Electric Motor Starting & Run Capacitor Types

Electric Motor Starting & Run Capacitor Types

Guide to Electric Motor Start-Boost or Run Capacitors

- POST a QUESTION or COMMENT about installing a hard-start capacitor to get an air conditioner motor, fan motor, or other electric motor running.

Types of electric motor start & run capacitors:

This article explains and gives an identification guide to types of electric motor capacitors: motor starting capacitor, motor run capacitor, dual-run capacitors, and hard start capacitors used on electric motors such as air conditioner & heat pump compressors, fan motors, some well pumps & some heating equipment motors.

We explain and illustrate how to recognize different types of motor capacitors and how to determine the use or identity of the different connector terminals on the capacitor.

This air conditioning, heat pump, or other electric motor repair article series discusses the selection, installation, testing, & use of electric motor starter start and run capacitors designed to get a hard-starting air conditioner compressor motor, fan motor, refrigerator, or freezer compressor or other electric motor (such as a well pump) going.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Types of Electric Motor Capacitors including Air Conditioning Compressor or Other Electric Motor Starting Capacitors

How to tell what type of capacitor is installed on your motor - difference between a starting capacitor, a run capacitor and a dual run capacitor

Capacitors are electric devices that, by storing and then releasing an electric charge. In many electric motors there are two types of capacitors present, a starting capacitor and a run capacitor.

Dual run capacitors support the operation of two motors from a single advice, such as an air conditioner compressor motor and a fan motor. Hard start capacitors give an extra large starting boost to hard-starting electric motors, possibly extending their service life.

[Click to enlarge any image]

For example, air conditioner and heat pump compressor motors (and lots of other electrical motors) that run on two-phase (220V) or single phase (120V) electrical power include a capacitor in the start circuit to help get the motor spinning and a capacitor can be put into the "run" circuit of the motor as well to increase motor efficiency.

Start Capacitors: Get a Motor Spinning

A starting capacitor such as the Global universal start capacitor shown at above-left has the single job of giving a large voltage boost to give extra turning force or torque to a motor to start it spinning in the right direction by providing about double that nominal system voltage.

See ELECTRIC MOTOR RUN DIRECTION

A start capacitor does not keep at the job once the motor is operating. The rating on a starting capacitor will include a high MFD number and the operating voltage range. Temperature ranges and other data may also be provided on all caps.

Starting capacitors will be of much higher microfarad uF or MFD rating than run capacitors. As you may notice from the forest of connection points on the top of the round capacitor shown above, there may be multiple wiring connections depending on the capacitor's use and features - connections we explain in this article series.

The start capacitor rating or power in microfarads (uF or MFD) required depends on the size, voltage, and other properties of the motor that it's starting.

Some manufacturer's capacitor models such as AmRad's MARS universal Turbo All-in-One capacitor (shown here) as many as six terminals will use color coding combined with markings on a label wrapped around the capacitor to indicate the uF rating of each connector, such as 5 uFD - White, 2 uFD - Green.

By using a combination of jumper wires the installer can generate and choose among up to 200 different uF ratings for her specific application.

Typical ranges for electrical motors likely to be found in a home (air conditioning compressor motors, fans, pumps) are from around 150 to 480 MFD and at voltages of 120-240-440. Prices for a start capacitor range widely from under $10. U.S. to over $100.

Watch your prices when buying a universal or any other replacement capacitor. I have seen the AmRad Turbo 200x universal motor run capacitor at about $10., $55., and $85. U.S.D.

If the start capacitor has failed the symptom is that the motor won't start. If either or both start and run capacitors are defective the motor may try to start but will hum and won't keep running. You may hear a compressor or fan motor humming or observe that it's getting hot.

Watch out: If you observe a humming electric motor that is not starting we suggest that to avoid damage you turn off the system while waiting for repairs.

Run Capacitors are Used to Improve Electric Motor Power & Efficiency

Function of a run capacitor

Once the motor has started, a run capacitor may be used to help the motor retain full power, providing 1.5 x the nominal system voltage and varying as needed depending on the load on the motor.

Copeland explains the run capacitor as follows:

Run capacitors are used on compressors to improve efficiency, raise the motor’s power factor, and lower noise.Run capacitors are continuously in the operating circuit and are normally of the metallized film type. They are manufactured in oval or round cans. - Copeland Electrical Handbook p.A7.

