Temperature & Pressure Relief Valves

Temperature & Pressure Relief Valves

TPR Valves or T&P Valves used on boilers, calorifiers, geysers, water heaters & all water heating equipment

- POST a QUESTION or COMMENT about pressure or pressure & temperature safety relief valves: inspection, diagnosis, installation requirements, relief valve testing, and relief valve repair procedures.

Guide to TP Valve Installation, Defects, & TPR Valve Inspection:

How to install, inspect, troubleshoot, repair pressure / temperature relief valves or straight pressure relief valves used on heating boilers, steam boilers, water heaters, and even on water pressure tanks. This article explains what TP or pressure relief safety valves are, why they are needed, how they work, and what goes wrong.

We describe how to test (or when not to test) relief valves, how to know that this important safety device is in trouble, including by simple visual inspection, and we answer just about any question about these important safety devices.

Our photo at page top shows what the typical boiler relief valve looks like. You may find this valve connected at the top of a heating boiler, at its side, or (less desirable) very nearby on boiler hot water piping. This T&P valve is unsafe, lacking a discharge tube.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A Guide to Temperature & Pressure Relief Valves, Inspection, Defects, Testing, Repair

A T&P valve or temperature and pressure relief valve is installed on all modern heating boilers, steam boilers, water heaters, and on certain other pressurized or heated tanks and equipment to release hot water and pressure should

the boiler's internal pressure or temperature rise to an unsafe level.

A T&P valve or temperature and pressure relief valve is installed on all modern heating boilers, steam boilers, water heaters, and on certain other pressurized or heated tanks and equipment to release hot water and pressure should

the boiler's internal pressure or temperature rise to an unsafe level.

[Click to enlarge any image]

Some equipment may have only a pressure relief valve with no temperature sensor. On a water pressure tank that's fine, but on water heaters and steam or hot water heating boilers such an installation is not safe and may not comply with building codes.

This guide to relief valve inspection, testing, installation, repair, answers most questions about the use of these safety devices on heating equipment such as central heating system boilers, water heaters, steam generators and even pressurized water tank. This information aids in troubleshooting, inspection, diagnosis, and repairs.

We include a discussion of temperature and pressure relief valves used as safety devices on heating boilers and other pressurized vessels.

We also discuss:

- Leaking or Previously Leaking Pressure/Temperature Relief Valves are Dangerous. Attic boiler pressure control tanks - Old Heating Boilers (steam or hot water) may have No Relief Valve at All - Check the Attic./li>

- List of Common Boiler Temperature/Pressure Relief Valve Defects. Temperature/Pressure Relief Valve Testing Advice. Photo examples of unsafe, dangerous pressure/temperature relief valve installations.

- Troubleshooting heating system boiler controls and switches.

Lots of controls are installed on modern water heaters, hot water cylinders, hot water and steam heating boilers. Many of these devices are principally concerned with safety.

The combination of these devices provide a tremendous margin of safety on home and commercial heating boilers, as evidenced by the rarity with which we read in modern times of boiler explosions.

Before these devices were in common use, and even today if the devices are improperly installed, poorly maintained, or damaged, the heating systems they are supposed to protect are in fact un-protected.

Watch out: A defective relief valve is a latent safety hazard in that the valve does not by itself cause a water heater or heating boiler to explode, but it may fail to protect against that event should other dangerous conditions causing over temperature or over pressure arise in a heating boiler or water heater.

Inspection Points for T&P or Easing Valve Safety Hazards

Watts Corporation and other manufacturers list at least six inspection points for TPR valves.

- Operate the T&P valve test lever annually - see details of TPR test procedures

at RELIEF VALVE, TP VALVE TEST - Observe the T&P Valve location:

the valve's sensor must be immersed in the tank's water and located in the top 6-inches of the tank. - Observe the size and routing of the T&P Valve Discharge Piping:

improper routing direction, piping size, materials, or destination can render the system unsafe. Details are

at RELIEF VALVE DISCHARGE TUBE - Observe the T&P Valve Nameplate:

check that the pressure relief setting is above the tank's working pressure, that the CSA rating is greater than the heater's input BTUH, that the valve responds to both pressure and temperature (some valves may be designed to respond only to pressure), and check the date code of the valve.

