Hazards of Asbestos-containing Transite Pipe HVAC Ducts

Hazards of Asbestos-containing Transite Pipe HVAC Ducts

Risks & Remedies

- POST a QUESTION or COMMENT about transite air ducts: asbestos cement air duct issues: identification, sealing, removing or abandoning procedures

Transite HVAC air ducts are a form of asbestos cement that can pose health hazards in buildings and, where routed below floor slabs, may also be contaminated by water and mold.

This article explains the potential hazards of transite (cement asbestos) air ducts - asbestos fiber release, radon, and indoor air quality concerns, and duct collapse when transite air ducts are found in buildings.

Transite pipe, an asbestos-cement product, was used for HVAC ducts and for chimney or flue material to vent gas-fired appliances.

Cement-asbestos transite pipe may also have been used for water piping in some communities. We discuss how to identify cement asbestos transite air ducts, what the safety & health hazards are, how to seal or abandon the ductwork, & alternative approaches.

This document assists building buyers, owners or inspectors who need to identify asbestos materials (or probable asbestos) in buildings by simple visual inspection.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Transite Pipe HVAC Ducts: Asbestos Heating or Air Conditioning Duct Material Warnings

Transite pipe, which contains significant percentage of asbestos fibers, was often used for heating ducts and on occasion heating and cooling ducts in older buildings.

Article Contents

- MATERIAL WARNINGS - TRANSITE PIPE HVAC DUCTS

- DEFINITION & COMPOSITION OF TRANSITE MATERIALS

- WARNINGS & HAZARD DETAILS - TRANSITE-TYPE HVAC OR AIR DUCT

- RECOMMENDATIONS WHERE TRANSITE ASBESTOS HVAC DUCTS ARE INSTALLED

- RESEARCH ON HAZARDS OF CEMENT-ASBESTOS TRANSITE HVAC DUCTS

...

Transite Pipe HVAC Ducts: Material Warnings

Transite pipe used as HVAC ducts or air ducts for heating and air conditioning was often installed buried in a concrete floor slab - methods that placed the asbestos-cement transite piping below or in a building floor slab.

AC pipe was typically made by adding chrysotile and/or crocidolite asbestos, ranging from 10 to 75 percent, to Portland cement, water and silica. ... AC [Asbestos Cement] pipes usually contain anywhere from 10 to 75 percent asbestos. (McKenna 2016).

Asbestos-containing transite pipe HVAC ducts were also used in exposed areas such as shown in the crawl space photograph at the top of this page. And transite pipes were also used as flues or chimneys for some heating equipment, usually where gas fired heaters were installed.

Asbestos-cement HVAC Ducts & Airborne Asbestos Risk?

A preliminary study performed by the New Jersey Department of Health (1986) on a small number of homes found that in some homes asbestos-cement (transite) HVAC ducts can result in unacceptably high airborne asbestos hazards.

That is not to say that every home with asbestos-cement ductwork is dangerous, and we infer from the study and other research that several factors probably increase the indoor asbestos hazard in such homes, including particularly the condition of the transite pipe ducts, the use of the HVAC system and its condition, and general housekeeping.

In our OPINION there are both potential airborne asbestos hazards associated with asbestos-cement ductwork and also mold and other health hazards from ducts in slabs in general, sufficient that an evaluation of such buildings and (possibly) remedial action are warranted.

...

Definition & Composition of Transite materials

While the term "transite" has been used to describe many asbestos-cement products (pipes, ducts), Transite™ is the trademarked name used by Johns-Manfille for asbestos-cement products that were manufactured by that company to its own specifications.

Those specifications varied by individual products but typically included a mixture of 15-25% chrysotile asbestos, 45-55% portland cement, and another 25-35% silica "flour" (that I read as finely ground sand).

We emphasize that while Transite™ pipe materials, if they have not been painted nor exposed to the weather, usually will display a black stencil-stamp identifying the company and product, for example "JM-TRANSITE-FLUE", many other asbestos-cement products of similar formulation were produced by other companies including Celotex, CertainTeed, GAF, National Gypsum, and others.

See ASBESTOS PRODUCING COMPANIES & TRUSTS.