The oval motor-run capacitor sold by Dayton (made in China) and here is the simplest two-terminal run capacitor you'll encounter and is sold in a range of MFD ratings, voltage ranges, and in oval and round shapes.

This is a single-purpose capacitor with one uF or microfarad rating intended to support one electric motor. Below you'll read about more-complex capacitors that can provide both start and run support or that can provide run assistance for two different motors at two different capacitances, such as a compressor motor and a fan motor.

In some old-school class views adding a run capacitor is similar to making two-phase out of one-phase electricity and is a common practice on air conditioners.

What these folks really are saying is that "With capacitive reactive power of about 75% of the nominal power of the motor, the comparison of power is slightly lower than that of a three-phase motor of equal size." [2]

Technical notes: Single phase electric motors such as those used in air conditioner compressors and fan motors contain two different stator windings: an auxiliary starter winding fed by an electric capacitor and a main run winding fed by the principal electrical circuit.

The auxiliary starter winding is used to provide an extra boost (and proper direction

see details at ELECTRIC MOTOR RUN DIRECTION)

to get the motor spinning at start-up.

Three phase electric motors do not use start/run capacitors.

Definition of PSC, CSR and CSCR capacitors

Electric motors that use start/run capacitors may be PSC (permanent split capacitor) and CSR / CSCR (capacitor start, capacitor run) designs.

Unlike a PSC motor, a CSR/CSCR motor must also have a starting relay that will cut the start capacitor out of the electrical circuit once the motor has gotten up to run speed.

The run capacitor then remains in the circuit to keep the motor spinning properly.

Definition of a PTC Start Assist Resistor

The PTC (Positive Temperature Coefficient) resistor is used for applications where high starting torque is not required.

The PTC resistor is connected in parallel with the run capacitor, placing it in series with the start winding (Figure 6). The PTC has a low resistance when it is cold. When the motor starts, the low resistance causes a large current to fl ow through the resistor.

The current drawn by the resistor is out of phase with the current drawn by the motor windings, and this provides the torque to start. As soon as the resistor draws current, it begins to heat, and the positive temperature effect of the resistor causes it to rapidly increase its resistance. By the time the motor reaches full speed, very little current is drawn by the resistor.

Although it remains connected to the motor circuit, it has no significance in the operation of the compressor. - Copeland Electrical Handbook p.A7- A8.

Dual run capacitors operate two different electric motors at once

A dual run capacitor for electric motors combines two different microfarad-rated (MFD/uF) capacitors in a single housing or container such as the Dayton capacitor examples shown at left, and provides run support for two different motors.

In a common air conditioning application these would be the compressor (marked Herm), and the compressor/condenser unit fan (marked F or Fan).

To spot a dual run capacitor that operates both the compressor and the fan motor, look for three terminals on the capacitor: one will be marked "common" or may be marked with a red dot to indicate that role.

A dual run capacitor will always have [at least] three wiring terminals - as you can see on both examples above, while a simple single-use "run" capacitor will have only two terminals providing a single MFD capacity.

In contrast with a dual run capacitor that serves two motors, single-run capacitor serves just one motor.

As we explain next, usually you'll find that on a typical HVAC capacitor you have multiple ways to identify the connecting terminals or clips or "tines":

How to Identify Which Connecting Terminal is Which on a Dual Run Capacitor

On a dual run capacitor the terminals will be marked "C", "HERM" and "FAN". Check the markings, color code and number of connecting clips at each of the three terminals on your capacitor.

On a dual run capacitor the terminals will be marked "C", "HERM" and "FAN". Check the markings, color code and number of connecting clips at each of the three terminals on your capacitor.

Shown here, color coded terminals on an AmRad Engineering Run Capacitor, part # USA2236. The individual capacitor data label will give its rating such as 45+5 MFD 370 or 440 VAC 50-60 HZ. AmRad's product code for the part shown is #3460.

[Click to enlarge any image]

- F - Fan will be marked with an "F" or "FAN" and usually has just two connecting clips at that terminal. The Fan terminal is used to connect the capacitor to the fan motor in an air conditioner or heat pump compressor/condenser unit.

On a typical round dual-run capacitor this terminal may also be referred to as the "Low Cap" and will typically have just two connecting spaces or tines.

