Hardboard Siding

Hardboard Siding

Identify, Inspect, Repair,

Hardboard/Fiberboard Siding Failures

Warranty Claims for Hardboard, Fiberboard, Pressboard, Engineered Wood Siding

- POST a QUESTION or COMMENT about hardboard siding failures, claims, replacement, repair, painting, maintenance

Hardboard siding, made from wood fiber & additional ingredients: identification, failures, claims.

Here we explain how to identify brands & types of hardboard siding, how to find, diagnose, and repair building exterior hardboard siding defects, and we give links to hardboard siding failure claims websites.

Hardboard siding, often named by a particular brand such as Masonite is a wood-based exterior wall covering combines wood fibers, perhaps sawdust, along with adhesives, resins, heat and pressure to produce siding boards with a smooth or an embossed wood-grain pattern surface.

At page top we show a bottom-grooved hardboard siding photographed in 1999. We think this is a Weyerhaeuser or Hardieboard siding product dating from the 1990's.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Hardboard, Composite, List of "Masonite"-type Siding Failures & Claims Information, Hardboard Siding Failure Diagnosis, Repair, Proper Installation

As we've seen in decades of building inspections, several hardboard-based and fiber cement based building exterior siding products have not performed as well as originally anticipated, experienced early failure, and were the subject of building siding warranty claims.

Failures of hardboard or pressboard siding are usually obvious: loss of the surface coating, swelling, softening, and ultimately loss of board material, as you'll see in photos on this page. That damage usually is worst near the wall bottom where it is more likely to be wet by rain splash-up of water falling off of the building roof.

Failed hardboard/pressboard siding is not repairable. It will need to be replaced.

Most U.S. manufacturers stopped producing the type of hardboard siding described on this page after 1994 when class action litigation (Naes et al. v. Masonite Corp. and International Paper Co., No. CV-94-4033 (AL Cir. Ct., Mobile Cty.) was settled, providing damage reimbursement for owners of buildings on which this siding product type was installed over the eighteen year period of January 1 1980 through January 15 1998.

A similar case involving Weyerhauser Co. hardboard siding was settled in 2000, with payout to owners of buildings where Weyerhauser hardboard siding was installed between 1 January 1981 and 31 December 1999.

Below on this page we provide an alphabetical index to hardboard siding brands or manufacturers.

[Click to enlarge any image]

Watch out: don't confuse fiber cement siding products, including asbestos cement siding boards or shingles with the wood based pressboard products described on this page.

For help distinguishing between wood- or plant- based hardboard siding products and cement-based or asbestos-cement siding products see

HARDBOARD END CUT PHOTOS - below on this page, photos courtesy of an InspectApedia reader.

Hardboard, Composite, "Masonite"-type Siding: failure and leak inspection, siding repair, siding litigation, hardboard siding class action lawsuits and settlements are listed here.

Alphabetical List of Hardboard / Pressboard Siding Products

- Abatibi-Price Hardboard Siding Failures:

see ABATIBI ABTCO SIDING FAILURE CLAIMS - ABTCO hardboard Siding Failures & Claims:

see www.abtcoclaims.com. ABTCO is an LP (Louisiana Pacific) brand. Also referred to as AbtCo/Abitibi Price

- AHA-marked Siding: See Weyerhaeuser fiberboard siding details appearing later in this list.

- Asbestos Cement and Fiber Cement Siding & Roof Shingles:

See SIDING, ASBESTOS CEMENT

and see

ASBESTOS & FIBER CEMENT ROOFING - Boise Cascade Hardboard Siding Failures: examples and documentation.

See BOISE CASCADE SIDING CLAIMS

Mail claim to: Boise Cascade Corporation, Timber & Wood Products Division, Attn: Tana Rasmussen, P.O. Box 62, Boise, ID 83707, 208/384-6162; A Boise Cascade hardboard siding claim needs to include six photos, one of each side of the building & two close-ups that show the problems. - CERTAINTEED WeatherBoards™- see this page:

CERTAINTEED WeatherBoards identification - Champion Siding - identified by a blue all-caps stamp on the siding back "CHAMPION BUILDING PRODUCTS"

another hardboard siding product. Sold in both smooth-surfaced and wood-grain pattern p1/2" thick fiberboard / pressboard panels. The back surface may show a screen type moire imprint.

