Celotex® Cemesto Board

Celotex® Cemesto Board

History, ingredients, maintenance, repair

- POST a QUESTION or COMMENT about Celotex Cemesto Board

History of Cemesto board by Celotex and its ingredients and use as a construction panel in North America beginning in the late 1930s.

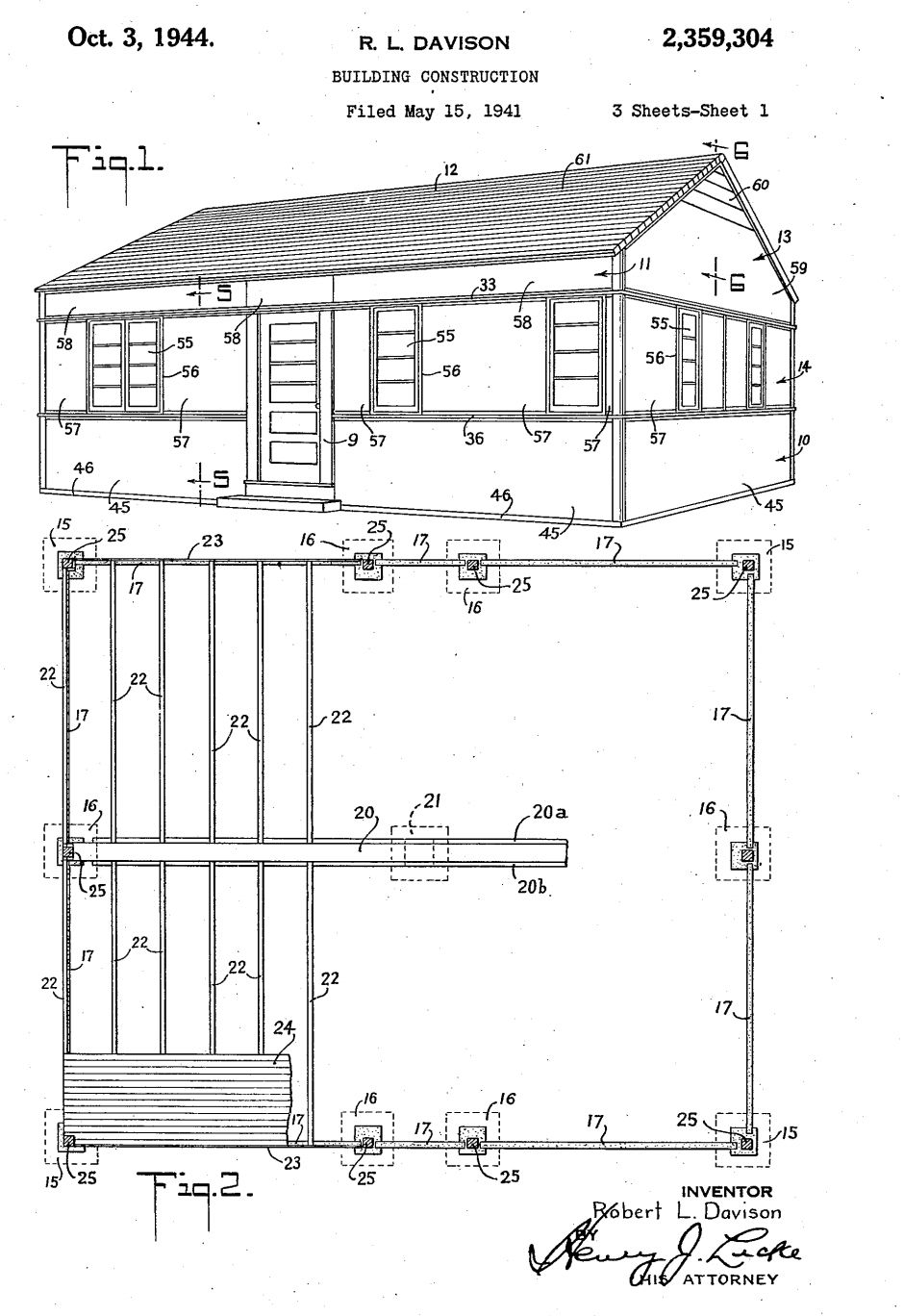

Page top: excepted from Robert L. Davison's 1945 patent of building construction methods using a beam and panel method illustrates use of Cemesto panels. Davison's patent was assigned to the John B. Pierce Foundation of New York who, with Celotex, producer of Cemesto board, popularized rapid, low-cost panel-based home construction.

