Building Freeze Protection Methods

Building Freeze Protection Methods

How to avoid ice, frost, freeze damage at & in buildings

Building plumbing & heating system frostproofing or winterizing procedures

- POST a QUESTION or COMMENT about how to protect buildings, piping, heating equipment, water softeners, wells, & foundations from freezing, ice, & frost damage

Building winterizing or freeze-proofing guide: this article series provides step by step details in winterizing a building or freeze protection for buildings where heat may be lowered or left turned off. Avoiding freezing pipes in buildings also means avoiding later leaks, water damage, or possibly mold contamination.

The articles at this website will answer most questions about freeze protection for piping and other building plumbing and heating system components: how to winterize a building to avoid frozen pipes, and how to thaw frozen water supply & drain piping, wells, & water tanks.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A Detailed Guide to Winterizing a Building to Protect from Frozen Pipes, Leaks, Water Damage

What happens when water freezes in a copper pipe?

Our separated copper pipe solder joint (above left) shows how freeze damage to a heating system baseboard pipe can cause the copper pipe to simply slip apart at the solder joint. Our freeze-bulged and split copper water pipe (above right) shows how a copper water pipe can freeze, expand, and burst.

The resultant building water flooding and damage can be extensive and in some cases may involve a costly mold remediation project as well. Also, failure of an owner to take appropriate steps to prevent freezing pipes and water damage can result in loss of insurance coverage in some instances.

For example, turning off heat without also winterizing a home would be an improper practice likely to lead to frozen burst pipes and water damage and mold contamination.

Our photo at left shows a separated solder joint caused by freezing at a heating baseboard copper pipe. The repair of this leak is shown later in this article.

Our page top photo shows a frozen, burst water pipe close to an elbow. We suspect that the process of heating the pipe during soldering of the elbow connection might soften the copper in this location, permitting the very rounded expansion shape at the point of pipe rupture. The elbow itself may be more resistant to bursting during freezing.

Details about the forces exerted by ice in or on buildings are at FREEZING FORCE of ICE.

Key Building Winterizing Topics to Avoid Freeze Damage

Freezing water pipes or drain pipes in a building are worse than inconvenient: often the frozen pipes burst, risking serious water damage and even toxic mold growth in a building when the frozen, burst pipe later thaws and leaks into the structure.

Our photo (left) shows what we found on arriving at an unoccupied home that was for sale in New York. Shortly after freezing conditions had lifted a water trail was visible running down the curb adjacent to the home. We thought perhaps there was a leak at that fire hydrant but that was not the problem. The water supply line beween the home and the curb had burst.

The most extreme water and mold damage to buildings where pipes burst occurs in unoccupied structures whose conditions are not being monitored, such as a house for sale, or a remote, weekend home.

Other freezing weather damage besides floods from frozen pipes can include cracked plaster in older homes or cracked and dislocated wood flooring.

For buildings facing these extra risks, we provide a range of suggestions for winterizing or freeze-proofing a building as well as for monitoring building conditions so that prompt action can be taken to deal with a burst pipe.

Here is our list of key topics to consider when working to winterize or freeze-proof a building, along with links to more detail on these subjects:

1. Prepare the building to be left unattended: regardless of whether heat is to be left on or off:

- Turn off unneeded electrical components.

Modern TV's and items that use plug-in wall chargers and voltage converters are always using electricity. Unplug sensitive electronic equipment to protect against power surges or lightning. - Protect against rodents and animal damage:

close openings into soffits, attics, basements, crawl spaces; be sure all trash and garbage have been removed from the building. Raccoons used to play with the Christmas ornaments in our attic, and mice would come into the building to eat anything, even books and bars of soap.

How we keep mice our of our building:

It's almost impossible to keep mice out of a building if they want to come in for the winter (they do). Beyond calling for regular visits from a pest control expert, here is what we recommend>

Removing any open food, storing food in cans or closed heavy plastic containers, and closing obvious mouse entry points will help. Our attorney ignored these suggestions and was plagued with mice, tolerating them until the morning that bleary-eyed, hardly awake, she was pouring rice crispies into her cereal bowl.

A mouse leapt out of the box right into her cereal!

We leave mothballs (naphtha) in areas and even in equipment that tends to be invaded by pests looking for a sheltered place to spend the winter. Mothballs keep mice out of the filing cabinets in our unheated garage. Just put the whole box of mothballs, opened, but not poured out, into the cabinet, closet, or vehicle. - Insurance coverage:

review your building insurance policy with your agent to be sure the property is covered when it is unoccupied. - Windows and doors:

make sure that all windows are closed. If the building has triple-track storm and screen windows, make sure that the storm windows are closed with the glass "down" - not just the screens down. Latch and lock these openings. - Other building button-up details:

Make sure building exhaust fans are off. If the building has an exhaust fan that leaks or blows cold air in or leaks warm air out, cover the opening (remember to remove those covers before use to avoid a fire risk.) Stop mail and magazine or newspaper deliveries. Let a trusted neighbor know you'll be away and ask them to keep an eye on the property. - Building winterizing & monitoring services:

decide if you want or need a professional to winterize your building and or to monitor it during the time that it will be shut down.in some locales companies offer a winterized building protection service that ranges from weekly or even daily visits to check on a property to emergency response to a no-heat call or water-entry call that can be made automatically by a home security system when those conditions occur.

If power outages are common in the area, a battery-backup for alarms and sump pumps would be a smart addition to the building.

2. Decide if the building heat going to be left "on" or "off" :

the answer determines the type and extent of freeze-proofing steps needed.

- If heat is to be left on in a partially winterized building see the procedure

at: WINTERIZE - HEAT ON PROCEDURE - If heat is to be turned off and the building completely winterized, see the procedure

at: WINTERIZE - HEAT OFF PROCEDURE

Winterizing Advice When Leaving a Building Unattended in Freezing Weather

Freeze Alarms: systems that warn of loss of heat or freezing conditions in a building can notify you or a building manager when something needs attention.

buildings with an existing security system can add freeze-alarms. If your building already has a security alarm system it's usually a small matter to add low-temperature, loss of heat, loss of electrical power, and water flood sensors to the system.

