Electrical Box Types & Sizes for Receptacles

Electrical Box Types & Sizes for Receptacles

How to choose the proper type of electrical box

when wiring electrical receptacles (

wall plugs or "outlets")

- POST a QUESTION or COMMENT about how to install and wire electrical outlets or receptacles in buildings.

Guide to types of electrical receptacles (wall "outlets" or "wall plugs"):

How to choose the right type of electrical receptacle when adding or replacing a wall outlet in a building.

Here we describe matching 15-Amp receptacles to 15-Amp circuits, 20-Amp receptacles to 20-Amp circuits, two-wire receptacles where no ground is present, GFCI and AFCI electrical receptacles, and the proper electrical box to hold and mount these devices.

This article series describes how to choose, locate, and wire an electrical receptacle in a home. Electrical receptacles (also called electrical outlets or "plugs" or "sockets") are simple devices that are easy to install, but there are details to get right if you want to be safe.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Choose the Proper Electrical Junction Box When Adding a Receptacle

- The proper sized and type of junction box must be used

to house the electrical receptacle, must be properly secured in the wall, and must be located at the proper height from the floor. - The National Electrical Code Article 314

contains complete details and tables of electrical box sizes in dimensions and cubic inches and should be consulted for complete accuracy because the actual size of the box required, in cubic inches, depends on the number of wires that will be within that enclosure.

We give some basic electrical box size examples just below. - If the junction box is too small

you face several problems such as crowding which forces wires to be jammed and bent into the box, increasing the chance of a loose connection or damaged wiring, and worse, arcing. - If the clearance between the metal box and other live electrical parts is too small,

arcs and short circuits could occur, as we depict in this sketch courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Illustration above, courtesy of Carson Dunlop Associates, a Toronto home inspection & report writing tool & education firm.

Article Contents

Table of Electrical Box Sizes vs Number of Wires Allowed

The electricl box size table below is an excerpt from the complete NEC Table 314.16 (A) Metal Electrical Boxes for Devices given in the U.S. National Electrical code.

| NEC Table 314.16 (A) Metal Electrical Boxes for Devices | |||

|---|---|---|---|

| Rectangular Metal Box Dimensions (Inches)& Trade Name |

Minimum 2Cu. In. | Max # Conductors AWG 14 | Max # Conductors AWG 12 |

| 3 x 2 x 1 1/2" Device Box | 7.5 cu. in. | 3 | 3 |

| 3 x 2 x 2 " Device Box | 10 | 5 | 4 |

| 3 x 2 x 2 1/2" Device Box | 12.5 | 6 | 5 |

| 3 x 2 x 3 1/2" Device Box | 18 | 9 | 8 |

| 4 x 2 1/2 x 1 1/2" Device Box | 10.3 | 5 | 4 |

| 4 x 2 1/2 x 1 7/8" Device Box | 13 | 6 | 5 |

| 4 x 2 1/2 x 2 1/8" Device Box | 18 | 7 | 6 |

| 4 x 4 x 1 1/4" square | 18 | 9 | 8 |

| 4 x 4 x 1 1/2" square | 21 | 10 | 9 |

| 4 x 4 x 2 1/8" square | 30.3 | 15 | 13 |

Notes to the table above

- The National Electrical Code Article 314 contains complete details and tables of electrical box sizes in dimensions and cubic inches and should be consulted for complete accuracy because the actual size of the box required, in cubic inches, depends on the number of wires that will be within that enclosure.

This is an excerpt pertinent to wiring electrical receptacles and switches; other wire sized and applications are given in the source NEC, Chapter 3, Wiring Methods and Materials [PDF] as adopted by the U.S. state of Minnesota, that you can see in a for-pay copy of the whole US National Electrical Code - available from NFPA at nfpa.org/product/nfpa-70-code ($153.00 U.S.),

or where adopted by your state or city government, as local law provided at no cost by up.codes.com at up.codes/viewer/minnesota/nfpa-70-2023/chapter/3/wiring-methods-and-materials#3 - as retrieved 2023/11/24 - example from the Minnesota electrical code.

OPINION: Notice that the table describes the Minimum Cu. In. for these metal electrical boxes and then the maximum number of conductors that can be wired in a box of that size.

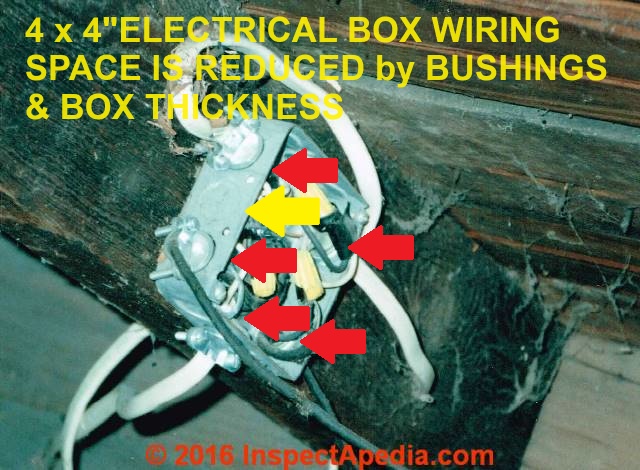

You'll see that the minimum size is a NEC requirement for the minimum available wiring space: in effect the available working space and is actually a number that is always smaller than the nominal metal box cubic inches.

