Duct Sizing Tables & Duct Defects

Duct Sizing Tables & Duct Defects

HVAC Air Duct Size, Adequacy, Safety, Defective Materials, Asbestos, Mold

- POST a QUESTION or COMMENT about Air Duct & Air Flow Problems on Heating & Air Conditioning Systems

How to specify the size of HVAC ducts & how to inspect duct systems for defects, leaks, damage.

This article explains how to inspect and diagnose trouble with heating or cooling air flow, air ducts, air registers and zone components of heating and air conditioning (HVAC) duct systems.

This diagnostic article describes common defects found in HVAC duct work such as incomplete supply or return ducts, poor choice of location or size for supply and return registers, locating ducts in problem areas, leaks into and corrosion of duct work, leaky duct connections, and special notes on product failures by two manufacturers of flexible duct work.

The article includes important safety warnings about dangerous openings in HVAC duct work.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Diagnostic List of Heating & Cooling Air Duct Defects: Things to Inspect, Check, Repair, or Replace

We explain how to find and correct air duct problems such as missing air conditioning cool air supply

or return air registers, undersized air conditioning duct openings, improper cooling duct routing, cooling (or heating) air duct corrosion, leaky air duct connections,

defective heating or cooling ductwork materials such as Goodman gray flex-duct, some Owens Corning Flex-duct, and asbestos-containing air conditioning or heating duct work.

We explain how to find and correct air duct problems such as missing air conditioning cool air supply

or return air registers, undersized air conditioning duct openings, improper cooling duct routing, cooling (or heating) air duct corrosion, leaky air duct connections,

defective heating or cooling ductwork materials such as Goodman gray flex-duct, some Owens Corning Flex-duct, and asbestos-containing air conditioning or heating duct work.

Article Contents

- HVAC DUCT SIZING GUIDES

- HVAC Supply & Return Air Duct Leaks & Obstructions - Theory vs Practice

- AIR DUCT THEORY: The D'Arcy-Weisbach formula

- AIR DUCT PRACTICE: List of Common Air Flow Obstructions in HVAC Systems & Ductwork

Air conditioning duct system defects include a remarkably wide range of errors, from failure to supply cool air or failure to even circulate air in the building, to health hazards such as use of asbestos material in or on duct work, to very dangerous conditions such as drawing heating equipment combustion gases into the building cooling (or heating) air.

The master document, of which this is a chapter, describes the inspection of residential air conditioning systems (A/C systems) to inform home buyers, owners, and home inspectors of common cooling system defects. Asbestos in or on HVAC ducts is a possible hazard for which we provide links to a separate document - see "Asbestos HVAC Ducts" at below left.

Below we list some common sources of poor air flow from air conditioning or heating duct systems: check these first before ordering a more costly survey or repair job.

HVAC Duct Sizing Guidelines

Question:

Question:

2019/11/14 Charlie said:

Hi My name is Charlie I have a question? .

I'm installing a 3ton with Furnace unit 1200 CFM locating the unit in the middle of the basement doing a extended trunk off each side from what i have looked up I can install 16x8 duct @ 700 CFM with two trunks would give me 1400 CFM. is this correct.

[Click to enlarge any image]

This Q&A were posted originally

Reply: factors in sizing ducts for a given CFM provided at the blower or air handler unit AHU

Charlie

I'm not a mechanical engineer nor duct sizing expert but indeed there are quite a few duct sizing guidelines we can check out.

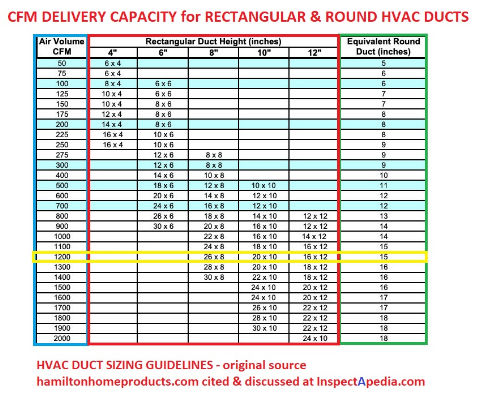

The table shown here is adapted from the original guideline provided by Hamilton Home Products cited below.

There are also some simple HVAC air duct sizing and CFM rules of thumb that we provide below on this page .

If your furnace blower capacity is 1200 cfm, that's a capacity measured right at the air handler output plenum. Restrictions in the ductwork such as in diameter or elbows and bends will reduce the effective CFM from that number (as will a dirty blower fan).

Extending two ducts off of the supply plenum in two directions is of course a common practice.

In the duct sizing reference chart shown here, adapted from Hamilton Home Products cited below, I have outlined the chart's 1200 CFM line in yellow to show the recommended duct sizes.

To supply 1200 CFM and sticking to your 8-inch duct size, if your duct is RECTANGULAR then according to our duct chart you'd need an 8" duct that's 26" x 8"

OR if you're using round duct you'd need a 15-inch diameter round duct.

Seems to me you can of course split off the 1200 CFM at the air handler (AHU) into two smaller trunks as long as the total meets or exceeds the original number.