As of 22024/03/16 we have no record of a class action claim suit against Champion.

For Champion siding claims involving siding installed from 1980 through 1985 contact the Masonite Corporation's warranty department.

MASONITE® SIDING CLAIMS

For Champion siding claims involving siding installed after 1985 and th rough 1999, contact the Georgia Pacific Corporation's Warranty Department.

GEORGIA PACIFIC SIDING CLAIMS

Above: example of current Stimson Lumber hardboard products, excerptd from the company's website cited in detail below.

- Forestex Hardboard Siding Failures & Claims:

Contact Stimson Corporation, 520 S.W. Yamhill, Suite 325, Portland, Oregon, 97204-1319. Stimson Lumber Website: https://www.stimsonlumber.com/contact-us/

In 2003 the company was subject to a class action lawsuit involving product failures for Forestex siding - Stimson Series 400 or Series 500 hardboard siding) installed after January 1985 on buildings in California, Colorado, Hawaii, Oregon, Utah and Washington State (Gardner, et al, vs. Stimson Lumber Company and also “Civil No. 01-514-HA. ” California Insurance Company v. Stimson Lumber Company, Civil No. 01-514-HA, (D. Or. May. 26, 2004)" ).

The lawsuit cited siding failures characterized as buckling, delaminating, deteriorating, rotting when exposed to normal weather conditions.

The class action settlement ended on 12 November 2011.

Independent claims administrator: Rust Consulting: P.O. Box 1371, Minneapolis, MN 55440-1371 , Tel: 1-800-427-2763

OPINION: In our field experience over many decades we never once found evidence of actual "rot" in hardboard siding, probably because its other constituents such as binders and resins resist actual organic rot, but we think that many owners of Forestex siding would not distinguish between swelling, crumbilng, and deterioration when exposed to the weather from "rot".

Stimson Forestex "lap" siding is no longer manufactured but the company does produce other hardboard siding panels in solid and pegboard form including some that are pre-finished and embossed with a wood grain (shown above) and that the company describes as

Hardboard products are eco-certified composite products that have a high internal bond, exceptional stability and smoothness. They’re ideal for paneling, furniture, fixtures, toys, general manufacturing and applications where painting or die cutting is required. - rertrieved 2024/03/17, original source: https://www.stimsonlumber.com/hardboard/ (March 2024).

Stimson Forestex hardboard siding, like some others discussed on this page, was embossed with a wood grain pattern including an occasional knot that very much resembles LP hardboard siding. A hard to find detail above the knot pattern can often identify the siding as Forestex - shown below.

- Georgia Pacific Hardboard Siding Failures & Claims: (INcluding Catawba Siding)

last date for filing claims under the settlement was August 18, 1998. Brands included Cadence siding and Sundance hardboard siding. Also Catawba hardboard siding pattern.

Georgia Pacific's Jarrett (manufactured at the Jarratt plant 1979-1987) siding and Catawba hardboard siding (asserted by the manufacturer to not include the defects sited for Jarrett) were named in that action.

The class action group was closed after 18 August 1998.

The Georgia Pacific company continued to produce hardboard siding at its Catawba plant until December 2006.

Warranty or other claims may be possible by contacting the company at 1-800-284-5347 in the USA (or possibly 404-652-8375 ) or by the company's website http://www.gp.com/

The company has no open class actions concerning these siding products. - James Hardie Siding, Hardieplank Siding

See JAMES HARDIEPLANK® FC SIDING

- Jefferson Smurfit Cladwood hardboard siding products were distributed by North Pacific (Landmark Corp.).

A class action suit regarding Jefferson Smurfit Cladwood siding was brought against Smurfit Stone Container who later declared bankruptcy. The class action was closed 1 February 2002.

Smurfit Cladwood siding may be indentified by the characteristic knot pattern shown above, though some readers report that their LP siding has a very similar pattern on its embossed surface.