If your building does not already have a security system some simple devices can turn on a light to alert neighbors to a heat loss or building flood.

Freeze-damage risk points in buildings: where building piping, mechanical systems, or other components are likely to freeze. Identifying drafts and cold spots, sealing drafts, using insulation, or adding a little heat can prevent freezing.

Our photo shows an example of a problem spot: piping under sinks in un-insulated pipe chases, piping in attics, crawl spaces, walls, garages, under floors.

Different piping materials (copper, steel, plastic) and different grades of water piping material [image] affect the freeze-resistance of the piping. Installation details such as piping slope, routing, and insulation are important factors in pipe freeze problems.

We discuss the procedure for finding and protecting building freeze-points

at FINDING PIPE FREEZE POINTS.

Frozen hot water heating baseboards & radiators:

how to prevent this problem which leads to loss of heat and more extensive freeze and later water damage to buildings. Our photo just shows a frozen, burst hot water baseboard heating pipe.

If a building heating system shuts down due to an operating problem (loss of electricity, a problem with the heater itself, or simply due to running out of oil) the heating system failure is likely to lead to frozen pipes which, when the weather warms, can cause serious building flooding and water or mold damage.

A burst heating baseboard line such as the ones we show here and at the top of this page can occur at more than one point in the heating system piping.

See our HEAT-ON WINTERIZING GUIDE.

PIPE FREEZE-UP POINTS, warns about burst building drains as well as splits or separations in supply piping & heating system piping how to prevent freezing drain piping when water pipes area exposed to drafts or freezing temperatures.

Pipes run through a cold corner or subjected to drafts may freeze and burst even when some building areas are quite warm.

Watch out: for

for leaks and slow drips into drain systems.

Even though you think the building is warm enough, slow water trickling down a shallow drain line outside of the building can build up enough ice to block the drain or even freeze and burst the drain pipe.

That is because a dripping faucet or a toilet that runs can send a slow trickle of water down a drain line through the heated building into an outdoor shallow drain exposed to freezing conditions and leading to freezing or even a burst drain pipe. These breaks also occur in an un-heated crawl space, basement.

Outdoor drain lines may be above the frost line and may be depending on proper slope to avoid retaining water that then freezes.

But a slow trickle or drip of water can still freeze in those locations and it can also flood a septic drainfield or soak pit.

See also SEPTIC TANK & DRAINFIELD FREEZE PROTECTION

Heat tapes & other heat sources

to avoid frozen pipes: safely to avoid freezing pipes but also avoid fires.

Using fans to move air, small point-source electric heaters or light bulbs, adding heat to crawl spaces, opening cabinet doors and similar steps can protect problem spots from freezing in a building when its temperatures are set low.

We discuss use of heating cables on plumbing supply and drain pipes

We discuss where & how to add heat or insulation to prevent frozen pipes

at HEAT TAPES, HEAT, INSULATION PREVENT FREEZE-UP

Watch out: as we explain at HEAT TAPE GUIDE, some models of heat tapes used for freeze protection can cause a building fire if the tapes are not installed according to the manufacturer's recommendations, particularly if the tape crosses over itself.

As Ryan Duffy points out, connecting the heat tape to a GFCI-protected circuit can substantially reduce the risk of heat tape fires.

However if the GFCI-protected heat tape circuit trips-off during typical current leakage conditions and without drawing attention of the building occupants, the risk of freeze damaged piping, leaks, water damage, and mold damage will be increased.

The US CPSC GFCI HEAT TAPE CIRCUIT RECOMMENDATIONS 1994 [PDF] suggested that HUD consider dropping its no-GFCI-on-Heat-Tape-Circuit provision, and that heat tape powering electrical circuits be be protected with a GFCI device in the electrical panel rather than at the electrical receptacle or "outlet".

Ground fault protection was first required in the 1987 NEC for heat tapes that did not have a metal covering. In 1996/1999 the NEC expanded the requirements for GFCI protection and specified that mobile homes would have at least one heat tape receptacle.

[A significant number of heat tape-related fires occurred in mobile and manufactured homes.]

- We discuss use of heating cables on plumbing supply and drain pipes

at HEAT TAPE GUIDE - We discuss where & how to add heat or insulation to prevent frozen pipes

at HEAT SOURCES to AVOID FROZEN PIPES - Pipe insulation to prevent freezing is discussed

at PIPE FREEZE-UP POINTS - Steps to prevent freezing building drains and traps are discussed

at DRAIN FREEZE PROTECTION - Steps to protect building sewer lines, septic tanks and soakaways or leach fields from freezing are discussed

at SEPTIC TANK & DRAINFIELD FREEZE PROTECTION

See FREEZE-PROOF A BUILDING where we describe GFCI protection on heat tape circuits powering heat tapes for manufactured and mobile homes. Similar issues regarding building water entry control are discussed

at SUMP PUMP INSPECTION

Also see TESTING RECEPTACLES GFCIs AFCIs.

AFCI's are discussed at AFCIs ARC FAULT CIRCUIT INTERRUPTERS.

Heating systems and their effect on building winterizing plans

Heating systems should be inspected and if necessary cleaned and tuned before leaving heat on in a building in order to assure that the heater is in reliable condition.

Heating boilers that are to be left turned on also need water supply left turned-on for both hydronic (hot water) and steam heat systems, but we outline a little plumbing trick will let you turn off all other water supply in a building.

Furnaces & electric heating systems do not need water to be left on in a building.

Hot water heat continuous circulation can be used in hydronic systems to reduce building freeze-ups. Steam heat system condensate returns need to be freeze-protected.

Heat-ON Winterization:

See WINTERIZE - HEAT ON PROCEDURE for a discussion of what to do to assure that your warm air furnace or hot water heating boiler or steam boiler will operate safely and reliably throughout the heating season.

