List of Best Practices Guides for Building Interiors

List of Best Practices Guides for Building Interiors

Interior Finishes, Trim, Doors, Floors, Walls, Ceilings

- POST a QUESTION or COMMENT about buying & installing building interior surfaces & finishes

Guide to best building interior finishes:

Selection, installation, maintenance - this article series discusses and provides a best construction practices guide to the selection and installation of building interior surface materials, carpeting, doors, drywall, trim, flooring, lighting, plaster, materials, finishes, and sound control materials.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Selecting & Installing Interior Finishes

Drywall, Plaster, Wood walls & floors, cabinets & trim, lighting & other interior features

Drywall, Plaster, Wood walls & floors, cabinets & trim, lighting & other interior features

[Click to enlarge any image]

This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons. Photo above courtesy of Galow Homes.

As described in the book, Best Practices Guide to Residential Construction Chapter 5, Interior Finish:

Interior finishes are the most visible and, on a square-foot basis, often the most expensive components in a house. However, since many of these products and materials are marketed directly to consumers, they are often not well understood by builders and designers.

Making good decisions on such finish materials as flooring, carpeting, and lighting fixtures can make a critical difference to homeowner satisfaction.

The builder or designer can play a key role in helping the homeowner choose finishes that are well-suited to the intended use, as well as providing the structural support and prep work the materials require for good performance.

Index to Interior Finish Topics & Best Practices

- BEST PRACTICES GUIDE TO RESIDENTIAL CONSTRUCTION BOOK REVIEW & master index

- INTERIOR FINISHES: BEST PRACTICES - home

- BUY INTERIOR PRODUCTS, RESOURCES

- CARPETING, SELECTION & INSTALLATION

- CASEWORK, CABINETS, SHELVING INSTALLATION

- CORK FLOORING

- DOORS, BEST PRACTICES

- DRYWALL, FIBERBOARD, PLASTER INTERIORS

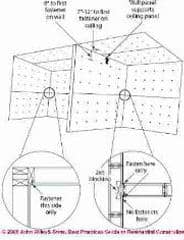

- DRYWALL INSTALLATION Best Practices

- DRYWALL INSTALLATION HORIZONTAL vs VERTICAL

- LAMINATE PLASTIC FLOORING

- LINOLEUM & OTHER SHEET FLOORING

- LINOLEUM & SHEET FLOORING FAQs

- LIGHTING, INTERIOR GUIDE

- NOISE / SOUND DIAGNOSIS & CURE - home

- PLASTIC LAMINATE FLOOR INSTALLATION

- PLASTER VENEER Best Practices

- RESILIENT VINYL or CORK FLOORING

- SOUND CONTROL in BUILDINGS

- STAINS & FINISHES, INTERIOR

- STAIRS, RAILINGS, LANDINGS, RAMPS

- TRIM, INTERIOR INSTALLATION

- VINYL FLOOR SELECT INSTALL

- WINDOWS BEST PRACTICES

- WINDOW MATERIALS & CONSTRUCTION

- WINDOW TYPES, GUIDE

- WOOD FLOORING, BAMBOO

- WOOD FLOOR CHOICES

- WOOD FLOOR ENGINEERED, LAMINATE

- WOOD FLOOR INSTALLATION GUIDE

- WOOD FLOOR MOISTURE EFFECTS

- WOOD FLOOR SOLID STRIP, PLANK

- WOOD FLOOR FINISHES

- WOOD FLOOR RADIANT HEATED

Drywall Types & Installation Procedures

Details about the best pracrtices to be followed when installing drywall are found at DRYWALL INSTALLATION Best Practices. Excerpts are below.

Single-layer, 1/2-inch drywall is the default wall and ceiling treatment in most residential construction.

Photo at left courtesy of Eric Galow, Galow Homes.

Done well, it goes largely unnoticed. Nail pops and cracks, however, are very conspicuous and remain the leading cause of builder callbacks.

With wet or poor-quality framing, there are bound to be problems in the drywall finish. With dry lumber and proper detailing, however, drywall problems can be kept to a minimum.

Types of Drywall

Drywall consists of a gypsum core covered by two layers of treated paper. The long sides are tapered for easy finishing with joint compound. The short or “butt” ends are not tapered.

Also see CHINESE DRYWALL HAZARDS.

Standard Drywall Properties

This material comes in four thicknesses: 1/4-inch, 3/8-inch, 1/2-inch, and 5/8-inch. A single layer of 1/2-inch drywall covers most residential walls and ceilings.

For a stiffer wall and better sound deadening, use 5/8-inch drywall or a double layer of 1/2-inch drywall, with all joints staggered between layers and the second layer glued to the first for best performance.