Transite air ducts in slabs often collect water, mold, pathogens. We provide photographs and descriptive text of asbestos insulation and other asbestos-containing products to permit identification of definite, probable, or possible asbestos materials in buildings.

The photo (above left) of a sewer line routed immediately below a transite asbestos in-slab floor heating duct was provided courtesy of reader Conrad.

This case is illustrated in more detail

While an expert lab test using polarized light microscopy may be needed to identify the specific type of

asbestos fiber, or to identify the presence of asbestos in air or dust or water samples, many asbestos-containing building products

not only are obvious and easy to recognize, but since there were not other look-alike products that were not asbestos, a visual identification of this material can be virtually a certainty in many cases.

Page top photo of transite duct material courtesy of Thomas Hauswirth, a Connecticut home inspector.

...

Asbestos Warnings & Hazard Details for Transite-type HVAC or Air Duct

Transite ducts used for HVAC air flow, especially when used buried in building

concrete floors or slabs, may break, collapse, leak water in (forming a mold and bacterial reservoir in the HVAC system),

or may release asbestos and other particles in building air when the HVAC system is operating.

Transite ducts used for HVAC air flow, especially when used buried in building

concrete floors or slabs, may break, collapse, leak water in (forming a mold and bacterial reservoir in the HVAC system),

or may release asbestos and other particles in building air when the HVAC system is operating.

An up flow or down flow furnace in a building with concrete slab and with perimeter duct work

raises some important health and cost questions:

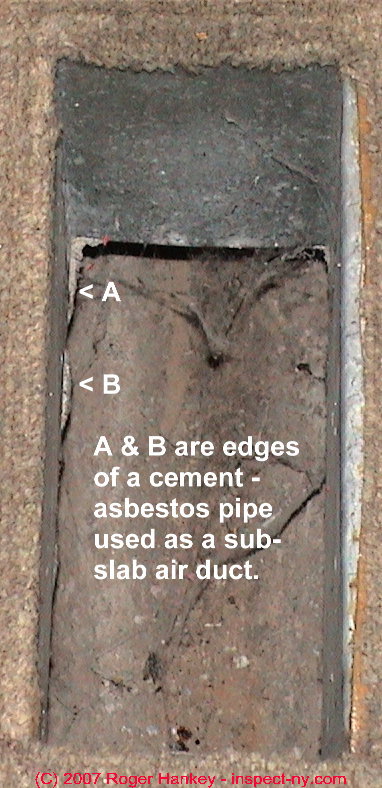

The photograph above shows a transite cement asbestos heating duct in a carpeted floor slab. We recommend that in-slab heating or air conditioning ducts made of transite be sealed and abandoned, and alternate heat sources installed. This improvement removes an asbestos hazard, a flooded duct and mold hazard, and in some locales, also a radon gas entry point.

The photograph shows the edges as well as surface of the transite material. Transite pipe HVAC ducts get quite dirty and are not always easy to identify.

Photo and some of our comments on transite in-slab HVAC ducts are provided courtesy of Roger Hankey, a Minnesota home inspector.

- Asbestos hazards of transite ducts: Cementious duct material may contain asbestos. What is this "cement"

duct work made of Cement and asbestos fibers.

How much asbestos is in Transite pipe? While it's cementious, transite ducts or even transite pipe used for heating flue vents is a potential asbestos hazard in buildings. Transite pipe typically contains about 15% to 25% asbestos fibers, typically fibrous chrysotile asbestos.

A careful asbestos testing lab may report both fibrous and fragmented asbestos which can occur in still smaller pieces (thus more easily remaining airborne and increasing human exposure to asbestos).

The balance will be cement and possibly other fibers or binders. If transite pipe is damaged or is cut mechanically (such as by using power equipment), friable, airborne asbestos fibers may be generated - a health and costly cleanup concern.