On a Watts T&P valve the serial number encodes year (first two digits) and week of manufacture (last two digits), found either on the valve's data tag or on the under-side of the valve's test lever. - Complete T&P Valve Inspection:

by removal of the valve from the water tank and visual inspection, with replacement if needed, at least once every three years. - Record T&P Valve Inspection:

in an inspection log to be kept at the site (record the T&P valve inspection date and inspection results). On a residential water heater the inspection log may be kept with or even written on the heater's service and repair manual.

Details about these inspection points and examples of unsafe T&P valve installations or conditions are below.

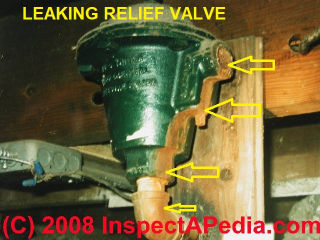

Our photo above shows an older (obsolete) type of pressure relief safety device that may be mounted close to the boiler but not right on it. This type of pressure relief device may not sense boiler temperature, just boiler pressure.

You can see that this pressure relief valve (shown above) has been leaking - it may be unsafe, as we discuss further below. Both the page top relief valve and the one in this photo are missing their discharge tubes.

Watch out: shown above is a single example of an unsafe condition at an antiquated pressure safety valve. A more complete explanation and illustration of safety hazards around TPR valves are provided in detail in each of the TPR valve categories listed above in this article.

Above is another unsafe temperature/pressure relief valve installation: the test lever that would be used to manually open, test or flush the TP valve is blocked first by having been placed up against a plaster wall and second by having had foam insulation sprayed into an opening that some smarter plumber cut into the wall to permit the lever to move.

Watch out: If the lift/test lever on a temperature/pressure relief valve is blocked from movement that prevents the valve from being tested - a step recommended at least annually by relief valve manufacturers.

Watch out: Depending on the relief valve model and design, a blocked relief valve test lever may prevent the valve from opening in response to pressure or temperature:

Details are at RELIEF VALVE, TP VALVE TEST

Special thanks to home inspector "anonymous", a member of the ASHI Technical Review Committee, for suggesting clarification of the hazards of blocked pressure or temperature relief valve test lever hazards - by private email 2017/04/21

Be sure that the Relief Capacity of the TPR Valve Is Properly Matched to the Heating Appliance

The data tag that should be found on a boiler relief valve (photo at left) gives key information and lets the owner or inspector know if the proper type of safety device has been installed.

The maximum pressure and/or temperature that the relief valve will allow is marked on the valve's metal tag.

Compare this data with the boiler capacity which will be given on the heating boiler or water heater's data tag. Use the Input BTUh value of the heating appliance when comparing to the venting capacity of the T&) valve.

At an inspection of Vassar Temple in Poughkeepsie, NY we observed that a pressure relief valve with capacity to handle 40,000 BTUs but the heating boiler was rated for 4,000,000 BTUh!

The heating boiler was unsafe - it would normally be a simple repair to install the proper valve. The service tech had simply installed a residential-range TPR valve on a huge commercial hydronic boiler.

We told Rabbi Steve Arnold that we were worried that if the boiler exploded it would kill all of the Reform Jewish worshippers in Poughkeepsie.

He replied, no, only during the high holy days.

See RELIEF VALVE LEAKS for details.

Check for Leaking Pressure/Temperature Relief Valves

If a relief valve has been leaking it is unsafe. Above on this page we showed an obsolete relief valve with leak stains down its front.

If a relief valve has been leaking it is unsafe. Above on this page we showed an obsolete relief valve with leak stains down its front.

We don't know if the valve has stopped leaking because a problem has been fixed (such as something else causing boiler overpressure) or if the valve has stopped leaking simply because its internals have become clogged with mineral debris which has been left behind as hot water evaporated.

The pressure temperature relief valve shown at left was dripping, but visual inspection showed that it was clogged with mineral debris left behind as boiler water leaked out and evaporated.

The mineral debris can, as you see in this photo, obstruct movement of the spring and valve internal parts, preventing it from opening when it's needed.

At RELIEF VALVE DISCHARGE TUBE we include a catalog of methods to detect past or ongoing or current leakage at the TPR valve.

