Fiberboard Building Wall, Ceiling & Roof Sheathing

Fiberboard Building Wall, Ceiling & Roof Sheathing

Insulating Board Sheathing, Sound Insulation Board Product Guide

- POST a QUESTION or COMMENT about fiberboard building sheathing: how to identify fiberboard products, fiberboard uses, fiberboard, Celotex, Homasote, Insulite & other brands, fiberboard ingredients,

Fiberboard insulating sheathing was and continues to be used on or in buildings as an insulating sheathing and nail base.

Here we give, for fiberboard, its definition, ingredients, history, use, fire resistance & insulating properties o.

Fiberboard was also used indoors as both a finish-surface to be painted or as a base to which plaster and then paint were applied.

This article describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as Homasote, Celotex, Insulite, and Masonite insulating board sheathing products.

The author has inspected, restored, repaired and installed fiberboard sheathing on buildings during building repair and construction projects since the 1970s, and has also worked as a home inspector and building environmental forensic investigator. Technical reviewers for this article include several experts including fiberboard manufacturers.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Fiberboard Building Sheathing

Beaverboard®, black board, buffalo board, gray board, cane board, Celotex®, Homasote®, Insulite®, Nu-Wood® are some of the many names of fiberboard or plant-fiber board sheathing products used on roofs, exterior walls, interior walls & ceilings.

Beaverboard®, black board, buffalo board, gray board, cane board, Celotex®, Homasote®, Insulite®, Nu-Wood® are some of the many names of fiberboard or plant-fiber board sheathing products used on roofs, exterior walls, interior walls & ceilings.

Here we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products.

We also answer questions such as do Celotex® or Homasote® or other fiberboard and insulating board products contain asbestos? fiberboard water resistance, fiberboard recycling.

If your primary concern is possible asbestos in fiberboard

see SHEATHING, FIBERBOARD ASBESTOS CONTENT.

What is Fiberboard Insulating Sheathing?

Fiberboard insulating sheathing board was used and continues in use as a structural wall sheathing board 15/32-inches thick (one board was 1/2") and with R-value of about 1.5.

Fiberboard insulating sheathing was and continues to be made of plant cellulose such as wood fibers, combined with a binder, a water-resistive coating or component (such as paraffin and/or asphalt), and other treatments that we detail below.

Structural properties and moisture resistance were confirmed by US FPL testing. Moisture uptake did not exceed 2.2%. [15]

An extensive description of the composition of fiberboard products is found

at FIBERBOARD SHEATHING INGREDIENTS.

Our photo shows bits of damaged fiberboard interior wall sheathing removed by the author [DF] during inspection and repair of a water-damaged area.

Our photo shows bits of damaged fiberboard interior wall sheathing removed by the author [DF] during inspection and repair of a water-damaged area.

Shown at the start of this article is brown fiberboard sheathing used to enclose a soffit overhang. Fiberboard products have been widely used on building exteriors as a non-structural wall sheathing, even on some roofs as roof sheathing, and on building interiors as a ceiling or wall covering.

At DRYWALL, FIBERBOARD, PLASTER INTERIORS we also discuss other interior sheathing boards that were used on interior walls and ceilings.

At FIBERBOARD SHEATHING MOLD CONTAMINATION we discuss mold growth on or in fiberboard sheathing.

At SIDING HARDBOARD IDENTIFICATION & CLAIMS we discuss hardboard exterior building siding such as sold under the Abatibi and Boise Cascade brands.

At SHEATHING, EXTERIOR PRODUCT INDEX we describe products used on building exterior walls & roofs as a structural sheathing or as a nail-base sheathing.

Also see SHEATHING, GYPSUM BOARD used on both exteriors and interiors of buildings,

and SHEATHING, OSB as well

as SHEATHING, PLYWOOD for a discussion of these common building roof and wall sheathing products.

A History of Fiberboard Insulating Sheathing

In addition to plywood, OSB, and gypsum board, impregnated fiberboard produced in 4 ft. widths and varying lengths up to 12-feet has been used as exterior building insulating sheathing in North America since at least 1907.

See our discussion of Homasote™, below

and see HARDBOARD MASONITE™ & OTHER BRANDS™ where we give a detailed history of Masonite™ and a description of its properties as well as of similar hardboard products.

Actually hardboard and fiberboard are considerably older than that.

Henry Clay patented a paper-based wallboard panel for interior use on walls and as door panels in 1772. (Gould 2014).

According to the Boston Museum of Fine Arts, fiberboard was first patented in 1858 and was produced by a number of manufacturers (listed below) and made of a variety of plant fibers (including bagasse from sugar cane) or wood chips, wood byproducts, and by one company waste paper and by another company flax shives [12][15] .

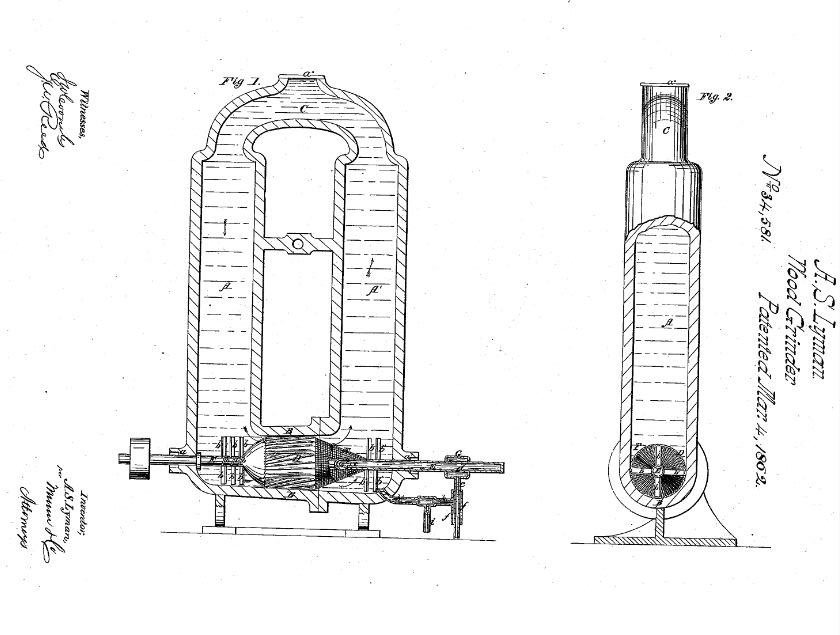

Indeed it was Lyman's 1858 invention of a method for separating the fibers of wood, probably born from other work on improving the cotton gin, felting hat bodies, and making paper, that made these products possible.[13]

Fiberboard wall sheathing (an example fiberboard product photograph is shown at above left), when intended for use on a building exterior is installed by nailing directly to the wall studs, most often with let-in diagonal bracing or plywood panel bracing at the building corners to assure building rigidity.

A 1955 U.S. FPL report offers the early history of growth in the use of insulating fiberboard sheathing.

Insulating fiberboard sheathing is used extensively in house construction. In 1920 insulating board accounted for only about 4 percent of the sheathing used for new residential construction. In 1940 its use had risen to 20 percent and by 1950 to 30 percent.

It is more popular in certain regions of the country than others. In 1950 about 50 percent of the wall sheathing used in the Middle West [of the U.S.] was of fiberboard, while in the Pacific Northwest where lumber is more easily obtained, insulating fiberboard was used in only about 10 percent of the new houses erected. [15]

In earliest use, fiberboard sheathing material was sold as a means of insulating the home at little additional cost since it was used to replace the horizontal or diagonal tongue-and-groove board sheathing that was in wide practice up to the 1940's or 50's.

But despite early claims (later dropped) that wood fiber sheathing was a structural material, in homes where fiberboard sheathing was used, additional framing was commonly constructed at the building corners as diagonal bracing to stiffen the building walls.

Modern product literature for fiberboard insulation[2] and standards for products such SturdyBrace® Structural Fiberboard Sheathing [14] make clear that the product is produced and used as structural sheathing. Quoting:

STURDYBRACE® improves the structural integrity of homes and light commercial buildings and eliminates the need for corner bracing. The product meets codes for wind shear and seismic conditions [2]

Individual fiberboard companies, brands, fiberboard patents by company and fiberboard history are also given in this page and at links found at the end of this article.

Synonyms for Fiberboard Insulating Sheathing

Beaverboard®, black board, buffalo board, gray board, cane board, Celotex®, Homasote®, Insulite®, Nu-Wood® are among the more-widely known names and brands for fiberboard products.

Fiberboard synonyms and fiberboard product names include

- aglomerado de madeira (Port.)

- Barrett board & Barrett R-Brace

- Beaver Board, Beaverboard, beaver board,

- brown board or Brownboard

- carton-fibre (Fr.)

- carton fort (Fr.)

- Celotex,

- composition board

- Feltex,

- fiber board

- fibre-board (Br.);

- fibreboard (Br.)

- Fir-tex, - see IDENTIFY Fir-Tex Firtex Firetex Insulating board

- Firtex

- Fire-Tex (pseudo-trademark for the above]

- Gutex

- Homasote,

- hardboard

- high-density fiberboard (HDF)

- insulating board

- Insulite

- low-density fiberboard (LDF) [11]

- Masonite,

- medium-density fiberboard (MDF)

- Nu-Wood,

- particle board;

- Upson Board

- wallboard

Additional fiberboard insulating sheathing product names appear throughout this article series.

Also see UNIDENTIFIED FIBERBOARD PRODUCTS

Fiberboard Manufacturers & Product Brand Names

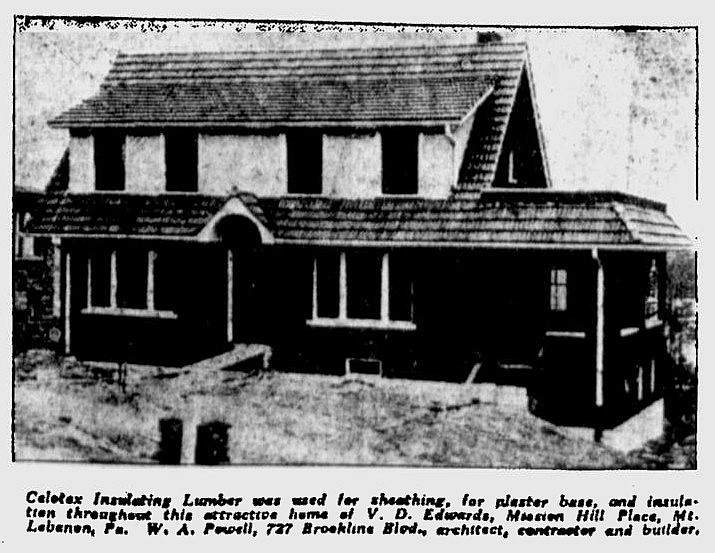

Photo: Celotex fiberboard marking identification. [Click to enlarge any image]

Note: our separate article SHEATHING, FIBERBOARD IDENTIFICATION includes identifying markings and photos of many of these products.

Alphabetical list of fiberboard products & brands

- Beaver Board, widely-used as both a brand name and as a generic for soft wood-fibre panels used on walls & ceilings.

See BEAVERBOARD Identification - Blue Ridge

- Buffalo Board - see Beaverboard above

- Sturdy-Brace

- Caneboard panels, also referred to as cane-board, Caneite, softboard, greyboard, pinboard.

