Old Electrical Systems

Old Electrical Systems

Wiring, Inspection & Repair

Electrical Service, Panel, Devices, Grounding, Knob & Tube, & Wiring in Older buildings; proper handling of abandoned electrical wires.

- POST a QUESTION or COMMENT about old house wiring, knob & tube, old fuse panels, old house wiring condition & safety

Inspecting & repairing old house or old building electrical wiring.

Here we list common old building electrical wiring system safety concerns and we illustrate types of old electrical wires and devices. We describe various old wiring safety hazards, code violations, and generally bad practices, some of which can be lethal such as leaving bare, cut-off but electrically-live wire ends in a building.

This article series answers basic questions about assessing and repairing the electrical service, capacity, wiring type, condition, and safety in older homes.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Electrical Wiring Safety Concerns in Older Homes

Older homes or other buildings often have inadequate, obsolete, damaged, modified, extended, or otherwise unsafe electrical system components including service entry wiring, electrical panels, overcurrent protection, and electrical devices such as switches, light fixtures, electrical receptacles.

Older homes or other buildings often have inadequate, obsolete, damaged, modified, extended, or otherwise unsafe electrical system components including service entry wiring, electrical panels, overcurrent protection, and electrical devices such as switches, light fixtures, electrical receptacles.

Older buildings also often have electrical receptacles and fixtures that are ungrounded, and many local codes do not require that they be rewired to provide electrical grounding.

Still, grounding is worth adding to your system because it adds protection against electrical shock.

Click to enlarge any image]

Absence of good electrical grounding at older homes

The building electrical grounding system provides a third path for electricity to travel along, so if there is a leak of any sort, it will flow into the earth rather than into the body of a person who touches a defective fixture, appliance, or tool.

A building or home electrical system is grounded with a grounding rod driven at least 8 feet into the ground outside the house or by connecting to a cold water pipe.

Each individual branch circuit must be grounded as well, either with a separate wire that leads to the neutral bar of the service panel or with metal sheathing that runs without a break from each outlet to the panel.

(In theory, electrical outlets could be grounded individually, but this is impractical.)

Readers of this article should also

Do Older Homes Have Proper & Safe Electrical Ground Wiring?

Often an older building has poor or no working local electrical ground, relying instead on the incoming neutral wire from the electrical service.

Or the building's main electrical ground may have relied on connection to a metal water pipe connected to a well;

we've found building ground wires connected to a metal water pipe which used to run out of the building and into earth (possibly a pretty effective ground) but where the metal piping exiting the building had been replaced with a newer plastic water line between the well and the building. In other words the local ground was completely ineffective.

Modern electrical grounding at residential properties requires use of one or more grounding electrodes connected by an un-spliced wire between the electrode and the ground and neutral bus in the main electrical panel.

Bare aluminum electrical ground wires are sometimes found to have corroded entirely through where the wire touched a damp foundation wall. We also find that the ground wire between the electrical panel and a building water pipe or grounding electrode has become separated, loose, spliced, or lost entirely, as shown in our photo.

Ungrounded, un polarized electrical circuits in older homes

If your outlets have two slots that are the same size, then they are neither polarized nor grounded. This leaves you with no protection against shocks from defective fixtures or appliances using that outlet. At the very least, you need to install polarized outlets.

You cannot and should not install grounded electrical outlets on circuits where no ground path is actually present (such as knob and tube wiring). To provide a grounded outlet where no ground is present is dangerous.

Some locations in your house- especially where the outlet and/or appliances may become wet- require ground-fault circuit-interrupter (GFCI) receptacles. Older, ungrounded circuits usually are protected by polarization, which is less effective than grounding but better than nothing. Grounded and polarized receptacles work only if they are wired correctly.

An older home may have electrical service that is inadequate or even unsafe. It can be confusing, as well. If you are unsure about your home’s wiring, have a professional check it out.

See ELECTRICAL GROUNDING in OLDER HOMES for details about this topic

Also see ELECTRICAL OUTLET, HOW TO ADD & WIRE where we discuss adding or updating electrical receptacles older homes that have no grounding conductor on receptacle circuits

See ELECTRICAL GROUND SYSTEM INSPECTION for details about electrical wiring of receptacles (outlets or "wall plugs") and how to inspect the electrical grounding system at a building.

Voltage Available at Older Homes

Some older homes have only 120-volt electrical service. The electrical cable bringing electricity to the building provides two wires - one live or "hot" (rather than two) and a neutral entering the house.

This means you will not be able to have any 240-volt circuits or large appliances.

