Steam Boiler Controls & Gauges

Steam Boiler Controls & Gauges

Identification Photos & Repair guides for Steam Boiler Parts & Controls

- POST a QUESTION or COMMENT about residential steam heating system controls, valves, gauges

Steam heat controls: here we provide a photo guide to all types of controls found on residential & light commercial steam heating systems.

We tell you what each control does, where it is located, what it looks like, and we link to in-depth information about setting controls or diagnosing & repairing problems with steam heat controls.

This article series provides an illustrated inspection and repair guide to Steam Heating Systems.

The page top photo shows a modern steam heating boiler.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Steam Heating Systems Guide: Controls Found on Residential Steam Heating Systems

All of the steam heating system controls described in our introduction are illustrated below and described in greater detail in individual articles found in this steam heat series.

If you don't know what kind of heat your building uses, we explain how to figure out the answer

If your heating system boiler is not working at all,

first see IS YOUR HEATER TURNED ON? - Check this first.

and also see NO HEAT - BOILER.

Sketch of a one-pipe typical steam heating system (left) is provided courtesy of Carson Dunlop Associates Associates.

In a one pipe system each radiator is served by a single pipe: steam rises into the radiator and condensate (water) returns from the radiator through the same pipe loop, as you can see at left.

A two-pipe steam heating system is similar but provides a separate loop of piping that collects condensate and returns it from the radiator to the boiler.

Below we give identifying photos to help you identify each type of steam boiler control, and with those photos we provide links to more-detailed articles about the control's installation, operation, adjustment, troubleshooting or repair.

Article Contents

- STEAM HEATING SYSTEM CONTROLS - definitions & identifying photographs

- STEAM BOILER SAFETY DEVICES

- HARTFORD LOOP: DEFINITION & PIPING

- SIGHT GLASS on STEAM BOILERS

- PRESSURE CONTROL SWITCH on STEAM BOILERS

- LWCO LOW WATER CUTOFF on STEAM BOILERS

- WATER FEEDER VALVE on STEAM BOILERS

- TEMPERATURE / PRESSURE RELIEF VALVE on STEAM BOILERS

- STEAM TRAPS on BOILERS

- STEAM VENTS on STEAM BOILERS & RADIATORS

- CONDENSATE RETURNS & CONDENSATE RETURN PUMPS

- PRESSURE GAUGES on STEAM BOILERS

- STEAM HEAT TROUBLE SHOOTING MANUALS

Definitions, Uses & Photographs of Steam Heating System Controls

If your heating system looks like a heating boiler but your heating radiators have valves which hiss and let air escape as heat is coming on your heat is probably being delivered in pipes which circulate steam from the steam boiler up through radiators in the occupied space.

Although both hot water - hydronic heating systems (discussed at BOILERS, HEATING)

and steam boilers (discussed here at STEAM HEATING SYSTEMS)

use a boiler that heats water, the heat distribution method and most of the heating boiler controls are different between these two systems.

Both steam boilers and hot water boilers may share certain controls that monitor and manage the heating source such as an oil burner or gas burner. Heater burner controls make sure that there is a safe proper combustion flame, control draft, and protect against flue gas spillage.

Examples include the CAD CELL RELAY SWITCH (oil burners)

or FLUE GAS SPILL SWITCH TRIPPING & RESET (gas burners).

At the end of this page we provide a STEAM BOILER CONTROL LIST of articles explaining each of the controls found on steam heating systems, but before jumping off on one of those links I suggest reviewing the rest of the article below this list.

Five Common Safety Devices on a Steam Heating Boiler

- SIGHT GLASS, STEAM BOILER described below is just one of the safety devices found on a steam boiler.

The sight glass tells us the level of water in the boiler; a required boiler water level mark is normally visible on the boiler jacket behind the sight glass, or it may be marked on the sight glass itself. - RELIEF VALVE, TP VALVE, STEAM BOILER, a pressure/temperature relief valve - a protection

against BLEVE EXPLOSIONS - LOW WATER CUTOFF VALVE - abbreviated as LWCO - that turns off the burner if water level falls dangerously low