Since 2 X 16x8" ducts is roughly (not exactly) = 1 32 x 8" duct which would be bigger than the 1200 cfm required 26" duct, that looks reasonable to me.

However - and maybe this was just a typo on your part - using supply ducts that are larger than the required minimum will NOT increase the CFM - you said two trunks would give you 1400 CFM;

Factors Determining HVAC Air Duct Size & Duct System Design

A more-accurate HVAC duct sizing procedure has to take into account the factors I list below; of course some of these are overlapping and not all apply to every duct system design.

- Air velocity

in CFM being delivered by the AHU or blower fan - also measured in Velocity Pressure or in FPM - air flow in feet per minute;

CFM = fpm x cross sectional area of the duct but with adjustments for rectangular vs round.

1000 CFM = 1000 FPM x 1 sq.ft. of cross sectional area (though duct shape can be a factor too)

There are recommended air velocity ranges; too fast or too slow CFM will create noise or adequacy or efficiency & cost issues. - Available Space

for ductwork - the duct system choices will be impacted by just how much space is available to route the ductwork - Duct Size

in cross sectional area expressed in square feet or sq.ft. - Duct Shape

round vs. rectangular and aspect ration of width to height; friction losses are greater in rectangular ducts than in round ducts (dead areas in corners), and friction losses are increased at higher aspect ratios.

E.g. a 3x3 ft square duct has an aspect ratio of 1:1 and is almost equivalent in flow restriction to a round 40.7 inch diameter duct (both give 9 sq.ft. of cross-sectional area).

But squeezing down that 3x3 ft duct into a 1ft. x 9 ft. rectangle (admittedly extreme) reduces the flow to the equivalent of a 34.5 sq.in. round duct - you give up roughly 16% of duct flow capacity by flattening out the duct. (Chow 2005). - Duct Length

there are maximum effective duct design lengths before there is just too much flow loss. Longer ducts = reduced CFM. - Duct Direction & air temperature

engineers will have another way of explaining this but in essence, it's easier to send hot air "up" from a basement air handler in heating mode, and it's easier to send cool air "down" from an upper floor or attic air handler in air conditioning mode.

For dual-use systems whose single air handler provides both heating and cooling, the blower capacity and duct sizing need to take into account both heating and cooling air flow CFM delivery demands which will be different. - Duct Airflow Limiting factors

while in theory inlet CFM from all of the air returns = CFM outlet at all the supply registers in the "Real world" I doubt that this holds.

It may be more accurate to say that the system effective or maximum CFM of air delivered into the occupied space will be limited by the smaller of total inlet CFM or outlet CFM from the return or supply duct systems. - Duct Codes

there are both duct standards such as by ASHRAE in the U.S. or CSA in Canada, and there are building ventilation codes that will impose requirements on HVAC duct design, size, routing, (the mechanical codes), safety (building codes), and efficiency (energy codes). - Duct Defects

such as leaks or lost, damaged, incomplete insulation - Duct Material or friction losses

in the duct system - worse for non-smooth duct surfaces - we give the D'Arcy-Weisbach equation and other fancier references in the article on this page.

E.g. A straight section of helical wire core flex-duct that is 1 ft. in length will have the same air flow resistance as 3.2 ft. of rigid, smooth-interior round HVAC duct. In other words the flex duct is more than 3 x rougher and has a proportional cost in airflow over smooth round ducts. - Duct Noise

in some installations managing noise of both air flow in ducts and at registers and noise transmission between building areas will affect duct design - Duct Routing

the location, radius of, and number of bends or elbows in a duct system affects the air velocity or CFM that the duct system will provide; more bends = more constrictions and reduced CFM

Typical duct installation guides for all applications, HVAC systems, dryer vents, bath or kitchen exhaust vents, will include tables of equivalent duct length to be accounted for by each elbow or bend. This is the "equivalent length" (EL) method. Engineers calculate the same effects as a Dynamic Loss (Cv) method. - Supply & return air balance:

this ought not be a design guide but as you'll read in our duct defects discussion quite often we find inadequate return air limiting the effectiveness of a heating or cooling duct system, as might errors in supply or return register location.

A perfectly-engineered duct size can be completely subverted by poor location of supply and return registers or by mis-use or even omission of balancing dampers in the duct system.

If you want to try an easy DIY class on how to size and layout HVAC ducts I like the Carrier power point presentation by Ray Chow cited below.

HVAC Duct Design Velocities in Feet per Minute - fpm |

|

| Component | Recommended FPM |

| Supply registers (louvered) | 400 fpm |

| Return registers (louvered) | 500 fpm |

| Air Filter - Common pleated | 750 fpm |

| Air Filter - Bag / Cartridge | 500 fpm |

| Air Filter - Electrostatic | 150-350 fpm |

| Air Filter - HEPA | 250 fpm |

| Across Cooling Coil | 400-500 fpm |

| Across Heating Coil | 500 - 1000 fpm |

Notes to the table above:

- Adapted from Chow 1995 cited just below.