Heat-OFF Winterization guidelines are

at WINTERIZE - HEAT OFF PROCEDURE

- BURST / LEAKY PIPE REPAIRS - how to quickly find and repair frost-damaged piping, avoiding water damage and mold contamination due to frozen burst piping are discussed in a detailed procedure

- DE-WINTERIZE a BUILDING: what to turn on first, how to watch for hidden freeze-damage to piping, mechanical systems, appliances, and fixtures are discussed in a detailed procedure

at De-Winterized a Building. - FROZEN PIPE THAW-OUT how to un-freeze pipes, how to find where the pipes are frozen, how to avoid setting the building on fire is discussed in detail

- THERMOSTAT SET-BACK GUIDE to avoid freezing pipes in buildings: how to find the optimum low-temperature setting for a building thermostat is discussed in detail

- WATER SOFTENER / TREATMENT TURN OFF winterization and freeze-proof recommendations for water treatment equipment

- WATER TURN OFF? where to turn off building water, what water to leave on, how to safely leave hot water heat on with other water shut off. Draining water tanks, water pumps, hot water tanks.

-

WINTERIZING STEPS to take in a building - (in this article) winterizing or freeze-protection for building water supply piping, turning off water, preventing freezing pipes, draining piping systems, shutting down a building entirely: draining piping, turning off heat and electricity.

- WINTERIZE - HEAT OFF PROCEDURE: heating systems, water tanks & pumps, toilets, drain traps are discussed

How to Protect Shallow Water Lines from Freezing

Reader Question: how can I prevent a too-shallow water line from freezing outside

I have an outside pump and tank attached to 50' 3/4" hose (buried in ground about 12")which draws water from a buried tank. The tank is deep enough to not freeze but my poor design does not allow me to drain the tank or the 50' length of hose with a foot valve at the end of it.

What can I put down the line to prevent freezing like last year which blew up my hose. - Tony 10/13/2012

Reply: 4 tips on how to freezeproof a buried water that is too shallow for normal frost protection

Tony, I can think of several suggestions in escalating levels of trouble and detail

- Use compressed air:

If the home is being shut down entirely you can try blowing all water out of the buried water line using compressed air; you'll have to make-shift some fittings to make it easy to send air through the buried water line from one end, leaving the other end open; even so this may not get all of the water out of the hose or water line but it may be enough.

I converted a used A/C refrigerant gas canister that I pressurize either using a home tire inflator or at a gas station - taking care not to exceed the pressure ratings of the can (which could kill you). HVAC suppliers sell a kit that will convert the used canister to accept a schrader valve type tire inflator fitting that makes the job easier.

A friend used this approach, forcing air back down a water supply line, to keep a water pick line from a lake from freezing in winter. - Use RV type food-grade antifreeze:

use a food-grade antifreeze intended for RVs, forcing it into the buried water line. Do not use automotive antifreeze which will first make you blind, then may be fatal. - Excavate, insulate and install a suitable heating tape or wire along the pipe run. This approach requires that you trust elecrical power will remain on.

- Excavate, insulate, and install a heating loop in an insulated piping trench.

Where rocky soils prevent getting a water pipe below grade it can be difficult to solve a freeze-up problem. An engineering friend, Stu Tucker designed, and I helped install an expensive freeze-proofing system for an uphill septic effluent piping system.

Stuart's design included trenching around the existing buried piping, insulating the whole trench with solid foam insulation, and the installation of a small diameter fluid heater tubing loop that is connected to a tiny water heater.

We filled that system with an antifreeze mix, added a timer, temperature sensor, and pump to circulate the heated antifreeze mixture through the trench.

The system worked, though it was so expensive you wouldn't want to hire someone to do the project. This approach requires that you trust elecrical power will remain on. - Excavate and bury the water line below the frost line.

This may be the best approach in some areas, but in Northern Minnesota plumbers place outdoor lines six to eight feet below ground level for frost protection - it's not a trivial job.

Reader Question: can I add a recirculating pump to prevent heating zone pipes from freezing?

Question: 1/27/2014 Roni said: [posted originally at COLD HOT WATER RADIATOR or BASEBOARD ]

Have an Ultimate oil burner/boiler ( DHW coil removed), with 4 zones.

1st zone main floor,

2nd zone upstairs,

3rd zone sunroom addition,

4th zone Amtrol indirect HW maker

Problem:

2nd heating zone piping freezes up with cold weather (usually below 20F).

Thermostat in master br must be kept at 59-60F otherwise other two bdr's get way too hot.(poorly designed loops for the pipes, too $$ to fix)

Question:

Is there a way to add a recirculating pump to keep a small flow of HW moving thru the 2nd zone even when the zone isn't "officially" calling for heat?

Kinda like the idea where a pump is added to the furthest HW faucet in a home that keeps HW flowing so there's no need to run the water forever to finally have the HW reach the faucet.

Only other way to describe it would be for the 2nd zone valve to have variable flow-trickle to prevent pipe freeze and fully open when stat calls for heat. Crazy idea? Impossible solution?

Reply: adding a variable speed hot water heat circulator pump or an auxiliary circuilator pump or re-wiring for continuos water circulation

Roni:

Yes there are several possible solutions:

- Turn up the thermostat:

immediately pending other steps, keep the temperature high enough to avoid freezing - in your case 60F - Set the circulator to run continuously:

Assuming that your system runs with a single circulator and multiple zone valves, you can have your heating tech wire the circulator to run continuously.

This is how homes in Canada are usually heated; it's custom in the U.S. to have the thermostat call for heat by turning on the circulator and the boiler temperature turn on the boiler via the aquastat. But in Canada the circs run all during the heating season (at least on many systems) and the TT is wired to turn on the heating boiler. - You could install a variable speed circulator

for the above application (see extra notes at 4. below)

See CIRCULATORS VARIABLE SPEED - You could install a booster or extra circulator

just on the freeze-prone zone. In this arrangement you would think you'd want to latch open the zone valve manually so that the circ could push water around, but you may have to also change the zone valve wiring to NOT call for heat - otherwise when the zone valve is manually latched open, its internal end-switch will also turn on the main circulator.

In other words, you can convert the problem zone to one that is always circulating. If you install a variable speed circulator you can circulate water more slowly through that zone (or all zones) continuously. When the boiler temperature drops below the cut-in the boiler will cycle and provide heat.

