Drywall & Plasterboard

Drywall & Plasterboard

Age, composition, tests, history

- POST a QUESTION or COMMENT about ages & types of wall & ceiling materials, installations & practices

Gypsum board, plasterboard, or drywall used on building exterior or interior surfaces:

Composition and early history of drywall.

This article series discusses the identification and history of older interior building surface materials such plaster and lath, Beaverboard, and Drywall - materials that were used to form the (usually) non-structural surface of building interior ceilings and walls. Our page top photo shows hand-split wooden lath backing for a plaster interior wall.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Drywall Composition, Ingredients, History

While modern drywall or gypsum board is usually composed of a single inner layer of gypsum, sometimes reinforced with other fibres, and covered on both sides and at least two edges with paper, earlier versions of this product included Sackett Board, shown here, a wallboard comprised ofr multiple layers of gypsum and paper, generally intended to be covered by a final layer of hand-applied plaster.

Details of the earlier product are at SACKETT BOARD.

In the U.S., ASTM C11 defines gypsum board as the generic name for a family of board products consisting of a non-combustible core primarily of gypsum with a paper facing.

How is drywall made & what are the ingredients of gypsum wallboard ("drywall" or "Sheetrock™") ?

According to an ATSDR study of asbestos exposure from vermiculite and some forms of drywall, gypsum wallboard is currently (2008) manufactured in the following steps:

- Gypsum rock is crushed to form small pieces, dried to evaporate surface moisture, and ground;

- The dried gypsum is “calcined” or heated to remove excess water that is chemically bonded to the gypsum, forming what is called “stucco;”

- Dry additives (e.g., vermiculite, perlite, starch, fiberglass, or sugar) are mixed into the stucco depending on the properties needed in the specific product;

Note: in special applications including the development of fire-resistant drywall, some formulations included the addition of asbestos fibres or powder. - Water is added to produce a slurry;

- The slurry is mechanically spread over a paper backing;

- A top layer of paper backing is applied to form a “sandwich” with the slurry in the middle;

- The long, continuous sheet of wallboard moves on conveyor belts while the slurry hardens, and the sheets are cut into specified lengths;

- The cut boards are flipped and sent into a multi-stage kiln to dry and become hard; and

- The hardened wallboards are trimmed to an exact length, end-taped, stacked, and placed onto skids, ready to be shipped.

Desirable Properties for Drywall

.. it is an important object of the present invention to enable the physical characteristics such as resistance to shock, nailability, flexibility, strength and similar characteristics of plaster casts to be enhanced in a simple and economical manner and in such a.way that ready workability of the set composition is attained.

Another and related object of the' invention is to accomplish this in such a way that the mixing and forming operations that must be applied to the plaster composition may be readily and easily performed.

Experiments with Inclusions in Gypsum board to Improve its Properties

Again excerpting from Croce 1951, some ingredients included in gypsum board or plasterboard reduced its strength:

In an effort to impart more desirable physical characteristics to plaster walls and wallboard, such as resistance to sudden, localized forces, many different ways or expedients have been employed.

For example, the plaster composition utilized in the making of wallboards has in many instances been made so as to incorporate a fairly large percentage of fibrous organic material such as sawdust, sisal fibers, paper pulp and the like.

Study of such prior gypsum plaster wallboard indicates that while these expedients serve to increase the nailability, certain disadvantages are encountered, and particularly it is found that the relatively high percentage of such filler or the like that must be used in such instances serves to correspondingly reduce the amount of plaster that is used, and the resulting plaster wall or wallboard possesses less strength than is desirable to resist the stresses and strains applied to such structures.

Another characteristic that is extremely desirable in plaster compositions that are used for building purposes is the workability of the resulting cast insofar as sawing or cutting may be concerned after the plaster has hardened or been put in place.

For example, normal building construction in many instances requires that an opening be cut into a plaster or plasterboard wall so that an electrical outlet box may be mounted in position, and this opening must in many instances be cut into the ceiling of a room.

In such instances it is found with conventional plaster compositions that there is a tendency for the plaster to break away from and at an angle to the line upon which the cut is to be made, and there is also a tendency for the plaster to break apart into fine dust, and this breaking and dusting, of course, is undesirable, particularly when the work is being done in a home or the like that is occupied.

