Guide to Heating Oil Burner Fire Safety Controls & Electrical Switches

Guide to Heating Oil Burner Fire Safety Controls & Electrical Switches

- POST a QUESTION or COMMENT about selecting, installing, or using safety controls and switches on oil-fired heating equipment

This document describes defects in heating oil and oil burner safety controls, safety valves and electrical switches. All of the oil storage tank and piping installation defects described here can easily be found by visual inspection.

Beyond the costly problem of leaky oil piping, this document lists other important safety or oil-fired equipment operational defects in home and light commercial heating oil storage and piping systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

OIL BURNER SAFETY SWITCHES & CONTROLS- How to Inspect & Report Oil Heat or Oil Hot Water Heater Defects by Visual Inspection

The list of oil heat safety controls that follows also provides a guide to determining where there are missing or defective "off on reset" safety controls & switches at the Oil Tank & Oil Burner, beginning with electrical shutoff switches for heat or fossil fuel fired appliances and followed by oil line shut off valves.

The list of oil heat safety controls that follows also provides a guide to determining where there are missing or defective "off on reset" safety controls & switches at the Oil Tank & Oil Burner, beginning with electrical shutoff switches for heat or fossil fuel fired appliances and followed by oil line shut off valves.

[Click to enlarge any image]

Because some controls are used in common on hot water heat, hot air heat, and steam boilers, readers should see these other articles:

see BOILER CONTROLS & SWITCHES, and

also see BOILER COMPONENTS & PARTS for a detailed list of heating boiler controls, other heating system components, parts such as circulator pumps & draft regulators.

If your building uses warm air heat,

see FURNACE CONTROLS & SWITCHES.

If your building uses steam heat

Where do we Install an Electrical Switch to Turn off the Oil Burner?

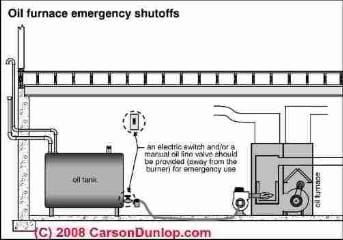

Carson Dunlop Associates' sketch shows an electrical switch to turn off the oil burner and a manual oil line valve, both of which should be located away from the oil burner.

An oil fired heating system should have the following safety controls and valves installed:

- An oil burner electric power emergency-shutoff switch remote from the oil burner, best located at the top of the basement stairs or in the nearby living space (you don't want to have to enter a smoke-filled basement to turn off the heating system in an emergency).

The electrical switch is usually located at the entry to the basement, garage, boiler room or similar utility room so that in an emergency power to the heating equipment can be shut off without having to enter the equipment room. - An oil burner electrical power service-shutoff, a duplicate of the switch just cited above and controlling each of the same heating appliances is installed near the oil burner for the service technician (below left). For details

see ELECTRICAL POWER SWITCH FOR HEAT.

In some jurisdictions, an additional thermally-fused electrical safety switch is required at oil fired and possibly gas fired heating equipment.

Below we an older-style Fire-o-Matic fusible link electrical safety switch. Details of this switch and its newer successors are

at FIREMATIC FUSIBLE ELECTRICAL SWITCH

- An oil line safety valve (OSV) for details

see OIL SUPPLY LINE SAFETY VALVES, OSVs - A draft regulator - for details

see DRAFT REGULATOR, DAMPER, BOOSTER

How & Where do We Install a Fusible-Link Firematic™ Oil Safety Valve?

The Firematic fusible-link automatic oil line shutoff valve (photo at left) should only be present on the oil supply line. This is a manual or automatic valve that will stop the flow of oil in the oil line.

This valve controls flow of fuel oil to the oil burner of heating boilers, furnaces, and water heaters.

Fusible link Oil Valve: Oil line safety valves have a lead or other soft metal core that melts and closes the valve so that the system won't keep feeding oil to the heating equipment if the area is on fire.