Our photo shows a single hot wire and a single neutral wire which is grounded by the utility company somewhere upstream from this home.

See DEFINITIONS of ELECTRICAL TERMS if you're not sure about the definitions of volts.

See AMPS VOLTS DETERMINATION for a detailed procedure on determining the whether your building is served by 120V or 240V.

Amperage Available at Older Homes

Modern electrical service provides at least 100 amps of power, which is enough to power, a medium-size house with average number of appliances.

A house built in the 1950s or before may only have 30-amp service (the circuit box will have only two fuses) or 60-amp service (four fuses - see our photo). With so few circuits, the number of appliances you can run will be limited.

Even if a building has had additional electrical circuits installed, thus improving the distribution of electrical power in the home, if the main electrical panel has not been up-graded it is possible that it is too small for the current usage in the building.

If your building has been wired correctly, the circuit breakers or fuses should protect the building from a fire due to overloaded circuits, and what will remain is an inconvenience: having to replace fuses or re-set circuit breakers.

If the building wiring is incorrect, damaged, or obsolete, the combination of those conditions with insufficient incoming building amperage may increase the risk of fire.

See DEFINITIONS of ELECTRICAL TERMS if you're not sure about the definitions of Amps, Watts, or similar electrical terms.

See AMPS VOLTS DETERMINATION for a detailed procedure on determining the ampacity available at a building.

Some Potential Electrical Problems in Older Home

Here are a few things to consider when inspecting the electrical system in an older home.

Warning: this list of electrical wiring defects and safety concerns in older homes is incomplete.

CONTACT US to suggest corrections, changes, or to add additional items.

Knob-and-tube wiring in older homes

Knob and tube electrical of wiring has been installed in homes from the 1920s right up into the 1970's in some jurisdictions in North America and it is still used in new electrical installations in some other countries including Japan.

Knob and tube electrical wiring may be functional in a home and it was in its original concept a safe wiring method, separating the two conductors in air (see our photo at left) and using durable ceramic insulating knobs and tubes to mount the wire.

Knob and tube electrical wiring may not need to be replaced, but it certainly deserves careful inspection and possibly replacement or repair, because knob and tube systems lack an electrical ground (less safe), may have damaged insulation (less safe), or may have been improperly modified or extended (unsafe).

Watch out: for improperly abandoned knob and tube electrical wiring, knob and tube circuits that have been extended to include new circuits and devices, damaged knob and tube wire and wire insulation, knob and tube wire that has been insulated-over or around, changing its heat rating and perhaps creating a fire risk, and other K&T damage or defects that make the wiring system unsafe.

Above: a knob and tube wiring circuit has been run to an electrical box where it is used to extend to additional circuits in the building: not permitted.

Then there's the DIY wiring, missing box cover, overcrowded electrical box, unprotected knob and tube conductor run through the electrical box opening, damaged wiring conductors, exposed bare wires at splices, possible evidence of wire overheating, and more.

[Click to enlarge any image]

Please see KNOB & TUBE WIRING for a detailed discussion of the identification, inspection, and repair of this electrical wiring system.

Improperly-Abandoned Electrical Circuits

Comment: NH FireBear comments on improperly-abandoned electrical wiring: suddenly there was a cool flash of blue and a big BANG!

Comment: NH FireBear comments on improperly-abandoned electrical wiring: suddenly there was a cool flash of blue and a big BANG!

I recently inspected a facility having exposed Knob&Tube wires cut off and dangling in the basement and attic where the BX guys came through and BX cables cut off and dangling (or laying on the floor) where the Romex guys came through.

I have given them a preliminary notice of intent to cite them for "improperly abandoned wiring", where it is unclear that BOTH ends of all conductors are, in fact, dead.

Under the NEC (e.g., 2014), there is no particular requirement to properly terminate (either open, shorted or grounded), let alone remove, conductors permanently disconnected from power, other than specific requirements for removal of fire alarm and communication cables of various kinds (apparently based upon concerned unrelated to electrocution).

[Click to enlarge any image] Shown here: cut-off, abandoned armored cable in a New York home.

This leaves it up to each electrician to implement their own practices. Carson Dunlop Associates' book on Principles of Home Inspection: Electrical Systems (2003) states "The best practice is to remove any abandoned wire so there is no possibility of leaving a live wire exposed". p.138, section 5.15.17.

I happen to agree, but there has to be a CODE requirement if I want to "make it stick." [ Carson Dunlop Associates is a Toronto home inspection & education company who also provide home inspection report writing tools. The company is a frequent contributor to technical content and illustrations at InspectApedfia.com - Ed.]