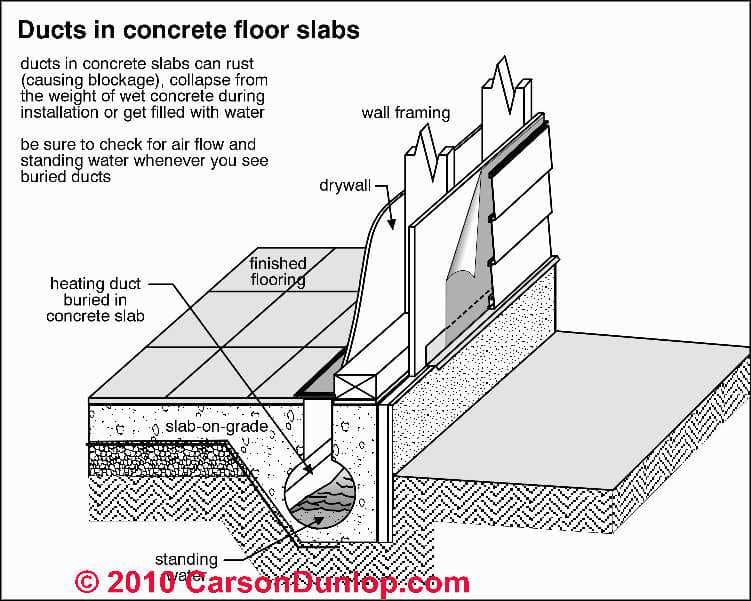

- HVAC air ducts located inside concrete slab floors invite flooding, mold, insects, and where transite - cement asbestos - ductwork was used, asbestos particle contamination or collapsed ductwork.

Sketch at left courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

SLAB DUCTWORK - catalogs the functional and environmental problems found when HVAC air ducts are routed in or below floor slabs

- Air quality hazards of in-slab duct systems:

include water leaks into the duct system which can in turn generate a mold or bacterial hazard or can cause softening, collapse, and blockage of the in-slab transite pipe duct.

While there are companies offering duct cleaning and duct sealing services, we remain cautious that such a "sealing" project creates a false sense of confidence that no remaining duct issues exist, causing the occupants to miss the discovery of future leaks and in-duct problems. - Radon entry through in-slab duct systems:

can occur in areas where radon is present at problem levels in the soils. In particular, because a return air duct is often at negative pressure (when the blower is operating), the movement of radon gas from the soil into the building air through a leaky in-slab duct can be significant, certainly greater than the movement into the building from other openings such as through a basement slab crack.

- Sewer Gas entry into the HVAC duct system

through in-slab transite asbestos ductwork: as reader Conrad discovered while tracking down the odor of sewer gas that was appearing in a home's in-slab ductwork. Placing in-slab ducts close to sewer piping (or septic system piping ) invites any future sewer gases leaking out of the piping right into the HVAC duct system.

The owner tracked the sewer gas odor that was coming out of the building's heating ducts to a break in the sewer piping located in the same floor.

The repair of the sewer gas odor involved jack-hammering out the floor slab, removing and replacing the leaky cast iron sewer pipe, and repairing the floor.

Because of the inconvenience and cost of relocating these air ducts or converting to an alternate heating distribution method, the owner elected to retain the transite in-slab floor ducts.

This case of cast iron drain leaking sewer gas into a transite asbestos heating air duct is illustrated in more detail

at CAST IRON DRAIN PIPING.

Also see SEWER SEPTIC ODORS in HVAC DUCTS

Additional measures useful in tracking down the source of odors coming from duct work can be found

at DUCT & AIR HANDLER ODORS. - Asbestos fiber release hazards during removal of demolition of transite piping are discussed

at TRANSITE PIPE CHIMNEYS & FLUES.

Incorrect spellings of transite asbestos piping or transite duct material that we've seen include transit pipe, transit ducts, transite chimneys, transide pipe, transide ducts, and transight pipe or transight ducts. "Transite" is the correct spelling.

...

Recommendations where Transite Asbestos HVAC Ducts are Installed

Apply an internal transite HVAC air duct sealant

There are also duct-sealants that some contractors offer as an in-duct sealant/spray. The contractor extends a spray wand into the HVAC ducts to deliver a coating that, if perfectly successful, can prevent or at least reduce the risk of asbestos fiber release into the building air.