This article series describes Celotex products and panelized construction methods and materials and their history and constituents.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Celotex™ Cemesto History, Ingredients, Preservation

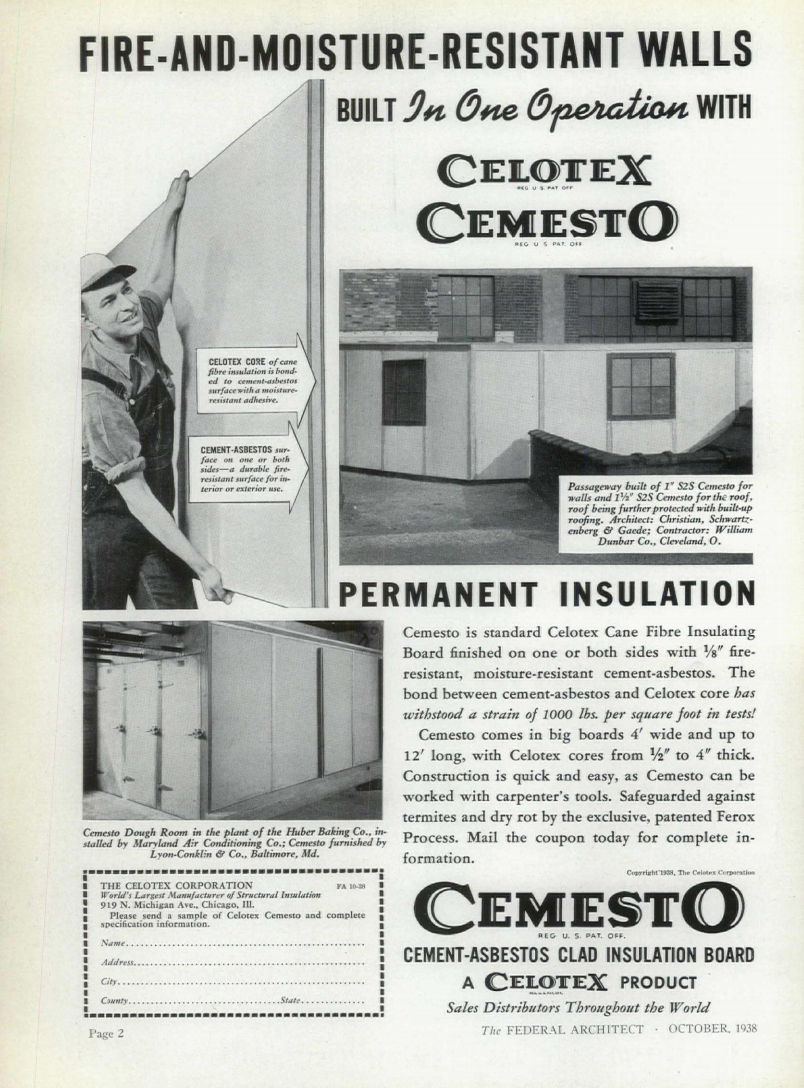

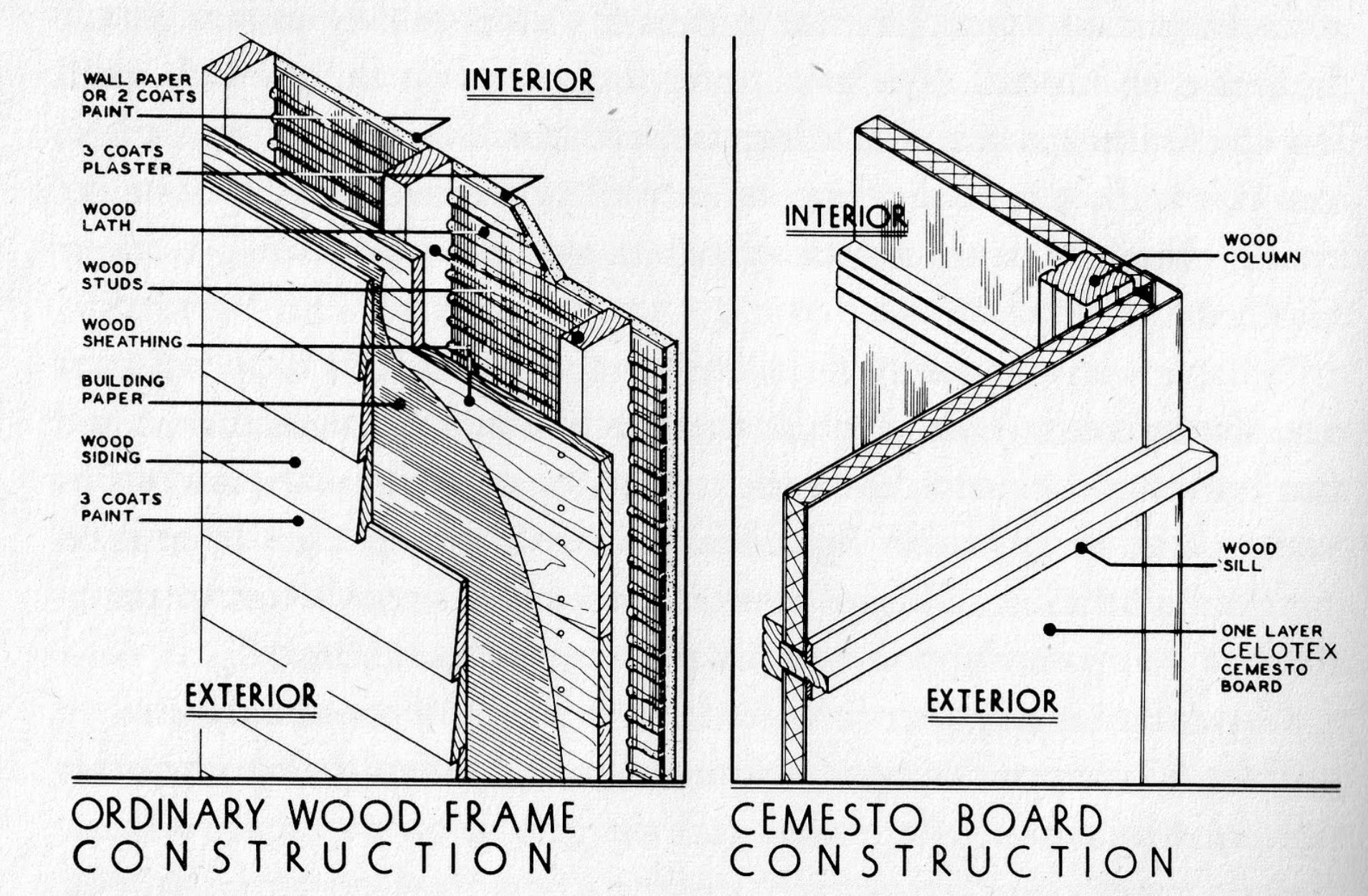

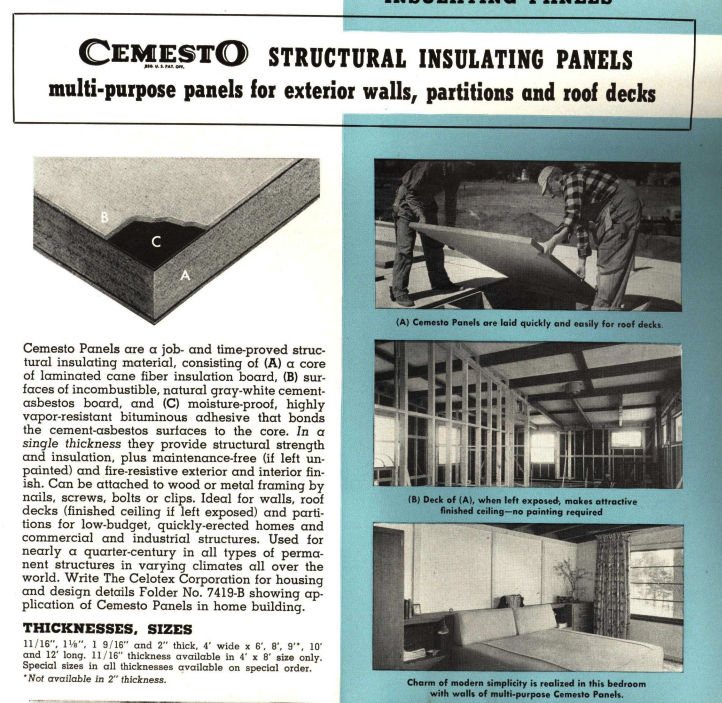

Cemesto-Board,1 1/2 to 2-inch thick 4' x 8' or 12' panels comprised of asbestos-cement panels adhered to a vegetable-fibre core (Celotex sugar cane), first introduced by Celotex in 1937 and described here by research articles and U.S. patent disclosures.

Cemesto-Board,1 1/2 to 2-inch thick 4' x 8' or 12' panels comprised of asbestos-cement panels adhered to a vegetable-fibre core (Celotex sugar cane), first introduced by Celotex in 1937 and described here by research articles and U.S. patent disclosures.

Cemesto-Board was the first commercially available sandwich panel board used in home construction in the U.S. A Cemesto-board 4x12' panel weighed 265 pounds and was considered a lightweight structural panel.

These boards did not need painting. All panels, ceiling boards, and structural members were delivered cut to specified sizes by the manufacturer.

Assembly work was done mainly in a field shop. Workers of each team knew only their own specific task, much as a worker on an assembly line repeats a series of work. (Jung 2008)

