History & Components of Asbestos-Containing Flooring

History & Components of Asbestos-Containing Flooring

Compainies that produced floor tiles with or without asbestos

- POST a QUESTION or COMMENT about the history & asbestos or other contents of floor tiles.

History of resilient floor tiles & asbestos-containing flooring:

Asphalt Floor Tiles, Asphalt-Asbestos Flooring, Vinyl-Asbestos Flooring, Linoleum, Ceramic & Cork floors, Painted Floor Canvas, Floor Tiles.

This document describes the history of resilient floor tiles and sheet flooring, including the production and ingredients in asphalt-based floor tiles and vinyl-asbestos floor tiles. We list companies producing floor coverings along with historic dates and types of products manufactured.

What is the history and age of asphalt flooring? What is the history and age of vinyl-asbestos flooring?

How were asphalt floor tiles made? History of asphalt-asbestos floor tile production & history of vinyl-asbestos floor tile production & Photographs of types of floor tiles & floor tile production machines; List of companies that produced asbestos-containing flooring products.

Page top image, excerpted from Rosato's book about asbestos, shows asbestos-based sheet flooring being manufactured from a rolling machine.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Flooring & Floor Tile History & Asbestos Floor Tile Companies

This article explains the origins, history, production, and ingredients of asphalt-based and vinyl-asbestos based resilient flooring.

This article explains the origins, history, production, and ingredients of asphalt-based and vinyl-asbestos based resilient flooring.

In the U.S. federal regulations addressing the management of asbestos-containing materials (ACM) are issued by two agencies: the US Environmental Protection Agency (EPA) rules for the handling and disposal of ACM.

Occupational Safety and Health Administration (OSHA) provides regulations specifying practices for worker protection. [4]

Our photo at page top (Rosato) shows the "caramel-like" asphalt-asbestos flooring mixture coming out of the rolling machine.

At the end of this article you will find a list of guides to identify different types of floor coverings, sheet flooring, linoleum, Armstrong flooring, Congoleum rugs, sheet flooring, tiles, and other floor tiles that may contain asbestos.

Article Contents

- SORT OUT FLOORING COMPANY NAMES - Armstrong, Congoleum-Nairn, Linoleum, Linocrusta

- AMITCO FLOORING

- ARMSTRONG FLOORING

- ASPHALT-BASED FLOOR TILES - history, ingredients & use of asbestos

- ASPHALT FELT PAPER BACKED FLOOR TILES

- ASPHALT FLOORING IDENTIFICATION GUIDES - list of keys, links to more information

- CERAMIC FLOOR TILE

- CONGOLEUM-NAIRN FLOORING

- EVER-WEAR FLOOR TILE

- GOODYEAR FLOOR TILES

- KENTILE FLOORING

- MATICO FLOOR TILES

- MONTGOMERY WARDS FLOORING

- OTHER FLOORING COMPANIES: American Biltrite, Bonafide Mills,

- PEEL & STICK FLOOR TILES - modern, self-adhesive vinyl flooring with and without asbestos

- ROBBINS FLOOR TILES

- SEARS ROEBUCK FLOORING

- NON-RESILIENT FLOORING - examples, links to more information - carpeting, ceramic tile, wood

- VINYL FLOOR TILES - history, ingredients & use of asbestos

Major resilient flooring manufacturers or retailers whose products are believed or known to have included asphalt-asbestos or vinyl-asbestos flooring included the floor covering producers discussed below.

In 1920 asphalt roofing manufacturers, who had been using asphalt and fiber binders to make asphalt roofing shingles for some time, tried to develop a rigid product that could be a substitute for (more costly) slate roofing.

The material did not perform acceptably as a roof covering, but it led to the development of asphalt floor tiles.

Asphalt floor tiles are 9" square (or other sized) tiles which used asphalt as the main binding material. the original asphalt tiles were produced only in dark colors because asphalt was a main ingredient.

Rosato (ASBESTOS TILE MANUFACTURE) indicates that the first publicized asphalt tile installation was in 1920 in New York City's Western Union office. The product was very successful and by 1936 over four million square yards of asphalt floor tiles were being sold annually.

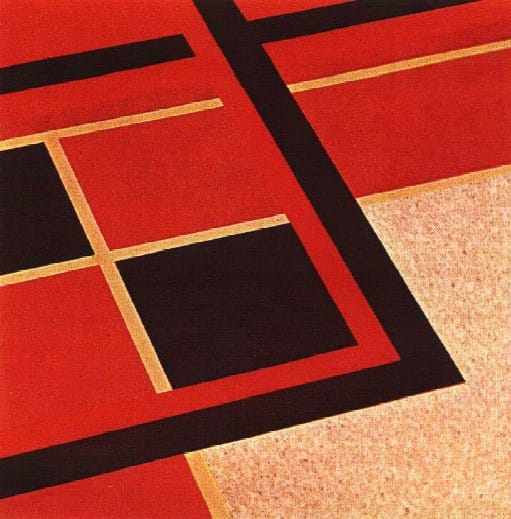

By 1940, 5% of floor coverings sold in the U.S. were asphalt tile. -- Rosato. Our photo (above left) also from Rosato, shows an Armstrong asphalt floor tile installation.

In the U.S. the 1940's saw a tremendous expansion in the sales of this flooring material, largely because other materials were more difficult to obtain.

At the end of World War II and combined with the reduction in military consumption of the product, asphalt floor tile sales increased to about 12% of the flooring market (1946), selling 41 million square yards.

By 1949 the post-war construction boom led to asphalt floor tile sales of 61 million square yards

Sorting out Flooring Names: Armstrong, Congoleum-Nairn, Linoleum, Linocrusta

This photograph of sheet flooring was identified by a reader in a 1964 home. She found remnants in the bottom of a kitchen cabinet on which was imprinted "Armstrong".

While the reader referred to this as "Armstrong Congoleum sheet flooring", Armstrong and Congoleum are separate individual companies.

The sheet flooring shown at left is identified as an Armstrong resilient flooring product from the 1970's, tested and found to contain chrysotile asbestos.

As we detail at our FAQs section at the bottom of this page, another reader had a sample of this resilient flooring tested and confirmed a 70% asbestos content.

Details about sheet flooring or older sheet type resilient floors that may contain asbestos are

at RESILIENT SHEET FLOORING ID GUIDE

Amitco Flooring

Amitco International, another larger producer of floor tiles has operated from 1964 to the present.

Amico flooring is discussed and illustrated in more detail

at AMITCO ASBESTOS FLOOR TILES.

Example of Amitco product packaging description:

Amtico Duravinyl Tile 12x12 1/16 ga 7LDF18 AH084 1 AL1102

Zip Stik self adhering duravinyl tile; made by American Biltrite Inc. Trenton, NJ.

Armstrong Flooring History, Use, Components - 1909 - Present

Armstrong Flooring: In the U.S. Thomas Armstrong, a Scotch-Irish immigrant, began his business as a cork cutter in 1860, delivering hand-carved bottle corks by wheelbarrow.

Armstrong Flooring: In the U.S. Thomas Armstrong, a Scotch-Irish immigrant, began his business as a cork cutter in 1860, delivering hand-carved bottle corks by wheelbarrow.

The use of cork expanded to the construction of corkboards (bulletin boards) and cork-insulated brick. By 1909 Armstrong had begun producing linoleum.

Photo: a 1960's floor tile fragment that we collected from a Two Harbors, Minnesota home built in 1962.

"Corkboard led to fiberboard, fiberboard led to ceiling board, cork floor tile led to linoleum that ultimately led to vinyl floor coverings, in both tile and sheet vinyl forms. Armstrong's familiarity with cork grew into today's Armstrong Corporation worldwide as one of the largest flooring producers. " - Armstrong.

One of the most significant flooring producers in the U.S. has been Armstrong World Industries (Lancaster PA), founded in 1860 by Thomas Armstrong.

In its original business, Armstrong was at one time the largest cork supplier (their first product: cork stoppers), produced corkboard and brick.

By 1906 Armstrong began producing linoleum, later vinyl flooring and many other flooring products.

Asbestos litigation [appears to have] led to a bankruptcy filing in 2000, from which the company emerged to continue as a successful flooring producer.

The Armstrong Flooring company continues today as one of the largest floor covering producers in the world, with plants in Canada, England, France, Germany, Switzerland, Sweden, Belgium, Austria, Spain, and China. The company's modern flooring products do not contain asbestos.

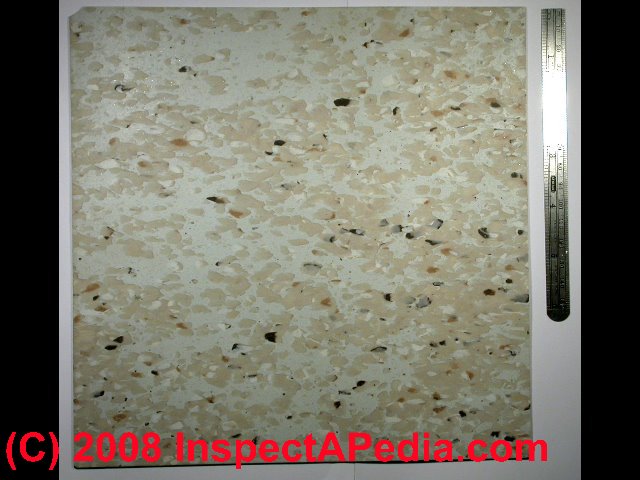

Below: a sample of Armstrong Excelon floor tile.