- See CANEBOARD PANEL IDENTIFICATION

- Celotex or Knight Celotex [11]

-

see IDENTIFY CELOTEX® INSULATING BOARD & FIBERBOARD PRODUCTS

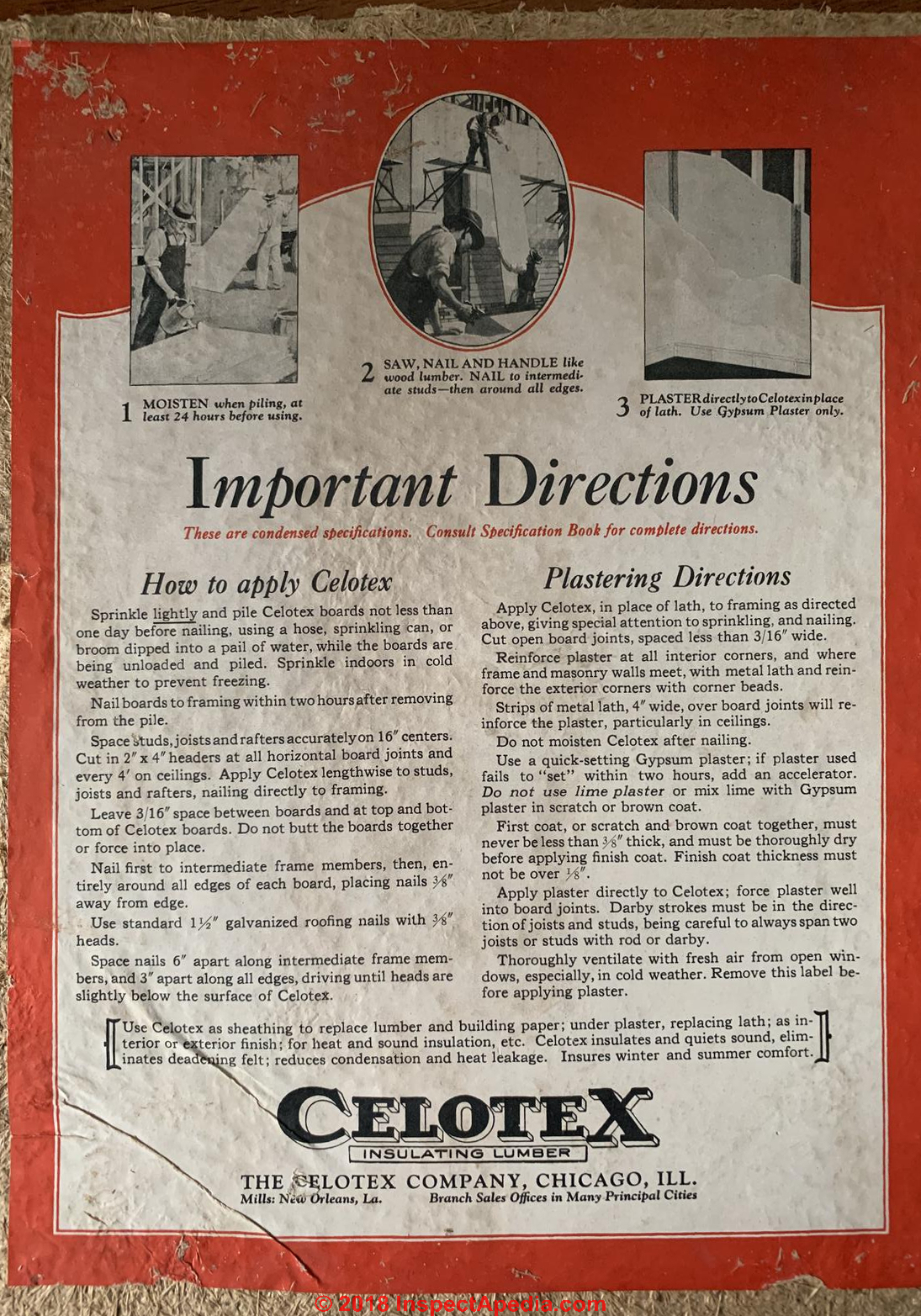

Also see CELOTEX HISTORY & PRODUCTS where we include instructions for the installation of Celotex fiberboard sheathing and also instructions for use of Celotex as a plaster base.

Special thanks to reader Lisa for the photo of Celotex installation instructions on a label.- Celotex Blue Ridge™ Fiberboard

- Celotex SturdyBrace®

- see also CELOTEX HISTORY & PRODUCTS

- Premium Fiberboard Insulating Sheathing

- StructoDek®

- Cornell Board;

- C-X Board;

- Dierks Intermediate Sheathing - Dierks Lumber Company, Arkansas, 1880's, expandding to Nebraska, Missouri, other locations, bought by Weyerhaeuser in 1968.

See

DIERKS LUMBER COMPANY HISTORY [PDF] Arkansas Heritage - retrieved 2022/10/04, Source: arkansasheritage.com/arkansas-register/dierks-lumber-company-building

See IDENTIFY Dierks Fiberboard Sheathing - Duron® [IPI];

- Feltex;

- Fir-Tex, FirTex, FireTex, Fire-Tex

- Gold Bond IB Insulating Board, cellulose based (brownboard or blackboard) produced by National Gypsum Corporation.

See IDENTIFY NATIONAL GYPSUM GOLD BOND® INSULATING BOARD - Gutex Wood Fiberboard Insulation,

GUTEX Holzfaserplattenwerk

H. Henselmann GmbH + Co KG

Gutenburg 5

D-79761 Waldshut-Tiengen

Phone: +49 7741 6099-0

Fax: +49 7741 6099-57

E-mail: info@gutex.de

Website: https://gutex.de/en/home/

Website excerpt:

Gutex, based in the Black Forest of Germany, has produced insulation from wood for over 85 years. .... Gutex uses a mixture of post-industrial, recycled wood chips and shavings and milled wood that has been harvested and grown using sustainable forestry management practices.

Homasote Wallboard & Sheathing Products

- Homasote®;

- 440 SoundBarrier

- Firestall®

- EasyPly® Roof Deck

- Thermasote® Nailbase Roof Insulation

- N.C.F.R.® Thermasote® Nailbase Roof Insulation

- See IDENTIFY HOMASOTE® Brand FIBERBOARD

List of Fiberboard products & brands, continued

- Insulite

- see IDENTIFY INSULITE or GRAYLITE cellulose fiber board product useful for plasterboard

- Bildrite Sheathing (exterior building sheathing)

- Fiberite (interior finish)

- Graylite (interior finish)

- Graylite Lok-Joint Lath

- Insulite (see below)

- Insulite Lok-Joint Lath

- Ins-Lite Lok-Joint Lath

- Satincote

- Smoothcote

- Masonite® [IPI] hardboard first produced by the Mason Fiber Company in 1926, later re-named Masonite

See HARDBOARD MASONITE™ & OTHER BRANDS - Medex; Medite

- Nu-Wood® - low-density fiberboard panels used on walls & ceilings & as a plaster lath support. Nu Wood ceiling tiles were also produced.

Some Nu-wood (Conwed) ceiling tiles contained asbestos.

Details about Nu-Wood are

at IDENTIFY NU-WOOD PANELS. Excerpts are below.

- Presdwood®;

- Quartrboard;

- Thermafiber® - also see ASBESTOS CEILING TILE IDENTIFICATION

and ASBESTOS-FREE CEILING TILES - Upson & Upsonboard - see UPSON BOARD

- US Gypsum United States Typsum or USG structural & insulating sheathing products:

- USG WEATHERWOOD STRUCTURAL INSULATING SHEATHING [PDF] - also

see USG US GYPSUM INSULATING SHEATHING ASBESTOS - USG SHEETROCK PYROFILL ROOF DECKS [PDF] - US Gypsum Insulating Pyrofill & USG Asbestos Board Pyrofill & USG Acoustical Pyrofill product descriptions, specifications, installation details, from USG 1952 Technical Specifications

- Weyerhaeuser IB -

See IDENTIFY Weyerhaeuser IB INSULATING FIBERBOARD SHEATHING

See this Fiberboard Identification Key FIBERBOARD SHEATHING IDENTIFICATION

Fiberboard Roof Sheathing

Fiberboard products were also used for roof sheathing produced by several manufacturers and are still found on some homes in North America, often dating from the 1960s or early 1970s.

Above and below: shown from the building interior, 2 1/2" or 3" thick fiberboard roof sheathing used on this Minnesota home also formed the finish for the interior ceilings.

Our second photo above shows the tar and gravel "flat roof" on this home - with considerable ponding. The owners later abandoned this low slope roof by constructing a sloped gable roof over the structure.

Above: a closer look at the thick insulating fiberboard roof / ceiling panels used in the original construction of this home in 1960.

Below: an InspectApedia.com reader provided this image of the cross-section of a 3-inch thick fiberboard roof panel.

As you will note the groove in these fiberboard panels was to accommodate a spline used to joint the panels during construction; similarly splines are used currently in foam core SIPS discussed below.

Durability of Fiberboard Roof Panels

Homasote Says Properly-Installed Fiberboard Sheathing Never Fails. According to Homasote[1], at least two important clarifications are in order:

Our roof application is a structural roof deck (2’ X 8’) product which in the 46 years I’ve been associated with Homasote has never failed if installed properly. Our deck will wick out any water if installed properly.

One should not refer to fiberboards as if all fiberboards were the same. Our [Homasote®] products are much denser then the other fragile ones manufactured in the U.S. and are thus considered superior by the industry.

Homasote® roofing products include

- Firestall®

- EasyPly® Roof Deck

- Thermasote® Nailbase Roof Insulation

- N.C.F.R.® Thermasote® Nailbase Roof Insulation

When stripping existing roof shingles to perform a shingle tear-off for re roofing, Homasote® and other fiberboard roof sheathed roofs require special precautions to avoid damaging the roof sheathing during shingle tear-off. Homasote® provides the following advice: [Quoting from "Roof Shingle Tear-Off Procedure for Homasote Products" available from Homasote ].

The removal of existing shingles to re-roof Homasote roof deck or nailbase roof insulation requires a change from the conventional tear-off method used to re-roof wood surfaces.

To strip existing shingles from a Homasote roofing product, the following must be done:

- Instead of getting under shingles with a “shoveling motion” and then scraping forward to get the nails out you must use a stripping tool or roof shovel to pry up shingles away from the deck, by pulling the nails straight out.

- Care must be taken so that the roof shovel does not damage the surface of the deck.

Inspect the condition of the deck as the tear-off continues.

Any stubborn nails remaining after the shingles are removed should be pulled out using a crowbar or claw hammer along with a wood block as a fulcrum to prevent damage to the deck. - Inspect the stripped deck for any signs of deterioration or physical damage. Any damaged areas should be replaced with the same Homasote product.

- Prepare deck for the new finish roof installation in accordance with standard roofing practice and the roofing materials manufacturer’s installation instructions. The Homasote Company requires the use of a ring-shank roofing nail for all shingle installations.

Installation instructions, general requirements and the most up-to-date information on Homasote roofing products are available from Homasote.®.

Leak Damaged Fiberboard Roof Panels

Photos below, courtesy of a roofing company illustrate the use of fiberboard roof panels on a 1960s home with a 3 1/2" pitch asphalt-shingled roof in Waterford Michigan; the second photo displays a section of leak-damaged fiberboard roof panel.

