Heating Boiler Aquastat Immersion Well Grease

Heating Boiler Aquastat Immersion Well Grease

Thermal Conductive Paste Used with heating system aquastats

- POST a QUESTION or COMMENT about Aquastats controls used on Heating Boilers

Heating aquastat sensor probe immersion well thermal-conductive compound is used to assure good thermal contact between the sensor well (itself immersed in hot boiler water at a representative location) and the aquastat's temperature sensing probe.

This article series describes common operating problems with heating system aquastat controls and how these troubles are diagnosed and fixed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Do we need that heat-conductive grease in the aquastat sensor probe well?

To communicate the temperature of the water in the boiler to the controlling aquastat heat must flow from the boiler water to the surface of the sensor well - basically a steel tube mounted through an opening in the boiler body.

To communicate the temperature of the water in the boiler to the controlling aquastat heat must flow from the boiler water to the surface of the sensor well - basically a steel tube mounted through an opening in the boiler body.

The water heats the sensor well steel.

Heat flows from the water through the steel of the sensor well to the surface of the aquastat's temperature sensing probe.

If this probe is not in very good thermal contact with the interior surface of the sensor well the aquastat may not always control the boiler on-off cycles properly.

[Click to enlarge any image]

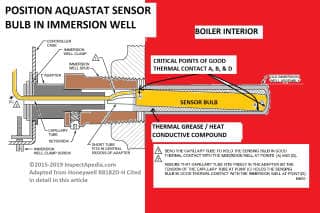

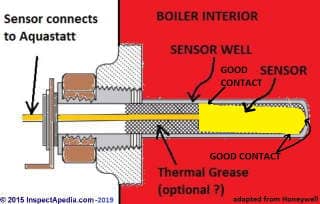

Boiler aquastat manufacturers like Honeywell recommend two main installation details to assure good thermal contact between the aquastat temperature sensor and the sensor well into which it mounts:

- Temperature Sensing Probe contact:

When installing the probe, gently bend the cap tube to assure that the outer top, inner bottom and end of the sensor probe are in solid contact with the immersion well surfaces - Heat conductive compound:

For immersion wells that are not a snug fit to the sensor probe, use a thermal-conductive compound such as Honeywell's Tradeline 107408 Heat Conductive Compound [grease] discussed here.

The thermal or heat-conductive compound or "grease" assures good thermal contact between the aquastat temperature sensing probe and the inner surface of the sensor well into which the probe is inserted.

Without this conductive compound in the boiler's aquastat temperature sensing probe well, even bending the aquastat sensor line to try to assure that it will have good thermal contact with the sensor well sides, that contact may vary over time, causing the sensor to flip the boiler on and off in too-short on-cycles.

The boiler aquastat may begin to misbehave, short cycling on and off or failing to turn on properly or turn off properly in response to boiler temperatures.

Watch out: if a boiler safety control such as an aquastat or limit control cannot sense the boiler temperature accurately the system is unsafe.

Illustration: Honeywell 107408, 120650, 197007 HEAT CONDUCTIVE COMPOUND [PDF] (1999) Honeywell Inc., 1985 Douglas Drive North, Minneapolis, MN 55422 USA, basic ingredients include Lithium complex grease (70%) and Aluminum paste (30%) in a stable compound. This product is specifically designed for installing aquastat sensor probes.

Watch out: be sure that the thermal-conductive compound you buy for installing a boiler aquastat probe is the correct product.

Sold by independent suppliers is also Accutemp AT0H-3412-2 Thermal Paste, type 120 Silicone Thermal Joint Compound, more information is at www.wakefield-vette.com described by the company as follows:

The 120 Series Silicone Oil-Based Thermal Joint Compound fills the minute air gap between mating surfaces with a grease-like material containing zinc oxide in a silicone oil carrier. It possesses an excellent thermal resistance of only 0.05°C/W for a 0.001 in. film with an area of one square inch.

There is no measurable increase in case temperature of a mounted semiconductor on a heat sink after the 6-month stabilization period. - source: http://www.wakefield-vette.com/resource-center/downloads/brochures/thermal-management-accessories-wakefield.pdf retrieved 2019/05/14

Notice that nothing in the Accutemp silicone joint compound mentions its use on heating boilers! For an even greater snafu, note that Wakefield-Vette's thermal compounds include not only a range of thermal greases and but also thermal epoxies. If some fool uses thermal epoxy to mount the sensor probe on a boiler aquastat we're sunk.

