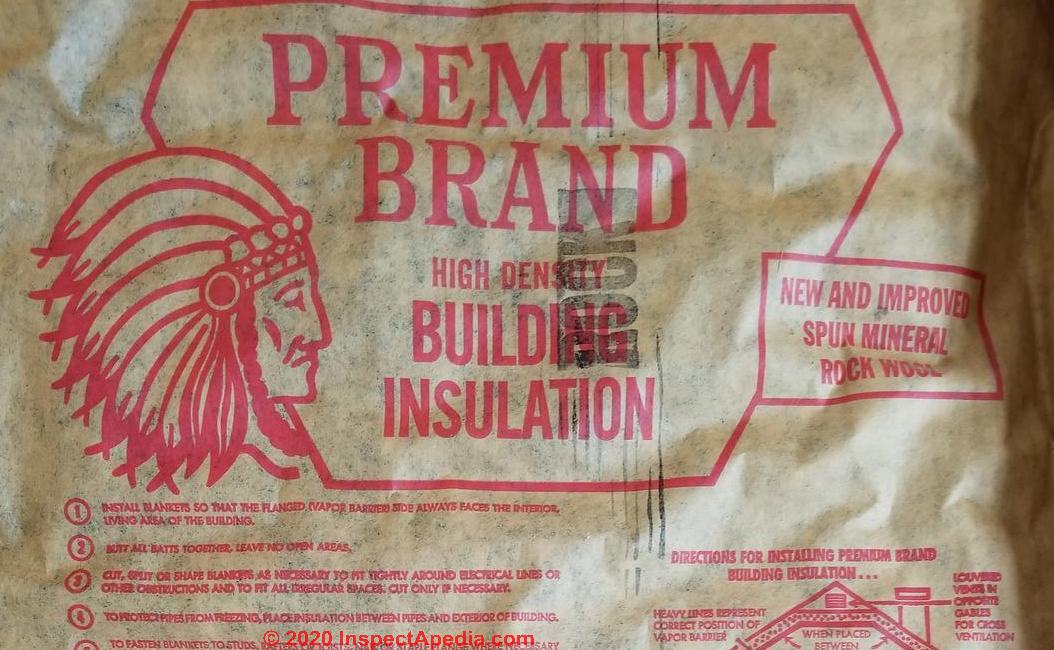

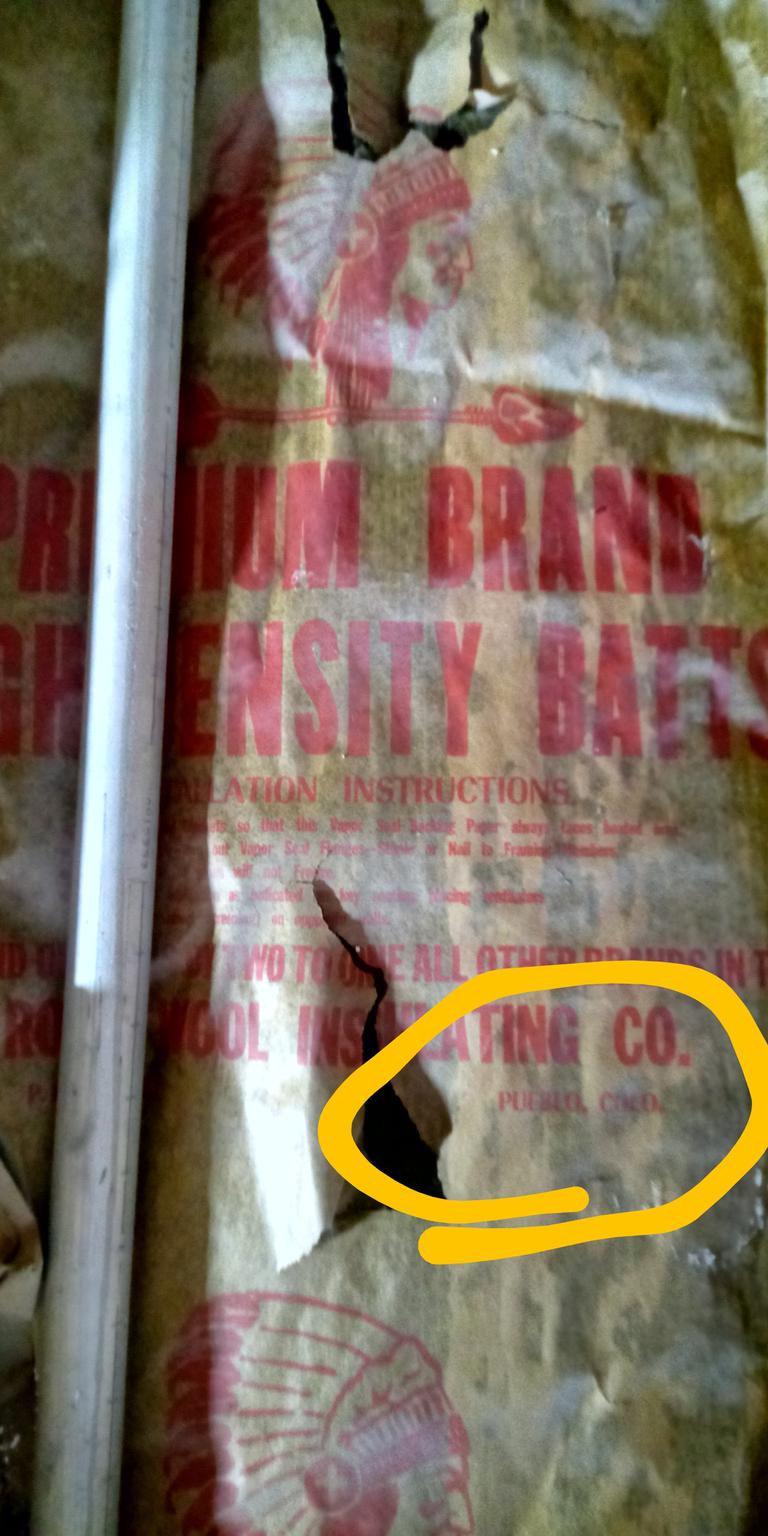

- Premium Brand Insulation Group, produced rock wool insulation under the following brands:

Indiana Rock Wool Division, Alexandria Indiana, - shown in our illustration, courtesy of reader Dave, June 2018.

Mineral Wool Insulations Division, Fontana, California

Rock Wool Insulating Division, Pueblo, Colorado - shown below, courtesy of reader Ernie Duncan

Texas Rock Wool Division, Belton, Texas

Comment: Premium Brand Rock Wool made in Pueblo CO

Hey there, thank you for what you do, while investigating asbestos content in materials uncovered while doing a remodel I came across your page, just wanted to pass this along if it helps with identification for people and to possibly correct a typo, under the premium insulation portion of this post I noticed "Pueblo, Indiana" as a corporation location I believe that should probably say Pueblo, Colorado rather than Indiana,

Hey there, thank you for what you do, while investigating asbestos content in materials uncovered while doing a remodel I came across your page, just wanted to pass this along if it helps with identification for people and to possibly correct a typo, under the premium insulation portion of this post I noticed "Pueblo, Indiana" as a corporation location I believe that should probably say Pueblo, Colorado rather than Indiana,

[Click to enlarge any image]

the remodel I'm doing is in Pueblo, CO, and Pueblo is also known for it's Steel plant which is responsible for all of the steel railroad tracks west of the Mississippi,

and would also make sense in terms of Rockwool manufacture as all of the associated resources and facilities for Rockwool would have been and still are available here in abundance since the early 1900's, hope this helps and thanks again for what you do. - Ernie Duncan, 2022/01/11

Moderator reply:

@Ernie Duncan,

Thanks so much, that Kraft facing certainly says that that insulation was produced or labeled as Pueblo Colorado. We'll be sure to keep it with this article.

MOST references to Rockwool production in Pueblo do indeed refer to Pueblo, Colorado, as shown in your photo and noted in your post.

There were mineral wool and rock wool and rockwool manufacturing facilities in multiple locations, and as we found in some EPA document searches, there were referenced Pueblo Illinois as location of a rock wool manufacturing plant too. [Or that original source was in error - we are researching that question further]