Alternatively if you disconnected the trouble zone's zone valve end switch wires (that normally turn on the main circulator), then latch the zone open, then add an additional variable speed circulator just for that zone, you'll circulate water more slowly.

How to Empty the Water Tank or Pressure Tank - Building Freeze Damage Protection

Question: How do we get water out of inaccessible water heater & water pressure tanks?

Concern: We have a crawlspace containing a hot water tank and pressure tank. The water supply is from our well. We need to close-up for the winter and need to let the water out. The crawlspace door is at other side of the cottage. Kinda far to crawl back and forth over hilly ground.

The crawlspace vents are screened. We almost bought a tube that is powered by a drill, to let the water out via hose, I believe it is called; a drill pump. I asked a nearby plumber and he said, take it back, may not work next year, etc. Also this plumber does the service for us, with a pump. Also a plumber will remove the sediment from the tank.

Our photo (above left) of a horizontal water pressure tank was provided courtesy of reader Doug Mehak.

We want to empty the hot water tank and pressure tank ourselves, have been doing so for over 35 years. This crawlspace is new, this year. My husband just emptied the other 02 house pipes, in case it got below zero this week, and water is everywhere

. Next week, we will go to the cottage one more time and then close for the winter, any suggestions as to how we can empty the hot water tank and pressure tank, ourselves?

Cottage with crawlspace is in Haliburton, Ontario, Canada.

At least thanks for reading my concern, Ha Ha. - R.M., Ontario, Canada. 10/2/12

P.S. These are some solutions we are considering: --empty water by opening kitchen and bathroom faucets above, then only a bucket full will remain in hot water tank. take the bucket out with you and voila.

(my husband says must mean city piping because we have a well) --just let the water go through dirt floor, in time will go through ground. (we are talking a 40 gallon tank, it will be muddy for a long time) --another hardware guy suggested, drain the water into a bucket or pail, creating a contained puddle, so to speak. then sump pump that water out.

Reply:

A competent onsite inspection by an expert usually finds additional clues that help accurately diagnose a problem, such as noting the location, position of the problem water tank, what tappings on the tank are actually present and just where they are located, e.g. where there are only top tappings on the tank it may be possible to pump it out via a TP valve opening.

That said, thanks for writing with your own suggestions; on first reading your question, I hesitated in a prescription because lacking a clear description of the tanks involved, it appears that it not be possible to remove water from a water heater tank nor a water pressure tank located in an inaccessible crawl area.

While I'm not surprised at the description as often we find tanks squeezed into such areas, the installation does not sound correct, nor does it afford a means to empty the vessel; the result is not just a risk of freeze damage, but also other servicing cannot really be accomplished.

Watch out: water pressure tanks or hot water tanks in an inaccessible location are not only hard or expensive to service, repair, or replace, they may be unsafe - because the lack of ability to inspect the tanks means that safety devices such as temperature/pressure relief valves could be leaking or clogged - resulting in risk of a dangerous explosion.

And of course a tank could be leaking into a hard-to-access crawl area for a long time before anyone discovers the problem.

The view that "only a bucket full will remain in hot water tank" does not sound reliable to me; the output from a water heater is delivered by the pressure of incoming water to the tank; if the tank has no drain whatsoever and we simply run water in the building with incoming water shut off (say by an inlet valve or by turning off a well pump) water is delivered only until the pressure in the whole system drops down close to zero (actual pressure depends on location and elevation of components).

But the tank will still be full of water.

Watch out: I do not advise dumping water into a crawl area - it's asking for mold and insect problems.

Draining water pressure tanks and hot water tanks using the tank drain

Usually both water pressure tanks and hot water tanks have a drain valve at the tank bottom.

and WATER HEATER FLUSH PROCEDURE for photos of those typical tank drains.

When the water tank or hot water tank is located in a below-grade basement or crawl space or any other location where it is not convenient to drain the tank by gravity using a garden hose, we attach a pony pump to the tank drain and pump the water out of the tank and over to a suitable drainage location.

Details about types of pony pumps (or transfer pumps) including both self-contained pumps and the drill powered transfer pump you mention, are given

Some bladderless water pressure tanks and some water tanks using an internal bladder can work in any position. Most water heater tanks are intended to work properly installed in an upright position, not jammed horizontally into a crawl space.

Watch out: if a water heater tank or water pressure tank that was designed to be installed in an upright position is installed horizontally the installation is improper, violates the manufacturer's installation instructions and warranty, may have a reduced life, will not work properly, and may be unsafe.

Emptying plumbing systems using compressed air

Some winterizing companies charged with emptying building tanks and pipes to prevent freeze damage open all pipes and drains to drain out what water they can (after shutting off incoming water of course), and then try blowing compressed air through the system.

While this helps move water out of pipes and might push some water out of water tanks or water heater tanks, I have not found this a completely reliable approach.

Air can move through water pipes or tanks while leaving water behind, more so for piping that is not straight and pitched and still more so for tanks and vessels.

Nevertheless, it's a useful step that reduces water in the system even it it can't completely eliminate it.

Emptying plumbing by cutting pipes

Professionals will also actually cut pipes if necessary to assure the piping system is drained fully, figuring that it's much less expensive to later repair the cut than to repair burst pipes in unexpected locations and to clean up and repair water damage to a building left unattended.

How to empty a water pressure tank or water heater tank using a pony pump or a drill pump

I agree that based just on the description provided, the most effective means of getting most of the water out of the tank in this circumstance would be to use an available tapping on the upper tank to insert a tube and use a pony pump or drill pump to pump water out of the tank, through a hose, to outdoors or to a nearby drain.

When circumstances demand tank replacement or when there is an opportunity for any other reason, I'd either relocate these tanks to an accessible area or provide easier access (in one such case we made an openable floor panel).

Our photo (left) shows our little pony pump at a job where we used it to empty a water heater tank through a garden hose to an outdoor location. Here I had not yet hooked up the pump but you can see the white pump body and the washing machine hose needed to hook it up to a tank drain.

See PUMPS, PONY PUMPS for details.

