Steam Boiler Sight Glass Replacement

Steam Boiler Sight Glass Replacement

How to change out, clean, fix or replace the sight gauge to set the water level steam boiler

- POST a QUESTION or COMMENT about the sight glass on steam boilers

Steam boiler sight glass repair or replacement:

This article describes how to fix a leaky or broken steam boiler sight glass to obtain an accurate reading of the water level in the boiler.

We discuss emergency steps such as simply shutting off water into and out of a leaky sight glass as well as sight glass replacement.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Steam Boiler Sight Glass Leaks, Breaks, Repairs or Replacement

Watch out: partly because of crud that develops inside the steam boiler, debris can ultimately occlude the view of water level in the sight glass. Your heating service technician can clean or replace the glass if needed.

Watch out: partly because of crud that develops inside the steam boiler, debris can ultimately occlude the view of water level in the sight glass. Your heating service technician can clean or replace the glass if needed.

If some Klutz (like me) breaks the sight glass you may be able to keep the boiler going and stop water from pouring out of the broken glass by closing the two valves found at the top and bottom of the glass tube - those round black handles in my photo.

In an emergency, if the sight glass is leaky try closing the control valves at the top and bottom of the glass (that's one of the reasons they're there). Don't use so much force that you break the valve or you'll be sorry.

A drip like the one in our photo (left) is annoying but not a catastrophe - it's not dripping onto a control.

[Click to enlarge any image]

Ask your heating service company to replace the leaky parts and while you're at it, if the glass is etched and horrible just replace that as well.

Reader Question: is replacing the steam boiler sight glass difficult?

Is replacing the sight glass on a Weil McClain steam boiler difficult? - Carl 4/17/11

Reply:

It's not mechanically difficult to replace the steam boiler sight glass, but you have to shut down power to the boiler, let it cool down, and drain down the water level in the boiler low enough to be able to disassemble the fittings and install the new glass.

It's not mechanically difficult to replace the steam boiler sight glass, but you have to shut down power to the boiler, let it cool down, and drain down the water level in the boiler low enough to be able to disassemble the fittings and install the new glass.

That's if everything goes well. If you encounter corroded fittings that you can't get apart, snap off a fitting at its mount to the boiler, etc. it could turn into a bigger job - not something to attempt on Sunday night when there are no open spare parts stores and you don't want to be without heat.

I'd take a careful look at the condition of the fittings and make sure I had the proper glass and other repair tools and pipe dope, etc on hand. - editor

I should add that on some steam boiler sight glass setups the shutoff valves are working and you might be able to just shut off water there provided the boiler's not too hot to work on.

The ease of slipping in the new sight glass depends on its fittings and their condition.

Below: a steam boiler sight glass replacement kit available from plumbing suppliers and other vendors.

Article Contents

- BOILER SIGHT GLASS (GAGE) REPLACEMENT STEPS

- BOILER SIGHT GLASS CLEANING PROCEDURE

- BOILER SIGHT GLASS WATER LEVEL vs ADDING WATER

- BOILER SIGHT GLASS REPLACEMENT SOURCES & INSTRUCTIONS

Steps in Replacing the Boiler Sight Glass

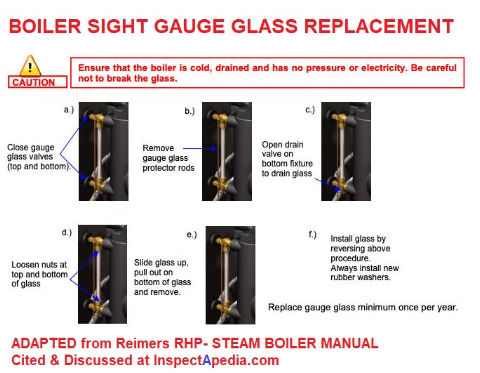

Below, adapted from Reimer's RHP Steam Boiler instructions (Electra Steam, Inc., cited below) are typical steps in replacing a steam boiler sight glass.