- See air flow rates (CFM) and Velocity (FPM) details

at AIR FLOW RATES in HVAC SYSTEMS

Residential HVAC Duct Sizing Tables

Round Air Duct Size Table |

|

Air Volume |

Duct Diameter (Inches / mm) |

| 50 cfm | 5" / 127 mm |

| 75 | 6 / 152 |

| 100 | 6 / 152 |

| 125 | 7 / 178 |

| 150 | 7 / 178 |

| 175 | 8 / 203 |

| 200 | 8 / 203 |

| 225 | 8 / 203 |

| 250 | 9 / 229 |

| 275 | 9 / 229 |

| 300 | 9 / 229 |

| 400 | 10 / 254 |

| 500 | 11 / 279 |

| 600 | 12 / 305 |

| 700 | 12 / 305 |

| 800 | 13 / 330 |

| 900 | 14 / 356 |

| 1000 | 14 / 356 |

| 1100 | 15 / 381 |

| 1200 | 15 / 381 |

| 1300 | 16 / 406 |

| 1400 | 16 / 406 |

| 1500 | 16 / 406 |

| 1600 | 17 / 432 |

| 1700 | 17 / 432 |

| 1800 | 18 / 203 |

| 1900 | 18 / 203 |

| 2000 | 18 / 203 |

...

Rectangular Air Duct |

HVAC |

||

| Air Volume CFM |

4" x ??" / mm | 6" x ??" | 8" x ??" |

| 50 cfm | 4 x 6" / 102 x 152 mm | ||

| 75 | 4 x 6 / 102 x 152 | ||

| 100 | 4 x 8 / 102 x 203 | 6 x 6" / 152 x 152mm | |

| 125 | 4 x 10 / 102 x 254 | 6 x 6 / 152 x 152mm | |

| 150 | 4 x 10 / 102 x 254 | 6 x 8 / 152 x 203 | |

| 175 | 4 x 12 / 102 x 305 | 6 x 8 / 152 x 203 | |

| 200 | 4 x 14 / 102 x 356 | 6 x 8 / 152 x 203 | |

| 225 | 4 x 16 / 102 x 406 | 6 x 10 / 152 x 254 | |

| 250 | 4 x 16 / 102 x 406 | 6 x 10 / 152 x 254 | |

| 275 | 6 x 12 / 152 x 305 | 8 x 8" / 203 x 203mm | |

| 300 | 6 x 12 / 152 x 305 | 8 x 8 / 203 x 203 | |

| 400 | 6 x 14 / 152 x 356 | 8 x 10 / 203 x 254 | |

| 500 | 6 x 18 / 152 x 457 | 8 x 12 / 203 x 305 | |

| 600 | 6 x 20 / 152 x 508 | 8 x 14 / 203 x 356 | |

| 700 | 6 x 24 / 152 x 610 | 8 x 16 / 203 x 406 | |

| 800 | 6 x 26 / 152 x 660 | 8 x 18 / 203 x 457 | |

| 900 | 6 x 30 / 152 x 762 | 8 x 20 / 203 x 508 | |

| 1000 | 8 x 22 / 203 x 559 | ||

| 1100 | 8 x 24 / 203 x 610 | ||

| 1200 | 8 x 28 / 203 x 711 | ||

| 1300 | 8 x 28 / 203 x 711 | ||

| 1400 | 8 x 30 / 203 x 762 | ||

...

Rectangular Air Duct |

Duct Dimensions " / mm |

|

| Air Volume CFM |

10" x ??" / mm x ??mm | 12" x ??" / mm x ??mm |

| 500 cfm | 10 x 10" / 254 x 254 mm | |

| 600 | 10 x 12 / 254 x 305 | |

| 700 | 10 x 12 / 254 x 305 | |

| 800 | 10 x 14 / 254 x 356 | 12 x 12" / 305 x 305 mm |

| 900 | 10 x 16 / 254 x 406 | 12 x 12 / 305 x 305 mm |

| 1000 | 10 x 16 / 254 x 406 | 12 x 14 / 305 x 356 |

| 1100 | 10 x 18 / 254 x 457 | 12 x 16 / 305 x 406 |

| 1200 | 10 x 20 / 254 x 508 | 12 x 16 / 305 x 406 |

| 1300 | 10 x 20 / 254 x 508 | 12 x 18 / 305 x 457 |

| 1400 | 10 x 22 / 254 x 559 | 12 x 18 / 305 x 457 |

| 1500 | 10 x 24 / 254 x 610 | 12 x 20 / 305 x 508 |

| 1600 | 10 x 24 / 254 x 610 | 12 x 20 / 305 x 508 |

| 1700 | 10 x 28 / 254 x 711 | 12 x 22 / 305 x 559 |

| 1800 | 10 x 30 / 254 x 762 | 12 x 22 / 305 x 559 |

| 1900 | 12 x 22 / 305 x 559 | |

| 2000 | 12 x 24 / 305 x 610 | |

Notes to the tables above

Adapted from the following:

- Chow, Ray, HVAC DUCT DESIGN LEVEL 1 FUNDAMENTALS [PDF], (2005) Carrier Corporation, retrieved 2019/11/14 original source: Sigler Commercial at siglercommercial.com/wp-content/uploads/2018/10/181010-Duct-Design-Presentation-RC-1.pdf