That difference allows for the loss of wiring space that may otherwise taken up by other elements that project into the electrical box such as the space used up by a metal strain relief or wire bushing.

Example: a

4 x 4 x 1.25" Device Box like the one shown just above has an actual cubic inches of 20 cubic inches, but that's before allowing for the thickness of the box walls and the intrusion of electrical wire strain relief fittings into the box's interior.

That's why the table says that 18" is the minimum wiring space that the box has to provide for wiring connections and connectors.

- Excerpting from NEC 314.16(A)

The volume of a wiring enclosure (box) shall be the total volume of the assembled sections and, where used, the space provided by plaster rings, domed covers, extension rings, and so forth, that are marked with their volume or are made from boxes the dimensions of which are listed in Table 314.16(A).

Where a box is provided with one or more securely installed barriers, the volume shall be apportioned to each of the resulting spaces.

Each barrier, if not marked with its volume, shall be considered to take up 8.2 cm3 (1/2 in.3) if metal, and 16.4 cm3 (1.0 in.3) if nonmetallic. - "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

| NEC 314.16(B) Electrical Box Volume Required Per Conductor (wire) | |

|---|---|

| Conductor size (wire size) | Free space within the box for each conductor |

| No. 14 | 2 cubic inches |

| No. 12 | 2.25 cubic inches |

| No. 10 | 2.5 cubic inches |

Notes to the table above

This is an excerpt pertinent to wiring electrical receptacles and switches; other wire sized and applications are given in the source NEC.

Typical Electrical Boxes for Single Receptacles, Switches, or Splices

Typical electrical junction boxes used for receptacle installation to accommodates a single receptacle are 2" x 4" metal or plastic boxes of varying depth.

- NFPA - the National Fire Protection Association can be found online at www.nfpa.org

- The 2023 NEC National Electrical Code NFPA CODES Online Access LINK (you'll need to sign in as a professional or as a visitor or to buy a copy of the code at retail price)

Choose a deeper box if you have more than the minimum number of wires entering & leaving the box or it will be over-crowded and may violate building electrical codes.

Below are an older style steel electrical boxes nailed to wood framing in a building. The box is carrying six wires in total: two "hot", two neutral, and two grounds.

At above right in addition to aluminum wiring hazards the box is overcrowded.

See ALUMINUM WIRE REPAIR SPLICE SPACE.

Also

See ALUMINUM WIRING HAZARDS & REPAIRS.

It's likely to be permitted and safe to install a larger sized junction box than you need for an outlet or switch or wire splice, but you may need to purchase a special adapter-cover for the box in order to properly secure an electrical outlet therein. Installing a junction box that is too small is illegal and unsafe.

Typical 4-inch Electrical Boxes used for Single (or more often) Duplex Electrical Receptacles

Below we show a typical 4-inch metal junction box,

and below a common and deeper plastic junction box.

Below: a weatherproof electrical box and receptacle mounted on a home in northern Minnesota.

This weatherproof box is designed to provide an outdoor electrical receptacle. In this installation the box and receptacle are installed high on the building exterior wall, under the soffit. GFCI protection is also required.

Electrical junction boxes are required for all wall plugs ?

Reader Question: Do I really need an electrical box to put a new wall plug in ? - Thomas

Reader Question: Do I really need an electrical box to put a new wall plug in ? - Thomas

Reply:

Yes, Thomas, electrical devices such as switches and receptacles (wall plugs) need to be mounted in a code-approved plastic or metal receptacle (box) for fire safety as well as to assure that the device is mechanically secure.

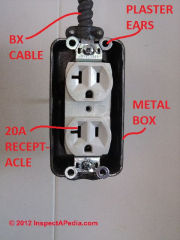

In fact when you purchase a "wall plug" you'll see that its metal mounting ears and screws are spaced and designed to connect to an electrical box.

Watch out: while it's physically possible to install a wall receptacle or "plug" without using an enclosure, doing so is dangerous, risking fire and shock, and of course, it's also illegal in virtually every building code jurisdiction.

Take a look at our photograph at left - a fire was contained within this electrical junction box. Had the box been omitted there is a good chance the fire would have spread to the building itself.

When we hear a question like this it makes me very afraid for you and for future building occupants - as amateur electrical wiring is dangerous.

Details about how to wire up an electrical receptacle are

at ELECTRICAL RECEPTACLE CONNECTION DETAILS - where to connect black, white, red, green, ground wire.

Gang Boxes - built-up electrical boxes for more space

Gang boxes are steel electrical boxes with removable sides and screw fittings that permit multiple metal boxes to be joined together to obtain more space. As we discuss

Gang boxes are steel electrical boxes with removable sides and screw fittings that permit multiple metal boxes to be joined together to obtain more space. As we discuss

at ALUMINUM WIRE REPAIR SPLICE SPACE,

Some electrical boxes installed as original work are stamped out of a single piece of steel and cannot be expanded. Others called "gangable" metallic boxes such as by (Thomas & Betts - Steel City Brand) installed as original work included side plates that could be removed to install a sidecar extension.

