Water System Backflow Preventers & Check Valves

Water System Backflow Preventers & Check Valves

- POST a QUESTION or COMMENT about locating, using, diagnosing, repairing, or replacing well pump check valves and foot valves.

Check valves on water supply systems:

This article explains water supply piping check valves used on both municipal water supply piping (usually near the water meter) and on private pump and well water supply systems (usually near the well pump).

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water Supply System Backflow Preventers & Check Valves

All types of check valves used on building plumbing and heating systems. Where do we find the water system check valve (if any) and why are check valves used on pump and well systems?

Types of water supply system & well system check valves, flow control valves, water pressure regulators: gravity operated check valves, spring loaded check valves for wells and water piping: selection, installation, maintenance, repair.

How to diagnose a bad or leaky check valve - a cause of lost well pump prime.

Causes of well & pump check valve failure - Check valves & air at faucets.

[Click to enlarge any image]

Article Contents

- BACKFLOW PREVENTERS on WATER PIPES

- BACKFLOW PREVENTER, HEATER WATER FEEDER

- BACKFLOW PREVENTER VALVES on HEATING BOILERS

- CHECK VALVES on DRAINS, SEWAGE PUMPS, SUMP PUMPS

- CHECK VALVES on WATER PIPING & PUMPS & WELLS

- MUILTIPLE CHECK VALVES OK?

Backflow Preventers on Water Supply Piping

Definition of backflow preventer

A "backflow preventer" is a check valve installed on potable water supply piping to prevent possible contamination of the water supply system by backflowing but contaminated water from the building into the outside public water supply mains.

In our photo (left) the blue arrow shows direction of water flow from the building supply mains into other in-building plumbing fixtures & equipment. The green arrow points to the backflow prevention device.

Use Backflow Preventers to Protect Public Water Mains from Individual Home Water Piping Contaminants

Check valves installed at the right location on water system piping are a good idea and are required by national and local plumbing codes in many jurisdictions.

In a home served by public or municipal water from a public water main, the home should have a backflow preventer to make sure that potentially unsanitary water from an individual home's piping never flows backwards into the public water mains.

You will see backflow preventers - special check valves - installed on municipal water supply piping , to prevent possibly unsanitary water from inside a building's piping from back-flowing into and contaminating the municipal water supply system piping during a time of loss of municipal water pressure.

Check Valves on Water Supply Piping & Well PUmps

On private well water systems we still make use of check valves and backflow preventers, principally to prevent loss of well pump prime and to prevent the back-flow of water out of the pressure tank into the well when the pump is not running.

Above-Ground check valves: check-valves may be built into the well pump or physically separate check valves may be installed above-ground in the well piping (shown below).

Watch out: when trying to find that leaky check valve that's draining back into the well, don't forget that some water pumps include a check valve built right into the pump body. (Thanks to reader J.S. for this reminder.)

In-Well Foot Valves: A check valve mounted in the well at the bottom of well water piping is called a foot valve and is described separately

Here we focus on water supply system check valves found on water supply piping above ground, usually in the building or right at or even part of an above ground water well pump.

Check valves used on well water system piping are used to hold pressure in the system when the pump stops.

Check valves on well piping also prevent backspin of the well pump, water hammer and upthrust inside the pump.

These problems can damage the well pump. [1]

On a well and pump water supply system a check valve may be installed between the incoming water line from the well and the water pump and pressure tank, such as shown in this photograph of a one line jet pump with a check valve right at the water pump inlet.

You can see the check valve as a bronze assembly at the face of the pump, connected to well piping in this photo.

A similar check valve is visible closer to the foundation wall in a different water pump installation shown in the page top photo.

You'll notice that this is a single line jet pump - one water line rising from the pump assembly.

Details about one line jet pumps are

The water pump check valve helps avoid loss of prime (it keeps water from flowing backwards out of the pump and water tank and back into the well when the pump motor has stopped).

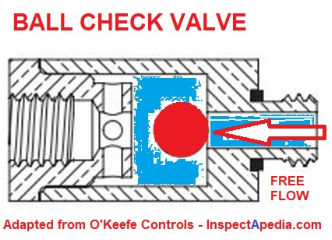

Ball Check Valves

Ball check valves are operated either by water pressure and flow or by a spring; in either case a smooth-surfaced ball closes against a machined seat inside the valve to stop water flow.

Ball valves are pretty trouble free unless subject to debris clogging or improper match of the ball valve type and ball-weight to the water velocity or drain requirements. For example a noisy ball check valve traced to water hammer noise and may be due to a valve whose ball is not heavy enough.

The life of larger or industrial ball check valves may be less than smaller residential valves. Larger check valves are typically rated at a 5-7 year life before replacement is needed.

Residential ball check valves may have an easier service life and last a bit longer.

Debris on the valve seat can prevent a ball valve from closing fully, or the valve seat may become deformed or damaged by wear or abrasion, also preventing the valve from closing as it should.

However some ball check valves (AVK, a European valve producer) are designed to be "self-cleaning". At each operation the valve rotates to avoid contaminates sticking to the ball surface.

The specific application, and the proper matching of the ball check valve to the intended use is important, as the manufacturer will supply a ball check valve with an internal ball of varying material (plastic or steel) and of varying weight, depending on how the check valve is to be used.

While a lightweight plastic ball check valve may need to be replaced after five to seven years, a heavier rubber ball type check valve might work trouble-free for 35-50 years or even longer.

Don't confuse ball check valves with ball-type shutoff valves used to manually open or close the supply of a liquid or gas through piping.

Those ball valves are discussed

at at BALL VALVES ON-OFF FLOW CONTROL

Below, a modified ball type check valve from Flood-Guard, uses a float to seal the ball against the plastic valve seal surface. Adapted from Flood-Guard valves at plumbingsupply.com

Flap or Swing Check Valves - Metal, Plastic or Rubber

Metal swing or flap type check valves use a hinged internal flapper made of metal (brass, copper, stainless steel, other) or plastic to close the valve.

The hinged flap or disc is mounted on a hinge or trunnion to allow movement between open and closed position.