Why Asbestos was Added to Plaster, Drywall, Gypsum Board

It should be observed also that in some instances asbestos has been used in plaster.

In one such use the asbestos fiber has been added to plaster primarily to improve the plaster workability or trowelling characteristics while in another instance, in the Croce Patent No. 2,526,066, such asbestos fiber was added as a means for retaining an expansive component of the plaster composition in place in the set cast. In each case the amount of asbestos was quite high, and the Water absorptive capacity of the asbestos has increased the drying time of casts thus made.

Drywall / Plasterboard Resistance to Cracking

Another important and desirable physical attribute in plaster casts, walls, and wallboard is high resistance to cracking due to settling stresses or fire, and to enable a marked improvement to be attained in respect to this important physical characteristic of plaster casts and the like is another important object of this invention.

Another and related object is to enable plaster compositions to attain such improved resistance to cracking and breaking when used in the ordinary manner to produce casts, walls, wallboard and the like.

Drywall Must Hold at Nail or Screw Fasteners

When plaster wallboard is put in place on walls or ceilings, it is secured in place by fastening elements such as nails, clips, screws or the like, and the permanence of such fastening is dependent in a large measure upon the shearing strength of the wallboard at its line of engagement with such fastening element.

This area of critical shearing strength has often constituted the point of first failure in such walls or ceilings, and it is therefore another important object to so constitute a plaster composition that plaster walls or wallboard made therefrom will exhibit a materially increased shearing strength; and a related object is to accomplish this in a simple and expeditious manner.

Reduced Fire Resistance if Wood, Sawdust, Other Organics are Added to Drywall / Plaster

... using added mixing water, with its resulting reduction in strength and increase in drying time for the casts, coupled with the further fact that the organic fibers constitute a fire hazard in a manufacturing plant, and that such organic fibers disintegrate at relatively low temperatures.

... It is well recognized that the use of plaster or plaster wallboard as a wall surfacing in buildings serves as a protection against the destructive action of fire, and many efforts have been made to increase the fire resistant or fire retardant action of gypsum plaster walls.

Such efforts have in most instances centered about the character of the lathing employed, while in another instance a heat-expansive material has been added to the plaster to compensate for heatinduced shrinkage of the plaster in the event of fire, as described in the aforesaid Croce patent.

It is another important object of the present invention to enable high-fire retardant characteristics to be attained in plaster compositions and products in an improved and simplified manher, and related object is to attain this result with the minimum of additives so as to thereby enble the maximum ratio of plaster to be used.

Advantages of Adding Fiberglass to Plasterboard or Drywall

Such disadvantages are eliminated under the present invention by affording a gypsum plaster composition which utilizes drawn textile glass fibers as a bodying and strengthening component in such a way and with such efiiciency as to be economically practical and in such a way that the mixing and forming, shaping and drying operations in respect to the mixed plaster or slurry may be readily and easily performed.

Plasterboard Resistance to Bending

At the outset it should be noted that suggestions have heretofore been made concerning the use of wool, and separation of individual fibers from the mass is quite difilcult because of the curled and interlaced or matter relationship of the fibers in the mass.

Such separation of individual fibers from the mass is also rendered difficult by reason of the relatively low physical strength characteristics of the blown fibers which bend quite easily and tend either to retain their bent form or to break at the bend.

Mechanical Tests of Drywall

[Click to enlarge any image]

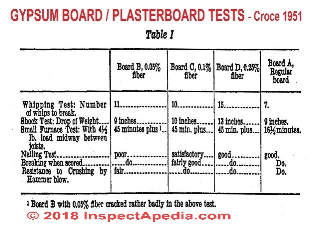

The tests included in Table I show that as co'mpared with conventional plaster wallboard as represented by board A, boards B, C and D attain a marked improvement in respect to fire resistance, while boards C and D attain satisfactory characteristics in the other tests.

Again excerpting from Croce 1951

Wallboard Whipping Test

The whipping test is one that is quite important from a practical standpoint in that it simulates a condition that is often encountered in the handling or installation of plaster wallboard.