On some manufacturers' capacitors (such as AmRad Engineering) the F or Fan connector tines are surrounded by a green plastic shroud

This connection provides the lower capacitor rating, in this example, 5 MFD or microfarads of capacitance. - H - Herm (hermetically sealed compressor) will be marked with an "H" or "HERM" and usually has three connecting clips at that terminal. The H terminal is used to connect the capacitor to the compressor motor in an air conditioning or heat pump compressor/condenser unit.

On some manufacturers' capacitors (such as AMRAD Engineering) the H or Herm connector tines are surrounded by a white plastic shroud

This may also be referred to as the "High Cap" and will typically have three connecting tines.

- C - Common terminal will be marked with a "C" or "COM" and usually has four connecting clips or connecting tines. The common terminal is used for incoming electrical power and on an air conditioner condenser unit is typically fed from the unit's contactor relay.

On some manufacturers' capacitors (such as AMRAD Engineering) the C connector tines are surrounded by a black plastic shroud

How to read the MFD or MicroFarad rating numbers on a dual run electric motor capacitor

The rating on a dual run cap will include two MFD ratings and a voltage range, such as 45/5/440 expressed in numbers separated by a slash and interpreted as follows:

- 45 MFD - the largest MFD number, A dual-run capacitor has two MFD ratings that are typically expressed in numbers separated by a slash, such as 5/40 or 5uf/40uf.

- 5 MFD - smaller number (5uf) is the smaller capacitor used to run the compressor/condenser unit's cooling fan motor.

- 440 (the maximum voltage range)

The particular starting capacitor to be purchased is matched to the horsepower range and voltage of the compressor or motor being repaired.

Many motor starter capacitors to support a pretty wide range of motors. For example our sample capacitor was rated for use on 115V electric motors rated from 1/12 horsepower to 1/2 horsepower.

Prices for typical air conditioner compressor starter capacitors range from around $10. to $50. U.S.

Hard-start start capacitors or "booster" capacitors?

If your air conditioner has stopped running a possible problem is the failure of the starting capacitor found on the outside compressor/condenser unit.

See details at LOST COOLING CAPACITY

If that unit has electrical power but the compressor and/or its cooling fan are not running, one of the components to check (and that is easy to replace) is the starter.

When an electrical motor is having trouble starting, such as an air conditioning compressor motor, blower motor, a refrigerator motor or a freezer motor, or even a fan motor, the repair technician may install a simple and inexpensive hard-start capacitor.

See details

at HARD STARTING COMPRESSOR MOTORS

The starting capacitor is a simple electrical device which can give an extra voltage jolt or "boost" to get the hard-starting motor spinning.

The capacitor in our page top photo is oval in cross section, but most replacement and many newer air conditioner motor starting capacitors are simply cylindrical in shape (photo at left).

We give capacitor wiring details

at MOTOR CAPACITOR WIRING GUIDE

These dual run caps are available at Grainger (http://grainger.com) as well as electrical and HVACR suppliers. Dayton Electric Manufacturing company, 14441 W Il Route 60,

Lake Forest, IL 60045

(847) 535-1000, produces electric motors, fans, pumps, electric capacitors, audio capacitors, tools, even hand trucks.

Examples & Sources of Start / Run Motor Capacitors & Dual Capacitors - Capacitor Number Decoding Charts

Shown here, a 50-5 uF dual run capacitor typical of those use on air conditioning compressor/condenser units.

Shown here, a 50-5 uF dual run capacitor typical of those use on air conditioning compressor/condenser units.

We have marked the identity of the three connectors found on the capacitor top. You may see identical-looking capacitors with labels indicating different manufacturers such as AmRad, Jard or MARS (Motors & Armatures). This is a MARS2 328PSH37N31ASZ9 # 12755, 50 uF + 5.0 uF 370VAC dual run capacitor.

Watch out: be sure to check the identification and use of the connectors on your replacement start / run or dual run capacitor. Some models like the MARS brand 5-97.5MFD Turbo 200X Universal Capacitor (370/440V) can have as many as six terminals on the capacitor top. Most-likely, in repairing an air conditioner condenser unit you will be using just three of them.

Also see MOTOR CAPACITOR WIRING GUIDE for details about wiring up a capacitor to a motor.

