The Hartford Loop on Steam Boilers

The Hartford Loop on Steam Boilers

Definition, function, safety features, piping for the Hartford Loop & comparison with the Gifford Loop

- POST a QUESTION or COMMENT about the Hartford Loop found on steam boilers

The Hartford Loop used on steam heating systems, definition, functions, inspection, installation, repair:

This article gives a definition of the Hartford Loop used on steam heating systems, explains why the Hartford Loop is necessary to protect against steam boiler damage, and gives a bit of the history of the development of the Hartford loop.

We include sketches and photographs of the Hartford Loop piping arrangement on steam boilers and list inspection & defect points of interest.

We have added sketches and an explanation of Henry Gifford's Gifford Loop, an improvement to the original Hartford Loop design.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Hartford Loop safety piping arrangement on steam boilers

Definition of the Hartford Loop - what is a Hartford Loop & Why is it Important on Steam Systems?

Invented in the U.S. in 1919 by the Hartford Steam Boiler and Inspection Company in response to an unacceptable rate of steam boiler damage, loss, and even explosions, the Hartford Loop is a piping arrangement at the steam boiler condensate return line that allows condensate to re-enter the boiler but prevents complete loss of steam boiler water should a leak develop elsewhere in the condensate return line.

Today the company refers to itself as the Hartford Steam Boiler Inspection and Insurance Company (founded in 1866) - not to be confused with the Hartford Fire Insurance Company (founded in 1810).

[Click to enlarge any image]

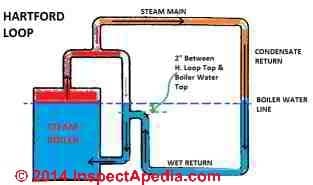

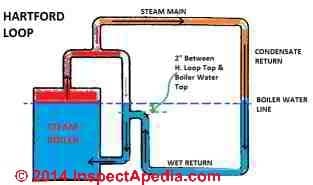

As you can infer by looking at our drawing at above left Boiler Without a Hartford Loop, a leak anywhere in the wet return portion of the condensate return piping that is below the boiler water line risks siphoning out all of the water from the heating boiler.

Our illustration at above right titled Hartford Loop shows where the Hartford Loop is located on a steam boiler. Above the drawing is adapted from ITT's The Steam Book.

The 2-inch Rule and the 24-inch Rule for Hartford Loops & Steam Headers

- Hartford Loop 2-Inch Rule:

In steam piping layout the top of the Hartford Loop will be located at a height that places it 2" below the water line in the steam boiler.

Explanation: If the top of the loop, through a close nipple, is higher than 2" below the water line in the boiler, late in the burner-on cycle when water is lowest in the steam boiler, steam in the boiler can push back into the returning condensate line, causing water hammer and delaying the return of condensate. - Hartford Loop Close Nipple Rule:

The connection of the right-hand Wet Return portion of the Hartford Loop to the first piping loop closest to the boiler is made using a close nipple.

Check out our blurry photo above. That yellow arrow points to what should be a 2-inch dimension.

Does that look like 2" to you? This Hartford Loop may be improperly piped, risking failure to keep a safe level of water in the boiler should a leak occur in the wet condensate return piping.

Explanation: a long nipple like the one shown in our photo can cause returning condensate to surge into the boiler as steam condenses in the equalizer, also causing banging or water hammer noise at the boiler.

If the short horizontal run (green arrow in our sketch) is made too long the anti-siphon benefit of the Hartford Loop could be lost.

The boiler manufacturer may provide additional steam piping specifications - as we continue below.

- Hartford Loop 24-Inch Rule:

Instead of specifying that the top of the Hartford Loop is two inches below the boiler water line the manufacturer may specify that the pipe fitters maintain at least 24 inches between the boiler water line and the bottom of the steam header.

The risk of steam condensate return water leaks was and can remain significant because of the corrosive acids that form in steam and other heating boilers and because not coincidentally, the more likely place where such leaks would develop is in the last and lowest run of the condensate return line along or close to the floor approaching the steam boiler.

In our discussion of steam condensate systems we illustrate a chemical injection system intended to reduce this corrosivity.

At below right our image is adapted from the piping schematic for a Weil McLain steam boiler - Weil McLain Model 78 (2014)

Boiler manufacturers typically specify that a Hartford Loop piping arrangement and a wet condensate return line are required for steam boilers.

In addition to the installation of Hartford Loop to prevent total boiler water loss from a leak in the condensate piping, [the wet condensate return line] a steam boiler specification will maintain at least 24 inches from the steam boiler water line to the bottom of the steam header.