Identify the Point of Leakage at the TPR Valve

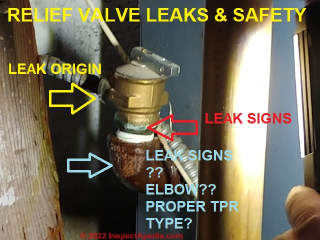

Above, inspection notes on a relief valve found on a 1990s Weil McLain gas fired boiler in Two Harbors, Minnesota, during a heating inspection and tune-up. The service technician indeed called for replacement of this TPR valve.

The yellow arrow points to leak stains at the mouth of the TPR valve - so we know that this is a leak point of origin, possibly the only one at this relief valve.

The red and light blue arrow point to additional leak stains below the point of origin.

For the TPR valve installation shown above one might also ask: why is this heating boiler TPR valve installed on a 90 degree elbow? Is this the proper TPR valve for a heating boiler?

Yes, for many hydronic heating (hot water) boiler applications, Watts, Apollo and other manufacturers provide some models of temperature/pressure relief valves that do not require a temperature probe that must insert into the boiler (and thus that would not fit on a pipe elbow).

Check that the Pressure / Temperature Relief Valve is the Proper Type, Size, & Capacity

Watch out: the relief valve on any heated or pressure vessel must be of the proper type for that type of equipment, and it must be capable of opening at the necessary temperature and pressure to protect the device, and finally, it must also have adequate venting capacity or venting rate.

For example, a heating boiler TPR like the Watts Series 335 is a smaller relief valve for popular size boilers up to 510,000 BTUs at 30psi (2.11 bar). If you found this TPR on a heating boiler whose input BTUH was greater than 510,000 BTUs that installation would be improper and unsafe.

Similarly, a low pressure commercial steam boiler requires a relief valve like the Watts Series 415 Steam Safety relief valve that opens at 8 psi.

Fortunately you can usually confirm the relief valve brand, model, and intended use as well as its venting capacity simply by inspecting the data tag found right on the valve itself.

Guide to Popular Temperature/Pressure Relief Valves

Above: the Watts 40L TPR valve discussed just below.

- WATTS Series 40, 140, 240 & 340 T&P RELIEF VALVES [PDF] (2014)

Excerpt:

Specifications Temperature & Pressure Relief Valves Each hot water storage heater shall be equipped with an automatic temperature and pressure relief valve to protect the heater from excessive pressure and excessive temperature.

The device shall be certified as meeting the requirements of ASME low pressure heating boiler code and ANSI Z21.22. The BTU discharge capacity of the device shall be in excess of the BTU input rating of the heater. The T&P valve shall be a Watts Series 40, 140, 240 or 340.

Above: the Watts 174A boiler relief valve.

- Watts 174A PRESSURE RELIEF VALVE INSTALLATION INSTUCTIONS & SAFETY TAG [PDF]

- Watts 174A PRESSURE RELIEF VALVE SPECIFICATIONS [PDF] - retrieved 2022/11/02, original source: https://www.watts.com/products/plumbing-flow-control-solutions/relief-valves/pressure-only-relief-valves/174a

Website excerpt:

Series 174A Boiler Pressure Relief Valves are used in hot water heating and domestic supply boiler applications to protect against excessive pressures on all types of hot water heating supply boiler equipment.

They have a bronze body construction with NPT threaded female inlet and NPT threaded female outlet (drain) connections, non-metallic disc-to-metal seating, stainless steel spring, and test lever. Series 174A resists corrosive water conditions, sticking, and freezing, and it prevents water and sediment from being trapped in the seat.

It is designed for emergency safety relief and shall not be used as an operating control. Standard Pressure Setting: 30psi (206.9 kPa).

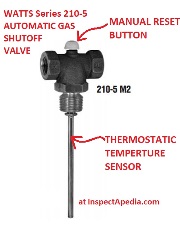

Pressure Range: In 5psi (34.5 kPa) increments from 30 to 150psi (2 to 10 bar) with corresponding high ratings from 650,000 to 14,370,000 BTU/hr. - WATTS Series LF210-5 / 210-5 Temperature Gas Shutoff Valves INSTALLATION INSTRUCTIONS [PDF]

Excerpt: Series 210-5 Automatic Gas Shutoff Valves are used in gas water heater applications to protect against overheating water in the domestic hot water supply heating system.