See our photo at below left for an example of a Firematic™ safety valve right at the oil burner. Synonyms: Fire-o-Matic valve, Fusible link valve, oil line shutoff valve, oil safety valve, and Fir-o-matic (aka "Fireamatic") valve.

The standard oil safety valve used at the oil burner and often found also at the oil tank is the Firematic™ fusible link safety valve.

The Firematic™ oil line valve can be installed in ANY position - (vertical, horizontal, upside down) at least that's what we were taught and what we have seen - the valve is spring loaded.

In a fire a lead core melts at 165°F and a spring in the valve assembly snaps the valve shut to assure that the heating system does not feed oil to a building fire. It has to work in any orientation.

See OIL SUPPLY LINE SAFETY VALVES, OSVs for details about the operation and use of this double duty-valve, used both as an oil piping supply-line shutoff valve and as a fusible link valve for fire safety.

Watch Out: If the oil line fire safety valves are missing or are not at the right location, we recommend immediate installation of a Fire-o-matic™ type fusible link oil line safety valve on the oil line at the burner.

Fusible-Link Firematic™ Thermally-Fused Electrical Switch

Fireomatic ™ or Firomatic™ (or its successors and possibly other companies) produced a Firomatic Thermal Switch TS-150 series (or other brand) electrical safety switch that interestingly uses a similar spring-loaded fusible switch to cut off electrical power to a heating appliance (boiler, furnace, water heater) in the event of a fire.

Details about this device are at FIREMATIC FUSIBLE ELECTRICAL SWITCH

Fire Safety for Two-Line Oil Piping Systems: OSVs & Oil Line Check Valves

If two oil lines are used to supply an oil burner, Do NOT install an automatic oil line shutoff on the return oil line between the oil burner and the oil tank.

Use an OIL LINE CHECK VALVE instead. The automatic oil line shutoff valve should only be present on the oil supply line. Further explanation is below.

Watch out: If oil line valves are missing or are not at the right location there is risk of system malfunction, oil leaks, and fire damage.

We recommend installation of a Firematic fusible link (Fire-o-matic)™ type oil line safety valve on the oil line at the burner.

This valve controls flow of fuel oil to the burner, and has a lead core which melts and shuts the valve, stopping the flow of oil in event of a fire in the building.

Even when a fusible link oil line valve is installed at the oil tank, the proper place for this protection is right at the burner as well. A valve in that location also makes servicing the heating equipment easier, faster, and cleaner.

Where do we Put the OSV or a Check Valve on a Heating Oil Line?

If two oil lines are used to supply an oil burner, install a fusible link oil line shutoff valve only on the oil supply line at the oil pump on the oil burner.

Do NOT install an automatic oil line shutoff on the return oil line between the oil burner and the oil tank.

See OIL SUPPLY LINE SAFETY VALVES, OSVs for details about this double duty-valve, used both as an oil piping supply-line shutoff valve and as a fusible link valve for fire safety.

Most sources also advise against installing a check valve on the return oil line - a topic we discuss ad nauseam over

at OIL SUPPLY LINE CHECK VALVES.

Watch out: The valve shown at above left should not be used as a check valve in the application we just discussed. This is a Webster vacuum-operated OSV & requires a vacuum to open. If installed in the return line the valve would be pressurized, not open, cause the shaft seal to rupture or blow out & result in a major oil leak. Thanks to reader Rick Johnston for adding clarification.

Oil Line De-Aerators & Prime Protection Devices

If your oil burner uses a Tigerloop® oil-line de-aerator (photo at left) to remove air or foam from the incoming oil line, the company notes that UL requires a fusible link oil valve installed in the (bottom) center (inlet) port of the Tigerloop™ device.

If your oil burner uses a Tigerloop® oil-line de-aerator (photo at left) to remove air or foam from the incoming oil line, the company notes that UL requires a fusible link oil valve installed in the (bottom) center (inlet) port of the Tigerloop™ device.