Chow include tables of recommended and maximum HVAC duct velocities and gives useful design velocities for individual HVAC system components (excerpted in the table above) - HVAC RECTANGULAR & ROUND DUCT SIZING CHART [PDF] Hamilton Home Products, retrieved 2019/11/19 original source: www.hamiltonhomeproducts.com/vb/Repository/InstallationManuals_PartsLists/Ductwork/Duct%20Sizing%20Chart.pdf

Excerpt: The following duct sizes are based on a fraction drop of .10 inches per 100 feet of lineal duct. This "Equal-Friction" method of duct sizing should be adequate for normal residential furnace heating and air conditioning applications. Larger volumes or higher static pressures should be dealt with on an individual job basis. - RESIDENTIAL DUCT SIZING GUIDE [PDF] Virginia Air Distributors, retrieved 2019/11/19 original source: www.virginiaair.com/ The company's technical documents include an Enthaply chart, the York psychometric chart, air handler wiring, residential duct sizing guide (given here) and other help.

References for HVAC Duct System Design & Sizing

- ACCA Manual D, Air Conditioning Contractors of America, 2800 Shirlington Rd, Suite 300 Arlington, VA 22206 (703) 575-4477 procedures used for designing residential duct systems. Source: www.acca.org/standards/technical-manuals

- Benningfield Group SIZING DUCTS in RESIDENTIAL HVAC SYSTEMS a QUICK GUIDE for CONTRACTORS [PDF] retrieved 2019/11/14 original source: http://cbpca-hpp.org/wp-content/uploads/2015/06/SMUDHPP_Quick-Guide-Duct-Sizing_Fnl.pdf

Excerpt: This Quick Guide focuses on sizing an entire duct system with the assumption the system includes air conditioning. Most of the time, a system properly sized for air conditioning will work fine for heating, and better still if you slightly increase the heating fan speed. - California, HVAC DUCT SIZING CHART [PDF] (2005) California Building Codes, retrieved 2019/11/14 developed by NCI, Inc. original source: buildingincalifornia.com/wp-content/uploads/2014/03/duct-sizing-chart.pdf

Other sources have widely copied this chart but many omit the instructions for its use as given just below:

Step One - Identify the volume of air that will be passing through the duct

Step Two - Select the duct size from the table that can carry that volume of air

Step Three - If desired airflow exceeds the CFM rating , increase to the next duct size

Step Four - Listed CFM is based on typical field results and may vary, install dampers

Step Five - If duct run exceeds 25', or has excessive transitions, increase to the next size

Step Six - Design alone is inadequate, always prove design by test and balance.

HVAC Supply & Return Air Duct Leaks & Obstructions - Theory vs Practice

Technical note: The D'Arcy-Weisbach equation for pressure and head loss can be used to calculate the actual pressure loss due to friction in a building piping or air duct system.

The D'Arcy-Weisbach formula

The Engineering Toolbox provides the D'Arcy-Weisbach formula:

Δp = λ (l / dh) (ρ v2 / 2)

where

Δp = pressure loss (Pa, N/m2),

l = length of duct or pipe (m)

dh = hydraulic diameter (m)

ρ = density (kg/m3).

HVAC Duct Air Velocity vs. Static Pressure in the Duct System

From Bernoulli's Law we have the following: any change in the air velocity (CFM) will cause a corresponding but inverse change in the static pressure inside the duct system.

"Static pressure" is a theoretical pressure inside of a closed system, while "Velocity pressure" is the force excerted by air moving through or out of a duct system. We find confusion on this topic is similar to normal people expressing as "water pressure" what is more accurately the water flow rate at a tap that would be measured in gpm (gallons per minute).

Ray Chow (2005) points out that the actual total duct system pressure is the sum of static pressure and velocity pressure.

List of Common Air Flow Obstructions in HVAC Systems & Ductwork

Watch out: But keep in mind that even this apparently accurate calculation of the effect of piping on air pressure and airflow loss will not include the effects of obstructions in the building return air or supply air duct system such as

- Air filter blocked by debris or

air filter / other item that has been sucked into the duct system.

Watch out: this will block air flow and can risk a fire if drawn into the blower assembly fan,

See DIRTY AIR FILTER PROBLEMS - perhaps the most common cause of unsatisfactory airflow in an HVAC system. - Blower Fan:

dirty blades on a squirrel cage blower assembly fan significantly reduce the blower fan's ability to move air into the HVAC system from the return-air side as well as reducing its ability to push conditioned air into the occupied space.

See DIRTY A/C BLOWERS - Fire damper that

has become stuck in the closed or partly-closed position interferes with proper airflow through the system

See FIRE & SMOKE DAMPERS, AUTOMATIC - Flex duct defects

Collapsed sections of flex duct block or stop airflow in either supply or return air system -

See DUCT ROUTING & SUPPORT - Insulation loose in air ducts

Collapsed duct interior insulation,

See FIBERGLASS DUCT, RIGID CONSTRUCTION - Leaks in the supply air duct system

are a very common HVAC duct defect that results in poor heating or cooling air flow.