Premium Brand Insulation Group, produced rock wool insulation under the following brands:

- Indiana Rock Wool Division, Alexandria Indiana, - shown in our illustration, courtesy of reader Dave, June 2018.

- Mineral Wool Insulations Division, Fontana, California

- Rock Wool Insulating Division, Pueblo, Colorado

- Texas Rock Wool Division, Belton, Texas

AND

Separately we had this location:

- Rockwool Industries Pueblo Illinois [this might be obsolete or was an error in the original EPA source document]

Information source:

- US EPA, Source Category Survey: Mineral Wool Manufacturing Industry [PDF] (1980) https://nepis.epa.gov/ cites

"Mineral wool is widely used as a structural and industrial insulation and in ... Rockwool Industries Fontana Colorado Rockwool Industries Pueblo Illinois ..." [this quote is a product of Google search 2022/01/11]

Determine the Age of Premium Brand Insulation Batts?

Can you help me determine when these Premium Brand battings were produced or direct me to a manufacturer's historical product site? - Stacey 2021/07/25

Moderator reply:

On this page you will want to see our description of the Premium Brand insulation company,

Indiana Rock Wool Division, Alexandria Indiana, -

As you will see, that product was produced over many years, so what you're going to need to look for are some black and letters and numbers stamped on the craft facing.

That will give a production run number.

If you can find those and post a photo that would be helpful.

- "Rock Wool Manufacturing Company Asbestos Trust Agreement", retrieved 2015/12/06, original source: http://www.resasb.org/Pdf%20Docs/trustagr.pdf

Excerpt:

Rock Wool filed a voluntary petition for relief under Title 11 of Chapter 11 of the United States Code (the "Bankruptcy Code") on November 18, 1996 - Rockwool Industries Fontana Colorado

- Rockwool Industries Pueblo Illinois

- ROCKWOOL International A/S

Hovedgaden 584, Entrance C

2640 Hedehusene, Denmark

The ROCKWOOL Group is a producer of

stone wool insulation Website: www.rockwool.com

Rockwool International BROCHURE [PDF] (PDF document on rock wool sustainability), Rockwool International A/S · Hovedgaden 584 · 2640 Hedehusene · Telephone (+45) 46 56 03 00 · Telefax (+45) 46 56 33 11 , products include Rockwool Comfortbatt™ fire and sound proofing insulation,

Website: http://www.rockwool.com/, is a current manufacturer of mineral wool insulation products, or as the company specifies, stone wool insulation, used for fire insulation, sound insulation, and building insulation.