This pony pump use procedure is described

at DEBRIS in WATER SUPPLY, Water Heater

Other examples of of use of a pony pump are

at AIR BOUND HEAT SYSTEM REPAIR by PUMP

and CLOGGED PIPES / TANKLESS COIL DE-SCALE.

How to Empty Well Piping or Prevent Well Pipe Freeze-ups When Winterizing a Building

Reader Question: When draining water for winterizing, how do we get water out of the well, well piping, and submersible well pump?

When draining the water from a dwelling that is allowed to freeze, how does the water supply from the submersible pump, supplied with foot valve, drain so the at or above grade pipes don't freeze and break? - Nate, 10/12/11

Reply:

Great question, Nate. There are two approaches to preventing water lines between the building and the upper part of piping inside the well from freezing

1. Frost Protection: Well water supply outdoor pipes

are buried below the frost line, including well piping from the point of exit of the well up to the building.

That's why at many older wells the well casing head was down in a "pit" - to protect it from freezing. Later the invention of the pitless adapter provided a fitting that permits the well piping to exit out of the side of the well casing below ground without leaking ground water into the casing at that point. That permits well casing tops to be brought up to above ground for improved sanitation.

2. Snifter Valved: On some wells that use both a submersible pump

and a bladderless water pressure tank, a snifter valve allows air to enter the well piping from inside the building near the water pressure tank.

To drain water out of the well piping inside the well a second drain fitting is installed in a tee in the well piping.

Search InspectAPedia for "Snifter Valve" and you'll find our details about this approach.

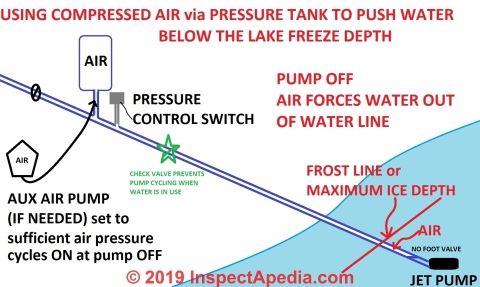

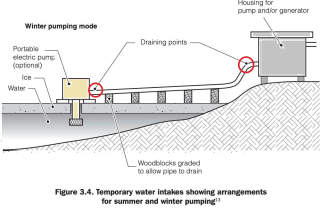

3. Air Push Empty Water Pipes: A third approach

that is not commonly used but that I participated in installing was designed by IBM Engineer Stu Tucker for his home at Lake George NY. The home draws its drinking water right from the lake. Normally homes in that area pull the well piping out of the lake in winter to avoid freezing.

Stu designed a system that pumps air from the water pressure tank back out the incoming water line at sufficient pressure that he could be confident that the water in the well piping was pushed backwards out of the pick-up strainer and into the lake to a depth that placed air into the well piping even in the lake to a depth below the lake freeze-over point.

The system was not as complicated as one might think. It amounted to an overcharge of air in the pressure tank and use of a submersible pump that is in the lake (so there is no issue with loss of prime).

Reader followup:

well with pitless adapter. I'm only concerned with the piping, inside the building, that is above frost level. I need to know if it will drain over a certain amount of time, or if I need to insert a tube and pump out the supply tubing to a level below frost line. Thanks - Nate

Reply:

Nate if your well pipes are NOT below frost line (option 1) the answer is that you need to determine if you have a snifter valve and in-well drain or not (option 2). If you don't, you'll need to use approach like #3 below or your own suggestion.

How to Winterize a building to Prevent Freeze Damage

First we decide the level of building winterization to be undertaken. There are two very different approaches to protecting a building and its mechanical systems from freezing-damage:

- Heat-on winterization:

the first approach to winterizing a building involves keeping the building heated, but to a lower temperature. This approach is usually best for a building as it helps avoid indoor humidity, moisture, and even freeze-cracking of some building materials such as flooring or drywall. We discuss "Heat-On" building winterization steps

at WINTERIZE - HEAT ON PROCEDURE - Heat-off winterization:

the second approach to winterizing a building is to turn off its heat, often also its electricity, drain piping, and take other steps to reduce the chances of freeze-damage.

This approach is taken when a building is to be left unoccupied for a long time, when the owners cannot pay for heat (though they may face later repairs that would have made the heating cost look attractive), or when a building has been abandoned, such as a foreclosed property. We discuss "Heat-Off" building winterization steps

at WINTERIZE - HEAT OFF PROCEDURE

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: Lake Water Supply: system pumps air back down the water line in winter to have lake water during freezing weather

I read in one of your posts:

“I've done the same thing with a friend who had this system at Lake George in NY. He also invented and we installed a typical over-engineered system that pumped air back down the water line in winter so that he could turn water on and off into his home during times when the lake was freezing.”

Would you be able to share the schematics of this system. I would like to build a similar system. - Anonymous by private email 2019/08/18

Reply: alternative to heat tapes & water pipe insulation for drawing water from a lake that freezes-over

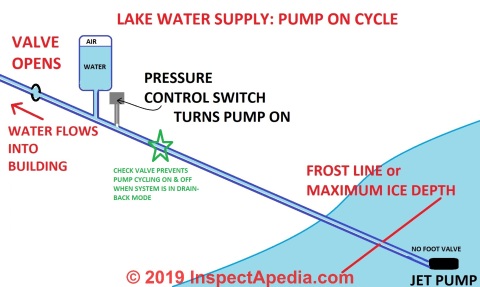

Basically this winter (freezing) lake water supply system involved a water pressure tank and air pre-charge in the tank.

Basically this winter (freezing) lake water supply system involved a water pressure tank and air pre-charge in the tank.

When the water pump runs water is drawn from the lake by a one line jet pump that is submerged deep enough and far enough out in the lake so as not to freeze. Water is sent up the line, compressing the air in the tank AND of course sending water into the house.

When the pump stops running the compressed air in the tank expands back out and down the water line far enough that it pushes water back out through the pump (no check valve or foot valve was installed).

You could do an engineering calculation of the pressures needed to push air down to a particular depth along a sufficient length (volume) of your in lake water line but an easier approach is to set the pressure tank air volume (or water volume) such that when the pump stops and air pushes back down the line you see air bubbles come out at the pump.