Illustration: Cemesto, combining asbestos-cement panels and a Celotex vegetable fibre core.

[Click to enlarge any image]

"Cemesto Board" is the proprietary name of the first

commercial sandwich board to be used in a house which was

built in 1933 using sandwich panels of fibreboard faces and

cement asbestos core [or vice versa - Ed.] in America. Many houses of that type

were built during World War II due to the demands for cheap,

rapidly built houses.

In 1947 a test house was built using sandwich panel in

the grounds of the U.S. Forest Products Laboratory at Madison

Wis. to investigate the long term behaviour of sandwich

panels.

The exposure test results over 15 years indicated that the wall panels made of resin-impregnated paper cores and plywood facings have demonstrated excellent performance, based on retention of stiffness and strength. In this case, the losses in stiffness and strength due to the passage of time are insignificant." (Shendy 1981)

Illustration: above: a Celotex CemestO advertisement from the October 1938 edition of The Federal Architect magazine cited below.

Below: CemestO wall construction compared with conventional wood stud wall framing as described in "The Cemesto Future", Time Magazine in a 31 May 1943 article accessible by Time Archive subscribers.

Robert Davison's 1944 "Building Construction" patent given in entirety as a link below was a significant step in the use of CemestO board as probably the earliest "structural insulated panel" or SIPs.