See LEAKY DUCT CONNECTIONS

Illustrations of a leaky cast iron sewer line that sent sewer gases into the building's transite (asbestos cement) heating duct system can be seen

at TRANSITE PIPE AIR DUCTS

and at CAST IRON DRAIN PIPING. - Return air inlet problems

Return air inlet grilles that are obstructed with dirt, debris, or furniture or that are improperly located or are just too small mean that because the heating or cooling system is "starved for air", the supply air flow into occupied spaces will also be reduced.

See RETURN AIR REGISTERS & DUCTS - Transite air ducts

Crushed or collapsed transite duct

Possible airborne asbestos hazard.

See TRANSITE PIPE AIR DUCT ASBESTOS RISKS - Zone dampers that

are stuck partly closed obstruct air supply into that building area, or if stuck "open" when the zone damper should be closed, airflow to other building areas will be reduced.

See ZONE DAMPER CONTROLS

Also see UNDERSIZED RETURN DUCTS.

HVAC Duct Codes & Specifications

- 2015 IRC CHAPTER 26 DUCT SYSTEMS [PDF] Section M1601 DUCT CONSTRUCTION as adopted by the state of Utah, retrieved 2019/10/03 original source: https://up.codes/viewer/utah/irc-2015/chapter/16/duct-systems#16

- HVAC CODES

- MECHANICAL SYSTEM CODES - complete index to down-loadable PDFs & code sources

- VENTILATION CODES

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-04-13 by InspectApedia Editor - find and fix rextrictions in HVAC ductwork

@Gail,

Please do keep me posted - what you find will certainly help other readers.

I'd like to see a photo (one per comment) of the zone dampers in question as well as of any crimps or openings you find in the ductwork.

On 2023-04-13 by Gail

@InspectApedia Editor , Thanks! We'll check that and see what happens.

On 2023-04-13 by InspectApedia Editor - check zone dampers for heating zones controlled by individual thermostats

@Gail,

Correct me if I've misunderstood but it sounds as if your four heating zones are controlled by individual thermostats, each of which operates a zone damper (that you're calling a "gate").

You say you think the forced hot air is forcing the duct damper "open" but that should not happen if the damper is properly secured to the shaft on which it rotates and provided the shaft gears in the zone damper control motor are intact.

If this problem has been there since day one of your heating system duct installation I might suspect that the zone damper isn't properly wired but I suspect you're reporting a "new" problem.

It's possible that inside the duct that keeps receiving hot air the zone damper is not working. An example could be a loss of connection between the actual damper plate inside the ductwork and the shaft that's supposed to turn-it, or the zone damper mechanism or control itself could be damaged.

So a good place to start with the "too hot" room is at its zone control damper. Turn the thermostat for that zone to its highest temperature while another of you watches the zone damper actuator to see what it does.

For the too-cold zone, the damper may be stuck closed so make the same test there.

If the too-cold zone damper is working correctly, look for crimped or open ductwork anywhere in the system.

See details at

ZONE DAMPER CONTROLS

and for Collapsed sections of flex duct block or stop airflow in either supply or return air system -

See DUCT ROUTING & SUPPORT

On 2023-04-13 by Gail

We have an electric forced air furnace, with four zones (originally five). Recently the "office zone" began supplying very little air flow to one room in that zone (keeping it around 65 degrees) while the remaining two rooms plus bath in that zone were above 80 degrees.

Meanwhile, upstairs, we turned off the heat in the bedroom zone, but hot air still blows out the registers. The controller for the bedroom was replaced and the gate indicates it is closed, but hot air still blows out. Hot air is forcing the spring in the gate partially open. Any suggestions?

On 2022-09-10 by InspectApedia-911 (mod) - clean air filter and clean blower fan will improve air flow

@Ronald,

I don't think suspending the duct will make much difference as long as its routing is as straight as possible AND it's not kinked, blocked (and is no longer leaking)

Start by assuring a clean air filter is installed

Follow by having the blower fan itself cleaned: I've seen a tremendous improvement in airflow from just those two steps.

On 2022-09-10 by Ronald

@InspectApedia-911, Thank you for the reply. I did crawl through the attic and inspect. the flex duct is laying on the ceiling joists and the canister in the trunk had air leaking from it. I sealed it off before I messaged you, however, I was going to suspend the duct so it is off the joists. If that does not fix the problem what would you recommend next? Thank you.

On 2022-09-09 by InspectApedia-911 (mod)

@Ronald,

I would start with a thorough inspection of the duct itself to make sure that it's not crimped, crushed, torn, or just connected.

On 2022-09-09 by Ronald

I have a bedroom where half the room is cool and the other half is warm. There is an 8-inch flex duct traveling 35 feet in the attic to the room. The room is 320 square feet. Do I need to go up to a 10-inch flex duct? The Heat pump in the home is a 5-ton. Thanks.

On 2022-04-07 by Inspectapedia Com Moderator - check for shorted TT wires

@Stephen semi-pro,

Thanks for the help.

I agree that checking for shorted TT wires is perhaps one of the first things to check.

We detail that at the THERMOSTAT WON'T TURN OFF article we mentioned earlier.