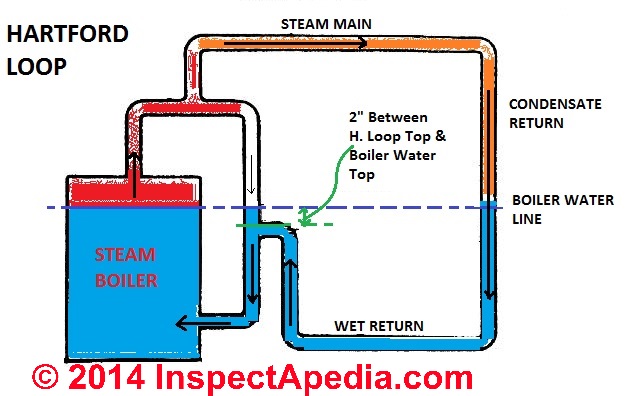

- HARTFORD LOOP (to prevent loss of water out of the boiler by siphoning out of boiler water from a piping leak), and on many modern residential steam systems, and on modern systems

- WATER FEEDER VALVE, STEAM - an automatic water feeder valve may also be installed to maintain boiler water level. Water feed valves on steam boilers include a manual flush valve that must be opened regularly, often weekly, to flush accumulated sludge from the water feed control and LWCO.

All of these steam heating system controls are illustrated and described below, along with all other controls and devices used to operate residential and most commercial steam heating systems.

Hartford Loop safety piping arrangement on steam boilers

As you can infer by looking at our drawing at above left Boiler Without a Hartford Loop, a leak anywhere in the wet return portion of the condensate return piping that is below the boiler water line risks siphoning out all of the water from the heating boiler.

Our illustration at above right titled Hartford Loop shows where the Hartford Loop is located on a steam boiler. Details about the Hartford Loop, why it's needed, how it works, and the history of the steam boiler Hartford loop are found

at HARTFORD LOOP.

Watch out: at CONDENSATE RETURN PIPES, PUMPS, STEAM we explain that

a leaky condensate line such as the one shown in our photo at above left can be lead to

dangerous BLEVE EXPLOSIONS.

You can check the water level in your steam boiler quite easily by using the

built-in STEAM BOILER SIGHT GLASS.

The Hartford Loop is also discussed further at

and at STEAM TRAPS

Steam Boiler Sight Glass

The steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the required water level in the steam boiler. A mark on the boiler body indicates the desired normal water level and a sight glass shows the current water level.

The steam boiler sight glass or water level gauge allows the building owner or maintenance person to monitor the required water level in the steam boiler. A mark on the boiler body indicates the desired normal water level and a sight glass shows the current water level.

But if a heating boiler loses its water without also being shut down it will certainly be damaged by the heat of the oil or gas burner (or coal or wood), and it could lead to a dangerous explosion or fire.

Watch out: The sight glass on a steam boiler is an important safety and operating device since it allows the homeowner to check and set a safe water level in the boiler or to check that the automatic water feed valve is working.

Even if your steam boiler has an automatic water feeder , you should still check the water level (and clarity) in the sight glass frequently, but the risk of a ruined boiler from lost water is of course much less.

Some folks refer to the sight glass as a sight gauge - it means the same thing: a vertical tube, usually of glass, that shows the current level of water in the steam boiler.

Details about using the sight glass on a steam boiler to check or set water level are found

If you need to clean or replace the sight glass on a boiler

see STEAM BOILER SIGHT GLASS REPLACEMENT.

Also see STEAM BOILER FLOODING / SURGING REPAIR where we explain the causes of water too high in the sight glass or in the steam boiler - causes of high water level in the steam boiler.

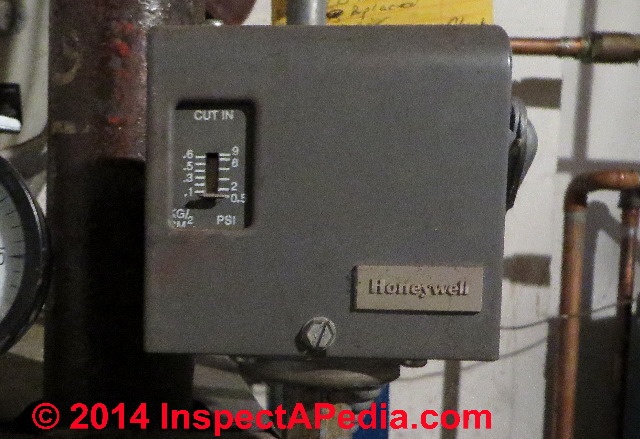

Steam Boiler Pressure Control Safety Switch

The pressure control switch on a steam heating boiler is designed to shut the heating system down should unsafe high pressures develop.