Reader Question: What Transfers Heat from the boiler immersion well to the aquastat sensor bulb?

6/1/2014 Heath M said:

I am curious about aquastats using immersion wells. I have 2 of them and i find that in general they are more accurate than the strap on type. However I find that they are still not as accurate as i would like to see them.

The 2 that i have there is nothing inside the well itself to transfer heat from the well to the copper bulb inside the well it just sits there making loose contact with the sides in some spots. It isn't even a semi snug fit they just dangle in there. Is there normally some sort of oil or heat sink compound that should fill the well for better heat transfer?

I can't help but think this would help increase accuracy.

Moderator reply: see our discussion below.

Aquastat Temperature Sensor Probe & Immersion Well Installation

Honeywell's R8182D-H AQUASTAT IO MANUAL [PDF] (2002) notes that included in the package for this control is a

Honeywell's R8182D-H AQUASTAT IO MANUAL [PDF] (2002) notes that included in the package for this control is a

Bag of heat-conductive compound for better heat transfer.

and includes these instructions:

IMPORTANT Be sure that the sensing bulb fits snugly inside the immersion well and that the sensing bulb rests against the bottom of the immersion well.

If the sensing bulb does not fit snugly inside the immersion well, use the heat-conductive compound as described below.

See Fig. 3. [see these figures, Adapted from Honeywell in 2015,Fig 3. revised 2019 - Ed.]

The following is excerpted from R8182 mounting instructions found in the Honeywell R78182-D-E-F-H-J AQUASTAT INSTALLATION MANUAL [PDF] (1995) - you 'll note that there is no mention of thermal conductive paste or grease in this older document.

3. Most boilers are equipped with a tapping that allows horizontal mounting of immersion well where average temperature boiler water circulates freely. If no tapping is provided, prepare one.

4. Install immersion well or compression fitting (ordered separately) by threading immersion well into tapped hole.

5. For R8182D,E,F models:

a. Loosen immersion well clamp screw on side of R8182 case.

b. Insert bulb into immersion well until it bottoms.

c. If necessary, bend capillary tube to hold bulb against bottom of immersion well. [Notice the three required points of good thermal contact at the sensor top, bottom, and end in our illustration below - Ed.]

NOTE: Do not make sharp bends in the tubing. A sharp bend can break the tubing and cause a loss of fill. In models with an adjustable tubing length, pull the extra tubing out of the controller case.

d. Fit controller case onto immersion well so that immersion well clamp slides over flange of immersion well.

e. Securely tighten immersion well clamp screw.

Reply: use of a thermal conducting grease with aquastat sensors

No question that strap-on units are less accurate and IMO less reliable so less safe.

I too am troubled by that contact-constancy problem and suspect it explains why there are sometimes short on-cycles of the equipment.

Watch out: IF the sensor probe does not fit snugly in the aquastat senor probe well then use of a heat conductive grease is recommended. And in all cases Honeywell advises that the cap tube is gently bent (no sharp radius) so as to assure good contact at three points in the immersion well - shown in more detail here.

Even when the sensor probe fits snugly into the sensor well, so that heat conductive grease is not going to be used, to guard against a future jam-up from corrosion some techs will wipe a think coating of silicone or an non-corroding stable lubricant on the probe surface before inserting it into the well.

[Click to enlarge any image]

If we read the installation instructions we're told to use a thermal conductive paste inside the well, as illustrated at above left in our adaptation from the installation instructions for

the AQUASTAT L7224U UNIVERSAL Universal programmable aquastat.

The use of the manufacturer's recommended thermal-conductive paste would go a long way towards overcoming the contact constancy question that you raise.

In discussing this with heating boiler service techs who do not bother with the thermal paste when installing the aquastat, I heard their complaints about the paste (thermal-conductive grease) asserting that using the grease makes it difficult to remove the device in the future as the grease "cements" the sensor into the well.

This may have been true for some products in the past but currently (2014 & recent years prior to that year) the thermal grease is not acting like a glue.

The manufacturer knows what makes their control work properly. The thermal-grease assures reliable and continuous thermal contact between interior surface of the immersion well on the boiler and the temperature sensing tip of the aquastat's heat probe.

Without this grease, thermal movement and possibly even slight corrosion that occur between the surface of the probe and the side of the immersion well can cause the temperature sensor to behave erratically.