Watch out: OPINION-DF: where fiberboard roof sheathing was used alone to support roof shingles or other roof coverings, and noting that fiberboard products and their performance varies by manufacturer, application, and installation details, some fiberboard products may become fragile with age, traffic, or leaks, risking roof shingle blow-off, or worker fall injuries.

On a roof replacement job one of our workers [DF] stepped onto an area where the roof decking had been damaged by leaks, and broke through to the attic below. Any significant or chronic water leakage in a roof whose shingles are supported by fiberboard insulating sheathing risks a roof surface collapse.

Repair Options for Damaged Structural Fiberboard Roof Panels?

Currently we have not found any manufacturer producing an exact replica replacement for these older, inches-thick spline-joined fiberboard roof panels. Some replacement possible options include SIPS.

SIPS Structural Insulated Panels

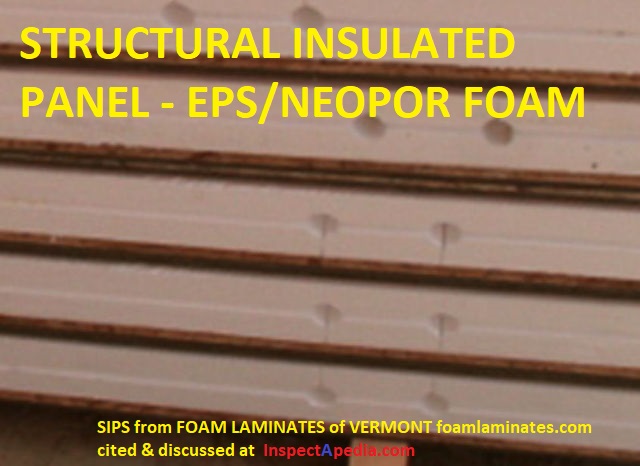

Illustration: a foam core structural insulated panel provided by Foam Laminates of Vermont, cited below.

Illustration: a foam core structural insulated panel provided by Foam Laminates of Vermont, cited below.

- STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs) (Structural Insulated Panels) includes a directory of manufacturers of SIPS - or Structural Insulated Panels -

In our OPINION these have their own shortcomings including difficulty of repair once leak-damaged, as we describe

at STRESS SKIN INSULATED PANEL REPAIR (SIP repair) - Foam Laminates of Vermont, a division of Energy Smart Buildings, Inc., 22 Varney Hill Road, Starksboro, VT 05487 USA Tel: (802) 453-4438 Toll free : 1-877-524-2530 Email: info@foamlaminates.com retrieved 2019/11/08, original source: https://www.foamlaminates.com/?gclid=CjwKCAiAwZTuBRAYEiwAcr67Oa7S_lL1on6ofjuJNop3pAMrK1v-p5vmGeBBG5zzatEFca2sl-yHBRoCcEoQAvD_BwE

Website Excerpt: Our SIPs are composed of an EPS or NEOPOR foam core sandwiched between two OSB facings and bonded with urethane adhesive. These panels are used as load bearing walls and as roof insulation. Our SIPs can be used to completely enclose a home or building and can partition individual rooms if desired.

Foam Laminates of Vermont makes extremely versatile SIPs. In fact, sheetrock, wood, vinyl siding, and other construction materials can be applied directly to the facings to result in a fast, efficient, and superior finished wall. - Foard Panels, 53 Stow Drive West Chesterfield, NH, 03466 USA Phone: \(866) 354-8893 or (604) 359-8179 Email: pete@foardpanel.com retrieved 2019/11/08,

- Malko Paul & Alison Moynihan, SIDING & ROOFING SYSTEM RECOMMENDATIONS using SIPs [PDF] Foard Panels, Op. Cit., retrieved from Foard Panels 2019/11/09

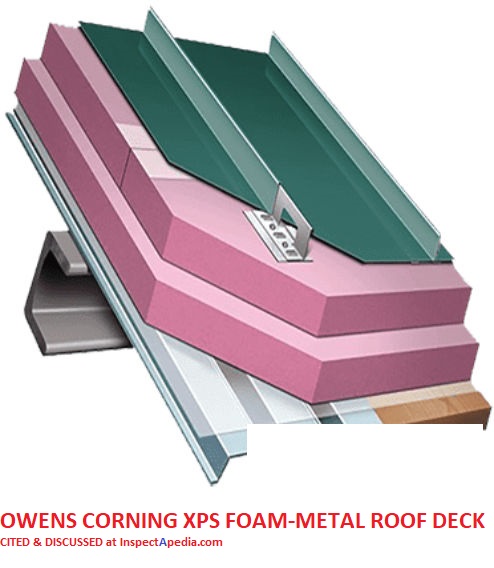

- Owens Corning provides panel and other products for foundations, walls, and roofs, focused on either sloped metal roof decks or flat/low-slope roofs using a variety of systems over concrete or metal roof decks; Contact: https://www.owenscorning.com/insulation/commercial/enclosure/applications/roof

Illustrated below: Owens Corning XPS-Metal Roof Deck system cited above

- RayCore SIP Roof Panels and Wall Panels, RAY-CORE SIPs ™ 305 E. Elva Street Idaho Falls, ID 83401 USA Tel: 1.877.552.2440 Email: info@raycore.com Website: https://raycore.com/

- SIPA, Structural Insulated Panel Association, P.O. Box 39848, Fort Lauderdale, FL 33339 USA, Tel: (253) 858-7472 Email: info@sips.org

Fiberboard Sound Insulation

Fiberboard products are also used for sound insulation, such as Homasote's 440 SoundBarrier used on walls and over subflooring or in ceilings.

According to Homasote this system is recognized in UL L500 Series Floor/Ceiling assemblies.

Also see CANEBOARD PANELS - soft cellulose fiber panel boards also referred to as cane-board, Caneite, softboard, greyboard, pinboard

Fiberboard Sheathing Asbestos, Off-gassing, VOCs, Health & Environmental Questions

ASBESTOS: Is there Asbestos Content in Insulating Board Products such as Celotex, Homasote, Insulite or Nu-Wood?

Asbestos is not an "official" ingredient in fiberboard insulating sheathing. However there are possibilities of cross-contamination of such products by asbestos as asbestos was processed at some of the same fabrication facilities that also made wood or vegetable fiber board products.

See details at SHEATHING, FIBERBOARD ASBESTOS CONTENT

and at FIBERBOARD SHEATHING MSDS

OFF-GASSING: Question: off-gassing hazards from low density fiberboard roof sheathing vs MDF Sheathing

5/9/2014 Anonymous said:

Are there any cases of individuals suffering health issues from exposure to a fiberboard roof? I"m thinking of off gassing due to excessive exterior heat conditions.

Reply:

Offgassing from fiberboard roof? Most likely you're asking about fiberboard roof sheathing, right? I'm doubtful you'll be able measure significant offgassing from low density roof sheathing products in service such as soft density or low density fiberboard.

However more recently there are indeed MDF products sold for use as structural panels including roof sheathing.

Details are at DEFINITION & CHARACTERISTICS of MDF Medium-Density Fiberboard

The article above on this page describes low density fiberboard products and explains that describes how that sheathing material is produced describes wood products and waxes. So to start we'll want to get clear what sort of roof sheathing you are actually describing.

Structural Requirements when Using Fiberboard Sheathing

- IRC R602.10.1 STRUCTURAL BRACING with FIBERBOARD ICC PUBLIC HEARING [PDF] September 2006 retrieved 2019/11 25 original source: https://www.iccsafe.org/cs/codes/Documents/2006-07cycle/ProposedChanges/volume_2/14-RB180-RB203.pdf

- [2] Celotex Corporation, PO Box 31602, Tampa FL 33631, USA, Web: celotex.com - offices in Atlanta, Chicago, Cincinnati, Dallas, Oakland and Philadelphia, and plants in six U.S. States is headquartered in Tampa, FL. Celotex is a national manufacturer of residential and commercial building materials. Website: www.celotex.com Tel: 800-CELOTEX

- Celotex BLUE RIDGE INSULATING SHEATHING GUIDE [PDF] "Blackboard" insulating sheathing specifications,Danville Plant

250 Celotex Dr.

Danville, VA 24541 blueridgefiberboard.com

info@blueridgefiberboard.com

Celotex THERMAX Insulation Selector Guide [PDF] (92000) Celotex Corporation, Atlanta, GA 2700 Cumberland Parkway Suite 550 Atlanta, Georgia 30339 (770) 436-6000 800-952-9978 web search 6/29/12, original source: silvercote.com/PDF/ThermaxInsulSelectorGuide.pdf -

Celotex Blue Ridge Fiberboard", SturdyBrace® [PDF] roduced by Blue Ridge Fiberboard Inc., 250 Celotex Dr., Danville VA 24541, product literature, web search 6/29/2012, original source: blueridgefiberboard.com/pages/sturdybrace.php,

MSDS: original source: blueridgefiberboard.com/pages/sturdybrace/pdfs/SturdyBrace-msds-br.pdf

Guide Specifications: SturdyBrace® Structural Fiberboard Wall Sheathing [PDF] 6/29/12, original source: blueridgefiberboard.com/pages/sturdybrace.php [Copy on file as SturdyBrace-guidespecs.pdf] - [5] "Roof Shingle Tear-Off Procedure for Homasote Products", PDF document, Homasote Co., 932 Lower Ferry Road, West Trenton, New Jersey 08628-024, U.S.A. 800-257-9491 website: at www.homasote.com

- Temple Inland FIBERBOARD WALL SHEATHING [PDF] (2010) Web: www.templeinland.com Tel: 800-0231-6060

- [6] Thermafiber, Inc., (now a division of Owens Corning®) at Thermafiber, Inc., 3711 Mill Street, Wabash, IN 46992, Tel: 888-834-2371 (U.S. & Canada) - 260-563-2111 Website: www.thermafiber.com or Thermafiber technical services at 888-834-2371 (U.S. & Canada) ; Phone: 260-569-0801, Fax: 260-563-8979 or Email: technicalservice@owenscorning.com

- [15] Properties of insulating fiberboard sheathing [PDF] Forest Products Laboratory (U.S.) Luxford, R. F. (Ronald Floyd), 1889 (1960), original report 1955, citation:hdl.handle.net/1957/2489, web search 6/29/12, original source: http://ir.library.oregonstate.edu/xmlui/handle/1957/2489

Disposal of Fiberboard Demolition Debris:

Reader Question: can we dispose of fiberboard by using it as mulch?

Is Celotex recyclable? We just removed some and I wondered if it could just be broken up on the ground like mulch or does it have chemicals in it. - Karen Bradshaw 7/25/11

Reply: fiberboard sheathing or insulating boards are not recommended as yard mulch

Karen the recycle-ability of fiberboard sheathing products like Celotex or Homasote is an interesting one. These products that are made principally of wood fibers or other plant fibers and a binder and are usually disposed of as construction debris.

The properties of insulating fiberboard sheathing were thoroughly described by the U.S. Forest Products Laboratory in a 1955 report[15] as well as in original and current manufacturer's product literature and MSDS sheets.

Watch out: trying to break up any fiberboard product into small mulch like fragments risks creating an irritating or problematic dust hazard for eyes and respiration.

I'm unsure how well the binder or coating chemicals are bonded to the material (some products used paraffin), but I wouldn't use this product for mulch in any case. Some newer insulating boards may contain plastics and some older ones appear to contain bituminous coatings or binders.

You will find that the treatments used to make these insulating boards moisture resistant and to impart stiffness also mean that they will not break down or bio-degrade as a yard mulch.

