Chronological History of Nails

Chronological History of Nails

Antique Wooden, Forged & Cut Nail Age & Use - Home Page

- POST a QUESTION or COMMENT about determining building age by examining its nails & other hardware

Antique & modern Nails, including wood treenails, hand-wrought nails, cut nails, wire nails, are compared and described here.

We give a chronology: the history of nails, types & methods of fabrication, and we describe antique and modern cut nails focusing on tree nails, wrought nails, and cut nails used in wood frame construction or interior finishing or carpentry work.

We include useful dates for the manufacture of different nail types along with supporting research for various countries from Australia and the U.K. to the U.S. to New Zealand.

The history, number and types of nails is both interesting and enormous, even if we confine our discussion to just those used in the construction of buildings. We continue to add examples and photographs here and welcome readers to CONTACT US with contributions or suggestions.

This article series describes and illustrates antique & modern hardware: door knobs, latches, hinges, window latches, hardware, nails & screws can help determine a building's age by noting how those parts were fabricated: by hand, by machine, by later generations of machine.

The author worked as a restoration contractor for four decades and is currently an environmental inspector and forensic microscopist. He has inspected, constructed, repaired, buildings since the 1970s

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

History of Nails & Building Hardware

Nail Photographs & Nails as Indicators of Building Age

Nail Photographs & Nails as Indicators of Building Age

As a carpenter’s nails are divided into wrought nails and cut nails; so mankind may be similarly divided. Little Flask was one of the wrought ones; made to clinch tight and last long. - Herman Melville, Moby Dick.

An examination of nails and fasteners and other building hardware is a complimentary effort useful in determining the age of a building and its components.

Photo: a hand wrought spike. This iron spike., detailed further below, was hand-made in the Northeastern U.S. at least before 1800 but could be still earlier.

A close observation of the type of fasteners used in a building is one of the most popular means of estimating its age.

The three types of nails found in North American construction include hand wrought nails, machine cut nails, modern round "wire" nails.

Nelson (NPS) and other nail chronologists point out, however that a wealth other details can describe the date of production and use of each of those three general nail types.

In turn, nail details can establish the time of original construction of a building and the time of modifications to the structure.

In addition to nails, building material, wood saw cut marks, and other hardware details can further assist in determining building age.

To provide a chronology of the production and types of nails we first describe wooden nails or "tree nails" followed by a chronological list of useful dates for iron nails.

Article Contents

- WOODEN NAILS TREENAILS POST & BEAM

- EARLY IRON NAILS - HISTORY - 300 B.C. to late 1770s

- FIRST CUT NAILS (TACKS) in AMERICA - 1779

- NAILS MADE COMPLETELY BY MACHINE - 1805 - PRESENT - direction of iron fibers, 1st railroad spikes & more

- ROUND SHANKED WIRE NAILS - 1850 - PRESENT

- MODERN POWER NAILER NAILS - 1950 - PRESENT

- CONTEXTUAL EVIDENCE HELPS SET NAIL/SPIKE AGE

...

Wooden nails - Tree Nails or Treenails, Post & Beam Construction

At AGE of a BUILDING, HOW to DETERMINE we note the following:

At AGE of a BUILDING, HOW to DETERMINE we note the following:

Post and beam construction (1700 - est. in North America): (timber framing) uses horizontal and vertical timbers that are connected (joined) using mortise and tenon joints pinned with wood pegs (treenails).

Timber frame construction initially used hand hewn beams, later manually or mechanically sawn beams cut by a pit saw. Later timber frame beams were sawn in mills using circular saws.

Timber framing using post and beam construction with mortise and tenon joint connections was used in Europe for at least 500 years before it was first employed in North America.

In our photo you can see the round sawn-off peg that secured the tenon of the lower vertical post into the mortise that had been cut into the horizontal beam.

The posts and beams were cut to size, mortises and tenons were cut, and the builders marked the corresponding joint components with numbers or letters - in my photo you can see the

I I I I

and

_

_

_

_

stamped into both the vertical post and horizontal beam to aid in assembly.

Below you can see the Treenail joining two rafters at the ridge of this 1790 home near Poughkeepsie New York.

By 1650 a typical timber frame building used multiple bents and girt beams, may have been more than one story tall, and included an exterior made of horsehair-reinforced cement stuccoed over hand-split lath.

More examples of uses of wooden pegs or treenails are at

...

A Tacky Little History of Iron Nails

Nail Head & Nail Body Details Help Set Nail Age

Nail Head & Nail Body Details Help Set Nail Age

Photo: sprites, small headless hand-wrought nails, discussed in more detail

at NAILS & HARDWARE, AGE FAQs.

Adapting from various sources including Nelson's article cited below we give a rough chronology of types and uses of nails, focusing on North America but including other earlier nail production and use as well.

Earliest Nails - 300 B.C.

The Mansfield, Massachusetts Tremont Nail company's historical notes (cited below) indicate that nails have been made (by hand) dating back to 300 B.C.

Nails in the 1400s

The denomination of nail sizes based on the price per 100 nails (e.g. ten penny nails or 10d nails) dates from the 1400s.

In medieval England nails were made

into a great variety of special shapes

and sizes and sold by the hundred, e.g.,

8d (pence) per 100 nails.

From this

practice developed the classification of

nail sizes according to their price per

hundred, a system which seems to have

been established by the fifteenth century.

After that time nails slowly became standardized by size rather than

price.

In 1471 for example, "fippenynayl" were only 4d per 100.