On 2022-04-07 by Stephen semi-pro

@Inspectapedia Com Moderator, RE Lewis: What is the actual temp at the thermostat when it is set at 74 and reads 74 and the HP is constantly running - is it different from 74? Is not enough heat getting to thermostat due to poor return and/or supply? Is 24V red shorted/connected/jumpered to HP so it never shuts off? Weird.

On 2022-02-11 by Inspectapedia Com Moderator

@Lewis,

Check that you're not running the system with a manual FAN ON switch set at the thermostat or at the fan limit switch.

On 2022-02-10 by Lewis

@Inspectapedia Com Moderator, I will be receiving the meter to check the air flow today. However the thermostat is set to 74and it reads that it is 74 in the house. I took some temperature of the registers and they are blowing 92 out and the return is 84. The thermostat never goes up or down and the system never turns off.

I can manually turn off the heat pump on the thermostat. After about 6 hours the temperature will stop dropping. However this is pretty normal for a spray foam insulated house. I have put an external thermometer by the thermostat to see if it’s about the same. The thermostat has been changed already. Any ideas?

On 2022-02-08 by Inspectapedia Com Moderator

@Lewis,

How frustrating;

That sure sounds like a system design or installation problem.

Check the airflow at supply regs and check the obvious like a duct crimp or dirty filter so we don't just embarrass ourselves here.

On 2022-02-08 by Lewis

@Inspectapedia Com Moderator, This is a brand new home. The condenser unit has been changed after 4 months of operation. It is still continuously running. The thermostat was also changed along with the txv. The temperature difference between the vents return is only about 10 degrees. The thermostat shows it to be the same temperature as it is set on. Airflow some rooms are cold and some are warm. I did get the it’s but not sure how to read it. Go figure.

On 2022-02-08 by Inspectapedia Com Moderator - why your heat pump unit runs continuously may be more than just duct length

@Lewis,

To address the question of why your heat pump unit runs continuously you need more onsite diagnosis than is offered by assuming the issue is duct length as there can be plenty of other causes.

If the air flow is quite weak at your supply registers and if you've got a new clean proper air filter installed, then start by checking for a crimp or obstruction or blockage in the duct system.

But if air flow has always been quite weak in your home, then yes there could be a duct design or layout defect.

But IMO, I'd want to rule out the easy and other causes of trouble before getting into a duct design and certainly well before trying to calculate duct lengths.

continuing:

If we GUESS that your unit runs continuously because the thermostat is never satisfied, you'd start by checking the easiest and most obvious causes (such as a dirty air filter) - a good place to start that diagnosis is

THERMOSTAT WON'T TURN OFF

also

See OPERATING TEMPERATURES HVAC

also see

CONTROLS & SWITCHES, A/C - HEAT PUMP

If the HVAC compressor motor will stop but the compressor / condenser fan is not working properly,

see

FAN, COMPRESSOR / CONDENSER UNIT

On 2022-02-08 by Lewis

I have a manual D of my hvac installation. It shows the total effective length of the ducts to be 144 ft. When I add the length of all the ducts together it shows I have 264 ft of ducts. The issue is the condenser for the heat pump runs continuously.

I have many questions like how does a 5 inch flexible duct 21.1 feet long put out 121 can? How does a 32.6 ft 7 inch flexible duct put out 184 cfm. Any help would be appreciated.

On 2020-01-07 - by (mod) -

Yes, I agree, Richard.

On 2020-01-07 by Richard Hartill

Thanks for your comments. It seems to me in order to balance the system they would need to add a main return trunk with dampers at the plenum to separate the upstairs and basement air the same way they did for the supply.

Then balance the return to the supply.

Does that seem correct?

On 2020-01-07 1 - by (mod) -

It sounds to me as if the basement heating air duct system is not properly designed.

You need a balance between Supply Air and Return air.

Elsewhere in this article series you'll read about return mistakes that are dangerous, such as taking the return air from a location to close to the heater and risking drawing in combustion gases or interfering with heater operation. So be sure you don't do that.

But you do need a balance of supply and return.

On 2020-01-07 by Richard Hartill

That's correct. When the heat is on in the basement there are a total of 7 supply's feeding hot air into the basement. There are only two 10" returns and they feed into the existing main return so air is being pulled from all the returns (2 10" down and 5 larger upstairs).

it seems that there is nowhere else for the air to go but out that door. I'm not so sure it's being pushed up and out or sucked up by the five larger returns upstairs. We also have a radon mitigation system and if the heating system is causing a negative pressure in the basement it might affect its operation.

On 2020-01-06 by (mod) - issues with warm air heat heat after adding heating zone for the basement

Let me get this right, Richard.

When you open the basement door are you feeling air rush OUT of the basement or INTO it?

On 2020-01-06 by Richard Hartill

I have a two stage gas hot air furnace (80,000 BTU) with a multi speed motor. The house is one level 2,200 sq. ft. with a full basement. I had no issues with the heat until I had a HVAC zone added to the basement.

They ran a 12" reduced to 10"towards both ends supply with six 6" drops and one 5" drop. They installed three electric controlled dampers on the supply trunk and a Honeywell control board. Nice work neat and clean.