Contact the company's ensuing entity at Smurfit-Stone Container Corporation 6 Cityplace Drive Creve Coeur, Missouri 63141 - Louisiana Pacific Innerseal® Siding Failures:

Closed: A class action settlement for LP Innerseal Siding ended on December 31, 2002.

The class group included homeowners with LP Innerseal Siding installed on homes between 1985 (manufacturing began) to 1 January 1996.

LP Claims: contact Louisiana Pacific Corporation's product warranty department 877-677-6722 for LP siding installed before January 1996 or call 800-450-6106 for LP installed after January 1996,including Smart System® Products by Louisiana Pacific

The company warrants its current siding products, in some cases for 25 years. For current product warranty information contact the company at 1-800-648-6893.

- Masonite® hardboard siding failures:

On January 15, 1998, the Circuit Court of Mobile County, Alabama, granted final approval to a Settlement in the lawsuit known as Naef v. Masonite, CV-94-4033.

The Settlement provided a program for eligible claimants to recover the costs associated with damage caused by the installation and incorporation of Masonite Hardboard Siding.

The deadline to file a claim has passed. For more information call 800-330-2722. Also see www.masoniteclaims.com -

see MASONITE WOODRUF® ROOFING OR MASONITE OMNIWOOD® SIDING LAWSUIT SETTLEMENT NOTICE - PDF file

These identifying Stamps can help Identify Masonite Hardboard Siding on most products. But nte the text is all in capital letters, one inch high, printed in black ink along the length of the back of the siding boards.

But because the stamp appeared only once per length of siding board, and because siding boards are typically cut to shorter lengths to fit shorter wall sections or around windows anddoors, not every piece of siding on a building will bear the identifying marks. C-6 (coating #6) products are stamped along 4', and C-5 products may be stamped along 14'.

- MASONITE BRAND X-90 ANSI/AHA 135.6 102797 17.37 C-6 A CA MADE IN USA

- MASONITE BRAND X-90 ANSI/AHA 135.6 102797 17.37 C-6 B CA MADE IN USA

- MASONITE BRAND ANSI/AHA 135.6 102997 13.14 L-4 C-5 A CA MADE IN USA

- MASONITE BRAND X-90 ANSI/AHA 135.6 102197 11.46 L-2 C-5 A CA MADE IN USA

- MASONITE BRAND X-90 ANSI/AHA 135.6 102197 11.46 L-2 C-5 B MADE IN USA

- MASONITE BRAND X-90 ANSI/AHA 135.6 102197 11.46 L-1 C-5 A CA MADE IN USA

- MASONITE BRAND X-90 ANSI/AHA 135.6 102197 11.46 L-1 C-5 B CA MADE IN USA

- Masonite Color Lock Hardboard Siding:

See MASONITE COLORLOCK SIDING - Masonite OmniWood

Siding claims: Masonite Omniwood is an OSB type siding product. On January 6, 1999, the Circuit Court of Mobile County, Alabama, granted final approval to a settlement in the lawsuit known as Cosby v. Masonite, CV-98-2446.

The Settlement provided a program for eligible claimants to recover the costs associated with damage caused by the installation and incorporation of Masonite Omniwood Siding.

The deadline to file a Masonite OmniWood hardboard siding claim has passed.

For more information call 800-256-6990 or try calling the company at 1-800-323-4591.

Omniwood® is a registered trademark of Masonite Corporation.

Watch out: Don't waste time seeking the purported Masonite claims website titled www.masoniteclaims.com - it has been converted to a "made for Adsense" advertising revenue page that provides no useful information whatsoever. - Current Masonite product warranties, supported by the parent company, International Paper: contact the company at 1-800-323-4591.

- Naturetch Engineered Wood Siding - KWP Engineered Wood Products Co., sold at Menards and other building suppliers. Shown above, Naturetech KWP 1/2 x 12 x 12' D5 Textured Siding

Model Number: WSD51250. (March 2024)

Contact: KWP Engineered Wood Products, 1367 Rue Nationale, Terrebonne, Quebec J6W 6H8, CA Tel: (450) 964-5786">(450) 964-5786 Web: https://kwpproducts.com/ - Website excerpt: "KWP uses 100% recycled wood." The company, founded in 1974, produces wood fiber based siding and trim products.

