HVAC Blower Fan Testing & Diagnosis

HVAC Blower Fan Testing & Diagnosis

Air Conditioning or Heating Furnace Blower Unit Blower Fan Won't Run or Airflow is Weak

- POST a QUESTION or COMMENT about heating or cooling system air handler blower fans

HVAC blower fan testing & diagnosis guide:

This article discusses how to inspect and test a heating or air conditioning indoor air handler blower fan that is not working.

We also discuss convector unit fans and we suggest diagnostic steps for squirrel cage blower fan squeaks and noises.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Heating or Air Conditioner / Heat Pump Blower Fan Testing & Diagnostic Procedures

How do I fix my indoor air conditioning or furnace blower fan: the air conditioning (or heat pump or furnace) blower fan just won't run

Our page top photo shows an air handler unit located in a building's attic - we removed the cover to show the blower fan assembly just to the left of the red tag) in this image of a Lennox™ horizontal HVAC system.

[Click to enlarge any image]

The blower fan is located inside a horizontal air conditioning unit in many home air conditioning systems, especially when the air handler is located in an attic or crawl area.

The location of a blower fan in vertical "up flow" or "down flow" heating and cooling systems is illustrated in additional sketches and photographs below.

Article Contents

- Testing cooling system or air conditioner blower fans

- Testing heat pump blower fans

- Problems when adding retrofit air conditioning to a warm air heating system

- How to find and test the blower fan in a furnace, air conditioner, or heat pump

- Diagnose an ECM Blower Motor causing circuit breaker to buzz

Initial, simple diagnostic checks of the air handler system are also described

at DUCT SYSTEM DESIGN SIZE & DEFECTS: Basic checks of the indoor air handler (blower), air ducts, and filter systems.

My issue is about an air conditioner fan that just won't start. The fan motor is not seized, and we had a recent blower motor starting capacitor change. The blower fan relay appears to pull in okay, the electrical connections reseated and tight.

But the cooling fan will still not start. This is an early 1990's York home air conditioning unit. - R.S.

Our photo (left), shows a modern blower assembly inside of an air handler. In this case the blower is a direct-drive unit - the electric motor that drives the air conditioner blower fan is mounted inside of and at the center of the blower assembly itself.

Other HVAC blower units may mount the motor separately from the squirrel cage fan, connecting the motor to the fan using a set of PULLEYS & a FAN BELT [image].

Steps to Diagnose an HVAC Blower Fan Problem

For completeness we have listed some blower fan diagnostic steps that you have already tried, as well as additional things to check.

The blower assembly is the green component in this illustration from Carson Dunlop Associates The Illustrated Home.

- A/C won't start or lost cooling capacity:

If your air conditioning or heat pump system has lost its cooling capacity or won't start

see REPAIR GUIDE for AIR CONDITIONERS. Make sure that all electrical power switches for the system are "on" and that the thermostat is properly set. - Heat won't start or lost capacity:

if your heating system or heat pump (warm air heat) won't start, see the links above, or

see HEATING LOSS DIAGNOSIS-FURNACES. - If it appears that it is specifically the blower fan for your HVAC system is not working,

first be sure that the thermostat is calling for heating or cooling.- For heating systems the set-temperature on the thermostat must be set higher than room temperature.

- For cooling or air conditioners the temperature must be set lower than room temperature.

See THERMOSTATS.

- Try overriding the thermostat

by forcing the blower fan "on" using the thermostat. A simple test is to disconnect the thermostat wires completely at the control and jumper the thermostat terminals there, or more conveniently, remove the wall thermostat and simply (temporarily) connect the controlling thermostat wires there.

The latter approach does not rule out a broken thermostat wire however.