As we emphasize at our description of pressure gaugesOn a steam boiler, residential steam heating systems are almost always designed to operate at very low pressures, perhaps around .5 psi - that' s 1/2 of one psi.

See STEAM BOILER PRESSURE for details about the operating pressures of steam boilers.

For details and pressure readings of the steam pressure control switch

Photo Guide to Identifying & Operating Steam Boiler Low Water Cutoff Valves & the Blowoff Flush Valve

Here's a photo of a Low Water CutOff safety valve (LWCO) on a steam boiler. The LWOC incorporates an internal float connected to an electrical switch. If water in the steam boiler falls to an unsafe low-level, the electric switch opens to shut down the heating system.

Here's a photo of a Low Water CutOff safety valve (LWCO) on a steam boiler. The LWOC incorporates an internal float connected to an electrical switch. If water in the steam boiler falls to an unsafe low-level, the electric switch opens to shut down the heating system.

This valve on a steam heating boiler needs to be flushed clean weekly (more or less) during the heating season using what heating techs refer to as the "blowdown valve". The yellow handle you see in the photo is used for that purpose.

The blowdown valve is opened briefly to allow sludge and grubby water from the LWCO valve interior to flush out into a bucket for disposal. On some LWCO valves the blowdown valve is spring-loaded so that it closes when released.

The yellow-handled ball valve shown in our photo is a manual flush valve.

While the LWCO blowdown valve is open and water is flushing out of the boiler, if an automatic water feed valve is installed it will automatically provide make-up water for the boiler to keep water level at the proper level.

If the steam boiler does not have an automatic water feeder, after you use the blowdown valve to flush the LWCO control you will need to use

the SIGHT GLASS, STEAM BOILER and a manual water feed valve to set proper boiler water level.

Typically we open and close this valve several times, for just a few seconds at a time, until water flushing out of the LWCO valve runs clean.

Watch out: we don't like to introduce a large volume of very cold water from the street into a very hot steam boiler.

While it's never happened to me I've heard reports of boiler cracks or damage from this thermal shock. Waiting until the boiler is at a cool state, or avoiding unnecessarily large volumes of flush water should keep you out of trouble.

Also check the installation and maintenance instructions for your boiler to see what the manufacturer recommends.

Details about low water cutoff valves on steam boilers & how to use the blowdown valve to regularly flush the LWCO can be read

Automatic and manual water feeders for steam boilers detailed

Water feed valves for hydronic boilers are discussed separately

at WATER FEEDER VALVE, HYDRONIC BOILER.

Steam Boiler Automatic Water Feeders

Above and below are photographs of a couple of different but still modern automatic water feeder valves on a steam boiler.

Here we show the "manual feed" button which can be found on the automatic water feeder in the photo at above left.

Details about water feeder valves can be found

Automatic and manual water feeders for steam boilers are detailed

Also see STEAM BOILER FLOODING / SURGING REPAIR

Temperature / Pressure Relief Valves on Steam Boilers

Low pressure steam boilers still require a pressure/temperature safety relief valve.

A pressure relief valve is a spring-loaded device that will open to spill excess pressure (and temperature) in the form of water, steam, or a mix of the two, at a pre-determined pressure in order to protect the heating appliance from damage, or worse, a dangerous BLEVE explosion.

See BLEVE EXPLOSIONS

However the steam boiler relief valve operates at different temperatures and pressures than found on a hydronic (hot water heating) boiler.

Residential steam boilers typically operate at below 1 psi, and on residential steam systems the pressure/relief valve is usually set to open at 15 psi.

These are much lower operating pressures than on hydronic heating systems.

Conversely, the operating temperature on steam systems in the boiler reach boiling - 212F or 100C - much hotter than hydronic heating systems.

If your boiler pressure/relief valve is leaking

see RELIEF VALVE LEAK for the steps in problem diagnosis & repair.

Our steam boiler TP relief valve photo at above left shows typical operating parameters for these safety controls.

This particular valve, a Watts No. 315-M1 is a 3/4-inch diameter valve set to open at 15 PSIG and has an energy release rate of 375 LBS/Hr.

Watch out: The steam heating boiler TP valve shown at left is leaking and lacks its discharge tube - this is an unsafe installation.

Not only are we worried that leakage may damage the boiler or its controls, a leaking TP valve may eventually clog itself with mineral debris and crud that block the valve, preventing it from opening as it should in the event of unsafe temperatures or pressures in the heating appliance.