There has been a lot of discussion in the trade press about whether to snip off conductors (at the last place you can reach), strip and bond/nut them together or insulate them separately, or to just ignore them, absent a specific reason to be concerned, since they are no longer part of an "electrical installation".

In my view, cut-off electrical wires left in place in a building are not just "random garbage" in the walls or conduits, but a potential hazard, if not "properly abandoned".

In my view, cut-off electrical wires left in place in a building are not just "random garbage" in the walls or conduits, but a potential hazard, if not "properly abandoned".

Shown here: cut-off wire ends along a basement joist.

Fortunately, here in New Hampshire we have not only the NEC but also the National Fire Code (NFPA 1).

In jurisdictions under NFPA 1 (e.g., 2000 and later) "Permanent wiring abandoned in place shall be tagged or otherwise identified at its termination and junction points as “Abandoned in Place” or removed from all accessible areas and insulated from contact with other live electrical wiring or devices."

I may present them with a choice: either remove them (where accessible) or else properly terminate them in junction boxes marked with proper tags, rather than leaving exposed conductors dangling around, forcing you to wonder whether the exposed ends are dead or if touching them could make YOU dead.

My favorite story about "it's SUPPOSED to be off" happened in Italy, with an industrial power cord improperly abandoned under a raised floor in a computer room, and someone had simply switched it on without asking "why is this 100-amp breaker off?"

We were pulling new cables for the Amdahl 470 and got a pretty cool flash of blue and a big bang when the un-terminated cable tips 20 feet away shorted to a support leg of the floor.

We went to lunch and told the customer they would need to pull up EVERY floor tile and verify EVERY cable before we got back... in about 4 hours, thank you very much. - NHFireBear 2016/09/19

Above: electric meters powering a pair of knob and tube circuits in an older building. At left in the photograph is an open meter base. Do not assume that this electrical wiring or these electric meter connections are "off" or dead and do not touch them.

Please see KNOB & TUBE WIRING for a detailed discussion of the identification, inspection, and repair of this electrical wiring system. - Ed.

Reply: field reports of live abandoned wiring in NY: a little voice said "Hey, wait a minute".

Inspectors & electricians are frequently coming across live old cut and flopping electrical wires.

When building owners and occupants exclaim that they think an electrical wire that's been cut off at both ends is totally harmless I point out that over the life of a building as people come and go, we cannot know when somebody will connect up a wire whose other end doesn't go where they thought. The risks include embarrassment, shock, fire, and death.

Sometimes it's physically impossible to completely remove old wires without extensive building demolition to open walls or ceilings, pull staples, etc.

Where it is not possible or considered "too expensive" to completely remove old abandoned electrical wires, I prefer to strip and splice the bare wire ends together and enclose them in a dedicated "dead" electrical box where no other in-use circuits are present, and labelled as "DEAD".

That way that when my grandson Tanner Gilligan or somebody else connects up the other end of these wires decades later, the result will immediately blow a fuse or breaker, giving a rather strong clue that something's wrong and maybe telling Tanner, "Hey Grandpa said you should hold up a minute!"

Abandoned Wires Case 1: live cut-off SEC ends.

You'd like to know about nearly touching a sawn-off SEC on an older home during a home inspection.

The new overhead SEC was in clear view going to a new service drop from the street . A new SEC cable ran down the wall to a new meter and thence to a new main distribution panel inside.

Outside at another house corner (shown above) was an old abandoned A-frame electrical meter box. My client is pointing to the old meter base in the photo. The cable ran out of this box and up the building wall to an end where we could see that it had been hack-sawn off. More of the cable sawn-ends were visible inside the meter pan.

I stood by the corner pointing to the interior of old obsolete meter box. We could see the shiny ends of the old SEC that had been hack-sawn off. I pointed to the cut-off wire saying - here's the old, disconnected cable that went indoors to the old electrical panel.

Absently as I yammered on my hand gestured towards the bare copper ends of the sawn-off electrical service entry wiring cable end. I continued to blather, drowning the client in details that had already driven his wife back to have tea with the real estate agent. The bare wire ends had no visible connection to anything relating to the new SEC. It disappeared into the wall - maybe 15 feet from the new panel.

My fingers moved closer to the attractively-shiny "dead" wire ends.

My fingers moved closer to the attractively-shiny "dead" wire ends.

Happily a little voice whispered in my ear: Wait a minute you stupid idiot. The president said "Trust but Verify".