History of Fiberboard Building Materials + Fiberboard Composition, Ingredients & Coatings

Here are citations that describe the ingredients, manufacturing process, and history of types fiberboard products.

Here are citations that describe the ingredients, manufacturing process, and history of types fiberboard products.

You will find citations (including some I give below) of outgassing of MDF fiberboard products used in other applications (not the soft "Homasote®" type roof sheathing board).

Ongoing research on the use of plant fibers or cellulose to produce fiberboard products as well as on numerous treatments for fire retardance, water proofing, and insect resistance make clear that interest in use of vegetable waste, wood waste, and other cellulosic fibers as well as treatments for those products continues to the present, and the list of materials used to produce fiberboards, from bamboo to willows, continues to grow.

Shown above: illustration from the Lyman wood grinder patent, US Patent No. 34,581 from March 1862.

In study of the history of the invention and production of plant-fiber (wood, cane, bagasse etc) fiberboard it's interesting to note the explosion of fiberboard producing machines in the U.S. between 1924 and 1929 - patents that we include below including patents by Shaw, Campbell, Redemski and in 1930 Walter, Borsodi, Mantius, Raynes, Edwards adn Hinde, all of whom announced improvements in the production of fiberboard with patents filed befor but granted in 1930.

- Akbulut, Turgay, S. Nami Kartal, and Frederick Green III. "Fiberboards treated with N'-N-(1, 8-Naphthalyl) hydroxylamine (NHA-Na), borax, and boric acid." Forest products journal 54, no. 10 (2004): 59.

- Ayrilmis, Nadir, Theodore L. Laufenberg, and Jerrold E. Winandy. "Dimensional stability and creep behavior of heat-treated exterior medium density fiberboard." European Journal of Wood and Wood Products 67, no. 3 (2009): 287-295.

- Ayrilmis, Nadir. "Effect of fire retardants on internal bond strength and bond durability of structural fiberboard." Building and environment 42, no. 3 (2007): 1200-1206.

- Baer, Norbert S., and Paul N. Banks. "Conservation notes: Microenvironments." (1987): 301-305.

- Borsodi, Morris, COMPOSITE FIBER BOARD [PDF] U.S. Patent 1,754,784, issued April 15, 1930.

Excerpt:

One of the objects of the invention is to provide a fiber board, which is exceedingly strong and rigid for its weight.

Another object of the invention is to provide a composite fiberboard of the type mentioned, which possesses great heat insulating properties by reason of its having closed air spaces.

A further object of the invention is to pro vide a composite fiber board of a substantial thickness, consisting of spaced apart, pref erably, cellular boards, the spacing means being in the form of strengthening ribs, impart ing to the structure rigidity and greatly re ducing its weight. - Çavdar, Ayfer Dönmez, Murat Ertaş, Hülya Kalaycıoğlu, and Mehmet Hakkı Alma. "Some properties of thin medium density fiberboard panels treated with sunflower waste oil vapor." Materials & Design (1980-2015) 31, no. 5 (2010): 2561-2567.

Abstract:

The objective of this study was to investigate the effect of hot waste oil vapor on some of the physical and bending properties of commercially manufactured thin medium density fiberboard (tMDF) panels. The samples were treated with waste oil vapor at a temperature of 220 °C for 10 and 20 min time durations.

Based on the findings in this work, the water absorption and thickness swelling of the samples were improved by the treated panels with hot vapor oil and heat. It appears that the samples had some discoloration as a result of treatment processes.

It was also observed that modulus of rupture (MOR) and modulus of elasticity (MOE) of the samples were adversely influenced.

However, it seems that the thermal conductivity of the samples enhanced by such treatments. Panel products treated with these processes could have some promising potential in various applications including outdoor use. - Campbell, Mark, and Ralph WB Reade. Method of reenforcing fiber board [PDF] U.S. Patent 1,600,396, issued September 21, 1926.

- Cane, Simon. "Museum density fibre board." Conservation news (United Kingdom Institute for Conservation of Historic and Artistic Works) 41 (1990): 1

- Carey, Patrick Joseph. WALL BOARD [PDF] U.S. Patent 1,156,753, issued October 12, 1915.

Excerpt: My wall board is constructed with a cen tral core- or base A manufactured from . paper, pulp or fibers of wood pulp ground and chemically treated and pressed together in layers B, the central core or base being. built up to form a board of any desired thickness. At each side of this central core or base, there is disposed a piece of vul canized fiber board C, the sheets of vulcan ized fiber board being preferably, one twentieth of an inch thick. - Carey, Philip PULP-BOARD for ROOFING PURPOSES [PDF] US Patent 300,946 application filed February 4, 1884

Excerpt:

... To this end the novelty of myu invention consists in a pulp-board composed of wood pulp, asbestos fiber, or any other mineral fiber, any suitable clay mixed together while in a pulp, then pressed or rolled into sheets or boards, dried, and afterward coated or saturated with asbestos, asphaltum, or any other fire or water proof paint, ... - Carter, John D. "Fiberboard." U.S. Patent 2,099,598, issued November 16, 1937.

[production of laminated fiberboard] - Carvalho, Luísa, F. Magalhães, and João Ferra. FORMALDEHYDE EMISSIONS FROM WOOD-BASED PANELS-TESTING METHODS AND INDUSTRIAL PERSPECTIVES [PDF] Nova Science Publishers, Inc., Hauppauge, NY (2012): 73-107.

- Case, Alfred Wells, and Lawrence W. Case. Pulp-board-making MACHINE [PDF] U.S. Patent 633,072, issued September 12, 1899.

Excerpt:

This invention relates to a machine for mak ing board from fibrous materials which is par ticularly adapted for working leather-pulp, but which can be employed for making thick or thin board from pulp containing other fibrous stock. - Case, Albert Willard. "Paper making machine." U.S. Patent 642,083, issued January 30, 1900.

- Case, Albert Willard. "Machine for smoothing fiber-board." U.S. Patent 1,106,492, issued August 11, 1914.

- Chow, Poo. "Phenol adhesive bonded medium-density fiberboard from Quercus rubra L. bark and sawdust." Wood and fiber Science 11, no. 2 (2007): 92-98.

Abstract:

Twelve-millimeter-thick medium density fiberboards made from double-disc, steam-pressure-refined red oak sawdust fibers at 6.5 and 9.0% phenol-formaldehyde levels for both, with and without the addition of sodium pentachlorophenate, meet most of the specifications required for exterior-grade, medium density, class 1 commercial particleboard and medium density hardboard.

Panels made from red oak bark fibers showed inferior properties to panels made from red oak sawdust fibers. However, at a 9% resin level, untreated bark fiberboard exhibited acceptable modulus of elasticity in bending, internal bond, and face screw-holding values.

The addition of the preservative to the adhesive had the effect of decreasing all of the strength properties and the linear expansion values of all untreated panels at three resin levels.

Three-layer type of panels made from red oak sawdust fiber faces and red oak bark fiber core had higher bending strength, stiffness, and face screw-holding values, but lower internal bond and tensile strength parallel to face values than a homogeneous type of panel made from a mixture of equal weight of sawdust and bark fibers.

Three-layer panels also showed lower linear expansion values than the homogeneous type of panel.

At a 6.5% resin level, both homogeneous and three-layer types of panels had acceptable strength properties except for the tensile strength parallel to face and linear expansion values. - Clapp, Albert C. "Water and fire resisting fiber-board and process of manufacture." U.S. Patent 1,280,400, issued October 1, 1918.

- Cobb, Judd M., Beloit Wisconsin, IMPROVEMENT in THE MANUFACTURE OF STRAW-BOARD FOR THE CONSTRUCTION OF BUILDINGS. [PDF] US Patent No. 111,611 granted 1871-02-07

- Cobb, Judd M., IMPROVEMENT IN PLASTERlNG BOARDS FOR WALLS. [PDF] US Patent No. 147,904 granted 1874-02-24

- Cobb, Judd M., IMPROVEMENT IN THICK PAPERS [PDF] US Patent NO. 147,903 granted 1874-02-24

Excerpt: My invention has for its object to produce a thick cheap paper for use as a floor-covering in place of oil-cloth and carpeting, as a covering for the interior walls and ceilings of buildings in place of laths and plastering, and as a soft pliable wrapping or express paper to protect machinery, furniture, and other heavy articles during transportation.

To this end the invention consists in a new article of manufacture, to wit, a thick paper or board laid up in webs in such a manner that the fine surfaces shall be upon the outside, and the coarse surfaces within the body of the paper, as I will now proceed to describe. - Cobb, Judd M., IMPROVEMENT IN BUILDING PAPER OR BOARD [PDF] US Patent No. 195,483 granted 1877-09-25

Excerpts:

Be it known that I, JUDD M. COBB, of Beloit, in the county of Rock and State of Wisconsin, have invented a new and useful Improvement in BuildingPaper or Board, which is fully described in the following specification

My invention relates to straw board or other like material adapted for use as a substitute for laths and plaster upon the walls and ceilings of building, or for siding upon the outside of buildings.

The invention is intended to produce an odorless building-board especially suitable for use as a substitute for laths and plaster in the interior ot'dwellings, and is an improvement upon the invention described in Letters Patent No. 111,611, granted to me February 7, 1871.

... In carrying out my present invention I employ only deodorized mineral or coal oil. I make a mixture of rosin with this oil in the proportion of forty pounds of oil to one hundred pounds of -rosin, or thereabout.

As the straw board leaves the driers of the papermachine without any additional treatment, it is passed through a vat filled with the mixture of rosin and oil above described in a warm condition. Both sides of the board are thus coated with the mixture, and, in fact, the board is nearly saturated therewith.

It is then passed through suitable scrapers, for the purpose of removing the surplus portion of the coating, and is conducted thence to calender-rolls, either hot or cold, through which it is passed. These calender rolls press the board, thereby forcing the oil and rosin coating into the substance of the board on both sides thereof, and giving it a hard smooth surface on each side.

In the process set forth in my patent mentioned above a different appearance and degree of finish are given to the two sides of the board; but by the process herein described both sides of the \board present the same appearance and have the same degree of finish.

On each side there will be a smooth glazed coating, and the board thus prepared may be used either side out with the same effect and appearance.

I prefer to use rosin, as it is a cheap material; but it is evident that any other suitable resinous material may be substituted therefor to make, with the oil,a water-proof coating to be applied as herein described.

The product thus obtained is entirely inodorous, and is also water-proof. It is especially adapted for use in the interior of dwellings as a substitute for laths and plaster, and the mineral oil is so cheap that this building-board will cost but little more than ordinary building-board, and there is, therefore, no obstacle to its substitution for the latter in all places where it is employed.

- Corneau, Diane. "Effectiveness of barriers to minimize VOC emissions including formaldehyde." Forest products journal 56, no. 9 (2006).

- Craddock, Ann Brooke. "Construction materials for museum storage." (1988).3.

- DeStefano, Jim, P. E., and David S. Gromala. "By Dirk M. Kestner, PE; Jennifer Goupil, PE; and Emily Lorenz, PE."

- Fir-Tex INSULATING BOARDS [PDF] (1945) (Product Catalog) Fir-Tex Insulating Board Co.

Note: The word "asbestos" does not appear in this Fir-Tex catalog.