And Andrew Oberta has described standards methods for repairing asbestos-cement products including underground transite piping.[5]

A down-side with in-slab ductwork is the difficulty in accessing for application of the spray and difficulty in inspection in the future to see what's going on inside the duct: collapsing walls, sealant falling off of duct interior, flooding, mold, asbestos-releasing scraps, rodents, etc.

Our in-slab air duct photo (left) shows evidence of a history of floods in the duct system as well as rodents (the rodent poison).

A second concern is that even if the coated transite air duct interior surfaces appear to have been treated successfully, especially with in-slab ducts we are not assured that the in-slab ducts remain clean, dry, and undamaged in the future nor that the transite duct interior coating remains bonded to the duct surfaces.

See SLAB DUCTWORK

But given the history of concerns with the product, in particular with in-slab ducts, we would give strong consideration to abandoning in-slab ductwork entirely.

Abandon in-slab and other transite asbestos HVAC air ducts

We recommend abandoning in-slab HVAC air ducts, including transite asbestos cement HVAC ducts, reasoning that there are multiple indoor air quality and potential health as well as functional concerns with such installations.

We described concerns with ductwork run in floor slabs in the article above, including risks of air duct collapse that interferes with air flow through the system, water leaks into the in-slab duct system (not a problem unique to transite ducts), and rodent or insect infestations or even mold contamination.

Odor complaints may be traced to the duct system because of these problems

See details at DUCT & AIR HANDLER ODORS

At SLAB DUCTWORK we give details about abandoning in-slab HVAC ductwork. That article also catalogs the functional and environmental problems found when HVAC air ducts are routed in or below floor slabs.

When abandoned, in-slab ductwork of any material can usually be left in place.

However where radon gas is an issue, we seal the ducts at the air delivery registers in the building floor slab, as well as sealing any slab cracks that may allow radon gas to enter the building at increased levels.

...

Research on Hazards of Cement-Asbestos Transite HVAC Ducts

- Ambler, Edward Alan, John Matthews, Lawrence Pultz, and Ryan Stowe. "The Path Forward for Pipe Bursting Asbestos Cement Pipe." In WEFTEC 2015. Water Environment Federation, 2015.

- [9] ASTM E2394, ASTM Standard Practice for Maintenance, Renovation and Repair of Installed Asbestos Cement Products, available from ASTM International, www.astm.org.

- Camplin, Jeffery C. ASBESTOS, a "Second wind" brings contaminant back into public eye [PDF] Professional Safety 48, no. 8 (2003): 32-39.

- Castleman, Barry I., and Manuel J. Vera Vera. "Impending proliferation of asbestos." International Journal of Health Services 10, no. 3 (1980): 389-403.

Excerpt:

Extremely hazardous conditions have also been described in the oldest asbestos cement … - Daugherty, Jason D. Asbestos Maintenance: A Wise Alternative to Asbestos Removal. [PDF] PhD diss., 2002.

- Giori, Phil, ENV SP Dudek, TESTING METHODS for ASBESTOS CEMENT PIPE [PDF of power point presentation], SCAP Collection Systems Committee, Irvine CA, retrieved 2019/05/09, original source: http://scap1.org/Collection Reference Library/Dudek 2016_3_30 SCAP 0AC 0Pipe Testing.pdf - Note: contains no technical specifics such as actual hardness measurements but shows cross section condition of pipe and other details.

- Gualtieri, A. F. "Mineral fibre-based building materials and their health hazards." In Toxicity of building materials, pp. 166-195. Woodhead Publishing, 2012.

- McKenna, Janet. WORKING SAFELY with ASBESTOS CEMENT [PDF] Journal of the New England Water Works Association 130, no. 4 (2016): 266.

Abstract:

Over the last hundred years, asbestos has been incorporated into thousands of products, including consumer products and building materials. One particular use of asbestos was cement pipe that became a staple for potable water, sanitary sewer and storm drain applications.

However, over the decades, these asbestos cement pipes (“AC pipes”) are showing signs of age, requiring replacement or extensive repairs. This paper will explore the best practices for accessing, removing and repairing AC pipes to minimize asbestos exposure to workers who must come in contact with these pipes.