See FAN ON AUTO MAN Thermostat Switch

or to test the blower unit by using manual fan-on switch

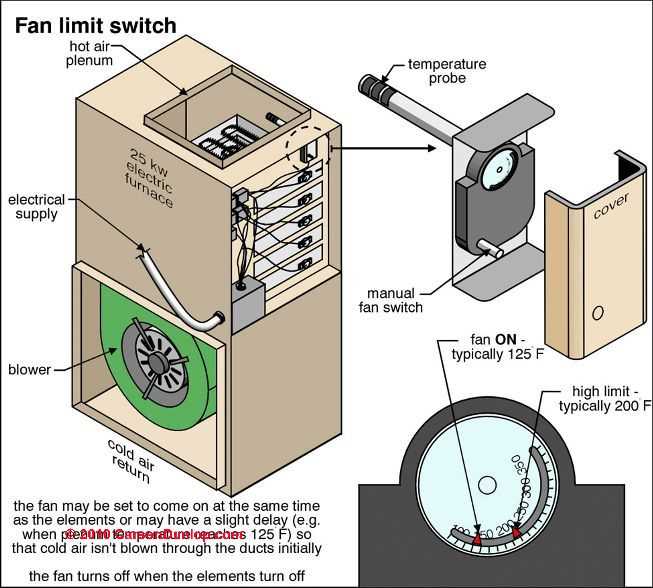

see FAN LIMIT SWITCH.

This switch is also illustrated

at FAN LIMIT SWITCH TROUBLESHOOTING. - If the blower fan motor won't turn ON or is noisy,

First check for a cover ajar on the air handler.

See BLOWER DOOR SAFETY SWITCH

and also see AIR HANDLER BLOWER DOORS

Don't forget also to look for other switches that could prevent the air conditioner from even starting, such as a condensate overflow pan sensor switch

see CONDENSATE DRIP TRAY DEFECTS that can shut down the air conditioning system to avoid damage from overflowing condensate pans.

Regardless of whether your air handler is for both heating and cooling, or for just one of these, see FAN WONT START to see a list of common reasons that the blower fan won't run or won't deliver air.

Next, there may be

an ELECTRIC MOTOR OVERLOAD RESET SWITCH that has tripped off due to thermal overload or an electric motor or voltage problem.

If the problem is suspected to be the blower motor itself, that is if all of the controls are calling for the blower to run and the motor has electrical power, then

see ELECTRIC MOTOR DIAGNOSTIC GUIDE to check for a motor that won't start.

If the blower motor hums or is slow or is having trouble starting, also

see CAPACITORS for HARD STARTING MOTORS.

Keep in mind that if the blower motor or fan bearings are shot the wobbling fan can make a horrible noise and can eventually ruin the motor shaft bearings. And if your blower motor misbehaves after checking bearings and the start/run capacitor, consider that the motor itself may be bad. An expert can measure current draw as part of diagnosing a failing electric motor.

BLOWER FAN NO START / NO STOP - weird blower behavior can also be diagnosed and fixed - this discussion,

found in our article

titled AIR CONDITIONER WON'T START provides a detailed list of things to check.

Other air handler blower fan noise diagnosis is at

BLOWER FAN SQUEAKY NOISE REPAIR - If the blower fan motor runs but little or no air is coming out of your heating or cooling supply registers,

see LOST COOLING CAPACITY

or HEATING LOSS DIAGNOSIS-FURNACES.

The problem may be as simple as a dirty air filter

see AIR FILTER CLOGGED

or the problem may be

a DIRT CLOGGED SQUIRREL CAGE FAN itself,

closed air supply registers

see AIR SUPPLY DUCTS

disconnected air ducts

see AIR DUCT LEAKS

a loose fan belt

see LOOSE FAN BELT PHOTO connecting the blower motor to the blower fan (if your fan is not a direct drive unit)

or an ICE BLOCKED COOLING COIL.

Check the blower assembly drive belt: if the blower assembly uses a separate motor to drive the blower fan assembly (as opposed to direct-drive blower fan units) an electric motor drive shaft spins a pulley that is connected to a separate pulley wheel on the blower fan assembly by a drive belt.

If the belt is broken the blower wont' spin. If the belt is too lowe the blower may not turn.