Then back off on the pressure until that outflow of air just stops (it may actually be self-adjusting, if you consider that the excess air only bubbles out once and on future cycles it'll stop short of the pump unless you added more air to the tank).

What we're doing in essence is installing a conventional water pressure tank but adjusting its air pre-charge to in essence empty the tank at the end of a pump cycle.

I'm not sure what tank my friend Stu used (it wasn't large) but I suspect that for this system to work we need to use a tank that does NOT use an internal bladder.

Extra Air Pressure Source: air pump

Some systems, depending on pipe length and thus volume, may require an auxiliary air pump that pushes extra air into the tank and water line at the end of a pump on-cycle.

That's because an internal bladder type water tank cannot be pre-charged with air to push out more volume than the size of the tank itself, while a bladderless tank can be "over-charged) with air enough to provide excess air that's in volume and pressure enough to push water not just out of the tank but out of the water line back down to the pump.

A typical installation of an air source pump for this lake water system requires an air source connected to the air inlet valve or schrader valve typically found on the top of a bladder type water tank but anywhere such as on the side or even at a bottom tee on a water pressure tank that does not use an internal bladder.

The valve core is removed from the Schrader valvce and using mini clamps a plastic air line is connected from the Schrader valve to the pressure control switch by adding a tee to the usual pressure control switch 1/8" diameter NPT tube or nipple.

To set the proper air charge in the tank you can simply follow the procedure I gave earlier, observing air discharge at the water pump in the lake. (Obviously this is done with the pump OFF.)

What about a simple check valve and air bleeder to drain the lake water line?

Watch out: few online chats we've read about keeping water on from a freezing lake advise a simple check valve and drainback valve (like a snifter valve used on some submersible well pumps). In my experience this won't work well.

Opening a valve to let air into a water line that slopes downhill (hopefully with no low spots or bellies that'd freeze) will let water drain back down out of the lake water supply pipe, but only just to the surface of the lake water. Without additional air pressure to push the water inside the water line to a deeper spot below the ice line, in freezing weather the water line will freeze at the lake surface just as ice freezes on the lake itself.

Also see WELL SNIFTER & DRAIN BACK VALVES

Watch out: however you will (probably) need a check valve installed on the water line to prevent the pump from simply cycling on and off when the water system is in use. This valve is NOT providing a drainback feature discussed just above. Rather, it's maintaining water pressure on the house side of the system (and house side of the pressure control switch) when the water system is in use. This means that when you're shutting down the home or leaving it without heat, you'll also need to drain the house water supply piping completely.

What about Freezing Drain Lines?

Watch out: you may be able to get water IN to your home from the lake in freezing weather, but you need to worry as well about freezing drain lines or even freezing up of a too-shallow septic system in cold weather - the drain and sewer or septic system for your home.

For the Lake George property we discussed above, a freeze-protection system involving insulation and an actual anti-freeze-protected hot water line and mini water heater were used to keep the drain system and septic system usable in cold weather.

Watch out: some writers suggest leaving water running slowly at your property to keep both water supply lines and drain lines working in freezing weather. In my opinion this is a bad idea. Even if your water supply is infinite and electricity is free, you still risk frozen, burst drain lines or a flooded, frozen septic system.

Many building drain lines between house and septic system or sewer are not below the frost line. In normal use during freezing weather the water running down the waste line is warm enough and moves fast enough to avoid freezing.

But if some fool leaves water trickling down a drain line in a cold climate (such as Two Harbors Minnesota) in freezing weather, that water will eventually freeze, blocking the drain line and possibly bursting it too. Don't do that.

When leaving the home shut-down with heat off in freezing weather additional steps were necessary. Those details are

at WINTERIZE - HEAT OFF PROCEDURE

Winter Lake Water Supply Resources

- Corder, Blair, "How To Prevent Frozen Lake & River Water Pipes with HotLine Internal Heat Trace Cable", Hotline Internal Pipe Heater Company, website: https://hotlineinternalpipeheater.com/blog/prevent-frozen-lake-river-water-pipes

This approach uses an internal heating line in the water pipe. Website excerpt:

HotLine's heating element consists of a modern alloy, insulated resistance wire, encased in a copper or plastic tube for protection. HotLine Internal Pipe Heaters are made from food-safe, FDA and EU approved Hytrel™ by Dupont. The HotLine heating element operates on 6 to 32 Volts of AC power, according to the length of the heating element.

- Cottage Water Supply,641B The Queensway

Toronto, Ontario M8Y 1K6 Canada Tel: 416-255-8087

Email: info@cottagewatersupply.com

Website: https://www.cottagewatersupply.com/winter-water-systems

This company provides winterized cottage water systems, self-draining water supply systems, etc. Their system uses a heating cable along the portion of the water supply line exposed to freezing where it passes through the lake ice. Using a drain-back system, above the lake level the line is empty of water. This is a simpler altrenative to Tucker's system using air pressure to push water in the water line down below the lowest level of ice in the lake. - Heat-Line Freeze Protection Systems, Heat-Line a division of Christopher MacLean Limited 1095 Green Lake Road Algonquin Highlands, ON, Canada K0M 1J1 Phone: 705-754-4545 Toll Free: 800-584-4944 Fax: 705-754-4567 Email: Info@heatline.com Submersible Pump Wire for Lake and River Applications, retrieved 2019/08/18 original source: https://heatline.com/blog/2018-05-17-submersible-pump-wire-for-lake-and-river-applications

- WATER SUPPLY [PDF], European Commission, retrieved 2019/08/18 original source: https://ec.europa.eu/echo/files/evaluation/watsan2005/annex_files/WEDC/oitc/oitc03.pdf

Introduction: Although the subject of water supply is well covered in many emergency manuals, there are additional factors which will affect the provision of fresh water for domestic supplies in conditions where the ambient temperature is close to or below 0°C. Chemical reactions are slower at low temperatures and biological processes also take more time.

The physical properties of water, in the form of water, ice or snow, are temperature dependent, therefore affect processes involved in supplying water and the range of technology that can be used.

The provision of water supply and sanitation is always closely related to the type of shelter in which the affected population is living. This is more so in cold regions where the provision of shelter is obviously a high priority. Specific shelter options are discussed at greater length in Section 5.4.