The 3/8-inch panels are useful for covering existing walls and ceilings in remodeling. One quarter- inch board, installed in layers, is useful for curves. Special 1/4-inch bending-type drywall has the smallest bending radius.

Fire-Resistant Drywall Specifications

Fire-code drywall has special additives, including glass fibers, to increase its fire resistance. Residential building codes typically require Type X 5/8-inch fire-code drywall with a one-hour rating for party walls, ceilings over furnaces, and common walls between living space and garages.

Moisture-Resistant Drywall

Moisture-resistant (MR) board, sometimes called “green board” because of its green paper facing, has limited water resistance from asphalt additives, and is recommended for high-humidity areas such as bathrooms and laundries.

The material is denser and less rigid than regular drywall, so it is prone to sag on ceilings unless the framing is 12 inches on-center or less. Also it will fall apart, like regular drywall, if it gets soaked. For that reason it should not be used as a tile substrate in any application where it might get wet.

Mold-Resistant Drywall

This is a relatively new product that uses an inorganic fiberglass matt instead of paper facing, since the paper facing readily supports mold growth. Panels are available with the fiberglass matt on one side or two. Glass fibers in the gypsum core add strength as well.

Details about mold resistant drywall are found at MOLD RESISTANT DRYWALL.

Installation Procedures for Drywall: Best Practices Guide

To prevent problems, use good quality framing lumber and follow the recommendations now found in this separate article: DRYWALL INSTALLATION Best Practices

Details about interior plaster veneer finishes are at PLASTER VENEER Best Practices. Excerpts are below.

Veneer or skim-coat plaster has, for the most part, replaced traditional three-coat plaster in residential work. It consists of a single coat of plaster 1 /1 6 to 1 /8- inch thick over a special type of gypsum board, commonly called blueboard, which is treated to bond well to plaster.

Guide to Selecting & Installing Wood Floors: Best Practices

Wood floors provide a natural warmth and beauty like no other flooring material. And new developments in finishes and engineered products have expanded their durability, versatility, and ease of installation.

Still, control of moisture levels in the flooring and structure around it remains the biggest issue influencing the success of a wood flooring installation, particularly with unfinished strip flooring, but with many of the engineered products as well.

Solid Wood Strip and Plank Wood Floor Choices

Details and information tables about solid wood strip and plank flooring are at FLOOR, WOOD SOLID STRIP, PLANK

Traditional unfinished 3/4-inch hardwood strip flooring in oak or maple remains the most common wood flooring type and the best choice where heavy use and frequent refinishing are likely. While the most common species are still oak and maple, an amazing variety of domestic and imported woods have become available in recent years.

Guide to the Effects of Moisture on Wood Flooring: Best Wood Floor Installation Practices

Details and information tables about the effects of moisture on wood flooring are at FLOOR, WOOD MOISTURE.

Understanding and controlling moisture levels is the key to success with wood flooring.

Installation Procedures for Solid Wood Flooring

Details and best construction practices for the installation of wood flooring, along with illustrations and tables are found at FLOOR, WOOD INSTALLATION GUIDE.

Standard 3/4-inch strip or plank flooring is nailed through the tongue into a sound, dry wood subfloor—either plywood, oriented-strand board (OSB), or solid planks. If installed over a slab, the subfloor can either be floated or nailed to the slab.

Wood Floor Finishing Guide

Details about our recommendations for finishing wood floors, including photos and tables are at FLOOR, WOOD FINISHES.

Guide to Choosing & Installing Engineered Wood Floors: Wood Laminates

Details about the properties of and installation of engineered wood floors, also referred to by some as wood laminate flooring, are found at FLOOR, WOOD ENGINEERED, LAMINATE, INSTALL.

Bamboo Flooring Sources, Properties, Installation Guide

A recent introduction to the flooring market, bamboo is not really a wood, but a type of grass that matures in three to five years on plantations, making it an environmentally friendly alternative to premium hardwoods. To make bamboo into flooring, thin strips are laminated to form planks from 3/8 to 3/4-inch thick.

The familiar nodes that separate bamboo stalks into short sections create darker cross markings, giving the product an attractive and unusual appearance. A more homogenous color is also available from some manufacturers by using laminated strands.

Engineered bamboo flooring is as hard as maple and more stable than oak, and comes either unfinished or prefinished with the same types of finishes as used on hardwood flooring.

Detailed Guide to Installing Wood Floors over Radiant Heating

Details about radiant-heat wood floor systems and best wood floor installation practices where a radiant heated floor is used are found at FLOOR, WOOD RADIANT HEAT.