Watch out: the term Rockwool is also a trademark for stone-wool insulation produced by Rockwool International, A/S, a Danish company who in our OPINION hold the confusing view that despite NAIMA and many other associations' ubiquitous use of the phrase "rock wool" for stone or rock-based fibrous insulation, their company should have right to use of that term, as explained in this

confusing ROCKWOOL TRADEMARK INFRINGEMENT LETTER [PDF] undated, but sent to us by email by Morten Krusaa, a trademark student assistant at Rockwool Int'l in November, 2016. The writer appears to believe that "rockwool" and also the phrase "Rock Wool" should "... not be used to describe insulation materials or any other products" - perhaps meaning not even their own products.Many companies, both current and previous producers of mineral wool in various forms, included products labeled as "Rock-Wool" including

Gold Bond Rock-Wool Insulation, Johns-Manville's Spintex Insulation labeled by the company as "Long Fiber Rock Wool"

at SPINTEX MINERAL WOOL PROPERTIES - MANSVILLE, and Susquehana Premium Brand Rock Wool Insulation

- Rock Wool Manufacturing Co., 8160 Spruiell St., Leeds, AL 35097 USA - apparently out of business, as mail to this address was returned to us (InspectApedia.com) in November 2020.

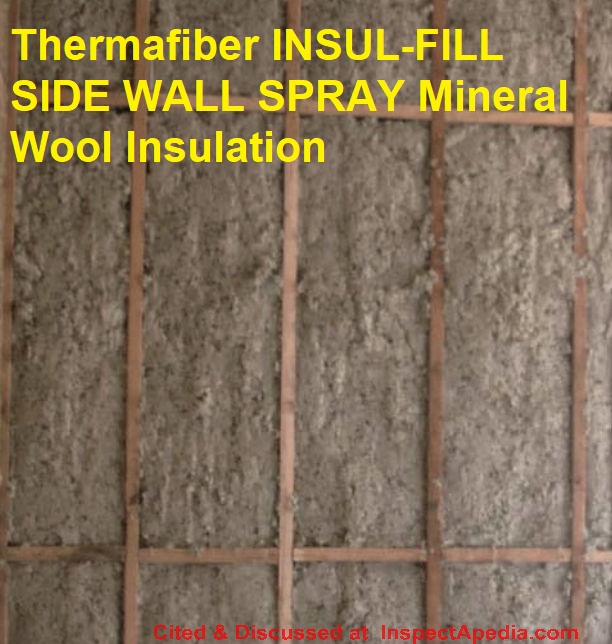

- ThermaFiber, Thermafiber, Inc., 3711 Mill Street, Wabash, Indiana 46992, Toll Free: 888-834-2371 (U.S. & Canada) ; Phone: 260-563-2111, is a current manufacturer of mineral wool insulation products. http://www.thermafiber.com/ Web search 07/28/2010, quoting:

Thermafiber manufactures and customizes mineral wool insulation for commercial buildings, industrial applications and residential construction. We specialize in high-rise construction - that's why we developed Thermafiber Insolutions™, a systematic approach to help you precisely plan and install insulation on time and on budget.

Product description excerpt:

THERMAFIBER FS-15 and FS-25 provide the best possible combination of fi re containment, sound control, thermal insulation, and energy conservation for external walls and ceilings of low-rise or residential structures.

These products are noncombustible, moisture-resistant, noncorrosive, nondeteriorating, mildew-proof and vermin-proof.

Both products resist temperatures over 2000°F as compared to fi berglass insulation that melts around 1000°F. FS-15 and FS-25 can be installed in both wood-frame and steel-frame structures.

- source: Thermafiber® Exterior Wall Insulation FS-15 & FS-25 product data sheet, 2018/06/08

Thermafiber Update: Owens Corning is ceasing its Thermafiber Insul-fill operations in October 2023 with no plans to restart them. - Thermafiber, Inc. One Owens Corning Parkway Toledo, Ohio, iUSA 43659

888-TFIBER1 [834-2371]

www.thermafiber.com

For questions relating to product specification, installation inquiries, and assemblies, code questions, LEED® credit information, and health and safety of product (MSDS) contact:

Direct: (260) 569-0801

Email: GETTECH@owenscorning.com

- Thermafiber INSUL-FILL BLOWN-IN ATTIC INSULATION [PDF] Thermafiber, Inc. (Owens Corning)

Excerpt:

Thermafiber® INSUL-FILL™ Blown-In Attic Mineral Wool Insulation is a premium loose fill product specifi cally designed for blown applications in new and existing structures. It can be used as the primary building insulation or as additional insulation in walls and ceilings of existing structures.

This loosefill product can be used to fill areas between cross bracing, truss bracing, and other uneven spaces that are difficult to insulate with traditional insulation batts. Thermafi ber® INSUL-FILL™ blown-in attic wool products are non-combustible, moisture-resistant, and mildew-resistant

- Owens Corning Thermafiber INSUL-FILL SIDE WALL SPRAY Mineral Wool Insulation [PDF] (2017) data sheet - illustrated above - Thermafiber, Inc.