Modern Armstrong 12"x12" x 1/16" (1.5mm) Self-Adhesive "Stick-on" Floor Tiles do not contain asbestos.

Modern Armstrong 12"x12" x 1/16" (1.5mm) Self-Adhesive "Stick-on" Floor Tiles do not contain asbestos.

As we detail at ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959, depending on the age of manufacture, some resilient flooring products used asbestos as a primary ingredient (well actually at up to about 50% content) typically chrysotile and some amosite asbestos.

Also see ASPHALT & VINYL FLOOR TILE HISTORY.

Contemporary resilient flooring products such as the vinyl floor tile shown at left do not contain asbestos however.

Above is a photo of Armstrong Excelon Vinyl Floor tile, a contemporary, popular resilient floor covering, sold in 70 colors at retail outlets including Home Depot stores, this modern resilient floor tile does not contain asbestos.

[Click any image to see an enlarged, detailed version]

A detailed photo guide to Armstrong Floor Tiles is found

at ARMSTRONG FLOOR TILE PHOTO ID GUIDE - detailed photo guide to asphalt asbestos and vinyl asbestos floor tiles, 1900 -1986 with Armstrong tile images

Modern Armstrong Flooring such as vinyl floor tiles, sheet flooring, and self-adhesive peel and stick fdlooring is described

at 1989 & LATER ARMSTRONG ACCOFLEX FLOORING & TILES

At FLOOR, RESILIENT VINYL or CORK we discuss the choices, selection and installation details for contemporary vinyl and other resilient flooring products.

Also see these Armstrong product descriptions:

ARMSTRONG SOLARIAN NO-WAX FLOORING HISTORY - the history of urethane-coated no-wax sheet and tile flooring.

SELF-ADHESIVE STICK-ON TILES, ASBESTOS - peel and stick floor tiles that contain asbestos, and in the same article we may identify modern peel and stick floor tiles that do not contain asbestos

Also see this complete

Index to Armstrong Floor Tiles by Year: ARMSTRONG FLOOR TILE IDENTIFICATION -

Asphalt-Impregnated Felt Paper-Backed Floor Tiles

The 9"x9" square asphalt-impregnated paper-backed floor tiles shown here are discussed in detail at FELT-PAPER-BACKED FLOOR TILES.

The homeowner explained that these painted, 9x9-inch asphalt-paper-backed floor tiles, indicated by our added-on green lines, were later painted-over here with a more-traditional sheet flooring "rug" pattern:

Ceramic Floor Tile & Ceramic Wall Tile

- Please see CERAMIC TILE, ASBESTOS / LEAD? and also see FLOOR, CERAMIC TILE

Congoleum-Nairn Flooring History, Use, Components - 1886 - Present

1886: Congoleum Nairn was founded by sailmaker Michael Nairn, Kearney New Jersey in 1886 (the same year my grandfather Louis Friedman arrived at Ellis Island from Yoniver, Lithuania), originally produced painted floor-cloth coverings using sailcloth.

1886: Congoleum Nairn was founded by sailmaker Michael Nairn, Kearney New Jersey in 1886 (the same year my grandfather Louis Friedman arrived at Ellis Island from Yoniver, Lithuania), originally produced painted floor-cloth coverings using sailcloth.

The company later produced early forms of linoleum backed by fabric including burlap-like fabrics.

See examples of CONGOLEUM - NAIRN CORPORATION FLOORING in this web article, with photos from the 1920's to 2003.

See an example photo above-left and discussed at the top of our building age determination article:

FLOORING MATERIALS, Age, Types - Note that this antique flooring may not be a Congoluem-Nairn product).

According to Congoleum-Nairn, Linoleum, the precursor of modern resilient floors, was a hard smooth-surfaced flooring made of solidified linseed oil and ground cork, adhered to a backing of canvas or burlap such as that shown in our example.

1919 Congoleum Art Rugs:

According to some sources, by 1919 Congoleum Art Rugs were in popular demand but the company's website history indicates that it was in the 1920's that Nairn joined with Congoleum (whose asphalt-based raw materials originated in the Belgian Congo) in the 1920's to produce Congoleum, a three-foot wide simulated wood grain floor covering product, and to produce linoleum - Congoleum Gold Seal Rugs and Nairn Linoleum into the 1930's.

See this 1928 CONGOLEUM RUGS SHEET FLOORING - a Canadian Congoleum art rug installed in a home in Nova Scotia.

1930: asphalt & red-backed Congoleum Gold Seal Rugs and Nairn Linoleum were sold into the 1930's until replaced by vinyl-based products.

1935: Congoleum vinyl flooring research: In the 1930's Congoleum-Nairn was researching vinyl flooring, a product whose use grew rapidly after 1945.

I [DF] speculate that while asbestos was in some asphalt-impregnated paper backers on flooring products, asbestos formed a still-higher proportion of light-colored backer found on vinyl flooring products made in the 1950's and later.

1950: Congoleum linoleum sheet flooring: by the 1950s Congoleum-Nairn were producing twelve-foot wide sheet flooring or modern "linoleum" and the company produced the Vinylbest™ vinyl asbestos floor tile series, and by 1955, the Congoleum Gold Seal inlaid linoleum flooring shown at left, Gold Seal Inlaid Linoleum "Fashion Floor" was featured in Life and other magazine advertisements as both sheet flooring and 9" x 9" floor tiles.

1950: Congoleum linoleum sheet flooring: by the 1950s Congoleum-Nairn were producing twelve-foot wide sheet flooring or modern "linoleum" and the company produced the Vinylbest™ vinyl asbestos floor tile series, and by 1955, the Congoleum Gold Seal inlaid linoleum flooring shown at left, Gold Seal Inlaid Linoleum "Fashion Floor" was featured in Life and other magazine advertisements as both sheet flooring and 9" x 9" floor tiles.

Watch out: Backing used on some vinyl flooring products may contain asbestos.

Other Congoleum products included Vinylfloor, Vinyltop (countertops), Congoleum, CongoWall, Ranchtile, Cork tile, Linoleum tile, Vinyl tile, Rubber tile, and Asphalt tile marketed under the Congoleum Gold Seal trademark. The Congoleum Sequin Pattern sheet linoleum provided a scattershot or color fleck pattern.

1993: Congoleum-Amitco venture: In 1993 Congoleum-Nairn formed a joint venture with Amtico Floors, also a manufacturer of resilient floor tiles.

2003: Congoleum bankruptcy: in response to liability from asbestos hazard or injury claims, Congoleum Nairn filed for bankruptcy under Chapter 11 on 31 Decembver 2003.

2010: Congoleum emerges from bankruptcy: the bankruptcy court approved Congoleum's reorganization plan by mid 2010.

Details about the Congoleum Trust formed to address asbestos-related claims can be found under Congoleum in our alphabetical listing

at ASBESTOS PRODUCING COMPANIES & TRUSTS

There you'll read that the principal asbestos exposure from Congoleum products was of people working in construction and remodeling in residential and commercial buildings.

2018: Currently Congoleum continues to produce a wide range of residential and commercial sheet flooring and floor tile products, made in the U.S. at the corporation's factory in Trenton, NJ.

2020: See also this history of Congoleum Flooring provided by the company

- HISTORY of CONGOLEUM FLOORING [PDF] 1828 - 2016, provided by Congoleum, retrieved 2020/12/17 Congoleum Corporation, Department C, P.O. Box 3127 Mercerville, NJ 08619-0127 USA, Tel: 609) 584-3601, original source: https://www.congoleum.com/history/

Details about Congoleum Nairn flooring and identification photos, catalogs, and more details are

at CONGOLEUM-NAIRN FLOOR TILES & LINOLEUM

Additional Images of Congoleum linoleum sheet flooring products are

at LINOLEUM & Other Sheet Flooring

More Images of Congoleum Nairn produced vinyl asbestos floor tiles in patterns and shades including examples shown

at ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959

Congoleum Nairn flooring and asphalt or vinyl tile flooring photos wanted - CONTACT US.

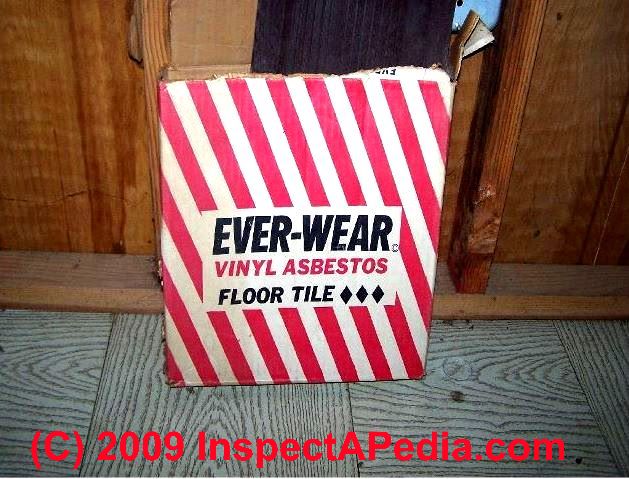

Ever-Wear Flooring History, Use, Components, Photo Guide to Ever-Wear Vinyl-Asbestos Floor Tile

These photographs of EverWear Vinyl Asbestos floor tiles were provided courtesy of home inspector David Grudzinski, who reported as follows:

While inspecting this home for a buyer I noticed this box and the tiles on the floor. All over the floor and next to the box are 1 inch holes drilled and filled with tiny plugs.

