Beaverboard Identification

Beaverboard Identification

Beaverboard & Buffalow Board Wall Sheathing,

Insulating Board Identification Key

- POST a QUESTION or COMMENT about Beaverboard brand building sheathing: how to identify fiberboard products, fiberboard uses, fiberboard, Celotex, Homasote, Insulite & other brands, fiberboard ingredients, does fiberboard contain asbestos?

How to identify Beaverboard brand fiberboard insulating sheathing or panels.

Photos and manufacturer's identification stamp can help identify true "beaverboard" paneling or fiberboard panels in buildings.

In this article series we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products. We also answer questions such as do Celotex or Homasote or other fiberboard and insulating board products contain asbestos? fiberboard water resistance, fiberboard recycling.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Identify Beaverboard Fiberboard & Insulating Sheathing Board

You can identify true Beaver Board sheathing on walls and ceilings by inspecting the cavity side of the material.

You can identify true Beaver Board sheathing on walls and ceilings by inspecting the cavity side of the material.

True Beaver Board made by the Beaver Board company was marked on the back of each sheet with an ink-stamped trademark and brand.

The Beaver Board Company was founded in Beaver Falls, New York and began producing fiberboard used for sheathing in 1907.

Beaver Board was described by several authors as the company who was most prolific in generating patents in the early development of fiberboard products. (Jester 2014) (Gould 2014).

The Beaver Falls Beaver Board company began producing (plant fiber based) fiberboard sheathing in Buffalo New York as early as 1907 - probably the source of the product name Buffalo Board.

Beaverboard or properly Beaver board and many (but not all) of the other low-density fiberboard sheathing or wallboard products were similar in being comprised of relatively-homogenous plant-fibers bonded together by the interlacing of the fibers and treated with a waterproofing agent.

While no doubt some ugly logs that wouldn't have made a nice stud or joist were ground into chips for processing, I think that most of these sheathing products were considered to take enormous advantage of sawmill waste in the form of wood chips, sawdust, and wood scrap, or for some manufacturers, in the form of other plant materials such as straw, sugar cane, or bagasse.

Where wood was the initial material the wood was chopped into chips, sized, ground to finer size, and smashed into individual wood cells using steam and rollers.

The combination of steam or water and pressure permitted the fibers to bond together into a sheet that was further pressed by hydraulic rams and rollers called platens (think of a huge typewriter platen or roller if you were born before 1980).

Randomly-crossed wood fibers make a strong product, a realization that appeared again later as MDF and HDF and similar products. To get the plant or wood fibers to adhere to one another beyond their mechanical arm linking, adhesives were used during the fiber consolidation process.

Jester names silicate of soda, flour paste, glues, dextrin, plaster of paris, waterglass and clay, rosin, turpentine, paraffin wax (see Homasote®), asphalt (giving a nice dark black color to the fiberboard panels and making them unattractive to termites and carpenter ants). (Jester 2014 pp 90-90).

Beaverboard, as other low density fiberboard products, was then trimmed, treated with a water repellent, and possibly colored, or for fancier products like Nuwood™ cut to bevels or tooled.

- Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

Watch out: as you will see in the reader Q&A section on this page, a different board product, gypsum based Beaverboard, was a completely different formula and might contain asbestos.

Beaver Board Company History Research

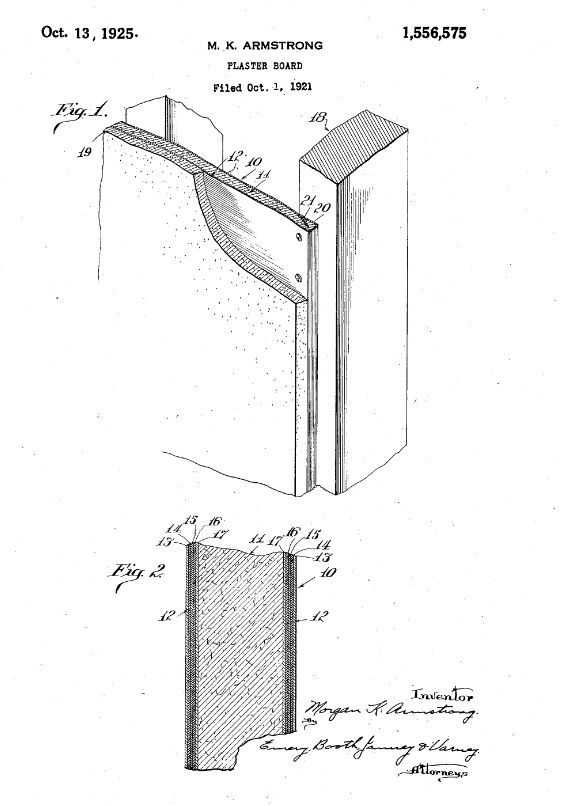

Illustration: M.K. Armstrong's Plaster Board U.S. Patent 1,556,575 filed by Beaver Products Co., in 1921, issued 1925.

