Guide to Blower Doors & Air Infiltration in buildings

Guide to Blower Doors & Air Infiltration in buildings

- POST a QUESTION or COMMENT about blower tests & equipment for measuring building air change rate and air leakage rates

Building blower door tests:

This article explains the use of blower door tests to evaluate building air infiltration and tight compared with leaky houses.

This website discusses how to inspect, diagnose problems in, and install or repair building insulation & ventilation systems including air leaks, air infiltration, heating cost, heat loss, moisture, & interior stains.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Blower Door Tests for Air Leaks in Homes

History of Blower Door Testing

History of Blower Door Testing

For decades, energy specialists have known that air infiltration accounts for one-third to one-half of a typical home's heat loss.

Yet efforts to curtail convective heat loss in both new and retrofit building projects have been for the most part haphazard and not always successful.

The blower door test provides a scientific approach to identifying and controlling air infiltration (air leaks) in buildings.

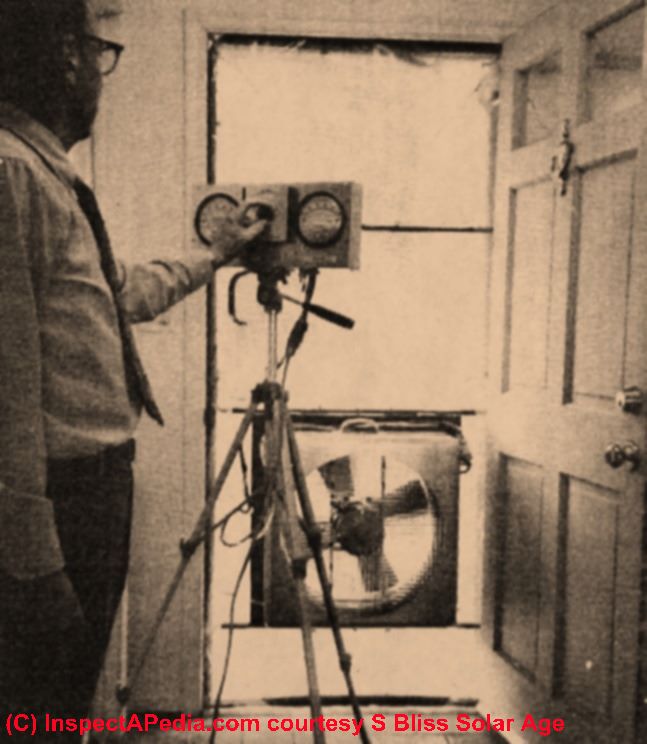

Developed in the mid-1970's at Princeton University's Environmental Studies Branch, the portable blower door successfully moved from the university to the construction industry and energy conservation consultant use.

The blower door also provided leads for active solar space heating, teaching contractors where they need to tighten the homes they build, and blower doors have added vigor to the home insulation and home weatherization business.

In Sweden pressurization testing is required by the building code; in Canada similar standards have been developed.

What is a Blower Door Test?

The heart of the blower door is a common fan, usually about 500 cfm (cubic feet per minute of air movement capacity), the same size as a typical 30-inch whole house fan. The blower door fan mounts into a door-sized housing that cleverly adjusts and seals to fit snugly in the main doorway of the building to be blower-door tested.

One type of blower door seals with an inflatable band around its perimeter. The unit then pressurizes (blows into) or de-pressurizes (blows out of) the house, typically to 50 pascals of pressure. This forces air to flow through cracks or leaks in the building envelope.

In the heat loss and air infiltration article AIR LEAK DETECTION TOOLS the energy team begin the building analysis with a blower door test to determine the starting point for a building energy savings tune-up. In that example case, the house leaked at 32 air changes perhour (ach) at 50 pascals.

Equivalent Leakage Area - ELA - is a Window Open?

Built-in instrumentation compares the air blown through the fan to the pressure drop across the blower door assembly (thus across the building doorway), giving a measure of the relative tightness of the house.