How tight should the furnace or air conditioner blower drive belt be? In the absence of a manufacturer's specification we set about 1 1/4" of free play in the blower drive belt. - If the blower fan motor won't run, see the motor test procedures

at ELECTRIC MOTOR DIAGNOSTIC GUIDE

Check to see if voltage is present at the fan motor wires. If voltage is present and if none of these steps will turn the blower fan on, and if you are certain that the motor starting capacitor is good

see CAPACITORS for HARD STARTING MOTORS

then we suspect that the motor may be seized.

Sometimes if we have to replace a starter capacitor that gets things going again for a while, but ultimately we discover that the motor itself was increasingly hard to start as it was moving towards seizing. Keeping the fireplace flue closed (if you have one) when not in use will improve both heating and cooling efficiency.

This photo shows a blower fan assembly with a motor starter capacitor installed on the upper right side of the squirrel cage fan. - If the air conditioner or furnace blower fan won't stop when it should, for example if the blower keeps running and blows cold air onto room occupants during the heating cycle, see the diagnostic article found

at FAN WONT STOP - LIMIT SWITCH

or for an ECM motor, check the motor's control module - If the HVAC Blower Motor causes the circuit breaker to buzz or hum

See ECM MOTOR CAUSING CIRCUIT BREAKER BUZZ

Thanks to reader Randy Shaffer for suggesting this topic.

Air Conditioner or Heater Wall Convector Unit Blower Fans

Wall convectors are often used for both heating and cooling in commercial installations and high-rise apartment buildings.

The unit shown has its own compressor mounted right in the cabinet, visible at lower center in the photo.

Wall-mounted heating and cooling convector installations may be designed with one central heater or cooling system which feeds multiple units with chilled or heated water or possibly refrigerant from a single remote heating and cooling heat pump.

Our photo (left) illustrates dual squirrel cage blower fans typically found in the bottom of a fan/convector heating or cooling unit such as this one found in a New York City apartment.

If the convector fan motors run and the squirrel cage fans spin but not enough air is coming out of your convector unit, turn off power and take a closer look at the fan blades themselves

- you may need a flashlight and a mirror to make this check without disassembling the unit further than shown here (we removed the convector unit cover).

Watch out: Dirt on the squirrel cage blower fan blades can significantly reduce airflow through the unit.

We have seen a 40 to 50% improvement in air flow simply by cleaning this blower fan assembly, yet it's something people rarely check.

Why? Because even a small amount of dirt in the cupped fan blade edges reduces airflow significantly, but it's not visually obvious.

You have to look carefully at the fan assembly. In our wall convector unit above you'd use a good flashlight and a mirror to inspect the blower assembly fan blades.

Also check the cooling or heating coil fins for blockage by dust and debris - a more common source of air flow blockage at heating and cooling convector units like the one shown.

Our photo (above left) illustrates a condensate handling problem in the cooling convector unit for the same apartment unit introduced above.

Air conditioning condensate was leaking inside of the convector unit due to a clogged condensate drain line.

The condensate leak exited the bottom of the convector, ran through a raised floor cavity, entered apartment building walls, and ran around the wall interiors in a metal stud-framed wall sill plate where it led to major toxic mold contamination over a wide area, floor damage, and the need for costly cleanup and repair work.

Details about wall convectors used for heating or cooling and about convector blower fans are found

at WALL CONVECTORS HVAC and

also

at FAN COIL & FAN CONVECTOR HEATERS & HYDRONIC COILS

Also see CONDENSATE HANDLING, HVAC for more about air conditioner or heat pump condensate drainage handling.

Where is the "Blower Fan" or Air Handler blower located?

Which air conditioner, heat pump, or furnace fan is located where?

