Roof & Structure Noise Traced to Temperature Changes

Roof & Structure Noise Traced to Temperature Changes

Thermal movement causes a variety of roof sounds

- POST a QUESTION or COMMENT about building roofs & noise or sound transmission or noises coming from roofs themselves

Roof & building structural noises caused by temperature changes: thermal movement of materials.

This article series explains how various exterior noises (rain, hail, highways, aircraft noise) transmit through a roof to the building interior and how can we soundproof building roofs for a quiet building interior?

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Diagnosis & Control of Roof Noises Due to Temperature Changes

Noise From Thermal Expansion in Metal Roofs

The metal roof expansion data given here is adapted from the New Zealand Steel Company's metal roof installation manual cited at the end of the table.

Metal Roof Expansions by Colour & Roof Panel Length |

|||

| Roof Colour Range | Expansion in 8 Metre Length | Expansion in 12 Metre Length | Expansion in 18 Metre Length |

| Light | 5 mm | 7 mm | 11 mm |

| Medium | 6 mm | 10 mm | 14 mm |

| Dark | 7 mm | 11 mm | 17 mm |

Notes to the table above

Notes:

These expansion amounts are based on 0.01 mm / m / °C for Zincalume® and steel roof panels.

Roof Thermal Expansion / Contraction Noise Research

- Ellen, C. H., C. V. Tu, and W. Y. D. Yuen. "Theory for thermally induced roof noise." Journal of Structural Engineering 111, no. 11 (1985): 2302-2319.

Abstract:

This paper presents a theoretical analysis of thermally induced noise in sheet metal roofs. A quasi‐static model of the roof behavior is developed based on roof support batten frictional forces constraining the thermal expansion and contraction of the sheeting. As a result, in‐plane stresses, set up in the sheeting, build up until the static frictional force limit is exceeded at one of the fasteners.

At this point the sheeting slips over the batten at that fastener, the local frictional force is reduced to the dynamic frictional force limit, and a redistribution of in‐plane stresses and fastener forces occurs.

The redistribution can cause an overload of an adjacent fastener frictional force to exceed its limit, thereby inducing another slip. The sequence will continue until all frictional forces are below the static frictional force limit. The change in deflection pattern of the roof accompanying each slip is used to estimate the noise generated.

With the assumptions that the curvature strain is small relative to the thermal strain, the coefficients of friction at each batten are identical and the batten spacing is uniform, the theory may be used to derive considerable detail of the slip cascade pattern and to determine expressions for the rate of noise bursts, for the necessary temperature change to cause a roof to change from “heating” to “cooling” cycling, and for the impulsive noise level. - Fisher, James. "Expansion joints: where, when, and how." In NASCC Proceedings, The Steel Conference, Montreal, Canada. 2005.

- Garden, George Kirby. "Thermal considerations in roof design." In Canadian building digest 1-100, p. 4. National research council of canada, 1968.

- Meyers, Larry R., Richard S. Koziol, Dennis K. Johnson, And Norbert V. Krogstad. "laboratory Testing Of Low Slope Standing Seam Metal Roof Application." In Proc., 4th Int. Symp. On Roofing Technology, Pp. 144-152. Nrca/nist, 1997.

- Movement, B. Thermal. "Rigidly fasten metal roof panels to structure at one and only one location for each panel." Allow remainder of panel to move freely for thermal expansion and contraction. Predrill panels for fasteners 1: 07411-8.

- Panels, Standing-Seam Roof. "Fasten to purlins with concealed clips at each standing-seam joint." Install clips over top of insulation. Crimp standing seams with manufacturerapproved motorized seamer tool. Rigidly fasten eave end of metal roof panels and allow ridge end free movement due to thermal expansion and contraction.

- Roof, C. "Roof to Wall Transition." Roof to Sheet Metal Roof Edging Transition Expansion-Joint Cover: Fabricate from the following material 1.