Gangable electrical boxes can be expanded by adding another box along the open (away from the stud or joist) side of the existing box (requiring a larger wall opening), or by adding a "side car" extension that hides behind the wall surface.

Sketch at left: illustrates the removable side-plates on a gang-type electrical box.

Boxes of this type can be expanded along their open side - the side that has not been already fastened to a stud or joist.

To add an electrical box extension you must have access to the top or bottom screw on the open side of the box to remove the side plate - that's where you'd add on a second gangable box as an extension or a side-car hidden box extension.

Watch out: it will be almost impossible to extend an original-work metallic box size using an extension without cutting open and thus damaging the wall at one side of the box.

However in my OPINION drywall repairs are trivial compared with the cost of complete re-wiring with all copper in a building with aluminum wired branch circuits.

Gang Box Extenders for More Wiring Space

In addition to screwing multiple gang boxes together to construct a large "new work" electrical installation, gang boxes can be extended behind the wall to obtain a small amount of additional wiring space: illustrated below.

At above left is a single "gang box" steel electrical box.

Below I've removed the left side of the gang box and I have installed a steel"side car" or "box extender" (yellow arrow in the photo below) to increase the cubic inches of wiring space in this electrical box.

These box extenders can be used to add a small amount of wiring space that can bring an otherwise too-small gang box up to code without having to cut a larger opening in the building wall.

You'll notice that the box extender is shaped to be recessed to slip behind the thickness of the plaster or drywall.

Below we see a modern GFCI electrical receptacle shoehorned into a too-small gang-box that has been extended with a box extender or "sidecar" in order to try to include AlumiConn™ aluminum-to-copper pigtailing connectors.

See ALUMINUM WIRE REPAIR SPLICE SPACE where we discuss all of the approaches to obtaining more wiring or device space in electrical boxes.

Where wall depth permits, a better approach where more wiring space is needed is to remove the existing electrical box and install a deeper box in the same opening.

Electrical box extensions & supplies for more wiring space or increased cubic inches of electrical box space

- Thomas & Betts (ABB Group) Steel City electrical boxes, Thomas & Betts Corporation 8155 T&B Boulevard Memphis, TN 38125 Phone: 901-252-5000, Phone: 800-816-7809 Fax: 800-816-7810 Email: elec_custserv@tnb.com Website: http://www.tnb.com/

- Home Depot stores

- Loews Building Supply stores

- Local electrical contracting suppliers in your area

- U.S. Patent No. 5,117,996, June 2, 1992 describes an electrical box extension submitted by William J. McShane, Philadelphia, PA. McShane patented a number of electrical box extension designs to accommodate wall thickness changes as well as space additions.

- Danbury toP&M Electric supply (29 Federal Road, Danbury CT 06810, Tel: 203-744-7445), The RAC535 X-cube adapter .5cui steel sidecar electrical box space extender retails for $1.79 and a RAC519 2 12/D NMC gang-type electrical switch steel box retails for $2.45.

New Work Compared with Old Work Electrical Boxes - Old Workboxes

New Work Electrical Box Examples

Normally a "new work" plastic electrical box installed during new construction is either nailed to the building framing (shown below) or if it needs to be spaced away from a stud or joist in a wall or ceiling it may be supported by a bracket that is in turn nailed to the building framing.

See ELECTRICAL JUNCTION BOX TYPES.

Examples of Old Work Electrical Boxes & Methods of Installation

When an electrical circuit and electrical boxes are being added to an existing structure wires are snaked through building cavities to the desired fixture location and an old-work electrical box or "junction box" is installed to contain electrical splices and devices.

Both metal and plastic old-work electrical boxes are available and there is a variety of clips, clamps, and other devices used to secure electrical boxes in a wall or ceiling when the box cannot be conveniently nailed or screwed directly to the structure.

[Click to enlarge any image]

At above is a steel gang box with mounting hardware to permit old-work installation: those metal brackets at the top and bottom of the box can be screwed to a wall surface.

In my opinion I'd prefer to see this box used in a wood or paneled wall or on a plaster wall on wood lath rather than on simple drywall as I worry that in a receptacle installation someone may find they pull the whole installation off of the drywall when removing a wall plug.

Above we illustrate thin steel clips (colored orange) that have been used (with considerable care) to secure a steel gang box in a drywall or plaster wall (adapted from Steel City products).

See details at OLD WORK ELECTRICAL BOXES for RETROFIT

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: When did blue plastic receptacle boxes (such as Carlon) come into use?

Daniel - 2022/08/01

When did blue plastic receptacle boxes (such as Carlon) come into use? thanks

This Q&A were posted originally at

ELECTRICAL OUTLET, HOW TO ADD in OLDER HOME

Moderator reply: history of plastic electrical boxes

@Daniel,

The history of plastic electrical boxes goes back to the development of bakelite plastic in the U.S. in the 1920s. (Developed by Leo Baekeland.) More about bakelite plastic and its history is

Newer thermoplastics were used for electrical boxes in the U.S. beginning in the 1950s.

