Cotton Building Insulation

Cotton Building Insulation

Identification, History, Properties

- POST a QUESTION or COMMENT about cotton batt building insulation

Cotton insulating batts:

This article illustrates and describes how to identify, inspect, and evaluate cotton insulation materials in buildings.

We provide photographs and descriptive text of cotton insulation and other insulation products to permit identification of these materials in buildings.

This document assists building buyers, owners or inspectors who need to identify various kinds of insulating materials and who need to evaluate the condition of building insulation by simple visual inspection.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Cotton Building Insulation Properties & Appearance

Here we include photos and history of brands and types of cotton building insulation along with a description of its insulating properties.

Article Contents

- LOCKPORT LO-K BATTS

- CELULITE COTTON INSULATION

- SEARS (HOMART) Flame-Proof COTTON INSULATION BATTS

- R-VALUE of COTTON INSULATION

- IS COTTON INSULATION a "GREEN" PRODUCT?

- HISTORY & SOURCES of COTTON BUILDING INSULATION

- MOLD RESISTSANCE of COTTON INSULATION

...

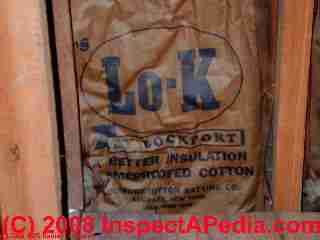

Lockport Lo-K Cotton Insulating Batts

Cotton building insulation was sold by the Lockport Cotton Batting Company under the product name Lo-K®.

Cotton insulation may have been made, sold, and distributed by other manufacturers or distributors of building insulation in the late 1940's, including Bristol Insulation, Cary Insulation, Insulation Industries, Inc., Janesville Cotton Mill, Sears Roebuck, and Gilman Brothers Co.

Cotton insulating batts appeared in the U.S. before 1900 and were installed in many homes in the U.S. from about 1935 to 1950, and this material has recently seen a surge in new interest as a "green" building material.

Watch out: don't mistake cotton buiilding insulation, a white fibrous material described here, for asbestos - a question raised by a number of our readers. Cotton isn't asbestos and cotton insulation isn't an environmental hazard.

...