I checked with my Tic tracer: the "abandoned electrical service wire, bare ends left easy-to-touch, was live.

See TOUCHING ELECTRICAL EQUIPMENT for a discussion of the dumb advice to lick your knuckles before wiping them across an electrical panel cover door.

Also see SAFETY for ELECTRICAL INSPECTORS for a more complete treatment of electrical inspection safety procedures for inspectors.

Abandoned Wires Case 2: wire rats in the attic.

Working on a New York cottage built along Wappingers Creek in the 1920's, I saw that nobody had been into the attic crawl space in decades. There was not even an access hatch.

Planning to do some insulating, structural repairs, and a bit of electrical wiring I cut an opening through the fiberboard ceiling and set up my ladder to crawl up to inspect the attic space.

It was difficult to push up the cutout section of fiberboard - something, not insulation was making it heavy. I slid the cutout to one side, exposing a rat's nest of old armored cable, mostly-coiled-up, and showing both open electrical boxes and bare wire ends.

I was about to pull the whole rats nest down onto the floor below when that little voice said "Hey, wait a minute!". I didn't have my Tic tracer handy but I did have a neon tester in my tool belt.

Sure enough several of the bare cut wire ends were live and just waiting for the day when that little voice had laryngitis.

See ELECTRICAL TOOLS BASIC for more about using a neon tester to check for live voltage.

Sources of electrical shorts and wiring faults in older homes

Look also for loose taped wires, old wire damaged because it’s exposed, and multiple wires slipping off a single terminal screw may seem like minor problems, but are not.

See ELECTRICAL CIRCUITS, SHORTS for more about short circuits, how they happen, how they are corrected.

Insufficient number of electrical circuits in older homes

As modern homes use more appliances and more electricity than folks did even twenty years ago, if the number of circuits in a home has not been increased it's likely that the home's electrical circuits are overloaded.

Too often in an older home we find that the electrical circuits have been "extended" by someone who has no idea about safe electrical wiring. People use lamp cord (Zip cord) or extension cords as permanent circuits, sometimes even routing such wires through walls and ceilings - a fire hazard, and certainly not in compliance with electrical codes.

At an inspection where we found lamp cord run through a wall to add wall-mounted lighting, a by standing real estate agent later asked the tenant to simply "cut and remove the wiring" - leading to a serious electrical shock event. It would have been a better idea to hire a licensed electrician.

Too often in an older home, especially one using a fuse panel, occupants are tempted to simply screw in a higher-amperage fuse to stop fuses from 'blowing". Over-fusing is dangerous: it risks setting the building on fire. Be sure that the amperage rating of your fuses or circuit breakers matches the wiring of each circuit:

- A 15-amp fuse or circuit breaker is what's needed on a 15-Amp #14-gauge copper electrical wire.

- A 20-amp fuse or circuit breaker can be used on a 20-Amp #12-gauge copper electrical wire.

For an example of installing an additional electrical receptacle,

see ELECTRICAL OUTLET, HOW TO ADD

Obsolete, Unsafe, or Inadequate Electrical Service Size, and Electrical Panels

Question: early 1900's electrical panel with circuit breakers

I am trying to find out the brand of this old circuit breaker box. The building was constructed in 1914 in Huntingdon PA and these appear that old. Does anyone there know this brand? - Anonymous by private email, 2016/09/19

Reply:

I don't recognize the panel brand. With your OK I'll publish these and solicit identification comments from our readers. Readers are invited to use the page top or bottom CONTACT link to offer more information about these antique electrical panels and their identity.

Also if your electrician removes the panel cover and you can send me some sharp photos of the circuit breakers, their details, any labels in the panel, and the panel bus design (that's the electrical bars to which the breakers connect) I may be able to identify the unit.

Look closely for labels attached to the circuit breakers themselves and send me a sharp close up even if there are no other markings in the panel.

Watch out: pulling off the cover of any electrical panel risks electric shock, injury or worse so don't mess with the box yourself if you're not qualified to do so. I don't want to hear from you from the hospital.

See ELECTRIC PANEL INSPECTION SAFETY

Reader follow-up:

Reader follow-up:

This is a panel in an old factory that I just inspected for their insurance. I do not dig into panels, but I like to be able to identify the brand at least. This one has me stumped. It is quite old so I will be recommending they replace them anyway.

The factory is four stories and the electrical seems to be updated in most of the building including mains. These panels were on the fourth floor which is used to warehouse motors. Very little except lighting on these panels.