Excerpt:

Thermafiber® INSUL-FILL™ Side Wall Spray Mineral Wool Insulation is a specifically formulated insulation that can be combined with a separate water/latex adhesive solution at the point of insertion. It is a time and labor saving solution providing easy installation into walls and cavities. - Thermafiber THERMAFIBER® INSUL-FILL® INSULATION ATTIC CARD & MANUFACTURER'S FACT SHEET [PDF] gives R-vaoues at various thicknesses

- Thermafiber BATT INSULATION INSTALLATION INSTRUCTIONS [PDF] - retrieved 2023/09/08, original source: cdn.thermafiber.com/wp-content/uploads/2018/03/10022787_Thermafiber_Res_Install_Instructions-Final.pdf

- Thermafiber SAFE USE INSTRUCTION SHEET [PDF] (2016) - retrieved 2023/09/08, original source: cdn.thermafiber.com/wp-content/uploads/2013/11/Granulated-Products-Safe-Use-Instruction-Sheet.pdf

- Owens Corning Thermafiber FREQUENTLY-ASKED QUESTIONS [PDF] (2017) - retrieved 2023/09/08, original source: thermafiber.ca/wp-content/uploads/2018/05/600022A-Thermafiber-FAQ-Document-ENG.pdf

- ICC-ES VAR ENVIRONMENTAL REPORT VAR-1025 on Thermafiber Insulation [PDF] (2023) on Owens Corning Mineral Wool Products (Thermafiber) - retrieved 2023/09/08, original source: icc-es.org/wp-content/uploads/report-directory/VAR-1025.pdf

- ABOUT THERMOFIBER [PDF] - retrieved 2023/09;08, original source: https://www.thermafiber.com/about-thermafiber/

- U. S. Gypsum Company Birmingham Leeds Birmingham California

- U. S. Gypsum Company : Lagro Huntington Wabash Alexandria (closed 9/79) Alexandria Wabash Minnesota

- U. S. Mineral Products Stanhope

According to Rockwool International1, headquartered in Denmark, in 2016 there remained just five mineral wool / stone wool producers in North America.

Rockwool is currently produced in the U.S. in Indiana, North Carolina, Texas, and Washington State as well as being produced in other countries.

- "Descriptive use of ROCK WOOL at InspectApedia, Fair Use + Research Citations", ROCKWOOL International A/S Hovedgaden 584 DK-2640 Hedehusene Denmark Tel: (+45) 46 56 03 00 Fax: (+45) 46 56 33 11 VAT-number: 54879415 Email: info@rockwool.com Personal correspondence, MK to DF 2016/11/22

- U.S. EPA, SOURCE CATEGORY SURVEY: MINERAL WOOL MANUFACTURING INDUSTRY [PDF] U.S. Environmental Protection Agency, Office of Air, Noise, and Radiation, Office of Air Quality Planning and Standards, Research Triangle Park, North Carolina 27711 (March 1980)

...

ROCKWOOL Trademark vs Rock wool & similar terms?

The letter [sent to InspectApedia demanding that InspectApedia.com stop using the word "rock wool" or "rockwool" as they claim it as a trademark] from ROCKWOOL isn't in the least confusing. They are trying to make you believe something that is patently (trademarkedly?) false.

The letter [sent to InspectApedia demanding that InspectApedia.com stop using the word "rock wool" or "rockwool" as they claim it as a trademark] from ROCKWOOL isn't in the least confusing. They are trying to make you believe something that is patently (trademarkedly?) false.

ROCKWOOL, one word, all caps is their trademark. Any other presentation is likely to be thrown out of any but the most corrupt court unless someone was actually labeling/marketing a product in a way that would be likely to be confused by the consumers of the product.

Their trademark only goes back to 1936. US Patents for a product described as rockwool predate the trademark. If you are not marketing a product using the word rockwool, or trying to trademark it yourself, you are in no more danger of infringing on or diluting their trademark than you would be for asking for a Kleenex instead of a facial tissue.

You could have your lawyer draw up a letter to them stating that you consider their letter to be harassment since rockwool is a generic term, that your use would be fair use if it were not, that your use is noncommercial, and that it falls under news reporting and commentary; they would go away because those are arguments they could not win against in court (2) (4).

They are obligated to their shareholders to defend their trademarks as they are considered assets, but that doesn't mean they should or will succeed (3).