Rubber flapper check valves operate like the metal or plastic swing or flapper valves illustrated above, but use a flapper made of rubber to resist mechanical wear or damage. Rubber swing check valves are more-likely to be used in lower-volume, flow, or lower pressure applications.

Swing type check valves may use a weighted disc to improve the positive close-off of the valve when flow slows or stops .

Spring type swing check valves add a spring to the check valve flapper to provide an assist to the valve's closing operation.

Swing type check valves are particularly suitable for large-diameter, high-flow-rate or high volume applications.

Illustration below: Coflex floor drain check valve. This valve is designed to be opened simply by the weighted of water that collects in the floor drain above the flapper.

Swing check valves can be clogged or jammed by debris or by damage to the valve seat, preventing the valve from closing completely.

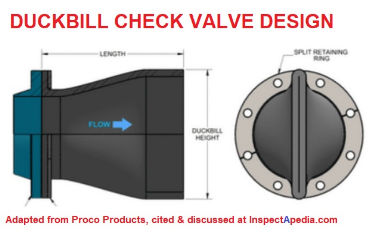

Diaphragm / Duck Bill Check Valves, Rubber

Duck bill type check valves use a flexible rubber valve mouth that is normally-closed by the simple pressure of the formed rubber, creating a normally-closed valve until water pressure forces the valve open. Other designs of duck bill valves can operate as a normally-opened valve that is closed by water pressure.

Duck bill or diaphragm check valves are used in low-pressure installations (such as a basement floor drain check valve). The effectiveness of a diaphragm valve may depend on the viscosity of the liquid flowing through it. The valve can also be blocked open by debris.

Manufacturers offer that rubber-type flapper or duck bill check valves are much less subject to mechanical wear and thus should have a longer life than their metal-flapper brothers.

Where are ball check valves and flapper check valves used

Both of these types of check valves are used in hundreds of applications and regulate flow of both liquids and gases, supplies, and drains.

For InspectApedia readers who are concerned with check valves used on building mechanical systems, the most-common check valves are used on plumbing water supply systems, drain systems, and in floor drains or condensate drains.

Check Valve Requirements for Water Wells

Backflow Prevention. All pump discharge pipes not discharging or open to the atmosphere shall be equipped with an automatic device to prevent backflow and/or back siphonage into a well.

Backflow Prevention. All pump discharge pipes not discharging or open to the atmosphere shall be equipped with an automatic device to prevent backflow and/or back siphonage into a well.

Specific backflow prevention measures are required for drinking water supply wells as prescribed in Title 17, Public Health, California Code of Regulations (Sections 7583-7585 and 7601-7605, effective June 25, 1987).

Irrigation well systems, including those used for landscape irrigation, and other well systems that employ, or which have been modified to employ, chemical feeders or injectors shall be equipped with a backflow prevention device(s) approved by the enforcing agency. - California DWR Chapter 10, 2016 cited below

What Types of Check Valves Should be Used on Well Water Piping Systems?

When installing, repairing, or updating well water piping systems, use a spring loaded check valve such as the type illustrated just below.

Spring loaded check valves close quickly, prevent water hammer, and protect the pump or impeller assembly from back-flowing; most importantly a properly functioning check valve prevents loss of prime in the well piping system.

Lost prime can result in burned-up well pump motors and of course loss of water pressure in the building.

"Drop pipe check valves" are spring loaded check valves that are designed to handle the extra weight of piping installed in deep wells where more than 100 feet of vertical well piping is installed.

Other well piping installation instructions recommend installing a check valve on every 250 feet of vertical well piping.

Do not install swing-type check valves on well piping systems. Swing type check valves permit water to flow backwards through the piping system as the valve closes, risking water hammer problems or even equipment damage. [1]

Our photos above show a typical brass well piping check valve.

A spring-loaded internal valve permits water to flow through the valve only in one direction.

The check valve helps assure that the jet pump can suck water out of a shallow well - most water pumps cannot move water if the inside of the pump assembly itself is air bound.

Atop some pump assemblies you'll see a removable pipe plug which permits water to be poured into the pump to prime it. (DO NOT pour water into or onto the electric motor itself.)

In summary, a well piping check valve prevents water from siphoning back out of the water tank and water pump and down into the (presumably lower) water well when the pump stops running.

A check valve at this location is a great idea and reduces the risk that a failure of the foot valve down in the well leads to inability of the pump to draw water.

The foot valve s located at the bottom of the well piping and intended to accomplish the same thing. This is "cheap insurance" or perhaps the foot valve has already failed (or was omitted) at this installation.

What about when we want water to siphon back out of part of a water supply system, such as when we want to drain water out of well piping exposed to freezing.

A similar check valve found typically at or close to the point at which well or lake water piping enters the base of a steel (bladderless) water pressure tank mounts both a pressure gauge and a snifter valve at tappings on the check valve top.

You can see one of these valves in our photo at left (the orange arrow points to the check valve body). This valve is installed at the water tank inlet.

Like the valve shown in our photos above, this check valve adds a 1/4" NPT tapping to accept the mount for a pressure control switch and a 1/8" tapping to accept the snifter valve for systems whose well pipes are exposed to freezing.

The blue arrow points to a snifter valve and the yellow arrow points to a rusty pipe plug where a 1/4" tapping could have been used to install a water pump pressure control switch.

See SNIFTER & DRAIN BACK VALVES for an example of where these check valves are used.

Question: I can't get the water tank to pump up.

I have an older pressure tank with bladder. I have been checking pressure yearly. This year the system started short cycling, so I drained the system after turning off power. No pressure indicated at Schrader valve.

After hooking an electric tire inflation compressor to the tank, I can't get the tank to pump up. No water comes out of the valve, and after shutting faucets and turning power back on, pressure on gauge shows 30 plus pounds kick on and just short of 50 pounds off.

Pressure at Schrader valve seems the same, but draining the system and trying to pump up to 28psi is not happening.

I would think that this means the tank bladder is ruptured, but wouldn't water come out the valve?