Anonymous by private email - 2016/09/20

Moderator reply:

Your photos show two different electrical panels, each with 12 circuits and no main breaker - currently not an acceptable design unless there is a clearly-marked MAIN switch attached or nearby.

Watch out: there are probably more serious and costly electrical system concerns here than just the two electrical panels themselves. Indeed depending on the anticipated use, the electrical panels you showed might reveal building electrical service that will be inadequate in ampacity, as would be, then, the service entry wiring and more important (in cost) the number and condition of electrical circuits in the building.

Each of your panels shows 12 electrical circuits, or a total of 24 circuits if these panels are serving the same building. That number of circuits is likely to be inadequate for the greater demands of a factory building.

Scope of electrical inspections by home & building inspectors

Being old myself, I don't assume that on "old" alone shot, nor that an old electrical panel is unsafe.

Some old equipment was very well made, using good materials.

A condition of property inspection that includes the building's electrical system might produce a dangerous report if it is not sufficiently comprehensive in scope, including the electrical service, overcurrent protection, branch distribution circuits, switches, receptacles, lighting and other components, as defects in any of these electrical components risk shock and fire hazards.

In addition, on a 1930's building it would be rare for there not to have been modifications and extensions to the electrical system. Assessment of the condition and quality of that work would also be important.

It may be helpful to review OLD ELECTRICAL WIRING TYPES

Also see DEFECTS LIST - ELECTRICAL SYSTEM for examples of professional inspection standards and scope of inspection coverage.

It's of course always safer to recommend replacement of components of which we're uncertain or to say "hire an electrician" but be warned that some electricians are themselves unfamiliar with old electrical work and don't know about widely-distributed but unsafe products such as FPE and other problem-brand electrical panels.

But a professional, working in a building for an owner, buyer, or insurance company, may nevertheless be held to common professional standards and would be expected to recognize and give appropriate advice about such hazards.

I'd welcome your opinion on this companion article about the cost of being over-cautious:

Reader follow-up:

I do not recommend this replacement by myself,

In fact, insurance companies always want knob & tube replaced, but I have seen some really nice [electrical] installations that are still functioning well. The same goes for older electrical panels

Insurance companies have long recorded histories of losses, and though sometimes a recommendation may seem unwarranted it is usually based on that on statistics. ... - Anon.

Moderator reply:

Thanks for the follow-up; working together makes us smarter.

Warnings about Polarized Electrical Plugs, Receptacles, and Lighting Fixtures

Reversed polarity shock hazards:

"Polarity" in an electrical receptacle and on the device that plugs into or connects to it means that we're making sure that we connect the "hot" or "live" side of the electrical circuit to the connection point in the appliance or device that was intended to be "hot" or "live".

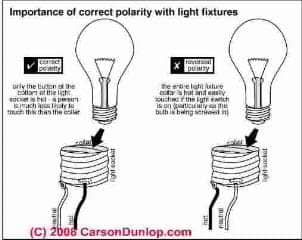

Carson Dunlop's sketches show why it's important to respect polarity when connecting an electrical receptacle, a lamp or any other appliance.

In short, reversed polarity on a light fixture means it's easier to receive a dangerous electrical shock by touching the shell of the bulb socket or even the side of the bulb itself while screwing in a new light bulb.

Reversed polarity device burn-up or fire hazards:

Never clip or file down the prongs on a grounded or polarized plug in order to force it to fit into an older electrical receptacle.

The risk is that your plug will be installed with reversed polarity - connecting the "hot" side of the electrical circuit to the normally neutral-wired side of the appliance.

We've found appliances (a coffee maker) that simply burned up when connected in this fashion.

Even though power was "off" according to the coffee maker "on-off" switch, feeding live voltage to the wrong side of the coffee make's circuit board led to a component burn-up and failure of the appliance.

Go to the heart of the problem: Test and upgrade your electrical circuit system.

See ELECTRICAL GROUND SYSTEM INSPECTION for details about how to inspect the electrical grounding system at a building.

Also, see details about electrical grounding

at ELECTRICAL CIRCUITS, SHORTS.

Watch Out Do not attempt to work on your electrical wiring, switches, or outlets unless you are properly trained and equipped to do so. Electrical components in a building can easily cause an electrical shock, burn, or even death.

Even when a hot line switch is off, one terminal on the switch is still connected to the power source. Before doing any work on the switch, the power source must be turned off by setting a circuit breaker to OFF or removing a fuse.

See SAFETY for ELECTRICAL INSPECTORS

Old Electrical Box Identification

On 2020-04-17

by Ken The Old House Guy

On 2020-04-17

by Ken The Old House Guy

Hi - I am a historic preservation consultant at oldhouseguy.com and I am having my wiring replaced.