The seller made the plugs to cover termite drill holes from treatment. he had no idea the danger of drilling these tiles and breathing the dust.

As you walk across the floor the tiles crack under your feet. The buyer was going to cover the tiles with a carpet and forget about it.

My opinion was that that would be dangerous.

The tiles are crumbling and the vacuuming of the carpet would sent the asbestos dust all through the house and be worse. further, the central heating ducts may be filled with the dust from past drilling and the home should be properly cleaned. only testing will tell the level of contamination from asbestos.

EVER WEAR FLOORING produced vinyl-asbestos floor tiles, as we illustrate at the same Floor Tile Photo ID Guide cited above.

Goodyear Flooring History, Use, Components

Goodyear Tire & Rubber Co., in Akron OH produced asbestos-containing floor tiles. I'd make the same suggestion: if your Goodyear flooring was installed before 1980 it's likely that it contains asbestos.

Goodyear Tire & Rubber Co., in Akron OH produced asbestos-containing floor tiles. I'd make the same suggestion: if your Goodyear flooring was installed before 1980 it's likely that it contains asbestos.

Example floor tile markings (reader contribution) include:

- Goodyear Tire & Rubber Co. Plant C Akron, Oh. and sold by color tile supermart with a Vancouver, WA

Reader Question: do these Goodyear Floor Tiles Contain Asbestos?

2019/11/25 Gloria said:

My 1925 bungalow basement is tiled with 9x9 what appear to be linoleum tiles. Brown and tan colors.

Some have popped off and underneath you can see a black glue on top of the concrete foundation.

[Click to enlarge any image]

The product is very hard, no fibers obvious, a clean break where pieces have cracked off. However, I found an empty box, see image, of Goodyear

All Vinyl 9x9 tiles, code 684, style 5329B, and am wondering if these may have been a box from the original tiles. If so, am trying to ascertain if Goodyear all vinyl tiles of this style contained asbestos. No clue to age of the tiles. Thank you for any guidance.

Reply: asbestos in Goodyear flooring? Maybe so.

Gloria

While the Goodyear company said their flooring did not contain asbestos, in at least one litigation file (Peter Komiak New York vs Goodyear 2019) it is reported that the company's own employee (Joseph A. Kemmerlingan engineer at Goodyear between 1968-1979) said the product was asbestos free, while another employee, a development engineer who testified in a different lawsuit is reported to have confirmed that the composition of Goodyear floor tiles between 1954 and 1975 (and possibly later) did include asbestos.

Watch out: also that black mastic tile adhesive may contain asbestos as well. Search InspectApedia.com

for MASTIC, CUTBACK ADHESIVE, FLASHING CEMENT ASBESTOS

I agree with you that if the flooring and adhesive are hard, not breaking, crumbling, nor being sanded, chopped, sawn, ground or otherwise processed to make dust, the material is generally not friable; the potential asbestos hazard from picking up and disposing of an intact but un-glued floor tile itself is most-likely beneath the limits of detection.

You should treat the floor as presumed to contain asbestos, or have a sample tested.

It would be very helpful if you'd post a photo of the floor tile itself.

If you decide to have a sample tested you can find a test lab

The cost is typically under $50. U.S. - you can use our page top or bottom CONTACT link to provide test results for which we'll reimburse your test cost.

...

More on

Did Goodyear Floor Tiles Contain Asbestos?

- 2015 NY Slip Op 31170(U) BRUCE J. BARDONE and KATHERINE BARDONE, Plaintiffs, v. A.O. SMITH WATER PRODUCTS CO., et al., Defendants. Supreme Court, New York County. July 8, 2015.5.

Excerpt:

PETER H. MOULTON, Judge.

Plaintiff Bruce J. Bardone ("plaintiff") worked personally, and in the presence of others, as an electrician at various job sites throughout New York City from the early 1960s through the 1970s.

While working at those job sites, plaintiff alleges that he was exposed to asbestos-containing floor tiles manufactured, sold, and distributed by Defendant Goodyear Tire & Rubber Company ("Goodyear" or "Defendant").

On March 25, 2014, plaintiff was diagnosed with lung cancer that he attributes, in part, to his alleged asbestos-exposure to Goodyear floor tiles.

...

Goodyear claims that it never made such boxes bearing the word "asbestos." It also claims that plaintiff's descriptions of the physical properties of the floor tiles he encountered (hard and inflexible), do not comport with the fact that Goodyear manufactured several floor tiles that were flexible and often sold in rolls.

Finally, Goodyear claims that plaintiff's physical description of the tiles he encountered correlates closest to Goodyear's "Deluxe On Grade" floor tiles, which it claims were, and have always been, asbestos-free.

According to several mesothelioma websites (who solicit asbestos litigation claims), Goodyear has 62,000 pending claims against it in Florida, Maryland, New York, Pennsylvania, and Texas. The cases involve asbestos exposure from products such as floor tiles, gaskets, and heat shields.

It would appear that many of these claims involve workers employeed at Goodyear production facilities.

Bottom line: it's quite possible that Goodyear Tire & Rubber Co., in Akron OH produced asbestos-containing floor tiles.

If your Goodyear flooring was installed before 1980 it's likely that it contains asbestos. Example floor tile markings (reader contribution) include:

- Goodyear Tire & Rubber Co. Plant C Akron, Oh. and sold by color tile supermart with a Vancouver, WA

See GOODYEAR ASBESTOS FLOOR TILES

Reader Question: Asbestos in 12x12 code 422 80 made by Goodyear Tire & Rubber Co. Plant C Akron, OH & American Biltrite, Trenton NJ

Do you have info about whether the following 2 tiles contain asbestos?

1. Box says Color Tile vinyl floor tile 12x12 code 422 80 made by Goodyear Tire & Rubber Co. Plant C Akron, Oh. and sold by color tile supermart with a Vancouver, Wa address.

2. Box says Amtico Suravinyl Tile 12x12 1/16 ga 7LDF18 AH084 1 AL1102 and also says Zip Stik self adhering duravinyl tile; made by American Biltrite Inc. Trenton, NJ.

Do I need to send photos to make ID possible? Any help is appreciated. - Nan Duncan 8/28/11

My previous email had a typo-- 2. should read Amtico Duravinyl.

Reply: American Biltrite in Trenton produced asbestos-containing floor tiles;

Nan,

American Biltrite in Trenton produced asbestos-containing floor tiles; if your American Biltrite flooring was installed before 1980 it's likely that it contains asbestos.

Goodyear also produced asbestos-containing floor tiles. I'd make the same suggestion: if your Goodyear flooring was installed before 1980 it's likely that it contains asbestos.

Kentile Flooring History, Use, Components - 1898 - 1992

Kentile KenFlex Floor Tiles Kentile was founded by Arthur Kennedy in 1898, had its primary location at 58 Second Ave., Brooklyn 15 NY.

Kentile KenFlex Floor Tiles Kentile was founded by Arthur Kennedy in 1898, had its primary location at 58 Second Ave., Brooklyn 15 NY.

Kentile produced Kentile (asphalt floor tiles of vinyl-asbestos floor tiles), Kencork (cork floor tiles), and Kenrubber (rubber floor tiles) (at least) as 9" x 9" resilient flooring including patterns and in 23 bold colors (1949) and in 26 colors (1952), many of which are shown in our separate article

at KENTILE KENFLEX ASBESTOS FLOOR TILE GUIDE - asbestos may be in Kentile products produced through 1986.

In 1949 Kentile was producing asphalt-based floor tiles. In the early 1950's, Kentile produced mostly asphalt-based floor tiles but also some cork-based floor tiles. In 1951 a 8' x 9' room floor cost $10.95 when it was consumer-installed. In 1969 Kentile was producing vinyl sheet flooring.

Some of Kentile's 26 colors/patterns included Breccia, Carnival (multi-color), Dog Tooth, Fleecy Cerulean, Gaiety, Genoa Green, Greek Skyros, Lamartine, Ovation, Toledo Red, Verde Antique, regular pattern, Marbelized, and die-cut theme tiles and solid color feature strips.

Kentile's sign, along the Gowanus Canal (Brooklyn New York, ca 1949) has been considered an important landmark in its own right. In Canada Kentile flooring was distributed by T. Eaton Co., Ltd. The company filed bankruptcy in 1992, ceasing operations in 1995.

Details about Kentile flooring: A brief history of Kentile KenFlex Vinyl-Asbestos flooring and more Kentile and asbestos-containing Kentile and KenFlex flooring photos are found

at KENTILE KENFLEX ASBESTOS FLOOR TILE GUIDE

Other Asbestos-Containing Flooring Producers & Distributors, History, Use, Ingredients

American Biltrite in Trenton, NJ produced asbestos-containing floor tiles from 1 January 1961 through December 1985; the company also produced sheet vinyl flooring whose backer contained asbestos fibers, from 1 January 1962 through 1968 and from 1975 - 1980.