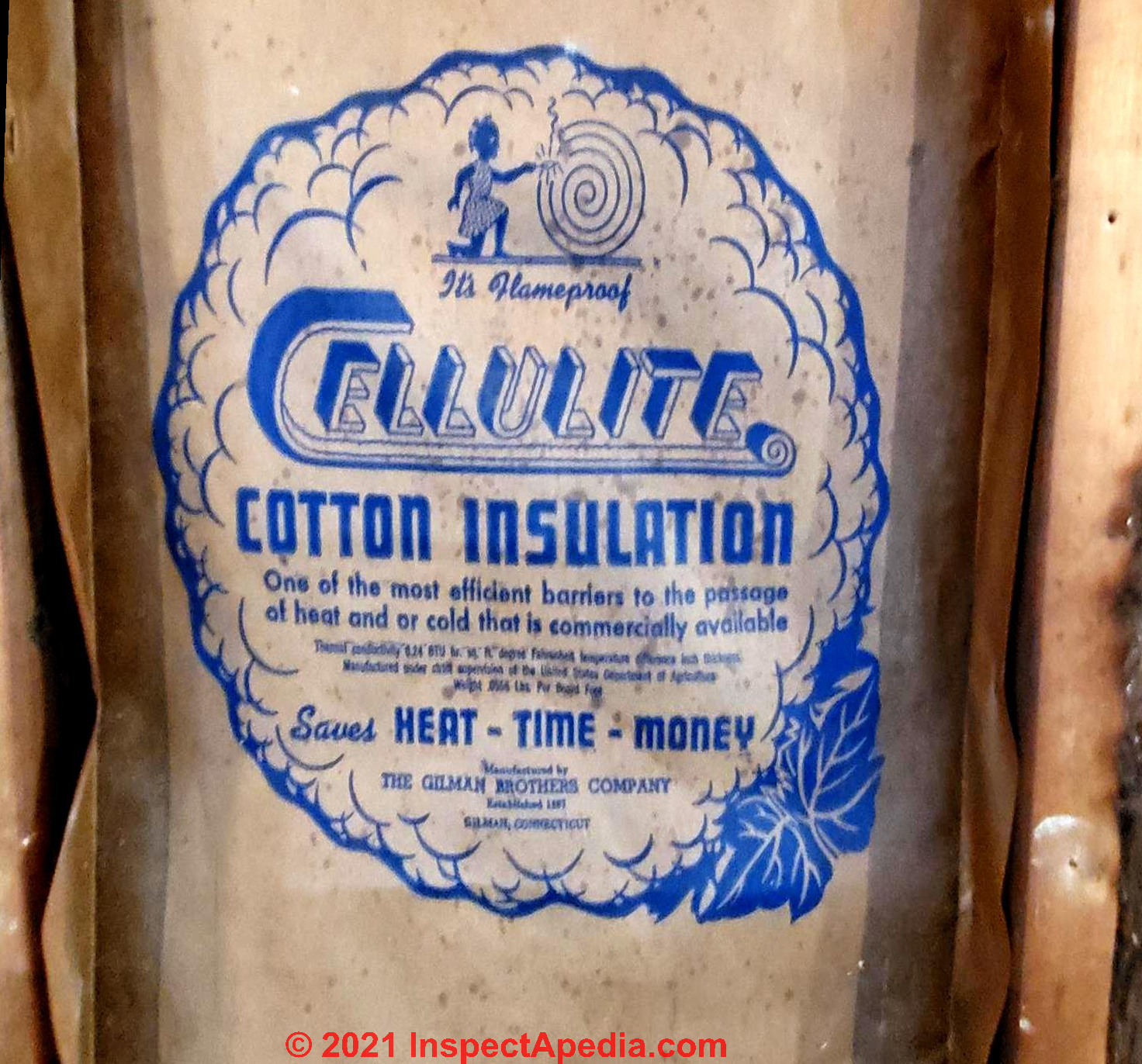

Cellulite Cotton Insulation

Photo: Cellulite Cotton Insulation, kraft faced cotton batts, was produced by the Gilman Brothers Company in Gilman, CT, founded, according to the cotton batt imprint, in 1887 [date uncertain - Ed.]

Photo: Cellulite Cotton Insulation, kraft faced cotton batts, was produced by the Gilman Brothers Company in Gilman, CT, founded, according to the cotton batt imprint, in 1887 [date uncertain - Ed.]

Photo of this cotton "Cellulite" insulation provided courtesy of InspectApedia reader Chris Fawcett (27 June 2021).

Mr. Fawcett noted that this Cellulite cotton insulation was uncovered in 2021 in a building in Nassau County, Long Island, U.S.A. He didn't give the age of the building where this cotton batting was found.

The Gillman Cellulite cotton batt imprint asserts that the product was "flameproof".

Today the Gillman company continues in business; the company's products include styrene-faced and other faced foam board sheets.

- Gillman Brothers, Gilman Rd., Gilman CT 06336 USA, TEl: 860-889-8444, Website: gilmanbrothers.com

Website excerpt:

The Gilman Brothers Company had its origins in New York City, where in 1897, Nathan Gilman established himself in the bedding business. From the start, the Company had direct ties to Connecticut for, in Bozrahville (now Gilman) on the banks of the Yantic River stood the Bozrahville Manufacturing Company, which supplied him with raw material.

As one of the oldest manufacturing sites in New London County, the first large-scale manufacturing began here in 1814.

Industrious and enterprising individuals were attracted to this site because of the rivers unique topography and ample volume provided the waterpower to drive their machines. - retrieved 2021/06/27 original source: https://gilmanbrothers.com/about-us/

...

Sears, Roebuck & Co. Cotton Building Insulation by Homart

Our photograph of Sears "Flame-Proof" cotton insulation covered with a paper facing shown was provided courtesy of InspectApedia.com reader Jason Minnich.

You'll see in the reader Q&A below on this page that he was worried about mold contamination in this insulation.

Mr. Minnich noted that this Sears and Roebuck insulation was found in a building built in 1947 in Colorado Springs, CO. USA.

Homart building materials, who produced this Sears Flame-Proof Cotton Insulation, were sold only through Sears, Roebuck and Company stores and catalogs.

Other Sears - Homart building insulation is described at

...

What is the insulating R-value of cotton batts?

Cotton insulation batts sold as Lockport's Lo-K® ranged in thickness from about 1/2" to 20" and its density ranged from 4.19 to 2991 kg· m-3 (about 1/4 pound per cubic foot up to more than 100 pounds/cubic foot(?))The heat transmission of various insulating materials including cotton can be viewed at the NIST website.

NIST data shows that cotton insulation had a resistance to heat transfer ranging from 0.025 to 9.1 h· ft2· °F· Btu-1 (depending on the thickness of the product). I'm guessing from the data that this translates into modern "R" values of about 0.5 per inch.

Currently marketed cotton insulation costs about 20% more than fiberglass insulation of roughly the same dimensions, and has a lower R value of R 3 to R 4 per inch of cotton insulation compared with an R value of R 5 to R 7 per inch for fiberglass batts.

To compare insulating material R-values see our table of

...

Is Cotton Insulation Batting a Green Insulation Building Product?