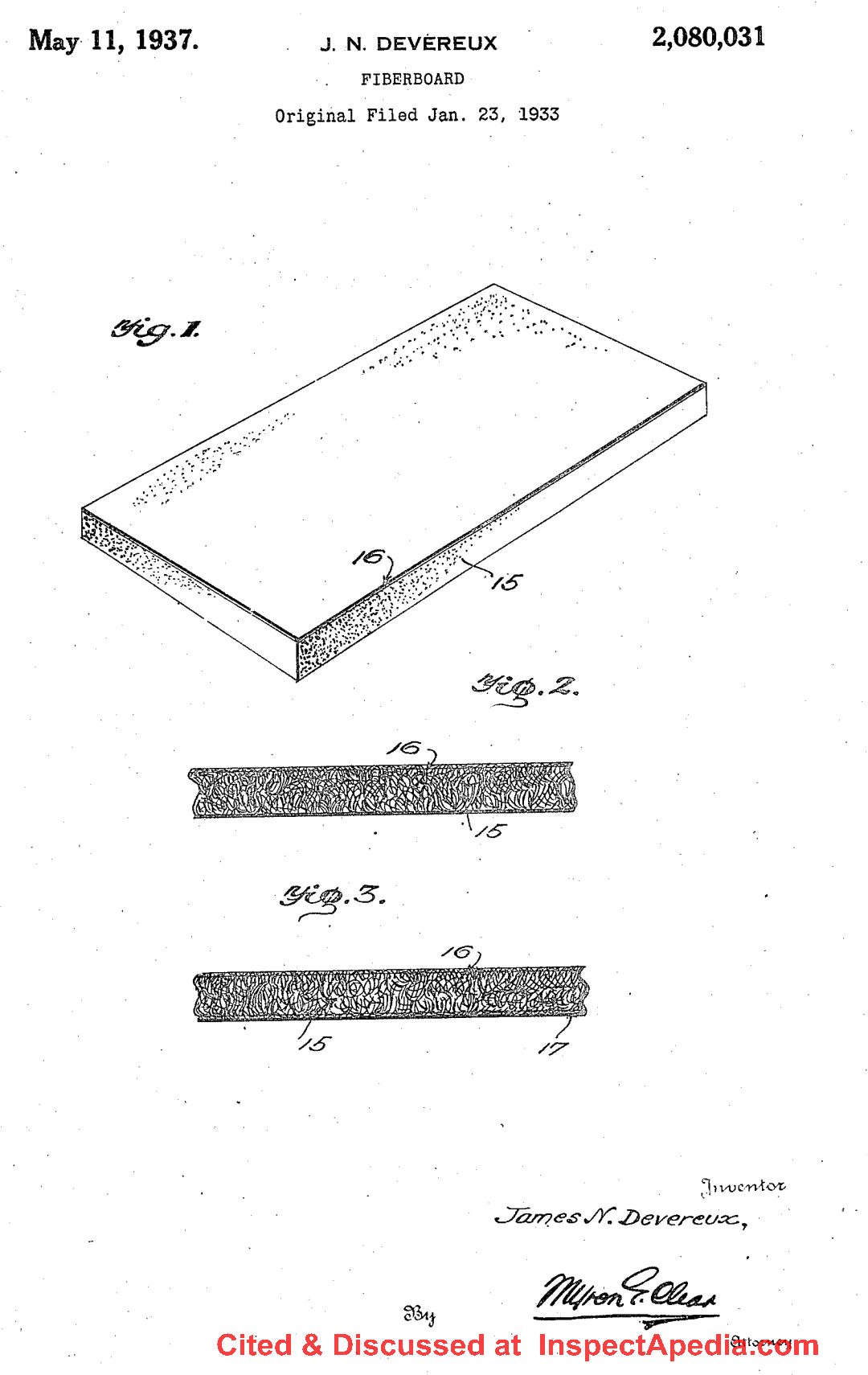

- Devereux, John N., FIBERBOARD [PDF] U.S. Patent 2,080,031, issued May 11, 1937.

Excerpts:

My present invention relates generally to fiber board or fiber sheets of the type commonly used in the construction of buildings, in walls, roofs, cellings, partitions, and the like, and more par ticularly to fiber board as manufactured accord ing to the method, and by means of the apparatus, described and claimed in my Patent Number 1,997,136, granted April 9, 1935, of which the pres ent application is a division.

Up to the present time, fiber board formed of Wood, cornstalk or other suitable flbers, in a sin gle ply, has been rough and unsightly in appear ance, and unsuitable for the direct application of paints, wall paper and other decorative materials, as Commonly used on building interiors.

Some effort has been made to combine two webs or plies, one of which is Smooth and waterresistant, but such plies have been in the nature of separate layers which are too readily torn apart and this ls highly objectionable.

It is the primary object of my invention, there fore, to provide flber board having a body andat least one surface constituting, in effect, two plies, although not separable, one from the other, and of which the surface ply is smooth and water resistant so that it may be washed when soiled, and is well adapted to receive plastic paints, wall paper, and the like applied directly thereto, with pleasing appearance.

A stillf urther objectis the provision of a multi ply flber board, one ply of which is in the nature of a non-separable skin on the body of the board, forming a tough, close grained surface, not only Smooth and water resistant, but having an ash :nt substantially greater than that of the

A still further object of my invention is to pro Vide fiber board having a body and at least one skin Surface of a tough, waterresistant character; the body and said surface being formed of the Same materials, of which the fine flbers and a pre ponderance of the chemical constituents are con 45 | centrated in the said skin surface. - Edwards, Earl S. Manufacture of fiber board [PDF] U.S. Patent 1,778,147, issued October 14, 1930.

Excerpt:

My invention relates to the manufacture of material, usually pressed in the form of boards, especially designed for electric insu lation and made of wood pulp, or other strong fibrous material having felting power in conjunction with other substances, such as gil sonite or other material of an organic as phaltic or bituminous nature, to act as a binder and otherwise, red gum or another gum 10 or resin to impart rigidity to the gilsonite, coloring material, such as a black dye, and a fireproofing material.

My invention has for its special object to make a material of this general character which is peculiarly fire resistant, and at the same time strongly resistant to electricity, moisture, and heat; can be cut, sawed, drilled, or otherwise worked like maple wood for ex ample; is strong and resistant to tensile, a compression and bending strains, and to shrinking and warping; does not absorb moisture and is not affected by climatic changes, acids, oil, or water; is of light weight and inexpensive to manufacture. - Evans, Charles S. "Fiberboard structure and method of making the same." U.S. Patent 2,203,084, issued June 4, 1940.

- Gilbert, Nicolas L., Mireille Guay, Denis Gauvin, Russell N. Dietz, Cecilia C. Chan, and Benoît Lévesque. "Air change rate and concentration of formaldehyde in residential indoor air." Atmospheric Environment 42, no. 10 (2008): 2424-2428.

- Gilbert, Nicolas L., Denis Gauvin, Mireille Guay, Marie-Ève Héroux, Geneviève Dupuis, Michel Legris, Cecilia C. Chan, Russell N. Dietz, and Benoît Lévesque. "Housing characteristics and indoor concentrations of nitrogen dioxide and formaldehyde in Quebec City, Canada." Environmental Research 102, no. 1 (2006): 1-8.

- Gould, Carol S., Kimberly L. Konrad, Kathleen Catalono MIlley, Rebecca Gallagher, "FIBERBOARD Dates of Production 1858 to the present, Common Trade Names" [American Wallboard, Beaver Board, Cornell BOard, C-X Boards, Feltex, Fir-Tex, Homasote, Insulite, J-M Board, Maftex, Masonite (presdwood Quartrboard, Tempered Presdwood), Nu-Wood, Upson Board), Chapter 12 in Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Hinde, James J. Apparatus for MANUFACTURING FIBER BOARD or analogous material [PDF] U.S. Patent 1,748,224, issued February 25, 1930.

- Kelly, George. Flexible vulcanized-fiber board and process for making the same [PDF] U.S. Patent 966,101, issued August 2, 1910.

- Li, Xiaobo. "Physical, chemical, and mechanical properties of bamboo and its utilization potential for fiberboard manufacturing." (2004).

- LI, Xiao-ping, Zhang-kang WU, Zhong-yong XU, and Xue-bao LIU. "Manufacture of industrial hemp stalk based on light heat preservation materials Ⅱ-heat Insulation properties of gypsum and cement panels." Wood Processing Machinery 1 (2014): 003.

- Love, Thomas. "Pressed ceramic fiber board and method of manufacture." (patent) US20020098336 A1 (2002)

- Lyman, Azel Stores, Wood Grinder: IMPROVED PROCESS OF SEPARATING THE FIBERS OF WOOD AND OTHER SUBSTANCES FOR THE MANUFACTURE OF PAPER-PULP. [PDF] US Patent No. 34,581, Granted 1862-03-04

Excerpts

Be it known that I, AZEL STORRs LYMAN, of the city, county, and State of New York, have invented a new and Improved Process of Separating the Fibers of Wood, Flax, Hemp, and other Substances, and Extracting the Col--oring-Mattes Therefrom; and I do hereby de clare that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawings, forming part of this specification ...

This invention is based upon the known fact that when Wood, hemp, flax, and other vegetable substances are heated in Water at a temperature at which it boils under a pressure of several atmospheres the gummy and coloring matters by which the fibers are held together are dissolved, or at least so much, softened that they hold the fibers but loosely together.

The invention consists in effecting the separation of the fibers of such substances by whippin g, beating, rubbing, grinding, or picking them while they are exposed to the action of water at such temperature and under such pressure as above mentioned. - Malcolm, Thomas. "Manufacture of fiber-board." U.S. Patent 906,043, issued December 8, 1908.

Excerpt: This invention relates to the art of manu facturing sheets of fibrous substances, and more especially to the manufacture of what is generally known as “leather board,'and it has for one of ... - Malcolm, Thomas. MANUFACTURE of FIBER BOARD [PDF] .S. Patent 906,044, issued December 8, 1908.

Excerpt:

... I ... have invented certain new and useful Improvements in the Manu facture of Fiber-Board, of which the foll lowing is a full, clear, and exact specification.

This invention relates to the art of manu facturing sheets of fibrous substances, and more especially to the manufacture of what 15 is generally known as “leather board,” and it has for one of its objects the production of such board the fibers of which are thoroughly knit together and compressed, this 20 25 knitting together or intermingling being the result of constant agitation during the com pression of the pulp mass, as for instance by a machine and a method shown, described, and claimed in a contemporaneously-pend ing application for Letters Patent, filed by me on May 18, 1907, under Serial Number 374,939, and to which reference may be had. - Minnesota Department of Health, "INFORMATION SHEET FOR FORMER CONWED WORKERS", [PDF] September 1993, retrieved 2015/12/04, original source: http://www.health.state.mn.us/divs/hpcd/cdee/occhealth/conwedfact.html

- Mantius, Otto, FIBER-BOARD MACHINE [PDF] U.S. Patent 1,764,456, issued June 17, 1930.

Excerpt:

This invention relates to the manufacture of fiberboard and is directed more particular ly to a machine for converting loose watery fiber into a solid sheet of board, and for si multaneously removing from the fiber a large part of the water embodied therein, so that the board may be suitable for drying. - Nelson, Lyman H. "Ping-pong racket." U.S. Patent 716,464, issued December 23, 1902.

Excerpt:

My invention consists of a racket made up of several thicknesses of paper or fiber board cemented together, with a thickened portion for the handle. - Pan, Mingzhu, Dingguo Zhou, Tao Ding, and Xiaoyan Zhou. "Water resistance and some mechanical properties of rice straw fiberboards affected by thermal modification." BioResources 5, no. 2 (2010): 758-769.