- Armstrong, Morgan K. "Plaster board." U.S. Patent 1,556,575, issued October 13, 1925. Application filed by Beaver Products Company, Inc.

Excerpts: This invention relates to composite board, known generallyl as plaster board. Among other objects, t e invention is .intended to provide improved boards having plaster receiving surfaces of uniform characteristics, wherebythe lastered or otherwise coated surfaces will e of uniform and improved quality` with a decreased' tendency to crack at the joints between adjacent boards.

Another object is to provide a board which will retain its .shape in a plaster w ceiling or analogous location.

The invention consists in the novel combinations and constructions to be hereinafter described and claimed for carrying out lthe above stated objects and such other objects as will appear from the description and claims.

The invention is illustrated in a preferred embodiment in the accompanying drawing wherein:

Fig. 1 is a fragmentary perspective view of a plaster wa l. employing a composite board embodying features of this invention.

Fig. 2 is an enlarged section of a plaster boar A Like characters of reference designate like parts in the several figures of the drawing. In the illustrative embodiment shown in the drawings,'the composite board 10, comprises a substantially rigid body, or core 11, having covering material 12 on one or both faces thereof. TheV body 11 may be of any suitable material such as plaster, to which the coveringmaterial 12 is adapted to adhere. - Gould, Carol S., Kimberly L. Konrad, Kathleen Catalono MIlley, Rebecca Gallagher, "FIBERBOARD Dates of Production 1858 to the present, Common Trade Names" [American Wallboard, Beaver Board, Cornell BOard, C-X Boards, Feltex, Fir-Tex, Homasote, Insulite, J-M Board, Maftex, Masonite (presdwood Quartrboard, Tempered Presdwood), Nu-Wood, Upson Board), Chapter 12 in Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Hammock, Claude S. "Folding screen." U.S. Patent 1,244,497, issued October 30, 1917. Application filed by Beaver Co.

- Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Lewis, James P., and Harry S. Lewis. COMPOSITE WOOD PULP SHEET [PDF] U.S. Patent 1,063,941, issued June 3, 1913.

James P. Lewis of Beaver Falls, New York (hence "Beaver Board" Ed.), Harry S. Lewis, Administrator of said James P. Lewis, Deceased.

Excerpt: This invention relates to a composite sheet made up of several sheets or layers of wood pulp cemented together and has the object to produce a sheet which is smooth and attractive in appearance, strong and durable and which does not warp, buckle or other'- wise change its shape in use, thereby enabling such sheets to be successfully used for a variety of purposes, for instance, for cover ing the walls of buildings instead of plaster. - Robinson, Charles G. "Composite board and method of treating the same." U.S. Patent 1,334,637, issued March 23, 1920. Application filed by Beaver Co.

Excerpt: The present invention relates to composite board composed of a plurality of plies of paper stock, such as wood fiber stock, cemented together by means of an appropriate adhesive. - Robinson, Charles G. "Compound board." U.S. Patent 1,334,796, issued March 23, 1920. Application filed by Beaver Co.

Excerpts: I, Charles G. Robinson, residing at 183 Highland avenue, Bufffalo, in the county of Erie, State of New York, have invented certain new and useful improvements in Compound Board ...

The present invention contemplates the provision of a compound board possessed of rigidity in a high degree. At the same time, this increased rigidity is secured without sacrificing any of the other recognized advantageous properties oi commercial wall board, such. as, for example, its lightness, its convenience of form and dimensions, its relative cheapness, etc.

The invention involves the provisionof a reinforcing member of reticular form interposed within. the body of the compound or composite board. Where the board is made up'of a plurality of plies of paper stock, the reinforcingI member may form an intermediate ply and in such cases is preterably embedded in the intermediate layer ot adhesive adjoining the two plies of paper sheet adjacent the reinforcing member.

lf desired, a plurality of intermediate plies or' reticular reinforcing members may be embodied in the composite board.

l have tound inter-woven wire, such as ordinary poultry wire, well adapted as the reinforcing member lor the purposes of the invention.

ln general, the reticular reinforcing member will preferably be ol metal, although other materials capable ol assuming reticular form and possessing the desired rigidity may, ot course, be employed.

ln some cases expanded metal, and simila reticulated metallic structures, may be used with advantage. lnterwoven Wire, such as ordinary poultry Wire, is peculiarly advantageous tor the purposes oli the invention. - Sidwell, Benjamin Wilson, WALL-BOARD [PDF] U.S. Patent 1,248,181 Granted 1917-11-17, mis-quoted by patent seearches as WILSON JR, SIDWELL BENJAMIN. "WALL-BOARD." U.S. Patent Application 1/248,181, filed April 27, 1916.

Excerpts: The present invention relates to wall board suitable for use in place of lumber for lining chicken houses, stables, dairy barns, and the like, andserves not only as a sheathing to keep the buildings warm in winter and cool in summer, but is impregnated with a vermin repellent of a kind particularly advantageous for these requirements.