Well sure it is insofar as we're using a natural, grown material rather than an insulation product made from petroleum products (plastics, foams).

Watch out: But the true "greenness" of building materials can be a little tough to pin down.

For example, when we evaluate the greeness of cotton insulating batts, the "green" claims we've read did not consider the petroleum product consumption in the production of cotton, the transport of cotton to the insulation producer, nor the effects of use of pesticides and fertilizers. These added complexities confound the environmental claims of lots of products, not just building insulation.

The health claim, that cotton produces fewer problem particles than fiberglass sounds reasonable, but a study of the health effects that plagued workers in 20th century cotton mills leaves some questions about this assertion as well, at least for the producers of the product.

The fiber release of any insulating product depends a lot on where and how it was installed and on its condition and its exposure to disturbance.

...

Cotton Insulation History, Research, Sources

- Bozsaky, David. NATURE-BASED THERMAL INSULATION MATERIALS FROM RENEWABLE RESOURCES—A STATE-OF-THE-ART [PDF] Rev. Slovak J. Civ. Eng 27 (2019): 52-59.

Excerpt:

3.8 Cotton

Cotton fibers are mainly used by the textile industry; moreover, their availability is very limited in Europe. Therefore, 80-90% of cotton-based thermal and sound insulation materials are produced from textile waste (e.g., jeans).

During its manufacture cotton fibers are combed and loosened (carding), mechanically stabilized, and treated with a small amount of additive (3-8% boric acid) to improve its fire resistance and mold-proofing.

What is advantageous is that it is a renewable raw material that has good vapor permeability; moreover, its manufacture involves low energy consumption (Novák, 2008; Briga-Sá et al., 2013).

It is also recyclable and compostable. It does not contain any food source for rodents and insects, so there is no need for protection against them. Its main disadvantage is high water absorption; therefore, cotton insulation is not permitted for insulating structures in direct contact with moisture (e.g., facades).

There are insulating blankets, felts, and strips made of cotton, but it can also be used as in-blown insulation similar to cellulose. It is primarily used for insulating attic spaces, attic floors, and pitched roofs (between rafters) (Pfundstein, 2007). Recent experiments have been conducted with compressed thermal insulation boards made from cotton.

Depending on the pressure used during manufacture, these products have a wide range of mechanical strength and a relatively high insulating quality (λ=0.0585-0.0815 W/mK) (Zhou et al., 2010). - Gaspar, Florindo, Aliaksandr Bakatovich, Nadezhda Davydenko, and Arpan Joshi. "Building insulation materials based on agricultural wastes." In Bio-Based Materials and Biotechnologies for Eco-Efficient Construction, pp. 149-170. Woodhead Publishing, 2020.

Abstract:

Abstract

Ecological insulation materials of vegetable raw materials are increasingly widespread. The agricultural wastes can have an interesting role because their use allows the revaluation of agricultural wastes, whose disposal is a serious issue. This chapter gives an overview about the use of agricultural wastes on insulating materials.

The source and characteristics of various types of wastes are described. The manufacturing processes considering the types of binders, including the main parameters involved, are explained.

An overview is given about the properties of the insulation materials, including thermal conductibility, density, mechanical strength, hygroscopic behavior, acoustic and fire performances, and environmental performance. Suggestions regarding the future research needs are also presented.

Excerpt:

… After the seeds are separated from the fibers, waste cotton fibers are formed. For the use as a thermal insulation material, it is first necessary to fluff up fiber waste and clean it from … - Johnson, Sara, Darlene Echeverria, Richard Venditti, Hasan Jameel, and Yuan Yao. "Supply chain of waste cotton recycling and reuse: A review." AATCC Journal of Research 7, no. 1 (2020): 19-31.

Excerpt:

… Quality of pre-consumer waste cotton is often easy to assess because the history of the fiber … for producing nonwoven materials or for building materials insulation ... - Yu, Tao, Yizhe Ren, Zhensheng Guo, Xiao Chen, Jinxiang Chen, and Elsafi Mohamed Adam Elbashiry. "Progress of research into cotton straw and corn straw cement-based building materials in China." Advances in Cement Research 30, no. 3 (2018): 93-102.

Abstract:

This paper reviews the development of cotton straw and corn straw cement-based materials in China. With the use of unmodified straw fibres, the compressive strength of the cement-based material decreases with an increase in corn and cotton straw content, but the rate of decrease is considerably lower than that of wheat and rice straw, mainly because of differences in the strength of the straw.

The incorporation of fly ash, urea formaldehyde resin and other materials can effectively improve the mechanical and thermal insulation properties of mixed-type building materials.