- Pertz, John Wm. "Paper or fiber board machine." U.S. Patent 1,272,847, issued July 16, 1918.

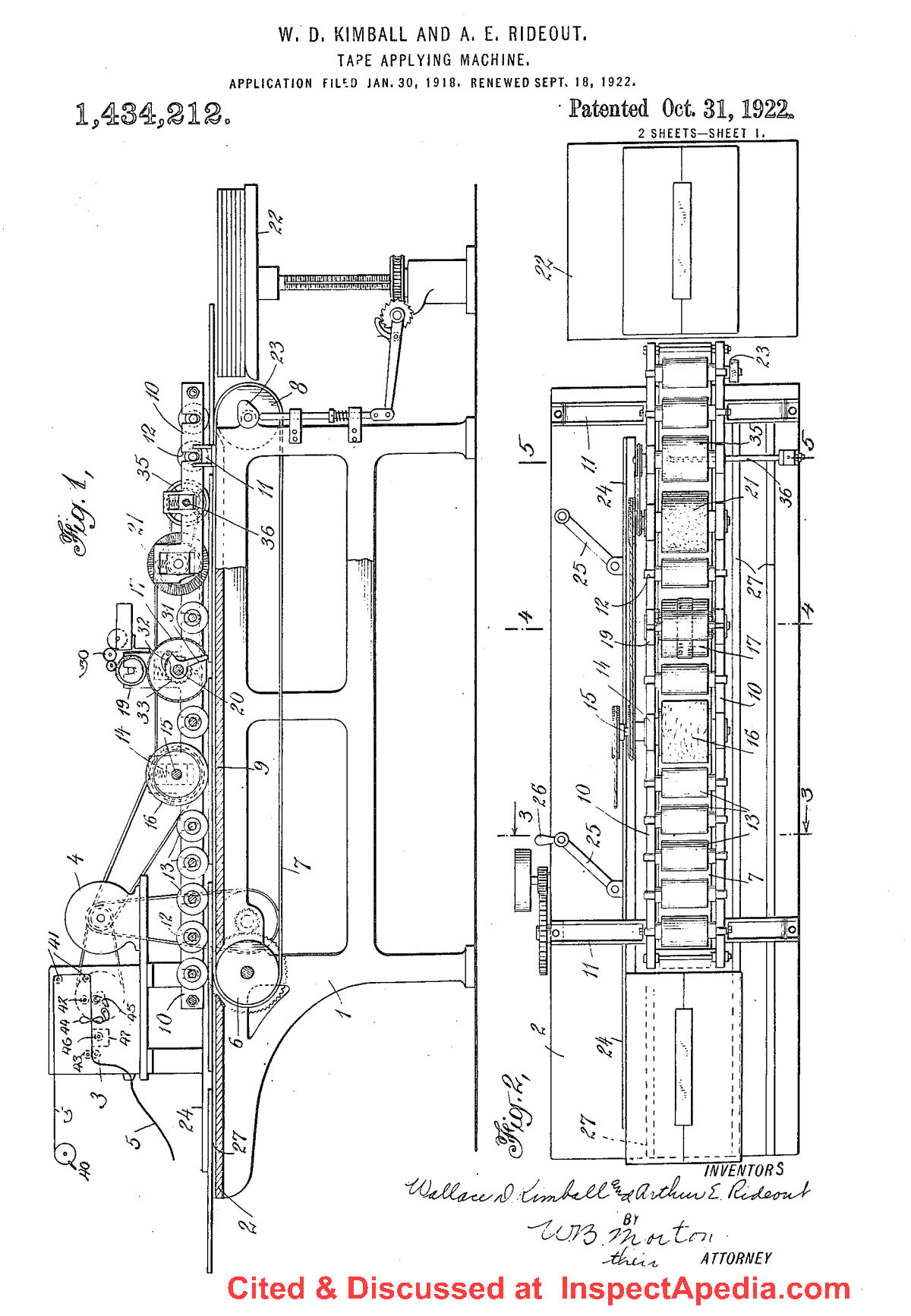

- Raynes, Harry C. WALL BOARD [PDF] U.S. Patent 1,434,212, issued October 31, 1922. Filed Jan 30 1918.

Excerpt:

The wall board or fibre board which is produced by the process of my invention may be made from a great number of varied raw materials such, for example, as Vegetable fibres, straw, trimmings, waste from saw mills, waste from cotton mills, waste from rag or wood fibre paper mills, unmerchantable stumpage, municipal waste, such as cloth, paper, wood or other fibres, waste from lumbming operations, such as slashings, and any other fibres of this general nature.

These various raw materials are fed preferably by a handling and sorting conveyor into a reducing mill which may be of the ball, tumbler, hog, or any other desired type in which the material may be preliminarily comminuted.

From the reducing mill the material way be fed by a collecting conveyor to a shredder or refining mill in which the material may be further comminuted, any suitable form of apparatus being employed for the purpose, such as a plug or fly bar drum refiner or a whirl beater for example.

The various kinds of fibres so prepared are then preferably taken to a precipitation system where they may be separated according to their different specific gravities, the differentiation being accentuated if desired by a chemical treatment of the fibres in the mixing conveyor. In this precipitation .tank the heavy material will be separated out to a large extent and the soft wood fibres separated from the hard wood fibres.

The hard wood fibres from the precipitation tank are then preferably directed to steaming kiers where they may be impregnated with sodium silicate and with sulphate of alumina forming an insoluble alumina silicate in or on the fibres.

The soft wood fibres are preferably separately directed to a chest or tank where they may be subjected to chemical treatment by means of alumina sulphate and copper oleate, for example.

The hard and soft wood fibres are then preferably combined together and mixed with the proper proportion of wood, waste paper or rag pulp.

The mixed pulp may then be subjected to a final chemical treatment to attain fire and moisture resisting properties.

The pulp so made is then taken to the apparatus forming the basis of this invention, made into fibre board and finally dried. The method by which this is accomplished may be best described with reference to Fig. 1 of the drawings.

- Raynes, Harry C. APPARATUS for PRODUCING FIBER BOARD [PDF] U.S. Patent 1,754,370, issued April 15, 1930.

- Rhiger, Hans. THE FIBER BOARD INDUSTRY [PDF] (1937). BSc Thesis, Oregon State Agricultural College (June 1937)

- Sean, S. Trek, and Michel Labrecque. "Use of short-rotation coppice willow clones of Salix viminalis as furnish in panel production." Forest products journal 56, no. 9 (2006): 47.

Excerpting & paraphrasing from the authors' abstract:

This study proposes substituting traditional raw materials in the wood composite paneling industry with a fast-growing willow species, thereby alleviating shortages of raw material in a cost-efficient manner and at the same time preserving our natural resources from overexploitation. ...

experimental board production, 3-year-old stems of Salix viminalis L. were manufactured in the laboratory ... - Shaw, John K. "Fiber board having ornamental surfaces." U.S. Patent 1,500,207, issued July 8, 1924.

- Sheesley, Horace A. APPARATUS FOR MANUFACTURING FIBERBOARD [PDF] U.S. Patent 2,222,633, issued November 26, 1940.

Excerpts:

This invention relates to a method and appa ratus for manufacturing fiberboard, and more particularly to an improved method and appara tus for converting pulp and other fibrous Waste into commercially useful sheets or rolls.

In the manufacture of board materials com Inonly known as pulp board, cardboard, fiber board, and paperboard, the so-called wet process of manufacture is universally used. In this proc ess, the fiber base, which may be old newsprint, paper Waste, or pulp of all kinds, is placed in a beater, where the Water and the desired paper sizing and color is added.

As it comes out of the beater more Water is added until the liquid comprises approximately 95% to 98% water and 2% to 5% fibrous stock. The liquid pulp is then conducted into a Jordan machine, which serves to brush the pulp so as to eliminate any lumpy material and leave the minute pulp fibers freely suspended in the carrier liquid or water.

From the Jordan machine the Water and pulp flows onto a paper machine, generally the Fourdrinier or cylinder type of machine. In the paper-mak ing machine the water must be removed first by draining, then by suction, and finally by drying over heated drums. The paper is then suitably calendered or otherwise treated to give the de sired surface finish.

...

It is an object of this invention to provide an improved method and apparatus for the manu facture of Such products as cardboard, paper board, fiberboard, pulp board, wallboard, and similar sheet material, more economically, more efficiently, and at a higher rate of production than present known processes.

It is further an object of this invention to provide an improved process and apparatus for manufacturing paperboard products and similar sheet material whereby the large amounts of Water, the capital and labor required, the expensive machines and equipment required, are great ly reduced, resulting in a product which is fully equal, if not superior, to the product manufac tured under the present wet processes.

Another object of my invention is to provide a dry proceSS for the preparation of materials or fibers for making paperboard products and like sheet materials. - Suchsland, Otto, George E. Woodson, FIBERBOARD MANUFACTURING PRACTICES

in the

United States, [PDF] (1987) USDA, United States Department of Agriculture, Forest Service Agriculture Handbook No. 640, 1986,

Introduction:

This handbook introduces the reader to the manufacture and fabrication of fiberboard as practiced today in the United States. A brief history of this industry is followed by a discussion of some important technological and chemical factors as well as a survey of the raw material base.

The bulk of the book describes the equipment and the processes including the insulation board process, the wet and dry hardboard processes, and the medium-density fiberboard process.

Modern finishing processes are discussed in some detail, and an entire chapter is devoted to the important subject of water use and water treatment.

The concluding chapter deals with product properties and applications including a discussion of various commercial standards. A special effort has been made throughout to illustrate the subject with in-plant photos and to explain important concepts by means of schematic drawings. - Teoh, Yi Peng, Mashitah Mat Don, and Salmiah Ujang. "Assessment of the properties, utilization, and preservation of rubberwood (Hevea brasiliensis): A case study in Malaysia." Journal of Wood Science 57, no. 4 (2011): 255-266.

- Teesdale, Laurence Victor. THERMAL INSULATION MADE OF WOOD-BASE MATERIALS: ITS APPLICATION AND USE IN HOUSES [PDF] (1958) Report No. 1740, US Forest Products Laboratory, U.S. Department of Agriculture, Madison 5, Wisconsin, in cooperation with the University of Wisconsin.

- Ustaomer, Derya, and Mustafa Usta. "The effects of boron compounds and different melamine contents in MUF resins on some properties of MDF panels." BioResources 7, no. 1 (2011): 0437-0446.

- USG WEATHERWOOD STRUCTURAL INSULATING SHEATHING [PDF] - 1952 product specifications, installation details, photos

- USG SHEETROCK PYROFILL ROOF DECKS [PDF] - US Gypsum Insulating Pyrofill & USG Asbestos Board Pyrofill & USG Acoustical Pyrofill product descriptions, specifications, installation details, from USG 1952 Technical Specifications including:

USG Insulation Formboard is a rigid type wood fiber insulation board, 1" thick, 32" wide (or 48" wide), and cut to specified lengths to fit purlin spacings. Treated to resist mildew effectively. Federal Specification LLL-F-321b. - US FPL, PROPERTIES of INSULATING FIBERBOARD SHEATHING [PDF] Forest Products Laboratory (U.S.) Luxford, R. F. (Ronald Floyd), 1889 (1960), original report 1955, citation:hdl.handle.net/1957/2489, web search 6/29/12, original source: http://ir.library.oregonstate.edu/xmlui/handle/1957/2489

- USFPS, INSULATING BOARD, HARDBOARD,

AND OTHER

STRUCTURAL FIBERBOARDS [PDF] U.S.D.A. U.S. Forest Service, FPL-077 Research Note (1965) - retrieved 2022/04/09 original source: https://www.fpl.fs.fed.us/documnts/fplrn/fplrn077.pdf

Summary

The wood-base fiber panel materials are a part of the rapidly evolving technology based on converting lignocellulose to fiber and reconstituting the fiber into large sheets and panels. While some equipment and techniques used are the same as for producing paper, there are enough differences in techniques used and other requirements for manufacture that a separate treatment of the subject is warranted.