Tigerloop™ is an oil de-aerator installed at the oil pump (fuel unit) on an oil burner. It can help avoid losing prime on heating oil lines if there is a problem with air leakage into the oil piping.

Watch out: Tigerloop™ adds that you should never install an oil line shutoff device between the de-aerator device and the oil pump. Shown is the Tigerloop S220. A variation is available, the Tigerloop-ultra™ S-220-8 that incorporates an oil filter as well.

Please see complete details on de-aerators on oil piping

at OIL SUPPLY & RETURN LINE DE-AERATORS Tigerloop™

Details about a suspected leak in oil line piping where a de-aerator or oil line air removal device is installed are in a Q&A discussion found

at OIL SUPPLY LINE PIPING LEAKS

Details about how to get rid of air already in the oil piping system are

at OIL BURNER FUEL UNIT AIR BLEED PROCEDURE for steps in removing air from oil piping and fuel units at oil burners such as after running out of heating oil.

Reader Comment: advice about oil burner emergency switches & their wiring

2 Feb 2015

NHFireBear said:

The "emergency" oil burner shutoff switch must be wired into the "burner supply circuit", according to NFPA 31. It is different from the "service switch" on the unit, which must be at or near the unit.

As mentioned in the article, the identified "emergency" switch must be located outside the boiler room and generally outside the door to the cellar steps, if the boiler is in the basement.

That way the switch can be turned off without opening the door, and serves as a marker for which door is the one to the basement.

Many installers simply run the appliance power feed through the "emergency" switch, which means it ALSO turns off any sidewall vents, circulators, fans, thermostats, and other devices powered through the appliance controls -- not just the burner.

The NFPA is presently evaluating whether such an installation is safe, let alone proper, under the existing Code.

Reply:

Thanks NHFireBear - we've added your note here and

at ELECTRICAL POWER SWITCH FOR HEAT. We can use all possible editing assistance. - Ed.

Watch out: It an interesting that if we shut off a blower fan on a furnace while the heat exchanger is still quite hot, the result could be a cracked (and thence unsafe) heat exchanger. On the other hand, if there is a building fire, particularly orignating in the furnace or boiler room, we hardly want to keep a furnace blower fan running.

...

Continue reading at AQUASTAT CONTROLS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CAD CELL RELAY SWITCH

- COOLING & HEATING CONTROL & SWITCH INDEX - index to all controls

Suggested citation for this web page

FIRE SAFETY CONTROLS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING OIL, OIL BURNERS, OIL FIRED HEATERS, OIL TANKS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about selecting, installing, or using safety controls and switches on oil-fired heating equipment

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

- [2] Beckett Model SR Oil Burner Instruction Manual, R.W. Beckett Corporation, PO Box 1289, Elyria OH 44036 and R.W. Beckett Canada, Ltd., 430 Laird St., Guelph, Ontario, Canada N1G 3x7

- [3] Thanks to Bottini Fuel service technician Bob for discussing the buzzing aquastat relay problem, 4/18/2012. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- [4] Beckett Model SF Oil Burner Instruction Manual, op. cit.

- [5] Sunstrand Corporation - Sunstrand Fuel Units, 4949 Harrison Avenue P.O. Box 7003 Rockford, Illinois 61125-7003 U.S.A. Telephone: (815) 226-6000 Fax: (815) 226-5399 http://www.sundstrand.com

- [6] Sunstrand Transmission Service Manual, May 1974, web search 08/19/2011, original source: http://www.cushmantrackster.com/pay-pdfs/sundstrand.pdf - Sunstrand Series 15 hydrostatic transmissions

- [7] Webster Fuel Pumps & Valves, Capitol City Tool, Inc., http://www.websterfuelpumps.com/

- [8] Suntec Model A-7400 Fuel Unit Solenoid Dumping Pump,

Suntec Industries Inc., 60 Aberdeen Drive - PO Box 5000 Glasgow, KY 42142-5000 - USA Tel : 270 651 7116 - Fax : 270 651 9276 e-Mail : info@suntecpumps.com and