- Smith, Thomas L., AIA, CRC, METAL ROOFING: 'FIXING' for THERMAL MOVEMENT [PDF] NRCA, National Roofing Contractors Association

- New Zealand Steel Installers Guide, NZ Steel Co. "New Zealand Steel Installers Guide, COLORSTEEL®, ZINCALUME® steel and GALVSTEEL™ Installer's Guide", [PDF], (2005), New Zealand Steel Limited, Private Bag 92 121, Auckland, New Zealand. Tel: 0800 100 523, or 0-9-375 8999 Fax 0-9-375 8213, Website: http://www.nzsteel.co.nz/, Email: info@colorsteel.co.nz - retrieved 2015/12/07, original source [check for and remove any blanks in the following URL] : http://www.nzsteel.co.nz/content/media/ 77012/New%20Zealand%20Steel%20Installers%20Guide%20-%20November%202005.pdf

Excerpt: [Metal roof panel] Fixing systems used must allow for expansion and accommodate the longitudinal movement which results. If this is not done, ‘canning’ of the profile may occur and ponding of low pitch roofs, or noise may become a problem. - Warseck, K. A. R. E. N. "Roof failure: effect and cause." Building Operating Management', Available from http://www. findarticles. com/p/articles/mi_qa3922/is_200304/ai_n9220745, accessed 8th December (2006).

Reader Question: What causes roof noise in our flat roof during cold nighttime weather? How can we fix it?

Roof noise - during the winter our torched-on membrane (180g. polyester base sheet & 280g. polyester SBS Cap Sheet) covered flat roof (installed 2002 on the apartment building) makes noises typically at night which disturbs the tenants and has caused some to move out.

There are no leaks and the roof looks properly installed. What causes the noise and what can be done about it? Regards, Steve Rickard

Reply: suggestions for diagnosing cold weather flat roof noise - the diagnosis will define the steps to cure roof noise

Steve:

re: how to diagnose & cure annoying night time noise from a flat roof.

With no information and no building inspection, we can't say with confidence exactly what is causing the annoying roof noise you report. An onsite expert should be able to help however. Here are some of the roof noise diagnosis observations that we would expect a roof noise consultant to consider:

- What are all of the materials in the roof structure: support, roof deck, layers and coatings - thermal expansion rate differences during night time cooling might explain movement between materials and thus the noise.

- How are the various roof layers fastened to the roof deck itself? What is the roof decking material? For example movement of materials over a metal roof deck may indeed telegraph noises to the interior

- What is the leak history of the roof; even a roof that is not leaking now may contain moisture from prior leaks or from condensation due to moisture penetration from the building interior (again material and installation dependent) that could in cold weather be forming ice or contributing to thermal movement and noises

- What is the roof insulation scheme - where has insulation been placed and using what materials. It may be possible to correct the noise problem by a review and improvement of the roof insulation.

For example, adding insulation at the building interior may reduce the differences in temperatures experienced by the two sides of the roof structure - the interior side vs the exterior side. If thermal changes are a key in movement that is the source of the roof noise problem. - What else is on or near the roof and the rest of the building structure that might be moving or otherwise serving as a noise

source: loose building components, antennae etc. ? - What HVAC or mechanical systems are mounted on the roof or penetrate the roof?

- Where is the building located? To what extremes of temperature is the roof exposed?

- Is there standing water on the roof - are the roof drains working? See our photo [above left] of a tar and gravel flat roof located in northern Minnesota.[5]

- Is there ice formation on the roof surface? In some climates such as northern Minnesota, as standing water on a flat roof freezes during temperature drops, very large booming sounds can be produced by the roof.

These roof booming noises are familiar to Minnesotans who live along the shores of Lake Superior, as ice freezing and fracturing on the lake itself produce the same sounds. [5] - Are there other nearby external sources of noises that may be transmitted through the roof (falling acorns, airports, road traffic)?

Other more general observations that can help track down roof noise sources

- Weather & roof noises: At what times, weather conditions, temperatures, wind directions, operation of

mechanical systems etc. map to when the noises are observed; where, spatially, are the noises loudest? Are there movable components on a building such as signs or weather vanes that may be noise sources during windy conditions?

Also see WIND NOISES at BUILDINGS - Building components & roof noises: Do those locations track possible noise sources to specific building components.

Comments, suggestions, or questions from readers are welcome in helping to diagnose this roof noise issue.