Charts or computers convert the pressure drop to an equivalent leakage area (ELA) - the size of a single gaping hole in the building shell that would result in the same amount of air leakage.

The equivalent leakage area (ELA) helps consumes understand the cumulative effect of the many small leaks that are present at a typical building as they may indeed add up to the equivalent of an open door or window on the building.

Air Changes per Hour - ACH - At What Rate is Air Leaking Into or Out Of the Building?

The computer can also generate an estimate of air changes per hour (ACH) of the house under normal winter conditions - that is, with windows and doors closed. The presence or absence of wind will, of course, change the ACH of a leaky home, as we discuss just below.

Air changes per hour (ACH) measures are readily recognized by building researchers and code officials and join R-Value as popular measures of the energy efficiency of a building.

See INSULATION R-VALUES & PROPERTIES.

Using a Smoke Test to Pinpoint Air Leaks & Direction of Air Movement: Infiltration & Exfiltration in buildings

We (DJF) often use a smoke pencil or smoke gun (shown below) in buildings to demonstrate that even without a blower door test one can observe air movement in buildings.

Without a blower door to pressureize or de-pressurize the entire building at once, we can observe air convection currents caused by temperature differences at each building level, and we see air movement caused by various building blowers and fans such as furnace or air conditioing air handlers, bath vents, kitchen vents, whole house fans and similar devices.

Often there are surprises: significant leak points that were not recognized and air movement in opposite direction to that anticipated such as warm air moving down from a roof vent rather than up and out in an air-conditioned two story home.

What is a Blower Door Test Really Measuring?

As our photographs above demonstrate (D. Friedman using a smoke tester to screen for leaks into an air handler cabinet), air movement through an opening in a building or through openings in the building's HVAC equipment and ducts changes dramatically depending on whether wind is blowing or not, or whether a fan is on or off in the building's HVAC system or ventilation system.

At above left the blower fan is off, and at above right the HVAC system blower fan was on.

There was no air movement into the HVAC system until the fan turned on, but at with fan-on the leakage rate was significant, drawing moldy air from a wet basement in this particular case, blowing these particles into the living area upstairs.

In fact, the blower door really measures only one thing. This is the amount of air leakage that would occur if an enormous wind blew or drew with equal force at all sides of the house -- which of course never actually occurs.

Typically, the leakage rate at 50 pascals is extrapolated down to 5-10 pascals to find the ELA (equivalent leakage area).

Deriving the natural ACH (air changes per hour in the building) is the more artful step.

The actual rate of air exchange depends on the interaction of the two driving forces -- the stack effect and wind -- with the shape of the house and the location of the cracks having an important effect on the actual leakage and thus the heating or cooling energy costs of the building

How Building Shape Affects Air Leakage

A tall skinny home in cold windy weather will leak more than a squat home in a milder climate with low or no wind present. Gaps open to north winds will leak more than gaps of similar size and shape that are buffered by porches or plantings around a home. Algorithms for predicting ACH are available and are continuously refined.

What is the Typical Rate of Building Air Leakage?

The best ACH algorithms still claim accuracy within 25 percent. For a rough estimate of normal air leakage at a building, divide the ACH at 50 pascals by 7.

How Should Blower Door, Air Leak, & Air Movement Tests be Used?

While the air change per hour and equivalent leakage area numbers help in research and sales, the blower door has a more direct and practical use for the tradesman intent on stopping building air leaks. Examples of this use are

In conjunction with a smoke pencil or similar smoke testing device, the pressurization allows workers to pinpoint the air leaks that will show up under normal winds and temperatures and thus to seal them systematically.

Air Movement Testing Without a Blower Door

Our photo (left) shows a test performed by website author Daniel Friedman demonstrating air movement under a building door.

It is easy to demonstrate that a home with warm air heating or central air conditioning does or does not have adequate return air flow to the air handler.

- Close all of the building's interior doors

- Turn on the warm air heat or air conditioner blower fan - use the "fan-on" switch.and let the fan run for five to ten minutes.