- Shakertown Panel Siding Failures: some writers report Shakertown panel siding failures on product manufactured before 1992.

Shakertown manufactures premium Western Red Cedar shingles for residential and commercial siding applications, available throughout the United States and Canada.

See shakertown.com - Sorbilite Plastron comments on Hardboard Siding Failures

See SORBILITE PLASTRON - Stimpson Forestex hardboard siding and Stimpson Duratex siding

See details at FORESTEX HARDBOARD SIDING above on this page. - Temple Inland hardboard siding: Endura lap siding, hardboard panels were out of manufacture in or before 2009 and were not subject of class action claims. Temple Inland was aquired by Georgia Pacific.

See GEORGIA PACIFIC SIDING CLAIMS

Photo above: built in the 1970s this Poughkeepsie New York home was sided in un-grooved plywood sheet siding.

- Weyerhaeuser Hardboard & Siding claims:

Typically Weyerhaeuser hardboard siding has one of several surface textures: smooth-surfaced, or a wood-grain resembling cedar clapboards, a texture resembling cedar shakes, a texture that shows a crosscut saw kerf type marking, or a stucco-surface texture pattern.

Fiberboard siding manufactured by Weyerhaeuser was sold in 16' lengths, in thicknesses of 1/2" or slightly less (7/16" thick) and in inch-widths of 6, 8, 9 1/2, 10 1/2, 12 and 16 inches.

Some Weyerhaeuser hardboard siding can be identified by a characteristic knots or pair of knot, 1 1/2 to 2" wide, and spaced about 61" apart. Look for knots on that spacing along siding boards that are more than five feet long.

Some Weyerhaeuser fiberboard siding includes a stamp on the siding back that is marked "AHA 10" or "AHA 20".

The company also produced siding sheets or panels in 4' x 8' or 4' x 9' sizes, in 1/2" or slightly thinner 7/16" thicknesses, with vertical grooves 4", 8", or 12" O.C. and resembling T-111 plywood siding panels. The siding sheet product was also sold in solid panels without a vertical groove and in a stucco-patterned surface texture.

A Class action closed on 31 Dec 1999, applying to siding installed between 1 January 1981 and 31 December 1999. See www.weyerclaims.com. Also Collinswood TruWood siding was another Weyerhaeuser hardboard siding brand.

Weyerhaeuser for warranty & claim information for siding installed between 1 Jan 1994 and 31 Dec 1999 : Gel: 1-800-365-0697

Photo above: another photo of the same 1970s Poughkeepsie New York home was sided in a combination of un-grooved plywood sheet siding and "T111" grooved plywood in some sections that we think had been replaced.

- Werzalit lap siding, hardboard. Werzalit of America, Inc. is currently (2017) a manufacturer of composite, interlocking siding in lap siding profiles, using a compressible gasket design, marketed as rainscreens.

The company makes a range of outdoor tabletops and other products. Werzalit lap siding rain screen materials are constructed of hardwoods and 24% resins bonded to phenolic cover sheets coated with a thermo-set acrylic finish.

Contact: Werzalit of America, Inc.40 Holley AvenueBradford Pa. 16701 Phone (US Only): (800) 999-3730 Phone: (814) 362-3881Fax: (814) 362-4237 Email: info@werzalitusa.com, Website: http://www.werzalitusa.com/

Werzalit product catalog : http://www.werzalitusa.com/wp-content/uploads/2015/07/Werzalit-catalog-final.pdf - Wolverine DuraPress® siding: this product is now sold as Weatherboard® by Certainteed. Website: https://www.certainteed.com/siding/products/wolverine-american-legend/ or see the CertainTeed information below.

Hardboard Siding Alternatives - Fiber Cement Siding

Fiber cement building siding, such as HardiePlank®, originated by James Hardie Products may be a more durable alternative to wood-fiber based hardboard siding. Information about the James Hardie company is

at JAMES HARDIEPLANK® FC SIDING. Other fiber cement siding product lines include Maxi-Panel, Maxi-Plank, Cemplank, & FortaFiber.