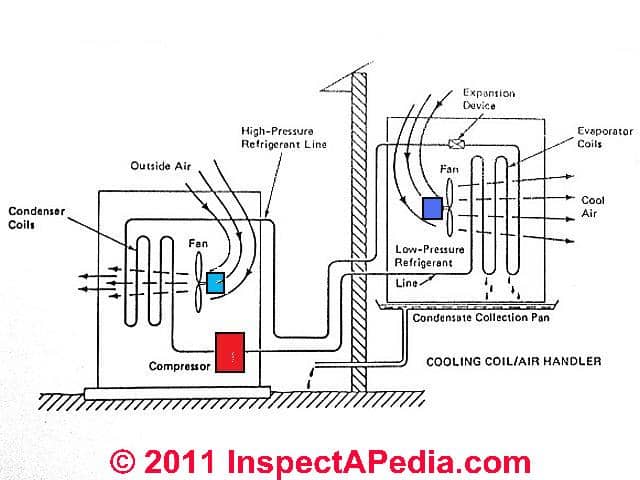

In our simple air conditioning (or heat pump) system sketch shown at left, the light blue fan shown at left in the sketch (above the red compressor box) is the outdoor compressor/condenser fan discussed

at FAN, COMPRESSOR / CONDENSER UNIT.

The dark blue fan shown at right in the sketch is the indoor air handler or blower compartment or cooling coil fan found inside the building. This fan blows building air across the evaporator coil (or cooling coil) to cool and dehumidify indoor building air.

We discuss this indoor fan

at FAN, AIR HANDLER BLOWER UNIT.

In a warm air heating system that does not include air conditioning as well, the indoor fan is still located in the indoor air handler

At BLOWER FAN ASSEMBLY CLEANING we describe and illustrate a detailed, thorough cleaning of the blower assembly in an air handler that is used for both heating and air conditioning.

...

Squeaky Squirrel Cage Blower Fan Noise Diagnosis, Cure

Check for and tighten any loose blower fan parts including the fan shaft bearings and fan mounting bolts; if the fan uses a pulley and drive belt be sure the pulley is tight and the belt properly tightened;

Lubricate the fan lubircation points with the proper oil or grease;

The squirrel cage fan or air handler blower fan is usually a round thin-bladed fan cage found inside the indoor air handler unit.

This fan moves building air through the duct system and across heating and/or cooling elements to condition the air as it is then supplied to the building through supply ducts and registers.

In an air conditioning system this is the dark blue fan shown in the right side of our sketch above. For combined heating/cooling systems the same fan assembly can blow heated air into the building and an additional

FAN LIMIT SWITCH will be found inside the furnace cabinet.

More about HVAC blower fans including squirrel cage fans is in this article, above beginning

at BLOWER FAN OPERATION & TESTING

but to start addressing a squeaky blower fan, note that your fan may be repairable by tightening one or more allen screws that secure the fan cage assembly (or the bearings that carry the fan) to its housing through which passes the fan motor drive shaft.

With power OFF for safety, if the fan and all components appear to have no loose screws or mounts, but you can still wiggle the fan from side to side, then the bearings are worn and need replacement.

If your fan is pulley-driven, check also that the pulley is secure on the shaft and that the fan belt is not so loose as to be squeaking.

I would not use WD40 on or near electric motor parts nor on greased bearings as it's not intended for a motor or bearing lubricant, though to be honest, I've sprayed WD40 on almost every problem that has ever arisen at one time or another. Better would be a lubricant intended for motors and motor shafts.

Some HVAC blower fan assemblies use a grease fitting not oil. In that case your service tech may need to re-pack the bearing with grease; often on older units there is a grease cap over the fitting that, if tightened, forces more grease into the bearing, so if you see one of those, try first giving the cap a turn. .

at NOISY AIR CONDITIONER / HEAT PUMP

and at NOISE CONTROL for HEATING SYSTEMS we discuss a range of noises can be traced to air conditioning and heating systems.

See also AIR HANDLER / BLOWER UNIT NOISE FAQs - fan makes squeaks or thumps or rattles, fan motor whines or buzzes

...

Troubleshooting an ECM Blower motor that causes circuit breaker to buzz

On 2021-10-13 by Morgan - humming at the electrical panel when blower motor is on

I'm an HVAC contractor

I'm an HVAC contractor

I installed a furnace recently that has an ECM blower motor.

Customer could here humming from panel when the blower was on.

I had originally wired #14 wire on a 15 amp pushmatic breaker.

After he called me I looked at the 1 hp motor again and the RLA is 11.5 amps if the inducer is running also.