Earliest use of PVC type plastic electrical boxes in the U.S. was in the 1960s, as you'll see by patent research. Hubbell, discussed in detail

at ANTIQUE & OLD ELECTRICAL RECEPTACLES purchased a plastics molding operation in 1958 and was producing plastic electrical components by 1960.

Plastics like the Carlon box about which you inquire were patented in the U.S. in the 1970s.

Carlon Products Corporation itself was founded by Brigham and Philip Britton and Geo. Quinn in 1929 as the Carter Prods. Corp, a metal specialties firm. The company began producing plastic products (piping) in 1940. By the 1960s Carlon was using polyvinyl chloride (PVC) plastics to make conduit and fittings, including electrical boxes such as that about which you asked.

Early-on the use of plastic was opposed by NFPA and the NEC but by 1984 both agencies had approved these plastics for use in residential electricalwiring systems.

EG:

- Appleton, Arthur I. Method of making a sealed electrical box [PDF] U.S. Patent 3,075,487, issued January 29, 1963.

- Brown, L. PLASTIC ELECTRICAL BOX [PDF] U.S. Patent 3,770,873, issued November 6, 1973.

Abstract:

An electrical junction box is integrally molded of a syn thetic organic plastic and includes rectangular side, rear and end walls defining a cavity for receipt of an electrical fixture and is open at its front.

A pair of laterally spaced knock-out plugs are located on each end wall forwardly of its rear edge and each plug is delin eated by front and side lines of weakness and a rear slot.

A recess with parallel tool guiding side faces ex tends from each slot to the rear wall, the recess front edge being the slot rear edge and being downwardly rearwardly offset from the slot front edge.

Integrally formed blocks extend along the inside corners between the rear wall and the end walls and have rear horizontal grooves with restricted throats oblique to the box rear face.- Hottel, Louis W. Means for forming plastic articles [PDF] U.S. Patent 1,652,940, issued December 13, 1927.

Except:

Cross reference is made to applicant's co pending application, Serial Number 66,312, filed Nov. 2, 1925, which contains some fea tures of construction of the present applica tion. No claim is made herein to any in vention claimed in said earlier application.

This invention relates to a molding press for forming hollow articles from plastic composition and has particular reference to a press construction possessing special utility for the manufacture of electrical storage battery boxes from plastic compositions of the kind that set and harden by cooling as distinguished from those compositions which are hardened or vulcanized by heat;

at the same time the press construction being adaptable for utilizing a steam circulating system in connection with the mold chamber and the core to provide for making hol low rubber articles such as battery boxes by pressing and vulcanization.

To that end a primary object of the invention is to provide a novel construction and organization of parts, in a press of the hydraulic type, whereby a battery box or equivalent article can be made economically and rapidly from a suitable acid-proof plastlc composition placed 1n a single mass m the mold and having sufiicient plasticity to permit the box or article to be formed by the closing of the mold and a sufficient set or hardening given to the formed box or article by cooling or chilling the same in-the mold before the removal of the completed article.- Kinney, David W., and William E. Baxter. ELECTRICAL BOX STRUCTURE [PDF] U.S. Patent 3,927,785, issued December 23, 1975.

Abstract:

An electrical wiring box structure. The electrical wiring box structure includes a first, main body portion for receiving an electrical device and a second, lateral portion extending from, and in open communication with, the first portion for increasing the volume of the first portion to permit the reception in the second portion of wires or other parts associated with or used in conjunction with the electrical device.

The first and second portions are offset with respect to each other and have offset openings defined therein by a plurality of walls. In accordance with the present invention, the opening of the second portion of the electrical wiring box structure is covered by a snap-fitting cover or lid. The electrical wiring box structure is arranged to be inserted into an opening provided in a flat wall structure with the opening in the first portion being aligned with the opening in the wall structure and with the covered second portion being disposed behind the wall structure adjacent to the opening in the wall structure.- Palmer, Lewis E., and Edith M. Parker. Molded plastic outlet boxes with concealed knockouts [PDF] U.S. Patent 2,959,633, issued November 8, 1960.

- Palmer, Lewis E. "Insulated wiring box made of selectively useable molded sections of thermoplastic material united by solvent welding to form a unitary box." U.S. Patent 3,168,613, issued February 2, 1965.

- Parker, Jr William M. Molded plastic articles such as outlet boxes [PDF] U.S. Patent 2,867,349, issued January 6, 1959.

Excerpt:

While the invention may be embodied in various articles, it is especially suitable for molded plastic outlet boxes used for mounting electric switches and other fixtures, or for forming junction boxes in electric wiring systems.- Rugg, Edward H. Outlet box arrangement for electrical wiring systems [PDF] U.S. Patent 2,374,622, issued April 24, 1945.

Excerpt:

The outlet box' arrangement shown in the drawing comprises a box l made of non-metallic material such as a ceramic or plastic material having front and rear walls ll and side walls It.

- Ware, Gordon K. OUTLET BOX and method of making the same [PDF] U.S. Patent 3,917,101, issued November 4, 1975.