On 2019-08-13 by (mod) - Roof thermal / temperature change noise investigation notes

Taking as a given the noise is probably movement due to differences in thermal expansion or contraction as temperatures change, rise, fall, across and through the roof structure in response to changes in outdoor temperature or sun exposure:

Let's think about what surfaces or materials may be moving against one another, and also about where the noises are loudest;

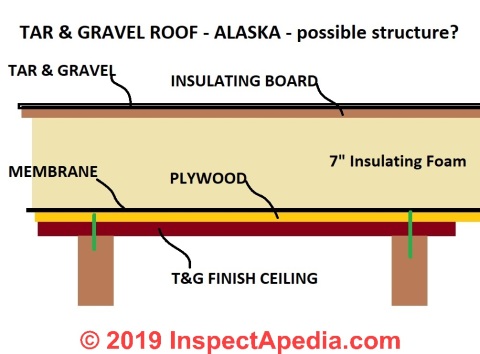

1. plywood creep over T&G ceiling / decking

2. insulation creep over plywood sheathing

3. roof membrane movement over insulation (unlikely)

4. flashing movements - likely only if noise tracks to those few locations

Resolution: IMO unlikley to be totally satisfactory without an inappropriately costly roof re-do, but possibly a color change on the rooftop - white gravel or aluminum reflective coating, for example, might reduce the temperature swing range - something to experiment with.

On 2019-08-13 by (mod) -

by the way are we missing a chimney cap? IF so that needs to be replaced.

On 2019-08-12 by Lee

...

On 2019-08-12 by Lee

Yes, that looks like our roof. It looks like the plywood was nailed to the T&G and then the whole roof was screwed through to the T&G. The T&G is 1 3/4” inch thick. The top of the roof is tar with gravel. I will attach a couple of photos o the roof in progress

. It was complicated by the fact that the T&G that was part of a 4 foot over hang had rotted on each end and needed to be replaced, but we special ordered that wood to match what we had in place previously.

On 2019-08-09 by (mod) -

Might be interesting to borrow an IR scanner or thermographic camera to look at the temperatures across the roof, then to understand how things are fastened mechanically or adhered through the roof structure so that we have an idea which surfaces are moving against one another.

Also - what's the color of the roof surface?

On 2019-08-09 by (mod) -

I'd also like to see photos from outside if possible.

With 7" of rigid foam INSULATION R-VALUES & PROPERTIES tells us -- if I assume polyurethane foam for the moment you have at least 6.25 x 7 + your insulating board - maybe nearly an R 50 roof.

That means even in cool (warming-fast) Alaska, in sunny weather we could have a tremendous temperature difference between the roof surface (hot mopped tar and gravel) and the room side of those attractive wood T&G boards.

How is the roof structure fastened? Plywood nailed into just those beams or plywood nailed to the T&G? (how thick is the T&G?);

Is this your roof?

How was the insulation secured? Adhesive? 12" screws down through the foam into the beams?

On 2019-08-07 by Lee

This morning it popped literally 250 times in one hour. Some soft, some quite loud. Four hours later still popping but not quite as frequently. It is sunny and 70 degrees today. I have attached a picture of our ceiling.

The plywood is sitting right on top of the T and G, then a membrane (water shield) on top of that and then 2 layers of 3.5 inch rigid foam, covered by a layer of thermal fiber board, then hot mopped tar and gravel. Does that help? Thanks for your time all the way from Mexico!

On 2019-08-07 by (mod) - common sources of noise in flat roofs

With the first of two reclamas: I don't understand your roof construction from your note (T&G ceiling attached to roof deck? Where are the rafters?)

and the second that I can't see well here from my perch across from the other side of the Donald's wall (I'm writing from Mexico),

I can speculate but it's just arm-waving, Lee. When there is sufficient thermal movement in a roof structure the moving parts include

- roof covering materials

- roof flashings

- roof decking

- rafters

- fasteners of decking to rafter, fasteners of roofing to decking, etc.

I suspect your roof is rubber EPDM or Modified bitumen - they're not themselves noisy materials (unlike metal) so most likely it's movement of roof decking against rafters or movement of flashings.

Photos would help.

On 2019-08-07 by Lee - loud popping noise in flat roof on log cabin

We have a log cabin with a hot, flat roof that was replaced in 2013. It has a T and G ceiling with the plywood decking attached to the T and G, There is 7 inches of rigid foam insulation with what I assume are the normal barriers etc.