Comment from Sorbilite about the History of Hardboard Siding Failures

Andrew Pohl M.Sc. - M.A. President, 1 Reflection Lane Hampton VA. 23666 USA, Email: apohl@sorbilite.com

Dear Editor,

I am writing to comment on the endless claims of hardboard siding products failures. This concerns a number of the biggest companies in the US.

We at Sorbilite observing this with quiet satisfaction because years ago we were warning most of these companies about the coming catastrophe. We didn’t just warned these companies but give objective suggestions and solutions which were ignored - probably out of arrogance. Now it cost them millions.

We manufacture and distribute world-wide our technology and make it available to third-world countries since decades and the products are not only green but perform under extreme conditions. It should have been good and profitable to listen a little bit…. But may be it isn’t too late.

If you like to have more information don’t hesitate to call on me. Regards

Note: Quoting from http://www.sorbilite.com/,

Sorbilite, GmbH was established in Germany in 1978. Extensive knowledge in the field of particle board and décor panel manufacturing was brought into the company through the chief scientists. They had worked on the Marshall Plan initiative, aimed to develop environmental technologies.

The price of a $ 30 million décor-panel plant (Formica, Resopal) was reduced by 90% but quality and design variety was dramatically increased. The same results were achieved designing a new type of “value-added” three-dimensional particle board plant (MDF).

In 1985 Sorbilite, Inc. was established in the US and it became headquarters for worldwide operations in 1988. Today Sorbilite is located in Hampton, Virginia, USA. Sorbilite has established factories worldwide for more than 25 years.

Andrew Pohl, president of Sorbilite Plastron

Moderator Reply

Dear Mr. Pohl,

While we can't say that we have observed the failure of hardboard siding products with much satisfaction, we would very much welcome hearing from you specific details about or seeing documents about Sorbilite's warnings to the hardboard manufacturers, as that information would assist in understanding the history and development of this particular product failure.

More, if you have specific suggestions for owners whose buildings still include hardboard siding products, particularly how those might best be maintained, that too would be of great value. We look forward to hearing further from you.

Respectfully, Daniel Friedman, Editor.

Pohl follow-up:

Thank you for your prompt reply.

I didn't say the failure of others give us satisfaction , I meant more the lesson of not listening as good exercise satisfy us. If you go into our history you discover that we brought the know-how of the German particleboard industry with us together with the investment results of the Marshall Plan which reformed the composite field.

I do not want to dig too deep into this "not listening" -- because which company want to be suicidal if quick help is available? All bigger companies have their own research facilities. Not the presidents but the head of their research- facilities get the rescuing information.

Unfortunately this information is bad news for them. A proof somebody can do what they couldn't. So most cooperative action ends in further research how you do it and not how to solve our companies problems.

The weather ability and the chemical composition of composites is a fairly common knowledge. The most kitchen chefs cannot understand why the big difference in taste using the same ingredients. The know-how and the oven and the chef....

So if you ask me what is your secret.... my answer is the know how ( the leading brain trust of the German industry going back to 1930) the oven (the special press and process equipment) and the chef (putting up over 100 factories around the world). Of course also the practical experience. We let our customer speak. (Attached : Plastron in China)

This letter starts to look as a company promotion. It is not. I personally stopped selling this system and plant in America, started using our own equipment (Plastron Inc. -- www.Plastronproducts.com) and making the same turnover with 5 operators as we did with 31 building presses.

Well we sell the plants as well - mainly in third-world countries. And we don't mind consulting companies in trouble - in America. This is the spirit of this letter.

Moderator reply:

Andrew,

Thank you. I'm glad to do a little editing to make clear to readers your comment about failure of others and satisfaction. As a forensic investigator I have found more than one case of a product that is such an obvious mistake that I am moved to look for other reasons that it remains on the market as long as it does.

In this article series we discuss all brands of hardboard or pressboard siding, including: Abatibi, ABTCO, Boise Cascade, Celotex hardboard siding, Champion hardboard siding (see Masonite), Certainteed Weatherboards (see Fiber Cement), Georgia Pacific, James Hardi HardiePlank, Louisiana Pacific, Masonite, Shakertown, Weyerhaeuser, Wolverine DuraPress® siding Abatibi hardboard siding, ABTCO siding, Forestex hardboard siding, Georgia Pacific hardboard siding, Louisiana Pacific hardboard siding, Masonite hardboard siding, Shakertown Panel Siding, Weyerhaeuser Hardboard Siding, and Wolverine DuraPress - examples of brands of hardboard siding that have suffered these problems.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Is there Warranty Assistance for Replacing or Painting Masonite Colorlok "Color lock" Hardboard Siding?