They can beat someone who tries to trademark rockwool, but they will never go after you for treating as the generic term it is for fear of losing their trademark. On 2021-10-20 by Gary Hillis -

Citations:

https://inspectapedia.com/insulation/Rock_Wool_Insulation.php - you are on this page

1) https://www.rockwool.com/asia/rockwool-trademark/

2) Rockwool International A/S & Anr. vs Thermocare Rockwool (India) Pvt. ... on 16 October, 2018 [PDF] retrieved 2021/10/21 original source: https://indiankanoon.org/doc/171023357/?__cf_chl_jschl_tk__=pmd_giQy5ImNMMaV_k5sXeckoQmJ7_QeAg5g20C09k1k7Ms-1634701452-0-gqNtZGzNAjujcnBszQi9

3) Garber, Megan, 'Kleenex is a Registered Trademark' (and Other Desperate Appeals), [PDF] The Atlantic, 25 September 2014, retrieved 2021/10/21 original source: https://www.theatlantic.com/business/archive/2014/09/kleenex-is-a-registered-trademark-and-other-appeals-to-journalists/380733/

4) Justia, TRADEMARK DILUTION [PDF] retrieved 2021/10/21 original source: https://www.justia.com/intellectual-property/trademarks/trademark-dilution/

Reply by inspectapedia.com.moderator (mod) - Trademark clarification for ROCKWOOL

@Gary Hillis,

Thank you for supportive comments. We [have now moved this discussion ] to a more appropriate page such as our discussion of mineral wool and rockwool products.In our response to the corporation whom you were discussing we simply sent them photographs of other products made by other companies that had the same "rock wool" phrase right on the product itself as well as in numerous magazine and newspaper advertisements.

Incidentally, the ROCKWOOL trademark shown above may be a bit amusing or confusing as there is no visible TM or "Trademark" indicator on the company's own web page discussing this topic. (https://www.rockwool.com/asia/rockwool-trademark/ ) discussing this topic.

...

Mineral Wool Rock Wool Insulation History & Research

- Antepara, Iñigo. "Moisture dependent thermal properties of hydrophilic mineral wool: application of the effective media theory." Materials Science 21, no. 3 (2015): 449-454.

Abstract

Thermal properties of mineral wool based materials appear to be of particular importance for their practical applications because the majority of them is used in the form of thermal insulation boards.

Every catalogue list of any material producer of mineral wool contains thermal conductivity, sometimes also specific heat capacity, but they give only single characteristic values for dry state of material mostly.

Exposure to outside climate or any other environment containing moisture can negatively affect the thermal insulation properties of mineral wool. Nevertheless, the mineral wool materials due to their climatic loading and their environmental exposure contain moisture that can negatively affect their thermal insulation properties.

Because the presence of water in mineral wool material is undesirable for the majority of applications, many products are provided with hydrophobic substances. Hydrophilic additives are seldom used in mineral wool products.

However, this kind of materials has a good potential for application for instance in interior thermal insulation systems, masonry desalination, green roofs, etc. For these materials, certain moisture content must be estimated and thus their thermal properties will be different than for the dry state.

On this account, moisture dependent thermal properties of hydrophilic mineral wool (HMW) are studied in a wide range of moisture content using a pulse technique. The experimentally determined thermal conductivity data is analysed using several homogenization formulas based on the effective media theory. In terms of homogenization, a porous material is considered as a mixture of two or three phases. In case of dry state, material consists from solid and gaseous phase. When moistened, liquid phase is also present.

Mineral wool consists of the solid phase represented by basalt fibers, the liquid phase by water and the gaseous phase by air. At first, the homogenization techniques are applied for the calculation of solid matrix thermal conductivity.

Subsequently, the thermal conductivity dependence on moisture content is evaluated by means of several mixing formulas. To verify the obtained results, Wiener’s and Hashin-Shtrikman’s bounds are used.

The results show that the application of homogenization techniques can provide useful estimates of measured data and can be successfully used for much less time consuming thermal conductivity evaluation even for the highly inhomogeneous fibrous material such as mineral wool.

The data on thermal properties can find use in building practice, especially in the design of thermal insulation building envelopes. - Bozsaky, Dávid. THE HISTORICAL DEVELOPMENT OF THERMAL INSULATION MATERIALS. Periodica Polytechnica Architecture 41, no. 2 (2010): 49-56., original source: pp.bme.hu/ar/article/view/12/12

ABSTRACT

The history of thermal insulation materials is not as long as that of other materials, but the necessity of insulation is as old as building activity. Prehistoric people built shelters to protect themselves from the elements, originally using organic materials and later more durable substitutes.

However people used not only materials that were found in nature, but discovered others which were suitable for insulating.

Processing organic materials produced the first insulated panels in the 19th century: meanwhile an increasing range of artificial materials were developed (rock wool, fibreglass, foam glass, hollow bricks, expanded perlite). The appearance of plastic foams caused a huge revolution. Although plastic production was well-known in the 19th century, the first plastic foam was not produced until 1941.

Nowadays the most popular insulation materials are plastic foams and mineral wool with only a small amount of natural materials being produced. The overall growth of these products has been substantial due to a wide range of reasons. - Dodgson, J., J. Cherrie, and S. Groat. "Estimates of past exposure to respirable man-made mineral fibres in the European insulation wool industry." The Annals of occupational hygiene 31, no. 4B (1987): 567-582.

- Esmen, Nurtan A., Yehia Y. Hammad, Morton Corn, Diane Whittier, Nancy Kotsko, Martin Haller, and Russell A. Kahn. "Exposure of employees to man-made mineral fibers: mineral wool production." Environmental research 15, no. 2 (1978): 262-277.

- Kiss, Bernadett, Clara González Manchón, and Lena Neij. "The role of policy instruments in supporting the development of mineral wool insulation in Germany, Sweden and the United Kingdom." Journal of Cleaner Production 48 (2013): 187-199.