Although its health hazards are well documented, asbestos products can be imported, and are found in a variety of applications. When left undisturbed, asbestos containing materials (“ACMs”) pose very little risk.

However, there are situations when disturbance of ACM is unavoidable, particularly in unforeseen circumstances or when emergency maintenance or repair is necessary. One common asbestos containing material is the cement pipe that constitutes a large portion of our utilities infrastructure.

Many municipalities have hundreds of miles of asbestos containing pipes that carry our drinking water, and serve as conduits for electrical and cable wiring.

AC pipes were used extensively during the 1940s, and the majority of them are still in service, although nearing the end of their useful life. Inevitably these AC pipes will need repairs or replacement with new nonasbestos containing pipes to keep municipal water and sewer systems operating effectively.

The repair or removal of AC pipes will require disturbance or contact with this asbestos containing material.

This piece will discuss why asbestos poses a health hazard, how to work safely with AC pipes, and the regulatory requirement established by the Massachusetts Department of Labor Standards (“DLS”) and the MA Department of Environmental Protection (“DEP”) to protect workers, the public and the environment from asbestos exposure. - Harrington, J. Malcolm, Gunther F. Craun, J. Wister Meigs, Philip J. Landrigan, John T. Flannery, And Richard S. Woodhull. "An investigation of the use of asbestos cement pipe for public water supply and the incidence of gastrointestinal cancer in Connecticut, 1935–1973." American Journal of Epidemiology 107, no. 2 (1978): 96-103.

- NJ PRELIMINARY REPORT on INDOOR ASBESTOS in HOMES BUILT WITH ASBESTOS CEMENT AIR DUCTS [PDF] (1986) New Jersey Department of Health, Environmental Health Protection Program - retrieved 2022/-08/20, original source: https://www.nj.gov/health/ceohs/documents/eohap/haz_sites/regional_state/asb_cement/prelim_asbes_ducts.pdf

Excerpts:

The New Hersey Department of Health conducted a pilot [study] of 8 homes with forced air heating and asbestos-cement ductwork and 1 home with radiant heat to determine the possibility of an indoor airborne asbestos problem.

Compared with outdoor airborne asbestos concentrations (none found), elevated levels of asbestos concentrations were found in 3 of the 8 homes with asbestos-cement duct works ranging from 13.4 to 35.7 ng/cuy M.

The lifetime risk estimates calculated for the elevated indoor airborne concentrations in the 3 homes ranged from 14.4 per 100,000 to 48.6 per 100,000.

These risks are higher than normally accepted in in environmental contamination episodes.

Because these homes were selected on the evidence of deteriorating ductwork and less frequent house cleaning, the results are not representative of conditions in homes built using this construction technique.

To our knowledge this is the first study to evaluate the relationship between residential airborne asbestos concentration and cement-asbestos ductworks.

In light of the limited information on asbestos-cement ductworks and the findings of this pilot study, the New Jersey Department of Health recommends the fdurther evaluation of the 3 homes with elevated airborne asbestos concentration to confirm the results and to determine home-specific activities that may be responsible for these levels.

The Department also recommends the sampling of additional homes with asbestos-cement ductworks and homes without ductworks to provide a firmer baseline in order to evaluate the impact of asbestos-cement ducdtworks on residential indoor air quality and to formulate public health policy accordingly. - NJ, ASBESTOS in the HOME, a Guide for New Jersey Residents [PDF] New Jersey Department of Health & Senior Services, onsumer, Environmental & Occupational Health Service Indoor Environments Program PO Box 369 Trenton, NJ 08625-0369 Tel: 609-826-4950 Web: www.state.nj.us/health/iep

- [5] Andrew F. Oberta, A NEW STANDARD FOR REPAIR AND MAINTENANCE OF INSTALLED ASBESTOS-CEMENT MATERIALS [PDF] web search 6/11/12, original source: http://www.worldasbestosreport.org/conferences/gac/gac2004/pl_6_06_e.pdf [copy on file as Asbestos_Cement_Repair_Oberta.pdf], Andrew F. Oberta, MPH, CIH

The Environmental Consultancy

www.asbestosguru-oberta.com

(512) 266-1368

andyobe@aol.com,

Abstract:

The ASTM Standard Practice for Maintenance, Renovation and Repair of Installed Asbestos Cement Products has been developed by ASTM International 1 and assigned the designation E2394.