Appreciate any information. I am hoping it is the tank, not the check valve in the submersible pump. -anonymous by private email 2018/05/15

Moderator Reply:

Water tank air bladder problems such as a burst bladder or one which has become collapsed and stuck to itself can also cause water pump short cycling and the loss of water pressure or flow shown above.

Less common in our experience but possible is water tank inlet clogging due to a high level of sediment in the water

- source: WATER TANK DIAGNOSIS & REPAIR

If the air valve itself is not damaged, perhaps that's the trouble.

Less common still is a leak somewhere in the well piping system.

Reader follow-up: Apparently the pump check valve is bad. Pump seems to work ok.

Thanks for the information. I replaced tank, pressure switch, and put a check valve in the line. The check valve worked. Apparently the pump check valve is bad. Pump seems to work ok.

The whole system needs upgraded. I am applying for senior grant to USDA rural home program. I hope to get help with the well situation this way.

Moderator reply:

If I understand correctly it was a check valve that was "built in" to the existing pump that had failed. I forgot that possibility and will be sure to include it in future advice I may offer - so thank you for the follow-up.

Pros & Cons of Installing Multiple Check Valves on Wells, Pumps, Water Piping

Question: Can I Install a Second Check Valve Near my (above-ground) Well Pump to Prevent Loss of Prime?

I have a small vacation place in VA. It has a 75' well with 1/2 HP jet pump that works fine. Of course, it has the check valve down in the well that works good but I've always been concerned that it may leak down and lose the prime over the winter months when we are not there.

So, I just leave the power on, although I would prefer to turn it off when winter is approaching.

My question is: could I not install another check valve near the pump inlet as a double protection against loosing my prime IF the power is cut off for a 3-4 month period? BUT, if I DID loose prime for some reason, would not the top check valve have to be removed to allow me to prime the pump? - C.S.

Reply: Multiple Check Valves are Generally Not Recommended

I've found the same problem C.S. - a well and pump system that seemed to be just fine and seemed never to lose prime, until we left power off to the pump for a few days. A leaky foot valve slowly leaked all of the water backwards into the well from the pressure tank and jet pump, losing pump prime in the process.

Most plumbing experts agree that if you are having a problem with a leaky check valve at the pump or in the well, it's best to replace the valve. Here are details and some explanation:

It seems so easy that it is tempting to can add a second check valve if the primary check valve, probably the foot valve in the well seems to be misbehaving.

Some Experts Recommend Multiple Check Valves on Well Piping

The Water Systems Council recommends multiple check valves on well piping in some conditions. Paraphrasing, editing and expanding the WSC advice on using check valves with well pump installations::

Jet pumps often incorporate a check valve in the front of the pump assembly.

More than one check valve should always be used in submersible pump installations.

On a submersible well pump installation, if your well water pump does not have a built-in check valve [many submersible pumps do have a check valve], a line check valve should be installed in the discharge pipe within 25 feet of the pump and below the drawdown level of the water inside the well.

For deeper well pump settings, a line check valve is recommended every 200 feet. [1]

Problems With Multiple Check Valve Installations on Well Water Piping

But there can be some problems where multiple check valves are installed:

- Reduced water flow:

Adding more check valves will also increase the friction loss or obstruction in the well piping, reducing water flow a bit. If your well pump and water flow were marginal you might notice that effect. - Water hammer caused by second check valve:

When there is a second check valve (besides the foot valve in the well) above ground at the pump, it is possible that the presence of the second valve will add to or even create water-hammer noise in the building.

Folks who write about water hammer and check valves argue that because the second valve allows the pump to start against so little resistance that the column of water in the piping between pump and foot valve rises rapidly and "bangs" into the second check valve and pump housing, causing water hammer.

We have read that this problem on large pump and well systems can actually interfere with proper operation of the pressure control switch by causing the switch to "bounce" between the "open" and "closed" positions.

Bottom line: replace the existing leaky check valve. If the leaky check valve is the foot valve in the well you'll face the more troublesome task of opening the well and pulling up the well line and foot valve.

But doing so allows inspection of the well line - you may discover that the problem was not even the foot valve, but a hole in the well piping.

See AIR DISCHARGE at FAUCETS, FIXTURES where this is discussed.

Many plumbing experts advise that unless the check valve is part of a water tank makeup air system, it's best to use just one check valve is needed and just one should be installed in most cases

. If the check valve on a jet pump has failed, it makes sense to replace the valve, or if needed, the pump assembly.

You can still go ahead and install the second valve if you want to give it a try - but be prepared to remove it if it causes these problems.

Watch out: some U.S. state plumbing codes (Wisconsin perhaps) may prohibit above-ground check valves on well lines, presumably to reduce the chances of drawing contaminants into the well piping and well.

Some Experts Advise Against Multiple Well Piping Check Valves

Watch out: Other well installers and plumbers do not agree with the Water Systems Council advice cited above.

These experts recommend that you do not install a second check valve on submersible well pump systems; rely on the valve that is on the submersible pump.

A second check valve can cause contaminants to be drawn into the piping system, or if the second check valve is inside the well (on the vertical well pipe but above the pump), as in our discussion above it may cause water hammer problems in the system.

If the check valve on a submersible pump has failed, you should pull the pump and replace that valve.

Where Multiple Check Valves Are Recommended on Well Piping Systems

You may need to install a check valve on the vertical well piping at a rate of one for every 250 feet of vertical rise in the well bore. We mentioned earlier in this article series that

"Drop pipe check valves" are spring loaded check valves that are designed to handle the extra weight of piping installed in deep wells where more than 100 feet of vertical well piping is installed.

Other well piping installation instructions recommend installing a check valve on every 250 feet of vertical well piping.

Short Cycling of the Water Pump Reduces Check Valve Life

Note: well pump "short cycling" or rapidly turning on and off increases check valve wear and so shortens their life. See our article on well pump short cycling. And variable speed pumping systems (Franklin Sub Drive/Mono-Drive) that cycle the pump on and off very rapidly are still harder on both the pump and the check valve.

Details are

Heating System Backflow Preventer Valves Protect Public Water Mains / Private Water Piping from Heating System Water Contaminants

Because a building potable water supply piping cold water line is used to deliver water to hydronic or steam heating boilers, we need to prevent heating system water from back-contaminating the building water supply piping.