In 1477

"xpenynayll" were only 8d per 100; and

in 1494 "sixpenynayle" were 5d per 100. (Nelson NPS)

Nails in the 1590s

The 1500s saw the first nail producing machines - First Nail Making Machines - 1590 Slitting Mills

The roots of producing nails by machine date from 1590.

Nails in the 1600s - 1900s: hand wrought nails

Hand wrought nails were used for construction and later more for decoration.

The scarcity of nails in colonial Virginia was reflected in a statute enacted in 1645 to prohibit settlers from burning down old buildings for their nails.

Some nails were made

in the colonies in the seventeenth and

eighteenth centuries, but despite this

local production very large quantities of

nails were imported during the same

period. (Nelson NPS)

Details are at NAILS, HAND WROUGHT

1766 - Iron Nails Used as Barter

Although traditional Tahitian culture did not sanction extramarital sexual relations, within 48 hours of Wallis's arrival, Tahitian husbands and fathers were encouraging their wives and daughters to swim out to the Dolphin and offer the sailors sex in exchange for iron nails.

Aware of the brisk trade in iron, later explorers such as Captain James Cook brought supplies of nails and hoop iron with them to barter for freshwater, fish, pork, and vegetables.

Cook's visits [to Tahiti] in April 1769, August 1773, and August 1777 only heightened the islanders' desire for iron and other western goods. (Denver, 2013 Tahiti, p. 682-683).

For more on the history of nails used as barter and in trade see

1775-1783 Nails During the American Revolution

The colonists shifted to local production of nails and nail import from England was reduced or ceased altogether.

...

1779 First "Cut Nails" in North America

1779 - 1780 Hand-Operated nail cutting machines.

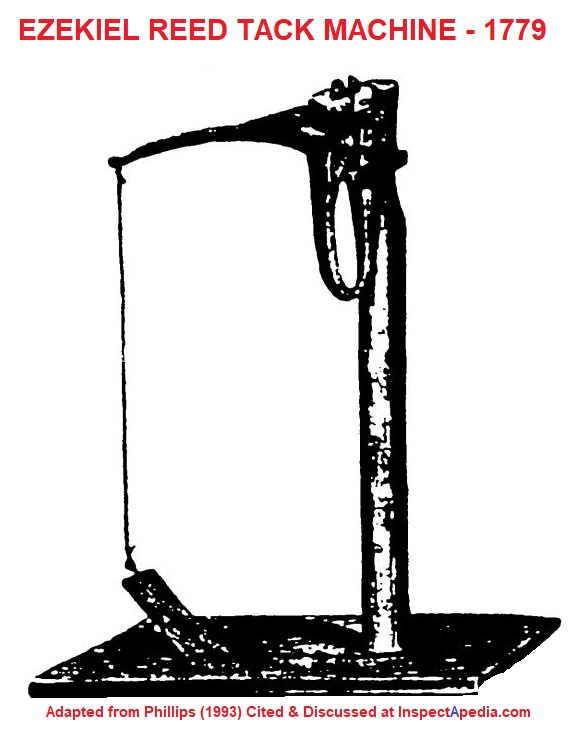

Ezekial Reed's 1779 Tack Machine,

(illustrated above, Phillips-1993) the first machine-made tacks,was operated by a foot treadle and was able to produce up to 3,000 tacks a day. Wedge-shaped iron blanks were cut by shears from a loop of strip hoop (such as used to construct wooden barrels).

The iron blank was placed tip-down in the jaws of the tack machine with the top protruding enough to be flattened by a hammer to form a head.

1788 - Adam Rogers machine to cut nails from iron hoops

1772 - 1820: In North America early machine cut nails

1772 - 1820: In North America early machine cut nails

Dating from 1590 in England, as the earliest report of nail production, the earliest reported cut nails in America are reported to have been cut, essentially by-hand, by Darrow in 1772 (Federal Writers Project 2013) with other authors crediting the Wilkinson brothers somewhat later, ca. 1783 (Benedict 1883).

Nelson notes the first generation of cut nail manufacturing involved cutting all nails from common sides with heads hammered on as a separate production step.

The first nail making machines in North America appeared during the late 1700's - earlier than one might have guessed.

The slitting mill, introduced to England in 1590, simplified the production of nail rods, but the real first efforts to merchandise the nail-making process itself occurred between 1790 and 1820, initially in the United States and England, when various machines were invented to automate and speed up the process of making nails from bars of wrought iron.

Above are nails used to secure accordion lath - a plaster base found in a rural U.S. post-and-beam home in Wyoming County, New York.

These two nails are from different machines.

Notice that the upper one has a rounded head. A closer look might show that the nail shank is constricted and rounded just below the head: marks from the vise that gripped the nail during the head-forming step.

The head on the lower nail is more-irregular.

More about the accordion wood lath in this building and our estimate of the building age are

1789 - U.S. Congress sets duty on imported nails

1790 - U.S. Congress passes first U.S. Patent Act - the second of two steps that encouraged development of nail making machines in North America.

1792 - Samuel Rogers (nephew of Adam Rogers) - expanded the hand-operated machine-cut nail operation.