The standard provides the underlying rationale and detailed procedures for working with asbestos cement products – roofing, siding, ducts, pipes and other construction materials – that have already been installed in and between buildings.

It covers operations that can produce dust and airborne asbestos fibers – drilling, cutting, breaking, filing, etc. – during routine maintenance, repairs and small-scale renovation.

Control of dust and fiber release using wet methods – soapy water, shaving cream and similar substances – is stressed. Four appendices cover underground pipes, buried ducts, drilling holes and removing panels, and additional appendices will be prepared to cover other operations and materials. Installation of new asbestos-cement products is not encouraged by the standard.

Large-scale abatement is not the intended purpose, although some of the procedures may apply to such operations. The procedures are intended for use in developing as well as industrialized countries; therefore, the use of hand tools and easily-obtained equipment and supplies is emphasized.

The use of power tools is discouraged to minimize the possibility of creating airborne fiber levels that would require wearing respiratory protection. E2394 is intended for use by supervisors and managers responsible for construction and maintenance as well as by government agencies and NGOs responsible for worker and community health programs.

The standard offers useful guidance for countries in the process of developing their asbestos laws and regulations. ASTM International intends to provide training on the use of this standard in countries where it will be used through arrangements with standards organizations in those countries. - Wang, D. L.; Hu, Y.; Chowdhury, R. SAFETY and WASTE MANAGEMENT of ASBESTOS CEMENT PIPES [PDF] ASCE Pipeline Conference 2010, Keystone, Colorado, USA, August 28- September 1, 2010, pp. 1-10

- See additional research at the page endReferences or Citations section.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

