Guide to Heating System Boiler Limit Controls & Strap-On Aquastats, their Settings & Wiring

Guide to Heating System Boiler Limit Controls & Strap-On Aquastats, their Settings & Wiring

- POST a QUESTION or COMMENT about temperature limit controls used on heating boilers: strap-on type limit controls & aquastats - diagnosis, repair & replacement advice

Single function boiler limit control switches, strap-on aquastats or limit controls on heating equipment: here we explain the functions and typical settings single function limit controls and for strap-on limit controls or aquastats used on both hot water heating boilers and on water heaters

This article series answers most questions about Heating System Boiler Controls on central heating systems to aid in troubleshooting, inspection, diagnosis, and repairs.

The photo above shows a Honeywell R8182D combination heating control, also called an "aquastat". Contact us to suggest text changes and additions and, if you wish, to receive online listing and credit for that contribution.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Single-Function Heating Boiler Limit Controls

Use of a single function limit switch on boilers & tankless coils

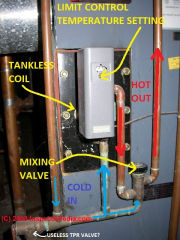

Here (above) is a photo of a more traditional single-function heating boiler limit controls. In this example the aquastat or limit switch is being used on a tankless coil that happens to be on steam boiler. If you click the image to enlarge the photo, you'll see that the temperature limit on the control is set to about 140 °F.

[Click to enlarge any image]

Our second photo (below shows a limit switch used on direct vent Energy Kinetics System 2000 boiler installed in 2004.

Click to enlarge the right hand photo and you'll see that this limit control is set to keep the boiler temperature between 96 °F. and 102 °F. A dab of red paint show at the 5'o-clock position on the dial enables the service technician to detect if someone has adjusted the control off of its factory setting.

When a heating boiler uses a tankless coil to produce domestic hot water, a third single-function control may be installed for that purpose.

In this photo a Honeywell limit control switch is being used to monitor hot water temperature at the tankless coil which is in turn mounted on a steam boiler of an older home in Portland, Maine. You can see the black-handled mixing valve in the lower right of this photo.

Cold water from the building is entering the tankless coil via the bottom pipe (green corrosion) and hot water, heated by the coil is leaving at the upper part of the tankless coil, where it turns downwards to enter the left side of the mixing valve.

Additional cold water is permitted to enter the bottom of the mixing valve, and tempered (non-scalding) hot water then leaves at the right side of the mixing valve in this photo.

More information about tankless coils, how they work, what goes wrong, and their controls, is

at TANKLESS COILS.

Use of Two Individual Single Limit Control Switches to Control Heating Boiler Hi and Low temperature settings

On heating boilers where individual limit controls are installed, you will find two similar devices, but mounted at different locations on the boiler, controlling the boiler's HIGH limit, or cut-off on a call for heat, and the boiler's LOW limit or cut-on point as the boiler water temperature falls.

We noticed three individual limit controls on this steam boiler in a photo contributed by reader H.H. who was discussing expansion tank draining.

There are two strap-on limit switches on the riser pipe at right, and an immersion-type limit switch that has been added over a plumbing tee atop the boiler behind and to the left of the steam gauge. I'm not sure that that immersion limit switch is installed according to the manufacturer's instructions.

They may want the switch mounted directly on the boiler not on a tee and riser above the boiler - just speculating.

Guide to Strap-on Aquastats as Heating Boiler or Water Heater Controls

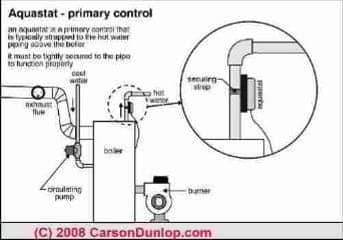

An older type of aquastat used to set boiler temperature limits was strapped to the hot water riser pipe close to the top of the heating boiler.

This device is shown in Carson Dunlop Associates' sketch and in our photograph above.

[Click any image to see an enlarged version.]

Rather than a temperature probe inserted directly into the heating boiler's water (as used by modern aquastats) the strap-on type aquastat relies on metal-to-metal contact between the control and the boiler water riser pipe.