The board is made up from wood pulp fiber, either ground or cooked, waste paper, or chemical pulp, or mixtures of these, and ismarketed in substantially rigid sheets 24 to 36 inches wide, and in lengths of 4,5,6,7,8, and 9 feet to meet all requirements with very little cutting.

These boards are ordinarily made out of several plies cemented together, and are smooth, sanitary, easily kept clean, and for use in chicken houses, stables, dairy barns, and the like, can be nailed directly to joists and studding or furred to brick or concrete walls.

The board has good insulating properties and keeps the quarters warm and comfortable, and in addition to the disinfecting qualities arising from its chemical impregnation, as herinafter explained in detail, it contributes to good sanitation because of its smooth surface and freedom from cracks and imperfection.

...

The vermin-proofing material which I prefer to use for treating both faces of the board, consists of creosote material, 50 parts by volume, and asphaltum thinned with naphtha to 30 to 35% Be.,[sic] 50 parts by volume, to which has been added a caustic, say caustic soda, in such quantity that it may unite with part, say 90% of the phenol in the mixture, to form a soluble alkalne phenolate. The exact percentage of caustic is not vital so long as an excess is not added.

Illustration: Sidwell's Wallboard - true Beaver Board made from wood, straw, or bagasse or similar cellulose materials. Sidwell's drawing suggests that the board filler may be a mixture of ground cork & cement (or equivalent materials).

Illustration: Sidwell's Wallboard - true Beaver Board made from wood, straw, or bagasse or similar cellulose materials. Sidwell's drawing suggests that the board filler may be a mixture of ground cork & cement (or equivalent materials).

- Sidwell, Benjamin Wilson. WALL-BOARD [PDF] U.S. Patent 1,285,433, issued November 19, 1918. Application filed by BEAVER Co.

This patent describes a wallboard made of "Lignocellulosic material, e.g. wood, straw, or bagasse.

Excerpts: The present invention relates to composite wall boards for use as a substitute for lath and plaster in building construction. ... Some composite wall boards at present in use are made with a filling of plaster which gives to the boards many of the disadvantages of ordinary plaster construction besides adding to their weight and rendering them dirty to work with.

In an attempt to overcome the disadvantages of plaster lling, various compositions have been suggested for use between the outer plies of a wall board but while these substances are cleaner and obviate many of the disadvantages of plaster fillings many of them impart to the resultant structure such characteristics as to make it unsuitable for use under ordinary conditions.

This is especially the case with composite wall boards formed of dense plies which afford but poor heat insulation and have unnecessary Weight.

The present invention aims to avoid the disadvantages of prior constructions of this nature. The board herein claimed is of considerable strength, while at the same time, is of light weight. It is cheap to manufacture, durable in service and neat in appearance.

It may be conveniently worked With ordinary tools and is clean to use. It is relatively unaffected by atmospheric moisture or climatic changes, is a good heat and sound insulator, and, being to some extent fire resistant, it may be used in the vicinity of radiators, stoves and the like without danger of disintegration from the heat It possesses the property of being proof against white ants and certain other insects, and thus is especially suitable for use in localities where these are troublesome.

The foregoing advantages and others which will hereinafter appear, are attained by providing a filling or inner ply of porous material as hereinafter described, and securing or ceinenting it between ordinary Specification of Letters Patent.

Outer plies of wood pulp, news, or chip board. Ground cork, made into a plastic mass with a small quantity of binder, such as sodium silicate, is suitable for this filling or inner ply of the board, but in case it is desired to produce a somewhat cheaper board, a mixture of ground cork and certain other waste materials may be used. - Sidwell, Benjamin Wilson, WALL BOARD SIZE [PDF] U.S. Patent 1,336,055, issued April 6, 1920., mis-labeled in some patent search results as [Wilson, Sidwell Benjamin. "Wall-board size." U.S. Patent 1,336,055, issued April 6, 1920.]

Excerpts: The present invention relates to a size suitable for use on articles formed from wood fiber, wood pulp, or the like, such, for instance. .as wall board. Wall board may be made from wood fiber or wood pulp, either ground wood pulp, waste aper or cooked pulp, used alone or intermixed, and ordinarily is marketed in substantially rigid sheets.

The wall board may consist of a single layer of material or of a plurality of ies pasted or cemented together.

Generally it is used as a building material bynailing or tacking it directly to the studding of a room, so that it may serve in place of lath and plaster as the inner wall of the room, being usually ornamented with paint, or the like, as desired.

The absorption of moisture and paint by wall board can be reduced by surface sizing.

Thus, it has heretofore been customary to surface size wall board by applying a solution of gums, resins, and other. materials. As far as I am aware, however, an entirely satisfactory size for wall board has not heretofore been available, and the principal object of the present invention is the ... vision of an improved size particularly adapted to be saisfactorily appied to wall board, and the like, under commercial manufacturing conditions.