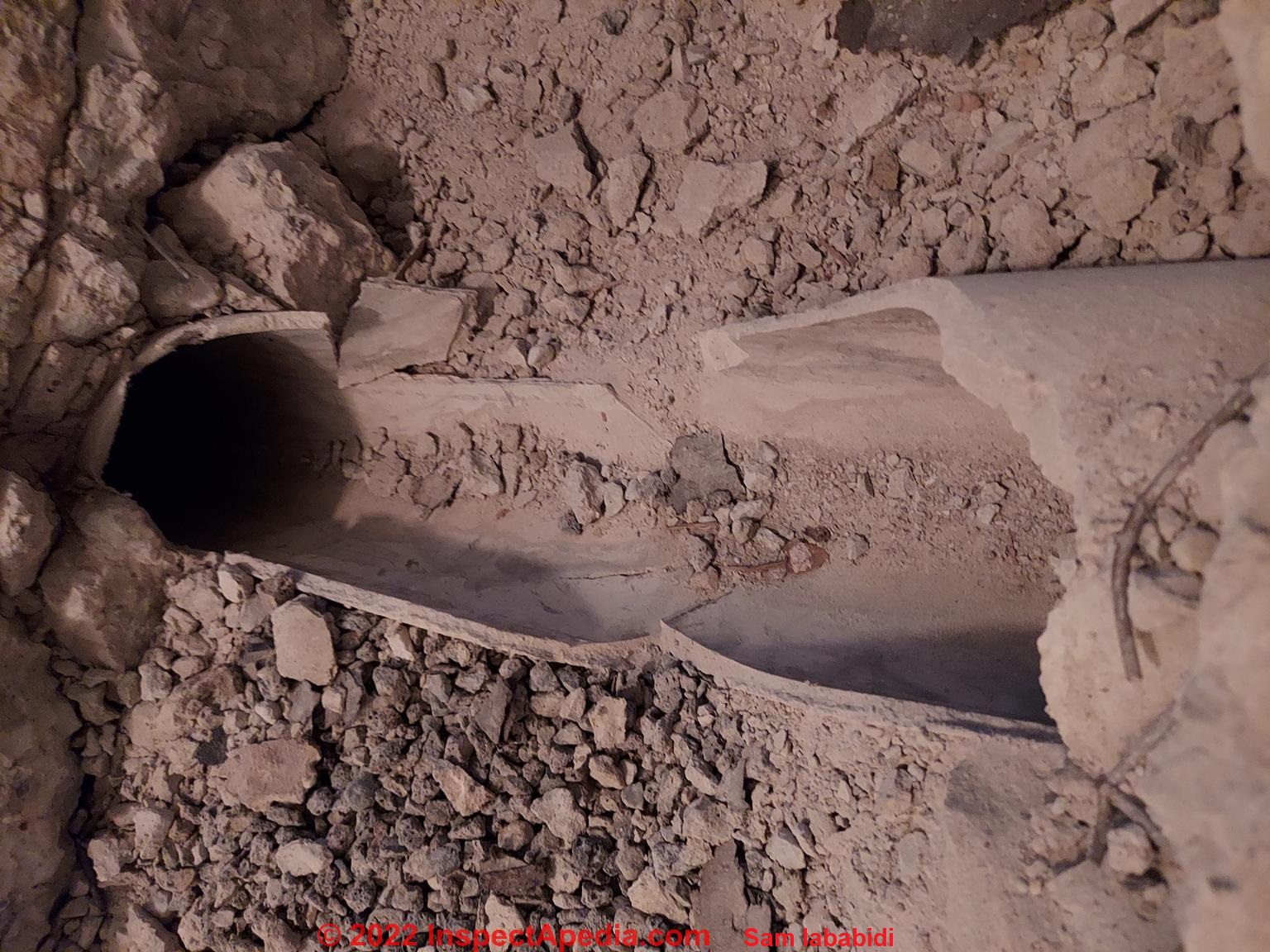

On 2022-08-18 by sam lababidi - is this asbestos piping found under my slab? Can it be fixed?

My plumber is replacing the sewer line under my slab.

My plumber is replacing the sewer line under my slab.

While doing so he damaged an cement air duct in the ground.

Can anyone tell if this is asbestos pipe.

House was built in the 1955.

Is there anyway to repair this air duct?

On 2022-08-20 by InspectApedia-911 (mod) - repair to damaged asbestos-cement (suspected) HVAC air duct in slab?

@Sam lababidi,

That could be transite pipe (asbestos cement) - though one can't say for dead certain from a photo, by building age and context that's a reasonable guess.

I hope you'll take a read through the article above for advice and opinion; ask any follow-up questions you need.

With apologies because I don't intend this to be glib, just about anything is "repairable" - the questions are about cost, benefit, and perspective.

It's certainly possible to patch in a section of PVC or similar duct material for a damaged in-slab transite air duct.

See Oberta (2004) cited at the end of the article above.

But as I ask you to read in this article series, there is such a long history of problems with in-slab HVAC ducts that spending on repairing such a duct system is in our opinion, questionable. You may be throwing good money after bad.

Those issues are explained more fully at SLAB DUCTWORK

On 2020-09-29 by Anonymous - how do I prevent a duct in an RCC slab from rusting?

How to prevent a duct in an RCC slab

from rust

On 2020-09-29 by danjoefriedman (mod) - metal ducts in concrete slabs risk trouble; Change the material, re-line the ducts, or best: abandon the system

Anon:

Thanks for a helpful question about condensation inside in-slab ductwork.

I don't think you can assure that there will not be rust in a metal duct installed in an RCC (Reinforced Concrete) slab;

The rust sources or really moisture sources extend beyond leaks into the duct system to include condensation problems and the fact that the slab won't be drained.

You'd need to use a non-metallic ductwork such as PVC, and even then, avoiding rust doesn't mean avoiding moisture and mold troubles.

Back to metal in-slab ductwork condensation and rust:

However insulating the ductwork exterior during construction and building a slab that's above grade level and protected from ground water entry would reduce those risks, as would

careful attention to catching any condensation in the air handler and draining that properly.A high indoor RH (relative humidity) level and the cooler temperature of the in-slab ductwork make condensation therein likely and so rust an ongoing risk, along with mold once there is a bit of organic dust in the slab system.

See details at WET CORRODED DUCT WORK and at WATER & ICE IN DUCT WORK

...