My house was built in 1910 and surprisingly does not have any gas lighting pipes unless they were removed but that seem unlikely.

The wiring is BX with 2 cloth wires inside that are crumbling apart.

There is also romex wire that is black tar coated with two wires.

My question is do you think the wires were originally installed in 1910.

If not when do you think the box and the romex wires were installed. I am documenting the history of the house.

Do you know the date of the electric box? It says Arrow and a number 6. Attached is my BX [armored cable] wire photo.

On 2020-04-18 - by (mod) -

I will answer in more detail.

Are there any patent numbers on the box?

On 2020-04-18 by Ken The Old House Guy

So if I understand correctly, In 1910 there was most likely knob and tube wiring and gas lighting in my house. There is currently no sign of either knob and tube or gas piping.

If the BX was added in the 1920's would the gas pipes and the knob and tube all be removed?

It seems like a lot of work to remove gas pipes. Again I only have access to see under the attic floor and basement ceiling.

On 2020-04-18 by Ken The Old House Guy

(mod) - no there are not. Just "Arrow" and "6"

On 2020-04-18 - by (mod) - Age of cast-iron electrical box & light fixture supports

I've found those shallow electrical boxes in homes with second generation electrical wiring, where K&T is the first wide-spread common-use generation ca 1900 and continuing into at least the 1970s in some areas, and fabric/rubber-insulated armored cable is the second generation, ca 1920 onwards.

I've found those shallow electrical boxes in homes with second generation electrical wiring, where K&T is the first wide-spread common-use generation ca 1900 and continuing into at least the 1970s in some areas, and fabric/rubber-insulated armored cable is the second generation, ca 1920 onwards.

A 1900-built home will typically have knob and tube as well as armored cable as well as NMC wiring as people updated and added circuits over the life of the home.

A brief patent search finds that the approximate age of your electrical box, assuming you're in the U.S. is 1913.

A similar cast iron electrical box to the one in your photo was produced by Hope Manufacturing, a "light covering" actually an ceiling or wall mount electrical box typically used to support a light fixture, is shown below for-sale on eBay in April 2020.

See

- ELECTRICAL OUTLET BOX PATENT W H HOPE US Patent No. 1072462, Patented Sept. 9,1913. Filed in 1911 [PDF]

Other William H. Hope Patents vary widely, which may explain why it's difficult to track down the Hope Electrical Manufacturing Co. history - still working on that.

- Hope, William H. "DOOR LOCK AND LATCH." U.S. Patent Application 817,713, filed February 18, 1904.

- Hope, William H. "PANTOGRAPH ENGRAVING-MACHINE." U.S. Patent Application 1/206,329, filed November 20, 1915.

- Hope, William H. "ENGRAVING-MACHINE." U.S. Patent Application 1/264,074, filed July 11, 1917.

- Hope, William H. "Ruling machine." U.S. Patent 1,461,002, issued July 3, 1923.

Old wiring types

About your BX wire, there were several generations of BX and "Greenfield" flexible armored cable.

See details at OLD ELECTRICAL WIRING TYPES

Gas piping removed or used for electrical wiring

People did not usually remove gas piping as you'd have to rip open walls and ceilings. In fact I've found both live gas piping still connected in buildings as well as gas piping that was later used as conduit for electrical wire.

In an older home, **IF** in fact there was natural gas piped into homes along the same street as your home, then your home might have had gas lights and gas piping earlier in its history. But not necessarily. Not everyone installed gas lighting before moving to electrical lights.

See details at GAS LIGHTING PIPES FIXTURES

The current, modern Hope Electrical Company is Hope Electrical Products Co., Inc. | 3 Fairfield Crescent | West Caldwell, NJ 07006 | Phone: 973.882.7400 | Fax: 973.244.9292 | E-mail: sales@hopeelectrical.com Website: www.hopeelectricalproducts.com

Photo Guide to Old Electrical Wire Types

We have moved our illustrations of a variety of types of electrical wiring found in older buildings to a separate article now found

at OLD ELECTRICAL WIRING TYPES

The asbestos-insulated electrical wiring shown above is discussed

at ASBESTOS ELECTRICAL WIRE INSULATION

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-10-13 by inspectapedia.com.moderator (mod)

re-posting without dis-allowed promotional link

Happy Hiller

Great article! Another common problem that you’ll face with older houses is unprotected junction boxes.