Also see

Steam Traps on Residential Steam Heating Systems

Definition & function of the Hoffman trap:

Steam traps such as the Hoffman-style steam trap shown at left are installed on residential steam heating systems, usually at the bottom of the radiator at the opposite end from the steam input side.

The steam trap is installed in order to allow air and condensate out of the radiator while at the same time, stopping the escape of steam (or slowing it) until the steam can condense to water (thus transferring its heat to the radiator itself).

Details about steam traps: we explain the function, identification, & troubleshooting of steam traps

at STEAM TRAPS.

Steam Vents on Residential Heating Systems

Details about the inspection, repair, replacement, function, and identification of steam vents on one pipe and two pipe steam heating systems are

at STEAM VENTS

and at STEAM VENTS, 1-PIPE SYSTEMS.

Also see RADIATORS for ROOM HEAT for more extensive information about steam radiator troubleshooting such as how to diagnose and fix a cold radiator.

Condensate Return Pumps & Condensate Systems on Residential Steam Heating Systems

Our photos illustrate a steam condensate return pump system in a New York home

Our second steam condensate return system (above right) shows the reservoir and condensate pump motor (gray pump and new piping on the right side of the condensate reservoir at the left in that picture). This system also includes chemical injection into the steam condensate.

Details about steam condensate piping, return pumps, and leaks are found

at CONDENSATE RETURN PIPES, PUMPS, STEAM

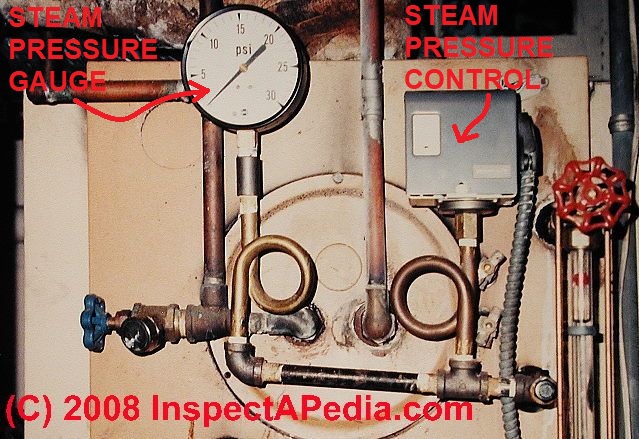

Steam Boiler Pressure Gauge and Normal Steam Pressure Range

Pressure and Temperature gauge on steam heating boilers: Residential steam heating systems are almost always designed to operate at very low pressures, perhaps around .5 psi - that' s 1/2 of one psi.

You should see similar settings on the pressure gauge (at left in our photograph) and on the steam pressure control switch (the gray box at right in our photo) on your boiler.

Details about normal steam heat system pressures are

Details about pressure gauges on steam heating equipment can be read

If your heating system uses forced or gravity circulated hot water rather than steam, controls and gauges are different:

see GAUGES on HOT WATER BOILERS

PRESSURE GAUGE, BOILER for more details about pressure gauges on hydronic (hot water) heating boilers. These are not steam systems.

Steam Heat Troubleshooting References

Shown here: the Mills water tube boiler as illustrated in H.B. Smith Co.'s 1929 catalog cited below. [Click to enlarge any image]

- Audel's 1946 Oil Burner Guide originally sold for $1.00 U.S. and includes photos and sketches of its generation of oil heating burners, boilers, furnaces, radiators, steam and hydronic systems, as well as control devices. Frank Graham's no-heat diagnostic steps are still useful today and is provided free at InspectApedia.com beginnning

at AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING - Donkin, Bryan. The Heat Efficiency of Steam Boilers: Land, Marine and Locomotive: With Tests and Experiments on Different Types, Heating Valve of Fuels, Analyses of Gases, Evaporation and Suggestions for Testing Boilers. Charles Griffin, 1898.

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- H.B. Smith & Co., BOILERS & RADIATORS CATALOG [PDF] (1929) 10 East 41st St., New York NY Catalog No. 1444

- Holohan, Dan, The Lost Art of Steam Heating, 516-579-3046 FAX

- Holohan, Dan, Principles of Steam Heating, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004

- ITT, The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update, (see next item in this list). ITT Fluid Technology,

1133 Westchester Avenue

White Plains, NY 10604, tel +1 914 304 1700 fax +1 914 696 2950 www.ittfluidbusiness.com - Jackson, James J. "Steam boiler operation: principles and practice." (1980).