At a hot water heating system a backflow preventer is installed to keep hot, high pressure water in the hydronic heating system from flowing backwards through a boiler water feed line into the building water supply - a sanitation concern.

On heating systems the backflow preventer may be built into the automatic water feed valve

BACKFLOW PREVENTER, HEATER WATER FEEDER

and/or a separate dedicated check valve

BACKFLOW PREVENTER VALVE, HEATING SYS - such as the one in our photo (left) may be installed..

In our heating system backflow preventer photo (green arrow, above) The blue arrow shows the direction of water flow into the water feeder and onwards into the heating boiler.

Reader Question: leaks from the Apollo dual check valve on my heating boiler

2015/12/15 David said:

My boiler system has an Apollo dual check valve with atmospheric port . Water continues to run out of the bottom of the valve

Reply:

David,

The Apollo check valve on your boiler probably needs repair or replacement.

First: check the operating pressure of the boiler. At full operating temperature the system pressure should be under 30 psi.

When the boiler is cold, the pressure should be around 12-18 psi. If the boiler pressure is abnormally high the problem is elsewhere - a bad water feeder or a tankless coil leaking into the boiler.

If the boiler pressures are normal then I suspect a valve seal, valve packing, or seat needs repair or replacement.

On some (not all) Apollo check valves, for example the Bronze 30 & 30LF series Models 101T/101TLF and similar model numbers, the valve includes a packing nut that can be tightened to stop leaks at the valve stem or bonnet.

If there is no more travel to tighten the nut further then the packing needs replacement. Your valve, whose model you didn't give, is likely to be a different model and will operate differently.

Make a note of the model of your Apollo valve. With that information you can download an installation and operation manual (IOM manual) from the manufacturer. Most likely you'll need to ask your heating service company or plumber to perform the repair.

- Apollo Valves Contact Information: Apollo Valves, 1418 S. Pearl St., Pageland SC 29728, USA,

Telephone: Customer support telephone 1-704-841-6000 / 1-843-672-1644

Website: http://www.apollovalves.com/

Above, an Apollo dual check valve, model 4ALF104A2F. This is a bronze valve rated for water up to 180 degF and a maximum pressure of 175 psi. This is a member of the Apollo series 4ALF-100 check valves.

Check Valves on Building Drains, Floor Drains, Sewer Lines, Sump, Effluent & Sewage Ejector Pumps

Our photo illustrates a brass check valve installed on the discharge line of a sewage ejector pump. As we note

Our photo illustrates a brass check valve installed on the discharge line of a sewage ejector pump. As we note

at SEPTIC / SEWAGE PUMP DISCHARGE VENT,

a small vent opening is recommended in the discharge line below the basin cover. See that article for details and for a warning that you may not want the vent hole on high head (high lift) sewage, sump, or effluent pump installations.

Check valves on sump pumps:

Check valves are used in other plumbing applications as well, such as on sump pump drain lines to prevent back-flow of water from the sump pump exit piping into the sump pit when the sump pump turns off.

See SUMP PUMPS GUIDE

Check valves on sewage ejector pumps:

check valves on sewage pumps are used to prevent backflow of sewage into the building piping or sewage pumping chamber from a sewer main (or septic tank) located higher than the building.

See SEWAGE PUMPS for details.

Check valves on building drains

are installed to prevent sewage backups into buildings. Check valves are also installed on drain piping such as on some sewer lines (where sewer backups are likely) and on sump pumps discussed

at this article on sewer backup prevention by using

Check valves or self-priming traps on floor drains:

Keep in mind that many basement floor drains don't include a trap and may need one to stop smells from that source.

Dry traps at un-used sinks in a basement or other building area are also common sources of sewer smells in buildings. Because sewer gas contains explosive methane, it can be dangerous.

Details are at FLOOR DRAIN / TRAP ODORS

While some floor drains are routed independently to an acceptable drainage destination such as daylight above-ground or to a storm drain, others are connected to the building DWV system and ultimately to a septic or sewer piping system.

Piping the floor drain to a septic system is not a smart idea as it risks overloading and damaging the septic system.

Piping floor drains to a community sewer or storm drain system is prohibited in some jurisdictions.

Shown just above and in detail below, a silent check valve combined with a water hammer arrestor that might be used on an ejector pump or sump pump system, the "Basement Watchdog" model KCV.

Description of Types of Water Flow Control Valves & Water Pressure Regulators

Question: What's a flow control valve and why are they used on water well piping systems

I've heard that some well water systems need a flow control valve. What is a flow control valve and why would one be used on well piping? - Anon

Reply: Description of the water flow control valves & types of water pressure regulators & their applications

According to the Water Systems Council [paraphrased, edited, and expanded-Ed.]

Flow-control valves are used on well water piping systems in order to reduce or limit the amount of pump capacity - that is, to control the rate or flow of water delivered by the well pump. Flow control valves are installed mainly to prevent an overload on the well pump motor (thus limiting the current or amps drawn by the well pump) and also to control the degree of up thrust pressure on the water pump.

When well flow rate and well pump flow rate capacity conditions could allow the water pump to deliver too much capacity, a flow control valve may be installed to restrict the water flow to an adequate amount while preventing it from being excessive.

For example, a flow rate valve may be installed on a well system at which the well flow rate is rather poor. This prevents the pump from getting "ahead" of the in-flow rate of water into the well, thus protecting the well pump from running dry and becoming damaged.

Flow-control valves of this type are also installed on showers or other water-using appliances to limit the gallons-per-minute flow to these outlets. A set flow rate to equipment such as irrigation systems can also be maintained with flow-control valves. [1]

Flow control of municipal water supply into a building

is provided by a water pressure regulator, a similar device that drops high incoming pressure at the water main down to (typically) 70 psi or less in order to protect the building piping from leaks caused by excessive water pressure. Details are

at WATER PRESSURE REDUCER / REGULATOR

Flow-control of domestic hot water

is also often limited by a flow control valve or tempering valve where the hot water source is of limited flow rate capacity, such as at tankless coils and at demand or tankless water heaters.