And if a separate condensate receiver is used, a feed pump to move condensate back to the boiler must be energized by a boiler-mounted condensate return pump controller.

See CONDENSATE RETURN PIPES, PUMPS, STEAM adapted from Weil McLain 78 boiler instructions.

Hartford Loop Prevents Pushing Condensate Back Up the Return Line

A separate worry for Hartford-loopless steam boilers has been suggesteed by Steam Boiler Gurur Dan Holohan - paraphrasing

The Hartford loop is needed to prevent steam pressure in the condensate return line from forcing the liquid condensate (water) out of the boiler and back into the return piping system - something that could be a serious problem resulting in boiler water loss and boiler damage or destruction.

The “wet” gravity return line, which returns the condensate from the system, rises up from the floor to join with the equalizer at a point about 2 in. below the boiler’s lowest operating waterline.

[Steam boiler installers ...] didn’t always use this piping arrangement. They used to bring the return directly back into the bottom of the boiler without the benefit of either a Hartford Loop or an equalizer. When they piped a boiler this way, however, the slightest steam pressure would push water out of the boiler and into the return. [Emphasis ours - Ed.]

They solved this problem by using a check valve in the wet return (that’s the pipe below the boiler waterline).

Before long, though, they found the check valve would fill with sediment and get stuck open.

That caused the water to back out of the boiler again, so they developed the equalizer pipe to replace the check valve. ... - Dan Holohan,PM Mag, online, un-dated, retrieved 4/7/2017 cited atReferences or Citations

Dan continues to point out that leaks at the return line were catastrophic for steam boilers and adds that the low water cutoff valve (LWCO) was not invented until E.N. McDonnell invented it in 1923.

Really? The pressure in a residential steam heating system is normally less than 0.5 psi.

At WATER PRESSURE MEASUREMENT (not specifically a heating system article) we describe how to compute the pressure exerted by water at the bottom of any vertical column of water - say a condensate return pipe, for example.

Even without a Hartford loop, and assuming for argument that the steam boiler is in a building basement and that the normal or "safe" water level in the boiler itself is at most 4 ft. above the floor, we can calculate that

The pressure of a column of water is about 0.433 psi per foot of column height.

The pressure of a 4 ft. height of water in the steam boiler and also in the riser of the condensate return pipe wherever it mounts to upper floors, measured at the bottom of that column of water, will be

Water pressure in the steam system at floor level (WPfl) = 4 x 0.433 psi = 1.732 psi.

If my calculations are right (I'm not a boiler engineer) we have about 1.7 psi of resistance to water leaving the steam boiler and 0.5 psi or less of steam pressure trying to push water out of the boiler.

So I think that for low-pressure residential steam systems the greater risk is not steam pressure pushing much water out of the boiler, but rather a leak anywhere in that close-to-floor-level condensate return line. (However the risk of boiler water push-out at high pressure steam boilers would be another and still more serious matter entirely. )

Leaks Do Occur in the Condensate Return Line

Do leaks actually occur in the wet return portion of a steam heat condensate return piping system? You bet they do.

Do leaks actually occur in the wet return portion of a steam heat condensate return piping system? You bet they do.

Depending on what's done to manage steam boiler chemistry, the condensate may be quite corrosive. Our photo at left shows two leaks at the condensate wet return at a boiler located in in the U.S. in Poughkeepsie, NY.

Watch out: at CONDENSATE RETURN PIPES, PUMPS, STEAM we explain that a leaky condensate line such as the one shown in our photo at above left can be lead to

dangerous BLEVE EXPLOSIONS.

You can check the water level in your steam boiler quite easily by using

the built-in STEAM BOILER SIGHT GLASS.

The Hartford Loop is also discussed

and at STEAM TRAPS

History of the Hartford Loop & the Hartford Steam Boiler & Insurance Company

Comment: the Hartford Steam Boiler & Inspection Company

2017/04/07 Nancy said:

Quick correction. The loop was invented by the The Hartford Steam Boiler Insurance and Inspection Company (Where I work - we're 150 years old!). The Hartford Insurance co. is a different entity all together.

Nice job with a basic, easy to understand explanation!

Reply: The Hartford Steam Boiler Inspection and Insurance Company is not the Hartford Fire Insurance Company

Thanks for the clarification, Nancy. Indeed it's easy to be confused about Hartford Insurance and Hartford Fire Insurance companies. The Hartford Insurance and Hartford Boiler company were of a piece.