(See FAN ON AUTO MAN Thermostat Switch) - At each interior room you can detect whether or not the room is being pressurized by suppy air either by opening the door to the room an inch or so and feeling for a rush of air leaving the room at that moment, or by using a smoke generator such as we demonstrate in our photograph (above).

In buildings with central air returns and room doors that have not been under-cut, or perhaps were doors were originally undercut but thick wall-to-wall carpeting has been added, blocking that air path, you may find that simply leaving doors open or ajar will significantly improve air-flow to the air return ducts and thus will improve room air heating or cooling - a step that also reduces heating and cooling costs.

Sealing Leaks in A Building & Equivalent Savings in Heating Cost

As reported in Solar Age magazine in the 1980's, James McGarvey, a licensed dealer with Canada-based Ener-Corp Management, Ltd., seals any gap that the smoke test reveals at 10 pascals, equivalent to a 9-13 mph head wind.

Sealing anything beyond that, he said, is not cost effective. The ELA of a typical Victorian home, according to McGarvey, might be cut in half to 300 to 400 square inches, reducing the air infiltration rate to .8 or .9 ACH.

The annual fuel bill in a leaky Victorian home can be cut by 30-365 percent using this approach. A large old house will take 3000 - 5000 linear feet of silicone caulk applied indoors, and a variety of weather strips and seals applied carefully.

Also as reported in Solar Age, Princeton Energy Partners (PEP) took a slightly different approach. An outgrowth of Princeton University's Center for Energy and Environmental Studies - birthplace in 1977 of the first portable fan door - PEP offers franchised crews marketing and technical support but sells no products.

Franchised crews in the Eastern U.S. improve home energy efficiency by using a combination of infrared thermography and building pressurization testing methods to identify areas of heat loss and air leaks. PEP remarked that plenty of time is spent in the attics of homes where convective loops from wall partitions into building attics pump more heat out of a house than most people realize. Air infiltration is thus only part of the heat loss story.

The contractors then perform the highest priority procedures and leave the client with recommendations for additional savings.

Also see ENERGY SAVINGS PRIORITIES for our discussion of setting priorities when saving on heating or cooling costs at a building.

Here we include solar energy, solar heating, solar hot water, and related building energy efficiency improvement articles reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Readers should also see INDOOR AIR QUALITY IMPROVEMENT GUIDE which includes details about whole house ventilation systems. Our page top photo, courtesy of Steven Bliss, shows an Infiltec blower door test being performed at a home.

Accompanying text is reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Blower Door Testing Research

- Also see the page end References or Citations

- Cuce, Erdem. "Role of airtightness in energy loss from windows: Experimental results from in-situ tests." Energy and Buildings 139 (2017): 449-455.

- Emmerich, Steven J., and Andrew K. Persily. "Analysis of US commercial building envelope air leakage database to support sustainable building design." International Journal of Ventilation 12, no. 4 (2014): 331-344.

Abstract:

In 1998, NIST published a review of commercial and institutional building airtightness data that found significant levels of air leakage and debunked the “myth” of the airtight commercial building (Persily, 1998). Since then, NIST has expanded and maintained a database of whole building envelope leakage measurements of U.S. commercial and institutional buildings.

In addition to building leakage values collected from research publications, low-energy building programs and private pressurization testing firms, the database includes basic building characteristics such as year built, building type, floor area, number of storeys, location, and wall construction type for many of the buildings.

The purposes of the database are to support the design and construction of low-energy buildings, to establish default values for building simulation, to estimate the energy savings potential of airtightness requirements in standards and codes, and to identify opportunities for additional improvements in building airtightness performance.

The U.S. commercial building envelope leakage database contains data for almost 400 buildings including about 70 constructed in the past decade. The average air leakage for the buildings is 20% tighter than the average for the 228 buildings included in a similar 2011 analysis.

The data were analysed to determine the factors that impact airtightness such as building type and height. Recent additions to the database include numerous buildings constructed to meet the specifications of sustainable building programs such as the U.S. Green Building Council’s LEED rating system, as well as buildings designed and constructed with air barriers.