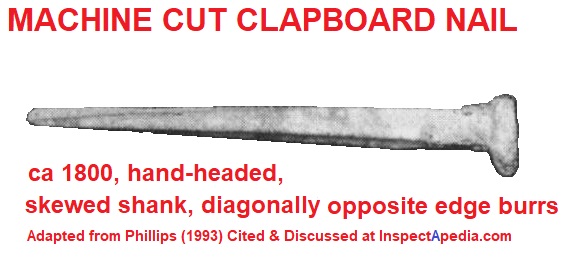

These nails have shanks with two tapering and the other two parallel sides, cutting die burrs appearing on diagonally-opposite edges. (Phillips 1993). The cross-section of the nail shank is a "skewed rectangle" and the nail tips are rounded. Heads on these nails were hand-formed as a "T" or as a rose-faceted head.

1794 - Perkins Nail Cutting Machine. Jacob Perkins, inventor of a water-powered nail-cutting machine, began producing machine-made cut nails in 1794 and in 1795 received the first U.S. nail-cutting machine patent. (Phillips 1993)

Perkins' machine, powered by water rather than by hand would have been capable of producing a greater quantity of nails per day.

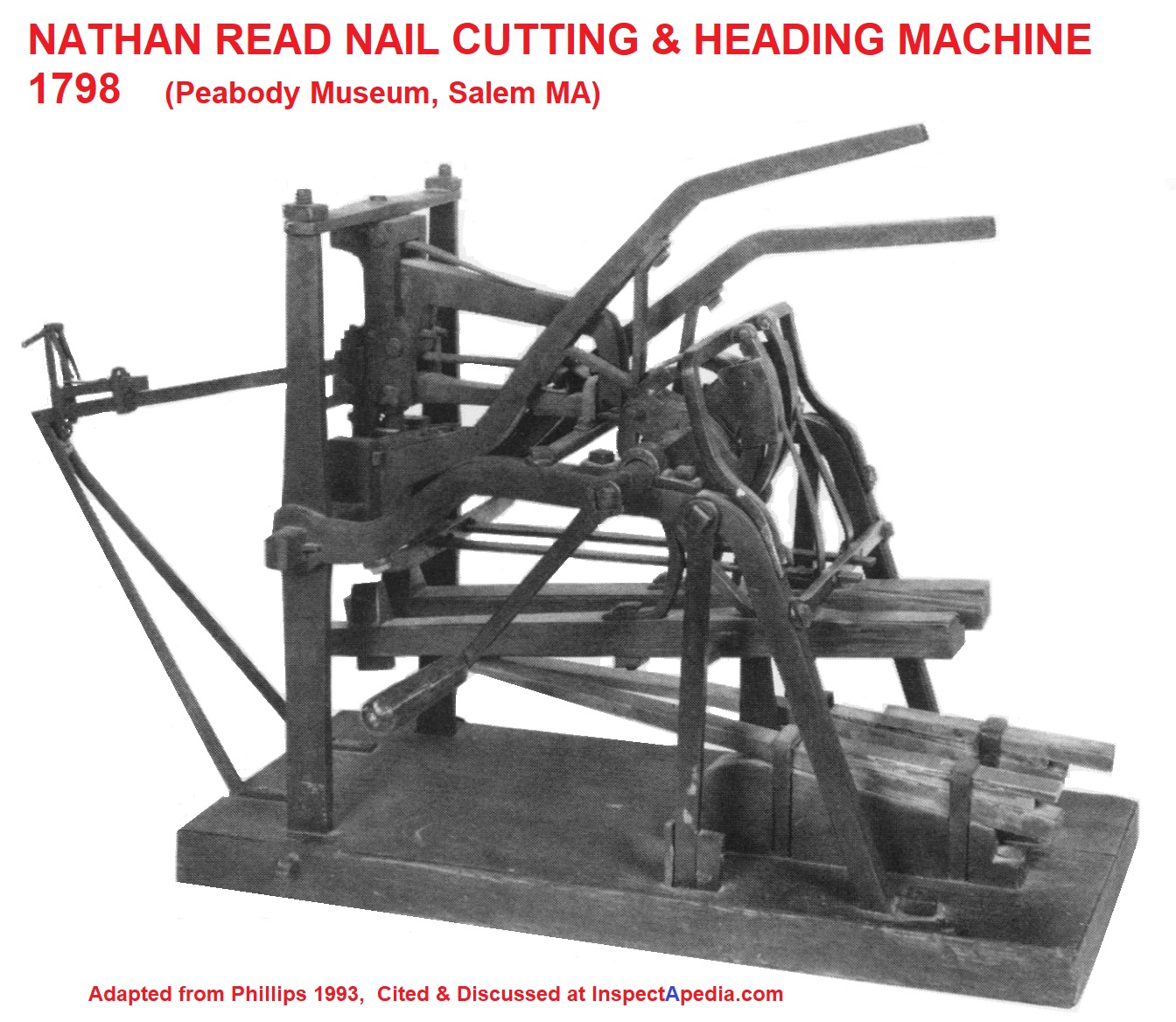

1798 - Read Nail Cutting Machine. Nathan Read produced cut nails at their Salem Iron Factory beginning in 1798.

Details about both of these inventors, their nail making machinery, and nail properties are in our separate guide to cut nails at

NAIL ID & AGE: CUT NAILS - photos of types of cut nails and details about determining their age where we describe early nail-making machines in North America and include English and U.S. patents for such equipment.

Our first illustration shows a skewed-shank machine-cut clapboard nail.