This research note describes the various requirements for raw materials and equipment, describes various steps in manufacture, and presents summaries of important strength and physical properties of insulating board, mediumdensity building fiberboard, and hardboard. - Walter, Harrison B. "Fiber-board crate." U.S. Patent 1,767,629, issued June 24, 1930.

- Wilson, Rich, Kathleen Snodgrass, "EARLY 20TH-CENTURY BUILDING MATERIALS: FIBERBOARD AND PLYWOOD", [PDF] U.S. Forest Service, Technology & Development Program, March 2007, retrieved 2015/12/04, original source: http://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/

- Youngquist, John A., Brent E. English, Roger C. Scharmer, Poo Chow, and Steven R. Shook. "Literature review on use of nonwood plant fibers for building materials and panels." (1994).

- Zhang, Luoping, Craig Steinmaus, David A. Eastmond, Xianjun K. Xin, and Martyn T. Smith. "Formaldehyde exposure and leukemia: a new meta-analysis and potential mechanisms." Mutation Research/Reviews in Mutation Research 681, no. 2 (2009): 150-16

Research on Structural Support & Shear Bracing Where Fiberboard Panels are in Use

- Erickson, E.C.O., Eng., RIGIDITY AND STRENGTH OF WALL FRAMES BRACED WITH METAL STRAPPING [PDF] US Forest Products Service, USDA, Agriculture-Madison, 1960, Report No. R1603,

- Holladay, Martin, "4 Options for Shear Bracing Foam-Sheathed Walls", Fine Homebuilding, The Taunton Press, Inc. 63 South Main St., PO Box 5506 Newtown, CT 06470-5506 USA Phone: 203-426-8171 , No. 220, retrieved 2016/09/28, original source: http://www.finehomebuilding.com/2011/05/19/4-options-for-shear-bracing-foam-sheathed-walls

- Simpson Strong Tie, 20-Gauge 14 Ft. 2 In. Wall Bracing, Model RCWB14, Simpson Strong-Tie Company Inc., Tel: (800) 999-5099, Website: https://www2.strongtie.com

Research on Mold in or on Fiberboard Sheathing or Panel Products

See research cited at

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-11-11 by chuck donley - Civil Engineer needs to evaluate fiberboard sheathing as a base for hot mop roof installation

I am a Civil Engineer . A roofing contractor called me out to satisfy the building inspectors request for structural approval for installing new hot mop roofing over existing 1-3/4" thick T&G fiberboard sheathing/insulation spanning 30" between rafters.

This is a first for me having never seen this material used for this purpose. None of the references in your article gives specific values for roof load capacity usually required for designing this product for use as structural sheathing.

Any help available? Thanks, Chuck Donley

Reply by InspectApedia Publisher - specific values for roof load capacity for use as structural sheathing

@chuck donley,

Bottom line: typical 1/2" thick fiberboard sheathing insulation is not by itself a suitable structural roof deck material.It might, however be perfectly fine installed as an insulating and smoothing layer atop an existing structural roof deck.

Here's an excerpt from the patents cited in our article on fiberboard:

"Insulating Structural Board", U.S. Patent 2,159,300, Armen H. Tashjian et als, assigned to William B. Miller, Lakewood OH, 23 May 1939,

describes insulating structural boards of laminated construction for use as roof or floor slabs, and refers to "Standard insulating fiber boards, such as "Celotex", "Masonite", "Insulite", etc. that had excellent insulating properties but have relatively slight structural strength in flexure or bending under load, hence are not and cannot be used as structural slabs for load sustaining purposes, as roof or floor slabs, for example.Details:

Fiberboard is an insulating sheathing that has been widely used on exterior walls and much less often, on roofs. In fact during a re-roof job years ago my helper, who weighed less than 150 lbs, fell right through an older roof sheathed only with 1/2" thick fiberboard.

Some of the confusion on this topic may stem from someone not being clear about just what sheathing material was put on the roof that you were called to inspect. Fiberboard may include Low Density (LDF), Medium Density (MDF) or High Density (HDF) each with different structural properties.

Most likely you'll see LDF fiberboard insulation laid down (screwed down with big metal washers) atop a plywood or other structural sheathing material and then covered with the roof membrane.

If there is attic access or roof cavity access from below, you should see plywood or OSB, and in some locations you can usually find the APA or similar stamps on that sheathing material that gives its specs including loading, rating as structural sheathing, and the allowable spans.

Similarly, where OLDER gypsum board or soft fiberboard sheathing like the product described on this page is used on exterior walls, the building inspector usually requires either solid plywood or diagonal bracing at the building corners. However SOME contemporary fiberboard sheathing manufacturers say that such corner bracing is not required with their product (on walls).

What's confusing is that the phrase "fiberboard sheathing" or the word "structure" or "structurally" might be used ambiguously in some texts, even Chapter 23 (WOOD) of the Florida Building Code (for example) as a description of "structural sheathing".

Here's a typical code excerpt:2303.1.6 Fiberboard.

Fiberboard for its various uses shall conform to ASTM C208. [See this standard cited below - Ed.] Fiberboard sheathing, when used structurally, shall be identified by an approved agency as conforming to ASTM C208.

2303.1.6.1 Jointing.

To ensure tight-fitting assemblies, edges shall be manufactured with square, shiplapped, beveled, tongue-and-groove or U-shaped joints.

2303.1.6.2 Roof insulation.

Where used as roof insulation in all types of construction, fiberboard shall be protected with an approved roof covering.

2303.1.6.3 Wall insulation.

Where installed and fire-blocked to comply with Chapter 7, fiberboards are permitted as wall insulation in all types of construction. In fire walls and fire barriers, unless treated to comply with Section 803.1 for Class A materials, the boards shall be cemented directly to the concrete, masonry or other noncombustible base and shall be protected with an approved noncombustible veneer anchored to the base without intervening airspaces.

2303.1.6.3.1 Protection.

Fiberboard wall insulation applied on the exterior of foundation walls shall be protected below ground level with a bituminous coating.

---

Here's the ASTM Standard being cited. Notice that ALL of this text describes an INSULATING material.ASTM C208-22 - Standard Specification for Cellulosic Fiber Insulating Board

Abstract

This specification covers the principal cellulosic fiber insulating board types, grades, and sizes. Insulating board covered by this specification consists of six types:Types I, II (Grades 1 and 2), III (Grades 1 and 2), IV (Grades 1 and 2), V, and VI.

Cellulosic fiber insulating board shall be manufactured from refined or partially refined ligno-cellulosic (wood or cane) fibers, by felting or molding process, into homogeneous panels.The insulating board shall conform to the physical properties specified.

---

Our friends over at UpCodes offer more code excerpts on fiberboard at https://up.codes/s/fiberboard (summary) or https://up.codes/viewer/portland/ibc-2021/chapter/23/wood#2303.1.6 (detail)

Excerpts: - note these are two different sections2303.1.5 Wood Structural Panels

Wood structural panels, where used structurally (including those used for siding, roof and wall sheathing, subflooring, diaphragms and built-up members), shall conform to the requirements for their type in DOC PS 1, DOC PS 2 or ANSI/APA PRP 210.

Each panel or member shall be identified for grade, bond classification, and Performance Category by the trademarks of an approved testing and grading agency.The Performance Category value shall be used as the "nominal panel thickness" or "panel thickness" whenever referenced in this code.

Wood structural panel components shall be designed and fabricated in accordance with the applicable standards listed in Section 2306.1 and identified by the trademarks of an approved testing and inspection agency indicating conformance to the applicable standard.

In addition, wood structural panels where permanently exposed in outdoor applications shall be of exterior type, except that wood structural panel roof sheathing exposed to the outdoors on the underside is permitted to be Exposure 1 type.2303.1.6 Fiberboard

Fiberboard for its various uses shall conform to ASTM C208.

Fiberboard sheathing, where used structurally, shall be identified by an approved agency as conforming to ASTM C208.

Bottom line:

the SPECIFIC fiberboard sheathing at your job MIGHT be acceptable as a structural sheathing but before you can possibly conclude that you have to know just what product was used - and you'll look for the product identification stamp or if that's not visible, some other documentation that you trust actually matches the product used by the roofer.See references in the article above including

IRC R602.10.1 STRUCTURAL BRACING with FIBERBOARD ICC PUBLIC HEARING [PDF] September 2006 retrieved 2019/11 25 original source: iccsafe.org/cs/codes/Documents/2006-07cycle/ProposedChanges/volume_2/14-RB180-RB203.pdf

On 2023-04-01 by Tim - What are the typical thicknesses of fiberboard over the last century?

What are the typical thicknesses of fiberboard over the last century? Were all types 1/2" or were some 3/8", etc. Thanks you, answers would be very helpful!

On 2023-04-02 by InspectApedia Editor

@Tim,

Thank you for an interesting question, and at the same time forgive me for being a bit dense (pun but true) in not being able to give a single simple answer, but the answer to your fiberboard thickness question is, as Mark Cramer says, ... it depends.Bottom line: Fiberboard sheathing thicknesses range roughly from 2.5mm to 8".

But in fact the answer toyour "how thick were and are fiberboard products" depends on what product we're discussing:

- LDF

- MDF

- HDF

Insulating sheathing

Insulating roof panels under flat roofs

or Panel and plank siding materials

or hardboard products used indoors as wall paneling as well as of course many other products.FYI

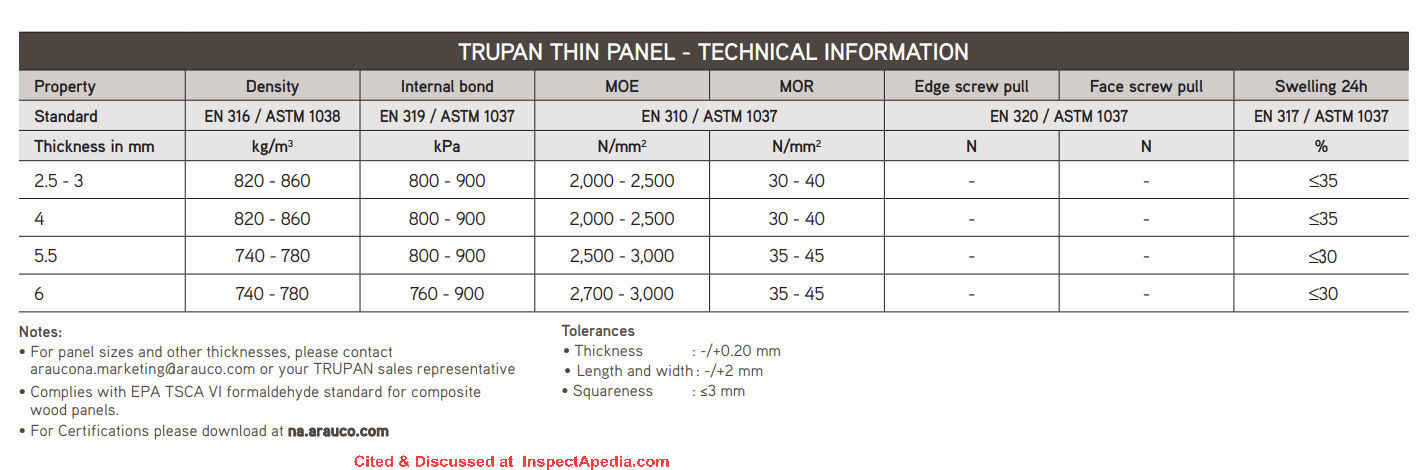

see this TRUPAN THIN PANEL SPECIFICATIONS SHEET [PDF] from original source: na.arauco[dot]com/en/resources/download/TRUPAN_spec-ThinPanel

---

Softer LDF fiberboard insulating sheathing might be 1/2" thick but some products used in flat or low-slope roofing are 3-6" thick.