In sum it would be fair to say that the Hartford Loop was invented by and a key feature of The Hartford Steam Boiler Inspection and Insurance Company founded on June 30, 1866.

While the Hartford FIRE Insurance company was and remains a different company.

Munich RE, parent company of the HSB group, publishing as the Hartford Steam Boiler Inspection and Insurance Company at www.munichre.com/HSB/hsb-history/index.html

says

The Hartford Steam Boiler Inspection and Insurance Company was founded on June 30, 1866. Our first president considered HSB as “the first company in America devoted primarily to industrial safety.” “Hartford Standards” quickly became the specifications for boiler design, manufacture and maintenance.

...

Insurance incentive for boiler inspection

The Polytechnic Club spent much time debating about an idea that combined insurance with a boiler inspection. They reasoned that inspections would increase boiler safety and the insurance would function as an incentive to inspect and a guarantee of a quality inspection.

Though the insurance offered financial interests, it was secondary to safety and loss prevention – a totally new concept for an insurance offering.

Under that premise, The Hartford Steam Boiler Inspection and Insurance Company was founded in 1866.

Separately at the Hartford Insurance Comany's website www.thehartford.com/about-us/hartford-history one sees that the company was founded as the Hartford Fire Insurance Company.

The Hartford was founded in 1810 in Hartford, Connecticut. A group of local merchants gathered in a Hartford inn and, with working capital of $15,000, founded the Hartford Fire Insurance Company. ...

In 1810, we started as a fire insurance company, employing our own fire department to protect customers. Fifteen years later, we wrote the first insurance policy for an institution of higher learning – Yale University.

The Gifford Loop - a variation on the Hartford Loop on Steam Systems

On steam condensate return pipes an alternative to the time-honored Hartford Loop is a much newer alternative invented by Henry Gifford of New York City, whose patent was filed in 1999 and granted in 2002.

You can see that Gifford is essentially adding a drip leg on the steam main at #13 in the sketch. This allows condensate in the steam main to return directly to the top of an equivalent of the older Hartford Loop.

[Color in the above sketch was added by InspectApedia]

In Gifford's design, the bottom surface of the inside of the top of the "Hartford Loop" - now a "Gifford Loop" - is level with the top of the water inside the boiler rather than 2" below it as in the Hartford Loop design.

Gifford's invention is designed to reduce the variation of water level in the boiler that occurs in systems using the traditional Hartford Loop for condensate return.

The Gifford patent, given below, is worth a read for a nice description of the Hartford Loop and how it functioned as well as an explanation of Gifford's alternative, show above as one of the illuostrations from his patent application.

- Gifford, Henry. STEAM BOILER PIPING [PDF] U.S. Patent 6,349,677, issued February 26, 2002.

Abstract: A steam boiler's condensate return piping is connected to the piping that directly connects the boiler outlet pipe to the boiler's water return connection above the boiler's water level to reduce water level fluctuations in the boiler.

Excerpts:

The present invention comprises a condensate return pipe connected to the equalizer pipe above the boiler's water level.

The condensate return pipe 12 connects to the equalizer pipe 13 above the boiler's water level. In the preferred embodiment the condensate return pipe 12 connection to the equalizer pipe 13 is located where the bottom of the inside of the condensate return pipe 12 is located 1 inch above the boiler's water level as shown in FIG. 3.

Neither leaks in the condensate return pipe 12 nor Steam pressure inside the boiler 11 can lower the water lower than the bottom of the inside of the condensate return pipe 12 where it connects to the equalizer pipe 13.

Fluctuations in the preSSure difference between the condensate return piping 12 and the Steam System piping 14 can push water into the boiler 11 but not out of the boiler 11.

This piping arrangement performs the function of a check valve but Suffers from none of the reliability issues associated with check valves.

This has the advantage of making the boiler's water level Steady and easy to control by use of automatic water level control apparatus. - Gifford, Henry & Jonathan Flothow, AN IMPROVEMENT to the HARTFORD LOOP [PDF] Advantages of the Gifford Loop include the Hartford Loop’s

safety features, plus stabilization of the boiler

water line, drier steam, and elimination of

some condensate pumps, Heating/Piping/AirConditioning, November 1999 pp. 51-53.

Excerpt:

The Hartford Loop has been around for eight decades and has prevented thousands of boiler explosions and failures. Still, it is time to consider an improvement. It has been discovered that a boiler’s waterline can be stabilized greatly by installing a Gifford Loop—a Hartford Loop with the bottom of the close-nipple at least 1/2 in. abovethe water level where the automatic feeder starts to add water.