Suntec Industries France, 1 Rue Lavoisier - B.P. 102 F-21603 LONGVIC Cedex - FRANCE Tel : +33 (0)3 80 70 60 70 - Fax : +33 (0)3 80 70 61 11 e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Sunted_Solenoid_DumpingPPump.pdf] ,

Also /Suntech_Solonoid_Safety_Valves.pdf (brochure)

web search 4/19/12, original source: http://www.suntecpumps.com/Suntecus/PDFs/Form%202740%20

-%20Solenoid%20Dumping%20Pump.pdf - [9] Suntec Model PRV-38 Oil Safety Valve Installation Information, Suntec Industries Inc., 60 Aberdeen Drive - PO Box 5000

Glasgow, KY 42142-5000 - USA

Tel : 270 651 7116 - Fax : 270 651 9276

e-Mail : info@suntecpumps.com and

Suntec Industries France, 1 Rue Lavoisier - B.P. 102 F-21603 LONGVIC Cedex - FRANCE Tel : +33 (0)3 80 70 60 70 - Fax : +33 (0)3 80 70 61 11 e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Form 2155 - PRV-38 Installation.pdf]. You can download this file from Suntec's website. , - [10] Firomatic Globe Type Oil Line Valves & Lever Type Fusible Link Control Valves: ISP Automation, Inc., 1035 Old Georges Road, North Brunswick, NJ 08902, Phone: 866-383-3481, FAX 866-383-3482, Email: support@ispautomation.com

- [11] Fusible link oil line control valves for commercial equipment: ASCO products by Emerson Industrial Automation, P.O.Box 160, 17 Airport Road Brantford, Ontario Canada N3T 5M8 Tel: (519) 758-2700 Fax: (519) 758-5540

- [12] Fuel oil safety valves, Webster Fuel Pumps & Valves, 219 Hahn Road Frankfort, Ky. 40601, Tel: (800) 766-1233 Email: czahalka@cctoolinc.com (Curtis Zahalka Sales Mgr/Mkt /Cust Service/Tech Support/Webmaster ) web search 10/12/2011 original source http://www.websterfuelpumps.com/pdffiles/osv1.pdf

- [13] Webster Service Technicians' Handbook, Webster Fuel Pumps & Valves, 219 Hahn Road Frankfort, Ky. 40601, Tel: (800) 766-1233

- [14] "The Oil Safety Valve (Service)", Charles Bursey, Sr., Fuel Oil News, February 2006 (Still trying to get the full article - October 2008 - DF) Charles W. Bursey Sr. can be reached at F.W. Webb Co. www.fwwebb.com/

- [15] "Installation Information for Suntec A-2000, A-7000 Single Stage and B-8000 two stage fuel units"Suntec Industries, 60 Aberdeen Drive, Glasgow KY 42141, 270-651-7116 (1725 rpm black label, 3450 rpm white label)

- [16] Tigerloop: oil line de-aerator devices, Westwood Products Inc., 330 William St., PO Box 610, South River, NJ 08882-0610 - (732) 651-7700

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Dave Ferris - M&S Environmental Systems, Dutchess County, New York. Mr. Ferris was an HVAC expert. Personal communication to DJF 1987. Remove the firematic or fusible oil supply line valve on return oil-line side - in case of fire if this one closes first the pump continues to run, blows its seal, and sprays oil all over the fire. Proper installation is to have a fusible link valve only on the supply side, and to install a check valve on the return line to prevent back-siphonage from the tank.

- Thanks to Rick Johnston for pointing out that the more likely cause of a fire safety valve in the return oil line is a burst seal on the fuel unit 4/6/2009

- Thanks to reader T.R. for suggesting clarity on where oil safety valves should or should not be installed and for discussing the proper hook-up location for the Tigerloop and similar oil line prime protection & air removal devices. April 2011.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.