Abstract:

A molded plastic box for receiving electrical outlets, switches, cover plates and the like of standard size and including a portion insertable through an opening in a wall and projecting laterally of the opening when fully assembled for increasing the interior volume of the box.

The box has knockouts with feeder lugs shaped and positioned to insure filling of the knockout cavity during molding of the box. A cover plate is provided that is secured by upset pins integrally molded with the box.Also see

OLD ELECTRICAL WIRING TYPES for more history of building electrical wiring materials & practices.

OLD HOUSE ELECTRICAL SYSTEMS - home

Reader Question: Is 14/3 wire ok to use to wire between the light switch and the light? What about an electrical outlet on the same circuit as the ceiling light fixture?

is it okay to use 14/3 wire for power to light to switch to receptacle?

Reply:

Anon:

If you are asking about using a shared neutral wire on a lighting circuit combined with an electrical receptacle circuit, see (search InspectAPedia.com for) our article on "multi wire branch circuits" or "shared neutral electrical wiring".

In general we'd use 14-2 wire on a 15 amp circuit to power electrical receptacles and a SEPARATE circuit to power the lighting fixtures. If we lose power on one circuit we want the other still working so that there is safe lighting in the area.

For a light fixture such as a ceiling light, in addition to bringing power to the junction box where the light fixture is to be mounted (using 14-2 copper wire) we'd use a separate length of 14-2 wire to run from the light switch to the junction box to control the light.Tape the white wire at both ends of the switch circuit with black tape so that the next worker knows that this is a switch circuit and that the white wire is not a neutral wire.

Watch out: we do not wire fixed lighting fixtures such as ceiling lights on the same circuit as electrical receptacles ("wall plugs"). If one of the two circuits should be switched off by a circuit breaker (perhaps detecting a fault or over current) we want the other circuit to remain on so that room occupants are less likely to be left in darkness.

On 2020-10-06 by Bob - do I need to install a nunction box where wiring a light onto a wall?

I will be installing a new wall mount light fixture in a powder room (toilet and sink only). The current light is also wall mounted. Wiring for the current light comes through a hole in the drywall behind the light and the splice between the wire and light rests on the metal backplate of the light fixture.

There is no junction box in the wall behind the light. Will I need to install a junction box and make the splice between the wire and light within the junction box? Thanks.

On 2020-10-06 - by (mod) - yes

Yes, Bob,

ALL electrical wiring splices for lighting and receptacles in a building, including the bath, need to be in a metal or plastic electrical box.

It's not technically difficult to add a box - use an "old work" box - those are sold with various mounting methods that make it easy.

Watch out: IMO if your light is within touching distance of the sink it should be GFCI protected as well.

See OLD WORK ELECTRICAL BOXES for RETROFIT

On 2020-07-12 by Mike - how can I install a cluster of electrical receptacles in one location

I need to install a cluster of 10 receptacles on a center wall to support a home computer lab. The wall section is actually 4 foot x 2 foot with a gas fire place on of the 4 foot faces. I will be using the other side. I also want to run a dedicate 15 amp circuit. Any code issues with that? Luckily, the breaker box is only about 10 feet away.

The receptacle layout would look like this:

[] [] [] [] []

[] [] [] [] []

On 2020-07-12 - by (mod) -

how to install a cluster of electrical receptacles in one location

Mike

You are certainly allowed to install a cluster of electrical receptacles, and I've done that many times myself. However in my opinion you'll be sorry if you put them all on one 15 amp circuit. It seems likely that you will overload the circuit.

At the very least I would prefer to run two or more 20 A circuits to that location and connect the receptacles accordingly so that you don't simply overload the circuit.

Also the electrical box(es) or gang box needs to be big enough to permit all of the electrical connections, wires, and devices.

On 2020-06-25 by Jodie Naker - how big does the receptacle box need to be for two switches

Hello - how large of a receptacle box is needed for two light switches / one a single toggle and the other a duplex/ double toggle - use one larger box or two smaller?

On 2020-06-25 - by (mod) -

Jodie

Thank you for a helpful question on electrical box size for two light switches.

A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box. Take a look at the tables above on this page for details and you'll see that more connectors means more cubic inches means a deeper box.See also LIGHT SWITCH WIRING DETAILS

On 2019-10-23 by Glen - Is one electrical box considered "one opening" ?

For new construction/remodeling permit , is one box no matter the size, single, double or multi switch considered one opening

On 2019-10-23 - by (mod) -

Glen

I'm not sure how you're using the word opening or where the concern lies in the question.Obviously the front of the box as a single opening into which devices are secured. However electrical box may have multiple openings for wiring connections. The number of those will vary as the box size varies.

On 2019-04-30 6 by lakelyn - Why are there different sizes of outlet boxes in a commercial construction?

Why are there different sizes of outlet boxes in a commercial constructio

On 2019-04-30 - by (mod) -

Lake

We use electrical boxes of varying sizes or capacity (in cubic inches) because the number of electrical wires, connectors, devices varies as well. More devices require more cubic inches, as per tables of electrical box size given in this article series.

Good luck on your test.

On 2018-08-31 by Mike - Can I use an old-work plastic box for a 50 amp outlet?

Can I use an old-work plastic box for a 50 amp outlet?