- AAFA, The FEDERAL ARCHITECT [PDF] October 1938, Association of Federal Architects, 1700 Eye St., Washington D.C. retrieved 2020/01/20 original source: https://www.usmodernist.org/FED/FED-1938-10-12.pdf

- Anderson, Richard. "USA/USSR: architecture and war." Grey Room (2009): 80-103.

Excerpt:

Cemesto board developed by the John B. Pierce Foundation and the Celotex Corporation... - CELOTEX ASBESTOS PRODUCTS - Catalog of Celotex® Insulating & Sheathing products that contain asbestos or that are asbestos-free

- Celotex, "Cemesto, Five Tested Ways to Meet Today's Building Needs with Minimum Use of Critical Materials", The Celotex Corporation, Chicago, Architectural Record, October 1943 p. 16 [Advertisement] The ad describes several Celotex wallboard and sheathing products including:

- Celotex Asbestos Board builds walls fast. This new Celotex product is a hard, durable combin ation of portland cement and asbestos fibre, 3/16" or 1/4" thick, available in boards 4' x 8', for fast erection of interior walls and ceilings. Can also be used for exterior finish on temporary or permanent structures.

- Celotex gypsum interior wall units save studding, save time. These extra-thick gypsum wall board are either 1" or 1 1/2" thick, and building strong, sturdy, good-looking interior parttions in the shortest possible time, with only a simple wood framework. Known as "single wall construction" this method saves much critical lumber.