Thus in this test the opposite ends of 4 foot by 8 foot sheet of plaster board are grasped by two men and the board is moved up and down so as to cause the central portion of the board to bow downwardly and then upwardly with what might be termed a whipping action.

In such handling, any weakness inthe board is liable to cause breakage, and by counting the number of whips or up and down movements necessary to break such a board, a munerical index is afforded which is representative of the strength characteristics of the board.

Wallboard Shock Test

The shock test was made by supporting a piece of board one foot wide and four feet long on three feet centers, and in this instance the grain of the paper extended transversely of the width of the sample.

A loading board was then placed in the center of the span and a sling arrangement was attached to the loading board.

A weight of 660 grams was then attached to the sling by means of a rope. This weight was raised up one inch and then dropped and this dropping action was repeated through progressively larger distances, the increase between drops being one inchin each instance, and this was continued until failure or breakage of the test board.

The results of this test were indicated by the number of inches of the final dropping movement of such weight.

Wallboard Furnace Test

In the furnace test the board samples were :nailed on 6-inch centers to the lower faces of joists spaced on 16-inch centers and a 4 lb. load was placed on the board midway between the joists.

The board as thus supported formed what may be termed the upper wall of the furnace and the temperature developed in the furnace was substantially 1200 to 1300 degrees F. at the end of minutes and was thereafter maintained at 1300 to 1500 degrees F.

Wallboard / Drywall / Plasterboard Nailing Test

The nailing test is performed by driving 5 penny cement coated wallboard nails into a wallboard near an open or out edge, and observing whether and to what extent the plaster core splits out or breaks.

The first such nail was driven at a point inch in from the cut edge of the board, and successive nails were driven at points located progressively close to such edge.

Wallboard / Drywall / Plasterboard Break Test

The break test was performed by cutting one paper cover of the board along a straight line entirely across the sample, and then breaking to determine whether the board would break along a straight line as is desired in use of such board.

Wallboard / Drywall / Plasterboard Hammer Blow Test

The test relating to resistance to hammer blows was performed by striking the boards near an open or cut edge and at different distances from the edge, and the quality of the board in this respect is judged by the extent to which the core shatters or flies out of such edge in response to the blows.

- (Croce 1951)

Drywall, Gypsum Board, Plaster Board, Adamant, Sackett Board, Sheetrock Early History & Dates

-

1888: In the U.K. the first plasterboard production facility opened in 1888.

In London, Gyproc Products Ltd., produced a plaster-board that included rust-resistant metal reinforcement for use as ready-made partitions. -

1890-1894: In 1890 Sackett Board was invented by Augustine Sackett - details are

at SACKETT BOARD -

1890:Adamant Plaster Company: in the U.S. . The Connecticut Adamant Plaster Company opened on River Street in 1890 and turned gypsum into wall plaster there until it closed in 1935. (Beal 1951) in (Baris 2001)

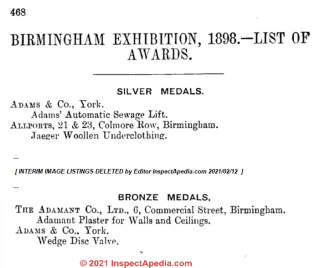

- 1898 Adamant plaster: Early versions of plasterboard produced by USG (ca 1909) were referrred to as Adamant board. We find a reference to Adamant plaster for walls and ceilings (by the Adams & Co.) cited at least as early as 1898 (Law, 1898)

However in 1899 in the U.S. the use of adamant plaster was still considered a development rather than a dominant product (Grimsley `1899)

We still find, on occasion, an Adamant identification stamp on the back of very old gypsum-board. The term "adamant plaster" is still used in current texts and refers to a cementious plaster still used to form wallboard as well as decorative plaster elements, and tiles. (Kaphle 2018) - 1901 U.S. Gypsum Company (USG) founded in the United States

- 1909 Adamant plasterboard: Early versions of plasterboard produced by USG (ca 1909) were referrred to as Adamant board - as discussed at SACKETT BOARD.

- 1912 USG Utzman Patent for Plaster Board closed edges paper wrapped plasterboard improving on his 1911 patent.