Since the time it was replaced we have had extensive and very loud popping in the morning when the sun warms it and in the evening as it cools, usually the popping lasts about 2 hours or so and it is heard through out the house. We live in Alaska.

There is no popping appreciated during the winter when the sun angle stays low and there is snow in the roof. Occasionally we hear it when it is breezy. It has no vents. It is obviously caused by thermal changes. Our roofer does not know what could be causing the noise. Any ideas? Thanks

On 2017-03-02 by (mod) - slate roof noise causes: thermal movement

Anon:

Yes, on many slate-roofed homes as temperatures change, such as cooling at night or heating during the day, thermal expansion or contraction of the slates may cause movement that in turn causes snapping, popping, or cracking noises, even bangs and clanks or clicks from the roof. I'm a little concerned about slates nailed too tightly, or use of cement as a sealant or ridge cap, as the roof should accommodate thermal changes without damage.

I've read claims that housewrap such as Tyek used under slate can cause noises, or prevent them - I'm skeptical about that claim.

More likely is thermal expansion/contraction of metal on-roof components such as flashings along a valley or around a chimney.

On 2017-03-01 by Anonymous - slate roof prone to cracking noises

Is a slate roof prone to cracking noises because of thermal expansion and contraction.

Question: squeaky roof insulating board at start / end of day

(June 21, 2012) geoffm52536@charter.net said:

I stripped existing shingles off the roof added 2 inch thick blue board on top of existing OSB then added 3/4 OSB and reshingled with architectural shingles.

Now get cereaking noises in the roof at beginning and end of day probably expansion/contraction but what of? Blue board was fastened to OSB with nails and top layer of OSB with screws. Ideas?

Reply: temperature changes: squeaking roof at start & end of day

Goeff,

About squeaking creaking roof surfaces using foam board insulation:

I suspect that because the solid foam insulating board is just nailed, not glued, to the two layers of plywood and OSB, that foam and sheathing sandwich is making the creaking noise due to thermal expansion and contraction of the whole roof deck assembly.

Roof surface temperatures run through a very wide range of temperature swings, even moreso if the shingles are dark in color.

Solid foam board, moving over plywood or OSB, will sometimes make a creaking or squeaking noise.

It's possible that you might get a slight reduction in the noise if you assure that you have good under-roof ventilation, as cooling the whole roof assembly may have a small effect on temperatures throughout your plywood-solid foam insulating board-OSB sandwich.

At the time of construction one might reduce noise from foam board roof insulation panels by applying a glue rated for use with the particular insulating material. But once you've sandwiched it between plywood, without glue, securing the plywood further may not do much about this noise complaint.

Otherwise, I'm afraid you're stuck with those noises until it's re-roof time.

...

Continue reading at ROOF NOISE TRANSMISSION - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BANGING BOOMING NOISE DIAGNOSIS & CURE

- CLICKING NOISE DIAGNOSIS & CURE

- DECIBEL METER dB METER CHOICES

- NOISE EXPOSURE STANDARDS, CODES, GUIDES

- NOISE / SOUND DIAGNOSIS & CURE - topic home, where we describe how to locate the source of, identify and correct various building sounds and noises indoors or on occasion, noises from outside that penetrate indoors at annoying levels.

- POPPING SNAPPING NOISE DIAGNOSIS

- ROOF NOISE TRANSMISSION - topic home

- SOUND ABSORPTION vs. SOUND ISOLATION

- SOUND CONTROL in BUILDINGS - topic home, we provide a series of detailed articles on reducing unwanted building noise levels through building design, insulation, sound isolation, and noise barriers.

- SOUND CONTROL for FLOORS - methods that may help with roof noise control

- SOUND LEVEL MEASUREMENT, HOW TO

- TEMPERATURE CHANGE & ROOF NOISE

- THERMAL EXPANSION of MATERIALS

- TICKING NOISE DIAGNOSIS

- WIND NOISES ON ROOFS

Suggested citation for this web page

TEMPERATURE CHANGE & ROOF NOISE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ACGIH "A Guide For the Control of Audible Sound Hazards" 1st Ed., ACGIH, American Conference of Government Industrial Hygienists, Threshold Limit Value for Physical Agents Committee, (2020) Website: acgih.org

- Acoustical Society of AmericaElaine Moran, ASA Office Manager, Suite 1NO1, 2 Huntington Quadrangle, Melville, NY 11747-4502

516) 576-2360, FAX: (516) 576-2377 email: asa@aip.org. - http://asa.aip.org/standards/s_development.html -

ASA is an excellent source of noise and sound standards. Quoting from the associations history page:

"From the Society's inception, its members have been involved in the development of acoustical standards concerned with terminology, measurement procedures, and criteria for determining the effects of noise and vibration. In 1932, The American National Standards Institute (ANSI), then called the American Standards Association, appointed the Acoustical Society as sponsor of a committee, designated as Z-24, to standardize acoustical terminology and measurements.