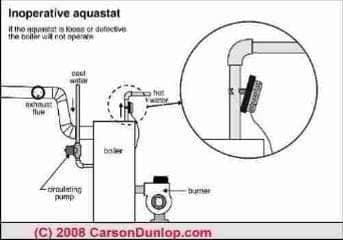

If your heating system is controlled by a strap-on aquastat such as shown here in Carson Dunlop Associates 's, you'll want to check that it has remained securely in place.

If the aquastat becomes loose its contact with the hot water pipe is lost and the system is unsafe.

How to test the limit control switch

Reader question: How do I test my Operator Limit Control.on my Lochinvar boiler to see if it is bad? - Kelley 12/15/2012

Reader question: How do I test my Operator Limit Control.on my Lochinvar boiler to see if it is bad? - Kelley 12/15/2012

Shown here: Honeywell L4006-series high-limit aquastat.

Find manuals for this and other aquastats

at BOILERS - HOT WATER HEAT CONTROLS used on heating boilers & some water heaters

Reply:

Kelly,

Most single function limit controls do not have owner-accessible test functions, buttons, or devices. Here are some simple tests that a trained heating service technician might do with a single function limit switch:

- Compare the actual boiler temperature (on the boiler gauge) to the setting on the limit control. If you see the boiler temperature above the setting on the limit control we suspect the control is not functioning or is not properly mounted or installed

. For example poor contact between the control sensor and the heat source can cause misreading of boiler temperature. Don't panic if the difference is just a degree or two - as these controls are not that precise. - With the boiler operating at its normal maximum temperature - after it has been running continuously for five minutes or more, notice the actual boiler temperature on the boiler TP gauge.

Now set the limit switch to 5-10 degrees below the actual current temperature. That should cause the oil or gas burner to shut down. I must say that while this procedure should work, it is not a part of normal heating system service and inspection, and it's something I never did during my years of work as a service tech.

Watch out: don't keep cycling the control setting back and forth, turning the oil or gas burner on and off repeatedly. Turn off the boiler, wait five minutes, then restore the limit control to its original setting. Then turn the heating boiler back on.

- Inspect the control for visible damage or worries such as leaks onto or into the control, loose mounting, or signs of overheating of wiring or electrical components, bent components, tampering. And for strap-on controls, see our warnings about proper control mounting.

- If you give us the brand and model of your limit switch we (or you) can ask the manufacturer for a copy of the installation and maintenance instructions for that specific device.

Often the instructions contain specific advice about testing the control. In general, information about Lochinvar heating equipment is available from the company - give them a call at 615-889-8900, or contact Lochinvar Technical Service at 1-800-722-2101.

Snap-Action Temperature Limit Controls

Reader question: where to buy a Klixon replacement limit control for an American Standard heating boiler

todd said:

I am working on an american standard boiler that has two klixon limits for high limit control, Stemco K4, one at 198 the other at 220. are they still available 2/25/2014

Reply: Klixon - Sensata Snap-Action thermostatic sensors for HVAC/R applications

Todd, I don't know if the original Klixon limit controls you describe are still available, but the company is certainly around. You can contact the manufacturer at:

Sensata Technologies

529 Pleasant Street, MS B19

Attleboro, MA 02703-2964

Phone 1-888-438-2214

email: sensors@sensata.com

www.sensata.com

www.

Klixon.com

Sensata is a huge company, with offices world-wide, so you'll want to make clear what you want so as to be directed to the proper supply outlet without a lot of arm waving. The Klixon type limit controls rely on a snap-action temperature sensitive electronic switch that may be replaceable if that's all that's failed.

Send me sharp photos of the parts you seek and I may be able to comment further - use the CONTACT link found at page bottom or top.

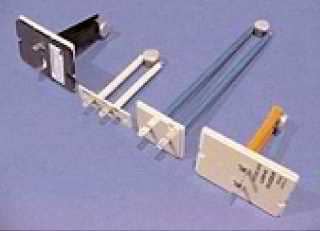

For forced air furnaces the company describes their HIGH TEMPERATURE LIMIT THERMOSTATS - 1NT Series “Stat-on-Stilts”™ Extended Airstream Mount for Gas and Electric Furnaces . I found this by searching the company's site for "furnace limit control".

Designed as a safety switch for gas and electric furnaces the Sensata “Stat-on-Stilts”™ may be used anywhere a temperature switch must be mounted remotely from electrical terminations. The most common application is as the primary temperature limit in gas furnaces and unit heaters.