[Click to enlarge any image]

- COPELAND ELECTRICAL HANDBOOK [PDF], Emerson Climate Technologies, White-Rodgers US 8100 West Florissant Avenue Saint Louis MO 63136 USA, Customer Support: email: wr.techsupport@emerson.com, Tel: 1-888-725-9797 U.S. & Canada

- Cornell Dubilier Electronics (CDE) Dual Run Capacitor rated at 45-4K MFD, typical application in Lennox and other air conditioning compressor units to operate the compressor motor and fan motor.

- MOTOR START and RUN CAPACITORS [PDF] AFCAP (African Capacitors Limited), Metallized polypropylene film capacitors for motor running applications web search 08/05/2011, original source: http: //www.afcap.co.za /manual/Part2.pdf; 2018/07/11 update: the original source link is no longer valid - Ed.

- TYPE SF DUAL, ROUND & OVAL, OIL-FILLED MOTOR RUN CAPACITOR SPECIFICATIONS [PDF] CDE Cornell Dubilier Electronics, 1605 E. Rodney French Blvd.., New Bedford, MA 02744 USA, Tel: (508)996-8561 Website: www.cde.com

Lists CDE dual capacitor models and features

Description: Type SF dual rated oil filled motor run capacitors made with self-healing metallized polypropylene film are commonly used in air conditioning, motors and compressor applications.

The dual ratings in a single can provide two capacitors - one may be used as a fan capacitor and the other as a compressor or motor run capacitor. Three terminals allow one terminal to act as a common while the other two are connected to the individual capacitors. - TYPE SF DUAL, ROUND & OVAL, OIL-FILLED MOTOR RUN CAPACITOR NUMBER DECODER [PDF] from CDE, Op. CIt.

Description: Type SF dual rated oil filled motor run capacitors made with self-healing metallized polypropylene film are commonly used in air conditioning, motors and compressor applications.

The dual ratings in a single can provide two capacitors - one may be used as a fan capacitor and the other as a compressor or motor run capacitor. Three terminals allow one terminal to act as a common while the other two are connected to the individual capacitors. - TYPE SF MOTOR-RUN AND POWER SUPPLY CAPACITOR NUMBER DECODER [PDF] CDE, Op. Cit.

Description: Type SF, AC rated metallized polypropylene capacitors provide starting torque and power factor correction for split phase motors typically used in refrigeration and air conditioning motor run applications.

Type SF also may be used to provide noise suppression, voltage regulation and line current reduction in power supply applications. - Packard 370V 45+5 MFD Round Run Capacitor

- Supco™ 30+5 MFD 440V 440 Volt 50/60 Hz Round Motor Capacitor (typical application for Amana, Carrier, Rheem, Trane equipment)

- Supco™ 45+5 MFD 440V 440 Vol 50/60 Hz Round Motor Capacitor (typical application for Amana, Carrier, Rheem, Trane equipment)

- Supco HS6 (SPP6) Hard Start Relay Capacitor (230V) gives a starting torque boost of up to 500%. Quoting from product sales literature:

The SUPCO SPP6 Super Boost hard start capacitor increases starting torque up to 500%. Features: Installs in seconds across run capacitor terminals Contains specially designed relay and large start capacitor for severe hard start problems.

Applications: Room A/C units, Residential and commercial PSC A/C units and heat pumps, For all PSC A/C units from 4,000 thru 120,000 BTU's (1/2 thru 10 H.P.) Can be used on 120 thru 288 VAC units, For severe low voltage and hard starting compressors. SPP6 Specifications: Voltage: 115V - 230V. Increased Torque: 390 ounce inches. - retrieved 6/16/14 Amazon.com sales - Supco™ Universal (broad application) Capacitor, 10 MFD at 370V

Question: What's the Difference between dual capacitors and single capacitors?

Hi guys. Watching all of these videos online about no start a/c compressor fans or motors they all change the dual run capacitor and the unit starts.

Hi guys. Watching all of these videos online about no start a/c compressor fans or motors they all change the dual run capacitor and the unit starts.

Are they really run capacitors, start capacitors, or both. Is the 45 for the compressor, and the 5 for the fan to jump start the starter windings, or is 45 the start for both motors, and the 5 for running of both motors. Nobody seems to clarify those numbers.