- 1915 (ca) Sheetrock® brand: A USG sales representative suggested the company brand their plasterboard as Sheetrock®, a non-warping, non-burning wall covering. (US Gypsum ret. 2021)

- 1917 USG produced single-layer solid plaster-core plasterboard covered with paper

- 1921 fire-resistance properties of plasterboard promoted by USG

- 1927 CertainTeed Corporation introduced its own open-edge, paper-covered plasterboard

- 1933 Chicago World's Fair demonstrated use of USG's Sheetrock® panel in construction, leading to a surge of interest

Drywall / Gypsum Board Composition & Testing History References

Above: listing of the Adamant Co. Ltd., 6 Commercial Street, Birmingham, as recipient of a bronze medal for its Adamant plaster for walls and ceiligns, in the Birmingham Exhibition, 1898 list of awards.

The Birmingham Exhibition of 1898 was a Worlds Fair organized in Birmingham, in the United Kingdom, in that year. Birmingham previously hosted a better-known worlds fair Exhibition of Industrial Arts and Manufacturers in 1949.

[Click to enlarge any image]

- Baris, Mackenzie, Katharine Dion, Chris Nelson, and Yujun Zhang. "Industrial Symbiosis in New Haven Harbor: English Station West 2001." Developing Industrial Ecosystems: Approaches, Cases, and Tools.

- Bowlzer, Alfred H., LATH SPACING TABLE and TIE [PDF] U.S. Patent 738,979 also listed as Application US 10408102, granted 1903-09-15

Excerpt:

My invention relates to lathwork in which a single lath at a time is placed into the framework of a building and nailed thereto, usually in sections of ten laths each in order to break the joints properly, and are later overlaid with common plaster or adamant plaster, the space between the laths being governed by the kind of plaster used;

and the objects of my improvements are, first, to provide means for placing and tacking onto the framework of a building a whole lath-section of laths at a single instant, to be severally nailed afterward, the lath-section to contain as many laths as it is desired to break joints with;

second, to provide a table on which to properly butt and space the required number of laths to fill a lath-section; third, to provide facilities with the table for tie-bars on which to bind a section of laths previously butted and spaced;

fourth, to afford facilities with the tie-bars for the holding of thick and thin laths for suitable engagement with the wall and the proper spacing of the laths on the wall and the section putting on; fifth, to afford facilities with the tie-bars for the rigid engagement of the laths and their quick release therefrom in order'to be refilled; sixth, to afford facilities with the tie-bars for lateral adjustment of the lath to accommodate the kind of plaster to be used and with the table for longitudinal adjustment to suit long or short lath-sections. - Clarke, Addison Henry. Architect's Hand-book on Cements. WW Clarke & son, 1899. [Available from Google Play as a free eBook]

- CROCE DRYWALL PATENT No. 2,681,863 [PDF] (1951) US Patent No. 2681863 Croce Michele, Clarence G Shuttleworth, Original Assignee: Certain Teed Products Corp, Priority date 1951-07-07

This patent disclosure is of particular interest to anyone studying the history and composition of drywall or plasterboard as it describes various both various compositions or mixtures and constituents of drywall as well as the tests that were developed to try out the suitability of those compositions in actual use.

See details at CERTAINTEED DRYWALL ASBESTOS

- Drywall is available in various compositions including "mold-resistant" and fire-resistant materials.

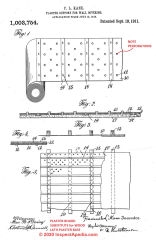

Illustration below: perforated multi-layer plaster board base used for plaster wall and ceiling systems, from F.L. Kane US1003754A (1911).

- Friedman, Kane, Julius B. Blumenfeld, and Louis Strimban. PLASTER BOARD [PDF] U.S. Patent 912,664, issued February 16, 1909.

Excerpts:

Be it known that we, KANE FRIEDMAN and Julius B. BLUMENFFLD, subjects of the Czar of Russia, residing at the borough of Brooklyn, in the city of New York, county of Kings, and State of New York, and LOUIS STRIMBAN, a citizen of the United States, residing at Stepney, in the county of Fairlield and State of Connecticut, have invented certain new and useful Improvements in Plaster-Boards, of which the following is a specification, reference being had therein to the accompanying drawings, which form a part thereof.