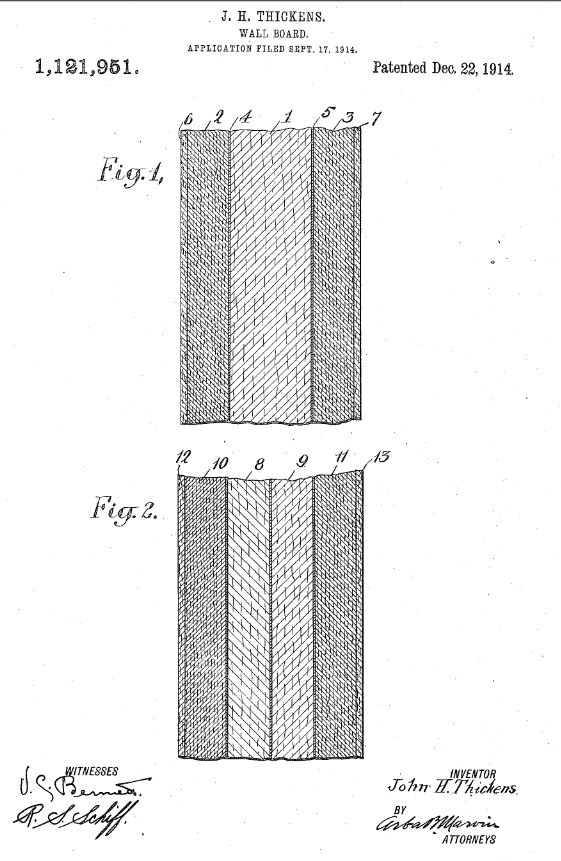

Illustrated here: Beaverboard early patent drawing from the Thickens / Beaver Board patent of 1914 - cited just below.

Illustrated here: Beaverboard early patent drawing from the Thickens / Beaver Board patent of 1914 - cited just below.

- Stanbro, Mark S. WALL BOARD FASTENER [PDF] U.S. Patent 1,564,455, issued December 8, 1925. Application filed by Beaver Products Company

- Thickens, John H. WALL BOARD [PDF] U.S. Patent 1,121,951, issued December 22, 1914

Application filed by BEAVER Co.

Excerpts: The present invention relates to composite wood pulp sheets suitable for use in buildings in place of lath and plaster. It is an object of thepresent invention to produce a. wall board having high rigidity, high tensile strength, low moisture absorption, high resistance to puncture and having good heat-insulating and sound-deadening properties. y

lt is a further object of the invention to produce a composite Wood pulp sheet which is to some extent fire resistant, and which can be used behind radiators, and around registers, and the like without danger of disintegration from the heat.

It is a furtherobject of the present in vention to produce a wall board, smooth and attractive on the surface, and well suited for ornamentation and so constituted as to be relatively free from warping, buckling and excessive shrinkage, to the end that the sheets of material may be nailed or tacked to the studding of a room and there decorated by painting or tinting to serve in place of lath and plaster.

ln accomplishing the foregoing objects and others which will hereinafter appear, I form the composite sheet or wall board with a core of ground wood pulp to which is secured a facing of cooked wood pulp.

The core may be multi-ply if desired, and the facing may be on both sides of the coreand held in place with a silicate cement. Preferably, the cooked wood facings are covered with a thin layer of ground wood, light in color, to facilitate ornamentation.