Radiant heating is a challenging application for wood floors due to the high temperatures, excessive drying, and greater temperature cycling to which the wood and finish are subjected. Careful monitoring and control of the moisture levels of the flooring and structure at the time of installation are critical for success.

Resilient Flooring: Selection & Installation Guide to Sheet Vinyl & Vinyl Tile Floors

Details and illustrations about selecting and installing resilient flooring, sheet vinyl, vinyl tiles, or cork floors are at FLOOR, RESILIENT VINYL or CORK.

Solid Vinyl Floor Tiles

Similar to inlaid sheet vinyl, the color and pattern in solid vinyl tiles run through the full thickness of the tile, making them very durable. Because the color and pattern extend through the tile, they do not wear away with heavy use, but choices are limited. Solid vinyl tiles are cut from a solid block of material and come with a low-gloss finish.

One type, vinyl composition tile or VCT, is essentially the same product as solid vinyl, but with other binders and fillers. Both types require waxing and buffing, both to seal any gaps between tiles and to create an easy-to-clean surface.

Details are at RESILIENT VINYL or CORK FLOOR

Natural Alternatives to Vinyl Floors: Cork Floors

Homeowners who want a resilient floor covering but are looking for an alternative to vinyl should consider the new cork products as well as traditional linoleum, which is enjoying a comeback in residential applications.

Details about cork flooring are at CORK FLOORING

Guide to Modern Linoleum Floors

Details are at MODERN LINOLEUM FLOORS

Also see the history and ingredients of true linoleum sheet flooring at LINOLEUM & SHEET FLOORING

For the last 50 years or so, linoleum has been used almost exclusively in commercial settings, but it is making a comeback in residential settings, due largely to its use of all-natural ingredients and reputation for durability.

Linoleum is made by boiling oil to form a thick cement paste that is mixed with pine rosin, wood flour, and other fillers such as clay or limestone to make a durable, resilient sheet flooring that wears well and resists indentation.

Guidelines for Selecting & Installing Plastic Laminate Flooring

Details and illustrations for Selecting & Installing Plastic Laminate Flooring are at FLOOR, LAMINATE PLASTIC. Excerpts are below.

Plastic laminate flooring was introduced to the U.S. market in the mid-1990s and now competes with vinyl as a low maintenance floor covering. Similar to the high-density plastic laminate used on countertops, the flooring is protected by a clear melamine layer, in some cases reinforced with aluminum oxide.

Guide to Selecting Indoor Wall-to-Wall Carpeting: Materials, Grades & Carpeting Installation Best Practices

Details about choosing and installing wall-to-wall indoor carpeting & carpet padding are found at CARPETING, SELECTION & INSTALLATION. Excerpts are below.

Also see

- CARPET DUST IDENTIFICATION

- CARPET TEST GUIDE

- CARPETING & INDOOR AIR QUALITY

- ENVIRONMENTAL HAZARDS - INSPECT, TEST, REMEDY for our full list of environmental hazard identification and remedy related to buildings.

Guide to Selecting & Installing Interior Trim: Best Practices

Details and illustrations about selecting and installing interior trim in buildings are found at TRIM, INTERIOR INSTALLATION. Excerpts are below.

Once the domain of premium softwoods, such as clear pine, poplar, and other easily machined woods, interior trim is just as likely now to contain a mix of finger-jointed stock, medium density fiberboard (MDF) molded urethane for decorative trim, and flexible polyester moldings that must bend around curved surfaces.

Wood moldings and other finish lumber are graded for visual properties only. In general, the higher the grade, the more uniform the grain and color will be, and the fewer the defects, such as small knots, pitch pockets, and other natural markings

In some species, there is also a marked color difference between heartwood and sapwood. Some customers might like the natural variation found in lower grades; others find it objectionable.

Casework: Guide to Selecting Materials for Built-In Cabinets & Shelving

Details about building shelving and other casework are at CASEWORK, CABINETS, SHELVING INSTALLATION. Excerpts are below.

For shelving, built-ins, and other casework, contractors can choose from a wide array of panel products. The most widely used are veneer-core plywood, MDF, and particleboard. MDF and particleboard are available either unfinished or with a wood veneer or melamine facing. Medium density overlay (MDO) is a good option for cabinets exposed to very high humidity or exterior uses.

Best Practices Guide to Choosing & Installing Interior Doors

Details about how to select an interior door, the types of doors and their properties, and how to install them are found at DOORS, INTERIOR. Excerpts are below.