In that case we limit the flow rate of cold water through the hot water heating device to a rate slow enough that the water will be adequately heated.

See TANKLESS COILS

and TANKLESS WATER HEATERS for details.

Water feeders & pressure regulators

for heating equipment: hot water heating boilers & steam boilers are also protected from water loss by several types of automatic water feed valves that add water to the heating system when needed.

Hot water heating system automatic water feeder/pressure reducing valves at factory setting typically will feed water into a Hydronic heating boiler up to a 12 psi cutoff (or higher if necessary) if the system pressure when cold falls below 12 psi. Details are

at WATER FEEDER VALVES, HYDRONIC BOILER

and at WATER FEEDER VALVE, STEAM or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Check Valve Research: types, sources, life

Research on the Use of Check Valves on Heating Systems

- Charoensawan, Piyanun, Sameer Khandekar, Manfred Groll, and Pradit Terdtoon. "Closed loop pulsating heat pipes: Part A: parametric experimental investigations." Applied Thermal Engineering 23, no. 16 (2003): 2009-2020.

- Meena, P., S. Rittidech, and N. Poomsa-Ad. "Closed-loop oscillating heat-pipe with check valves (CLOHP/CVs) air-preheater for reducing relative humidity in drying systems." Applied Energy 84, no. 4 (2007): 363-373.

- Pandula, Zoltán, and Gábor Halász. "Dynamic model for simulation of check valves in pipe systems." Mechanical Engineering 46, no. 2 (2002): 91-100.

- Rafferty, Kevin. "Design aspects of commercial open-loop heat pump systems." Geo-Heat Center Quarterly Bulletin 22 (2001): 16-24.

- Rittidech, S., N. Pipatpaiboon, and S. Thongdaeng. "Thermal performance of horizontal closed-loop oscillating heat-pipe with check valves." Journal of mechanical science and technology 24, no. 2 (2010): 545-550.

Check valves used on sewage and other drain systems

- Also see the citations and references

at SEWER BACKUP PREVENTION - American Water Works Association, AWWA C508. “Check Valves 2 in. through 24 in”, Denver, Colo.

- AquaTech, CHECK VALVES: OUR ESSENTIAL GUIDE TO WATER'S UNSUNG HERO [PDF] AquaTech, RAI Amsterdam Aquatech P.O. Box 77777 1070 MS Amsterdam Europaplein 24 1078 GZ Amsterdam The Netherlands - retrieved 2022/07/23, original source: https://www.aquatechtrade.com/news/water-treatment/check-valves-essential-guide/\

- Ballun, John V., (2007). “A Methodology for Predicting Check Valve Slam”, Journal AWWA, March 2007, 60‐65.

- Ballun, John V. "Choosing the Right Valve for Surge Control." Opflow 31, no. 3 (2005): 14-16.

- FLOOR DRAIN / TRAP ODORS details solutions to odor or sewage backup problems at un-trapped or dry-trapped floor drains

- Des Champs, Nicholas, H., Ph.D., P.E., Fellow ASHRAE, HVAC, CHECK VALVE ALTERNATIVE to P-TRAP for HVAC CONDENSATE [PDF] (2020) HPAC Engineering, eNewsletter, Web: hpac.com - retrieved 2022/07/23, original source: https://www.hpac.com/piping-pumping/article/21130312/time-to-reconsider-use-of-ptraps-for-condensate-removal

- Dickenson, T. Christopher. Valves, Piping, and Pipelines Handbook. Elsevier, 1999.

- Gagliardi, Michael G., and Louis J. Liberatore. "WATER SYSTEMS PIPING." in PIPING HANDBOOK (7th Ed.) [PDF] (2000) McGraw Hill, ISBN 0-07-047106-1 - retrieved 2022/07/23, original source: https://d1wqtxts1xzle7.cloudfront.net/

- Lee, Joseph HW, David L. Wilkinson, and Ian R. Wood. "On the head-discharge relation of a" duckbill" elastomer check valve." Journal of Hydraulic Research 39, no. 6 (2001): 619-627.

- Lee, Joseph HW, Jaydeep Karandikar, and Peter R. Horton. "Hydraulics of “duckbill” elastomer check valves." Journal of Hydraulic Engineering 124, no. 4 (1998): 394-405.

- Thomasnet, PREVENTIVE MEASURES TO AVOID CHECK VALVE FAILURES, IN THE ESSENTIAL GUIDE TO PREVENTING CHECK VALVE FAILURE, [PDF] (2018) Thomas Engineering, - retrieved 2022/07/23, original source: https://www.thomasnet.com/insights/guide-to-preventing-check-valve-failure/

- Valmatic, DESIGN and SELECTION of CHECK VALVES [PDF] (2018) White Paper, Val‐Matic Valve & Mfg. Corp. • www.valmatic.com • valves@valmatic.com • PH: 630‐941‐7600, - retrieved 2022/07/23 original source: https://www.valmatic.com/Portals/0/pdfs/DesignSelectionCheckValves.pdf

Check valve research of interest for water supply & well piping systems

- AVK, WHAT is A BALL CHECK VALVE [PDF] AVK International, AVK International A/S Bizonvej 1, Skovby, 8464 Galten, Denmark Tel: +45 87 54 21 00 - retrieved 2022/07/23 original source: https://www.avkvalves.eu/en/insights/product-insights/check-valves/ball-check-valves

- Lee, Joseph HW, David L. Wilkinson, and Ian R. Wood. "On the head-discharge relation of a" duckbill" elastomer check valve." Journal of Hydraulic Research 39, no. 6 (2001): 619-627.

- Lee, Joseph HW, Jaydeep Karandikar, and Peter R. Horton. "Hydraulics of “duckbill” elastomer check valves." Journal of Hydraulic Engineering 124, no. 4 (1998): 394-405.