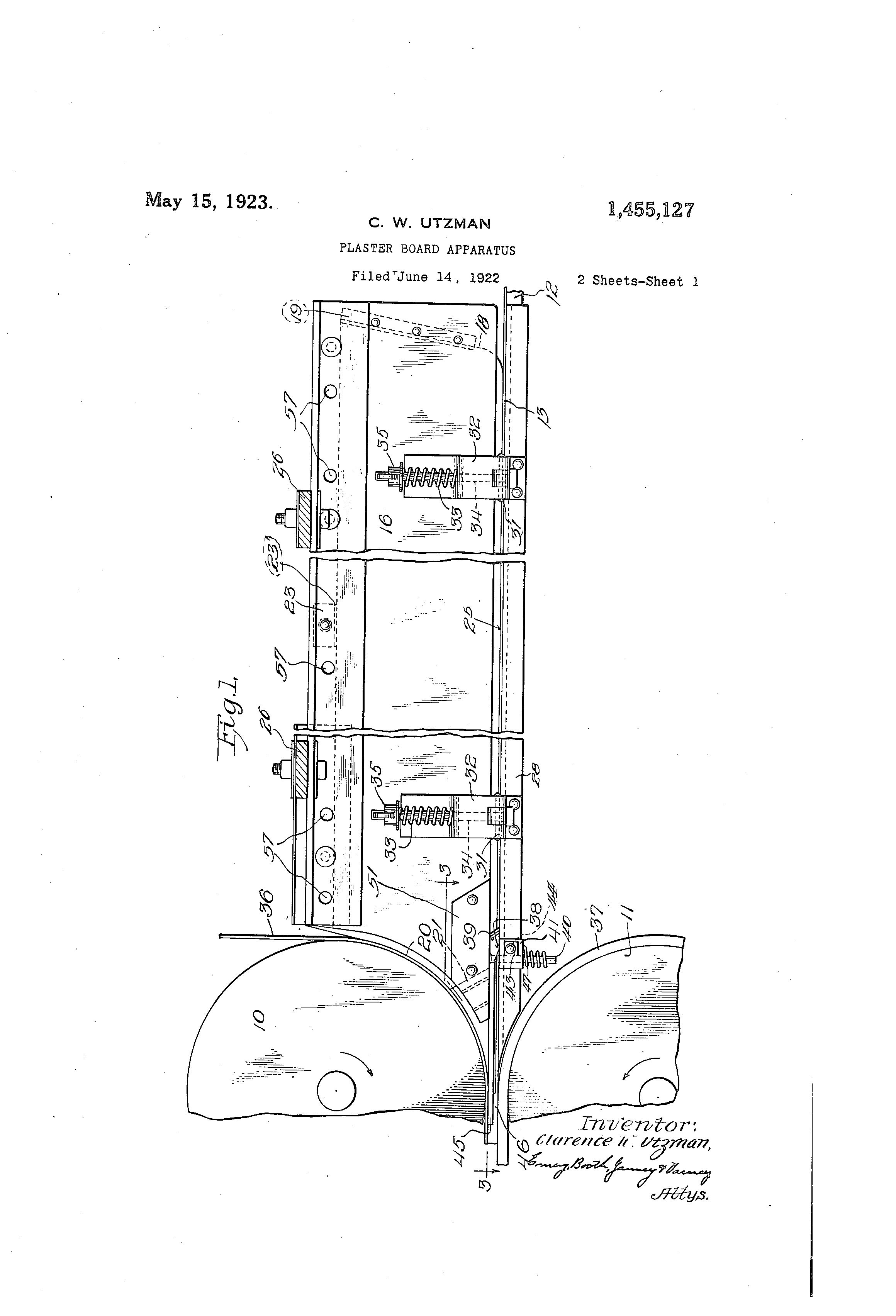

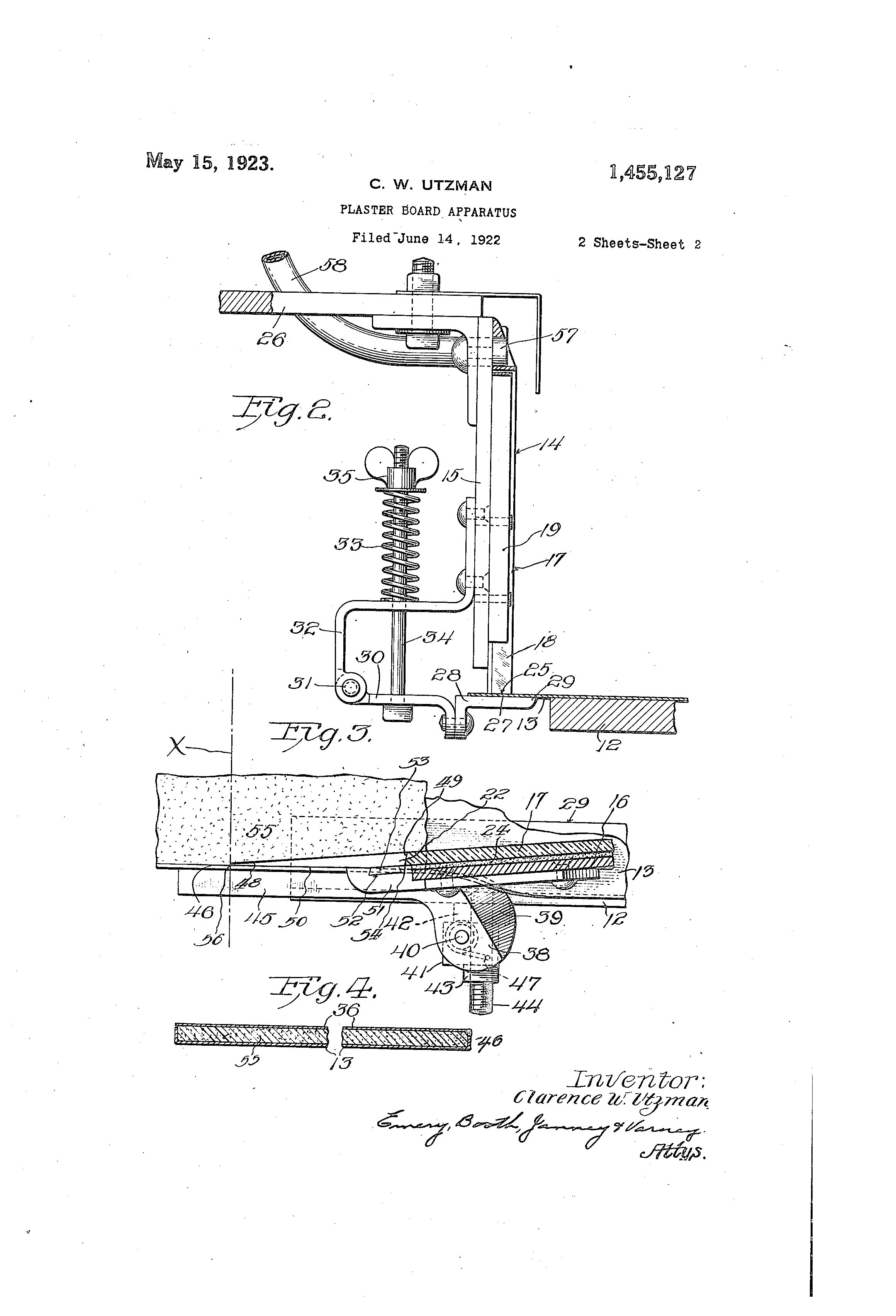

Below: Drawings from Utzman's 1923 Beaver Board patent: Plaster-Board Apparatus. Fig. 1 is a side elevation of a part of the plaster board apparatus.

Fig. 2 is an end view, (certain parts being in section) of the hopper sides.

- UPSON BOARD - similar product, medium density fiberboard

- Utzman, Clarence W. PLASTER BOARD APPARATUS [PDF] U.S. Patent 1,455,127, issued May 15, 1923. Application filed by Beaver Products Company Inc.

Note that this is a plasterboard product. - Utzman, C.W., Beaver Products Company Inc, 1924. COMPOSITE BUILDING BOARD and METHOD OF MAKING SAME [PDF] U.S. Patent 1,492,588.

Excerpt: The invention is illustrated as applied to a double-face plaster board, that is, a board either side of which may be employed as the face side of the board. In the drawing, - Wilson, Richa, & Kathaleen Snodgrass, EARLY 20th CENTURY BUILDING MATERIALS: FIBERBOARD AND PLYWOOD [PDF], U.S. Forest Service, U.S. Department of Agriculture, Technology & Development Program, 0773-2308-MTDC, retrieved 2021/07/06, original source: https://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/index.htm

- Also see SHEATHING, FIBERBOARD - Sheathing Celotex Homasote & Other for a discussion of exterior wall sheathing fiberboard products such as Homasote® and Celotex® insulating roof, wall, and foundation board products. There we also include photographs of insulating wallboard products that have been attacked by mold or insects.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