- Celotex insulating board sheathing comprised of 1/8" Cement-asbestosboard for exterior and interior finish, a water and vapor proof bituminous adhesive, Celotex Ferox-treated Cane-Fibre Insulation.

- Cemesto, Cemesto combines strength, insulation, interior and exterior finish, sold in panels from 4' x 4' to 4' x 12'. "Cemesto is a revolutionary building material that comes in panels from 4' x 4' to 4' x 12' to provide a complete fire-retardant wall or roof unit. Thickness ranges from 1 1/8", 1 9/16" to 2". Today, Cemesto with 12 years of research behind it is speeding construction ofmillions of dollars' worth of wartime homes, housing projects, factories, shops and hangars using a minimum of critical material. Can be sued with either wood or steel framing. Saves time, labor, lulmber and nails.

- Celo-Siding combines siding, sheathing, insulation. This new multiple function insulating siding consists of cane fibre insulation, coated on both sides with moisture-proof asphalt, with a weather surface of crushed mineral granules in colors to provide a permanent exterior finish. It is applied direct to studding. Two thicknesses 7/8" and 5/8".

- Celotex Gypsum Roof Slabs replace wood roof decks. These new laminated gypsum roo9f deck slabs are offered in 1", 1 1/2" or 2" thicknesses, 2' wide, 8, 9', or 10' long, rigid, strong, light in weight and easy to handle. The big units cover roof areas quickly, saving important time. Roof covering can be applied immediately.

- CELOTEX STRUCTURAL INSULATION AND OTHER BUILDING PRODUCTS [PDF] (1954) from Sweets 1955 Construction Guide.

Here is similar, HIGH RESOLUTION [PDF] copy of the same document.

- Davison, Robert L. BUILDING CONSTRUCTION [PDF] U.S. Patent 2,359,304, issued October 3, 1944.

Excerpts: [original scanned text has been edited and in-filled for clarity by us]

This invention relates to building construction, and has particular reference to types of building construction wherein panels are employed as structural elements in the wall structure.

... the lower floor of the building is supported directly by the foundation, while the upper floor, and/or the roof, is supported by an upper course, and/or courses, of structural panels, extending between and secure to relatively widely spaced column uprights, or posts, which are anchored to the foundation.

The wall structure is further made up of panels, composite in nature, forming a lower course. These composite panels are employed chiefly for their insulating value, since they are relatively thick, and comprise insulating material which is reinforced and weather-resistantly faced.

It has been found that, while it is not advantageous, in most instances, to employ such composite panels as deep beams or girders, they do provide sufficient structural connection of the relatively widely spaced column uprights, or posts, adjacent to their lower ends, to effectively reinforce the building against substantially horizontal stresses, such as wind pressures.

And, by facing the upper course of structural panels with similar composite panels, it has been found that important insulation is added, strength of the building is increased, and the resulting exterior appearance is enhanced in architectural appeal.

The roof construction may be of any suitable well known type.

As here illustrated fragmentarily, see Fig. 5. it comprises rafters 42 and ceiling joists 43 joined together to provide respective prefabricated gable-formed truss units which commercially as Cemesto board, wherein an inner thickness 45 a of cellular board material, such as commercial Celotex," is laminated between outer thicknesses 45b, 45b of asbestos cement board.

The inner lamination 45a. of cellular board material is of considerable thickness relative to the laminations 45b, 45b of asbestos cement board, and provides adequate insulation for the building.

The outer asbestos cement laminations 45b; 45b provide weather-resistant facings of such rigidity and strength as effectively render' the composite panel capable of performing a structural function in addition to merely curtaining the space between respective posts.

- Davison, Robert L. BUILDING CONSTRUCTION U.S. Patent 2,372,768, issued April 3, 1945 using Cemesto panels in construction.

Excerpts:

The panel 80 is completed by an external facing 85 of composite wallboard such as Cemesto board, in which a central core of pulp insulation material is formed on each side with an asbestos cement layer which is weatherproof for external surfaces, and capable of receiving any suitable interior decorative treatment.

...

Said upper panels 80 are the principal load-carrying panels for the roof structure; they operate as deep beams and successive roof trusses rest upon and are secured to the longitudinally extending cap 84 as indicated [sic] in Fig. 19.