On 2021-10-10 by inspectapedia.com.moderator (mod)

@Beverly,

At this time, we have little to add to our previous response to your question. Further research is needed.

As stated earlier, if you have any photos of the type of box that was removed, that would be helpful. And also, the total amount of materials in an individual electrical enclosure or box would not be a meaningful source of particle contamination throughout a building.

It would help us research an answer more fully if you could tell us your source of information where you said "made in the 50's and they stopped using them because with age they deteriate and apon impact or , demolishing it to remove it. Can cause a fine dust to be released into the air."

Bottom line: from what we know at this point

- we can't say for sure that your maintenance person's guess at the electrical panel box material was correct,

- the box is removed and not available for inspection and there are no photos or other information for us to consider in identifying it

- there is no reasonable probability that the removal of an electrical panel box would fill an apartment with dust

- if you still live in the subject apartment and are concerned about harmful levels of any sort of inorganic dust, a reasonable course of action would be to clean thoroughly including damp wiping and HEPA vacuuming surfaces.

On 2021-10-04 by Beverly

This apartment building was built in 1978. And the state I am in is Spokane Washington. Specifically the town of Cheney. This building is a government subsidized housing project. We know that they cut corners and end run around city and state Building Codes and State L&I permit requirements.

This electrical wiring box was demolished and removed. The back yard maintanence man who removed this box told me it was fiberglass. And right after he did this my apartment filled up with dust. And this dust acted just like fiberglass dust.

On 2021-10-03 by inspectapedia.com.moderator (mod) - Old Black Fiberglass Electrical Wiring Box ? Bakelite electrical boxes.

@Beverly,

@Beverly,

Thank you for the question about antique electrical panel boxes made from fiberglass. A product with which we are familiar so we'll have to do some research and post more information here.

There is a long history of fiberglass-reinforced building materials including fiberglass-reinforced electrical boxes and specialty enclosures like the Vevor fiberglass enclosure I'll show below, but none of those is an electrical service panel.

Photo: These brown plastic Bakelite fuse enclosures, used in the U.K. are provided as props by ElectroProp, an electronics prop house supporting the film and theatre industry. Electroprops, 17 B & C Aintree Road, Perivale, Middlesex, UB6 7LA, United Kingdom Tel Office: +44 020 8991 0191 Email: info@electroprops.co.ukWeb: https://www.electroprops.co.uk/

If you have any details such as photographs of the electrical panel or of its labels or information about the country and city of location and the age of the building that would be helpful.

And it would be especially helpful if you or your source who told you that defective fiberglass electrical panels were manufactured in the 1950s could provide even the smallest source or citation, as by U.S. patent search I've not yet found such a product - meanwhile we'll research the question a bit further.

In any event, because of its limited total material volume, the total materials comprising an individual electrical enclosure or box would not be a meaningful source of particle contamination throughout a building.

Is it possible you're actually referring not to a fiberglass product but to Bakelite plastic that was used for electrical products such as fuse panels and fuse pull-out blocks?

You can see our photos of those "plastic" electrical panel components at

inspectapedia.com/electric/Fuse-Replacement.php BLOWN FUSE REPLACEMENT

In the U.S. those Bakelite plastic electrical components were enclosed in a steel panel box. In the U.K. and some other countries, in the 1950s there were indeed some fuse box enclosures made entirely of Bakellite.

Above in this discussion we show an example still available (to rent) as a theatrical prop.

While Bakelite plastic can be cracked or broken, and while some of these plastics contained asbestos, none of them is friable, none crumble to dust over time, and none would be a meaningful source of building dust.

Below: Plastic electrical box, modern, made by Vevor and sold in the UK and elsewhere.

On 2021-10-02 by Beverly

An Old Black Fiberglass Electrical Wiring Box was removed we believe because it was old it desinergarded into a fine fiberglass dust that contaminated the indoor air of an apartment.

I was told these boxes where made in the 50's and they stopped using them because with age they deteriate and apon impact or , demolishing it to remove it.

Can cause a fine dust to be released into the air.

What can you tell me. What year were these Fiberglass Electrical Wiring Boxes made. And do they deteriate over time. What percaugtions would be taken to demolish one to take it out.

On 2021-03-21 by (mod)

1950s or 1960s copper wiring, un-damaged by fire or other means, and including a grounding conductor, may be safe to use.

On 2021-03-21 by davidcollins8406

Is it appropriate to use 1950s 1960 wiring in an old house that has a ground wire

On 2021-03-19 by (mod)

@Jim Navotney, thank you for that helpful comment, I read with you.