The temperature-conductive grease is needed and should be used.

Honeywell feels so strongly on this point that a packet of heat conductive grease is packaged with new aquastats. I've read that the formula for the conductive grease was amended to remove a drying agent, preventing the heat transfer grease from gluing the sensor into the sensor well.

Worse, once the aquastat control has been installed without the recommended grease, if the boiler is cycling erratically and you want to add the conductive grease, and if it's a close-mount aquastat whose sensor probe extends off the back of the aquastat directly into the temperature sensor well on the boiler, taking the aquastat back off to then add the conductive paste or grease is a fair amount of trouble that the tech certainly doesn't want to tackle.

Unless the senor well is snug around the sensor probe, get some heat conductive grease and use it, along with bending to get the proper thermal contact points, when installing the heating boiler aquastat sensor into the aquastat well.

Also see SPA / HOT TUB HEATER REPAIR

Reader Question: my bad heating system aquastat only runs after we give it a good smack

Thank you for a wonderful and informative website! We have an boiler for our radiator system in our home but it's not starting up unless we smack the cover of the aquastat repeatedly ... and then it clicks a few times the burner flames eventually starts up - after a few smacks. If you can provide any insight to our problem, we'd greatly appreciate it. Thank you, J.D. 11/27/2013

Reply: smacking the aquastat - things to check: loose wires, buzzing, overheating, burning, damaged aquastat control

Nice question.

Where is the aquastat mounted? On the boiler itself or remotely say, on or next to the oil burner?

Nice question.

Where is the aquastat mounted? On the boiler itself or remotely say, on or next to the oil burner?

I ask because part of diagnosing why smacking or tapping on an electrical control does something involves figuring out what you may be jiggling in the control when you rap, tap, or smack it.

I suspect a loose wire, loose connection, failing aquastat relay, or possibly a bad connection between the aquastat's temperature sensor and the sides of the well into which the sensor is inserted.

Of course there may be some other issue we haven't thought-of - something that would be immediately apparent to an astute heating service technician.

Start by turning power off (watch out for fatal electrocution hazards) and checking that all of the connections are tight.

Don't forget to check the thermostat wires too. Also listen for buzzing relays in the aquastat.

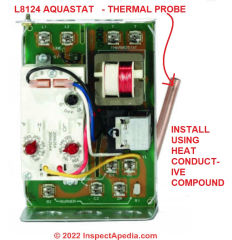

In the aquastat photo above left I'm pointing to a relay that may be buzzing if it's failing.

While the cover is off of the control, look with care for evidence of overheating or burning around any of the wire connectors or contacts.

Below we see overheating - burn marks around the lower-left power-connection screw.

In my photo below right my pencil points to burn marks on the printed circuit board of a Honeywell L8124A aquastat on the reverse side of the overheated wire connection terminal shown above.

This aquastat was behaving erratically for a year or more before a sharp heating service tech from Bottini Oil (Poughkeepsie) spotted the damage.

We replaced the control.

Some contemporary aquastat wells are smaller in internal diameter (often 3/8" ID) than those found on some older boilers (sometimes 1/2" or 3/4" ID) and are typically 1/2" or 3/4" in nominal spud thread or tapping diameter and in varying lengths, comprised of brass, copper or stainless steel, also referred to as insertion wells or shells.

Oil Burner Short Cycling Traced to Poor Aquastat Temperature Sensor Contact: use the heat conductive grease

We have observed occasional short or sporadic oil burner (and some gas burner) "on" cycles that were hard to track down. Technicians even replaced aquastats on a test system we've been monitoring, only to have the problem continue.

Way back we traced the burner on cycle problem to poor contact of the aquastat's temperature sensor in the sensor well.

After assuring that the problem was not in the room thermostat, that there were no loose wires, that the aquastat relay was working normally and in fact that the whole aquastat was new, it was following the manufacturer's installation instructions to use a heat-conductive grease in the aquastat sensor well that fixed the problem.

On 2019-02-16 8 by Paul - Burners won’t shut off

Burners won’t shut off at set aquastat temp. Only shuts off after overheating. Had a new pump and aquastat installed but the problem is still occurring.

On 2019-02-16 by (mod) - Burners won’t shut off at set aquastat temp.