It is an immersion-type valve that automatically shuts off the gas supply to the heater if the temperature reaches 210°F (99°C).

It is a self-contained device that consists of Buna-N disc-to-metal seating, manual reset button to reopen the valve after an automatic shutoff, trip latch assembly and stainless steel spring seats to close the valve at a controlled temperature, and thermostat with extension tube which operates trip latch in response to water temperature.

Design certified by CSA. Models L210-5 M2, LL210-5 M2 and LLL210-5 M2 feature extended shanks for use with water heaters containing extra thick insulation, up to 3 in. - WATTS Series 210-5 Automatic Gas Shutoff Valves SPECIFICATIONS [PDF]

Shown below is a Watts 335M2, 3/4" Female Pressure Relief Valve described by Watts as:

- WATTS SERIES 335 RELIEF VALVE INSTALLATION INSTRUCTIONS [PDF] (2019) Watts Corporation, Web: www.watts.com Tel: (978) 689-6066 retrieved 2022/04/01 original source: https://www.watts.com/dfsmedia/0533dbba17714b1ab581ab07a4cbb521/24691-source/es-335-pdf

Excerpt:

Series 335 ASME rated Boiler Pressure Relief Valves were developed to fill the OEM need of the hydronic industry for a smaller valve on popular size boilers up to 510,000 BTU at 30psi (2.11 bar).

The compact design, all bronze construction and modern appearance make them an ideal choice for a wide variety of smaller size OEM boilers. - (Watts 2019).

Below is a Watts 40L - using a temperature probe.

This type of TPR valve is typically used on water heaters, calorifiers, geysers.

- WATTS SERIES 415 STEAM SAFETY RELIEF VALVE INSETALLATION INSTRUCTIONS [PDF] (2019) Op. Cit.

Excerpt:

Series 415 Steam Safety Relief Valves are used in commercial and industrial applications for low-pressure, steam heating boilers and process equipment.

They have a brass body (size 1/4 in.) or a bronze body (sizes 1, 1 1/4, 1 1/2 in.) construction with NPT threaded male inlet and threaded female outlet (drain) connection, stainless steel spring, top-guided stem, and non-stick Teflon disc-to-metal seating. Model 415SC has satin chrome finish.

Model 415L has low pressure setting at 8psi (55 kPa) for pressure cookers and steam cleaning equipment. ASME Section IV at 15psi (103 kPa) set point. - (Watts, 2019)

Check for Defects in the TPR Valve Drain Piping

The TP valve shown in our photo at left displays the most common safety defect found with this equipment - failure to pipe the valve's potential discharge of hot water to a safe location.

The TP valve shown in our photo at left displays the most common safety defect found with this equipment - failure to pipe the valve's potential discharge of hot water to a safe location.

The relief valve should be piped to a few inches from the floor with the end of the discharge tube always in a visible location so that if it is leaking or open the building owner or manager can observe that (unsafe) condition.

A client described finding her son and his friends in the basement playing "steam boat". They had tied a string through the little hole in the relief valve discharge lever, running the string up over a boiler pipe near the ceiling.

By pulling on the string the boys created an exciting blast of hot steamy water coming out of the boiler. Luckily none of them was scalded by this game.

But when the TP relief valve discharge extension is missing from a heating device, someone can be badly scalded.

At a home inspection in New York a real estate agent burst into tears while telling us how her son had lost an eye when he and friends played with a boiler relief valve and he was shot in the face with scalding water. A proper discharge tube could have prevented this tragedy.

See RELIEF VALVE DISCHARGE TUBE for complete details about the installation specifications & inspection defects of TPR valve drain piping and handling of spillage from TPR valves

Temperature/Pressure Relief Valve Inspection & Testing Advice

Watch out: While it is possible to "open" a boiler TP relief valve by lifting its "test" lever, unless you are a trained heating service technician or plumber, and unless you have a spare TP valve of the proper size in your hand, we advise against "testing" a TP relief valve by opening this lever during a building inspection.

And in our OPINION, even though T&P valve instructions provided by the manufacturer recommend annually testing the valve using its try-lever, that's better done by your trained heating service technician or plumber during annual service.