The lowermost course 90, and the intermediate course 91 are not essentially load-bearing structures and comprise merely the composite "Cemesto" panels, battens, and sills delineating the respective courses.

The said courtesies 90 and 91 are nailed or otherwise secured to the posts 74, and the lowermost course 90 is additionally nailed through the stringers 16 into the ends of the floor joists.- - Frank, Kullme, PREFABRICATED METAL PANEL JOINING MEMBER U.S. Patent 2,667,242, issued January 26, 1954.

Excerpt:

Although the present invention can be used to advantage with any number of types of panels, it has been found that a type of laminated panel sold under the trade name Cemesto-Board and made up of a central core of cane sugar fibre faced on both sides with a relatively hard and smooth layer of cement and asbestos mixture is particularly satisfactory, especially in localities where extremely varied climatic conditions exist.

This latter mentioned type of panel possesses qualities of low moisture absorption and excellent heat insulation se desirable in territories where heavy rainfall is not uncommon and extreme variations in temperature are to be expected. - Jung, Hyun Tae, EVOLUTION OF “EXPERIMENTAL HOUSE”: MASS PRODUCTION OF THE HOUSE AND SOM DURING THE SECOND WORLD WARr [PDF] in Evolution of the Experimental House, (2008), Dietmar Froehlich & Michaele Pride Eds., pp. 597-601 ISBN

978-0-935502-65-7 in 96th ASCA Annual Meeting Proceedings, Association of Collegiate Schools of Architecture, Website: https://www.acsa-arch.org/ [Good luck finding an email or address - Ed.] retrieved 2020/01/20 original source: https://www.acsa-arch.org/proceedings/Annual%20Meeting%20Proceedings/ACSA.AM.96/ACSA.AM.96.70.pdf

Excerpt:

The main building material was ‘Cemesto’ board, a product of the Celotex Corporation. Cemesto board consisted of a cane-fiber insulation board core, sealed with a special compound between two layers of a combination of asbestos and cement.

- Lorman, W. R., And C. K. Wiehle. PRECAST CONCRETE CONSTRUCTION AT FORRESTAL VILLAGE HOUSING PROJECT, Great Lakes, Illinois. No. Ncel-tm-069 [PDF] Naval Civil Engineering Lab Port Hueneme Ca, 1952.

Excerpt:

Partition walls in 12 individual dwelling units are comprised either of gypsum boards mounted on 2- by 4-inch wood studs or of cement-asbestos (Cemesto) boards with a vegetable-fibre (Celotex) inner core, the total thickness being two inches. Partitions are installed by attaching them to wood plates bolted to the concrete floor and to the ceiling; the joints thus created are covered with suitable baseboards and molding trim. - Lyles, C., and M. Conner. MACHINING COMPLEX AND SUPPORT BUILDINGS DEACTIVATION AND DECOMMISSIONING PROJECT AT THE PANTEX PLANT [PDF] WM Symposia, 1628 E. Southern Avenue, Suite 9-332, Tempe, AZ 85282 (United States), 2007.

- Marks, Elyse Marguerite. "The World War II Defense Housing Community of Aero Acres: Case Study for the Future Preservation of Historic Planned Suburban Communities." (2012).

Excerpt:

A large percentage of the original wartime units survive, though altered by their owners in a variety of ways. In most cases, the Cemesto panels are sealed inside the interior and exterior wall siding of other materials.

- Strickler, T. D., and John A. Auxier. Experimental evaluation of the radiation protection afforded by typical Oak Ridge homes against distributed sources. No. CEX-59.13. Oak Ridge National Lab., Tenn., 1960.

A House A was an Oak Ridge type "A" Cemesto* house with wood siding - Pyron, Bernard. "Wright's Small Rectangular Houses: His Structures of the Forties and Fifties." Art Journal 23, no. 1 (1963): 20-24.

Excerpt:

To form the ceiling, boards grooved on their edges are placed at 90 degree angles to each other to form a pattern of squares contained within each other … built partly by the owner, is similar to the Carlson structure with its light colored cemesto board ... - Shendy El Barbary, Mohamed E. THE PROPERTIES OF CONCRETE SANDWICH BEAMS WITH POLYSTYRENE CONCRETE CORES [PDF] PhD diss., Durham University, 1981.