Question from an InspectApedia reader

I am considering buying a home that was built in 1998 and was sided with Colorlock [Masonite Colorlok®] siding.

The siding looks terrible. It is exposed and there is no paint left on the lowest part of each piece of the lap siding where it has swelled and looks like its coming apart.

The home is beautiful with that exception. I saw your article and my question is could it be covered under the claim you write about. Its a big house and the siding is a big issue. If I knew that it could be replaced under some type of warranty it would help me with the decision of buying it. - R.H.

Moderator reply:

A competent onsite inspection by an expert usually finds additional clues that help assess the condition of the siding, the extent of replacement needed, and the possibility that water has penetrated the building walls - points where additional investigation would be appropriate.

That said, as we noted above, The deadline to file a claim has passed. For more information call 800-330-2722.

See MASONITE WOODRUF® ROOFING OR MASONITE OMNIWOOD® SIDING LAWSUIT SETTLEMENT NOTICE - PDF file.

Colorlok® Masonite hardboard siding was a 1970's product (the Masonite Colorlok siding ad shown at left appeared in April and May 1981 Popular Science Magazine), subsequently removed from the market following delamination failures and the class action litigation we discuss above.

In as this SIDING COST TABLE [PDF] shows, in the 1970's the installed cost of hardboard siding was less than vinyl, aluminum, or steel siding. [3]

Where your Masonite (or other brand) hardboard siding has swollen and delaminated, painting it would be a stopgap measure that yields cosmetically poor results.

You will want to replace those damaged siding sections. Try contacting Masonite - the company may still have retained reserves of replacement siding that they may be willing and able to provide to people who present a siding warranty claim to the company even though the class action settlement period has expired.

However considering the poor performance of hardboard siding products over time, I'd consider replacing entire walls using an alternative and more durable contemporary product, perhaps a fiber cement product or something else

. On 6 March 2001, Masonite ANNOUNCED [PDF] that the company was phasing out all of its hardboard siding products including Colorlok®, Woodsman® Lap & Panel, SuperSide®, and HiddenRidge® siding, and Modulux® industrial board.

In many cases hardboard siding that has not delaminated can be painted after priming with a latex primer. Check with your paint supplier and be sure to use compatible paints. Keeping hardboard siding painted, especially at cuts and penetrations (nails, end cuts, openings cut for fixtures,etc) can slow its deterioration significantly.

Note: don't waste time seeking the Masonite claims website titled www.masoniteclaims.com - it has been converted to a "made for Adsense" advertising revenue page that provides no useful information whatsoever.

Reader comment: Photos of end-cut view of hardboard siding - is this asbestos?

Thank you for your website and the great amount of information you’ve assembled.

Thank you for your website and the great amount of information you’ve assembled.

While replacing a window in my 60’s era house, I discovered vinyl siding installed over a former siding.

I don’t believe it to be asbestos, primarily because it is wood colored and appears to be wood fiber. I have no visibility to the old siding to determine the length of the panels, only these end cuts.

I thought perhaps these photos could be helpful on your website in helping others to identify their siding as I didn’t see very many end cut photos.

These are 12” wide and about 7/16” thick. They are wood colored and seem to best match your description of fiberboard. Are you able to confirm that from photos alone?

Could these be asbestos? - Anonymous by privat email 2022/03/22

Moderator reply: brown woody fibres identify plant-based siding: hardboard siding - different from cement-board products

Thank you for the siding identification discussion and photos.

At SIDING, FIBER CEMENT IDENTIFICATION you wills see that we do have some photos of factory end-cuts of FC siding, but your images will be a helpful addition.

Your first photo [above} where board siding ends are exposed (and apparently covered over byt vinyl siding) the ends are painted, making a certain identification of material more-difficult without a closer-look or a bit of probing.