The problem ( I think? ) is they cut two 10" returns in to the existing return trunk and put grills on them. Now when the heat in the basement goes on air is being pulled from those two returns plus the five much larger returns upstairs.

When you open the basement door your hit with a rush of cooler air (because we keep the heat lower down there).

It will keep the door open and if I push it closed air whistles under and around it. What do you think of this and if you think it's wrong what should I tell them to do to fix it. If you don't want to answer on this web site you can email me at rhartill62@gmail.com. Thanks, Rich

On 2019-03-29 - by (mod) -

Eli

Before adding booster fans or return or supply air ducts and registers let's be sure we have properly diagnosed the poor air flow problem.

Where is the air handler?

An attic air handler on a three floor house will have a devil of a time blowing warm air (for heat) down to the lower two floors,

while a basement or crawl space air handler will have a hard time blowing cool air up three floors in a home.

If there is inadequate return air volume then neither air handler is going to work very well..

If the air handler blower is dirty or if ducts are crimped etc. then air flow will be horrible.

See details at AIR FLOW IMPROVEMENT, HVAC https://inspectapedia.com/aircond/Duct_Air_Flow.php

On 2018-07-08 by Eli

Hi! Have a problem in the house — the cold/warm air is coming out only on the 3rd floor, and just barely from 1st and 2nd. The most reasonable and expected thing to do is, quite probably, balancing.

But, I’m considering other problems, that may have been overlooked by the experts that came. First of all, I’m concerned that there is only one air return register, on the third floor, just between two bedrooms and near the stairs.

Could this be a bigger factor than the lack of proper in-duct balancing? Next, could installing air boosters for each floor be a better and more stable option in such case?

Boosters would essentially set the pressure difference between duct and room, and so mirror the pressure between floors in the ductwork, making a sort of auto-balancing, is this correct? Any other options I missed? Thanks.

On 2013-01-09 by (mod) - how to inspect inaccessible HVAC ducts

Basil,

You will want to find an air conditioning service company or duct cleaning company who have a duct inspection camera that can be inserted into the ductwork.

On 2013-01-09 by basil

i want to make inspection for ducts(leakage test) but all duct is hidden above the decorative sealing i cant see the duct..how can i make smoke test or any other way???

On 2012-10-08 - by (mod) - stinky air coming out of air supply registers

Mike, i agree with your one of investigation. check at the air handler and return air inlet, also some of the supply ducts deliver air with your blower unit off. Scan inaccessible ductwork via camera.

On 2012-10-08 by Mike

I rent a unit in an old industrial building that as converted to condos in 2005. All the interior systems and finishes were new with the conversion, the building was gutted. Each unit has its own HVAC unit.

Our unit's central air conditioner vents air into our unit that has obviously come from somewhere else - it's full of second-hand cigarette smoke and cooking odors. Sometimes it smells like someone is smoking a cigarette in the same room.

This stinky used air comes in even when the fans are off, but much more so when the unit is AC unit is running.

The building has a common vent that sucks air out of the bathrooms. It's always on and is rather strong.

Does it sound like a return air vent leak?

The only thing I can figure is that both the intake in our unit is leaky and the common vent (which would be sucking air out of the other condos, including the cigarette smoke) is also leaking, letting our AC pull in the exhaust from the common vent. I think this would account for the bad air coming in when the AC fans are off.

I need to have a contractor come take a look, but I have to educate the landlord so he understands that this is both plausible and serious before he'll authorize it.

Thanks

On 2012-10-07 by Anonymous

will air condition make your eyes water if so whu

On 2012-10-07 - by (mod) - soot coming out of the duct registers

Check first for unsafe conditions like oil burner or gas burner sooting, a leaky heat exchanger, or a burning up wire, blower fan belt, etc.

Then I'd start tracking down the dirt or soot source at the return air register, and look at general house dust levels. So far we don't even know if it's really soot.

On 2012-10-05 by Harley

I get a phone call from My Dad and he is telling me they have soot coming out of all there registers and asked if it could be a motor problem well I already know the answer to that since I am a union industrial electrician he told me he changes the filters every 3 weeks so I am wondering why do the have soot coming out of the registers and will not come clean

they thought it was a fridge problem so they replaced the fridge but the problem has gotten worse and isnt just at the fridge anymore I surely am no A.c. guy but I am thinking they have a problem with filters and lots of nasty dirt in the A.c. handler so before I drive almost 2 hours to there home in Arizona

I would like to have a fairly good idea what I need to be looking for oh and talking to my Mom today she has been instructed to tell my Dad to stop spraying the filters with Pledge since he was told it helps collect more dirt being they literally live in the middle of no where in the desert 18 miles to the closest town!

On 2012-07-26 - by (mod) - what if the air register has no operable levers or controls over air-flow?

Tanner, if the "vent" has no operable louvers to open and shut it then indeed it could be a return air register. Bur return ducts should be under negative pressure - air moving in not out of the register.

First map out the duct system to see what is installed.

Next look for a misrouted or improperly connected duct - it would be very unusual for air movement through a return duct system to cause one of it's branches to blow out instead.

Any mistake where a small add on return duct was connected, say right atop and ahead of the cooling coil would however cause the problem you describe.