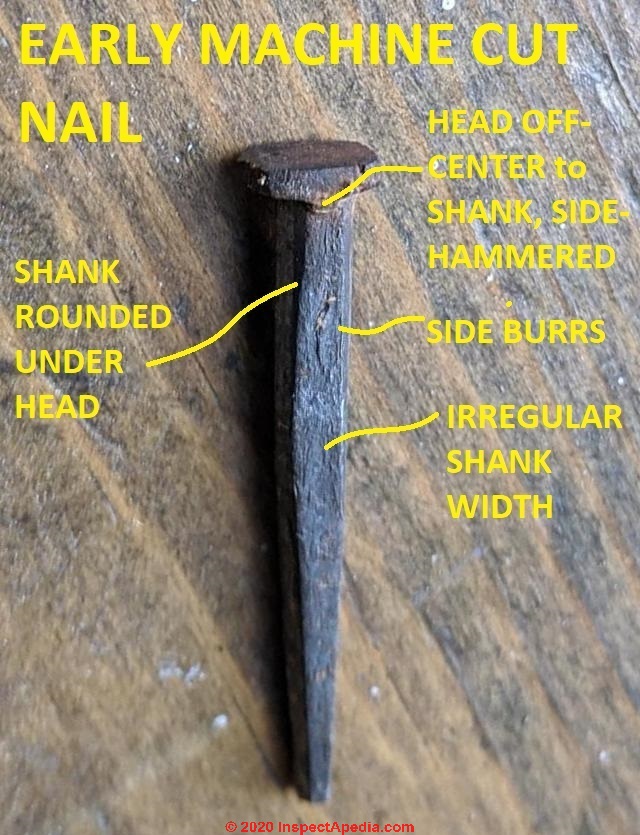

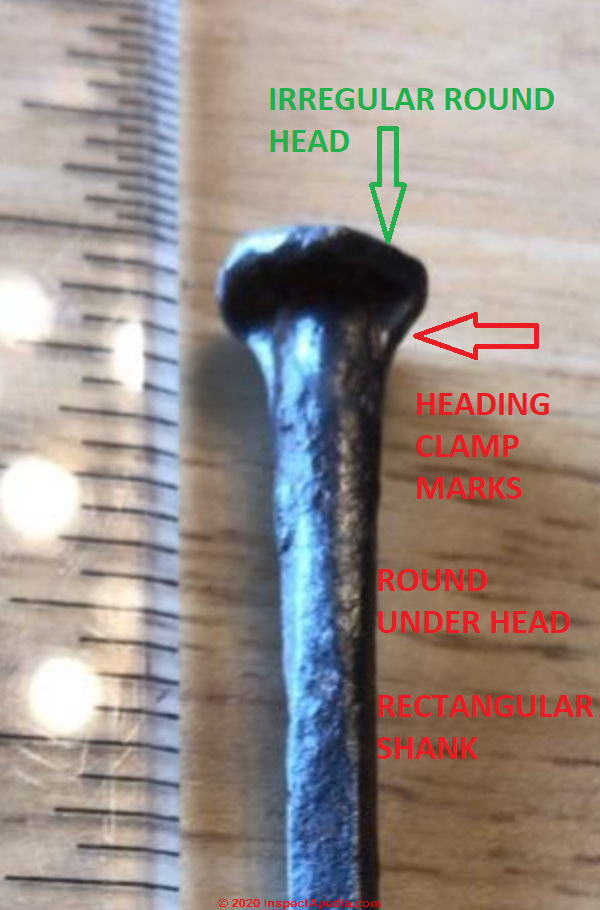

In our second illustration, (both adapted from Phillips 1993) note the rounded and narrowed shank just under the head as deformed when gripped in the machine vise to form the head (red arrow) and the irregular-shaped head (blue arrow) and also the rounded nail tips on both of these early machine-made nails.

...

1805 - present: nails made completely by machine

By some sources nails made completely by machine, including the nail head, appeared as sprigs and brads as early as 1805, and continue in use to the present.

(Nelson US NPS cited below.)

Really? Phillips (1993) reports that actually cut nails made entirely by machine are credited to Jacob Perkins- cited above.

- 1806 - Blanchard Tack Making Machine - 1806

Thomas Blanchard was born on June 24th, 1788, in Sutton, Massachusetts, near Worcester. His first invention was a tack making machine which he invented at age eighteen and perfected over the next six years.

This made production of tacks, which Thomas and his brother had been previously engaged in making, easier and more efficient at a rate of five-hundred per minute. - U.S. NPS cited below. - 1807 Read, Ezekiel nail cutting machine:

one machine producing both shank and head. Ezekiel Reed (un-related to Nathan) is credited with inventing the one-operation nail cutting machine in 1807. (Phillips 1993).

- 1810 - 1820: cut nails

were made cut from opposing sides and used heads hammered on as a separate production step.

Cutting from opposing sides means that the shear cut that produced the nail was made from opposing sides of an iron or steel blank slab.

Take a look at the shear marks on your nail to see if they are both on one side or if they appear on opposing sides. See the "burrs" illustrated as adapted from Nelson in the citations at the end of this article.

- 1815 - late 1830s: crude machine made or machine cut nails, first machine made heads.

Illustration above: properties of early machine-headed cut nails, - US NPS, Lee Nelson (cited below).

Photo above: early machine cut nail photo, courtesy of reader J - 2020/05/23

[Click to enlarge any image]

Recognizing an early machine-cut nail

I was recently repairing an old dresser I had gotten from a thrift store and found some very old looking square nails, which led me here.

They appear to be early machine cut nails based on your photos. Is my assessment correct?