Besides a leak problem that could require you to shut down the equipment and make you sorry you ever touched the valve, there are scalding-burn hazards.

Either ask your service technician to test the TPR valve or just confine your own TPR valve check to the following steps:

- Pressure:

See that the boiler pressure is at or below the rated valve-opening pressure or temperature by checking the (imprecise) boiler gauge readings against the valve tag data when the boiler has heated it self up to its "shut off" point. - Modifications:

Inspect the Temperature/Pressure relief valve for evidence of tampering - Leak History:

Inspect the Temperature/Pressure relief valve for evidence of a history of leaks by observing the following- Visible Corrosion: any leak or corrosion stains around the mouth of the valve

- Drip Marks: any drip stains on the floor below the valve discharge tube (photo at left)

- Wet: Using your finger, feel the inside of the tip of the discharge tube and check for water - it should be dry.

See RELIEF VALVE DISCHARGE TUBE for more examples of tests and inspection points at the T&P valve. - Mounting Leaks: Check for leaks around the valve where it is mounted on the boiler or boiler piping

- Discharge tube:

Check that the Temperature/Pressure relief valve has a discharge tube properly installed and that the discharge is not blocked by anything whatsoever, that it has not been reduced in size, is not crimped, damaged, corroded, leaking, nor piped "up" nor piped to a hidden location.

See RELIEF VALVE DISCHARGE TUBE

Also

see TUNDISH used in PLUMBING - BTU Discharge Rating:

as we explain above in this article, the BTUh discharge capacity of the pressure/temperature relief valve must be greater than the input BTUh rating of the heating appliance it is intended to protect.

For pressure-only relief valves such as those used on water pressure tanks, the valve must be able to discharge pressure at a rate greater than the pump or other pressure source can deliver water under pressure to the storage tank. - Data tag:

Check that the Temperature/Pressure relief valve data tag is in place - you need this information to check the valve's capacity and your plumber or heating technician will need it when replacing a leaky or defective TPR valve. - Read more about your particular equipment's TPR valve requirements in the articles listed at the start of this page. Or if you think worrying about T&P valves is a bunch of hooey,

See BLEVE EXPLOSIONS

Below: a temperature and pressure relief valve that opens at 15 psig, used on a Mr. Steam MS90E series steambath generator.

That installation is described

at STEAM BATH / SHOWER GENERATOR INSTALLATION.

Automatic Gas Shutoff Valves

Some equipment such as some gas fired water heaters may use an automatic gas shutoff valve instead of a conventional water-dumping pressure/temperature relief valve.

An automatic gas shutoff valve will close to stop the fuel supply to a gas fired water heater if the temperature is found to be too high and thus unsafe.

WATTS Water Heater Controls - automatic gas shutoff - provides details about that automatic gas shutoff control that uses a manual reset

Details about the installation, testing, and functions of this device are

at GAS WATER HEATER AUTOMATIC SHUTOFF

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: Better to rebuild or replace leaky pressure relief valve?

I have a Bryant model # 234B 6PW 160,000 BTU boiler in a home I bought and the 174A watts pressure relief valve is leaking slowly.

Can it be rebuilt or can I use another valve such as a Watts 335 M2 to replace it. the Watts 174a is fairly expensive. - 2022/10/27 by private email from Anonymous

Moderator reply:

Although I have made emergency midnight repairs to leaking relief valves in order to keep heat going, it's not a procedure that I would recommend. The risks are simply too great.

There are rebuild kits sold by Watts and other manufacturers for some of their pressure/temperature relief valves, but considering the product of multiplying the small probability that you make a mistake times the tremendous penalty if there is a BLEVE explosion in your building, I'd still prefer to simply replace the valve, especially in a residential application where there are not trained and experienced PRV rebuild technicians at hand.

In my opinion it's very dangerous to try to rebuild a pressure relief valve and much quicker and less expensive to simply replace it with the proper unit.

Reader follow-up:

Thank you. Do you think I could use the Watts 335 instead of the 174A?

Moderator reply:

Critical is the valve's BTU dump rating. You can always put on a valve that would dump BTUs faster but you can never put on a valve that would dump be to use at a lower rate than the factory requirement.

Home heating boiler of the valve is of course going to be rated to open at temperatures over 200 or pressures over 30 PSI. So it's the dump rate capacity that's critical along with the tapping diameter.