On 2018-08-31 - by (mod) - yes if it's big enough

The answer to your perfectly good question depends on the cubic inches that the Box provides matched against the table of cubic inches required for the number of wires and connectors by wire size in the circuit that you are wiring

Reader Question: When adding an electrical outlet in a garage, what's code: metal or plastic junction box?

I am putting outlet in garage wall that has kitchen on the other side. What is code, plastic or metal? I would think in a garage fire that a plastic box would melt and fire would go through the wall faster? - Steve Smith

Reply:

Steve both plastic and metal receptacle boxes are code-approved and neither, properly installed and wired, should violate the fire-rating of the wall.

Reader Question: how do I increase the projection of outlets into a room so I can add a kitchen backsplash

I am unable to find instructions on how to increase the projection into the room of existing electrical outlets so that I can tile the kitchen backsplash and have the outlets be at the appropriate depth for use and safety. Do I move forward the box to which the outlet is screwed and if so how? - Anne 3/22/12

I am unable to find instructions on how to increase the projection into the room of existing electrical outlets so that I can tile the kitchen backsplash and have the outlets be at the appropriate depth for use and safety. Do I move forward the box to which the outlet is screwed and if so how? - Anne 3/22/12

Reply: use electrical box extenders - shop for an "electrical box extension" of the proper thickness

Anne,

Building suppliers like Home Depot and also your electrical supply house sell "box extenders" in varying thicknesses, made of plastic, code approved, for the purpose you describe. The electrical box extender is sized and shaped to match the electrical receptacle box to which it is to fit.

By removing the electrical receptacle from its mount on the existing box, the box extender is fit as a sort of large rectangular plastic washer, mounting between the existing box edge or surface and the mounting ears of the receptacle or switch.

Electrical box extensions are sold in plastic and steel and in thicknesses from about 1/8" up to an inch or even more.

The plastic electrical "gang box extension" shown at above left is produced by Arlington Industries but there are several manufacturers. Just choose an electrical box extender that brings your receptacles far enough forward to suit the thickness of the kitchen backsplash or tile.

Watch out: don't try a makeshift substitute using washers or junk - that's an improper and unsafe repair, leaving a gap around the electrical box sides.

Reader Comments:

Anne,

I'm in the midst of a remodel that posed the same 'problem'. Work box extender rings are available at Home Depot and Lowes in the electrical department.They are plastic, color-coded frames that fit between the front edge of the box and the outlet/switch. The screws that secure the outlet/switch to the box also secure the frame in place.

The frames are available in multiple thicknesses. I suggest you take a tile sample with you so that you can get the correct thickness for your project. Depending on the thickness of the tile, you may need to combine two frames of different thicknesses.

While I was changing a failed plug I noticed that the box was too deep. I looked into extenders, and plastic ones (Arlington BE1) are less expensive. Are CSA approved plastic box extenders code compliant for homes? - Gary 7/19/12

Question: how many electrical receptacles are allowed on a 20-amp circuit? How many receptacles on a 15-amp circuit?

How many receptacles can be wired To one 20 amp circuit No. 12. Wire - John K.

Reply: 10 electrical receptacles to be wired on a 15-Amp (#14 copper) wire circuit

Our photo (left) shows a 20-Amp electrical receptacle - you can recognize it by that horizontal opening that makes the left-hand slot look like the letter "T" on its side.

In general, the Electrical Code [NEC] allows

- 10 electrical receptacles to be wired on a 15-Amp (#14 copper) wire circuit, and the Electrical Code [NEC] allows

- 13 receptacles on a 20-amp (#12 copper) wire circuit.

Watch out: When purchasing the receptacles to use on a 20A circuit, be sure to also buy receptacles that are themselves rated for 20Amp use.

You'll see that those least-costly receptacles found in a big pile at building supply stores are more likely intended only for 15-Amp use.Our photo (left) illustrates an electrical receptacle intended for use on a 20-Amp circuit.

Notice that extra horizontal slot? You won't see that on a 15-Amp electrical receptacle.

Reader Question: what is the minimum height that indoor house wiring must be above the ground or floor level?

When running wire for a basement, is there a min height the wires must be off the ground? Not the outlet box, but the wire running through the joists. Justin Sheppard

Reply: minimum heights for electrical receptacles is not specified in the electrical code NEC

No, Justin. But if there is the slightest danger that wires will be nicked by someone driving a nail into a stud though which the wires are run be sure to use steel plates to protect the wire where it passes through the studs.

Simple nail plates are available at any building supplier.

See ELECTRICAL RECEPTACLE HEIGHT & CLEARANCES for details.

Question: are electrical junction boxes required for wall plugs?

Do I really need an electrical box to put a new wall plug in ? - Thomas

Do I really need an electrical box to put a new wall plug in ? - Thomas

Reply:

Yes, Thomas, electrical devices such as switches and receptacles (wall plugs) need to be mounted in a code-approved plastic or metal receptacle (box) for fire safety as well as to assure that the device is mechanically secure.

In fact when you purchase a "wall plug" you'll see that its metal mounting ears and screws are spaced and designed to connect to an electrical box.