Moderator reply:

The observation that your nail is irregularly tapered from below the head, getting wider, then narrowing again, suggests that it's an early machine-cut nail, perhaps roughly between 1815 - 1839 according to Nelson in our references.

NAIL ID & AGE: HAND FORGED NAILS

In the article above and also again at NAILS HAND-WROUGHT & REPRODUCTIONS we note from Nelson's research that ...

If your cut nail is irregular in shank width and has the "A" type side burrs it's likely to have been made before the late 1830s.

- 1820s - 1830s: crude machine made heads

Before the 1830s the iron fibres in machine cut nails ran across the nail shank, causing the nail to break off if the user tried to clinch it's protruding end.

For this reason, before the 1830s and where nail clinching was needed carpenters continued to use hand-wrought nails. (Nelson).

Cut nails made before the late 1830s will typically have:

- an irregular and possibly off-center head

- a head that may have been hammered to permit counter-sinking

- a shank of irregular width

- burrs that maybe on opposing sides of the nail shank depending on the cutting machine

Above and below: photos of Dan Nelson's early machine-made nail discussed just below.

Question: New England Nail estimated age 1810 +

2020/04/20 Dan Nelson said:

Hi,

I found this nail while metal detecting an old hayfield in northern Vermont.

The head is round.

The first quarter inch or so of the shank from the head is round-oval.

From there to the point, the nail is very square and tapered.

I do not understand why there are fins on the shank directly below the head. I have found coins I the area as far back as 1787.

I would like to be able to know the rough age of this nail. Thank you.

Reply: details of early machine made nails, rounded head & upper shank, rectangular lower shank

Dan,

Thank you for the helpful photos of your antique nail. My estimate of the age of your nail is 1830 or a bit older, with an "earliest" date of 1815.

As you are a Nelson, perhaps you will enjoy this companion article:

At NAILS & HARDWARE, AGE RESEARCH

On that page I cite Lee Nelson:

- Nelson, Lee, Nail Chronology As An Aid to Dating Old Buildings, Technical Leaflet 48. Nashville: American Association for State and Local History, 1968

and - Nelson, Lee H., NAIL CHRONOLOGY as an AID to DATING OLD BUILDINGS [PDF], U.S. National Park Service, Technical Leaflet No. 48. retrieved 2019/01/08, original source: npshistory.com/publications/nail-chronology.pdf

Looking carefully at the irregular-round nail head in your photo and the pinch marks just below the nail head, the earliest we could date this nail might be 1815-1830,

or in my OPINION, probably a bit later, as late as 1850. I think some early nail making machinery often had a longer life than ascribed by Nelson. In some communities, old nail making machine may have, for a time, continued in production alongside later, more-sophisticated machines producing more-rounded and more-uniform nails.

Made in the U.S. in the East, this is an early machine-made nail characterized, per Nelson, by its irregular-round head and the combination of a rounded shank and pinch marks from the nail heading clamp, transitioning to a rectangular shank for the remainder of the nail.

Your nail is large enough that it would not have been later modified (by hammering the head) to convert to a "finishing nail" that could be countersunk. Instead this 3 1/2" long nail would have been used as a structural connector.

In the U.S. the earliest manufactured nails (1790-1830) were operated by hand, later by water mills and still later by steam engines.

Because the rounded upper nail shank looks regular I suspect this is one of the later members of "Early Machine Headed Cut Nails" nails, 1830 - 1850 described by your namesake.

Nelson points out that these early machine-made nails were more readily available than machine-made finishing nails, and that they were often irregular in both length and diameter or width - something you cannot see when we have just one nail but that we might see if we were examining multiple nails from an old New England building.

A close look at the rectangular sides of the nail shank may show the remains of a long burr along the shank characteristic of early cut nails. The burr remains on the side of the nail that was cut from a flat iron plate that was opposite the descending shear blade.

Tapering was produced by "wiggling" the iron plate side to side as the shear descended to cut individual nails.

The irregular rounded head was made in a subsequent step by first clamping the nail shank so that the head could be compressed - hence the rounded shank with pinch marks on the upper part of the nail just under the nail head.

1810 - Present: Modern Machine Made Nails

Note direction of iron fibres in nails and spikes - fibers along shank = 1830 or later

Photos below: large iron spike found near Elmira, Ontario by Vern M shows laminar splitting along the length of the nail shank, giving an earliest date that some sources put at 1830.

The Perkins first cut nail machine patent (1795) was succeeded by an 1810 patent filed by the same inventor in England in 1810.

That improved nail cutting machine produced nails with fibres along the length of the shank. (Phillips, 1993 citing English Patent No. 3365, application dated July 26, 1810; specifications filed January 26, 1811.)

So we have an earliest-date for nails like the one below, produced in the U.S., of 1810.

See more of our discussion on reader Vern's iron spike splits

at NAIL SPLITS & CRACKS vs AGE

Below: Tony's RR spike found on the Oregon Coast is an example of how rust patterns can suggest the direction of iron fibers in a nail. [Click to enlarge any image]

1832 - Present: Cut Spikes, Railroad Spikes

In our images above and below you'll notice that the head of these large railroad spikes sport an offset head. The larger lip of the offset head on these large spikes, also called crampons, was used to secure the bottom edge of the rail to the steel plate upon which the rail rests.

As the railroad spike is driven through the plate and onwards into the railroad tie or (sleeper), the combination of spike, tie-plate, and sleeper hold the rail in place in the stone-covered bed (ballast) of the railway.