Our invention relates to lathing and more particularly to that class thereof commonly known as plaster-boards.

'Plaster boards, as now commonly used, comprise a plurality of superimpose layers of paper and a plaster, or lime, cement between same, the paper being relied upon to give the required toughness to permit nails to be driven there through and the plaster being relied upon to give permanency and rigidity to the board. ordinarily these boards will be made up of from eight to ten layers and will run from 3/16 to 5/16 of an inch in thickness, and are applied in parallel , flat surfaces by being nailed to the joists or beams.

In practice, however, it has been found to be impossible to shape these boards to irregular surfaces, owing to the tendency of the plastic cement to break and crumble when bent, thus causing the disintegration of the entire composition entering into the board at the bend and adjacent thereto.

A further difficulty in this type of board is that a large surface and a correspondingly large body is required to insure the required rigidity, it being impossible to separate a board into strips an use such strips as an ordinary lath, when such ma be desired for purposes of economy in building construction, or to secure a good holding surface for the plaster wall, or finishing coating.

The main object of our invention is to provide a plaster board which will possess the toughness and rigidity of those of the ordinary type above referred to, and will, in addition thereto, be so reinforced bb a flexible metallic member as to be rea il bent to fit any irregular location and still have the entire board remain intact. - Grimsley, George Perry, and Edgar Henry Summerfield Bailey. Special report on gypsum and gypsum cement plasters. Vol. 5. Kansas Geological Survey, 1899.

Excerpt from p. 5

With the increase of the adamant wall-plaster business there will probably be an increase over present production of the gypsum businesses of new York state, but as this business is hardly well started yet, the effect may not be noted for some time.

- Grimsley, George Perry. The gypsum of Michigan and the plaster industry. Vol. 9. R. Smith Printing Company, 1904.

- Gypsum Association, "Gypsum Through the Ages" [web article], retrieved 2018/09/05, original source: https://www.gypsum.org/about/gypsum-101/history-gypsum/

- HEALTH CONSULTATION, Domtar Gypsum American, Inc., 801 Minaker Drive Antioch, Contra Costa County, California Epa Facility Id Cad089182810 May 7, 2008, [PDF] U.S. Department Of Health And Human Services, Public Health Service, Agency For Toxic Substances And Disease Registry, Division Of Health Assessment And Consultation, Atlanta, Georgia 30333 Contact ATSDR 1-800-CDC-INFO http://www.atsdr.cdc.gov

- Hodgson, Frederick Thomas. Mortars, plasters, stuccos, artificial marbles, concretes, portland cements and compositions: being a thorough and practical treatise on the latest and most improved methods of preparing and using limes, mortars, cements, mastics and compositions in constructive and decorative work, including a practical treatise on reinforced concretes. FJ Drake & Company, 1914.

Excerpt, p. 31:

Adamant is another white cement, which is useful for work where hardness, facility of application, quick drying, and a fine surface are required. - Kane, Frederick L. "Plaster-support for wall-covering." U.S. Patent 1,003,754, issued September 19, 1911.

- Kane, Frederick L. PLASTER SUPPORT for WALL COVERING [PDF] U.S. Patent 1,103,362, issued July 14, 1914.

Excerpt:

It is well understood in the trade that a paper surface is a most excellent material to which wet plaster may be applied, as the plaster enters the pores of the paper and anchors itself thereto.

A difficulty has been found, however, in the fact that plaster when applied is saturated with water and paper or analogous fabric, becomes quickly saturated, loses its tensile strength, and either breaks away while wet or else sags to such an extent that a good deal of extra plaster is necessary in the finishing coat or coats in order to make the surface level.

To overcome this objection I have used a paper preferably laminated and provided with thin flexible cross strengthening strips as disclosed in my application for Letters Patent of the United States No. 572,088, filed July 15th, 1910. - Kane, Frederick L. "Plaster-support for walls." U.S. Patent 1,121,017, issued December 15, 1914.