On 2017-02-08 by Jan Thompson

hi my building is outside about two car lenths from my house my unit froze Sunday went outside sat on a bail of hay and tried to thaw it with blow dryer didn't work called a pluming company near me he came down said the unit was frozen I knew that so he tool the unit in the house turned on little heater in building to thaw the pies in there well

he came back Monday got it working when I came home went to bed got up no water called again waited all day I,m glad I brought some water with me sitting in my kitchen on my rubber mat in front of wood stove is my unit again don't know what to do about it thanks jan

On 2016-10-13 by bob

I have a water reservoir under house, how do I keep it from freezing?

On 2016-06-01 by Heather

Thank you for your response

It would be shut down/emptied Dec 15-Mar 15 each year. Leaving only the dilemma of rebooting March 15 when things here are still pretty much frozen down.

On 2016-06-01 by (mod) - burying a water line at a cottage in QC

No amount of insulation without any heat source is going to be freezeproof through several very cold months. I'd consider a more complicated but reliable system as my friend Stu Tucker designed for a home at Lake George that also pulls lake water in winter.

We lined the trench on all sides with 2" foam but in the trench along the water line we included a small diameter heating tubing loop that connects to an anti-freeze filled mini electric water heater in the home. A pump circulates heated water that combined with insulation keeps the water line from freezing even though rock prevented getting it below the frost line.

The foam was done neatly but not glued. In some projects I used finishing nails and construction adhesive to pin and glue foam in place but of course gluing it means you'll have to destroy it if you need to get in later for repairs.

An alternative that we also have used is a system with an air-filled pressure tank that blows all water back out of the riser from the lake, down to a depth below the ice, at the end of a pump-on cycle.

Black ABS well piping is pretty frost damage resistant but you may find the plastic or brass connectors breaking.

On 2016-06-01 by Heather

I am burying a water line at a cottage in QC that pulls water from a river that freezes solid most winters. I hope to be able to have a running water supply until mid December, shut down until mid March and then be able to re-boot at that point.

The trench was dug by hand and we could not get down lower than 2.5-3 ft which is deep, but not below the frost line. We have foamboard insulation that we plan to put in under, over and on the sides of the pipe, although I cant quite picture how that will be able to be sealed.

The line is quite long:75 ft river to pump (in insulated, somewhat buried box with a lightbulb in it) and 85 ft, pump to house, .

There seem to be a variety of opinions and options of what kind of pipe to use that might resist breaking/freezing. Also I plan on putting in 2 pipes, 1 active and one backup, inside a bigger 4"pipe of some kind that needs to be flexible to take some curves that are in the trench. WHAT KIND OF PIPE should I use?

On 2016-01-14 by Terry

I bought a home in Northern (UP northern) Michigan. The water supply is a natural spring, but is pumped from an old (long-ago vacated, no roof old) home on the other side of a pond that the spring also feeds. The pump is enclosed in a big styrofoam-type box that has an incandescent light bulb left on to, I was told, keep it from freezing.

I moved in less than a month ago and its already frozen twice. Any help would be greatly appreciated.

On 2015-01-06 by (mod) -

If the water heater is located in an area exposed to freezing I'd leave it on. The stand-by losses for a water heater that's not in use are rather small so most liekly it's not going to run often.

On 2015-01-06 by Jessica

I have a vacation home in Hamlin PA. The house is heated by a propane boiler that requires water to stay running. We left the heat on in the home at 50 degrees , but my boyfriend shut off the Hot water heater switch. He doesn't like me questioining his decisions, but neither of us has ever owned a vacation home before and I want to make sure the pipes don't freeze during the winter?

Of course, money is a concern and our propane bill has been high. I go back to the house next weekend. Should I leave that hot water switch on or is it ok to leave that switch off?

On 2014-04-24 by (mod) -

Hi Dave, interesting question. I dunno, but here's how I'd seek an answer.

You describe a 24" high crawl space into which electric heaters have been installed. And you suggest that the floor and walls are foam-covered. You don't give the size of the heaters nor actual distances from the heaters to the nearest foamed surface, but I can figure it may be (24-8)=16".

Now take a look at the manufacturer's specs, or give them a call with the heater model name and number. I believe we'll be told that there is a minimum safe clearance distance between the heater's various sides and the nearest combustible.

Probably you're ok but I'd check.

Using a Marley heater installation guide (Home Depot) as an example the instructions want a minimum of 6" above or 1" in front of the heater to drapes (a potentially combustible material). Here's what they say about carpeting (another combustible) "Heaters may be mounted on any floor surface, including carpeting".

King Electric warns about installing the heater against vinyl wallpaper (makes you think of that foam, right?)

Runtal's electric baseboard heater instructions - the company says the heaters must be installed against the floor. And adds " Do not install heaters against combustible low-density cellulose fiberboard surfaces. Keep drapes 2 inches away from the electric baseboard radiator.

Do not install the baseboard heater below an electrical convenience receptacle. To reduce the risk of fire, do not store or use gasoline or other flammable vapors and liquids in the vicinity of the heater. Only install as illustrated in this manual."

On 2014-04-24 by Dave Redgers

I own a year around cottage about 2 hours north of Toronto. Currently we have electric baseboard heaters in all rooms including 2 in the crawl space which is approximately 50'x 30'x 2'in height. the 2 heaters are hung down from the floor joist about 8".

The floor in concrete and the block walls have been sprayed with 3M's closed cell purple foam. The ceiling or cottage floor has had the installation removed many years ago. We have no freezing issues as the air vents are closed for the winter months however my question is concerning how safe these heaters are in this confined area.

Question: will an un-heated house develop a mold contamination problem?

Is it true that if a house is left unheated in the winter, it will grow moldy? - James 9/1/11

Is it true that if a house is left unheated in the winter, it will grow moldy? - James 9/1/11

Reply: maybe.

James, no, yes, well ... it depends.

Simply leaving a home unheated, starting by confining the discussion to temperatures, does not cause mold growth, in fact some mold growth is retarded by low temperatures.