Details are

1848 - Present: Original as well as Reproduction of Antique Nails

- 1848 - Present - Original-use and currently reproduction of antique nails, Tremont Nail Company

Details are at TREMONT ANTIQUE NAIL REPRODUCTIONS - 1850 - present: Modern wire-nails (nails that are round in cross-section) appeared in North America in the 1850s and continue to the present.

Round or "wire nails" are produced by cutting a round drawn wire into lengths to which a point and head are added by the machine.

Details and more images are at WIRE NAILS just below

...

1850 - Present: Modern Round Shanked / Wire Nails

Below, an example of modern round or wire nails, galvanized fasteners. These 4d 1 1/2" galvanized nails are designed for use with steel joist hangers.

- 1850 - Wire nails were produced in North America beginning in the 1850's, became the dominant nail in the U.S. by the 1890s, and continue in use to the present.

"Wire nails" refers to nails that were cut from a continuous pulled round "wire" of varying diameter. The wire is cut to the appropriate length for the desired nail length, allowing for the later machine-formed nail head and machine-cut nail tip.

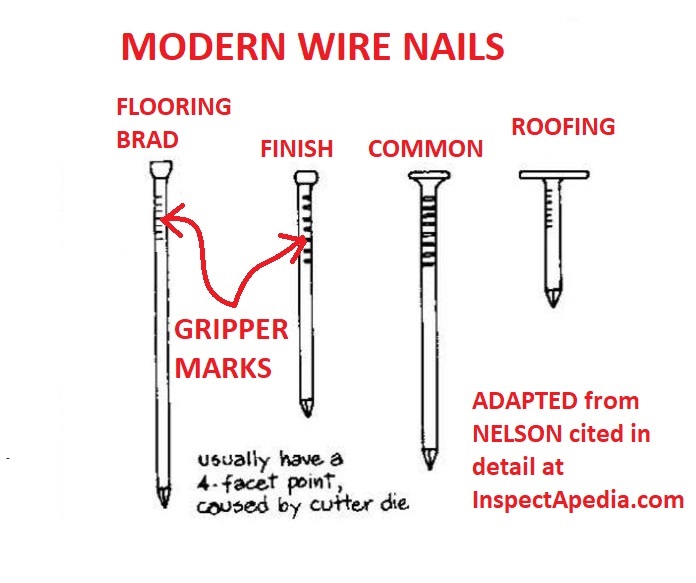

In our illustration below you'll notice that modern "wire nails" show a series of parallel "gripper" marks along the upper end of the shank, just below the nail head.

Really:? Note that some earlier rectangular-shanked cut nails may also contain gripper marks under the head - formed by pinching individual nails, one-by-one, in a vise to permit the fabricator to use a hammer to form that nail's hand-wrought head. The gripper marks on thise earlier hand-headed rectangular shanked nails will generally be larger and of course those nail shanks won't be round.

Early wire nails were made first in smaller sizes.

If we exclude nails coated with a galvanized or other material, most modern wire-type nails will show parallel indentations across the top of the nail below the head, indicating the grip on the nail shank as the nail's head was formed.

- 1870 - Competition from Wire Nails (round) - 1870

The Birmingham industry expanded in the following decades, and reached its greatest extent in the 1860s, after which it declined due to competition from wire nails, but continued until the outbreak of World War I. (Sjögren 2013) - source: https://en.wikipedia.org/wiki/Nail_(fastener) retrieved 2018/06/15

Ezekiel Reed from Bridgewater Massachusetts developed the first machine that could cut a nail including its head in one operation.

In the U.S. the Parker Mills nail company was built in 1819 on the original site of the Parker Mills cotton mill that had been burned by the British during the War of 1812.

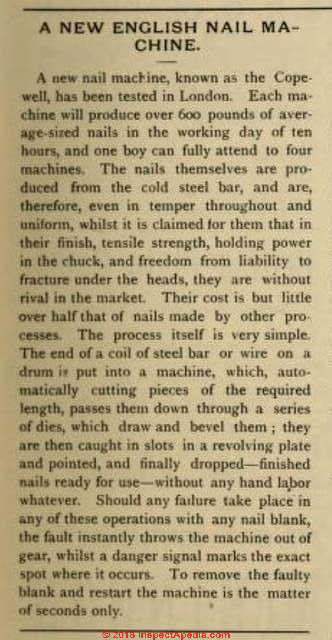

Above and below: Hardware Merchandising magazine article discussing a new English nail making machine, 7 February 1890.

...