Check that the aquastat's temperature sensor is properly installed in the sensor well and that you used the heat-conductive grease recommended by the manufacturer.

Check also for mis-wiring or a failed control relay.

On 2018-03-04 by Brandon - will not shut off at temp it's set to 180 but it is blowing off at 240

So I changed the s8610f because of a bad ignition module with s8610u the furnace fires over but will not shut off at temp it's set to 180 but it is blowing off at 240 could this be a bad aquastat or is aomething changed on the new s8610u module I have had 2 hvac people hear and they can't figure out the problem as well

On 2018-03-05 by (mod) -

One of the first things to check is whether or not the sensor probe is in good contact in the sensor well in the boiler.

Also know that the manufacturer usually suggests using a thermal conductive Grease. It's also possible that the sensor itself is actually bad.

Free Up Aquastat Temperature Sensor Probe Stuck in Old Thermal Grease?

Question: How do you get a aquastat out of the thermal grease

Question: How do you get a aquastat out of the thermal grease

On 2019-05-13 by Skip

How do you get a aquastat out of the thermal grease that is acting like glue??

Reply: How to free a stuck aquastat probe when thermal grease in the sensor well has hardened:

On 2019-05-14 by (mod) -

Skip

Thanks for posting what is indeed a more-serious problem that meets the eye.

I've gotten stuck wires out of the thermal well by opening the well cap and probing into the well - it's basically a steel tube with a closed end - to loosen gunk around the probe - until I could remove the probe assembly.

Some service techs make a tapered "shim" or chisel out of a section of copper tubing or copper pipe of an appropriate OD size (such as 3/8 OD). That rounded tool, shaped and sized to be just smaller than half the diameter of the aquastat senor probe sensor well interior is then tapped into the well while being held against the well side.

A few taps in and you can (sometimes) free the probe and clean out the remaining dried out grease.

Really? Well not always: you may be able to use a thin steel shim to free-up a stuck aquastat sensor probe if it is stuck in an older, larger-diameter sensor well, but if the jammed sensor probe itself is quite close in size to the sensor probe well internal diameter, then there may not be much working room to use a tool to free-up the probe.

In that case you will probably have to drain the boiler and replace the aquastat well as well as the aquastat temperature sensing probe.

Above: a Honeywell® 3/4" spud diameter 3" long x 3/8" ID sensor probe well or aquastat well intended to receive an aquastat probe that is 5/64" in diameter. That's inserting a 5/64" OD sensor into a 24/64" OD sensor well ID, still leaving considerable wiggle room.

Watch out: doing that will perhaps ruin the thermal sensor end of the probe and you'll ned to replace that assembly.

Boiler and aquastat manufacturers learned about the glued-in aquastat probe problem quite some time ago and improved the thermal grease to stop the problem in newer installations.

Unfortunately some old-school heating techs had so much trouble with stuck-in probes in the old thermal grease that after trying solvents (dangerous on hot boiler) and resorting to chipping and hacking, and in a few cases resorting to boiler drain-down and replacement of the whole thermal well - after all that aggravation the techs just started leaving off the thermal grease entirely.

If you have to replace the thermal well - aka aquastat well or sensor probe well, the job is of course a longer and more-expensive one.

Watch out: Don't forget to check the sensor well tapping area for leaks after you've re-filled the boiler and returned it to operating temperature.

Contemporary aquastat wells are smaller in internal diameter (often 3/8" ID) than those found on some older boilers (sometimes 1/2" or 3/4" ID) and are typically 1/2" or 3/4" in nominal spud thread or tapping diameter and in varying lengths, comprised of brass, copper or stainless steel, also referred to as insertion wells or shells.

If you can absolutely not get the sensor probe out of the well it's possible that someone used expanding foam sealant or an adhesive or simply didn't use the proper thermal grease.

Today's thermal grease products may get thick and viscous but they won't leave the sensor probe glued into the sensor well.

That led to a different problem: at least for larger sensor immersion wells with smaller probes, you NEED that thermal grease to assure good contact between the aquastat's temperature probe and the side of the well into which the probe is inserted.

If you leave out the grease entirely there is poor and unreliable contact between probe and sensor well body.

Watch out: The result is an aquastat that does not respond properly to boiler temperature, turning on or off at the wrong temperature, or sometimes a bounce problem that causes very short cycling on and off at the burner - in turn that can lead to loss of heat or on an oil boiler even to a puffback explosion.