Over 90% of interior doors today are either flush or molded. In either case, a facing of wood veneer or hardboard is glued to a core, providing the door with its strength. Traditional rail-and-style construction is still used, primarily for stain grade work, although composites and veneered construction are widely used with this type of door as well.

Best Practices Guide to Choosing & Using Interior Stains & Finishes

Details about the selection and application of interiot stains and finishes are at STAINS & FINISHES, INTERIOR. Excerpts are below.

Finishing stain-grade trim is equal parts art and science. There are a wide range of products and application techniques. With all finishes, careful prep work and control of dust on the job site are critical for a professional quality finish.

Procedures for Noise & Sound Control in buildings: Best Practices

See SOUND CONTROL in BUILDINGS for Steve Bliss's guidelines for best practices for indoor noise & sound control.

Also see NOISE / SOUND DIAGNOSIS & CURE - home

Sound Isolation Strategies

To keep airborne sound from passing through walls and floors, there are four main strategies:

- Add Mass: Increase the mass of the wall or floor by using heavy, dense materials.

- Decoupling: Break the path of vibration with a break in the framing or a resilient connection to the drywall.

- Absorption: Provide sound-absorptive material, such as fiberglass batts, in the cavity.

- Sealing: Block airborne sound from leaking through gaps and cracks.

Details are at FLANKING SOUND PATHWAY CUT-OFF

How effectively a wall or floor reduces airborne sound is measured by STC ratings (sound transmission class) given at SOUND TRANSMISSION CLASS RATINGS

Choosing & Installing Interior Lighting: Best Practices Guide

Details, tables, and illustrations describing the selection of and standards for interior lighting are found at LIGHTING, INTERIOR GUIDE. Excerpts are below.

With the exception of purely decorative lighting fixtures, all lighting fits into one of three main categories: ambient, task, and accent. Most rooms use a mixture of lighting types to create visual interest and to meet the functional needs of the space. A space lit only by indirect light sources can seem visually flat, while a space lit only by directed light from spots and floods can seem harsh and cast dark shadows

Ambient lighting is the general background illumination that is bright enough to allow people to move about safely and perform simple tasks. Ambient lighting can be achieved by directly lighting the lower part of the room (direct lighting), or by reflecting light off the ceiling and upper half of the room (indirect lighting).

Task lighting is bright light directed to a specific surface, like a countertop or desk, to illuminate activities such as reading, homework, meal preparation, or laundry.

For details see TASK LIGHTING, DEFINITION, USES.

Guide to Recommended Lighting Levels Indoors

For details see GUIDE TO RECOMMENDED LIGHTING LEVELS FOR INDOOR AREAS, TABLES & RULES OF THUMB FOR INTERIOR LIGHTING

Lamp Types & Types of Bulbs for Indoor Lighting

There is a vast array of choices in light bulbs, known in the lighting industry as “lamps.” For residential lighting, the main choices are incandescent, halogen, low-voltage, tubular fluorescent, and compact fluorescent. Which lamp to choose for a given application will depend upon the amount of light needed (lumens), color of light desired, type of fixture (luminaire), and whether the application calls for a directed beam or a diffused light source.

For details see LAMP & BULBS TYPES, INDOOR

Common Lamp (Light Bulb) Abbreviations & Types

There are literally thousands of lamps to choose from, but the most common in residential lighting are standard incandescent A lamps, 120-volt BR and PAR directional lamps, and low-voltage PAR and MR lamps, along with a variety of tubular and compact fluorescent's.

For details see LAMP (LIGHT BULB) ABBREVIATIONS & TYPES

Color Temperature and CRI for Indoor Lights & Bulbs

Color temperature and color rendering index (CRI) are two different ways to characterize how colors appear under a light source. Color Temperature is expressed in degrees Kelvin, and for incandescent lights equals the temperature of the metal filament. For fluorescent's and other bulbs without filaments, it is the theoretical equivalent temperature.

See COLOR TEMPERATURE AND CRI FOR INDOOR LIGHTS - color codes

and see COLOR TEMPERATURE BULB COMPARISONS

Luminaires

See LUMINAIRES, DEFINITION, USES

Lamps (Bulbs) Used with Recessed & Track Lights

Beam spreads for directional lights vary depending on the lamp and fixture. For general lighting, choose a wide flood with a beam spread of at least 50 degrees. BR lamps are the most economical directional lamp and provide good enough beam control for general lighting.

See GUIDE TO RECESSED & TRACK LIGHT BULBS

Closet Lighting

Due to risk of fire, the International Building Code and the National Electrical Code require that all fixtures installed in closets must be either surface-mounted or recessed and must completely enclose the bulb. Only incandescent or fluorescent lamps are allowed.