- 1880's - special purpose nails,

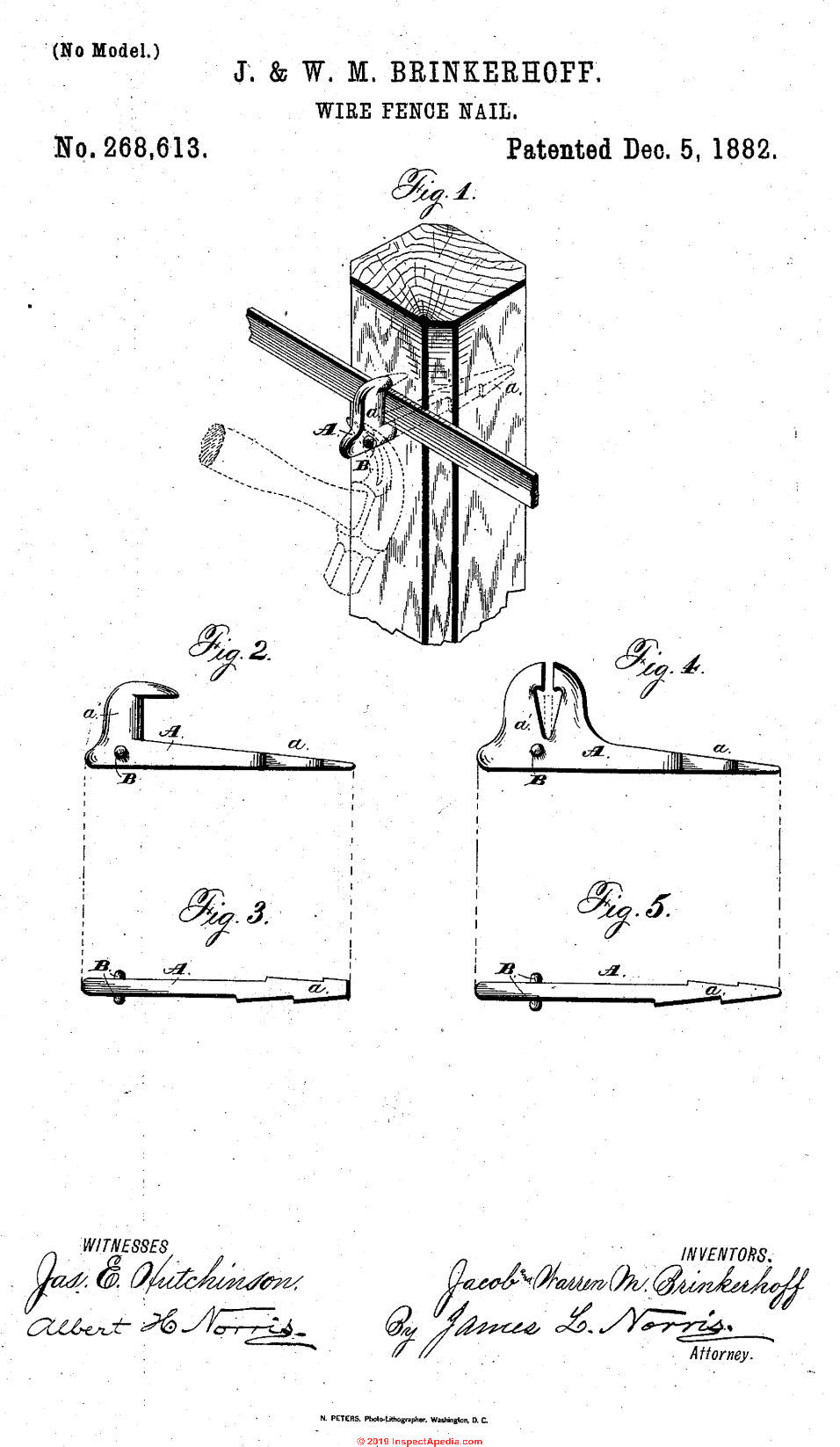

eg. wire nails and barbed-wire fencing nails using hooked nail heads and sometimes, shank details that resisted inadvertent withdrawal from wood fenceposts but making future removal possible when wire fencing needed to be repaired or adjusted - shown above the Brinkerhoff wire fence nail patented Dec. 5 1882.

The nail head featured details that eased withdrawal of the nail using a hammer. - Brinkerhoff, Jacob & Warren M. Brinkerhoff, WIRE-FENCE-NAIL [PDF] U.S. Patent No. 268,813, December 5, 1882

- 1890 - High Volume Production of Cut Nails Continues - 1890

By 1890 nail making machinery had advanced to produce cut nails at high volume and low cost and at improved reliability. (Hardware Merchandising 7 Feb 1890)

The Parker Mills nail company became the Tremont Nail company that continues to produce traditional machine-made "cut nails" today. [1]

The development of machine made nails that could be produced in high volume was critical to this change in construction methods. But even in the 1930's and 40's nails were a meaningful cost of construction.

Above, a advertisement for wire-nails appearing in The Iron Age magazine, ca 1893.

- George, Washington. "Nail-staple for barbed wire." U.S. Patent 1,389,540, issued August 30, 1921.

...

1950 - Present: Modern Nail Guns & Power Nailers

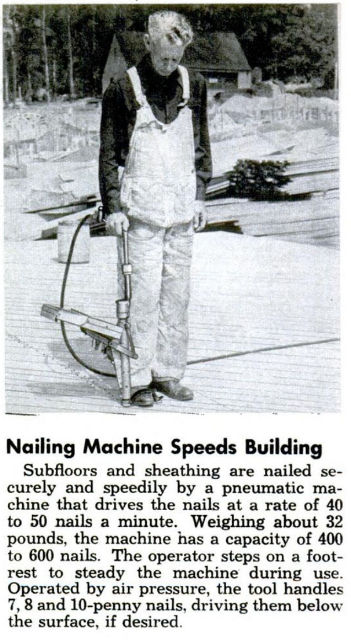

Illustration above: Popular Mechanics, March 1950, p. 96 describing the new "nail gun".

- 1950 nail guns in use in wood frame construction.

Modern round or wire nails dominate nail use in conventional framing and construction, actually replaced by nails formed to work in power nailers or "nail guns" for much wood-frame construction.

The nail gun was designed by Morris Pynoos, a civil engineer by training, for his work on Howard Hughes' Hughes H-4 Hercules (known as the Spruce Goose). The wooden fuselage was nailed together and glued, and then the nails were removed.