If you don't have the manual for your Bryant heating boiler, see

BRYANT HVAC AGE MANUALS & PARTS GUIDES - also see Carrier

Reader follow-up:

I'm appreciative your help and all I needed was an ok to switch from the 174A to the 335 valve. I will keep looking.

Moderator reply:

Keep in mind that I have zero information about your boiler installation. The two valves are not identical.

Where you'd get into trouble would be, at the very least, a case of putting that relief valve on a high BTUh boiler - which isn't your case as you gave your boiler's BTUH (input?) as 160,000.

The Watts 335 PRV is described as

Smaller relief valve for popular size boilers up to 510,000 BUT at 30psi (2.11 bar)

The Watts 174 PRV is described as

Standard Pressure Setting: 30psi (206.9 kPa). Pressure Range: In 5psi (34.5 kPa) increments from 30 to 150psi (2 to 10 bar) with corresponding high ratings from 650,000 to 14,370,000 BTU/hr.

Either of those can vent energy at a rate far greater than your boiler if your original note meant Input BTUH of 160,000 BTUh

Both valves use the same safety warning and "installation" tag - given below

Excerpt:

This valve must be installed by a licensed plumbing contractor in accordance with these instructions. Repair or alteration of valve in any way is prohibited by national safety standards/local codes.

Below are the specifications sheets for the two valves.

Comment: this relief valve draining "up" plus a "pigtail" temperature sensor reported acceptable in California?

For your TPR pages, my local AJH having dealt with too many botched basement TPR's under the California Plumbing Code, has adopted this - Bryce Nesbitt

[The design and function of this pigtail is not defined in the question nor photo: we see relief valve that drains upwards and uses a "pigtail" whose function is not known: is this a temperature sensor shutoff control, at its base? - Ed.]

Moderator reply:

This discussion has moved to

RELIEF VALVE DISCHARGE TUBE ROUTED "UP"

On 2020-07-08 by (mod) - do not use a boiler pressure relief valve on a water storage tank

No, CS you can't use a boiler pressure relief valve on a water storage tank - not from a steam boiler nor from a hot water or hydronic boiler.

No, CS you can't use a boiler pressure relief valve on a water storage tank - not from a steam boiler nor from a hot water or hydronic boiler.

The operating pressure ranges are different, and the water temperature sensor on the steam or hot water boiler TPR valve would of course prevent mounting it directly onto a water pipe.

It's the wrong device and would be unsafe.

Instead, you'll want a water pressure relief valve similar to this Eastman 1/2 in. Brass IPS Pressure Relief Valve - costing less than $10. U.S.

A low pressure steam boiler PRV would open at less than 5 or 10 psi while a water pressure tank at a typical home may see normal pressures up to 50 to even 75 psi.

On 2020-07-08 by CS

will a low pressure steam boiler pressure relief valve work on a water storage tank ?

On 2020-03-02 by Frank

Thank you!

On 2020-02-29 - by (mod) -

Frank

To change the relief valve the boiler needs to be cool and relieved of pressure.

If you do not drain the boiler to below the point of attachment of the relief. You need to be prepared for water viewing or leaking out during the changeover but some plumbers are able to cope with that by being prepared with the new valve already taped with Teflon tape and ready to screw in and of course bucket in a mop.

On 2020-02-28 by Frank

To install a new relief valve on an oil fired boiler do you have to drain the boiler or can you just pop the relief valve, relieve the pressure, shut the water feed to the boiler then remove the old relief valve

On 2019-11-23 - by (mod) -

Michael

It's possible that the thermostat on your water heater is not calibrated accurately. Try turning it down. If it then behave normally in the temperatures are stable you may be okay. If it doesn't you're going to need to replace the thermostat control

On 2019-11-23 by Michael65

Replaced water pipes with Pex, installed Pex rated relief valve set my heater to 120* but when it turns on it heats to 130* and my relief valve opens at 117*?

On 2019-02-19 - by (mod) -

Check the water temperature

On 2019-02-17 by Barry

Pressure relief valve continues to drip, I replaced valve and expansion tank, water pressure gauge is around 12psi and rises to about 18psi when running yet it still starts to drip when furnace is running

On 2017-12-19 by (mod) - Is a pressure relieve valve required for hot water boiler since it has a water header tank ?