Also see CLOSET LIGHTING FIRE SAFETY

Kitchen Lighting

Kitchens require general ambient lighting as well as task lighting on sinks, ranges, counters, and eating areas. Given the high lighting needs of a kitchen, the energy savings from fluorescent lights can be substantial. Look for fluorescent bulbs with a CRI over 80 and a color temperature near 2800K to match standard incandescent lights, or 3500K to match halogen lights.See details at

- KITCHEN LIGHTING REQUIREMENTS - specifications & details

- AMBIENT KITCHEN LIGHTING SPECIFICATIONS

- KITCHEN LIGHTING COUNTERS, SINKS, COOKTOPS

- TABLE TOP LIGHTING SPECIFICATIONS

Bathroom Lighting

See BATHROOM LIGHTING GUIDELINES

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Resources:

Drywall Trims and Accessories

- Clinch-On Products, A Deitrich Metal Framing Company www.dietrichindustries.com Nail-on and clinch-on galvanized metal corner beads

- Con-Form International/Strait Flex www.straitflex.com Strait-Flex fiber-composite mud-on corner bead for inside and outside off-90 degree angles

- Drywall Systems International www.no-coat.com No-Coat prefinished drywall tapes for inside and outside corners, off angles and bullnose trims

- Flex-Ability Concepts www.flexc.com Curved metal top and bottom plates for curved wood or metal stud walls

- Grabber Construction Products www.grabberman.com Drywall screws, corner clips, and fiberglass mesh tapes

- Insta Arch Corp. www.instaarch.com Galvanized steel preformed and custom arches for drywall

- National Gypsum Co. www.nationalgypsum.com ProForm tapes and finishing compounds

- Pla-Cor www.pla-cor.com ABS corner trims, bullnose, 3-way corner caps, and flexible arches

- Phillips Manufacturing Co. www.phillipsmfg.com Metal and vinyl corner beads, bullnose trim, and flexible bullnose and angled arch trim

- Trim-Tex www.trim-tex.com Vinyl drywall beads, flexible arch beads, and finishing accessories

- U.S. Gypsum Beadex and Sheetrock-brand tape-on metal corner beads and trims. Complete line of drywall finishing compounds

- Vinyl Corp., A Deitrich Metal Framing Company www.vinylcorp.com Full line of vinyl beads and trim

Polymer (Urethane), MDF, and Vinyl Trim Producers & Sources

- Burton Mouldings Web: burton-mouldings.com MDF(medium-density fiberboard), polymer, flex, and wood

- Fypon Web: ypon.com Polymer moldings and components

- Nu-Wood Web: nu-wood.com Polymer moldings and components

- Outwater Plastics Web: utwater.com Polymer moldings and components

- RAS Industries Web: asindustries.com Polymer moldings and components

- Royal Mouldings (formerly Marley Mouldings) Web: royalmouldings.com Polymer, polystyrene, expanded-PVC, CPVC, and acrylic molding profiles and components

Flexible Trim Manufacturers & Sources

- Flex Trim www.flextrim.com Flexible polymer moldings

- Resin Art www.resinart.com Flexible polymer moldings

Industry & Trade Associations

- American Lighting Association www.americanlightingassoc.com

- Association of the Wall and Ceiling Industries - Web: awci.org

- Carpet and Rug Institute (CRI) www.carpet-rug.org

- Drywall Finishing Council www.dwfc.org

- Forest Stewardship Program www.fscus.org

- FloorFacts www.floorfacts.com

- The Gypsum Association www.gypsum.org

- National Oak Flooring Manufacturers Association (NOFMA) www.nofma.com

- National Wood Flooring Association www.woodfloors.org

- Painting and Decorating Contractors of America www.pdca.org Smartwood/Rainforest Alliance www.smartwood.org

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

...

Continue reading at CARPETING, SELECTION & INSTALLATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

INTERIOR FINISHES: BEST PRACTICES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about buying & installing building interior surfaces & finishes.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- "An Example of Colonial Paneling", Norman Morrison Isham, The Metropolitan Museum of Art Bulletin, Vol. 6, No. 5 (May, 1911), pp. 112-116, available by JSTOR.

- Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- Lath & Plaster Systems [copy on file as /interiors/LathPlaster_Nat_Gypsum.pdf ] - , 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- Pergo AB, division of Perstorp AB, is a Swedish manufacturer or modern laminate flooring products. Information about the U.S. company can be found at http://www.pergo.com where we obtained historical data used in our discussion of the age of flooring materials in buildings.

- Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

[copy on file as/interiors/Plastering_USG.pdf ] -

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.