- Soroka, Walter W. "Noise Control in Office Buildings." Noise Control 3, no. 4 (1957): 43-49. [Using Cemesto board panels - Ed.]

- Swenson, George E. [Cemesto] WALL CONSTRUCTION [PDF] U.S. Patent 2,347,756, issued May 2, 1944.

Excerpt:

Each wall panel may be fabricated as desired of any suitable material or materials, and of any suitable dimensions, though it is highly desirable to form each panel of durable material which has heat-insulating characteristics, each panel preferably being of considerablesize in order to reduce the number of panels comprising the wall. In practice it has been found convenient and highly practical to provide a panel substantially ten feet long by four feet wide by two inches thick, the core of such panel comprising a relatively fibrous compressed material, with a lamination of a relatively hard substance such as cementitious material on each of the two large surfaces, and such a panel is to be found on the market under the trade name Cemesto" manufactured by'The Celotex Corporation, of Chicago, Illinois. - Whitehouse, Irving P., Wolfgang W. Krauss, and Austin G. Damon. "Wall construction." U.S. Patent 2,612,246, issued September 30, 1952. cites Cemesto Board

- Wikipedia, Cemesto, retrieved 2020/01/20 https://en.wikipedia.org/wiki/Cemesto

On 2017-06-26 by Dawn - Cemesto Walls, Oak Ridge TN

I own a Cemesto home in Oak Ridge, TN, built in 1943 by the army.

Most of the cemesto in the interior has been covered over with drywall. However, I have discovered after removing wallpaper in the kitchen that I do have a couple of exposed cemesto walls.

They are not punctured. I am wondering if it would be an appropriate installation to attach tile directly to the cemesto using thinset.

My other option would be to install backerboard, but I am concerned that attaching with screws could potentially create dust. Do you have any insight?

Photo: CemestO homes under construction, Oak Ridge TN in 1943, photo by Ed Westcott, Manhattan Project official photographer.

Moderator reply:

Dawn,

Asbestos is safe and legal in homes if it is intact and can be left undisturbed. Particularly in cementious form such as in the outer layers of CemestO board, the material, if undamaged, is not friable.

If the CemestO panels are intact and sound, it seems quite reasonable to me to cover them over with ceramic tile as you describe. CemestO was a light-weight structural panel suitable for rapid, low-cost home construction.

...

Continue reading at CELOTEX ASBESTOS PRODUCTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS TESTING LAB LIST

- CEILING TILE MATERIALS

- CELOTEX ASBESTOS PRODUCTS

- CELOTEX CemestO BOARD HOMES

- CELOTEX DRYWALL ASBESTOS

- CELOTEX HISTORY & PRODUCTS

- CELOTEX: IDENTIFY Celotex® Insulating Board and Fiberboard Products

- FIBER CEMENT SIDING - home

- FIBERBOARD SHEATHING IDENTIFICATION

- FRAMING METHODS, AGE, TYPES

- PANELIZED CONSTRUCTION

- STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs)

Suggested citation for this web page

CELOTEX CemestO BOARD HOMES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Celotex 1973 Celotex Acoustical Systems catalog, January 1973

- [2] Celotex Home Building Materials, 1947 catalog, lists: Cane fiber products: Celotex sheathing, Celotex insulating lath (board), Celotex interior finish, Celo-Siding, Celo-Rok Gypsum products [may contain asbestos]: Celo-Rok anchor lath, Celo-Rock wallboards, Celo-Rok plasters, and Other Products: Celotex rock wool, Celotex roofing, Celotex hard boards, Celotex Cemesta, Celotex Corporation, Chicago IL

- [3] Celotex Insulating Cane Board, product catalog

- [4] Celotex Building Insulating Materials, 1948 Catalog, listing: Cemesto insulation, Cemesto roof decks, Cemesto exterior wall coverings, Cemesto interior wall coverings [we believe the Cemesto lines refer to cement-asbestos products - ed. ]

- [5] Celotex Sound Conditioning, 1948 Catalog, including perforated asbestos board sheets

- Celotex ceiling products division was purchased by Ceiling Products & Gypsum Wallboard (BPB) of the U.K. beginning in 1999

- Celotex roofing products division was purchased by Certainteed Corporation (Valley Forge PA) beginning in 1999

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.