Yes Soko, EVERY pressurised vessel must have a relief valve. That's true for hot water, steam, even cold water (well tanks).

On 2017-12-19 by Soko

Is a pressure relieve valve required for hot water boiler since it has a water header tank and produces hot water rather than steam

...

Continue reading at RELIEF VALVE DISCHARGE TUBE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see RELIEF VALVE - TP VALVE FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- BLEVE EXPLOSIONS

- GAS WATER HEATER AUTOMATIC SHUTOFF - shuts of gas burner if heater reaches 210F

- HOT WATER PRESSURE EXPANSION RATE

- HOT WATER EXPANSION TANKS

- RELIEF VALVES - TP VALVES - home

- EXPANSION TANK WATERLOGGED, RELIEF VALVE LEAK

- RELIEF VALVE INSPECTION POINTS

- RELIEF VALVE DISCHARGE TUBE

- RELIEF VALVE LEAKS

- RELIEF VALVE LEAK DUE TO EXPANSION TANK

- RELIEF VALVE on STEAMBATH GENERATOR

- RELIEF VALVE, TP VALVE, BOILER

- RELIEF VALVE, TP VALVE, STEAM BOILER

- RELIEF VALVE, TP VALVE TEST

- RELIEF VALVE, WATER HEATER

- RELIEF VALVE, WATER TANK

- THERMAL EXPANSION TPR VALVE LEAKS

- TUNDISH used in PLUMBING

- WATER HEATER PRESSURE-ONLY RELIEF VALVES

- EXPANSION TANKS, BOILERS - tanks to prevent T&P valve leaks due to normal heating system pressure cycling

- HOT WATER EXPANSION TANKS - tanks & special pressure relief valves to stop TPR valve leaks due to normal water heater pressure cycling

- WATER PUMP SAFETY - building water tank pressure relief valves sensing pressure only are required on pressurized tanks such as water tanks in buildings.

Suggested citation for this web page

RELIEF VALVES - TP VALVES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to T&P RELIEF VALVES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Thanks to Henry Torres (Boiler Inspector), for calling to our attention an error in our BTU rating statement about relief valves.

- [2] Thanks to Ron Wells, Wells Inspection Services, Inc., Chapel Hill, NC 27515, Tel: 919-968-4981, Cell: 919-302-2652 License Number: 75 - Mr. Wells is a professional home inspector and a member of ASHI, the American Society of Home Inspectors. He can be reached at Ron@weelsinspections.com

- [3] Thanks to reader B.T. for pointing out the hazards of relief valves that drain to a remote location where freezing may occur, 1/27/2013

- [4]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

- [5] Boiler Chemicals 101, NCDENR, - Retrieved 12/24/2010, original source http://www.p2pays.org/ref/32/31321.pdf

Quoting from the North Carolina Division of Pollution Prevention and Environmental Assistance: The N.C. Division of Pollution Prevention and Environmental Assistance provides free, non-regulatory technical assistance and education on methods to eliminate, reduce, or recycle wastes before they become pollutants or require disposal. Contact DPPEA at (919) 715-6500 or (800) 763-0136 for assistance with issues in this fact sheet or any of your waste reduction concerns. - [16] Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- [17] Installation Guide for Residential Hydronic Heating Systems

- [81] Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- [19] The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- [20] SCALE FORMATION in WATER HEATERS and METHODS of PREVENTION free download as [PDF] Krappe,

Justus Maximilian, Engineering experiment station. Gas engineering bulletin; no. 6; Research series; no. 74; On cover: Engineering bulletin, Purdue university. Vol. xxiv, no. 3a. June, 1940 (Layfayette Indiana) commonly referred to in some references as "Purdue University Bulletin No. 74" - thanks to researcher Robyn Goldstein for the full citation. LCCN: 40028844 & OCLC: 1038544 - Water analysis, water softening, hot-water supply. 27pages.

You can also obtain this document through your local library. (full copy file at InspectAPedia 3/31/2010) Purdue B074 can be hard to locate online.

Also Bradford White Corporation (a manufacturer of water heaters) previously published

SCALE FORMATION in WATER HEATERS - EXCERPTS [PDF] from that document made available by Purdue University. - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.