The work of this committee expanded to such an extent that it was replaced in 1957 by three committees, S1 on Acoustics, S2 on Mechanical Shock and Vibration, and S3 on Bioacoustics, with a fourth, S12 on Noise, added in 1981. These four committees are each responsible for producing, developing a consensus for, and adopting standards in accordance with procedures approved by ANSI. Although these committees are independent of the Acoustical Society, the Society provide s the financial support and an administrative Secretariat to facilitate their work.

After a standard is adopted by one of these committees and approved by ANSI, the Secretariat arranges for its publication by ASA through the American Institute of Physics. The ASA also distributes ISO and IEC standards. Abstracts of standards and ordering information can be found online on the ASA Standards Page. More than 100 acoustical standards have been published in this way; a catalog is also available from the Standards Secretariat (631-390-0215; Fax: 631-390-0217). The Society also provides administrative support for several international standards committees and acts as the administrative Secretariat (on behalf of ANSI) for the International Technical Committee on Vibration and Shock (TC-108)." - http://asa.aip.org/history.html - ANSI/ASA S12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools, 2002.

- [1] Connelly, Maureen, Hodgson, Murray, "Thermal and Acoustical Performance of Green Roofs", Sound Transmission Loss of Green roofs, [presentation, Session 1.5], Greening Rooftops for Sustainable Communities, conference, awards, trade show, Baltimore MD, 30 April-2 may 2008. Web search 4/3/2011 original source: http://commons.bcit.ca/greenroof/publications/

2008_grhc_connelly_hodgson.pdf. These authors provide an excellent bibliography of references for sound transmission in buildings, including some of the references cited just below:- Sharp, BH 1973, Study of Techniques to Increase the Sound Insulation of Building Elements. U.S. Department of Commerce PB-222 829, Washington.

- Sharp, BH & Martin S 1996, "The Measurement of Aircraft Noise Reduction in Residences", Proceedings of Inter-Noise, Liverpool, 1996, pp. 2747-2752.

- Friberg, R 1973, "Transmission Loss and Absorption Factors for Corrugated Steel Roofs, Insulation on the Outside", Proceedings of Inter-Noise, Copenhagen, 1973, pp. 213-217.

- [2] Colbond, EnkaTech Note, "Acoustical Benefits of Roof Underlayments", Colbond Inc., PO Box 1057, Enka NC 28728, gtel: 800-365-7391, website: www.colbond-usa.com web search 4/3/2011, original source: http://products.construction.com/

swts_content_files/1329/E835617.pdf - [3] General Steel Corporation, "The Facts About the Acoustical Performance of Metal Building Insulation 2", Sound Transmission Class, General Steel Corporation, 10639 W. Bradford Road, Littleton, CO 80127, web search 4/3/11, original source: http://www.gensteel.com/insulation_facts-5a.htm

- [4] North American Insulation Manufacturers Association NAIMA, "Insulation Facts #58: The Facts About the Acoustical Performance of Metal Building Insulation", NAIMA, 44 Canal Plaza, Suite 310, Alexandria VA 22314, tel: 703-684-0084, website: http://www.naima.org/

- [5] Booming roof noises in Northern Minnesota caused by freezing water and ice fracturing, personal communication, JC to DF, 12/8/2011

- [6] "New Zealand Steel Installers Guide, COLORSTEEL®, ZINCALUME® steel and GALVSTEEL™ Installer's Guide", [PDF], New Zealand Steel Limited, Private Bag 92 121, Auckland, New Zealand. Tel: 0800 100 523, or 0-9-375 8999 Fax 0-9-375 8213, Website: http://www.nzsteel.co.nz/, Email: info@colorsteel.co.nz - retrieved 2015/12/07, original source: http://www.nzsteel.co.nz/content/media/ 77012/New%20Zealand%20Steel%20Installers%20Guide%20-%20November%202005.pdf