If your American Biltrite tile flooring was installed before 1986 it's likely that it contains asbestos. If your sheet vinyl flooring from American Biltrite was installed before 1981 it's likely to contain asbestos in its backer.

American Biltrite was founded in 1908 as the Ewell Rubber Company, originally producing shoe heels and soles. The company began producing flooring in 1917. American Biltrite merged with Congoleum Corporation in 1993-1995. The company also acquired another manufacturer of asbestos-containing flooring, Bonafied Milles, in 1961. Example floor tile markings (reader contribution) include:

Bonafide Milles, manufacturer of asbestos-containing flooring, merged with American Biltrite in 1961.

Mannington Mills, flooring, founded in Salem, new Jersey in 1915 was, early in its life, a small vinyl-flooring manufacturer

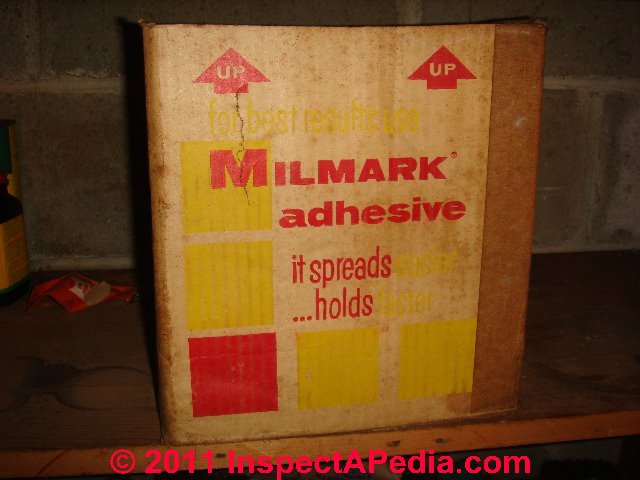

Matico Flooring & Floor Tiles & Asbestos Content

Matico (Mastic Tile Corporation of America) distributed plastic reinforced asphalt tile. Matico advertised "factory waxed" 9x9 floor tiles (1953) produced in plants in Houston TX, Joliet IL, Long Beach CA, and Newburgh NY. The company also distributed Milmark adhesive for floor tile application.

(We believe that both the floor tiles and the mastic contained asbestos). Tile thickness (Lot B405-02259A43) was indicated to be 1/8". The Matico 9x9 floor tile packaging and the floor tile photos below were contributed by reader M.Z.

Notice though that the brown and beige floor tiles in the accompanying photos look very much like an asbestos-containing Armstrong Product - see 1957 - Armstrong Excelon Vinyl Asbestos Floor Floor Tiles, Patterns & Color Guide at

ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959 where we include similar images of Excelon WOODTONE 9 x 9 x 1/16" & 1/8" Floor Tiles [image file].

In that same article you'll see that by 1973 there were some very similar looking floor tiles made without asbestos.

Photos of Matico Floor Tiles & Packaging

...

...

...

...

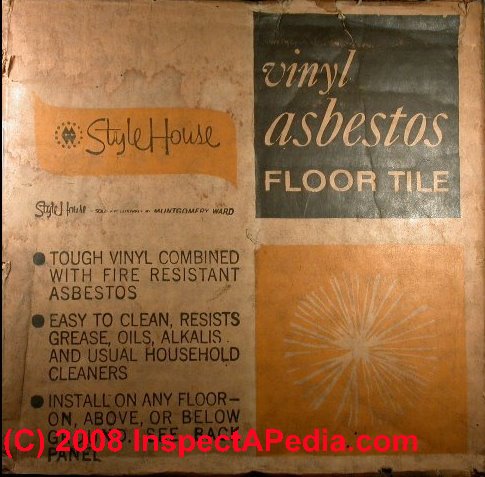

Montgomery Wards Vinyl Asbestos Floor Tiles

Montgomery Ward vinyl asbestos tile flooring are described a

at MONTGOMERY WARD ASBESTOS FLOOR TILE IDENTIFICATION. Excepts are below.

Above is a photograph of of Montgomery Ward Style-House Vinyl-Asbestos floor tile packaging, ca 1965 Montgomery Wards asbestos containing floor tiles and Ever-Wear asbestos containing floor tiles are also described and photographs of these (and other brands of floor tiles and sheet flooring containing asbestos) are provided

at ASBESTOS FLOORING IDENTIFICATION and a

our ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959

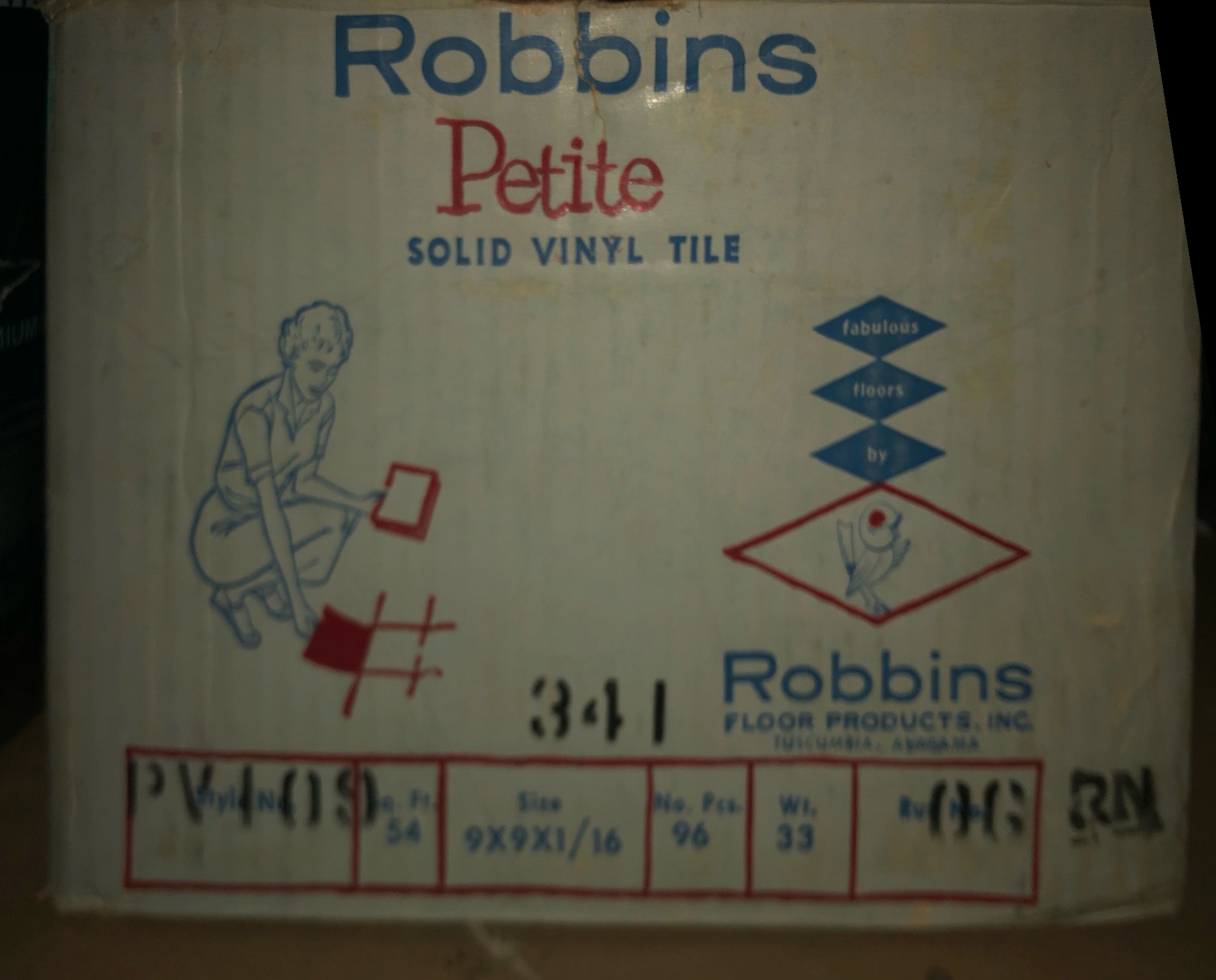

Robbins Vinyl Floor Tile 1960s

Question: asbestos in Robbins Petite solid vinyl floor tiles from 1960s

I have a question:

I suspect I have asbestos tile. It's 9x9 and installed in 1951. [sic - later this was corrected to 1961 - Ed]

I found an original box that is "solid vinyl tile" from Robbins petite. If it doesn't say it has asbestos, should I assume it doesn't? - Anonymous by private email 2021/05/24

Moderator reply: treat unfamiliar unknown 1950s floor tiles or sheet flooring as PACM

I would treat that floor tile as "PACM" (Presumed Asbestos Containing Material") until a test shows otherwise.

Is your installed-floor in good shape? If so you probably read at InspectApedia that best is to leave it in place and cover it over. (Or coat it as I've done with some of these floors).

What is your plan?