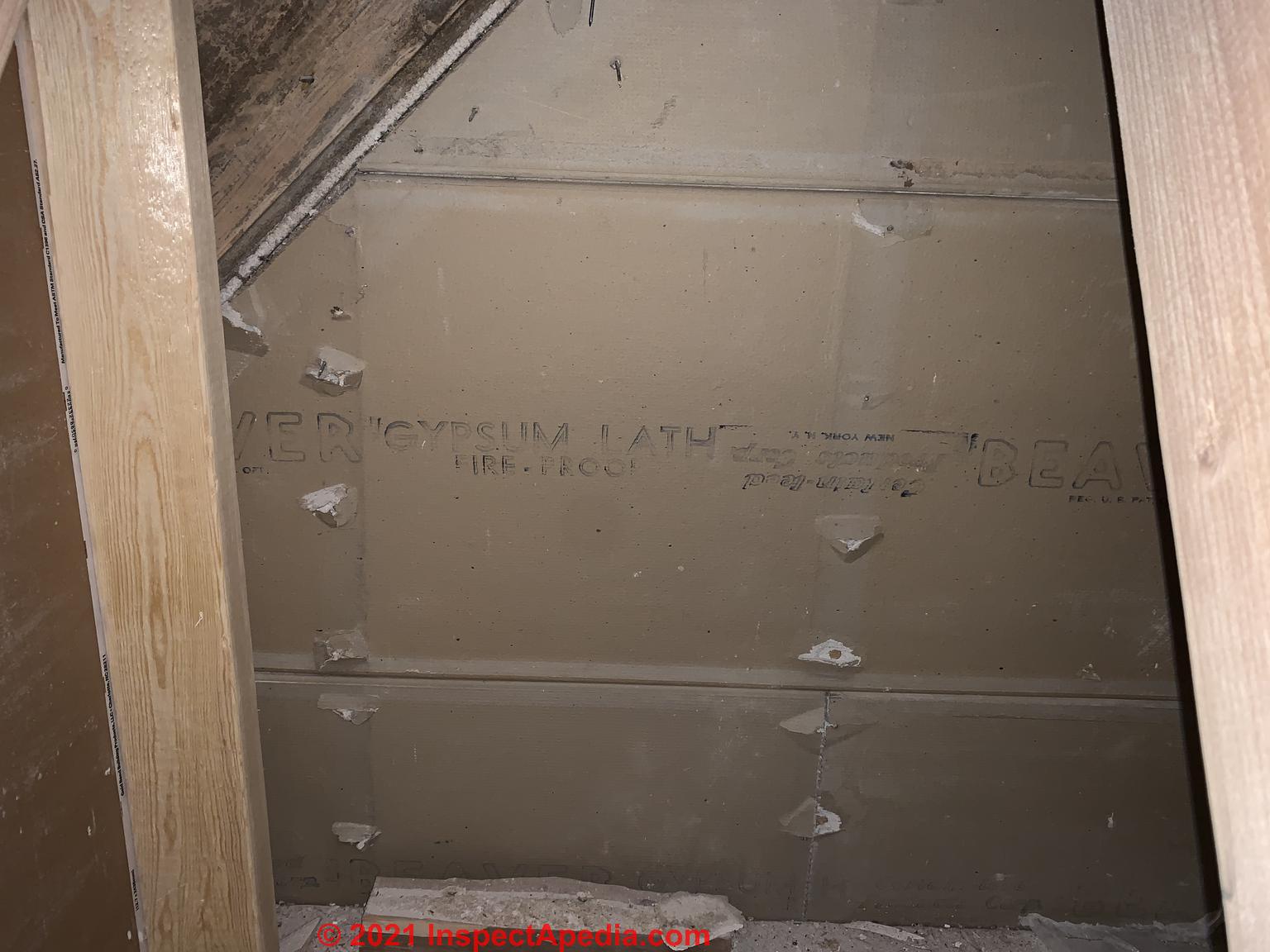

On 2022-01-10 by Inspectapedia Com Moderator (mod) - asbestos in Certain-Teed BestWall & Suspect in Certain-Teed Beaver Fireproof Gypsum Lath - NOT a wood fiber product

The Certain-teed Corporation purchased Beaver Products in 1928.

Certain-Teed's Bestwall Gypsum board contained asbestos through 1976 or possibly 1977 depending on when the product installed in that year may actually have been manufactured.

You should also consider that joint compound used with the product may also have contained asbestos.

Notice that we are discussing a gypsum-based "plasterboard" or rock-lath, NOT a wood-fibre-based fiberboard as was the constituent of early Beaverboard products described on this page.

These Certain-Teed Beaver rock-lath boards, found in a 1940s home in Ironwood MI, USA, are stamped: BEAVER GYPSUM LATH, FIRE PROOF, CertainTeed ? ? Corp, New York NY.

Asbestos-containing materials are safe and legal to leave in place as long as they're un-damaged.

And where large sheets of drywall are removed basically intact with minimal dust creation, the remaining dust hazards should be trivial: easily cleaned up with HEPA vacuuming and damp wiping.

If you need to remove this drywall, you'll want to minimize dust during removal: remove largest possible pieces of drywall, without cutting with power tools, wetting or dampening dusty or damaged areas, and using a HEPA rated vacuum cleaner for dust clean-up, followed by damp-wiping.

Use appropriate personal protection equipment (PPE) including a HEPA-rated respirator; I prefer not to rely on a simple paper N-95 dust mask and during the current COVID pandemic, expected to end no-time soon, N-95 masks are in short supply.

Please see details on how to remove asbestos-containing drywall or asbestos-suspect drywall

at ASBESTOS-DRYWALL REMEDIATION / REMOVAL

Is there asbestos in Certain-Teed Beaver Gypsum Lath Board?

I’ve been curious for sometime around the walls in my 1940’s build home since there is no lath. I’m in Ironwood, MI. I took possession of the home a little over a year ago and started renovations right away. I finally did a search on my walls and came to this site (thank you!).

I’m concerned I have asbestos walls given the fire proofing mark on the Beaver Gypsom Lath product. Also marked is “certain teed”. I was only able to upload one image. Appreciate your thoughts on this.

Above in this discussion (at the moderator's reply) is the other photo I took on the same wall where you can see “certain teed”. 2022-01-10 by lulutalulu -

This Q&A were posted originally

Reply by Inspectapedia Com Moderator (mod) - post one image per comment but multiple comments = multiple images

@lulutalulu,

You can only add one image per comment but can post as many comments as you wish. Feel free to post more photos if you have them and we'll take a look.

Question: home built in 1929 that has "buffalo board" inside

We are busing a home built in 1929 that has "buffalo board" inside instead of sheetrock. I am wondering if we should replace it with common sheetrock used in structure today (my husband thinks it is an inferior building material) or if we should leave it alone.

Advise please? Let me know what we should do. My husband is inclined to tear it down and replace it with sheetrock, but I like to leave the original on in its rightful place. Let me know what you think! - (Aug 2, 2017) Betsy

Reply: best to leave old fiberboard or buffalo board or beaver board interior sheating in place

Bottom line: Betsy I would not bother to replace the Buffalo Board wall sheathing in the home unless it were absolutely necessary to remove it for other reasons. Instead I would consider installing drywall over the existing Buffalo Board to improve the building's fire-resistance.

Installing drywall over existing indoor fiberboard or buffaloboard sheathing

- Is less expensive than removing the old buffalo board

- Is safer than removing the old buffao board as you are not disturbing it - avoiding creating a dusty mess

- Will nevertheless require some additional work to build out or add spacers at electrical receptacles, switches, possibly also some interior trim: still this is less total labor than removing and replacing the Buffalo-board.