No matter how many videos that I watch, they always call it a dual run capacitor, and I never seen them change a single capacitor that is just a start capacitor. Just don't get it. Thanks.

- Anon by private email 2017/11/24

Shown here: a CDE (Cornell Dubilier Electronics) Dual Run Capacitor. For this run capacitor, CDE # 100335-48 rated at 45-4uF +/- 10% 440VAC 50/60 Hz the two microfarad or MFD ratings are 45 MFD and 5 MFD (the higher number for the compressor motor the lower number for the fan motor)

Reply: how to identify your capacitor and how to decode its number markings.

Thanks for asking, I agree that these capacitor types and names can be confusing.

Electric motors and how they run and use capacitors vary:

1. Some electric motors use no capacitors at all. We'll skip those for now.

2. Other electric motors require a capacitor to get the motor spinning (the start capacitor) and another capacitor keep the motor spinning after it's up to speed (the run capacitor).

First Let's Summarize Three A/C Capacitor Types

Start capacitor - start the motor spinning - we need more of a kick to start up a motor that's not moving. Typical start capacitors on equipment you'll typically see are in the 70 to 120 uF or microfarads. It's giving the motor a big kick in the patuchka to get it started up.

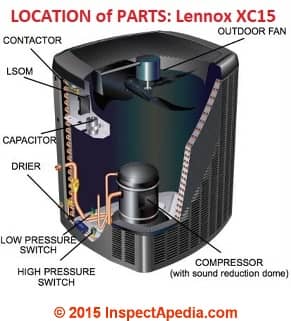

Your Lennox XC15 does not sport a Start Capacitor.

Run capacitor - keep the motor spinning - A typical run capacitor doesn't need so much oomph as the motor is already spinning, so it'll be in the 7-9 uF range. It's giving the motor just a little extra torque force to keep the motor spinning.

The term "dual capacitor" can be confusing because there are two kinds of "dual capacitors":

Dual Start/Run Capacitors - three- lead capacitors to combine "start" function and "run" function in a single device. So a dual capacitor for a fan motor will have three leads,

- Common - incoming power

- Start - power used just while the motor is starting up

- Run - power used while the motor is running

I like to call those "dual function" capacitors as they combine two functions: start, and run, in one physical device. They would not work any differently than if two physically separate capacitors were installed, one for starting and one for running, but in a single device less space is needed.

Your Lennox XC15 does not sport a dual start-run Capacitor. Recapping notes given earlier in this article,

Dual Motor Run Capacitors - three lead capacitors to combine the "run" function for two physically separate motors in a single device. So a dual capacitor for an air conditioning condenser unit will have three leads

- Common - incoming electrical power

- F - for Fan - to run the fan motor

- H - for HERMetically sealed compressor motor - to run that big compressor motor

I like to call these dual motor capacitors since the same cap runs two different motors.

This is the type of capacitor found on your Lennox XC-15 condenser unit. So if you search for "Where is the start capacitor on a Lennox XC15" you'll find only references to this dual motor capacitor.

Reader follow-up: What Type of Capacitor is Installed in my Lennox Condenser Unit?

Thank you for your quick reply. But I still have a problem. The system is a Lennox xc15-036-230-04.

Thank you for your quick reply. But I still have a problem. The system is a Lennox xc15-036-230-04.

The capacitor is a 45-4 uf. At 440 ac.

The way the schematics read, there is a dual capacitor with wires going to both the compressor s winding and the fan motor. The fan motor [ on my XC15 ] does not have C H F on it but it does have three wires. When I look up those 45-4 numbers on the internet, it comes back as a dual run relay.

Unless s stands for stator, I just don't get it. A start capacitor is supposed to have high microfarads. This seems like the run of the mill dual run relay. But why does the h terminal on the capacitor go to the s on the compressor motor.

I thought a run capacitor would not be in the s circuit of a compressor motor. And since the fan motor has no winding letters, I don't know if that 4 is in the start or run windings. Thanks. It is just very conflicting.

Reply: yours is a dual run capacitor

On your photo of the wiring diagram shown above, one that you took from inside of your Lennox XC15 condenser, unit I've marked the electrical wire connections between the capacitor and the compressor and fan motors.