I would really appreciate some sharp photos of

- the installed floor

- an individual tile itself from the box

- the back of the tile if there is a manufacturer's stamp or data

- all sides of the box that have any writing or text

because that's not a brand I've seen

Reader Follow-up - asbestos not found in Robbins Petite 9x9 Solid vinyl floor tiles

We don’t actually own the house yet. We close on June 25 and I can take and share photos after we get asbestos test results back.

We have asbestos test results in!

When I wrote to you, I shared:

“i suspect I have asbestos tile. It's 9x9 and installed in 1951. [sic - now corrected to 1960s - Ed.]

I found an original box that is "solid vinyl tile" from Robbins petite. If it doesn't say it has asbestos, should I assume it doesn't?”

According to the EMSL test result, it doesn’t seem to have it!

Moderator reply

That's quite interesting, and as you later clarified in a follow-up, this Robbins white and black vinyl floor tile is from the 1960s, not 1950s;

in the 1950s these resilient floor tiles were made of an aspalt-base not a vinyl base; it would be rare for an asphalt- or vinyl- based floor tile to omit asbestos in the 1950s or 1960s, but indeed some early vinyl based flooring used different fillers and fibres and no asbestos.

Conversely, I have not found vinyl (asbestos free and not using asphalt) floor floor tiles dating back to 1951.

Is it possible that the tile was installed later, though perhaps in the late 1950s or early 1960s?

Below we give contact information for the Robbins Flooring Company (Robbins Sports Surfaces) who indeed trace their history back to 1894 and who began manufacturing flooring products in the U.S. in the 1930s.

Today the Robbins Flooring company specializes in wood and sports-related flooring such as gym floors.

- Contact: Robbins Flooring, 4777 Eastern Avenue

Cincinnati, OH 45226 USA, Tel: 800.543.1913, Website: https://www.robbinsfloor.com/

Excerpt:

Robbins was established as a family-owned flooring installation company in 1894 and began manufacturing in the mid-1930s. From the start, our focus was on delivering the highest quality products possible. Through the years we innovated and pushed the limits of what should be expected in flooring.

We saw opportunities to rethink sports flooring and began honing in on design, manufacturing and distribution in the 1980s.

This renewed focus led us to engineering breakthroughs in quality, longevity, safety and benefits to athletes from the floor. Our full line of Performing Arts and Stage Flooring, introduced in 2015, is a natural extension of our passion for ensuring athletes and artists have the very best surfaces on which to perform.

Other Robbins Flooring Companies & Products

There is also a Robbins Hardwood Flooring Company (below), apparently a different concern, established in 1990 in Connecticut and operated by Kent Robbins and not related to the original company cited above nor to the AFL Products brand cited below nor to flooring distributed by Home Depot stores. .

- Robbins Hardwood Flooring - Kent Robbins, Simsmore Square 540 Hopmeadow St. Simsbury, CT USA, Website: http://www.robbinshardwoodfloors.com/history

There is also a current Robbins Flooring brand owned by AHF (American Hardwood Flooring). The current AHF Robbins flooring products refer to solid hardwood, engineered hardwood, or rigid-core vinyl interlocking flooring patterns and a waterproof interlocking hardwood floor product line.

Neither of the the present Robbins Flooring brands include vinyl floor tiles.

- AHF Products Customer Care P.O. Box 4905 Lancaster, PA 17604 USA, Tel: 1-866-243-2726, Website: https://www.robbins.com/

Sears Vinyl Asbestos Floor Tiles

Sears vinyl asbestos tile flooring are found at SEARS ROEBUCK VINYL ASBESTOS FLOOR TILE RECOGNITION

and at our ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959. Excepts are below.

Above and below our photographs show the embossed pattern on these Sears vinyl asbestos floor tiles. The tiles are solid through in color and material and are about 1/16" thick and 9" x 9" in size. Below right shows these Sears floor tiles installed.

(Photos wanted for Sears Roebuck, Montgomery Ward and other asphalt & vinyl-asbestos floor tile producers or distributors - CONTACT US)

SEARS ROEBUCK VINYL ASBESTOS FLOOR TILE RECOGNITION also sold and sells a variety of other flooring materials including asphalt and vinyl asbestos resilient floor tiles.

- SELF-ADHESIVE PEEL & STICK ON ASBESTOS TILE IDENTIFICATION

- SELF ADHESIVE PEEL & STICK ASBESTOS TILE ID FAQs

- SELF ADHESIVE PEEL & STICK ASBESTOS TILE ID FAQs-2

- VINYL-ASBESTOS FLOOR TILE PHOTOS

Flooring adhesive or mastic (glue) that contained asbestos

Watch out: floor tile adhesives or mastics used for bonding floor tiles and sheet flooring to the subfloor also contained asbestos into the 1970's.[1].

Asphalt-based (Asbestos-containing) Floor Tile Production & Ingredients

Details about the manufacturing process and ingredients in both asphalt-asbestos and vinyl asbestos flooring products are

Details about the manufacturing process and ingredients in both asphalt-asbestos and vinyl asbestos flooring products are

"Asphalt" tile refers to flooring that used asphalt as the principal binder.

Asphalt -asbestos floor tiles that were manufactured early in the product life (1920's) were either black, near black, brown, or a gray-brown tone.

Dark vinyl-asbestos tiles used, for example, a mixture of 40 parts asphalt or gilsonite, 60 parts asbestos floats, 30 parts powdered limestone, and pigments (parts by weight).

Another typical mixture cited by Rosato contained 70% asbestos fiber.

Originally, asphalt floor tile was produced by mixing heavy asphalt solutions with a high percentage of asbestos fiber, hardening the tile by evaporation of the solvent. This procedure produced very dark floor tiles,. To obtain brown or intermediate colors, Gilsonite was used, dissolved in naphtha.

"Modern" asphalt tile (1950 and later) contained little or no asphalt. Rather than using asphalt or gilsonite binders, this later product used synthetic organic resins and additives or plasticizers based on petroleum or vegetable pitches. But asbestos fillers remained the main ingredient in "asphalt" tile. - Rosato.

Our photo (Rosato) shows the "caramel-like" asphalt-asbestos flooring mixture coming out of the rolling machine [image] as a soft sheet where the operator pulled the material from the machine and sent it to calendar rolls for thinning before it was hardened and cut into squares.

This photo shows the calendar rolls used to thin and polish the asphalt-asbestos floor tile during its final manufacturing stage (Johns-Manville Corp. - Rosato).

Rosato [reference] cites another flooring material from the 1950's called asbetic flooring which was a mixture of ground mother rock and the shortest, otherwise unusable asbestos fibers.

Ingredients / Components of Vinyl Asbestos Floor Tile

Other sources such as the Rotterdam Convention [reference] PIC archive, [citation needed] note that while vinyl-asbestos floor tile ingredient mixes varied by manufacturer, typically vinyl-asbestos floor tiles contained:

- Asbestos - 5 - 25%

- Binder - 15 - 20%

- Limestone - 53 - 73% [note that some products used asbestos powder as filler]

- Plasticizer - 5%

- Stabilizer - 1 - 2%

- Pigment - 0.5 - 5%

Short asbestos fibers may also be among the more hazardous if airborne. Asbestos was also used in a mixture with waterglass (a clear binder used in many chemical applications and even for cementing stove gaskets) as a hard binding compound.

Details about the manufacture, ingredients, and production levels of asbestos-containing flooring are

Our detailed photo guide to asbestos containing floor tiles is at

See ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959

Also see FELT-PAPER-BACKED FLOOR TILES

See ASBESTOS FLOOR TILE COMPOSITION where we compare the asbestos content and types of asbestos used in ceiling tiles, spray fire-resistant coatings, and floor tiles.

Asbestos-Containing Floor Tiles or Sheet Flooring Contain Lead?

This discussion has moved to

ASBESTOS TILE MANUFACTURE where we discuss the manufacturing process and ingredients in asbestos-containing floor tile in more detail in a section

titled LEAD in FLOORING PRODUCTS & POLISHES

Reader Comment:

... We are definitely having it recovered because I had the paint tested for lead and while it was negative the floor came back positive. Though that was also confusing because they used a soil setting as there wasn't one for vinyl tile. - Anon. 3 July 2015 [Email]

Vinyl-Asbestos (Asbestos-containing) Floor Tile Production & Ingredients

Vinyl-based (asbestos-containing) floor tiles became the most important and most widely-produced form of plastic floor tiles after World War II.

Vinyl-based (asbestos-containing) floor tiles became the most important and most widely-produced form of plastic floor tiles after World War II.

The product was similar to asphalt-based flooring, but was more flexible. Vinyl-based floor tile could thus be produced more economically and installed more easily as it was thinner, typically 1/16" to 3/32" (residential) and 1/8" thick "gauge" (commercial) versions.

Our photo (left) shows the calendar roll processing stage for floor tile (Rosato - Johns-Manville).

The use of vinyl as the tile base also permitted a wider range of lighter colors and patterns than was achieved with asphalt-based floor tiles.

Rosato described the principal vinyl-asbestos floor tile production process:

Vinyl-asbestos tile [was] used above or below grade on smooth wood or concrete base. As it wears it gets smoother and takes waxing very well. Its resistance to scratching or marring and to strong detergents is excellent.