The analysis found that the 79 buildings with an air barrier had an average air leakage almost 70% less than the average for the 290 buildings not specified as having an air barrier thus demonstrating the critical need to design and construct commercial buildings with an air barrier to support sustainable building design. - Jeong, J. W., J. Firrantello, W. P. Bahnfleth, J. D. Freihaut, and A. Musser. "Case studies of building envelope leakage measurement using an air-handler fan pressurisation approach." Building Services Engineering Research and Technology 29, no. 2 (2008): 137-155.

Abstract:

The air-handler fan pressurisation method can be a practical way to estimate envelope leakage in large scale or tall buildings where a conventional blower door test is not practical. Standards such as CGSB 149.15 describe desirable test conditions and protocols for such tests.

However, because of the variety of building air handling system constructions and site conditions, and limited time and budget available for testing, one may not be able to perform the test under the recommended standard conditions, especially when the system configuration and operation at the site are unfavourable.

This study describes air-handler fan pressurisation tests performed for two existing buildings having problematic site conditions affected the ability to perform standard test protocols.

Envelope leakage was measured with and without sealing of elevator shafts. Both buildings were found to have standard leakage flow rates that exceed typical levels, with or without elevator shaft leakage. This paper provides some insight into what should be done to ensure a successful air-handler fan pressurisation test by describing what was done to deal with undesirable site conditions which could occur in many buildings.

Practical applications:

This study shows that air-handler fan pressurisation tests can be performed even in problematic buildings by improving test conditions at the site by adjusting the system operation and by utilising site specific measurement techniques and instrumentation.

The applicability of recently developed fan airflow and outdoor intake flow measuring sensors to the air-handler fan pressurisation test is also discussed.

However, it also shows that perfect implementation of standard air-handler fan pressurisation test procedure may be difficult in real buildings for a reasonable cost. Published case studies providing methods for solving various practical problems at the test site are very rare.

This paper is useful for engineers who are seeking practical information about the air-handler fan pressurisation. - Kalamees, Targo. "Air tightness and air leakages of new lightweight single-family detached houses in Estonia." Building and environment 42, no. 6 (2007): 2369-2377.

- Mélois, Adeline Bailly, Bassam Moujalled, Gaëlle Guyot, and Valérie Leprince. "Improving building envelope knowledge from analysis of 219,000 certified on-site air leakage measurements in France." Building and Environment 159 (2019): 106145.

Abstract:

The French air leakage testers' scheme led to the development of a national database, which includes about 219,000 airtightness measurements, mainly from residential buildings built since 2010. This paper first presents the measurement methodology and the requirements of the testers’ scheme regarding the reliability of the data included in the database.

Different analyses are then presented, to:

- give a general overview of the new French building stock;

- analyse several factors, including insulation, ventilation systems, and main building materials, that may significantly impact building leakage measurement results;

- identifying levers to improve the practices of building construction stakeholders and testers.

These analyses reveal influential factors, such as the main material of the building, the thermal insulation technique and the type of ventilation system. The most frequently identified leaks and the most influential leaks have been identified, in order to improve building airtightness.

The common use of last-minute correction has also been identified, despite the impact on airtightness durability. Finally, these analyses confirm that the multi-point testing method fits well with the French context, buildings and climates. - Sherman, Max. "The Use of Blower‐Door Data 1." Indoor Air 5, no. 3 (1995): 215-224. https://doi.org/10.1111/j.1600-0668.1995.t01-1-00008.x

Abstract:

The role of ventilation in the housing stock is to provide fresh air and to dilute internally generated pollutants in order to assure adequate indoor air quality. Blower doors are used to measure the air tightness and air leakage of building envelopes.

As existing dwellings in the United States are ventilated primarily through leaks in the building shell (i.e., infiltration) rather than by whole-house mechanical ventilation systems, accurate understanding of the uses of blower-door data is critical Blower doors can be used to answer the following questions:

• What is the Construction Quality of the Building Envelope?