[Click to enlarge any image] We also provide a complete copy of the wiring diagram for the Lennox XC15 series condensers

at LENNOX XC15 SERIES SPLIT SYSTEM CONDENSER UNIT WIRING DIAGRAM [PDF]

Where to Find the Condenser Unit Capacitor

First we have to look in the right place. C H F will be marked on the start/run capacitor, NOT on the fan motor and NOT on the compressor motor.

First we have to look in the right place. C H F will be marked on the start/run capacitor, NOT on the fan motor and NOT on the compressor motor.

If you click to enlarge the image shown here, (adapted from the Lennox XC15 Installation Manual found at at LENNOX HVAC MANUALS & PARTS GUIDES Industries Air Conditioners, Furnaces, Heat Pumps , Manuals, Guides) you'll see the capacitor's location marked in the unit's left side. The letters C F H are marked on the top of the capacitor by its terminals.

Below in these notes I'll explain two other ways to figure out which terminal on the dual run capacitor is which and to what wire each of these terminals should be connected.

Even before decoding the markings on your capacitor we can be pretty sure this is a "run" capacitor not a "start" capacitor because of its comparatively low 45-4 MFD rating. That's 45 microfarads or 45 MFD for the compressor motor. If this were a start capacitor it's rating would be more likely in the 180-200 MFD range.

Decode the Data Tag on your Capacitor from CDE: this is a run capacitor.

The CDE capacitor # 1--335-48 is produced by Cornell Dubilier Electronics (CDE)

45-4uF +/- 10% 440VAC 50/60 Hz gives the two microfarad or MFD ratings 45 and 5 (the higher number for the compressor motor the lower number for the fan motor)

SFS44S45-4K475E gives the capacitor model

SF-capacitor series

S - case type (Round)

44 - 440VAC voltage rating (maximum)

S - case material (steel)

45-4K - the two MFD ratings for the capacitor

475 - case height (or length) 4.75"

E - variety, where yours = Dual 2,3,4 70 ºC

The C H F indicators as I noted earlier, will be marked not on the fan motor but rather on the capacitor itself, usually on its top surface next to the connectors but on some capacitors the terminals may be identified by imprints on the sides of the capacitor on a label just below the connector.

F to Fan: So on the Cap the terminal marked F would go to the fan motor - in your wiring diagram showing the capacitor that'd be the purple wire.

H to Compressor: And on the Cap the terminal marked H (as in HERMetic Compressor) goes to the compressor - that'd be the yellow wire from H on the capacitor to S on the compressor.

C to Common: And on the Cap the terminal marked C (Common) gets the incoming red wire that's supply voltage.

At CDE this capacitor is Part No. 100335-48 (and is available from some online vendors like lennoxpros.com

I found replacement units of the same range for sale from many vendors.

Here is an excerpt from a similar product spec sheet for CDE SF type Motor Run Capacitors

Type SF dual rated oil filled motor run capacitors made with self-healing metallized polypropylene film are commonly used in air conditioning, motors and compressor applications.

The dual ratings in a single can provide two capacitors - one may be used as a fan capacitor and the other as a compressor or motor run capacitor.

Three terminals allow one terminal to act as a common while the other two are connected to the individual capacitors.

Trust the wiring diagram.

Here is a typical SF type capacitor specification sheet:

- TYPE SF DUAL, ROUND & OVAL, OIL-FILLED MOTOR RUN CAPACITORS [PDF] CDE Cornell Dubilier Electronics, 1605 E. Rodney French Blvd.., New Bedford, MA 02744 USA, Tel: (508)996-8561 Website: www.cde.com

Sorry, I know this can be confusing. Also see this service guide for your Lennox condenser unit:

- LENNOX XC15 SERIES SPLIT SYSTEM CONDENSER UNIT SERVICE MANUAL [PDF], (2009) Lennox Industries Inc.

Description: The XC15 is a high efficiency residential split−system condensing unit, which features a scroll compressor and R−410A refrigerant. Units are available in 2, 2−1/2, 3, 3−1/2, 4 and 5 ton sizes. The series is designed for use with an expansion valve only (approved for use with R−410A) in the indoor unit.