The batch type-continuous process type of flooring [was] made by a combination of batch type and continuous process. It consists of vinyl-chloride vinyl-acetate copolymer resin mixed with plasticizers, stabilizers, asbestos, limestone and color pigments. Various types of mixing equipment [were] used to fuse these ingredients into a hot mass of the base, or field color.

Then, this base [could] be decorated on a two-roll differential speed mill by adding previously made granules of the proper shapes and colors to produce the desired design.

The thick blanket of tile material was cut from the mill, butted to a previous slab, fed into a two-roll calendar to squeeze tile to the required thickness, moving on to a cooling stage and a blanket press where rows of 3 to 5 tiles were cut from the sheet.

The thick blanket of tile material was cut from the mill, butted to a previous slab, fed into a two-roll calendar to squeeze tile to the required thickness, moving on to a cooling stage and a blanket press where rows of 3 to 5 tiles were cut from the sheet.

Rosato also describes a different vinyl-asbestos floor tile production method:

An entirely different approach to the processing of vinyl resins into flooring materials [was] the use of vinyl plastisols or organosols.

These materials are dispersions of vinyl resins in plasticizer (plastisols).

These dispersions are of a fluid nature; the methods for their application are based on their flow characteristic, on their ability, when heated to 350 degF to fuse into the same tough resilient vinyl plastic that requires the process described above.

Armstrong Asphalt Floor Tiles - to mid 1950's

Armstrong produced asphalt-based floor tiles, possibly including asbestos in their formulation, before 1952 and in later years as we indicate with examples and photographs in the detailed photo guide that is found below.

For more information about these older flooring types

, see ASPHALT & VINYL FLOOR TILE HISTORY - history, dates, and description of the production process and ingredients in asphalt floor tiles, asphalt-asbestos floor tiles, & vinyl-asbestos floor tiles 1900 to present.

Also don't assume that only "vinyl asbestos floor tiles" include asbestos.

According to Rosato, asbestos filler (powder) and fibers were used in asphalt based products too. "The first publicized installation of asphalt tile was in the Western Union office in New York City (1920). By the end of 1930, 3 million square yards of tile was being produced annually.

By 1952 "asphalt-asbestos" floor tiles contained much less asphalt or gilsonite. Those binders produced only dark tiles. IN the 1950's manufacturers changed to use of synthetic organic resins and solvents made of vegetable or petroleum pitches.

These new synthetic binders permitted manufacture of lighter colored, brighter floor tiles in a wider range of colors. But asbestos continued to be the main filler ingredient in these tiles.

Vinyl asbestos floor tiles were produced from approximately 1954 to 1980. Early vinyl asbestos flooring was made in 9" x9" floor tiles, and also sold as decorative or accent solid color strips, typically 1" wide by 24" long. By 1960 12" x 12" vinyl asbestos floor tiles were produced by Armstrong™, particularly their Excelon™ line. Asbestos was also used in sheet flooring.

By 1973 only a small portion of flooring was produced as asphalt-based floor tiles (9"x9") as vinyl asbestos flooring was dominating production. The size, thickness, color, and patterns of floor tiles can distinguish between asphalt-asbestos and vinyl-asbestos flooring.

While asbestos-containing floor tiles were made in a wide variety of colors and patterns (see ASBESTOS FLOOR TILE PHOTO ID GUIDE), if you encounter black or very dark asphalt floor tiles they are probably particularly high in asbestos fibers.

We discuss floor tiles as an asbestos fiber source in buildings in more detail

at ASBESTOS FLOORING IDENTIFICATION.

Vinyl Asbestos Flooring Topics

- ASBESTOS FLOOR TILE COMPOSITION

- VINYL ASBESTOS FLOOR TILE AGE

- VINYL-ASBESTOS FLOOR TILE HISTORY

- VINYL ASBESTOS FLOOR TILE PACKAGING

- VINYL ASBESTOS FLOOR THICKNESS & DIMENSIONS

- VINYL ASBESTOS SHEET FLOORING

Armstrong & Other Peel-and-Stick Floor Tiles May Contain Asbestos

Some self-adhesive floor tiles made by Armstrong also contained asbestos. Armstrong introduced peel and stick tiles in late 1969.

Some self-adhesive floor tiles made by Armstrong also contained asbestos. Armstrong introduced peel and stick tiles in late 1969.

The company stopped manufacturing these tiles with asbestos in December of 1982. Not all adhesive floor tiles produced during this period contain asbestos.

It is necessary to know the flooring product model number or collection name of a tile in question, or to submit a sample to an asbestos test laboratory to make a final determination. - information courtesy of Armstrong Corporation.

More about asbestos-containing peel and stick floor tiles can be found

at SELF-ADHESIVE PEEL & STICK ON ASBESTOS TILE IDENTIFICATION.

If you can identify your floor tile collection name or model number, laboratory testing of the sample to screen for asbestos may be unnecessary.

(See ASBESTOS FLOOR TILE PHOTO ID GUIDE)

Asphalt-saturated Asbestos Felt Backed Flooring Tiles

Finally, Rosato described use of a felt underlayment to produce flooring materials:

Another application of asbestos with vinyl tile involves the use of asphalt saturated asbestos felt applied under 1/8 inch thick tile. This felt underlay provides for smoother finished flooring.

It is possible that this development is what led to continuous-sheet asbestos-felt-underlayment backed sheet flooring. But we point out that continuous sheet flooring and asphalt tile flooring has an older history.

The original resilient floor covering, linoleum, was used as a floor decking on British naval ships. Asphalt tile was first made as a mastic type of floor covering. The mastic was troweled on as a deck covering over wood. The original mixes included asphaltic binders, with fillers of asbestos; mixing was done on a rubber mill.

Details are at FELT-PAPER-BACKED FLOOR TILES

Colors and Patterns of Resilient Floor Tiles Can Indicate When They Were Produced

Asphalt -asbestos tiles manufactured early in their life (1920's) were either black, near black, brown, or a gray-brown tone.

Asphalt -asbestos tiles manufactured early in their life (1920's) were either black, near black, brown, or a gray-brown tone.

Brown asphalt-asbestos tiles were made by substituting gilsonite as a binder. In both cases the tiles were hardened by evaporating a solvent used in the fabrication process, or by cooling of hot asphalt used in the mixture.

Gilsonite could be used to produce a wider range of mixtures, but required some asphalt as a softener.

Dark vinyl-asbestos tiles used, for example, a mixture of 40 parts asphalt or gilsonite, 60 parts asbestos floats, 30 parts powdered limestone, and pigments (parts by weight).

Another typical mixture cited by Rosato contained 70% asbestos fiber.

Asphalt asbestos floor tiles were popular in the U.S. from 1920 into the 1960's. Asphalt-asbestos floor tiles were produced at first in dark colors using a heavy asphalt binder combined with a very high percentage of asbestos filler fibers.

It would be uncommon to find these floors still in use today, but if you encounter black or very dark asphalt floor tiles they are probably very high in asbestos fibers.

(The black tiles shown at left were not dated and may be a newer product, but in general, if you find very old black floor tiles they are probably an asphalt-asbestos product. )

Source of High Levels of Asbestos in Asphalt Floor Tiles:

Asphalt-asbestos floor tiles were produced at first in dark colors using a heavy asphalt binder combined with a very high percentage of asbestos filler fibers.

It would be uncommon to find these floors still in use today, but if you encounter black or very dark asphalt floor tiles they are probably very high in asbestos fibers.

Depending on the particular mixture of asphalt, gilsonite, asbestos, limestone, and pigment used, these floor tiles could contain as much as 70% asbestos by weight. One reason that so much asbestos was used in flooring tiles was simply the wish to find an application for asbestos waste product from asbestos mining operations.

Mastic Use with Floor Tiles

As we introduced above, the earliest use of asphalt-based flooring reported by Rosato was as a troweled-on mastic applied as a deck covering for ships in the U.S. Navy in 1917.

Older nine-inch "thicker" vinyl or asphalt-based floor tiles, many more recent 12-inch floor tiles (1960 - 1980), and some more recent sheet linoleum as well as the mastic used to bed or glue down older flooring materials are likely to contain asbestos fibers and should not be disturbed by grinding, sanding, or demolition without taking the appropriate precautions.

We discuss the inspection, diagnosis, and repair of various flooring products

Asphalt or Vinyl Asbestos Floor Tile Thickness and Dimensions: 9x9 inch and 12x12 inch flooring

The Wards vinyl asbestos floor tiles shown by example here are nominally 1/16 gauge (4mm) in thickness 9" x 9" square.

The Wards vinyl asbestos floor tiles shown by example here are nominally 1/16 gauge (4mm) in thickness 9" x 9" square.

Armstrong vinyl asbestos 9" x 9" floor tiles may also have been produced in three thicknesses, depending on the cost and durability desired by the consumer: 1/16", 3/32", and 1/8" thickness.

Our 9" x9" lab sample of Armstrong vinyl asbestos floor tile was measured at 3/32" (about 2mm) thick

. The 1/8" thick floor tiles were considered commercial or heavy-duty grade.

Armstrong also made 12" x 12" vinyl asbestos floor tiles beginning in 1960. By 1972 most Armstrong vinyl asbestos floor tiles were sold in the 12" x 12" dimension.

From 1973 to 1980 all Armstrong Excelon vinyl asbestos floor tiles were sold in 12" x 12" size.