- O'Keefe, LONG LIFE CHECK VALVES [PDF] O'Keefe Controls Co.,., PO BOx Q, Trumbull CT 06611 USA, Tel: 800-533-3285 Web: www.okcc.com Email: ca@okcc.com

- Puchovsky, Milosh, P.E., FSFPE, " NFPA 20: Changes to the standard on fire pumps - Regardless of whether the 2013 edition of NFPA 20 will be applicable to your next project, fire protection engineers need to be aware of the changes to the standard." - CSE Magazine - By Milosh Puchovsky, PE, FSFPE, Worcester Polytechnic Institute, Worcester, Mass 11/15/2012

- Pandula, Zoltán, and Gábor Halász. "Dynamic model for simulation of check valves in pipe systems." Mechanical Engineering 46, no. 2 (2002): 91-100.

- Spears CHECK VALVES [PDF] Spears Manufacturing, retrieved 2022/07/23

This catalog illustrates True Union ball check valves, Industrial Swing Check Valves, smaller Utility Swing & Spring Check Valves, Compression Swnig & Spring check valves, Y-Check Valves, Butterfly Check Valves, Diaphragm Check Valves, In-Line Adjustable Check Valves, noise-eliminating Check Valves used on sump pumps or sewage ejector systems, and Backwater valves.

The catalog is helpful in giving typicall applications of each of these types of check valves. - Thorley, A. R. D. "Check valve behavior under transient flow conditions: a state-of-the-art review." Journal of Fluids Engineering 111, no. 2 (1989): 178-183.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-08-23 by InspectApedia Publisher

@Wane,

Thanks that's a helpful question - and one that needs some research; did you look at the check valve installation instruction examples given at our lead article above on this page?

Also, please help us out by telling me what led you to post this question on our Contact page rather than on the article topic page? Was the website confusing or hard to navigate?

On 2023-08-23 by Wane

Hi,

To prevent a sewer backup, we installed a normally closed check valve, the city requirement are to add a venting downstream the ckeck valve, what is the maximum distance to add from the check valve? Thanks.

This reader's Q&A were originally posted at HOW TO CONTACT InspectApedia.com

On 2020-11-15 - by (mod) -

Timothy

In the article index you want to take a look at our article on WATER HAMMER

To see the diagnostic suggestions there.

The fact that you have repaired the line between pump and house several times and certainly suggested that there may be a leak somewhere in that piping system

On 2020-11-14 - by (mod) -

Greg

That's a good guess;

Or there could be a subtle leak - a running toilet or a leak in well piping.

See WATER PUMP INTERMITTENT CYCLING https://inspectapedia.com/water/Intermittent-Water-Pump-Cycling.php

for some diagnostic suggestions

On 2020-11-14 by Greg lueders

Water pressure drops at well tank when water is not in use,could this be a bad check valve

On 2020-11-13 by Timothy Bennett

Our house is on a hill. We have City water but it requires a boost pump to lift it 700 ft to the house. The house has a pressure tank under it. Built in 1978. We have been here 4 years. When the pump kicks in there is a loud bang under the house as the incoming pipe hits the joists.

Usually this is at its worse when the pump has not been needed for a while. Now we are getting some air in the pipes in the house. I have checked under the house for leaks.

Checked around the boost pump for leaks. The PVC line from the pump to the house has been repaired 3 times by me and several times by the previous owners. The pressure tank seems to be working fine. I suspect a leak in the main line. Any suggestions?

Thanks

On 2020-11-11 by Mod: ball valve life, noise, & troubleshooting

@Anthony:

We're discussing ball valves used to shut off water or heating water flow (not ball check valves that are described above on this page).

The control valve about which you are asking is discussed

at BALL VALVES ON-OFF FLOW CONTROL

On 2020-11-11 by Anthony

Dan - appreciate the quick response. I will have a plumber come fix the leak for me since I'm nervous about doing my own plumbing work.

Thanks for also pointing out the GFCI issue - I checked and was surprised to find it's not downstream of one of the existing GFCIs in the kitchen.

If I were to buy a new cover for the receptacle box that fits two GCFI receptacles and replace the 2 existing duplex outlets with 2 GFCIs, would that be sufficient protection? Or is there something I should to do upstream of the receptacle box itself?

One other random question - do you know what is the typical useful life for the ball-type shutoff valves shown in the picture?

We have >20 of them in our apartment (because we also have hydronic heat) and they're all ~20 years old so I'm wondering when / if I should ever worry about one of them potentially failing.

On 2020-11-10 - by (mod) - hot water pressure regulator installed under kitchen sink

Anthony:

Anthony:

That's unusual, I agree; someone has installed a pressure regulator on the hot water line under your sink: we don't know why, but possibly to try to limit hot water flow there so as to help assure simultaneous hot water flow at other plumbing fixtures in a house with poor hot water pressure.

In my annotations on your photo I identify various components and leak indicators.

The fact that there is water inside the pressure gauge tells us the gauge has failed and is leaking internally. It might also be leaking from a poor seal on the gauge mounting base threads, too, but that's moot as the first observation means the gauge needs to be replaced.

As a temporary fix you could shut off water (the shutoff valve pointed-to by the yellow arrow near top right),

then open the fixture valve above or alternatively remove the drain plug to remove pressure (this is an optional step to avoid getting squirted with water)

then remove the gauge and install a pipe plug (probably 1/4" NPT) into the Tee where the gauge was mounted.

Or you can buy a new pressure gauge, coat the threads with pipe sealant or teflon tape, and install it.

Watch out: In general I am nervous about pressure gauges left in locations like this one as should the gauge break it will flood the home with water until someone notices the break and turns off the water supply.

If for some mysterious reason someone needed to be able to check the water pressure being delivered through that pressure regulator valve, a better installation would have been to include a shutoff valve between the gauge and the rest of the water supply piping (to the left of the gauge in your photo.

Then the shutoff valve could be left normally closed, avoiding the risk of a building flood from a burst gauge. When it is necessary to check pressure you'd simply open the valve, check the pressure, then close the valve again.

For your repair, to add a shutoff requires soldering or sweating copper piping - not technically difficult but if you don't already have the necessary soldering and pipe cutting equipoment and know how to do that I recommend hiring a plumber instead.

For your repair if you want to just install a new gauge or a pipe plug, that repair is easier and can be done by a handy homeowner.