I'm assuming pushmatic trips at 80 percent like the newer breakers, so I thought we are pushing 80 percent so we ran #12 to a 20 amp breaker(witch is the max breaker size on furnace name plate).

I've rounded up (2) used 20 amp breakers and they both up buzz when the motor is ping up and hum when motor is at full speed.

I'm think this is a frequency issue the ECM , any thoughts?

This Q&A were posted originally

at BULLDOG PUSHMATIC COMPATABILITY & FAQs

[Click to enlarge any image]

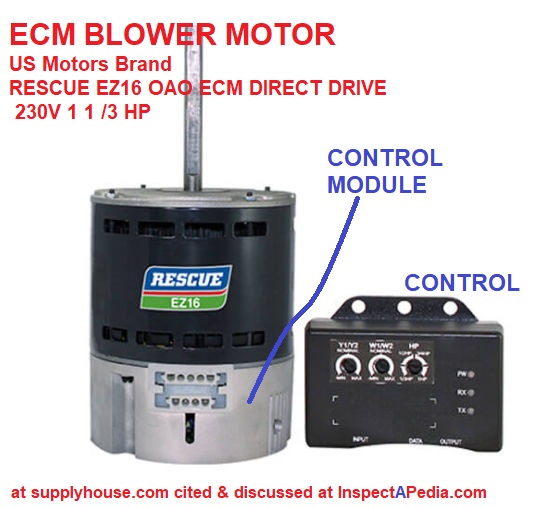

Illustrated above: an ECM blower motor produced by US-Motors as listed at supplyhouse.com, an HVAC and electrical components supplier. Details about this particular motor, a universal ECM HVAC furnace and air handler motor replacement, are at

RESCUE EZ16 ECM MOTOR PRODUCT DATA [PDF] Nidec Motor Corporation, 8050 W. Florissant Avenue | St. Louis, MO 63136 UDA, Tel: 855-487-6686. US Motors is a trademark of Nidec Motor Corp. This motor is sold in HP ratigns from 1/3 hp up to 1 1/3 HP. The 1-1/3 HP motor draws between 12.1A and 7.1A depending on start vs. run and on selected running speed. The motor can be set to run on 115/208-230VAC.

Moderator reply: causes of ECM Motor causing circuit breaker buzz or hum

@Morgan,Definition of ECM Motor

For other readers:

An ECM motor such as used on many HVACR systems, is a variable speed motor that uses an Electronically Commutated Motor (ECM). An ECM motor's control module includes a microprocessor that controls the motor's speed.

This design permits the blower motor to run more slowly when the HVAC system's heating or cooling load is reduced, (less air flow is needed), thus saving energy over a blower motor that always zips along at its one and only high speed.

Circuit breaker trip points - 80% ?

In clarification, I'm unsure where you found that circuit breaker tripping at 80% of rated amperage load is a rule of thumb. That's not my understanding, and I think its a mistake.

Circuit breakers trip at a load or current flow that is above their rated load, not at it and not below-it.

The time required for the breaker to trip from the start of the overload depends on the amount of overload.

So a 15A breaker through which 17A is being drawn may take minutes to trip off while the same 15A breaker will trip in seconds at 20-30A and in fractions of a second at a dead short.

Watch out: however you will read in the home page for this topic (PUSHMATIC - BULLDOG PANELS) that Pushmatic breakers, despite my long affection for their apparent quality, are not reliable and not safe in general. A Pushmatic may remain electrically "ON" even when you think it has been switched to the OFF position - an obvious and serious hazard.

Normal circuit breaker humming compared with loud buzz or hum breaker trouble indicators

I associate buzzing in a circuit breaker with arcing and malfunction but I acknowledge and am researching other causes of breaker buzzing that might be from an external cause. In general, loud buzzing at the breaker means it's being subjected to an over-current and is having trouble tripping-off as it should.

I associate buzzing in a circuit breaker with arcing and malfunction but I acknowledge and am researching other causes of breaker buzzing that might be from an external cause. In general, loud buzzing at the breaker means it's being subjected to an over-current and is having trouble tripping-off as it should.