Three methods of modification are proposed – alkali treatment, grafting treatment and direct addition of a modifier. A multiple linear regression equation between mechanical properties and the content of the main components of the cotton straw cement-based materials is obtained, which provides a theoretical basis to predict and design cement-based block materials.

Finally, to address the problems of the mix type (difficult stirring, slow hardening, and energy demands and environmental pollution during the modification process), the concept of a composite-type bionic straw cement-based building material is introduced, which provides direction towards the development of new bionic light straw materials. - Kuru, Arzu, and Sennur Alay Aksoy. "Cellulose–PEG grafts from cotton waste in thermo-regulating textiles." Textile Research Journal 84, no. 4 (2014): 337-346.

Excerpt:

… cotton fiber with latent heat storage properties, to be used in buildings for heat insulation. … - Liu, LiFang, HongQiang Li, Andrea Lazzaretto, Giovanni Manente, ChunYi Tong, QiBin Liu, and NianPing Li. "The development history and prospects of biomass-based insulation materials for buildings." Renewable and Sustainable Energy Reviews 69 (2017): 912-932.

Excerpt:

... carried out a research on a new environmental-friendly thermal insulation board made of cotton stalk by a hot-pressing manufacturing method. - Muthuraj, Rajendran, Clément Lacoste, Patrick Lacroix, and Anne Bergeret. "Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation." Industrial Crops and Products 135 (2019): 238-245.

Excerpt:

… These textile fibers were predominantly cotton with a minimum of 70% cotton content. … - Rahbar, S., M. M. Khan, M. Satish, F. Ma, and M. R. Islam. "Experimental and Numerical Studies of Natural Insulation Materials." In ASME International Mechanical Engineering Congress and Exposition, vol. 42347, pp. 181-185. 2005.

Note: includes study of cotton and waste hair used as building insulation. - Second Skin, Heat Wave "Jute" (Recycled Cotton) AUTOMOTIVE INSULATION [PDF] Second Skin Auto & Home Insulation, Second Skin Audio, 13825 W Business Center Drive, STE B, Green Oaks, IL 60045 USA Tel: 1-800-679-8511

- A Sèmiyou, Osseni, Lokossou M Melon, Osseni OG Sibiath, Vodounnou Edmond Claude, and Ahouannou Clément. "Cotton Stem Fibers and Natural Binders for the Manufacture of Thermal Insulation Panels: State of the Art of the Last Decade." (2021).

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Worried about mold in cotton building insulation

Worried about mold in cotton building insulation

@inspectapedia.com.moderator, the home was built in 1947, I believe this was original to the home.

Having just finished ripping out all of that insulation to put in spray foam some comments.

It is succeptible to mold which I thought was fire damage but the spray foam installer actually said it was likely mold damage, this causes the paper backing on the roof side to become very brittle and dark.

This could also be from when they installed the roof, honestly don't know. There were some pieces that came down in large sections and others in bits and pieces. - On 2021-12-24 by Jason Minnich

Reply by Inspectapedia Com Moderator (mod) - building moisture is key; flame retardants may retard mold in cotton insulation

@Jason Minnich,

I'd need to see the materials and attic conditions to understand better your situation.

But I'm a bit unclear about the meaning of "susceptible to mold" -

ALL buildings and nearly all materials are "susceptable" to mold if by that we mean mold may grow in or on them. Mold is everywhere, all the time, as airborne spores. And there are species of mold that will grow on or in just about anything.

Rather, it is the combination of exposure to air AND the presence of moisture that's a determining factor in mold growth in or on buildings, including in cotton or other building insulation.

So if your attic or under-roof area is un-vented it's at extra risk of mold contamination. Moreso depending on building moisture levels and sources.

Really? Considering that Sears advertised this cotton insulation as "Flame-Proof" it's likely that it was treated with a fire-retardant, typically boric acid (Bozsaky, 2019).

We've found that other fire-retardant treated insulation such as cellulose (paper-based) is often more-resistant to mold growth than un-treated building insulation products, apparently because chemical properties of the flame retardant also are unfriendly to mold.

To understand where, how, and why we have identified mold in or on fibrous building insulation, please review

...

Continue reading at CELLULOSE INSULATION FIRE RESISTANCE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- INSULATION CHOICES & PROPERTIES

- INSULATION IDENTIFICATION GUIDE

- INSULATION INSPECTION & IMPROVEMENT - home

- INSULATION R-VALUES & PROPERTIES for an extensive table describing the properties of different insulating materials used in buildings.

Suggested citation for this web page

COTTON INSULATION BATTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about the properties & identification of balsam wool & other wood product insulation materials.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [3] Thanks to home inspector Stephen P. Shockley, Shore-Footed Property Services, for discussing "blackweld" cellulose-based (probably) insulation, August 2010

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.