• Where are the Air Leakage Pathways?

• How Tight is the Building?

• How Much Ventilation Does the Air Leakage Supply?

• How Much Energy Does the Air Leakage Lose?

• Is this Building Too Tight?

• Is this. Building Too Loose?

• When Should Mechanical Ventilation be Considered?

Various ASHRAE Standards (e.g., 62, 119, and 136) are used to determine acceptable ventilation levels and energy requirements. - Villi, Giacomo, Clara Peretti, Samantha Graci, and Michele De Carli. "Building leakage analysis and infiltration modelling for an Italian multi-family building." Journal of Building Performance Simulation 6, no. 2 (2013): 98-118.

- Zheng, Xiaofeng, Edward Cooper, Mark Gillott, and Christopher Wood. "A practical review of alternatives to the steady pressurisation method for determining building airtightness." Renewable and Sustainable Energy Reviews 132 (2020): 110049.

Abstract:

As an important indicator of construction quality and envelope integrity of buildings, airtightness is responsible for a considerable amount of energy losses associated with infiltration.

It is crucial to understand building airtightness during construction and retrofitting to achieve a suitable envelope airtightness which is essential for obtaining a desirable building energy efficiency, durability and indoor environment.

As a convenient means of measurement, the current steady pressurisation method has long been accepted as a standard testing method for measuring building airtightness.

It offers an intuitive and robust approach for measuring building airtightness and performing building diagnostics. However, it also has some shortcomings that are mainly related to its high pressure measurement, requirement for skilful operation, long test duration and change to the building envelope.

Efforts have been made by manufacturers and researchers to further improve its accuracy and practicality with much progress achieved. Work has also been done to develop alternative methods that can overcome some of the issues.

This paper provides a practical review on the incumbent methodology and efforts that have been made over the past decades in research and development of other methods to achieve a similar purpose.

It compares them in relation to aspects that are considered important in achieving an accurate, quick and practical measurement of building airtightness and the finding shows other methods such as acoustic and unsteady technique have their own advantages over the steady pressurisation method but also add some of their own restrictions, which therefore makes them suited for different applications.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question:

(Jan 13, 2015) Bonnie said:

If a home very tight home has high Co2 levels from it's occupants, does everyone feel affected in the same way? I was told my home had high Co2 levels because I have a tight house and no fresh air is being cycled into the home.

My son and I get asthma everytime we're in the house, but my husband who smokes and other people whom have visited and stayed have never felt any affects. Shouldn't everyone be feeling some kind of affects if in fact I have high Co2 levels in my home?

Reply:

No, Bonnie, people vary widely in how they react to CO2 levels. But you'll want to read about the reaction thresholds at

...

Continue reading at CONVECTIVE LOOPS & THERMAL BYPASS LEAKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Building Air Leakage Articles

- AIR LEAK SEALING STRATEGIES - home

- AIR MOVEMENT in BUILDINGS

- BLOWER DOORS & AIR INFILTRATION

- CONVECTIVE LOOPS & THERMAL BYPASS LEAKS

- HEAT LOSS in BUILDINGS - home

- HOUSE DOCTOR, how-to be

- INSULATION AIR & HEAT LEAKS

- PASCAL CALCULATIONS

- SMOKE GUNS for AIR LEAK DETECTION

Suggested citation for this web page

BLOWER DOORS & AIR INFILTRATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ENERGY SAVINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Enter the Blower Door", Steve Bliss, Solar Age, February 1984, p. 46-47 -- Adapted with permission, from original material to form this web page article.

- Princeton University's Center for Energy and Environmental Studies, http://www.princeton.edu/pei/energy/

- Retrotec Blower Door Sources: www.retrotecblowerdoor.com/ Minneapolis Blower Door Source Information

- Infiltec Blower Door Sources: Lightweight blower door and instrumentation are available from Infiltec - see their online catalog at www.infiltec.com/inf-catb.htm

- The Energy Conservatory Blower Door Source: - www.energyconservatory.com/products/products4.htm

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.