- Turn off the boiler and let it cool down completely

- Remove pressure from the boiler

- Drain the boiler at least to a level below the bottom fitting of the sight glass assembly

- Close the sight gauge valves

- Remove the protective rods at either side of the sight glass

- Use the bottom valve on the sight glass to drain the glass

- Loosen the packing nuts at the top and bottom of the sight glass

- Slide the sight glass tube up and gently pull the sight glass bottom out and down to remove it

- Replace the new sight glass by reversing the procedure above -

Rremember to open the valves at the top and bottom of the sight glass water level gauge and to close the sight glass drain petcock before re-filling the boiler. - Re-fill the boiler to the sight gauge water line, then check for leaks. Check again when the boiler has reached operating temperature.

IF there is water seepage at the sight glass you may try to gently snug the packing nut a very small amount - perhaps 1/8 of a turn.

Watch out: when tightening the packing nut, snug up gently by hand then tighten just 1/4 turn. Over tightening the packing nut is likely to break the glass or damage the control valve.

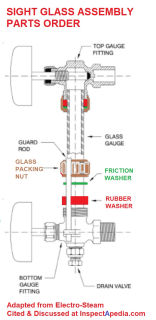

Watch out: if the sight glass packing and friction washer need to be replaced you'll need to completely unscrew those fittings, slide the packing nuts and friction washer and compression washer or packing onto the sight glass tube in the proper order then re-assemble the unit.

Slip the following items through the top of the glass gauge (tube) in this order:

- Friction Washer

- Glass Packing Nut (facing down)

- Glass Packing Nut (facing up)

- Friction Washer

- Rubber Washer

How to Clean the sight glass on a steam boiler

Some steam boiler additives intended to avoid frothing and to control the corrosive chemistry of water in the boiler will also help reduce soiling and scale formation inside the sight glass.

Some steam boiler additives intended to avoid frothing and to control the corrosive chemistry of water in the boiler will also help reduce soiling and scale formation inside the sight glass.

But in a badly obscured sight glass actual cleaning (or replacement) may be in order.

In fact many steam boiler instructions specifically call for annual (or even more-frequent) replacement of the sight glass itself.

To physically clean an otherwise intact sight glass that has become impossible to read due to scale and debris (like the sight gauge in our photo at left) you'll need to remove the glass (as described above) and use a small diameter bottle brush (or make-shift brush) to clean the tube interior.

As the sight glass crud is probably going to include a hard mineral scale, you may need to soak the sight glass in vinegar over night - making this a task to do when you don't need the heating system.

Frankly given the trouble involved I'd probably just replace the glass with a new one of the proper diameter and length.

Reader Question: what are those red knobs above and below the sight glass on my steam boiler and which way do I turn them

What are the red knobs above and below the sight glass for and how should they be turned? - Anon 10/15/12

Reply:

The red control valves at the top and bottom of the steam boiler sight glass are water shutoff controls used to isolate the sight glass from the boiler to permit glass replacement should it break.

Closing both valves on the steam boiler sight glass also permits emergency, temporary heating system use if the glass is broken, though of course you no longer know the boiler water level.

Usually you close a sight glass valve by turning it clockwise; some sight glass valves have an ON-OFF direction arrow on them. Or you may need to just try the opposite direction from the position in which you find the sight glass valve when it's found to be open, active, or leaking.

Relationship of the boiler sight glass to adding boiler water

Water is added to the steam boiler manually by opening a water feed valve, or it is added automagically by the automatic water feeder (if your boiler has this device).

Even if your steam boiler has an automatic water feeder, you should still check the water level (and clarity) in the sight glass frequently, but the risk of a ruined boiler from lost water is of course much less.

See details

Watch out: one more warning: the LOW WATER CUTOFF VALVE itself needs to be regularly flushed on most steam boilers - during that weekly check, more or less often depending on the rate at which your particular steam boiler consumes water.

