Boiler Low Water Cutoff LWCO Not Working

Boiler Low Water Cutoff LWCO Not Working

Fix a LWCO that is not working properly

- POST a QUESTION or COMMENT about diagnosing & repairing LWCOs low water cutoff switches & controls on heating boilers

Diagnose & fix a steam or hydronic boiler low water cutoff control LWCO that's not working properly.

A LWCO that does not respond to low boiler water level is unsafe and needs repair.

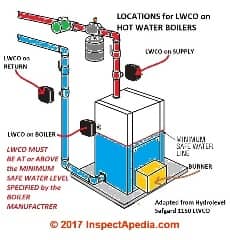

In this article series we explain Low Water Cutoff Controls: Guide to LWCOs on steam heating and hot water heating systems and we provide a low water cutoff switch Troubleshooting & Repair Guide.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Low Water Cutoff Valve not working: what to do

These questions and answers were posted originally

These questions and answers were posted originally

at LOW WATER CUTOFF VALVE - be sure to review the LWCO installation and troubleshooting advice given there.

Photo: a steam boiler sight glass showing no water on a boiler protected by Hydrolevel's CycleGard LWCO Model 450, courtesy of an InspectApedia.com reader.

Below we discuss what to do when the LWCO does not shut off the boiler in a low-water condition.

[Click to enlarge any image]

Watch out: do not allow a boiler to continue to run if it is too low or has run out of water. LWCOs are among multiple heating system safety controls that help prevent

boiler BLEVE EXPLOSIONS.

Water level too low or not visible in the sight glass / steam boiler doesn’t cut off

2019/02/10

Stafford said:

My steam boiler doesn’t cut off when the water level falls to a point where I can not see it the light donesn’t come on on it a manual feed and a cycle guard low water cut off middle CG450

This Q&A were posted originally

Reply: What to do when the HydroGard LWCO does not shut off the boiler at low water condition

Stafford,

Watch out: Thank you for asking Stafford, as you've touched on a very important safety feature designed to avoid boiler damage, destruction, or even more-dangerous conditions.

It appears that your CycleGard Low water cutoff LWCO is not working, perhaps needing sensor cleaning or, less likely, replacement of the control.

Periodic maintenance is needed to keep this LWCO working properly. I quote from the company:

To insure optimum performance, remove and inspect the probe annually. Clean any sediment or scale from the probe using a scouring pad or steel wool. Note: Do

not use caustic chemicals that could damage the probe.

Reinstall the probe and perform the Operating Test Procedure described [in the product installation sheet]..

Ask your heating service technician to perform that operation and let me know the result.

CycleGard LWCO Operation

The CycleGard LWCO should cut off the boiler 15 seconds after the boiler water level falls to below the LWCO sensor probe (that you can't see, it's behind the blue CycleGard control box and is inserted through a tapping into the steam boiler).

Using the CG400 as an example (your 450 has similar instructions for which we provide a link below) here is how the company describes its normal operation

Burner circuit contacts open after 15 second delay in a low water condition.

Delay prevents short cycling caused by momentary fluctuations in the boiler water level. Automatically reactivates burner circuit 30 seconds after water reaches the probe, allowing optional water feeder to raise water level above the probe. Intermittent Level Test (ILT) feature provides maximum boiler protection by removing power from the burner circuit at set intervals.

Models ending in “1090” perform the ILT every 10 minutes for 90 seconds.

Models ending in “2060” perform the ILT every 20 minutes for 60 seconds.

- Source: Hydrolevel Safgard™ 400 Series Steam LWCO [PDF], Hydrolevel Company, 126 Bailey Road, North Haven, CT 06473 USA, Tel: (203) 776-0473 Website: www.hydrolevel.com Retrieved 2017/04/06, original source: http://hydrolevel.com/safgard-400-series-steam/

Repair for a CycleGard LWCO that Does Not Detect Low Water in the Boiler

The fact that the LWCO indicating light doesn't turn on also suggests that it's not sensing the water drop.