Below is an enlarged bit of your first photo that we showed above.

Without a bit of scratching or probing we still can't say what the material is, but I do note that it's a poor practice to install vinyl siding over hardboard siding without also trimming out windows and doors so as to close off openings into the wall such as shown in the enlarged image above.

Your subsequent photos (below) show brown woody fibres - not a cemetious material.

However they belong not among cement-based siding identification photos but here (this page) among wood- or plant-based fiber siding identification.

Those brown fibres and absence of any cementious material argue for that identification. That is to say, your siding looks like fiberboard -a wood-based product, not a cement-based product.

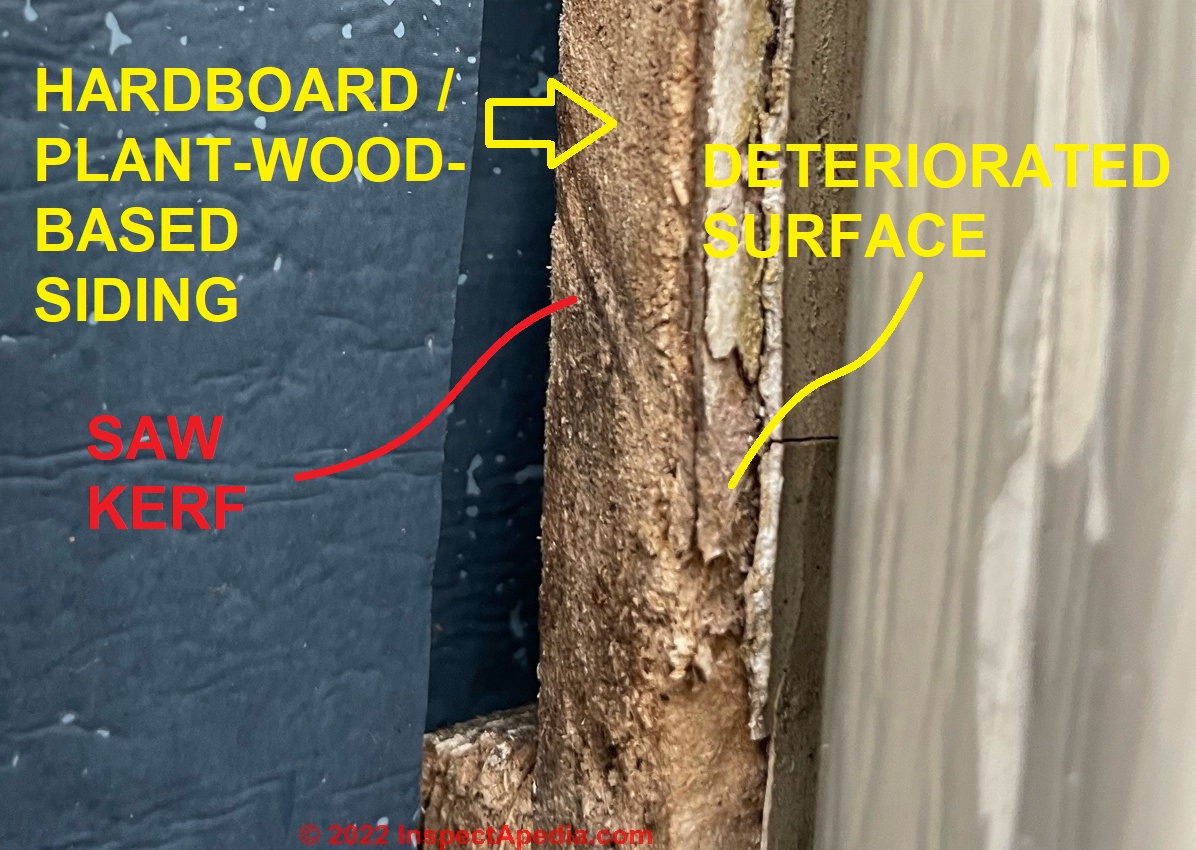

Below is a close-up view of this plant-based or wood-fiber based siding end cut. You can also see the kerf marks from the saw blade used to cut this siding board and if you look closely at the front surface of the old hardboard siding you can see that it is deteriorated - which may explain why the siding was covered over by vinyl.