Abstract: Following a brief historical review of steam generation and early steam engines, information is presented on the thermodynamics of boiling; boiler fuels; types of boilers; boiler accessories and control equipment; steam trapping; water treatment; boiler safety; and boiler operations in power plants. (LCL) - McAlear VACUUM AIR LINE HEATING SYSTEM [PDF] McAlear Manufacturing Co., 1901-7 Westeern Ave., Chicago IL USA

- Pierce, Edward Richmond, A PRACTICAL MANUAL of STEAM & HOT WATER HEATING [PDF] 1st Ed., Domestic Engineering Co., Chicago (1911) (also available from Google as an eBook)

- Sullivan, Timothy J. VACUUM REGULATOR U.S. Patent 2,461,666, issued February 15, 1949.

Excerpt: One of the objects of this invention is to provide a control to regulate the vacuum in each of "several units supplied from a common steam boilerso that the steam supply from the boiler will be proportionately distributed to the units. - Wolfe, William C., IMPROVEMENT in WATER-INDUCTORS for STEAM BOILERS [PDF] US Patent No. S206381 issued July 23, 1878, early automatic water feeder for steam boilers.

- Also seeReferences or Citations at the end of this page

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: I need to prepare for a steam boiler license and want book recommendations

I’m happy to have found this website. I’m getting back into heating and cooling and need to prepare for higher license. Question: Is there a DVD collection you recommended as an additional studying tool? I see that Harold J. Frost, Frederick M. Steingress, Daryl R. Walker’s collection is close to 600.00 which is very steep for my pocket.

Would you happen to know of a website or cheap place I can buy such DVD or a CD? If not these guys than another author is ok. Thanks for the feedback. Kym 11/23/11

Reply:

Kym if you are looking specifically for information on steam heating I'd pick up any of Dan Holihan's books on steam heat. He's the best.

Question: hissing boiler

I have 2 yr. Boiler. It hisses like venting steam off and on loudly. Seems like when heat comes on venting starts until off. -Mr. Ed 12/28/12

Reply:

Steam boilers include steam valves that hiss; we need more details.

See STEAM VENTS, 1-PIPE SYSTEMS for details about steam vents that could be what you are hearing.

Question: steam boiler not satisfying thermostat

(Mar 23, 2013) home able said:

Oil-fired steam boiler was functioning properly upto two weeks ago, now doesn't fully run to designated temperature on thermostat (digital). It will stop a degree or 2 short of desired setting even though thermostat says boiler is running. Why?

Reply:

Home able,

In general the gauges on heating equipment are not lab grade precise. It's possible that your gauge or its sensor port are debris clogged.

Try tapping gently on the gauge to see if the needle moves. Also watch the gauge to see its reading throughout the operating cycle.

If the gauge is questionable, repalce it.

Question: steam boiler problems

(Oct 16, 2014) Antonio said:

I just installed a 299 MBH gas fired steam boiler and connected to an existing system serving the second floor of an office building, approx floor area is 2,600 sq ft.

Existing EDR calculated as approx 900 sq. ft. The boiler started up successfully yesterday and I have been testing it ever since. Everything seems to be working fine. My question is what would be the right pressuretrol settings: I am using 1 psi cut-in and 1 psi differential and everything seems all right, but I may be missing something, maybe the boiler could work more efficiently with a lower or higher cut in pressure.

(Dec 15, 2014) Kevin M said:

I have a gas-fired steam boiler that has worked flawlessly since its installation six years ago.

Suddenly it is overfilling. I let out several extra gallons a day to reduce the level in the sight glass.

Should I replace the automatic feed? It is attached to the hot water heater, unlike previous installation I have had in other houses where it is connected to the cold water line.

Is it possible that excess pressure from the expansion in the hot water supply line is forcing water past the automatic feed? What could cause this condition?

Reply:

Kevin

Over-filling of a heating boiler is indeed usually a problem with the automatic water feeder, more rarely leaks into the boiler from a tankless coil.

See details at STEAM BOILER FLOODING / SURGING REPAIR

...