Am I correct that when you add water you do see water enter the sight glass? So we think the sight glass is accurately showing boiler water level and isn't blocked itself?

OK so what to do: Here are verbatim instructions from the CG400 Instruction Sheet.

1. Check to see if a foaming condition in the boiler is preventing the control

from accurately detecting the water level.

With power to the system on, and

water above the probe level, set the thermostat so there is no call for heat

and allow the burner to shut down. Then, slowly lower the water in the boiler

to a point below the probe.

The amber LED lamp should turn on and the relay

will open after a 15 second delay.

Once this has occurred, reestablish a call

for heat and the boiler should not fire.

Now raise the water level to an operating level.

The amber light should turn off and the control should reenergize

the burner circuit after a 30 second delay.

If the control functions normally

during this test, but allows water to drop below the level of the probe when

the test is conducted with the burner on (as described in the Operating Test

Procedure above), the boiler is foaming.

The CycleGard provides protection

for foaming boilers (see CycleGard Intermittent Level Test Feature above).

However, to provide optimal steaming performance, it is still recommended

that you clean the boiler in accordance with the manufacturer's instructions.

The foaming condition is caused by machining oils, elevated mineral content

from make-up water, grease and other contaminants in the boiler water.

Cleaning the boiler will eliminate foaming conditions in the boiler and provide

for optimal steaming performance.

See also BOILER CLEANER CHEMICALS / TREATMENTS

2. Check terminal block wiring to insure that all connections are correct.

3. Check the probe installation to insure that there is 1/4" clearance from any

surface within the boiler or pipe. (Refer to Step 3 on page 1 of this instruction

sheet.

If the Hydrolevel CycleGard 400 Amber Light is On

The amber LED lamp indicates that the water is below the probe. If the gauge

glass shows that the water is at the correct operating level and the amber LED

is lit check the following:

1. Check for plugged gauge glass.

2. Make sure probe lead wire is properly secured to the terminal.

3. Check for proper ground between probe and boiler shell. Excessive use of Teflon tape or sealing compound may isolate the probe from the boiler shell.

4. Remove probe and examine for oily residue. Clean probe with steel wool and

skim boiler.

If the Hydrolevel CycleGard 400 GREEN LED Light is on

The green LED lamp indicates that the control is conducting an Intermittent

Level Test.

The burner does not fire during the test period. See Intermittent

Level Test Feature on this page for more details.

See the complete instructions for your HydroGard™ CG450 at

Hydrolevel Safgard™ 450 Series Steam LWCO [PDF], retrieved 2017/04/06, original source: http://hydrolevel.com/safgard-400-series-steam/

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-02-08 by InspectApedia Publisher - green LED lamp indicates that the control is conducting an Intermittent

Level Test

@anthony zambrana,

The green LED lamp indicates that the control is conducting an Intermittent

Level Test.

The burner does not fire during the test period. See Intermittent

Level Test Feature on this page for more details.

On 2023-02-08 by anthony zambrana

green light is on what that means

On 2022-04-19 by Inspectapedia Com Moderator

@Mike,

I'm so sorry but I don't know an alternate-brand part that will fit inside of a Watts 89D LWCO for sure, but you might check with Watts about their San89 float and switch assembly to see if that can work.

Quoting:

Series SAN89 Float and Switch Assemblies for Servicing Low Water Cut-Offs feature a one piece unit that facilitates installation and ensures the most up-to-date construction. Model SAN89D is a complete float and dual switch assembly. Model SAN89S is a complete float and single switch assembly. Maximum Working Pressure: 15psi (103 kPa).