Above is our photo of an asbestos-containing floor tile sold by Montgomery Wards®.

In additional photographs below we show the examination of this "asbestos floor tile in the lab" as well as photos of the original labeling on the package in which these tiles were distributed.

We discuss the history of vinyl-asbestos floor tiles in our Age of House articles

We discuss the inspection and diagnosis of various flooring defects, including vinyl asbestos tiles,

According to Rosato, even when vinyl or other synthetic organic resins were used as the binder to produce light colored floor tiles, asbestos fibers continued to be the main ingredient in these floor tile products, and may be present at levels as much as 70% by weight.

Key to Thicknesses or Gauges of Vinyl-Asbestos Floor Tiles & Floor Tile Application or Usage by Thickness

Vinyl Asbestos Floor Tile Thickness & Usage Guide

Shown above is a vinyl-asbestos floor specification summary and usage guide from 1959 - Armstrong.

Montgomery Wards Vinyl Asbestos Floor Tile Packaging

Here is the information from the original package in which this Montgomery Wards asbestos-containing floor tile was sold.

See MONTGOMERY WARD ASBESTOS FLOOR TILE IDENTIFICATION for details.

At the time of its popularity, the addition of asbestos fibers to the binder making up these floor tiles was considered a benefit in fire resistance and durability.

Click on any of these images to enlarge them to read the packaging text.

Asbestos-containing Vinyl Based Sheet Flooring Product Photos

The resilient sheet flooring shown at left is a modern product (we are using this photo as a placeholder) and does not contain asbestos.

But before about 1978, in products that looked like this same material, asbestos fibers were used as a strengthen material on vinyl sheet flooring backing.

If the vinyl resilient sheet flooring backing material were dry-sanded or scraped during building demolition, for example, or if the sheet flooring is worn through so that foot traffic continues to damage the backing material, it is possible for unsafe levels of asbestos fibers to be released in a building. --EPA Guidance

During demolition or removal, this material should be disturbed as little as possible.

Additional demolition, renovation, and installation advice for dealing with resilient sheet flooring materials can be obtained from the Resilient Floor Covering Institute, by obtaining their publication on the topic.

Details about identifying older installations of sheet flooring or sheet-forms of resilient flooring that do or may contain asbestos are now found

at RESILIENT SHEET FLOORING ID GUIDE

Older sheet flooring products in buildings that do Not Contain Asbestos

This sheet flooring covering backed with burlap fabric is probably more than a century old. We examined it in an non-public area of the Justin Morrill Homestead, a historic building in Vermont. The material has not been tested for asbestos fibers.

But the backing material appears by visual inspection to be jute or "burlap".

Details about this non-asbestos floor covering material are

Modern Armstrong 12"x12" x 1/16" (1.5mm) Self-Adhesive "Stick-on" Floor Tiles

- SELF-ADHESIVE STICK-ON TILES, ASBESTOS - peel and stick floor tiles that contain asbestos - separate article

- SELF-ADHESIVE STICK-ON TILES, CURRENT - modern peel and stick floor tiles: information is shown below

This Armstrong flooring tile is 12" x 12" x 1/16" or 1.5mm thick.

Unlike the older vinyl-asbestos floor tiles whose photographs we provide below, this more recent flooring product is built from a thin vinyl layer containing the tile's design pattern and a fiber/paper backer (shown in our photo above) to which an adhesive was coated so that the tile could be installed without use of a mastic.

A typical pattern is the embossed design shown at left.

The floor tile thickness (about 1.5mm or 1/16") suggests that this product was produced after 1980 and probably does not contain asbestos.

Below we show a photo of the Armstrong© Stamp found on the under-side or "back" of 12 x 12 "stick-on" self-adhesive floor tiles produced by Armstrong.

Depending on the age of manufacture, some paper-backed flooring products used asbestos as a primary ingredient

see ASPHALT & VINYL FLOOR TILE HISTORY

Tests of our example floor sample (above) for asbestos confirmed that some early peel-and-stick floor tiles sold in the 1980's did contain asbestos.

Contemporary resilient flooring products do not contain asbestos however.

Shown at left: Armstrong Excelon Vinyl Floor tile, contemporary, popular, sold in 70 colors at retail outlets including Home Depot stores, this modern resilient floor tile does not contain asbestos. [Click any image to see an enlarged, detailed version].

A catalog of floor tile identification photographs for products that contained asbestos, 1952 - 1980, is provided below

at ARMSTRONG VINYL-ASBESTOS FLOOR TILE PHOTO ID CATALOG - 1952 - 1986..

And at ARMSTRONG FLOORING HISTORY we provide a history of Armstrong flooring and links to company information.

How to Find Your Floor Tile or Sheet Flooring in this Flooring Reference Photo Guide

See FLOOR TILE / SHEET FLOORING PHOTO GUIDES - list of photo guides. Examples of floor tile packaging, labeling, and other information can be found throughout the flooring photo collections listed here.

Guides to Asbestos-Containing Flooring Identification

See these articles on types, ages, characteristics, ingredients, & inspection of different types of floor coverings:

See these articles on types, ages, characteristics, ingredients, & inspection of different types of floor coverings:

- ASBESTOS FLOOR TILE COMPOSITION - comparing the most-common forms of asbestos found in ceiling tiles, fire-resistant sprays, and floor tiles.

- ASBESTOS FLOORING IDENTIFICATION - How to Identify Floor Tiles That May Contain Asbestos

- ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959 - home - detailed photo guide to asphalt asbestos and vinyl asbestos floor tiles, 1900 -1986

- ASBESTOS TILE MANUFACTURE - details how asphalt asbestos floor tiles and vinyl asbestos floor tiles were manufactured, their ingredients & composition including production quantities, asbestos content, other ingredients.

- FELT-PAPER-BACKED FLOOR TILES - some asphalt-impregnated felts contained asbestos

- FLOOR TILE / SHEET FLOORING PHOTO GUIDES - list of photo guides

- FLOOR TILE HISTORY & INGREDIENTS - history, dates, and description asphalt floor tiles, asphalt-asbestos floor tiles, & vinyl-asbestos floor tiles 1900 to present.

- FLOORING MATERIALS, Age, Types - Age of Building Flooring Materials - A Guide to Estimating Building Age, This article describes types and ingredients in flooring materials: Asphalt floor tile, Cork floor tile or planks, Laminate flooring (modern), Linoleum & older sheet flooring (painted canvas), Vinyl-asbestos floor tiles, Wood flooring.

- FLOOR TYPES & DEFECTS - Asphalt floor tiles, asphalt-saturated asbestos felt, carpeting, cork floor tiles & planks, laminate flooring (modern), linoleum (sheet flooring) & earlier painted fabric floor coverings, vinyl-asbestos tile floors, wood flooring.

- ASBESTOS FLOOR TILE LAB PROCEDURES - photos of how vinyl asbestos flooring is analyzed in the lab.

Our photo (left) shows 1972-vintage 12x12 vinyl asbestos flooring identified by a reader using our online floor tile

See ASBESTOS FLOOR TILE IDENTIFICATION PHOTOS 1949-1959.

Definition of resilient flooring

"Resilient flooring" is defined as materials softer than the non-resilient flooring materials such as stone, slate, brick, ceramic tile that we list just below..

Resilient flooring materials include organic types of flooring: asphalt based floor tiles, rubber floor tiles, vinyl-asbestos floor tiles, linoleum, and plastic tile.

So what's "wood flooring" ? Non-resilient, resilient, or just "wood"? Wood.

Definition of non-resilient flooring: Ceramic tile, stone tile, slate or brick.

"Non-resilient" flooring is defined as hard surfaced flooring material such as stone, brick, slate, or ceramic tile.

See NON-RESILIENT FLOORING for a quick guide and links to more-detailed information.

...

Continue reading at ASBESTOS FLOOR TILE PRODUCT NAMES - index to brands, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these FLOOR TILE HISTORY & INGREDIENTS FAQs - question & answers posted originally at this page.

Or see these

Recommended Articles

- ARMSTRONG CORLON FLOORING - Corlon® vinyl flooring & in CorAire, Hydrocord® & Nylex

- ARMSTRONG NYLEX FLOOR & WALL COVERINGS

- ARMSTRONG SOLARIAN NO-WAX FLOORING HISTORY

- ASBESTOS FLOOR TILE PRODUCT NAMES - index to floor tile and sheet flooring brands and companies

- ASBESTOS FLOORING HAZARD REDUCTION

- ASBESTOS FLOORING IDENTIFICATION GUIDE INDEX - all brands, all years

- ASBESTOS FLOORING REMOVAL GUIDE

- ASBESTOS MATERIAL REGULATIONS - dates of various asbestos bans & regulations

- ASBESTOS TESTING LAB LIST

- ASBESTOS TILE MANUFACTURE

- FLOOR COVERINGS: 1900 - 1949

- FLOOR TILE HISTORY & INGREDIENTS

- FLOOR TILE / SHEET FLOORING PHOTO GUIDES

- FLOOR TYPES & DEFECTS - home

- RESILIENT SHEET FLOORING ID GUIDE - Congoleum, Linoleum, etc.