As it will be helpful to other readers I include a redacted (to respect your privacy) version of this discussion in our article [on this current page, HARDBOARD SIDING GUIDE - Ed.]

Below is a closer view of the end cut of a fiber cement board product. You can see that these cemetious siding boards are harder than plant-based hardboard siding - they're "cemetious" and do not show brown plant fibres.

Also see COMPARE FIBER CEMENT to WOOD-FIBER SIDING - on our fiber cement siding identification page.

Question: Asbestos siding & Abitibi siding

(Oct 26, 2011) Asbestos siding & Abitibi siding said:

Hello. Are the two sidings noted above the same thing with the same properties?

Reply: no recall of Masonite siding

A&A.

No, Hardboard siding is a wood fiber product whose deterioration is described on this page.

Asbestos siding is a product made from a mixture of cement, asbestos (fibers and filler) and possibly other materials. In my experience cement asbestos siding is a durable and long-lasting product, it does not easily deteriorate from exposure, though on roofs and in some other hard wear locations it might become soft and porous.

The issues are different as well.

There are potential environmental and health concerns with the demolition of or mechanical operation on any asbestos-containing material if the process creates/releases asbestos dust.

...

Continue reading at ABATIBI ABTCO SIDING FAILURE CLAIMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- MASONITE WOODRUF FIBERBOARD ROOFING - hardboard and fiber cement roof shingle failures and warranty claims.

- SHEATHING, OSB - oriented strand board sheathing & siding

- SHEATHING, EXTERIOR PRODUCT INDEX

- SIDING, FIBER CEMENT IDENTIFICATION - identify fiber cement siding products

- SIDING HARDBOARD IDENTIFICATION & CLAIMS - home - identify wood-fiber based siding products

- ABATIBI ABTCO SIDING FAILURE CLAIMS

- BOISE CASCADE SIDING CLAIMS

- FORESTEX PACIFIC SIDING CLAIMS

- GEORGIA PACIFIC SIDING CLAIMS

- HARDBOARD MASONITE™ & OTHER BRANDS

- HARDBOARD Masonite™-like INGREDIENTS

- JEFFERSON SMURFIT SIDING CLAIMS

- LOUISIANA PACIFIC INNERSEAL SIDING CLAIMS

- JAMES HARDIEPLANK® FC SIDING - fiber cement siding failures

- MASONITE® SIDING CLAIMS

- NATURETECH SIDING IDENTIFICATION

- SHAKERTOWN® SIDING CLAIMS

- SORBILITE PLASTRON PARTICLE BOARD COMMENTS

- STIMNPSON FORETEX SIDING CLAIMS

- TEMPLE INLAND SIDING

- WEYERHAEUSER SIDING CLAIMS

- WERZALIT SIDING & RAINSCREENS

- WOLVERINE SIDING CLAIMS

- SIDING LEAK DIAGNOSIS & REPAIR

- SIDING TYPES, INSTALLATION, DEFECTS

- SIDING, WOOD PROFILES & SOURCES - identify types of wood siding

Suggested citation for this web page

SIDING HARDBOARD IDENTIFICATION & CLAIMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING SIDING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- Roger Hankey is principal of Hankey and Brown Inspections, Winter Park, CO. Mr. Hankey is a past chairman of the ASHI Standards Committee and served in other ASHI chapter and national leadership roles. Mr. Hankey is a National Radon Proficiency Program certified measurement professional and a Level II infrared thermographer. Contact Roger Hankey at: 970-393-6604 - rogerhankey47@gmail.com . Website: www.HankeyandBrown.com Mr. Hankey is a frequent contributor to InspectAPedia.com.

- Arlene Puentes [Website: www.octoberhome.com ] , an ASHI member and a licensed home inspector in Kingston, NY, and has served on ASHI national committees as well as HVASHI Chapter President. Ms. Puentes can be contacted at ap@octoberhome.com

- MASONITE WOODRUF® ROOFING OR MASONITE OMNIWOOD® SIDING LAWSUIT SETTLEMENT NOTICE - PDF file

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.