It is named after one of the co-authors of this article, Henry Gifford, a boiler mechanic in New York City who recently invented it.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Questions & answers about the Hartford Loop on steam boilers

On 2019-07-30 - by (mod) -

Typical would be on the boiler side of the Hartford Loop.

On 2019-07-30 by Anonymous

Where do you tie in makeup water

On 2019-01-30 - by (mod) -

Distributor boiler uap said:

you’re in reality a just right webmaster. The web site loading pace is amazing. It sort of feels that you are doing any unique trick. Moreover, The contents are masterpiece. you’ve done a wonderful process on this subject

On 2018-11-07 - by (mod) -

firetube boiler said:

I like to work online and now I open your blog. I think your blog's title and content are good articles to gain knowledge and are very useful

On 2018-03-23 - by (mod) -

I'm not sure I have a clear picture but it sounds like your plumbing Arrangement would defeat the Hartford Loop and would permit the complete loss of water from the boiler to siphonage

On 2018-03-22 by Mark Gettings

Why does the wet condensate return line need to be plumbed in below the 2” boiler water line into the equalizer? Why not gravity feed the condensate plumbing too the bull head of tee in the equalizer so no back flow can exist by shear gravity?

On 2018-01-31 - by (mod) -

Bill

Types of boiler heat loss and special heat losses ascribed to the Hartford Loop on a steam boiler:

From my research I have not found the basis of your question.

Speaking very generally however I can "make up" an answer: it is only condensate, not steam, that moves up through the Hartford loop and into the steam boiler.

So there would be no state change (water to steam or steam condensing back to water) inside of the piping that comprises the Hartford loop.

Therefore only sensible heat would be lost out of hot condensate and through the steel piping and into the air surrounding the boiler.

Now Bill, if you have a resource that discusses energy or heat losses ascribed to the Hartford Loop I would much appreciate knowing that citation so that we can research further.

The question is not particularly useful except perhaps as part of a heating exam to see if the students understand where the Hartford Loop is placed and what it contains. (Good luck on your exam).

For other readers:

Latent heat or latent heat loss refers to heat given off during a state change, such as from water to steam.

Latent heat is "hidden" energy that is added or removed to change the state of a substance without changing its temperature.

Sensible heat, or sensible heat loss refers to heat given off due to the temperature of a material, such as hot water, or more properly the temperature difference between a substance and its surroundings, since if for example water heated to 100F were surrounded by air at 100F there would be no heat transfer from the water to the air.

When sensible heat is exchanged the measurable temperature of the body or substance changes, increasing or decreasing depending on the direction of heat or energy movement.

Be sure to read DEFINITION of HEATING, COOLING & INSULATION TERMS - https://inspectapedia.com/heat/HVAC_Definitions.php for more details.

Quoting NRCAN,

Definition of Stack Losses

Stack losses represent the heat in the flue gas that is lost to the atmosphere upon entering the stack. Stack losses depend on fuel composition‚ firing conditions and flue gas temperature. They are the total of two types of losses:

Dry Flue Gas Losses – the (sensible) heat energy in the flue gas due to the flue gas temperature; and the

Flue Gas Loss Due to Moisture – the (latent) energy in the steam in the flue gas stream due to the water produced by the combustion reaction being vaporized from the high flue gas temperature.

They are addressed by assuming typical fuel analyses and a few reasonable assumptions that simplify calculations. - retrieved 2018/01/31, original source: Boiler System Energy Losses, Natural Resources Canada, www.nrcan.gc.ca/energy/efficiency/industry/technical-info/tools/boilers/5431

Heating experts discussing heat loss from a heating system such as a boiler also describe:

Radiation and convection heat losses: two forms of heat loss or movement from the hot surfaces of a boiler to its cooler surroundings.

Also see:

Cronin, Dave, "Heat Transfer, Re-thinking HX equipment & hook-ups for improved efficiency and control… while saving you money" [Power Point], ASSE International, 18927 Hickory Creek Drive, Suite 220 Mokena, Illinois 60448 USA, Retrieved 2018/01/31, original source: www.asse-plumbing.org/chapters/NOH_HeatTransfer-Spirax.pdf

On 2018-01-31 by Bill

Is it just latent heat lost in a Hartford Loop or is there a certain amount of sensible heat lost as well?

On 2017-04-07 - by (mod) -

Thanks Nancy, for your important clarification.,

I will edit the article above and add a distinction between the Hartford Steam Boiler and Insurance Company - as the company describes itself in historical articles - and the separate Hartford Fire Insurance Company.