This manual is divided into sections which discuss the major components, refrigerant system, charging procedure, maintenance and operation sequence. Information contained in this manual is intended for use by qualified service technicians only. All specifications are subject to change. - Other Lennox service manuals and contact information for the Lennox corporation are at LENNOX HVAC MANUALS & PARTS GUIDES Industries Air Conditioners, Furnaces, Heat Pumps , Manuals, Guides

Readers needing service manuals for other heating or cooling equipment can find them at MANUALS & PARTS GUIDES - HVAC - home - Master Index to All Brand Names & A-E HVAC manuals, wiring diagrams, installation and repair guides

Question:

(Feb 21, 2014) Anonymous said:

is it possible to rebuild a submersible well pump

Reply:

Yes ... maybe; it depends on the condition of the pump casing, parts, an in my opinion, an accurate diagnosis of the trouble; at some point rebuilding is not cost effective. Indeed there are specialists (H Shreck in Poughkeepsie used to be one of them) who rebuild electric motors of all kinds.

There are also many water pumps whose design makes it quite reasonable to replace pump impellers.

So to answer your question, I dunno - it depends on what's broken.

Question: fan will start but won't keep running.

(June 1, 2014) Anonymous said:

The fan on my Conquest 80 will not stay on (interior fan). It starts and then stops after a few seconds. It was installed in 2005. Help.

Reply:

Anon,

The start capacitor is for getting a motor started, not keeping it running.

Often motors have two windings, a start winding and a run winding. Your motor's run winding may be damaged.

Or your fan motor may require a dual capacitor (start and run) or a separate run capacitor to keep it spinning.

Or your system may have a faulty control.

Question: will a hard start capacitor reduce current drawn and stop tripping a breaker

(June 7, 2014) Joel said:

I have a commercial hood & exhaust fan (120v) running in a food truck that is used for catering. We occasionally need to run off a generator (3000w) and we've found that the fan cause the generator overload to trip. The fan has been tested and observed to draw 8 amps running at full speed. Given this, would it be possible to add a hard start kit, such as SUPCO SPP4E? Will need to confirm the motor size, just wondering if this would help.

The total draw of all items is less than 20 amps and the generator is capable of supplying 25 amps constant.

Thanks for the advice.

Reply:

Joel I think the problem lies elsewhere and needs some further diagnostics. I suspect that your total current draw is exceeding the ability of the generator - you may be running more than the fan, such as lighting, a cooler, toasters, other electrical appliances. If it were just the fan, drawing 8A, it has no business tripping the breaker.

Put another way if the problem is the fan and there are NO other appliances running, then there is a failing fan motor drawing high current, or an electrical short circuit or other unsafe condition to find and fix.

A start capacitor or a run capacitor won't change the current drawn by the motor.

...

Continue reading at LOCATE the STARTING CAPACITOR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see A/C or HEAT PUMP MOTOR CAPACITOR DIAGNOSTIC FAQs, diagnostic questions & answers about capacitors used on HVAC equipment.

Or see CAPACITORS for HARD STARTING MOTORS FAQs - questions & answers about starting capacitors posted here.

Or see CHOOSE a START RUN CAPACITOR FAQs

Or see these

Recommended Articles

- BASIC ELECTRICAL TESTS for BURNED OUT COMPRESSOR MOTORS

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CAUSES of HARD STARTING ELECTRIC MOTORS

- CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

- COPELAND ELECTRICAL HANDBOOK [PDF]

- HARD STARTING COMPRESSOR MOTORS

- HOW a STARTING CAPACITOR WORKS

- HOW to TEST the MOTOR to ID TERMINALS

- LOCATE the STARTING CAPACITOR

- MOTOR CAPACITOR WIRING GUIDE

- STARTING CAPACITOR SAFETY

- TEST a MOTOR START or RUN CAPACITOR

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- HARD STARTING ELECTRIC MOTOR CAUSES

Suggested citation for this web page

MOTOR CAPACITOR TYPES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Supco, Sealed Unit Parts Company, PO Box 21, 2230 Landmark Place, Allenwood, New Jersey, 08720, Tel: 732-223-6644, 201-449-3300, email: info@supco.com, provided the compressor starting capacitor and packaging information (purchased by the author from an air conditioning parts supplier in New York) - our example uses a Sealed Unit Parts Company Solid State part No. RSC 10 115V starting capacitor which was designed for installation on refrigerators and freezers. See www.supco.com/

- Essex, Brown: "Motor Repair Supplies" (Catalog), Essex Group, Inc., 1601 Wall St., Fort Wayne, Indiana 46801, Tel: 219-461-4633, Website: www.superioressex.com, retrieved 6/20/14, original source: http://www.essexbrownell.com/uploadedFiles/Content/Products/MR%20Supplies%20Catalog-s.pdf - see pp. 86-89.