Failure to flush the LWCO (using the "blowdown valve") means that crud accumulating in the LWCO can prevent its proper operation - an unsafe condition.

Sight Glass Clues to Boiler Water Feed or Heating Boiler or Piping Leak Problem

At STEAM BOILER SIGHT GLASS REPLACEMENT FAQs we discuss the concern with boilers having mysterious increases in water level beyone what is called for. For manual-feed steam boilers we suggested these checks:

- Condensate is returning to the system from steam radiators and condensate return piping. If you re-filled the boiler while condensate was still returning to the boiler the result may be over-filling. But the fill level would not continue to increase indefinitely.

- A manual water feed valve is leaking into the boiler - causing continuous or indefinite overfilling.

- A combination boiler that includes a tankless coil for making domestic hot water is suffering from a leak out of the tankless coil into the boiler - also causing continuous or indefinite overfilling.

Steam Boiler Sight Glass Repair Parts Sources & Installation Instructions

- Start at your local heating equipment and parts supplier

Illustration of the order of assembling parts when replacing a steam boiler sight glass, adapted from Electro-Steam cited below.

[Click to en large any image]

- Check with the manufacturer of your steam boiler for replacement parts that match exactly the spacing and tappings on the boiler - this may give the easiest repair.

However many steam boiler sight glass control valves and the glass tubes themselves can also be easily replaced with a more generic unit. You'll need to know the size of the boiler tappings and the spacing between them. - Apollo Valves, WATER GAUGE & GAUGE GLASS INSTALLATION INSTRUCTIONS [PDF] Apollo Valves, Conbdraco Industries, Inc., 1418 Pearl St., Pageland SC 29728 USA, Tel: 704-841-6000, Web: Apollovalves.com

- AU Simos Boiler, Co, Unit 1, 33 maddox st, Alexandria NSW 2015, Australia, Tel: +61 2 8338 8660. The company also has offices in Melbourne AU. Tel: +61 3 9462 6700.

- ElectroSteam ELECTRO STEAM LB-100 -> LB-240 STEAM BOILER INSTALLATION INSTRUCTIONS [PDF] Electro Steam, Web: electrosteam.com

This document recommends that the sight glass be replaced every six months, and gives detailed sight glass replacement instructions at section 3.4 Replacing Sight Gauge & Rubber Washers (pp. 8-9) - Emerson PENBERTHY SERIES M FLAT GLASS GAGES INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS [PDF]

Excerpts:

Penberthy gages comprise six basic components. Each component may vary slightly, depending on the desired physical and mechanical properties for the gage. Use the exploded parts view in Section 11 as additional reference material. Chamber, Gaskets, Glass, Cushion, Cover, Bolting, Shield. - U.K. Cochran Spares, Cochran Spares Newbie Annan Dumfries & Galloway DG12 5QU Tel: +44 (0) 1461 306019, U.K., Website: http://www.cochranspares.co.uk/, boiler sight glass and water level gauges,

- USA John C. Ernst Co., Inc. Sparta, NJ, Tel: 973-940-1600 Tel: 1-888-463-7678 Email: info@johnernst.com, Website: http://www.johnernst.com/

- USA MSC Industrial Supply Co., Tel: 800-645-7270, Website: http://www.mscdirect.com/

- USA Park Supply of America, Park Supply Of America, Inc. 4600 Pecos St. Denver, CO 80211, Tel: 800.877.9449, Email: info@parksupplyofamerica.com, Website: http://www.parksupplyofamerica.com/

- REIMERS RHP330 - RHP510 HIGH PRESSURE STEAM BOILERS INSTRUCTION MANUAL [PDF] Reimers, - by ELECTRA STEAM INC. (Reimers Steam Boilers)

Excerpts:

4.) GAUGE GLASS:

The gauge glass protector must be installed at all times. When replacing glass be sure that the unit is not under pressure and is cool to touch. To do otherwise could cause scalding. Gauge glasses should be replaced annually due to internal wear. HOT! The valves and piping on this unit are hot when under pressure or heating up. Don’t touch!