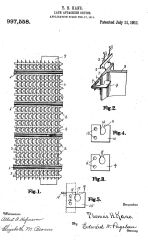

- Kane, Thomas Henry. LATH ATTACHING DEVICE [PDF] U.S. Patent 99,558, issued July 11, 1911. Patent assigned to the Trussed Concrete Steel Company of Detroit.

Early description of what was later called "expanded metal lath" used as a plaster base. This Kane, Thomas Henry, was from Youngstown, Ohio - steel town.

Excerpt:

Ribbed metal lath of the character shown in Fig. 1 comprises a series of parallel ribs 1, formed by bending parallel in perforated strips or bands of the sheet. metal, narrow strips 2 between the ribs, and tongues 3 connecting the adjacent strips and ribs.

The clips 4 shown in Fig. 3 are sheared from sheet metal, preferably hard spring steel, and formed with teeth 5 and holes (3.

When the metal lath is positioned, these slips may be driven onto the flanges 7 of the I beams 8, or onto other proper portions of structural members,

the teeth 5 engaging the flanges so securely that the clip can be removed only by the use of considerable force.

- Millar, William, and George P. Bankart, PLASTERING, PLAIN and DECORATIVE [PDF] 4th Ed., Donhead, London, B.T. Batsford, Ltd, 94 Holborn, New York, Dodd, Mead and Co (1929).

- New England Adamant Co., NEW ENGLAND ADAMANT CO. - MANUFACTURERS OF ADAMANT, WALL, PLASTER [PDF]

[Index to Text only] PIBN 10501121

ISBN 978-1-333-41125-1

ISBN (Hardcover) 978-0-666-25580-8 retrieved 2021/02/12 original source: https://www.forgottenbooks.com/en/books/NewEnglandAdamantCoManufacturersofAdamantWallPlaster_10501121

This text, on p.. 298, lists Adamant for floating walls,

Excerpt:

In recent years numberless improvements have been made in building materials generally, but until the introduction of Ada mant, a superior wall at moderate cost was unobtainable. In the ordinary way of making and applying common plaster, results are very uncertain. The varying qualities of lime and sand render fixed proportions unsafe. The plaster must be mixed weeks before it is used, so that the lime may become thoroughly slaked.'

Frequently the hair is destroyed by the action of the lime, and a wall made of such material will be rotten. Much care must be observed about the drying of one coat before the next is applied. The large quantity of water used in common plastering, to the injury of the wood-work, the time required to dry the building, and in winter the expense of fuel for that pur pose, are among the disadvantages inherent in its use. - Kaphle, Krishna P. GYPSUM PROSPECTS in Nepal and their Importance in Mineral Industries especially in Portland Cement Production [PDF] Bulletin of Nepal Geological Society 35 (2018). Retrieved 2021/02/12, original source: https://ngs.org.np/demo/wp-content/uploads /2019/09/ Gypsum-Prospects-in-Nepal-and-their-Importance-in-Mineral-Industries-especially-in-Portland-Cement-Production-Kaphle-2018.pdf

Excerpt:

When it is mixed with water it set as the calcium sulfate as stable dehydrated form. Gypsum is also used as filler in paper and various materials and in making adamant plaster for interior decoration and to manufacture wallboards, ceiling panels, tiles and fertilizer. - Law, Henry. "Birmingham Exhibition, 1898.—List of Awards: Silver Medals." Journal of the Sanitary Institute 19, no. 3 (1898): 468-472. Journal of the Sanitary Institute, Volume: 19 issue: 3, page(s): 468-472

Issue published: July 1, 1898

Excerpt: under "Bronze Medals" - illustrated above as an excerpt from the document, [p. 498]:

ADAMANT Co., LTD., 6, Commercial Street, Birmingham. Adamant Plaster for Walls and Ceilings. - Rosell, Thomas, "Quite Adamant, U.S. Gypsum. Sheetrock's Missing Link" [Web article] retrieved 202002/08, original source: https://misspreservation.com /2015/02/11/ quite-adamant-u-s-gypsum-sheetrocks-missing-link/#:~:text=In 1909 the US Gypsum, was an impressively fireproof material.&text =This product was coined ADAMANT Plaster Board.