Suggested citation for this web page

FLOOR TILE HISTORY & INGREDIENTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] EPA, U.S. Environmental Protection Agency, Asbestos in Your Home, web search 08/31/2011, original source: www.epa.gov/asbestos/pubs/ashome.html

- [2] EPA Guidance for Controlling Asbestos-Containing Materials in buildings, NIAST, National Institute on Abatement Sciences & Technology, [republishing EPA public documents] 1985 ed., Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- [3] EPA: "Asbestos Management", U.S. Environmental Protection Agency, Region 7, original author: Todd H. Dresser, Environmental Engineer, (formerly of), Burlington Board of Health, 29 Center Street, Burlington, MA 01803, web search 3/4/2012 original source: epa.gov/region07/education_resources/teachers/ehsstudy/ehs2.htm, [copy on file as: /hazmat/Asbestos Management _ Region 7 _ US EPA.pdf ]

- [4] US EPA, DECONSTRUCTION - BUILDING DISASSEMBLY AND MATERIAL SALVAGE - THE RIVERDALE CASE STUDY [PDF] U.S. EPA, web search 3/4/12, original source: epa.gov/wastes/conserve/rrr/imr/cdm/pubs/river.pdf, [copy on file as: /hazmat/Deconstruction_Riverdale_EPA.pdf]

- [5] TOXICS INFORMATION SERIES: ASBESTOS [PDF], U.S. EPA, April 1980

- [6] EVER WEAR TILE CO is currently (2009) in the Terrazzo, Tile, Marble, and Mosaic Work industry in Fallon, NV. 775) 423-6221. [We do not know the company history nor whether there is an association with EverWear vinyl asbestos floor tiles discussed in this article.]

- [7] HISTORY OF ASBESTOS IN THE UK - THE STORY SO FAR ..., Silverdell PLC, 14 Buckingham St., London WC2N 6DF TelP 0207 389 6906, email: info@silverdell.plc.uk website: www.silverdell.plc.uk. Web search 3/4/12, original source: issuu.com/silverdell_plc/docs/silverdell_history_of_asbestos_article

- [8] Armstrong ® Residential Flooring - Website 05/15/2010 https://www.armstrongflooring.com/ lists current flooring products provided by the Armstrong Corporation, including Armstrong's current vinyl floor tile products at https://www.armstrongflooring.com/flooring/products/vinyl-floors

- [9] Armstrong Corporation, Corporate History - https://www.armstrongflooring.com/corporate/corporate-history.html - Web Search 05/19/2010

- [10] Armstrong vinyl asbestos floor tiles: photos of asbestos floor tiles as catalog pages (PDF form) are at www.asbestosresource.com/asbestos/tile.html

- [11] Thanks to Armstrong Corporation (800-356-9301) for providing information about the dates of manufacture of peel-and-stick floor tiles, email July 2010

- [12] "Asbestos in your home or at work," Forsyth County Environmental Affairs Department, Winston-Salem NC 12/08

- [13] "Asbestos Floor Tile Removal", the University of Minnesota's advice on removing VAT (vinyl asbestos or asphalt asbestos floor tile) can be read in detail at www.health.state.mn.us/divs/eh/asbestos/floortile/index.html

- [14] ASBESTOS IN YOUR HOME U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- [15] Resilient Floor Covering Institute, 1030 15th St. NW, suite 350, Washington D.C.

- [16] Congoleum Corporation, "Company History", Congoleum Corporation, Department C, P.O. Box 3127, Mercerville, NJ 08619-0127 1-609-584-3601, web-search 03/14/2011, original source: http://www.congoleum.com/history.html

- [17] Congoleum Nairn, Congoleum Corporation, Department C, P.O. Box 3127, Mercerize, NJ 08619-0127

- [18] Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print).

- [20] LIFE Feb 14, 1955 p. 105, advertisement for Congoleum flooring products and listing of Gold Seal products by Congoleum.

- [21] Rotterdam Convention PIC, see http://www.pic.int/home.php?type=s&id=77, and for a PDF on the composition of vinyl-asbestos flooring, see http://www.pic.int/en/DGDs/Alternatives/USA/American%20alternatives%20part%203.pdf

where PIC refers to

Prior Informed Consent Procedure for Certain Hazardous Chemicals and Pesticides in International Trade on 10 September 1998.

Major Provisions of the Rotterdam Convention on Prior Informed Consent Procedure PIC

The Convention covers pesticides and industrial chemicals that have been banned or severely restricted for health or environmental reasons by Parties and which have been notified by Parties for inclusion in the PIC procedure.

One notification from each of two specified regions triggers consideration of addition of a chemical to Annex III of the Convention, Severely hazardous pesticide formulations that present a hazard under conditions of use in developing countries or countries with economies in transition may also be nominated for inclusion in Annex III.There are 40 chemicals listed in Annex III of the Convention and subject to the PIC procedure, including 25 pesticides, 4 severely hazardous pesticide formulations and 11 industrial chemicals.

Many more chemicals are expected to be added in the future. The Conference of the Parties decides on the inclusion of new chemicals.

Once a chemical is included in Annex III, a "decision guidance document" (DGD) containing information concerning the chemical and the regulatory decisions to ban or severely restrict the chemical for health or environmental reasons, is circulated to all Parties.Parties have nine months to prepare a response concerning the future import of the chemical. The response can consist of either a final decision (to allow import of the chemical, not to allow import, or to allow import subject to specified conditions) or an interim response.

Decisions by an importing country must be trade neutral (i.e., apply equally to domestic production for domestic use as well as to imports from any source).The import decisions are circulated and exporting country Parties are obligated under the Convention to take appropriate measure to ensure that exporters within its jurisdiction comply with the decisions.

- [22] CERAMIC TILE - WHAT IS ASBESTOS ? [PDF] Resource4Mesothelioma, Mesothelioma Information and Legal Guide web search 3/6/2012, original source: resource4mesothelioma.com/topics/whatisasbestos.html and

also

CERAMIC TILE ASBESTOS [local copy] original source mesothelioma.com/asbestos-exposure/products/ceramic-tiles.htm - [23] ASBESTOS, ITS INDUSTRIAL APPLICATIONS, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 [out of print, original copy, text and images provided by InspectAPedia.com (c)].

- [24] Microwave thermal inertisation of asbestos containing waste and its recycling in traditional ceramics.

Leonelli C, Veronesi P, Boccaccini DN, Rivasi MR, Barbieri L, Andreola F, Lancellotti I, Rabitti D, Pellacani GC.

Dipartimento di Ingegneria dei Materiali e dell'Ambiente, Università di Modena e Reggio Emilia, Via Vignolese 905, 41100 Modena, Italy. leonelli@unimore.it Journal of Hazardous Materials 135 (1–3): 149–155 - Citation: J Hazard Mater. 2006 Jul 31;135(1-3):149-55. Epub 2006 Jan 10., web search 3/6/2012, original source: http://www.ncbi.nlm.nih.gov/pubmed/16406335

Abstract: Asbestos was widely used as a building material prior to the 1970's. It is well known that asbestos is a health hazard and its progressive elimination is a priority for pollution prevention.

Asbestos can be transformed to non-hazardous silicate phases by microwave thermal treatment.

The aim of this investigation is to describe the microwave inertization process of asbestos containing waste (ACW) and its recycling in porcelain stoneware tiles, porous single-fired wall tiles and ceramic bricks following industrial manufacture procedure.

Inertised asbestos powder was added in the percentages of 1, 3, and 5 wt.% to commercially available compositions and then fired following industrial thermal cycles.

Water absorption and linear shrinkage of the obtained industrial products do not present significant variations with additions up to 5 wt.% of microwave inertised ACW. - [25] ASBESTEOS-CERAMIC, Wikipedia, web search 3/6/2012, original source: http://en.wikipedia.org/wiki/Asbestos-ceramic

- Thomas Hauswirth, Managing Member of Beacon Fine Home Inspections, LLC and (in 2007) Vice President, Connecticut Association of Home Inspectors Ph. 860-526-3355 Fax 860-526-2942 beaconinspections@sbcglobal.net 06/07: thanks for photographs of transite asbestos heating ducts

- Gary Randolph, Ounce of Prevention Home Inspection, LLC Buffalo, NY, for attentive reading and editing suggestions. Mr. Randolph can be reached in Buffalo, NY, at (716) 636-3865 or email: gary@ouncehome.com 3/07

- Kentile Floor Company History - see http://fadingad.wordpress.com/2007/08/25/kentile-floor-company-second-ave-ninth-street-brooklyn/ - Web Search 05/19/2010

- Mannington Mills Corporation - see http://www.mannington.com/Corporate/OurCompany/History.aspx

- Books, Complete List of Environmental Inspection, Diagnosis, Cleanup, Air Quality & Design, Inspection, Repair Books at the InspectAPedia Bookstore

- Asbestos Identification, Walter C.McCrone, McCrone Research Institute, Chicago, IL.1987 ISBN 0-904962-11-3. Dr. McCrone literally "wrote the book" on asbestos identification procedures which formed the basis for current work by asbestos identification laboratories.

- Stanton, .F., et al., National Bureau of Standards Special Publication 506: 143-151

- Pott, F., Staub-Reinhalf Luft 38, 486-490 (1978) cited by McCrone

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.