- DEVELOPMENTS in NOISE CONTROL [PDF] NRCC, National Research Council, Canada, suggestions for noise control, sound transmission through block walls, plumbing noise control, noise leaks, and sound control advice. Web search 01/17/2011, original source: www.nrc-cnrc.gc.ca/eng/ibp/irc/bsi/90-noise-control.html

- Thanks to audiologist Cheryl P. Harllee, licensed hearing specialist, for discussing noises and noise problems in preparation for this article. Ms. Harllee can be located at the Village Hearing Center, 249 U.S. Highway One, Tequesta FL 33469 561-744-0231

- Thanks to reader Sue Hazeldine, from the U.K. for discussing how she tracked down a whistling chimney noise to an antique hanging sign on the building exterior - 01/19/2010.

- Thanks to reader Michael Anderson, 8 May 2009, for discussing clicking sounds coming from air conditioning equipment.

- Thanks to reader Erna Ross who described loss of sleep due to a hissing noise at her home 06/15/2008.

- Marpac, produces white sound generators, a product that they identify as the Marpac sound conditioner. Marpac can be contacted at http://www.marpac.com/ or contact the Marpac Corporation, P.O. Box 560 Rocky Point, NC 28457 Phone: 800-999-6962 (USA and Canada) Fax: 910-602-1435 1-910-602-1421 (worldwide), 800-999- or email: info@marpac.com

- Sound Oasis sound conditioners are produced by Sound Oasis: http://www.sound-oasis.com/ email: info@sound-oasis.com or 1-866-625-3218

- Barrier Ultra-R super high-R building panels, produced by Glacier Bay, use Aerogel and are rated up to R-30 per inch, or in Barrier Ultra-r™ panels, R-50 per inch.

The company also produces acoustic panels that are Ultra-db resistant and lightweight. Unlike the appliance insulation panels discussed in the original Q&A above on miracle insulation, these Areogel based panels will continue to retain some, though reduced insulating value if punctured, performing at perhaps R-9 per inch. The product is used in marine refrigerators, but in the future may be available as a residential construction product. The company is researching specialized products in medical, transportation, and aerospace applications. Contact: Glacier Bay, Inc., 2930 Faber Street, Union City, CA 94587 U.S.A., (510) 437-9100, Sales and Technical Information - sales@glacierbay.com - Tremco, Tremco Global Sealants Division, 10701 Shaker Blvd., Cleveland OH 44104 - see www.tremcosealants.com/

- Ideal Tape, Inc., 1400 Middlesex St., Lowell MA 01853 - see www.abitape.com/tape/iframe_ideal.htm Tel: 1-800-284-3325

- 3-M Corporation, tape products, see solutions.3m.com/

- US EPA Noise Regulations & References

- Noise Control act - http://www.nonoise.org/epa/act.htm

- Quiet Communities Act - 1978

- Federal Regulations from the EPA's Office of Noise Abatement & Control - http://www.nonoise.org/epa/reg.htm

- A Basis for Limiting Noise Exposure for Hearing Conservation - http://www.nonoise.org/epa/Roll1/roll1doc1.pdf

- Noise - a Health Problem - http://www.nonoise.org/library/epahlth/epahlth.htm - quoted below

- "Measurement of Highway-Related Noise", US Department of Transportation, Federal Highway Administration, http://www.fhwa.dot.gov/environment/noise/measure/chap8.htm

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- "Insulation: Adding Insulation to an Existing Home," U.S. Department of Energy - tips on how to do your own check for the presence of absence of insulation in a home

- Insulation: Selecting Insulation for New Home Construction, U.S. Department of Energy - "Your state and local building codes probably include minimum insulation requirements, but to build an energy-efficient home, you may need or want to exceed them. For maximum energy efficiency, you should also consider the interaction between the insulation and other building components. This is called the whole-house systems design approach."

- Insulation Types, table of common building insulation properties from U.S. DOE. Readers should see INSULATION R-VALUES & PROPERTIES our own table of insulation properties that includes links to articles describing each insulation material in more detail.

- ...

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.