Watch out: Pending research that gives another explanation, I'd consider buzzing a danger sign risking a malfunction. Installing a used circuit breaker increases the risk since we don't know the conditions to which it has been exposed over its life nor its internal condition (such as corrosion or overheat damage).

Photo: Bulldog Pushmatic circuit breakers in an electrical panel.

Light or near-quiet buzzing in a circuit breaker may be "normal" and could be an artifact of the 120VAC or 240VAC current flow. I consider "light" buzzing to be so quiet that it's hard to hear unless listening closely.

If a circuit breaker is buzzing or clicking so that you can hear it from a few feet away, it is overloaded and the system is unsafe.

In the case you describe I suspect that the root problem is an over-current caused by the ECM blower motor itself.

An electrician, or you if you know how to do so safely, would measure the actual current draw on the circuit. Once the motor is running if you see current much above the rated RLA of 11.5A I'd consider the motor damaged and on the way to a hard failure.

DO NOT keep changing the circuit breaker or upping its amperage in this case as doing so invites an overheat and at worst, an electrical fire or shock.

Before replacing the motor, check for a bad or loose electrical connection, or a failing motor control or relay. Check or replace the ECM motor module, usually mounted on the service-end of the motor opposite to its drive shaft.

Watch out: Bottom line -Loud buzzing at a circuit breaker almost always means that it's experiencing an over-current and is not tripping-off - a dangerous condition that is not fixed just by swapping breakers and that should not be "fixed" by installing a higher amps-rated breaker. Turn the circuit off and find and fix the root cause, such as a failing motor or control.

Also see

ELECTRIC MOTOR DIAGNOSTIC GUIDE

...

...

Continue reading at FAN LIMIT SWITCH TROUBLESHOOTING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see BLOWER FAN OPERATION & TESTING FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- AIR HANDLER / BLOWER UNITS - home

- AIR HANDLER BLOWER DOORS

- AIR FLOW TOO WEAK

- BLOWER FAN OPERATION & TESTING - indoor HVAC air handler / blower unit fan

- BLOWER DOOR SAFETY SWITCH

- BLOWER FAN ASSEMBLY CLEANING

- BLOWER FAN CONTINUOUS OPERATION - switch the fan to stay on continuously

- BLOWER FAN CYCLES ON INTERMITTENTLY

- BLOWER FAN SPEED SETTINGS

- BLOWER FAN WON'T RUN in AUTO - COOL

- BLOWER FAN WON'T RUN in AUTO - HEAT

- BLOWER FAN WONT START

- BLOWER FAN WON'T START, BUZZING

- BLOWER FAN WONT STOP - LIMIT SWITCH

- BLOWER FAN WONT STOP - THERMOSTAT SWITCH

- DIRTY A/C BLOWERS

- ECM MOTOR CAUSING CIRCUIT BREAKER BUZZ

- FURNACE BLOWS COLD AIR

- FURNACE FAN CYCLES AFTER HEAT

- FURNACE FAN CYCLES DURING HEAT

- FURNACE FAN STOPS EARLY

- FURNACE FAN WONT START

- FURNACE FAN WONT STOP

- WOOD FURNACE FAN LIMIT CONTROL

- CONDENSER FAN WON'T START - outdoor HVAC condenser unit cooling fan

- DEHUMIDIFICATION PROBLEMS

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- FAN, AIR HANDLER BLOWER UNIT

- FAN LIMIT SWITCH TROUBLESHOOTING

- FAN MOTOR START CAPACITORS

- FAN NOISES, HVAC

- FAN ON AUTO MAN THERMOSTAT SWITCH

- FAN WONT STOP - THERMOSTAT SWITCH

- FROST BUILD-UP on AIR CONDITIONER COILS

- RETURN AIR, INCREASE

- TICKING NOISE DIAGNOSIS

Suggested citation for this web page

BLOWER FAN OPERATION & TESTING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING FURNACES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to reader Randy Shaffer, Manchester, PA for suggesting additional diagnostics for blower fan operation testing May 2010

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.