Continue reading at SLAB DUCTWORK or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see TRANSITE PIPE AIR DUCT ASBESTOS RISK FAQs - questions & answers posted originally at this page

Or see these

Recommended Articles

- ASBESTOS CEMENT PRODUCTS - topic home

- ASBESTOS DUCTS, HVAC

- CEMENT ASBESTOS PIPE MANUFACTURE

- SLAB DUCTWORK

- TRANSITE ASBESTOS CHIMNEYS, DUCTS, PIPES

- TRANSITE PIPE AIR DUCT ASBESTOS RISK

- TRANSITE PIPE CHIMNEYS & FLUES

- TRANSITE PIPE WATER SUPPLY PIPING

- TRANSITE WATER SEWER PIPE ASBESTOS RISK

- WET CORRODED DUCT WORK

- Also see Micro-Photographs of Dust from the World Trade Center collapse following the 9/11/01 attack.

Suggested citation for this web page

TRANSITE PIPE AIR DUCT ASBESTOS RISKS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about transite air ducts: asbestos cement air duct issues.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Thanks to astute reader Conrad for discussion of the procedure for diagnosing and curing the cause of sewer gas odors in ductwork, 01/31/2010.

- [2] Asbestos Identification, Walter C.McCrone, McCrone Research Institute, Chicago, IL.1987 ISBN 0-904962-11-3. Dr. McCrone literally "wrote the book" on asbestos identification procedures which formed the basis for current work by asbestos identification laboratories.

- [3] Stanton, .F., et al., National Bureau of Standards Special Publication 506: 143-151

- [4] Pott, F., Staub-Reinhalf Luft 38, 486-490 (1978) cited by McCrone

- [6] Anavi Z, Dizenhouse D, Oberta AF. Remediation of Land in Israel Contaminated by Asbestos Cement

Waste Material. Global Asbestos Congress, Osasco, Brazil. September 2000 - [7] Brown SK. Physical Properties of Asbestos-Cement Roof Sheeting after Long-term Exposure. J. Occup.

Health Safety-AustNZ 1998, 14(2), 129-134. - [8] Asbestos: Publication of Identifying Information; Notice. U S Environmental Protection Agency,

Washington, DC. Federal Register, February 13, 1990. - [10] ASTM E1368, ASTM Standard Practice for Visual Inspection of Asbestos Abatement Projects

- [11] ASTM E2356, ASTM Standard Practice for Comprehensive Building Asbestos Surveys

- [12] Nguyen, Tuan ; Hamilton, Jill, " Asbestos in Crawl Spaces", Corporate author: Naval Facilities Engineering Service Center, Port Hueneme CA, Oct. 1999, web search 6/11/12, PDF source: http://www.dtic.mil/cgi-bin/GetTRDoc?Location=U2&doc=GetTRDoc.pdf&AD=ADA370467,

Abstract : This document has been developed for use by Navy Asbestos Program Managers (APM), industrial hygenists, Safety and Health Managers, and facility managers to address asbestos contamination in crawl spaces. The contents provide direction for managing and abating asbestos hazards in these areas.

Section 1 contains primarily the technical and regulatory requirements. Sections 2 and 3 are checklists with detailed discussions for clean-up or abatement in crawl spaces.

These augment the NFESC Field Procedure Manuals for Managing Asbestos Abatement Demolition and Renovation Contracts, TM-2210-ENV and TM-2211-ENV, respectively. Section 4 lists the regulatory and technical references. - [13] Kenneth F. Cherry,Asbestos: Engineering, Management and Control, Lewis Publishers, 1990. [book]

- [14] Geoffrrey Tweedale, Magic Mineral to Killer Dust: Turner & Newall and the Asbestos Hazard, Oxford University Press, USA (May 24, 2001), ISBN-10: 0199243999 ISBN-13: 978-0199243990

- [15] J. Claydon,Control & Management of Asbestos in Buildings: System of Local Rules (HHSC Handbook), 1997

- [16] George A. Peters, Sourcebook on Asbestos Diseases: Asbestos Control & Medical Treatment, 1991

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.