But IF the home will also be at a high humidity for any reason (a leaky roof, plumbing leak, wet crawl or basement), when we turn off the heat we lose the added drying capacity that heating brings to the building. So the risk of mold contamination is greater than otherwise.

I've inspected plenty of homes left with no heat and found that they did not become a mold palace.

Wherever I've found an unheated home that had become a mold palace there were additional causes or conditions that led to wet or high humidity indoors, usually combined with the home being left unattended - no one watching for problems - which means that the mold palace could be horrible. The mold catastrophe shown in our photograph above occurred in a home that was left unattended for more than a month.

The home suffered a burst pipe leak that wet the interior with hot water; the combination of wet conditions, heat left on, and very delayed discovery of the leak and mold problem led to extensive mold and water damage throughout the home.

The most severely mold contaminated buildings I've investigated have usually been cases in which there was a significant leak such as from a burst water pipe (with water supply and pressure left on) or burst hot water heating system piping that soaked building areas in a building that was left unattended for a long period (from 5 days to several months).

So in sum, you have to know something about the house and its leakiness and general inclination to moisture before you can answer the question for a specific home.

Question: How do we winterize a home that has not been used in months and with no central heat?

I'm not seeing how to approach a house that hasn't been used in months. The owner died. No central heat, and the water heater leaked months ago too. Well water. Very well insulated home. Air is in the lines of the house.

Can I empty the pressure tank to the well, and run RV antifreeze and leave it at that? The house seems to go down to the lower 50's on average and has outstanding passive solar set-up. - Sean 12/15/11

When closing down a house with the Heat off method, will any frost damage occur to the drywall, etc. if So how would you prevent this? - Sean

Reply:

Sean,

When a home has already been unoccupied for some time and without heat as well, start by a complete inspection of the building for damage, including leaks, rodent infestation, etc. If the building is intact and undamaged, then proceed to winterizing it using the Heat-Off procedures we describe in this article series.

It is better for most buildings to be left with heat on, albeit at a low temperature to reduce the cost of that house "mothballing". Leaving heat "on" in a stored building means that the heating system must be safe and reliable, and still the building should be inspected frequently for leaks or damage. But if heat must be left off and the building is dry (without leaks) and winterized, it may survive reasonably well.

I agree that a building left with heat off in a freezing climate will be exposed to extreme temperature swings as well as humidity swings and that cracks and damage can occur as a result. Minor drywall cracks shouldn't be a significant repair problem, but leaks or even high humidity swings in a building can lead to serious damage to hardwood floors as well as risking a mold contamination problem.

...

Continue reading at THERMOSTAT SETTINGS to USE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Building Freeze Protection Articles

- ARTESIAN WELL FREEZE PROTECTION

- CHEMICAL TOILET FREEZE PROTECTION

- DE-WINTERIZE a BUILDING

- FAUCETS, OUTDOOR HOSE BIBBS

- FREEZING FORCE of ICE

- FROST HEAVES, FOUNDATION, SLAB

- FROZEN AEROBIC SEPTIC or WATER SUPPLY SYSTEM

- FROZEN PIPE THAW-OUT

- GREYWATER FREEZE PROTECTION

- PIPE INSULATION CHOICES, MATERIALS, TYPES

- PORTABLE ELECTRIC HEATER SAFETY

- SEPTIC FREEZE-UP SOLUTIONS

- SEPTIC TANK & DRAINFIELD FREEZE PROTECTION

- SPA / HOT TUB DRAIN / WINTERIZING PROCEDURE

- WINTERIZE A BUILDING - home

- WINTERIZE - HEAT ON PROCEDURE

- ANTIFREEZE for BOILERS

- DRAIN FREEZE PROTECTION

- DRAIN a WATER HEATER TANK

- FREEZING FORCE of ICE

- FROZEN AEROBIC SEPTIC or WATER SUPPLY SYSTEM

- GREYWATER FREEZE PROTECTION

- HEAT SOURCES to AVOID FROZEN PIPES

- INSULATION to AVOID FROZEN PIPES

- MORRISON WELL SYSTEM FUNCTION & REPAIR

- PIPE FREEZE PROTECTION - home

- SNIFTER & DRAIN BACK VALVES

- THERMOSTAT SETTINGS to USE

- WATER TURN OFF?

- WATER SOFTENER / TREATMENT TURN OFF

- WATER TANK & PUMP DRAIN & WINTERIZE

- WINTERIZE - HEAT OFF PROCEDURE

- WINTERIZING an RV or MOBILE HOME

Suggested citation for this web page

WINTERIZE A BUILDING - home at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING FREEZE PROTECTION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "New Electric Heat Tapes Help Prevent Fires," US Consumer Product Safety Commission (CPSC) #00936

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- "Freezeproof Your House," Mike McClintock, Rodale's New Shelter, p. 30, October 1985 (approximate date)

- "How to Winterize Your Pipes," Mike McClintock, Homeowners How-To Magazine, p. 59-62, Nov-Dec 1979.

- "HUD Regulation for Manufactured Homes; Requirement that Heat-Tape not include a GFCI [ copy on file as /plumbing/GFCI_Heat_Tapes_HUD_CPSC_Letter1994.pdf ] - ", Meeting Log, US CPSC, HUD, Dennis McCoskrie, ESEE, 2/14/1994

- "Houses in Hibernation," Steve Bailey, New York Times, 24 October 2008 p. D2.

- Thanks to reader Ryan T. Duffy for discussing the suggestion for GFCI's on heat tape circuits to reduce fire risk, October 2010.

- Thanks to reader David Gould, BC, Canada, for pony pump requirements discussion, 1/27/2010

- [8] Colorado Climate Center, "How deep is the frostline in the winter in various parts of Colorado?", website http://ccc.atmos.colostate.edu/questions.php, retrieved 3/1/13

- [9] Cyber Regs, " ICC Subscriptions International Residential Code for One- and Two-Family Dwellings". R403.3 Frost-protected shallow foundations, citing 2012 IRC, http://publicecodes.cyberregs.com/ icod/irc/2012/icod_irc_2012_4_par033.htm retrieved 3/1/2013

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.