- Kupczewska-Dobecka, Małgorzata, Katarzyna Konieczko, and Sławomir Czerczak. Occupational risk resulting from exposure to mineral wool when installing insulation in buildings. [PDF] International Journal of Occupational Medicine and Environmental Health 33, no. 6 (2020): 757-769.

- Lucia, Arianna, Hendrikus WG van Herwijnen, and Thomas Rosenau. "Wood-based resins and other bio-based binders for the production of mineral wool." Holzforschung 74, no. 6 (2020): 539-550.

Abstract:

The traditional binder used in mineral wool is phenolic resin that makes mineral wool insulations reliable and efficient. The toxicity and health hazards of phenol and formaldehyde are becoming more and more pressing, and the industrial production needs to focus on safer precursors.

Several formulations of bio-based binders for mineral wool have been developed, meeting the challenge of performing equally well as conven-tional binders. Technical lignins, due to their intrinsic structure and their abundance, are good candidates for future industrial adhesives.

Carbohydrates are other class of biomaterials widely used in both research and patent formulations toward mineral wool binders. Proteins and cardanol are still largely unknown precursors, although they have hidden potentials for reliable binder systems.

Even if conventional binders are not replaced com-pletely with bio-based alternatives today, a partial use is already a step forward in the right direction – toward future biorefinery-based industries and knowledge-based bioeconomies in general.

Also see ASBESTOS in PLASTICS for more about bakelite and phenolic resins. - Marabini, Anna Maria, Paolo Plescia, Dante Maccari, Francesco Burragato, and Mario Pelino. "New materials from industrial and mining wastes: glass-ceramics and glass-and rock-wool fibre." International journal of mineral processing 53, no. 1 (1998): 121-134.

Abstract:

The need to find economically and environmentally more viable methods for the management of industrial wastes has opened the way to the research and development of processes which were still in the laboratory only a few years ago.

The examples given concern two very common and acutely-felt problems: the inertization and recycling of hydrometallurgical red muds (RM) and of mine tailings. In the case of red mud, one potential process involves the extraction of metals (mainly Zn, but also Cd, Sn, Ph, Fe), and another involves mixing the RM with granite chippings and cullet to produce glass-ceramics materials via melting and crystallization.

The paper also discusses a new flowsheet in which mine tailings are utilized to produce either glass-wool or very strong glass-ceramic products, with good resistance to chemical attack. - Marsh, G., R. Stone, A. Youk, T. Smith, M. Quinn, V. Henderson, L. Schall, L. Wayne, and K. Lee. "Mortality among United States rock wool and slag wool workers: 1989 update." JOURNAL OF OCCUPATIONAL HEALTH AND SAFETY AUSTRALIA AND NEW ZEALAND 12 (1996): 297-312.

- Neuhaus, Thomas, O. Reinhard, and A. Clausen. FORMALDEHYDE EMISSIONS FROM MINERAL WOOL IN BUILDING CONSTRUCTIONS INTO INDOOR AIR [PDF] Indoor Air (2008). - Retrueved 2921/07/25 original source: https://www.eurofins.com/media/2266/formaldehyde_emissions_from_mineral_wool_in_building_constructions_1086.pdf

Abstract

One stone wool insulation product containing phenol-urea-formaldehyde binder was tested for the emissions of formaldehyde and volatile organic compounds (VOC) simulating real use in roof constructions.

Results are compared with earlier published results from tests with wall constructions and to international indoor air limit values. Possible future handling by using reductions factors when testing pure mineral wool products without constructions is discussed. - Öhberg, Ingemar. "Technological development of the mineral wool industry in Europe." The Annals of Occupational Hygiene 31, no. 4B (1987): 529-545.

Abstract

The technical development of the European mineral wool industry is presented with emphasis on its early history and those factors believed to be of significance for the working environment. Its early history was mainly based on trial and error and may have presented several potential hazards.

At first, most of the plants produced wool without effective dust suppression. The highest fibre concentration is assumed to have occurred by the end of that period.

Moreover, some plants had a short period of so-called batch operation, when the fibre exposure may have been high for a few workers. The exposure patterns for modern production and use are the same for glass wool and rock wool. In this presentation of the technological development of the MMMF industry in Europe, only the mineral (glass, slag and rock) wool insulation industry is covered. - Väntsi, Olli, and Timo Kärki. "Mineral wool waste in Europe: a review of mineral wool waste quantity, quality, and current recycling methods." Journal of Material Cycles and Waste Management 16, no. 1 (2014): 62-72.

Excerpt:

Mineral wool insulation materials were found to have the lowest total concentrations of fungi ...

[Also see INSULATION MOLD CONTAMINATION TEST - Ed.] - Sohn, Joshua L., Pradip P. Kalbar, Gary T. Banta, and Morten Birkved. "Life-cycle based dynamic assessment of mineral wool insulation in a Danish residential building application." Journal of cleaner production 142 (2017): 3243-3253.

Abstract excerpt:

The findings of this study discourage the over-insulation of houses connected to the district heating grid, which is potentially promoted at present in Danish regulation. It is further concluded that improvement of the mineral wool insulation production process could allow for greater levels of environmentally beneficial insulation and would also help in reducing the overall environmental burden from insulating buildings. - Veiseh, S., A. Hakkaki-Fard, and F. Kowsary. "Determination of the air/fiber conductivity of mineral wool insulations in building applications using nonlinear estimation methods." Journal of Building physics 32, no. 3 (2009): 243-260.