But

Watch out: when installing or removing a pressure gauge, never try turning the gauge by twisting the gauge itself; always use a wrench on the brass fitting at the gauge base.

Otherwise you may simply twist off and break the gauge, cut your hand, and flood the bathroom.

Watch out: also, that quad-electrical receptacle box is unsafe in that location unless that circuit is protected by a ground-fault circuit interrupter (GFCI) - search InspectApedia.com for GFCI requirements to read details.

More details are at

WATER PRESSURE GAUGE INSTALLATION GUIDE

On 2020-11-10 by Anthony - purpose of valve & pressure gauge on hot water supply under kitchen sink

I have this hot water plumbing setup under my kitchen sink.

Can anyone tell me what the purpose of the valve and pressure gauge is (and why the gauge reads 0 when water pressure is good/works well)? I live in a multi unit apartment building. The hot water leads to both the kitchen faucet as well as the dishwasher.

The pressure gauge has developed a very slow drip leak when hot water is running. It looks like maybe because Teflon tape isn’t fully watertight anymore? I’m not sure. Is this something I should just call a plumber to fix?

Thanks!

[Photo above]

On 2020-09-20 by (mod)

Joe

The problem could be a poor flow into your well.

But there are some other things to check. Lets start with our list of reasons that a water pump water stop running in the article you will find at

WATER PUMP WONT STOP RUNNING

On 2020-09-20 by Joe

I started to wash my truck yesterday and when I was rinsing it off, all of a sudden the water just stopped spraying. I went to check the well pump and found it to be running. I have a 40-60 pressure switch but as the pump continues to run, the pressure never builds to above 30-32 psi. It needs to get to 60 psi to shut off.

The tank pressure is at 38 psi. There is no foot valve in the well, just the sub. pump and a check valve above it.

Should I be suspecting a bad check valve or something else? Thanks very much. I really appreciate this site being here and have referenced it many times.

You folks are very kind to lend your expertise to those of us who seek it.

On 2020-04-13 by (mod) - bury a steel check valve underground?

Gord

Yes if you buy the right type of check valve. An example of a check valve that might be buried, provided it is protected from frost damage is this Simmons 1" NPT Bronze spring type check valve, described under "Resrictions" as "This product has been certified by a third party to be compliant with the “Safe Drinking Water Act” requirements for low lead in potable (human consumption - drinking and cooking) and non-potable water applications (non-human consumption)."

Common materials include plastic, brass, stainless steel, many of which (not all) are rated for use with potable water.

Shown here: a Simmons 503SB check valve cutaway to illustrate how the valve works and where the valve seat is located.

On 2020-04-13 by gord.gray59@gmail.com

Can you bury a steel check valve underground?

On 2020-03-06 by (mod) - source of bi-directional check valves - RV-use

Lac

Lac

Thanks for an interesting and very useful question: how do we get check valves working in two different directions.

Most water line check valves are uni-directional.

I'm looking for bi-directional check valves (allowing no flow in either direction ) which isn't exactly what you want - in hope that we might find one that includes a manual switchover.

Another easy option is installing a couple of stop valves, a bypass line, and then installing the a check valve facing in or permitting flow in the desired direction in each of the two water line passages.

For winter use you close off the into-house-loop and open the back-to-lake loop.

FYI JR Products makes a bi-directional checkvalve (for RVs) but from what I see that might not be what you want. Try giving the company a call re:

Product Description: Fresh Water Check Valve; Bi-Directional Flow; 1/2 Inch MPT x 1/2 Inch FPT; Lead Free Brass

JR Products Website: https://jrproducts.net/product/62195/ JR Products

9680 County Road

Clarence Center, NY 14032

Phone Number

1.800.269.7622

Consumer Email

Customer Service: customerservice@jrproducts.net

Commercial Accounts Email

Sales: sales@jrproducts.net

On 2020-03-06 by lacjustone@hotmail.com

looking for a check water check valve working on both ways : to feed a house on a hill ( 150' high X 300' long ), keeping the water in the pipe in the summer and pushing back the water into the pump into the lake in the winter time. Someone can answer that ?

On 2019-12-2 - by (mod) -

Douglas

I don't know where you heard that, but check valves are used regularly on well systems - otherwise water would flow backwards into the well and on a one line system would lose prime and the system would stop working. A deep well may in fact use multiple check valves on the well riser line in the well too.

On 2019-12-25 by douglas

I've heard a check valve, back flow preventer is illegal on a well pressure tank

Question: gauge jumps from 0 to 50 but we have no water

(Feb 23, 2016) larry.carpenter@windstream.net said:

Question: With no power on well, gauge is on 0. As soon as power is turned on, pressure jumps to 50 lbs, but NO water.

Reply:

Sounds wierd to me too. I wonder if the gauge is functioning properly and if the pump is even delivering water. I'd start by checking right at the pump to see if it's delivering water or not.

Search InspectApedia for DIAGNOSTIC TABLE for WATER PUMPS or search

for NO WATER PRESSURE to see detailed procedures and suggestions.

Question: water pressure gauge drops to zero - is this a bad switch or a clog?

(Apr 13, 2016) jeff said:

I have a problem the pump pool pump up to 60 shut off then if you turn the shower on and run it long enough it'll get to 40 and then the whole pressure switch gauge drops to zero and then later it gets back on is the switch bad or is there a clog in the line going to the switch

(July 6, 2016) Bryan said:

having issue with the pump/silinoid not cutting in when the pressure drops. it is a square D valve with the single but adjustment.

Reply:

Jeff, I'm a bit confused: a pool pump? that sounds like part of a swimming pool - it ought have nothing to do with shower water supply.

It sounds as if your water supply is running out (pressure drops to zero, later recovers) or the switch could be sticking and not switching on the pump when it should.

Bryan, Chances are the switch pressure sensing port or tube that carries pressure to the switch is clogged; I'd replace the switch and tube.

Question: check valves on water supply to fire fighting pumps

2 July 2015 Vincent Iweze said:

Can a check valve be mounted directly on a foot valve for negative suction in fire fighting pump installation

Reply:

VIncent

The foot valve is itself a check valve.