Watch out: while it's physically possible to install a wall receptacle or "plug" without using an enclosure, doing so is dangerous, risking fire and shock, and of course, it's also illegal in virtually every building code jurisdiction.

Take a look at our photograph at left - a fire was contained within this electrical junction box.

Had the box been omitted there is a good chance the fire would have spread to the building itself.

When we hear a question like this it makes me very afraid for you and for future building occupants - as amateur electrical wiring is dangerous.

Question: Which end of electrical outlets go "up"? The ground hole should be up, down, or sideways?

Can the outlet be installed any way? For example ground hole facing up, down, or sideways? thanks, - Anon

Reply:

Anon, the position of installation of an electrical outlet won't affect its operation and should not normally affect its approval by the electrical inspector.

In some areas I see the outlet installed with the ground connector always "up" as in our photo at left, though to me that's less attractive than the position shown in our electrical outlet photo at far left.

I've also seen arguments expressing the OPINION that the position of the grounding pin connector might help resist the tendency of a plug to fall out of its connection.

That's nonsense. If a plug is falling out of a receptacle, one of the two objects is worn or damaged and should be replaced to assure a safe, mechanically secure connection.

Please see details

Question: When adding an electrical outlet in a garage, what's code: metal or plastic junction box?

I am putting outlet in garage wall that has kitchen on the other side. What is code, plastic or metal? I would think in a garage fire that a plastic box would melt and fire would go through the wall faster? - Steve Smith

Reply:

Steve both plastic and metal receptacle boxes are code-approved and neither, properly installed and wired, should violate the fire-rating of the wall.

Question: can I connect a pigtail from multiple hot, neutral, or ground wires over to a receptacle

I have 2 receptacles that are both side and back wired, 3 hot and 3 neutral wires. I eliminated one receptacle (capping the 3 wires together) but want to keep the other. Is it safe to just run a pigtail from the 3 wires to the receptacle? - Greg

When wiring multiple boxes in series, how do you connect both incoming and outgoing ground wires to the back of the receptacle?

With 12 ga. wire, only one wire will fit under the green screw (and not very tightly, at that - there's no washer or clamp.) - Bob M.

Reply:

Yes, Greg, that's a common practice. Be sure that your junction box is big enough to contain all of the wires and twist-on connectors.

Bob, similar to Greg's question, I see two approaches to hooking up the ground wire in junction boxes and at electrical receptacles.

- If the incoming ground wire from the feed circuit was left long enough, it can be run continuously, connected to a grounding screw that connects the wire to the metal junction box (skip this step if plastic junction boxes are in use),

on to the ground screw terminal at each electrical receptacle, and ending with a ground clamp crimp connector that ties the incoming ground to the ground wire of the outgoing wire that continues to the next junction box.- If the incoming ground wire is not long enough to run as above, then an additional length of ground wire is pigtailed to the incoming ground and makes the other connections I've described above.

In sum, all of the grounds are tied together in the box: the incoming ground, outgoing ground, and ground wires to each of the electrical receptacles.

Watch out: while the electrical receptacle ground may also be electrically connected to the metal strap that mounts the receptacle to the junction box (photo at left), and while the junction box may be metal, do not rely on the receptacle mounting screws and receptacle strap-to-box contact to serve as the grounding connection.

It's easy for the receptacle mounting screws to be deliberately left loose or to work loose - making that ground connection unreliable.

Use a ground wire.

Question: how many electrical receptacles are allowed on a 20-amp circuit? How many receptacles on a 15-amp circuit?

How many receptacles can be wired To one 20 amp circuit No. 12. Wire - John K.

How many receptacles can be wired To one 20 amp circuit No. 12. Wire - John K.

Reply:

John K:

Our photo (left) shows a 20-Amp electrical receptacle - you can recognize it by that horizontal opening that makes the left-hand slot look like the letter "T" on its side.

In general, the Electrical Code [NEC] allows

- 10 electrical receptacles to be wired on a 15-Amp (#14 copper) wire circuit, and the Electrical Code [NEC] allows

- 13 receptacles on a 20-amp (#12 copper) wire circuit.

Watch out: When purchasing the receptacles to use on a 20A circuit, be sure to also buy receptacles that are themselves rated for 20Amp use.

You'll see that those least-costly receptacles found in a big pile at building supply stores are more likely intended only for 15-Amp use.Our photo (left) illustrates an electrical receptacle intended for use on a 20-Amp circuit.

Notice that extra horizontal slot? You won't see that on a 15-Amp electrical receptacle.

Question: how to fix loose electrical receptacles in a ceramic tile or glass mirror wall wall

Is there a way to repair electrical outlets on finished (glass and ceramic tile) walls that were not installed properly without damaging the tile? The outlets and the covers pull away from the wall when the electrical cord plug in removed?

Also, what does it mean when an electrical switch with multiple switches which control recessed lights, the ceiling fan and light on the ceiling fan gets hot; what is happening? Is this a fire hazard? - Mrs. Spencer

Reply:

Mrs. Spencer:

It sounds as if you need a licensed electrician to check and secure your loose electrical outlets - I agree that a loose electrical receptacle is unsafe. But an inspection is needed to understand the underlying problem. It could be simply tightening screws, or it could be that the electrical box itself is not adequately secured in the wall. Luckily there are retrofit parts that can be used and inserted along the box to make it secure, usually without disturbing the surrounding ceramic tile.