WATTS SAN89 LWCO INSTALLATION INSTRUCTIONS [PDF] (2008) Watts USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

or Watts Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

at

https://inspectapedia.com/heat/Watts-San80-LWCO-Instructions.pdf

On 2022-04-19 by Mike

i have a Watts 89d low water cut off that is leaking inside the switch from tapping on it Are there any other LWCO's that will fit?

these old 89d lwco's are hard to find and very expensive Thanks, Mike

On 2021-11-15 by Inspectapedia Com Moderator - replacing glass tube with new gasket

@mike b,

YOu may need to flush the low water cutoff to remove debris

On 2021-11-15 by mike b

i drained water from Burnham steam boiler to replace leaking glass tube. after replacing glass tube with new gasket, now green light on mcdonnell low water shut of does not stay on as before repair, please hepl. tks mike b

On 2021-10-24 by inspectapedia.com.moderator - Could the probe need cleaning?

@Anonymous,

sorry you're quite right; I should have focused first on cleaning or descaling;

Still, the valve does have to have moving parts to open and close a water supply - electrically - in response to the probe's finding the absence of water

The probe is itself an electrical sensor; if de-scaling it doesn't fix it, we ought to be able to first test (electrically, using a VOM or DMM) the water feeder (at the probe contacts) to distinguish between a probe that is itself defective vs. a water feeder that's not responding properly to the probe's signal.

On 2021-10-24 by Anonymous

@inspectapedia.com.moderator, I thought if I have a probe I don’t have a float in the tank. This also seems to be what happened last year. As I went to flush it for this winter coming the sight glass was full. It’s not good to have it that much full and pressurized right? I also can’t seem to find my boiler safe fill line mark. So if cleaning the probe doesn’t fix it then it’s most likely the water feeder not working?

On 2021-10-20 by inspectapedia.com.moderator

@Robert,

It's just a guess but it sounds to me as if you are water feeder control or float is not working properly. Open that's corrected by cleaning and Flushing the controls otherwise it's time for control replacement.

On 2021-10-19 by Robert

I have a Burnham Boiler that by looking at the sight glass all the way full and excessive water feeder run time leads me to believe my boiler is flooded/flooding? My McDonnell PS-892-24 LWCO does the cut off and triggers the United match WFE-24 water feeder. But the water feeder seems to run all the way till the sight glass fills up and then some.

There’s no click shut off sound just as if it comes to a slow running water stop sound. Could the lwco not be satisfied? The probe is set at approx 2/5 of the sight glass. Once it passes that 2/5 mark the lwco red light goes away but the feeder keeps going. Could the probe need cleaning?

On 2020-03-25 by danjoefriedman (mod) - when the boiler calls for water I lose all my steam pressure

Pretty interesting use, Terry - I'd need to know more about what you've done to your boiler.

IN general a residential steam boiler operates at very low PSI - around 0.2 to 0.5 psi.

At those low pressures, if you are trying to jet your crabs to steam those fellows (I imagine they hate it), it makes sense that you'll lose all steam pressure in the boiler very quickly.

But I do NOT suggest fooling with the boiler's pressure settings as doing so can make the heating system unsafe.

Also watch out about adding frequent shots of very cold water to a hot steam boiler: you can crack the boiler.

On 2020-03-24 by Terry

Just hooked up a Utica steam boiler for steaming crabs when the boiler calls for water I lose all my steam pressure is there any way to keep my pressure or get get it back quickly.

On 2019-10-30 by Anonymous

Good through answer I commend you my friend

...

Continue reading at LOW WATER CUTOFF VALVE, BOILER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BOILER CLEANER CHEMICALS / TREATMENTS

- BOILER LOW WATER CUTOFF CONTROL LWCO MANUALS

- LOW WATER CUTOFF VALVE, BOILER

- LOW WATER CUTOFF VALVE NOT WORKING

- LOW WATER CUTOFF CONTROL MANUALS

- SIGHT GLASS, STEAM BOILER

- STEAM BOILER FLOODING / SURGING REPAIR

- STEAM HEATING SYSTEMS & CONTROLS - home

- WATER FEEDER VALVE, HYDRONIC BOILER

- WATER FEEDER VALVE, STEAM

Suggested citation for this web page

LOW WATER CUTOFF VALVE NOT WORKING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to STEAM BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about diagnosing & repairing LWCOs low water cutoff switches & controls on heating boilers

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Comments

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.