- Sackett, Augustine, INSIDE WALL COVERING [PDF], U.S. Patent No. 520,123, May, 22, 1894 - shown above [Click to enlarge any image], retrieved 2018/09/05, original source: https://patentimages.storage.googleapis.com/da/b1/d9/e909b90392f24a/US520123.pdf

- Sessions, George IV, PLASTER-BOARD PARTITION, [PDF] U.S. Patent No. 511809, issued 2 January 1894

Excerpt:

Be it known that I, GEORGE WV. SESSIONS, a citizen of the United States, and a resident of Montclair, in the State of New Jersey, have invented a new and useful Improvement in Plaster-Board Partitions, of which the following is a specification.

This invention relates primarily to the employment of the building-material known as mackite manufactured under United States Letters Patent No. 386,102, granted July 10, 1888, to Adolf Mack, of Ludwigsburg, Germany,but is applicable to the construction of partitions of plaster-boards of any known or improved composition.

The invention consists in certain novel combinations of parts embodied in an improved partition, in which suitably molded plaster-boards are supported by each other and by iron uprights in the same vertical plane, so that the thickness of the boards cletermines that of the unplastered partition, and provision is made for completely filling up and masking all joints, so as to inclose and conceal said uprights and render the partition absolutely tight and rigid, by means of a coat of cement on each side, as hereinafter set forth and claimed. - Sraub, Carl, COMPOSITION of BUILDING MATERIAL for ARCHITECTURAL PURPOSES [PDF] U.S. Patent No. 392,528, issued November 6, 1888

Excerpt:

Be it known that I, CARL STRAUB, of Syracuse, in the county of Onondaga, in the State of New York, have invented new and useful Improvements in Composition of Building Materials for Architectural Purposes, of which the following is a full, clear, and exact description.

This invention consists, chiefly, in mixing with any mineral cement for architectural purposes, chiefly for plastering walls, a certain proportion of magnesia, (carbonate of magnesia calcined, or silicate of magnesia,) or in the form of steatite, talc, or mica.

The addition of the magnesia to the cement or mortarrenders the latter more easily treated by the trowel and produces a very smooth and glossy surface. It may be added to any of the compounds described in either of my prior patents, No. 353,896, dated December 7, 1886, and No. 361,601, dated April 19, 1887, and to a greater or less extent in my pending applications for patents, Serial No. 265,305, filed February 25, 1888, and Serial No. 266,447, filed March 7, 1888.

However, I prefer to mix the magnesia or its aforesaid chemical equivalents With the following composition of matter and in the manner hereinafter specified, VIZ: - Utzman, Clarence W. METHOD of MANUFACTURING PLASTER BOARD [PDF] U.S. Patent 1,029,328, issued June 11, 1912. Application filed by United States Gypsum Co.

Excerpt:

This invention relates to the method of making plaster board and aims to produce a. boardv which shall be more durable than any plaster board heretofore made and which will give better'results and more satisfactory service in use and which will hetter withstand the handling to which all plaster board is necessarily subjected.

Plaster board of various kinds have been made prior to my invention, some of which have been made in molds and others of which have been made by a continuous process consisting in applying alternate layers of plaster and paper or other fibrous material upon a traveling base sheet. The mold method of making plaster board isobjectionable., however. for the reason that the size of each slab of board is necessarily limited and` furthermore`A for the reason that this method of making boards is a slow tedious and expensive operation.

In the continuous method of making plaster board it has been the practice to superimpose the alternate layers of plaster and paper and then to trim the edges of the board leaving the raw edges of the plaster and the raw edges of the paper at each side of the board.

The paper or covering material in this construction is very easily torn and the edges of' the board are readily chipped or broken so that after repeated handlings the boards when ready for use are usually mutilated to a considerable extent.

My present invention aims to obviate the disadvantages of the boards previously employed and to construct a board. the edges of which will he entirely inclosed by a` sheet of covering material and iu which there will be no free or exposed edges of covering material which will be liable to be torn. loosened or peeled back in the handling of the board. - Utzman, Clarence W. PLASTER BOARD [PDF] U.S. Patent 1,034,746, issued August 6, 1912. Application filed by United States Gypsum Co.