For deep wells (hundreds of feet) the well pump manufacturer will usually recommend additional check valves at intervals in the riser pipe.

But there are special requirements for check valves on water supply systems and pump systems used fire fighting applications.

Take a look at NFPA:20 available from nfpa.org:

NFPA 20 protects life and property by providing requirements for the selection and installation of pumps to ensure that systems will work as intended to deliver adequate and reliable water supplies in a fire emergency.

The following excerpt is quoted from an article by Milosh Puchovsky in CSE Magazine in 2012:

Certain devices in the suction piping can cause an undesirable degree of uneven flow and turbulence, and impede pump operation and performance. NFPA 20 currently states that within 50 ft of the pump suction flange, no valve other than a listed outside stem and yoke (OS&Y) valve can be installed in the suction piping.

This provision was revised to clarify that no “control” valve other than a listed OS&Y valve is to be installed within 50 ft. The provision was further revised to specifically address backflow devices.

These changes provide for better consistency with other provisions of the standard and clarify the intent of the requirement, which is to restrict only the use of butterfly valves, and allow the installation of OS&Y gate valves, check valves, and backflow devices in the suction piping.

Note, however, that the installation of check valves and backflow devices in the suction piping is only permitted where such devices are required by other standards or by the AHJ.

Where a check valve or backflow prevention device is required upstream of the fire pump suction, NFPA requires the device to be a minimum of 10 pipe diameters upstream of the pump suction flange. - Puchovsky, Milosh, P.E., FSFPE, " NFPA 20: Changes to the standard on fire pumps -

Regardless of whether the 2013 edition of NFPA 20 will be applicable to your next project, fire protection engineers need to be aware of the changes to the standard." - CSE Magazine - By Milosh Puchovsky, PE, FSFPE, Worcester Polytechnic Institute, Worcester, Mass

11/15/2012

On 2015-05-09 - by (mod) -

Joe

If you are unable to prime the pump because pouring water into the pump and through it down the well pipe never fills up those components I suspect either a leak in well piping or a failed foot valve. Search InspectApedia for "how to prime the well" if you want more help with that approach.

On 2015-05-09 by joe

my pump runs no water how can I tell if check valve is bad

On 2015-05-09 - by (mod) -

Leon

Match it as close as possible to the pipe diameter.

On 2015-05-07 by leon

what size check valve should I use on a shallow driven

well

On 2015-04-13 - by (mod) -

Walt

That's a common repair effort that might work; some pump manufacturers warn that multiple check valves in the system can cause malfunctions but that advice is inconsistent with standard advice for deep well submersible pump installations: there we're advised to install an additional check valve for every 150 feet of lift. So IMO bottom line, try it.

On 2015-04-11 by walt

is there a disadvantage to installing a check valve at the pressure tank if the check valve on the submersible pump is not working?

On 2015-02-25 - by (mod) -

JD

If your installer can show you a clogged check valve s/he'd be on reasonable ground, as if a pump can't push water into the pressure tank to satisfy the pressure control switch it'd keep running and risk burnout.

Flow reducers have a different purpose: to slow the flow rate out of the well in an effort to avoid burning up a pump in a well that has a slow recovery or flow rate into the well bore. The presence of that device on your system makes me suspect that the root problem is poor well flow rate; if the pump gets ahead of the flow rate into the well bore it can indeed burn up unless it's protected.

InspectApedia has more advice about well pump protection devices: See WATER PUMP PROTECTION SWITCH at https://inspectapedia.com/plumbing/Pump_Protection_Switches.php

On 2015-02-25 by JD

My well pump was replaced 15 months ago and burned out last week. The installer thought the problem was due to iron in the water clogging the check valves. Besides the check valve that comes in the pump there is a gate type check valve and an additional spring check valve above the pump. There is also a 6 GPM reducer in addition to the 3 check valves. Does this seem excessive?

...

Continue reading at WATER PRESSURE REDUCER / REGULATOR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CHECK VALVE FAQs - questions and answers posted originally on this page.

Or see these

Recommended Articles

- BACKFLOW PREVENTER VALVE, HEATING SYS

- BACKWATER VALVES, SEWER LINE

- CHECK VALVES, HEATING SYSTEM

- CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS

- FLOOR DRAIN / TRAP ODORS

- SEWER BACKUP PREVENTION - check valves to avoid a sewage backup

- SNIFTER & DRAIN BACK VALVES

- WATER FEEDER VALVES, HYDRONIC BOILER

- WATER HAMMER NOISE DIAGNOSE & CURE - check valves can reduce water hammer problems

- WATER PRESSURE REDUCER / REGULATOR

- WELL PIPING FOOT VALVES - check valves used in pump systems to prevent loss of prime

Suggested citation for this web page

CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING VALVES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Water Well Standards", [PDF] California Department of Water Rresources, 1416 9th Street, Sacramento CA 95814, TEl: 916-653-5791, DWR Chapter 10, retrieved 2016/06/10, original source: http://www.water.ca.gov/groundwater/well_info_and_other/california_well_standards/wws/wws_combined_sec10.html

- Pandula, Zoltán, and Gábor Halász. "Dynamic model for simulation of check valves in pipe systems." Mechanical Engineering 46, no. 2 (2002): 91-100.

- Thorley, A. R. D. "Check valve behavior under transient flow conditions: a state-of-the-art review." Journal of Fluids Engineering 111, no. 2 (1989): 178-183.

- Dickenson, T. Christopher. Valves, Piping, and Pipelines Handbook. Elsevier, 1999.

- [1] wellcare® information for you about Well Components: Valves, web search 12/3/2011, original source: http://www.watersystemscouncil.org/

VAiWebDocs/WSCDocs/789912Valves_FINAL_507.pdf Quoting:

wellcare® is a program of the Water Systems Council (WSC), the WSC website: www.watersystemscouncil.org.

This publication was developed in part under Assistance Agreement No. X-83256101-0 awarded by the U.S. Environmental Protection Agency. It has not been formally reviewed by EPA. The views expressed in this document are solely those of WSC. EPA does not endorse any products or commercial services mentioned in this publication. - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.