More common would be a cool air supply duct that is routed through a hot space and perhaps has lost its insulation.

On 2012-07-26 by Anonymous

The vent looks different than the return and cold air vents I think the suction of the return is causing it to draft hot air what could cause this?

On 2012-07-26 by Tanner b in SC

I have central air and a clean filter all the vents are blowing cold air. The problem is there is a vent above the thermostats and air return that is blowing out hot air when ever the air handler or fan is on. This is keeping the temp too high for the ac to turn off

...

Continue reading at AIR FILTERS for HVAC SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see DUCT SYSTEM & DUCT DEFECT FAQs - questions & answers about air duct problems posted originally at the end of this page

Or see these

Recommended Articles

- AIR FLOW IMPROVEMENT, HVAC

- AIR FLOW MEASUREMENT CFM

- DUCT SYSTEM DESIGN SIZE & DEFECTS - home

- ASBESTOS DUCTS, HVAC

- ASBESTOS PAPER on DUCTWORK

- ASBESTOS TRANSITE DUCTWORK

- BALANCING AIR DUCT FLOW

- DAMPERS & DRAFT REGULATOR TYPES

- DUCT CLEANING ADVICE

- DUCT in CONCRETE FLOOR

- DUCT DAMAGE, MECHANICAL

- DUCT INSULATION - Asbestos Paper

- DUCT ROUTING & SUPPORT

- DUCTWORK CONTAMINATION

- FIBERGLASS HAZARDS

- FIBERGLASS HVAC DUCTS

- FIRE & SMOKE DAMPERS, AUTOMATIC

- FLEX DUCT SOURCES & HISTORY

- FLOOD DAMAGE in DUCT WORK

- GRAY FLEXDUCT FAILURES - home

- MOLD in AIR HANDLERS & DUCT WORK

- NOISES in DUCT SYSTEM

- ODORS in AIR HANDLERS & DUCT WORK

- AIRBORNE PARTICLE & MOLD LEVELS in DUCTWORK

- REGISTER & DUCT LOCATION

- RETURN AIR REGISTERS & DUCTS

- SLAB DUCTWORK

- SOUNDPROOFING for DUCTWORK

- STAINS at HVAC REGISTERS

- STAINS HVAC SOOT or DUST

- SUPPLY DUCTS & REGISTERS

- UV DISINFECTION in HVAC SYSTEMS

- VIBRATION DAMPENERS

- WATER & ICE IN DUCT WORK

- WET CORRODED DUCT WORK

- ZONE DAMPER CONTROLS

Suggested citation for this web page

DUCT SYSTEM DESIGN SIZE & DEFECTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HVAC DUCT SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Mark Cramer, Tampa Florida, for assistance in technical review of the "Critical Defects" section and for the photograph of the deteriorating gray Owens Corning flex duct in a hot attic. Mr. Cramer is a Florida home inspector and home inspection educator.

- Thanks to Jon Bolton, an ASHI, FABI, and otherwise certified Florida home inspector who provided photos of failing Goodman gray flex duct in a hot attic.

- Engineering toolbox properties of water - http://www.engineeringtoolbox.com/water-thermal-properties-d_162.html and email: editor.engineeringtoolbox@gmail.com web search 09/16/2010

- Thanks to Scott at SJM Inspect for suggesting this EPA document and for technical editing remarks regarding our air conditioning website, SJM Inspection Service LLC, serves the entire state of CT, sjminspect.com 203-543-0447 or 203-877-4774 5/16/07

- Reference: Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- Reference: Principles of Refrigeration, R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- "Air Conditioning & Refrigeration I & II", BOCES Education, Warren Hilliard (instructor), Poughkeepsie, New York, May - July 1982, [classroom notes from air conditioning and refrigeration maintenance and repair course attended by the website author

- Thanks to Chris Van Rite, Vice President Sales, M&M Manufacturing Company, 4001 Mark IV Parkway Fort Worth, TX 76106, Office (817) 348-2241 Cell (817) 825-2363 - cvr@mmmfg.com - Mr. Van rite provided the HVAC & Duct System references listed just below 2/9/2009

- Consortium for Energy Efficiency (CEE) - http://www.cee1.org/resid/rs-ac/hvac_press_kit.pdf

- Air Diffusion Council (ADC) - http://www.flexibleduct.org/

- Static Pressure Losses in 6, 8, and 10-inch Non-Metallic Flexible Ducts,

Weaver, K.; Culp, C.

Texas A&M University Energy Systems Laboratory http://txspace.tamu.edu/handle/1969.1/5275 - A Study of Pressure Losses in Residential Air Distribution Systems, Bass Abushakra, Iain S. Walker, Max H. Sherman, Lawrence Berkeley National Laboratory - http://eetd.lbl.gov/ie/pdf/LBNL-49700.pdf

- ENERGY STAR® Homes Technical Standards - http://www.energystarhomes.com/documents/tech_standards.pdf

- ASHRAE Advanced Energy Design Guide for “Small Office buildings”, “Retail buildings” & “K-12 School buildings” available currently as a free download from ASHRAE Publications Store http://www.ashrae.org/publications/page/1604 (do not copy this PDF to networks)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.