Excerpt:

This invention relates tore plaster board, and aims to produce a board Which shall be more substantial, durable end efficient than any plaster board heretofore manufactured, which will give better result and more satisfactory service in use, and will better withstand he handling and rough usage to which all plsaster board is necessarily subjected.

The present application constitutes [an improved version] of my prior application, Serial No. 635,234, [patented on June ] 26th, 1911.

My invention further sims to produce a plaster boer-d the edges of which will be entirely inclosed by e sheet of covering material, end which Will have no free or exposed edges ot the covering materiel such as would be liable to be torn, loosened or peeled back in the handling of the board. - US Gypsum, History of USG [web article], retrieved 2021/02/10 original source: https://www.usg.com/content/usgcom/en/about-usg/history-of-usg.html

- Wittbecker, William A. "Inside-angle bead." U.S. Patent 1,030,044, issued June 18, 1912.

- Zippia: USG Company History Timeline [web article] retrieved 2021/02/11 original source: https://www.zippia.com/usg-careers-12236/history/

Identifying Stamps on Drywall Used for Interior Wall & Ceiling Surfaces

This discussion has moved to this separate page:

DRYWALL TYPE IDENTIFICATION STAMPS

Drywall Gypsum Board Used for Exterior Wall Sheathing

Details are now at SHEATHING, GYPSUM BOARD

Gypsum Board Lath Sheets

...

...

At GYPSUM BOARD PLASTER LATH SYSTEMS - we describe the use of perforated or solid gypsum boards as plaster base: "Rock lath", including the history of use of "rock lath" or perforated gypsum board or "button board" as a plaster base or lath-substitute material.

...

Continue reading at ASBESTOS in DRYWALL or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- ASBESTOS in DRYWALL

- ASBESTOS in DRYWALL MUD - TEST LOCATIONS

- ASBESTOS in DRYWALL TAPE?

- ASBESTOS-DRYWALL REMEDIATION / REMOVAL

- BESTWALL DRYWALL ASBESTOS

- CELOTEX DRYWALL ASBESTOS

- CERTAINTEED DRYWALL ASBESTOS

- CHINESE DRYWALL HAZARDS

- DOMTAR GYPROC ASBESTOS?

- DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- DRYWALL CONTROL JOINTS

- DRYWALL CRACK CAUSES & CURES

- DRYWALL FINISH LEVELS

- DRYWALL TYPE IDENTIFICATION STAMPS

- DRYWALL INSTALLATION Best Practices

- DRYWALL INSTALLATION HORIZONTAL vs VERTICAL

- DRYWALL GREEN LOW TOXICITY MAGNESIUM OXIDE MgO

- DRYWALL MOLD RESISTANT

- DRYWALL MOLD TESTING

- DRYWALL NAIL POPS & DENTS

- GYPSUM BOARD GYP ROCK SHEATHING

- GYPSUM BOARD PLASTER LATH SYSTEMS

- IGNIFUGE GYPSUM BOARD ASBESTOS?

- METAL LATH for PLASTER

- NATIONAL GYPSUM DRYWALL ASBESTOS?

- PICTURE HANGING NAILS to avoid damage/dust

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTER INGREDIENTS, MIX, PROPERTIES

- PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS

- SACKETT BOARD

- SHEATHING, GYPSUM BOARD

- UPSON BOARD

- WOOD LATH for PLASTER or STUCCO

- EXTERIOR-USE GYPSUM BOARD

- FM FACTORY MUTUAL DRYWALL

- GENSTAR GYPSUM LTD.

- GYPROC DOMTAR CANADIAN GYPSUM BOARD

- GYPROC IGNIFUGE FIRE RATED DRYWALL

- NATIONAL GYPSUM DRYWALL

- TruRoc DRYWALL - Canada

- ROCK LATH GYP LATH PLASTER BASE

- UL UNDERWRITERS LABORATORY STAMP on DRYWALL

- US GYPSUM SHEETROCK ASBESTOS - does Sheetrock® contain asbestos?

- US GYPSUM DRYWALL IDENTIFICATION STAMPS

Suggested citation for this web page

DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about ages & types of wall & ceiling materials, installations & practices.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.