- Sealed Unit Parts Co., Inc., PO Box 21, 2230 Landmark Place, Allenwood NJ 08720, USA, Tel: 732-223-6644, Website: www.supco.com, Email: info@supcocom, Supco Catalog, retrieved 6/20/14, original source: http://www.economicelectricmotors.com/cdrom/catalogs/Supco_catalog.pdf - see pp. 2-6.

- van Roon, Tony, "Capacitors", [online article], retrieved 6/20/14, original source: http://www.sentex.ca/~mec1995/gadgets/caps/caps.html, gives a very detailed history of the invention and history of electrical capcitors beginning with van Musschenbroek's Leyden jar in 1745. This article includes

"Capacitor Nomenclature" by Dean Huster. - Kaiser, Cletus J., The Capacitor Handbook: A Comprehensive Guide For Correct Component Selection In All Circuit Applications. Know What To Use When And Where, 2d Ed., [at Amazon.com] C.J. Publishing (2011), ISBN-10: 0962852538, ISBN-13: 978-0962852534 - product description

This book provides practical guidance and application information when using capacitors in electronics and electrical circuit design. This easy-to-use book covers the following capacitor types: Ceramic, Plastic Film, Aluminum Electrolytic, Tantalum, Glass, Mica, and others. This book also has a very comprehensive Glossary and Index. The Selection Guidelines and the Symbols and Equations sections have the answers to all of your daily application questions. This book is one in a series of component handbooks. - "The E Class Advantage", Supco (op cit), describes the company's advanced start/run capacitor products. Web search 08/04/2011, original source: http://www.supco.com/eclassadvantage.htm Quoting from that article:

The SUPCO E-Class Series comprise the most advanced developments in start device technology:

1. Voltage sensing technology that monitors for motor start (current sensing devices require internal fuse protection).

2. A 2-wire connection that simplifies installation

3. A secondary timing circuit that ensures that the capacitor is not permanently left in the start winding circuit

4. A fully electronic device - minimizing the limitations of mechanical devices and secondary fusing associated with triac devices

5. A start device matched with an appropriately sized capacitor to cover the range of compressors for the intended application (one size does not fit all)The use of compressor start devices results from a need to ensure that a compressor (usually air conditioning) will start under voltage conditions that are less than ideal. As discussed, several options exist in the market to address compressor start concerns. Start devices exist in many forms for specific applications. SUPCO provides a full range of products in all relevant technologies to effectively match the proper start device to the application. Care should be taken to utilize a device that meets the requirements of the job. Extra caution should be observed when employing the "one-size-fits-all" and "a bigger capacitor is better" approach to applying a start device. Consult SUPCO, a manufacturer with a complete product range, to ensure the greatest success in the start device application.

- [2] "Motor Start and Run Capacitors", AFCAP (African Capacitors Limited), web search 08/05/2011, original source: http://www.afcap.co.za/manual/Part2.pdf

- COPELAND ELECTRICAL HANDBOOK [PDF] free download from Emerson Climate Controls, at InspectApedia.com

- [3] "Kenmore model 580. 75121 room unit air conditioner wiring diagram", Sears Roebuck window air conditioner wiring diagram for a typical room or window air conditioner

- George Fazio, reader, contributed comments on failed starter capacitor diagnosis by noting the bulged capacitor ends. 09/25/2009

- Troubleshooting Compressor Problems," Henry Puzio, Fuel Oil & Oil Heat with Air Conditioning Magazine, June 1993, p. 39

Tom Morris, Engineer, capacitor discussion and correction to the original data. Email to D Friedman 5/29/2006 - Thanks Tom for critical editing. The text above explaining about capacitors was suggested by Mr. Morris. The original text of the 1993 compressor diagnosis article had the resistance explanation backwards. - Thanks to reader Diane McGivney for asking about air conditioner compressor motor starting capacitor costs and typical air conditioner service call fees - (May 2010)

- Thanks to reader James Oiler for reporting on the replacement of a heat pump starter capacitor, August 2010.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.