Hardboard products are often 1/8" or 3/16" or 1/4".

MDF products vary over a similar range.

The fiberboard siding used on buildings as a finish siding, SIDING HARDBOARD - home - wood-fiber based siding products - https://inspectapedia.com/structure/Fiberboard_Sheathing.php

may be tapered.

In general, the harder the fiberboard product the more-likely you are to find it in thinner productions. 1/8" and some modern thin panel materials, eg used as flooring underlayment, can be down to 2.5mm - this table is from Arauco's Trupan thin panel technical data sheet.

Take a look at the Recommended Articles list fat the end of this page for a range of product types, properties, descriptions.

On 2023-02-12 by Valerie K - what is this brown stuff from our attic? Is it asbestos?

We recently bought a house that was built in 1956. There is a walk-in attic space off of our bedroom in which I am concerned about the potential presence of asbestos. Your website has provided me with lots of great information. Thank you.

After reading different things I believe this particular insulation to be balsam-wool in which case I believe I do not need to worry about asbestos with this particular item. Does balsam-wool seem accurate to you based on this picture?

I can find no backing in the areas that are currently exposed. I am not sure if or when any updates to this space were completed, but overall the wall paper covering seems potentially original. I will be posting more comments with additional pictures.

On 2023-02-12 by InspectApedia Publisher

@Valerie K,

That looks like fiberboard insulating sheathing.Fiberboard sheathing is a wood- or plant-based product, not one that would be expected to contain asbestos.

See the article above to read details and then don't hesitate to ask if that leaves you with any questions.

On 2023-02-06 by Don stewart - What brand of asphalt-impregnated fiberboard contained asbestos?

What brand of asphalt impregnated fiberboard has asbestos been found in before as I have started remodeling vintage trailers from 50s and 60s

Reply by InspectApedia Publisher

@Don stewart,

Please take a look at our article on this question

FIBERBOARD SHEATHING ASBESTOS CONTENT

as that's a more complete answer than I can recreate here .Followup by Don stewart - what about asbestos in the asphaltic coating on fiberboard sheathing?

@InspectApedia Publisher, ok I'm aware that it would be uncommon to be found in the wood fiberboard but my concern is the asphalt coating part of it

Reply by InspectApedia Publisher - What brand of asphalt impregnated fiberboard has asbestos been found in vintage trailers

@Don stewart,

Excellent question, I haven't seen a study that addresses that specific feature - Use of asbestos in coatings for fiberboard.

I suspect that where you are going to find asbestos mixed in with asphalt compounds is in adhesive mastics and roof sealants.

I'm not sure there would have been a reason to include it in a coating that was put onto fiberboard to improve its moisture resistance.

You might try some patent research if you can't find any old product specifications. I'll also keep this as an open question to see what else we can find.Followup by Don stewart

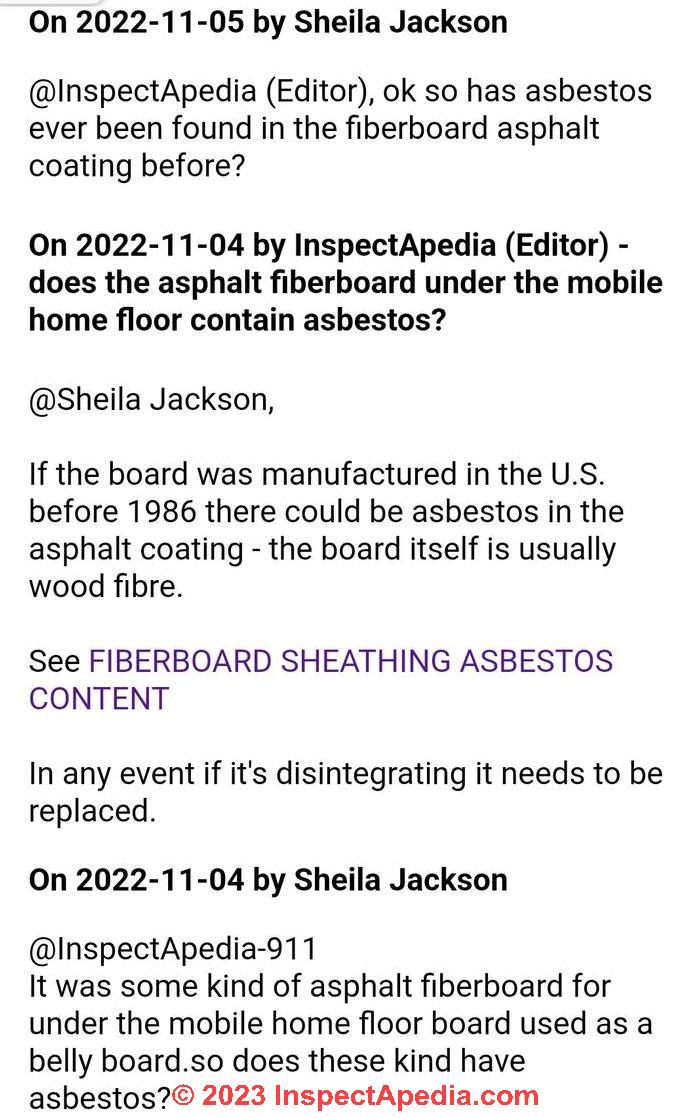

@InspectApedia Publisher, this is what I'm referring to as I saw it has been discussed about another mobile home

at SHEATHING, FIBERBOARD ASBESTOS CONTENT FAQs and saying possible asbestos containing if the asphalt coating was before 1986

On 2023-02-07 by InspectApedia Publisher - possible asbestos in asphalt-based roof coatings such as flashing cement

@Don stewart,

OK, so **IF** someone bought an asbestos coating product such as roof flashing cement or an asphalt roof sealant coating, and then applied it themselves to a building surface, and if that product was made in the U.S. before 1986 then yes that product might contain asbestos.

You and I are, here, discussing factory-applied damp-proofing or moisture-resistant coatings or additives - the basis of my earlier reply to you.

Thank you for careful reading. The complete discussion that we had with reader Sheila Jackson made distinction as well.

...

Continue reading at SHEATHING FIBERBOARD CONSTRUCTION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see FIBERBOARD SHEATHING FAQs - questions & answers posted originally on this page

Or see these

Recommended Articles

- DEFINITIONS, ENGINEERED WOOD HDF LDF LVL MDF MDO OSB

- FIBERBOARD SHEATHING - home

- CANEBOARD PANELS

- CARDBOARD CORRUGATED FIBERBOARD

- CELOTEX HISTORY & PRODUCTS

- DEFINITION of FIBERBOARD SHEATHING

- HISTORY of FIBERBOARD INSULATING SHEATHING

- HOMASOTE HISTORY & PRODUCTS

- SYNONYMS for FIBERBOARD SHEATHING

- FIBERBOARD CEILING & WALL COVERINGS

- FIBERBOARD MANUFACTURERS & BRAND NAMES

- FIBERBOARD PANEL REPAIR

- FIBERBOARD PLASTER BASE SYSTEMS

- FIBERBOARD ROOF SHEATHING

- FIBERBOARD SHEATHED WALL BRACING

- FIBERBOARD SHEATHING ASBESTOS CONTENT

- FIBERBOARD SHEATHING INGREDIENTS

- FIBERBOARD SHEATHING FIRE RATINGS

- FIBERBOARD SHEATHING IDENTIFICATION - Key to Identify Allied Chemical, Barrett, Beaverboard, Celotex, CemestO, DonnaCona, Fir-Tex, Firtex, Firetex, Graylite, Insulite, Masonite, National Gypsum, Gold Bond, Nu-Wood, PineX, Russian Fiberboard, Italian Fiberboard, Upson Board, US Gypsum, and others.

- FIBERBOARD SHEATHING INSECT DAMAGE

- FIBERBOARD SHEATHING MOLD CONTAMINATION

- FIBERBOARD SHEATHING MSDS

- FIBERBOARD ROOFING & FIBER-WOOD ROOFING

- FIBERBOARD PROTECT from WATER

- FIBERBOARD SOUND INSULATION

- HARDBOARD & MASONITE USED in WORKS OF ART

- IDENTIFY NU-WOOD PANELS

- IDENTIFY US GYPSUM INSULATING SHEATHING

- PAPERBOARD PRODUCTS CONTENTS

- SHEATHING, FIBERBOARD ASBESTOS CONTENT

- SHEATHING FIBERBOARD CONSTRUCTION

- SIDING HARDBOARD IDENTIFICATION & CLAIMS

- UNIDENTIFIED FIBERBOARD PRODUCTS

- WOOD FIBRE INSULATING PANELS

- HARDBOARD & MASONITE USED in WORKS OF ART

- INSULATION IDENTIFICATION GUIDE - home for identification of various insulating board products

- PROTECT FIBERBOARD from WATER

- SHEATHING, FIBERBOARD ASBESTOS CONTENT - do some wood or cellulose-based fiberboard or insulating board products contain asbestos? Maybe.

- STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs) - alternatives to fiberboard structural panels and roof panels

Suggested citation for this web page

FIBERBOARD SHEATHING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Homasote® Company, 932 Lower Ferry Road, West Trenton, NJ 08628-0240 Tel: 800-257-9491 Ext 1332, or from outside the U.S. call 609-883-3300. Website: http://www.homasote.com/ , Email: Sales@homasote.com .

- Thanks to Homasote CEO Warren Flicker for technical review and comment on this article.

- [3] Douglas Leen, Petersburg AK 99833, contributed the photograph of insulating board scraps from roof insulation removed from a building. Dr. Leen provides such a wide range of services, collectables, and historical information about the Northwest that a succinct description is difficult: flying dentist goes anywhere, antique forestry posters, historic campers, the tugboat Katahdin, in Alaska, Washington, and Wyoming. Mr. Leen can be contacted at mail@dougleen.com or at 907-518-0335

- [4] Georgia Pacific: information about DensGlas gypsum board building sheathing can be found at the company's website at gp.com/build/product.aspx?pid=4674

- [7] Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

- [8] Pittsburgh Press, "Yesterday - in costly homes alone, Today even the simplest home can have this hidden comfort", The Pittsburgh Press, 19 April 1925, classified ads section. Web search 6/22/12, [Copy on file as Celotex_Ad_023_PP.jpg and more]

- [9] pending research

- [10]

Patents pertaining to building insulation & insulating board, Celotex & Insulating Board type products