Buffalo board is one of many trade names for fiberboard sheathing whose ingredients are cited above

at FIBERBOARD SHEATHING INGREDIENTS

If your buffalo-board is coated with asphalt (as was often the case with fiberboard sheathing intended for exterior use but less likely for interior use) the asphalt itself is a potential healh hazard if airborne and inhaled or disturbed to create a dusty mess during demolition or renovation work.

See details at the top of this page.

Reader comment: NY Beaverboard company appears to have received shipments of ground vermiculite from Libby Montana

The NY Beaverboard company appears to have received shipments of ground vermiculite from Libby Montana, which is known to contain Tremolite, Winchite and Richterite amphibole asbestiforms (asbestos).

I have come across beaverboard with a gold reflective side which I suspect is the ground vermiculite adhered to the inside surface of the board. As such, it seems that there is a possibility that these types of materials could contain some asbestos. - On 2016-01-13 by Ethan W -

...

Continue reading at HISTORY of FIBERBOARD INSULATING SHEATHING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BESTWALL DRYWALL ASBESTOS - includes description of Beaver Bestwall wallboard gypsum board

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- HARDBOARD Masonite™-like INGREDIENTS

- HISTORY of FIBERBOARD INSULATING SHEATHING

- SHEATHING, FIBERBOARD

- SHEATHING, EXTERIOR PRODUCT INDEX

Suggested citation for this web page

BEAVERBOARD IDENTIFICATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- [10]

Patents pertaining to building insulation & insulating board, Celotex & Insulating Board type products

- "Sound absorbing board for walls and ceilings", Patent No. 1,554,180, issued to W.S. Trader, September 15,1925, first disclosed a wallboard constructed from "Celotex", a felted mass of strong bagasse fibers, so compacted as to be capable of use as an artificial lumber in that it can be sawed and nailed, and has sufficient strength in many cases to be substituted for lumber. That same patent mentions "Insulite", a building board made from wood pulp tailings and which likewise has a porous fibrous body portion and which is possessed of considerable strength so that the same can be nailed, etc. Celotex was preferred as an insulating material because its internal cells produce a sound-deadening insulating effect.

- "Method and apparatus for drying moving material", Treadway B. Munroe et als, assigned to Dahlberg & Co., U.S. Patent No. 1,598,980, 7 September 1926, described a method and apparatus for drying sheets of artificial heat insulating lumber, known on the market as Celotex, improving the original process.

- "Reenforced composition board", Treadway B. Munroe et als, U.S. Patent No. 1,578,344, 30 March 1926

- "Insulating Structural Board", U.S. Patent 2,159,300, Armen H. Tashjian et als, assigned to William B. Miller, Lakewood OH, 23 May 1939, describes insulating structural boards of laminated construction for use as roof or floor slabs, and refers to "Standard insulating fiber boards, such as "Celotex", "Masonite", "Insulite", etc. that had excellent insulating properties but have relatively slight structural strength in flexure or bending under load, hence are not and cannot be used as structural slabs for load sustaining purposes, as roof or floor slabs, for example. [Adding structural strength ran into the problem of reducing the insulating value of the product.]

- "Sound-absorbing chamber", Treadway B. Munroe et als, U.S. Patent No. 1,705,778, 19 March 1929 (using Celotex to construct a sound deadening chamber.

- "Method of and apparatus for drying moving material", U.S. Patent 2,376,612, Carl G. Muench, New Orleans, assigned to Celotex Corporation, described a method and apparatus for drying sheets of artificial heat insulating lumber, preferably formed by the felting of bagasse fiber along with other materials necessary to make a satisfactory structural fiber board. 22 May 1945

- "Sound-absorbing board for walls and ceilings," U.S. Patent 1,554,180, Sept. 15, 1925, Wilber S. Trader, assignor to Dahlberg & Company, Chicago IL. described an interior-use sound insulating product.

- [14] Standards pertaining to fiberboard insulating sheathing:

- ASTM C 208-95 (2001) – Standard Specification for Cellulosic Fiber Insulating Board. Type IV Grade 2 (Structural Wall Sheathing).

- ASTM C 846-94 (2003) – Application of Cellulosic Fiber Insulating Board for Wall Sheathing.

- ASTM D 1554 - Definitions of terms Relating to Wood Based Fiber and Particle Panel Materials.

- ASTM E-72 (1997)- Standard Method for Conducting Strength Tests of Panels for Building Construction.

- ANSI /AHA - A194.1, Cellulosic Fiberboard.

- U.S. Department of Commerce: PS57-73, Cellulosic Fiber Insulating Board

- A.F.A. (2003): Fiberboard Sheathing test results

- [15] "Properties of insulating fiberboard sheathing", Forest Products Laboratory (U.S.) Luxford, R. F. (Ronald Floyd), 1889 (1960), original report 1955, citation:hdl.handle.net/1957/2489, web search 6/29/12, original source: http://ir.library.oregonstate.edu/xmlui/handle/1957/2489

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.