The first nail gun used air pressure and was introduced to the market in 1950 to speed the construction of housing floor sheathing and sub-floors.

With the original nail gun, the operator used it while standing and could nail 40-60 nails a minute. It had a capacity of 400-600 nails. - Wikipedia, Nail Gun, retrieved 2019/01/09, original source: https://en.wikipedia.org/wiki/Nail_gun

Illustration below: Paslode nail gun nails sold in strips are still "wire nails" but are no round in cross-section.

- 2019: modern nail guns.

Modern nail guns are sold in models that operate by compressed air, electricity, or gas cartridges. Manufacturers of nail guns in 2019 include at least the following nailer brands: A.D.I. Atachi, aka ADACHI, AEG, AirPress, Bostitch, DeWalt, Heico,m Hitachi-Koki, Makita, Milwaukee, Paslode, Rigid, Senco, Spit-Impex (concrete nailers), Sumake,

Paslode, a division of Illinois Tool Works, is one of a number of manufacturers of modern nail guns, sold in both cordless and pneumatic (air powered) models. Paslode was founded by J.W. Leslie in the U.S. in 1935.

...

Supporting Information to Estimate the Age of a Nail

Nails cannot alone give the exact date of construction of a building because the nails themselves may have been made considerably earlier or even re-used from a still-older construction. But nail age can suggest date boundaries for the construction at a site.

In guessing the age of a nail or other hardware it is very helpful if you can tell us

- Country and city of the building or site where the nails were found

- Age of the building and/or the site if the nails were not in a building or building component. Documents and records providing evidence of the date of construction of the building or site are the most-reliable dating or aging source.

- Age of buildings in the same area where similar nails are found

- Technology of production of a specific nail combined with history of the availability of nails produced by a given technology in the area.

For example in the U.S. machine made nails would have been first most-abundant on the east cost, spreading more slowly across the continent to the west, probably with some nails arriving by ship on the west coast. - Nail metal and nail coatings, e.g. first use of galvanized coatings, use of aluminum nails, copper nails, stainless steel (all modern) vs. wood and iron.

- The mixture of nail types in the building help identify original construction, modifications, additions

- Proximity to water, to industrial sites, other possible nail sources

- Nail dimensions, or size, and style (include a ruler in the photograph) can indicate the nail's intended use

- Presence of any surrounding material, wood, cloth, etc. where the nail was used.

- Presence of surrounding artifacts that help date the structure

- Wood lumber or trim or other nailed material species and cutting details can help determine building age and nail age too, though wood beams and planks from an earlier building may also have been re-used in a later one.

See SAW & AXE CUTS, TOOL MARKS, AGE - We also look closely at the nail iron itself for splitting, machine-cut edges, etc.

Watch out: Documentary sources

should take priority whenever possible, and

other artifacts should be used as supportive

evidence. (Adams 2002) as cited

at NAILS, AGE & HISTORY

Watch out: keep in mind that the date of manufacture as well as the date of actual use of nails varies significantly by country and even smaller areas, so the physical location and context of the nail's use are important in understanding its probable age.

If we know when a type of nail first became available in the area where it was found or used and if we know when later machine made nails were available in the same area that can set an earliest date for a particular nail.

Hand Wrought Nail Details

Details of Hand-wrought nails used in North America in the 17th, 18th, and 19th century in American building construction as well as modern hand wrought nail reproductions are now found

at NAILS HAND-WROUGHT & REPRODUCTIONS

Research on History of Hand Wrought Nails, Cut Nails & Wire Nails

This section has moved to NAILS & HARDWARE, AGE RESEARCH

where we provide photos, text excerpts & research citations for the history of production and use of nails for various countries including Australia, India, the U.K., Scotland, Wales, The United States, and New Zealand.

...

...

Continue reading at NAIL AGE DETERMINATION KEY, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see NAILS & HARDWARE, AGE FAQs - questions & answers posted originally at this page and additional photos of old and newer nails

Or see these

Recommended Articles

- AGE of a BUILDING, HOW to DETERMINE - home

- DOOR HARDWARE AGE

- NAILS, AGE & HISTORY - home

- HORSESHOE & HORSESHOE NAIL AGE

- NAIL & HARDWARE, AGE RESEARCH

- NAIL & HARDWARE CLEAN-UP

- NAIL AGE DETERMINATION KEY - use this key to guess at the age of your nail or spike

- NAIL ID & AGE: CUT NAILS

- NAIL ID & AGE: HAND FORGED NAILS

- NAILS in BARTER & TRADE

- NAIL SPLITS & CRACKS vs AGE

- NAIL TYPE, ANTIQUE, IDENTIFICATION KEY

- RAILROAD SPIKES

- RAILROAD SPIKE AGE - CONTEXTUAL CLUES

- SAW & AXE CUTS, TOOL MARKS, AGE

- WINDOW HARDWARE AGE

Suggested citation for this web page

NAILS, AGE & HISTORY at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING AGE

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Chartier, Craig S. Samuel Fuller Homesite Report Series Volume 2 of 7 Architectural Analysis [PDF] Plymouth Archaeological Rediscovery Project (PARP) Web: www.plymoutharch.com Email: craig@plymoutharch.com - retrieved 2023/09/23, original source: plymoutharch.com/wp-content/uploads/2014/11/79694416-Archaeology-of-the-Samuel-Fuller-Homesite-Architecture.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.