If a leak is evident: Steam fittings can become loose during shipment and subsequently leak. Leaks through the gauge glass packing nuts occur more frequent than on other pipe fittings. It is easy to resolve these leaks if you are careful:

1. Ensure that the boiler is cold, drained and has no pressure or electricity.

2. Tighten leaking packing nut gently a quarter of a turn. Do not over tighten, as this will result in gauge glass breakage or in valve failure.

3. Fill boiler and operate normally.

4. Observe for more leaks and repeat steps 1 and 2 as required. - South Africa: Spirax Sarco South Africa, Sight Glasses, c/r Horn & Brine Street Chloorkop - Kempton Park Gauteng 1620 South Africa Contact Details Tel: +27 (11) 230 1300 Fax: +27 (11) 393 1478 Email: administrator@za.SpiraxSarco.com, Website: http://www.spiraxsarco.com/

The heating boiler leak diagnostic articles given below at "Continue reading" may also help troubleshoot steam boiler sight glass crud or leaks:

...

Continue reading at SIGHT GLASS, STEAM BOILER - home for this topic, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see STEAM BOILER SIGHT GLASS REPLACEMENT FAQs - questions & answers about fixing or replacing a sight glasss on steam boilers, posted originally at this article

Or see these

Boiler Water Control Articles

- BOILER CLEANER CHEMICALS / TREATMENTS

- BOILER LOW WATER CUTOFF CONTROL LWCO MANUALS

- LOW WATER CUTOFF VALVE, BOILER

- LOW WATER CUTOFF VALVE NOT WORKING

- LOW WATER CUTOFF CONTROL MANUALS

- SIGHT GLASS, STEAM BOILER

- STEAM BOILER FLOODING / SURGING REPAIR

- STEAM BOILERS GENERATORS CONTROLS, PRATT for some interesting history of steam generators & steam turbines.

- STEAM HEATING SYSTEMS & CONTROLS - home

- WATER FEEDER VALVE, HYDRONIC BOILER

- WATER FEEDER VALVE, STEAM

Suggested citation for this web page

SIGHT GLASS REPLACEMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to STEAM BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Power Technology and Engineering (formerly Hydrotechnical Construction), Volume 43, Number 4, 247-250, DOI: 10.1007/s10749-010-0105-4 - Thermal Power Stations, Temperature regime for damaged steam superheater coils, V. A. Bogachev (this is a PDF file - if you can't find contact SpringerLeak)

- [2] "Deaerator", Wikipedia, web search 12/18/11. Quoting:

The deaerators in the steam generating systems of most thermal power plants use low pressure steam obtained from an extraction point in their steam turbine system. However, the steam generators in many large industrial facilities such as petroleum refineries may use whatever low-pressure steam is available. - [3] Babcock & Wilcox Co. (2005). Steam: Its Generation and Use (41st ed.).

- [4] Thomas C. Elliott, Kao Chen, Robert Swanekamp (coauthors) (1997). Standard Handbook of Powerplant Engineering (2nd edition ed.). McGraw-Hill Professional. ISBN: 0-07-019435-1.

- Weil McLain Model 78 Boiler Manual, Boiler for gas, light oil, Gas/Light Oil fired Burners, Installation, Start-up, Parts, Maintenance instructions, Part No. 550-141-705/0600, Weil-McLain Administrative Office, 999 McClintock Drive, Suite 200, Burr Ridge, IL 60527

Tel: 855-248-1777

Consumer Inquiries: 800-368-2492

Technical Services: 800-526-6636 Technical Support for Contractors Only.

If you are a homeowner and are experiencing a problem with your Weil-McLain equipment, the first step you must take is to contact your installer or locate an HVAC contractor in your area. Website: http://www.weil-mclain.com - Bell & Gossett Air Separators and other heating system components, Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379.

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.