Abstract

The limitation of the experimental methods in determining the thermal conductivity due to the air/fiber conduction in mineral wools leads the use of inverse parameter estimation techniques. However, in some circumstances, the convergence of the inverse solution is impossible due to the correlation of the involving parameters and the existing noises in measurement data.

In this article two relations are obtained to model thermal conductivity of the air/fiber conduction k(T, ρ), for glass fiber and rock wool insulations in temperatures between 0°C and 20°C, commonly encountered in building applications. Levenberg Marquardt's (LM) method is used for estimating of the unknown parameters in this article.

Considering the nonlinear nature of the inverse problem and the correlation of the involving parameters and the existing noises in measurement data, the convergence of the problem is acceptable. The results obtained by the estimated parameters agree extremely well with experimental measurements of the Heat Flow Meter (HFM) apparatus conducted at the Building and Housing Research Center (BHRC).

...

Constituents of Rock Wool or Mineral Wool Insulation? (it's not asbestos)

Please see this separate page: MINERAL WOOL / "Rock Wool" COMPOSITION

Appearance of Mineral Wool Products

Mineral wool is generally a dull white but may be fairly homogeneous gray (shown earlier on this page) or mineral wool may have black components, especially in older buildings.

Current mineral wool batts are also manufactured in a brown color.

Please see details at MINERAL WOOL IDENTIFICATION, APPEARANCE VARIATIONS

...

...

Continue reading at MINERAL WOOL / "Rock Wool" COMPOSITION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see MINERAL WOOL - ROCK WOOL INSULATION FAQs - questions and answers posted originally on this page.

Or see these

Recommended Articles

- BALSAM WOOL BATT INSULATION - a cellulose product, not a mineral fiber

- FIBERGLASS INSULATION IDENTIFICATION & PROPERTIES - home

- INSULATION IDENTIFICATION GUIDE - home

- MINERAL WOOL - ROCK WOOL INSULATION

- CAREY ROCK WOOL CATALOG 1950 [PDF]

- MINERAL WOOL IDENTIFICATION, APPEARANCE

- MINERAL WOOL IDENTIFICATION by MICROSCOPE

- MINERAL / SLAG WOOL AIRBORNE PARTICLES

- MINERAL WOOL / STONE WOOL ASBESTOS CONTENT

- MINERAL WOOL / ROCK WOOL DEFINITIONS

- MINERAL WOOL / ROCKWOOL COMPOSITION

- MINERAL or SLAG WOOL HEALTH EFFECTS

- MINERAL / ROCK WOOL INSTALLATION, SETTLING

- MINERAL WOOL / STONE WOOL R-VALUES

- SPINTEX MINERAL WOOL PROPERTIES - MANSVILLE

- SHEEPS WOOL INSULATION

Suggested citation for this web page

MINERAL WOOL - ROCK WOOL INSULATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Cummings, J. M. "Possibilities for the Manufacture of Mineral Wool in British Columbia" [PDF], British Columbia Department of Mines, (1937)- includes tables comparing properties of various insulation and other materials to mineral wool and balsam wool, retrieved 12/6/2014, original source: http://142.32.76.167/Mining/Geoscience/ PublicationsCatalogue/MiscellaneousPublications/ Documents/PossibilitiesManufactureMineralWool1937.pdf

- [1] Seattle Energy Code, Seattle Energy Code History, web search 12/6/2011, original source: seattle.gov/dpd/Codes/Energy_Code/Overview/history.asp

- Adams, P. "Effects of increasing the salinity of the nutrient solution with major nutrients or sodium chloride on the yield, quality and composition of tomatoes grown in rockwool." Journal of Horticultural Science 66, no. 2 (1991): 201-207.

- Awang, Y. B., J. G. Atherton, and A. J. Taylor. "Salinity effects on strawberry plants grown in rockwool. I. Growth and leaf water relations." Journal of Horticultural Science 68, no. 5 (1993): 783-790.

- Awang, Yahya B., and J. G. Atherton. "Growth and fruiting responses of strawberry plants grown on rockwool to shading and salinity." Scientia Horticulturae 62, no. 1 (1995): 25-31.

- Eparvier, Agnès, Philippe Lemanceau, and Claude Alabouvette. "Population dynamics of non-pathogenic Fusarium and fluorescent Pseudomonas strains in rockwool, a substratum for soilless culture." FEMS Microbiology Letters 86, no. 2 (1991): 177-184.

Abstract

In soilless cropping systems, soil-borne plant pathogens, especially Fusarium oxysporum, are responsible for severe damage in vegetable and flower cultures. Non-pathogenic Fusarium and fluorescent Pseudomonas are able to control fusarium diseases, thereby increasing the yield. The association of the non-pathogenic Fusarium strain Fo47 and of the fluorescent Pseudomonas strain C7R12 gave a better control of fusarium diseases compared to single inoculations of each antagonistic microorganism.