On 2021-03-19 by Jim Navotney

I still vividly remember an electrician hired to install a 200 amp breaker box for my father cutting off the water pipe ground then drilling a hole in the sidewalk and driving in a ground rod.

When Dad showed me this i just laughed and said he was likely fresh out of his apprenticeship and still lacked common sense.

Since the place where he installed the ground rod was dry soil under a concrete sidewalk it was a poor ground to say the least and the copper water line that ran underground more than 60 feet to the water meter was a far better ground, i merely connected the water line ground back up as soon as he left.

And any electrician that would isolate all the copper plumbing and fixtures in a house by not attaching it to the ground should not hold a license in ANY state.

On 2021-02-26 by (mod)

@Chris, it would help me make a better guess if I could see a photo of the Box you're describing. Fine in at least some cases there is a threaded Center fitting which was designed to take 1/2 or 3/8 or similar national pipe thread that supported a light fixture

On 2021-02-26 by Chris

Age of cast-iron electrical box & light fixture supports, these vintage hope mounting boxes are all over my house, but I notice the threaded pipe jutting from the center? What can I screw onto that? I'm having trouble finding some type of locknut to fit it.

On 2020-12-05 by (mod) - What amp breaker can a 1950s tube wiring handle?

1950s electrical wiring used for branch circuits for lighting and receptacles is usualy #14 gauge or might be #12 gauge copper.

#14 wire gets a 15A breaker or fuse.

#12 wire would get a 20 amp breaker or fuse but it is always safer to limit the current on a circuit by putting in a smaller fuse or breaker. So on such where you could you see 15 amp protection device

On 2020-12-05 by J

What amp breaker can a 1950s tube wiring handle?

...

Continue reading at OLD ELECTRICAL WIRING TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see OLD HOUSE ELECTRICAL SYSTEM FAQs - questions and answers posted originally here.

Or see these

Recommended Articles

- AGE of a BUILDING, HOW to DETERMINE - Visual clues indicate the age of a building

- ELECTRICAL RECEPTACLE TYPES

- OLD HOUSE ELECTRICAL SYSTEMS - home

- 2-WIRE RECEPTACLE CONNECTIONS - no ground

- ALUMINUM WIRING IDENTIFICATION

- AMPACITY AVAILABLE in OLDER HOMES

- ANTIQUE & OLD ELECTRICAL RECEPTACLES

- ANTIQUE LAMPS (BULBS) & CONNECTOR TYPES

- ASBESTOS ELECTRICAL WIRE INSULATION

- ASBESTOS in LAMPS & LIGHT BULBS

- BULB & LAMP TYPES GUIDE - home

- ELECTRICAL COMPONENTS, AGE, TYPES

- ELECTRICAL GROUNDING in OLDER HOMES

- ELECTRICAL OUTLET, HOW TO ADD in OLDER HOME

- ELECTRICAL PANEL AGE

- ELECTRICAL PANEL FUSED NEUTRAL WIRE HAZARDS

- ELECTRICAL SHORT CIRCUITS

- FABRIC NMC WIRE INSULATION IDENTIFICATION - age of old electrical wire by trademark data

- GROUNDING, OLD HOUSE ELECTRICAL

- KNOB & TUBE WIRING

- KNOB and TUBE WIRING, OLD HOUSE

- NUMBER of CIRCUITS in OLD BUILDINGS

- OLD ELECTRICAL BOX TYPES

- OLD ELECTRICAL WIRING HISTORY

- OLD ELECTRICAL WIRING TYPES - timeline of use of different types of electrical wire & wire insulation

- OLD HOUSE ELECTRICAL SYSTEMS - home

- POLARIZED PLUGS, RECEPTACLES, LIGHTS

- SOLID PIPE EDISON DC CABLE HISTORY

- VOLTAGE AVAILABLE in OLDER HOMES

Suggested citation for this web page

OLD HOUSE ELECTRICAL SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Dini, David A. "Residential Electrical System Aging Research Project." Fire Protection Research Foundation, Quincy, MA (2008).

- Elizabeth Sluder, Montross, VA, the original author of this article, is a public school teacher who writes basic educational articles about a variety of building, construction, and other topics. Her husband, a licensed electrician, consults for her writing on electrical topics. Her articles appearing at the InspectAPedia TM Website have been edited, illustrated, and on occasion content has been added by the website author. These articles are © 2010 InspectAPedia copyright-protected, all rights reserved.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- Thanks to our reader Ed (anon) for assistance with technical page editing 03/29/2010.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.