Post a photo or two of your aquastat probe (one per comment) and if I can see enough to make more suggestions I'll be glad to do so.

2022/05/26 (Moderator) do I need to use thermal grease when installing the sensor for an aquastat control ?

@Anonymous,

Thank you for a helpful question about using the thermal grease when installing the sensor for an aquastat control.

The answer is yes, the thermal or heat-conducting compound is necessary.

I know that some older service technicians omit this important step, griping that the thermal paste used to get so hard that they couldn't remove the old sensor. That's not a problem with the current thermal conductive grease, and if you run into an old thermal sensor well that's not usable it should be replaced anyway.

The use of the heat-conductive compound when installing the aquastat sensor is important because without it the ability of the sensor to accurately and consistently sense the temperature of the boiler's water will be reduced and its performance can also be intermittent. A result is erratic operation of the control.

So follow the manufacturer's instructions and use the heat conductive compound.

The excerpt below is from installation instructions for the L8184 Aquastat - which I think is what you meant. I don't know of an aquastat with model No. L8123. If you have one do attach a photo.

I am guessing you meant to type

Honeywell L8124 Aquastat Relay described in

AQUASTAT L8124 A-M INSTALLATION & OPERATION MANUAL [PDF]

Instructions:

1. Shut off the electric power and remove the old control.

Leave the old immersion well in place if it is suitable for

use with the L8124, either with or without an adapter. A

124904 Well Adapter can be ordered separately; see

form 68-0040, Immersion Wells and Compression

Fittings, for ordering information.

2. If the old well is unsuitable, drain the system, remove the old well, and install a new immersion well. Refill the system. Refer to form 68-0040, Wells and Fittings for Temperature Controllers, to order a new well. Make sure the well is tightly screwed in to prevent leakage.

NOTE: Do not attempt to tighten the well using the case as a handle.

3. Loosen, but do not remove, the immersion well clamp

screw.

4. If the immersion well fits the L8124 Immersion Well

Clamp, proceed as follows:

a. Partially fill the immersion well with heat-conductive

compound.

b. Insert the bulb into the well. The bulb must bottom in

the well.

c. Make sure the well fits into the hole in the case.

Properly position the clamp on the well flange; then

tighten the clamp screw.

d. Center the loop of excess capillary tubing in front of

the immersion well so it cannot touch any electrical

parts.

Source:

AQUASTAT L8124 A-M INSTALLATION & OPERATION MANUAL [PDF]

These immersion type controllers provide high limit, low

limit, and circulator control in forced hydronic heating

systems that include domestic hot water.

Also more details about your aquastat and the thermal heat conductive compound at

AQUASTAT SENSOR PROBE HEAT CONDUCTING COMPOUND

and

AQUASTAT SENSOR PROBE STUCK in the AQUASTAT WELL

Thermal grease should be provided in the package with a new aquastat, but if yours is missing you can use a product widely-available such as this SUPER LUBE SILICONE HEAT SINK COMPOUND [PDF] shown below

and detailed at

https://inspectapedia.com/heat/Super-Lube-Silicone-Heat-Sink-Grease.pdf

On 2022-05-26 by Anonymous

Is heat conducting compound needed when installing l8123a aquastat

...

Continue reading at AQUASTAT TROUBLESHOOTING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

AQUASTAT SENSOR PROBE HEAT CONDUCTING COMPOUND at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Bottini Fuel service manager Ron Thomas for discussing aquastat functions, low limit controls, oil burner short cycling causes, and boiler maintenance, reliability, and service contracts 4/13/2010. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- Thanks to reader powderfinger5 for careful reading of this text and suggesting clarifications - August 2011

- Thanks to reader Gary (Buddy Cat) for careful reading & editing - November 2012

- Honeywell Corporation, control installation guides for Honeywell aquastats and other heating and cooling controls: see http://customer.honeywell.com

- Honeywell L4008E Aquastat high limit,manual reset, aquastat controller instructions

- Honeywell L4006, Manual Reset Strap-On Aquastat (high limit control, 100 to 240 °F) [we consider strap on controls less accurate and reliable than immersion type sensor controls; these were commonly found on older heating boilers including the GE series downfired boilers]

- Honeywell L4026B Aquastat control instructions (contact Honeywell Corporation) Here is some basic description of the Honeywell L4026B control, also available at www.honeywell.com

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.