Some dimmer switches use a resistor to dim the light and it is common for them to get warm. Very hot - a subjective judgment for homeowners - may indeed be a fire hazard and should be investigated.

Question: how do I increase the projection of outlets into a room so I can add a kitchen backsplash

I am unable to find instructions on how to increase the projection into the room of existing electrical outlets so that I can tile the kitchen backsplash and have the outlets be at the appropriate depth for use and safety.

I am unable to find instructions on how to increase the projection into the room of existing electrical outlets so that I can tile the kitchen backsplash and have the outlets be at the appropriate depth for use and safety.

Do I move forward the box to which the outlet is screwed and if so how? - Anne 3/22/12

Reply: use electrical box extenders - shop for an "electrical box extension" of the proper thickness

Anne,

Building suppliers like Home Depot and also your electrical supply house sell "box extenders" in varying thicknesses, made of plastic, code approved, for the purpose you describe. The electrical box extender is sized and shaped to match the electrical receptacle box to which it is to fit.

By removing the electrical receptacle from its mount on the existing box, the box extender is fit as a sort of large rectangular plastic washer, mounting between the existing box edge or surface and the mounting ears of the receptacle or switch.

Electrical box extensions are sold in plastic and steel and in thicknesses from about 1/8" up to an inch or even more.

The plastic electrical "gang box extension" shown at above left is produced by Arlington Industries but there are several manufacturers. Just choose an electrical box extender that brings your receptacles far enough forward to suit the thickness of the kitchen backsplash or tile.

Watch out: don't try a makeshift substitute using washers or junk - that's an improper and unsafe repair, leaving a gap around the electrical box sides.

Reader Comments:

Anne,

I'm in the midst of a remodel that posed the same 'problem'. Work box extender rings are available at Home Depot and Lowes in the electrical department. They are plastic, color-coded frames that fit between the front edge of the box and the outlet/switch.The screws that secure the outlet/switch to the box also secure the frame in place.

The frames are available in multiple thicknesses. I suggest you take a tile sample with you so that you can get the correct thickness for your project. Depending on the thickness of the tile, you may need to combine two frames of different thicknesses.

While I was changing a failed plug I noticed that the box was too deep. I looked into extenders, and plastic ones (Arlington BE1) are less expensive. Are CSA approved plastic box extenders code compliant for homes? - Gary 7/19/12

Question: electrical outlet height requirements - this is a very informational site.

I was looking at some height requirements on electrical outlets this is a very informational site.

thanks Jerm 4/19/12

Reply:

Jerm, in the article above at ELECTRICAL RECEPTACLE HEIGHT & CLEARANCES we give the data you want. Let me know if anything is unclear.

Question:

I have one line with power coming into a box that will have one two way switch, one three way switch and one power line exiting. Is it proper to splice the incoming black wire to make 3 black wires by pig tailing with wire connectors and doing the same for the white wire and ground? - is it ok? 12/13/12

Reply:

I'm sorry but I'm confused by the question. I think it's safe to say that in general it's common practice to use a twist-on connector to splice pigtails or individual wires at an individual hot or neutral wire where more connections are needed than fit with the original wire.

Just watch out to avoid violating the space or number of connectors permitted in a junction box of the particular size you're working on.

...

Continue reading at ELECTRICAL RECEPTACLE LOCATIONS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ELECTRICAL BOX TYPE FAQs - questions & answers posted originally at this article

Or see these

Recommended Articles

- ELECTRICAL BOX TYPES

- ELECTRICAL BOX GROUND WIRING

- ELECTRICAL OUTLET, HOW TO ADD & WIRE

- ELECTRICAL RECEPTACLE HEIGHT & CLEARANCES

- ELECTRICAL RECEPTACLE LOCATIONS

- ELECTRICAL RECEPTACLE TYPES

- SIZE of WIRE REQUIRED for ELECTRICAL RECEPTACLES for receptacle circuits and similar wiring situations

Suggested citation for this web page

ELECTRICAL JUNCTION BOX TYPES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Timothy Hemm has provided photographs of various electrical defects used at the InspectAPedia TM Website. Mr. Hemm is a professional electrical inspector in Yucala, CA.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- [5] Special thanks to our reader Steve who pointed out prior errors in our illustrations.

- [6] Simpson Strong-Tie, "Code Compliant Repair and Protection Guide for the Installation of Utilities in Wood Frame Construction", web search 5/21/12, original source strongtie.com/ftp/fliers/F-REPRPROTECT09.pdf, [copy on file as /Structures/Framing/Simpson_Framing_Protectors.pdf ]. "The information in this guide is a summary of requirements from the 2003, 2006 and 2009 International Residential Code (IRC), International Building Code (IBC), International Plumbing Code (IPC), International Mechanical Code (IMC), 2006 Uniform Plumbing Code (UPC) and the 2005 National Electrical Code."

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.

343_DJFs.jpg)