Continue reading at LOW WATER CUTOFF VALVE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see STEAM HEATING SYSTEMS & CONTROLS FAQs - questions & answers about steam heating system repairs posted originally on this page

Or see these

Recommended Articles

- STEAM HEATING SYSTEMS & CONTROLS - home

- AQUASTAT CONTROL FUNCTIONS

- AQUASTAT RESET BUTTON

- AQUASTAT SENSOR PROBE HEAT CONDUCTING COMPOUND

- AQUASTAT SENSOR PROBE STUCK in the AQUASTAT WELL

- AQUASTAT SETTINGS vs HEATING COST

- AQUASTAT SELECTION GUIDE

- BACKFLOW PREVENTER VALVE, HEATING

- BANGING HEATING PIPES RADIATORS

- CAD CELL RELAY SWITCH

- CHECK VALVES, HEATING SYSTEM

- CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS

- STEAM HEAT RADIATOR REPAIR - diagnose & repair

- CONDENSATE RETURN PIPES, PUMPS, STEAM

- DRAFT REGULATORS / HOODS GAS HEATERS

- DRAFT REGULATOR, DAMPER, BOOSTER

- ELECTRIC MOTOR OVERLOAD RESET SWITCH

- ELECTRICAL POWER SWITCH FOR HEAT

- FIRE SAFETY CONTROLS

- FLUE GAS SWITCH INSTALLATION & WIRING

- FLUE GAS SPILL SWITCH SOURCES & SELECTION

- FLUE GAS SPILL SWITCH TRIPPING & RESET

- FLUE SPILL SWITCH & COMBUSTION AIR TESTS

- GAUGE REPLACEMENT, BOILER

- GAUGES, STEAM BOILER

- HARTFORD LOOP

- IS YOUR HEATER TURNED ON? - Check this first.

- LIMIT SWITCH, BOILER

- LOW WATER CUTOFF VALVE, BOILER

- LOW WATER CUTOFF VALVE NOT WORKING

- LOW WATER CUTOFF CONTROL MANUALS

- MIXING / ANTI-SCALD VALVES

- OUTDOOR RESET MODULE AQUASTAT ADJUSTER

- PRESSURE CONTROL, STEAM BOILERS

- PRESSURE REDUCING VALVES

- PRESSURE REDUCING VALVE (BOILER) CLOG REPAIR

- PRESSURE REDUCING VALVE DISASSEMBLY

- PRESSURE REDUCING VALVE REPAIR KIT

- PRESSURE REDUCING VALVE WATER FEEDER INSTALLATION

- RADIATORS

- RADIATOR VALVES & HEAT CONTROLS

- RELIEF VALVE, TP VALVE, STEAM BOILER

- SIGHT GLASS, STEAM BOILER

- SIGHT GLASS REPLACEMENT

- SIGHT GLASS & HYDRONIC HEAT LOOPS on STEAM SYSTEMS

- STACK RELAY SWITCH

- STEAM BOILER FLOODING / SURGING REPAIR

- STEAM BOILER LEAK DAMAGE

- STEAM BOILER PRESSURE

- STEAM BOILER TEMPERATURE

- STEAM PRESSURE CONTROL

- STEAM PRESSURE GAUGE

- STEAM TRAPS

- STEAM VENTS - home

- STEAM VENTS, 1-PIPE SYSTEMS

- STEAM VENT TYPES, SELECTION

- STEAM VENTS, 2-PIPE SYSTEMS

- STEAM RADIATOR VENT CLEAN & TEST

- STEAM RADIATOR VENT REPAIR

- STEAM VENT TABLE, CROSS REFERENCE & SOURCES

- THERMOSTATS, HEATING / COOLING

- WATER FEEDER VALVE, STEAM

Suggested citation for this web page

STEAM HEATING SYSTEMS & CONTROLS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to STEAM BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Weil McLain Model 78 Boiler Manual, Boiler for gas, light oil, Gas/Light Oil fired Burners, Installation, Start-up, Parts, Maintenance instructions, Part No. 550-141-705/0600, Weil-McLain Administrative Office, 999 McClintock Drive, Suite 200, Burr Ridge, IL 60527 Tel: 855-248-1777

Consumer Inquiries: 800-368-2492

Technical Services: 800-526-6636 Technical Support for Contractors Only.

If you are a homeowner and are experiencing a problem with your Weil-McLain equipment, the first step you must take is to contact your installer or locate an HVAC contractor in your area. Website: http://www.weil-mclain.com - Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- McDonnell & Miller Controls - XYLEM Global Headquarters, 1133 Westchester Avenue, White Plains, NY 10604, Tel: +1-914-323-5700, Fax: +1-914-323-5800

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.