The new material should be here in 24 hours - at the end of the article above.

On 2017-04-07 by Nancy

Quick correction. The loop was invented by the The Hartford Steam Boiler Insurance and Inspection Company (Where I work - we're 150 years old!). The Hartford Insurance co. is a different entity all together.

Nice job with a basic, easy to understand explanation!

Question: steam pipe configuration question at the boiler

What's the term they call the 2 steam pipes that form an H above a steam boiler. in other words the pipes from both sides of the burner connected together? THANKS,Walter - 9/25/11

What's the term they call the 2 steam pipes that form an H above a steam boiler. in other words the pipes from both sides of the burner connected together? THANKS,Walter - 9/25/11

Reply: steam pipe header

Walter: sorry we couldn't give an instant reply; sometimes the volume of reader questions is considerable and takes some time to get thorough.

I am guessing you are referring to the steam header or manifold piping that allows steam to enter more than one steam supply line or riser.

A second piping configuration that will be along side, not above, the boiler is the Hartford loop - a loop of piping sort of like an upside down trap that prevents water from siphoning out of the boiler should there be a leak in the condensate return line.

See HARTFORD LOOP

Question: steam boiler parts identification

Wow, what a great web site. I am trying to identify a vessel on the side of an old National steam boiler/furnace.

It is about 12-18" tall, about 8" diameter and is attached to a manifold in the side that is about 12" off the floor. It is heavily rusted. The boiler is an old coal fired converted to oil. Can I send you photos? Thanks, Stephen strentsch@yahoo.com or strentsch 10/4/11

Reply:

sure Mr. Strentsch,

use the CONTACT link found at page top, left, or bottom to see our email and send along some sharp photos and we'll be glad to take a look

Question: is a missing Hartford Loop a problem on a steam boiler system?

(Aug 31, 2016) Ei said:

A recent inspection revealed no Hartford Loop on the boiler (replaced burner 2014). Is this a problem and what is the cost to install one.

Reply: yes

We replied in detail where you posted this question elsewhere.

Question:

(Oct 3, 2016) Anonymous said:

there is a question if a blowdown on the loop is needed since it is the lowest point of the boiler?

Reply:

No. Not that I've seen nor read about.

...

Continue reading at CONDENSATE RETURN PIPES, PUMPS, STEAM or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BANGING HEATING PIPES RADIATORS

- LOW WATER CUTOFF VALVE

- STEAM BOILER FLOODING / SURGING REPAIR

- STEAM BOILER LEAK DAMAGE

- STEAM BOILER SIGHT GLASS - how to read the steam boiler water level

- STEAM HEATING SYSTEMS & CONTROLS - home

- WATER HAMMER NOISE DIAGNOSE & CURE

Suggested citation for this web page

HARTFORD LOOP at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to STEAM BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Weil McLain Model 78 Boiler Manual, Boiler for gas, light oil, Gas/Light Oil fired Burners, Installation, Start-up, Parts, Maintenance instructions, Part No. 550-141-705/0600, Weil-McLain Administrative Office, 999 McClintock Drive, Suite 200, Burr Ridge, IL 60527

Tel: 855-248-1777

Consumer Inquiries: 800-368-2492

Technical Services: 800-526-6636 Technical Support for Contractors Only.

If you are a homeowner and are experiencing a problem with your Weil-McLain equipment, the first step you must take is to contact your installer or locate an HVAC contractor in your area. Website: http://www.weil-mclain.com - The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update, (see next item in this list). ITT Fluid Technology,

1133 Westchester Avenue

White Plains, NY 10604, tel +1 914 304 1700 fax +1 914 696 2950 www.ittfluidbusiness.com - Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- Holohan, Dan, "Top 10 facts about the Hartford Loop" [web article], Radiant & Hydronics, Plumbing & Mechanical Magazine, Main Office 2401 W. Big Beaver Rd., Suite 700 Troy, MI 48084-3333 USA Phone: 248-362-3700, website: pmmag.com, retrieved 2017/04/07, original source: http://www.pmmag.com/articles/96529-top-10-facts-about-the-harford-loop

- Holohan, Dan, The Lost Art of Steam Heating, [Book for sale at Amazon], Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- The Heat Efficiency of Steam Boilers, Bryan Donkin

- Steam Boiler Operation, Principles & Practice, James J. Jackson

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on

- McDonnell & Miller Controls - XYLEM Global Headquarters, 1133 Westchester Avenue, White Plains, NY 10604, Tel: +1-914-323-5700, Fax: +1-914-323-5800

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.