So far, no data have been available on the survival of these two microorganisms in soilless growing substrate. The results of this study indicate that both microorganisms survive well in rockwool when inoculated alone or together as well as in the absence or the presence of plants. Under the present experimental conditions, a single application of the antagonists appears to be enough to get a significant control of fusarium wilts. - Fonteno, William C., and Paul V. Nelson. "Physical properties of and plant responses to rockwool-amended media." Journal of the American Society for Horticultural Science 115, no. 3 (1990): 375-381.

Abstract:

Loose rockwool had a total porosity similar to peatmoss (92%, by volume) but with water retention capabilities similar to sand. Root media formulations containing loose rockwool were tested with seven plant species for plant response and nutrient uptake. The volume percent formulation, 20 rockwool : 10 peatmoss : 20 vermiculite : 45 pine bark : 5 perlite, was superior to formulations containing 10% or 30% rockwool. Plant response in this rockwool medium in bedding plant flats was superior to that in two high-performing commercial media for impatiens (Impatiens sultanii Hook), marigold (Tagetes patula L.), and petunia (Petunia hybrida Vilm) and equal to one commercial medium for tomato (Lycopersicon esculentum Mill.).

However, response of chrysanthemum (Chrysanthemum × morifolium Ramat.), geranium (Pelargonium × hortorum Bailey), and poinsettia (Euphorbia pulcherrima Willd. ex Kl.) in 1.58-liter pots was inferior to both commercial media in one-half of the trials. Differential plant responses in the root media treatments did not relate directly to differences found to occur in plant nutrient composition. The high initial pH level of rockwool necessitated reduced application of limestone and increased application of calcium sulfate to offset Ca deficiency. - Fuchs, J-G., Y. Moënne-Loccoz, and G. Défago. "Nonpathogenic Fusarium oxysporum strain Fo47 induces resistance to Fusarium wilt in tomato." Plant Disease 81, no. 5 (1997): 492-496.

- Galera, Melvin Maaliw, Eulsaeng Cho, Enkhdul Tuuguu, Shin-Jung Park, Changhee Lee, and Wook-Jin Chung. "Effects of pollutant concentration ratio on the simultaneous removal of NH 3, H 2 S and toluene gases using rock wool-compost biofilter." Journal of Hazardous Materials 152, no. 2 (2008): 624-631.

Abstract:

The need to find economically and environmentally more viable methods for the management of industrial wastes has opened the way to the research and development of processes which were still in the laboratory only a few years ago. The examples given concern two very common and acutely-felt problems: the inertization and recycling of hydrometallurgical red muds (RM) and of mine tailings.

In the case of red mud, one potential process involves the extraction of metals (mainly Zn, but also Cd, Sn, Ph, Fe), and another involves mixing the RM with granite chippings and cullet to produce glass-ceramics materials via melting and crystallization.

The paper also discusses a new flowsheet in which mine tailings are utilized to produce either glass-wool or very strong glass-ceramic products, with good resistance to chemical attack. - Kim, K-A., W. K. Lee, J. K. Kim, M-S. Seo, Y. Lim, K-H. Lee, G. Chae, S-H. Lee, and Y. Chung. "Mechanism of refractory ceramic fiber-and rock wool-induced cytotoxicity in alveolar macrophages." International archives of occupational and environmental health 74, no. 1 (2000): 9-15.

- Leeman, M., J. A. Van Pelt, F. M. Den Ouden, M. Heinsbroek, P. A. H. M. Bakker, and B. Schippers. "Induction of systemic resistance byPseudomonas fluorescens in radish cultivars differing in susceptibility to fusarium wilt, using a novel bioassay." European Journal of Plant Pathology 101, no. 6 (1995): 655-664.

- McCullagh, M., R. Utkhede, J. G. Menzies, Z. K. Punja, and T. C. Paulitz. "Evaluation of plant growth-promoting rhizobacteria for biological control of Pythium root rot of cucumbers grown in rockwool and effects on yield." European Journal of Plant Pathology 102, no. 8 (1996): 747-755.

- Mihuta-Grimm, L., W. A. Erb, and R. C. Rowe. "Fusarium crown and root rot of tomato in greenhouse rock wool systems: sources of inoculum and disease management with benomyl." Plant disease 74, no. 12 (1990): 996-1002.

- Postma, Joeke, Margarit JEIM Willemsen-de Klein, and Jan Dirk van Elsas. "Effect of the indigenous microflora on the development of root and crown rot caused by Pythium aphanidermatum in cucumber grown on rockwool." Phytopathology 90, no. 2 (2000): 125-133.

- Olympios, C. M. "Soilless media under protected cultivation rockwool, peat, perlite and other substrates." In Symposium on Soil and Soilless Media under Protected Cultivation in Mild Winter Climates 323, pp. 215-234. 1992.

- Savvas, D., and F. Lenz. "Effects of NaCl or nutrient-induced salinity on growth, yield, and composition of eggplants grown in rockwool." Scientia Horticulturae 84, no. 1 (2000): 37-47.

- Smith, Denis. Rockwool in horticulture. Grower Books, 1987.

- 3/07: thanks to Gary Randolph, Ounce of Prevention Home Inspection, LLC Buffalo, NY, for attentive reading and editing suggestions. Mr. Randolph can be reached in Buffalo, NY, at (716) 636-3865 or email: gary@ouncehome.com

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.