At below left you can see Sensata's Klixon snap action thermostat switch examples and at below right their intresting "Stat-on-Stilts" sensors. But to choose the correct product you'll need to consult the limit switch manufacturer directly.

For hydronic boilers the company describes Thermal cutouts includine the MA10, TH10, TH11, & TH21 and heating line break thermostats include the 20600 Series and 20490 series.

Also see FURNACE FAN CYCLES DURING HEAT where we discuss an example of using a snap-action heat sensing switch in furnaces, the Termo-o-Disc fan limit control. In that article we list sources of snap action type thermostat switches and controls for HVACR equipment.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: can you sell me a strap on limit control?

Sept 30, 2014) Jim Sambrook. Email: jafs2@btinternet.com said:

I am looking for a strap-on temperature switch to fit to the boiler outlet water pipe that switches the boiler on at a lower temperature and off at a higher temperature. Can you help.

Reply:

NO Jim, to avoid conflict of interest and maintain reader trust we don't sell anything. Stop by your local heating supplier for an aquastat controller but better, install an immersion well type if you can.

Question: setting the strap on limit control on a wood-oil boiler

(Oct 18, 2014) Mark said:

I have an Addon Harmon wood boiler and a peerless gas boiler. I already have Johnson controls on the wood boiler and I was thinking of adding a Honywell 4006 strap on Aquastat like there was before. What shot I set these controls to. 160-180 for the main circulator? And 140-160 for the strap on so the Gas comes on when the Wood boiler goes out?

Reply:

Please see WOOD-OIL COMBINATION HEATERSfor a discussion of the tricks of controlling these systems.

Question: two aquastats, one is rusted and tehre's a leak

(Nov 14, 2014) Tony said:

I have two AquaStats snap on, recently one has been rusting due to a water leak on the Actuator's valve. The leak happens when when the AC is on, during Heat mode, the Actuator closes one of the valve and there no leaks.

Are both of the AquaStats snap on suppose to be on the same pipe (Heat). Is there a way I can send you pictures as I have model numbers and comparisons pictures of new replacement parts and picture of my parts.

Reply:

Not necessarily: where the aquastats are mounted depends on what each is controlling. Use our page bottom CONTACT link to send me system photos for comment.

Question: wood gas boiler combination controls

(Nov 20, 2014) WadeMc said:

I have set up my wood/gas boiler, I included an emergency bypass N/O held closed by pass valve incase of a runaway wood boiler.

I was to use a clip on RTD to attach to a 1" pipe. What kind of set up, or aquastat will work at a tripping temperature of 180 degrees F?

Thanks, Wade

Reply:

Wade

Watch out: I don't have the whole picture but this does not sound safe to me. Normally one protects a boiler from explosion using a properly sized and located TP relief valve not an electrically operated zone valve. Solid fuel systems also include damper controls to avoid overheating.

Question: figuring out the temperature scales on a limit control switch

(Nov 28, 2014) Anonymous said:

Click to enlarge the right hand photo and you'll see that this limit control is set to keep the boiler temperature between 96 °F. and 102 °F.

I think this might be wrong (top right photo).

The lower scale is Celsius (96 C. to 102 C.).

So in Fahrenheit (upper scale) it's 205 F. to 215 F.

Please correct me if I'm wrong. I'm trying to figure out why there are two temperature scales. I'm also trying to figure out why someone would keep their boiler at 102 F. I'm also trying to figure out why some one would keep their boiler at 215 F.

Reply:

Anon

Indeed on the limit switch control dials in one of our photos above you can see both F (Farenheit) and C (Celsius) temperature scales - the manufacturer intends the control to be used in marketplaces that use either of those temperature reading scales.

You can convince yourself that you understand the scale by noting that at 200F on the Farenheit scale you'll see the Centigrade scale reading about 93C.

Keep in mind that these instruments are not lag grade in precision. A service tech may have adjusted a setting slightly up or down from common levels to obtain equipment performance that was wanted.

Typically we won't see a residential heating boiler operating at over 200F.

We might see domestic hot water temperatures (water heaters, or boiler water when only a tankless coil is in use) at much lower temperatures, typically under 120F.

Question: what is the right setting the strap on limit control?

(Dec 4, 2014) Jim said:

We just bought a house with an old oil-fired boiler with a single zone and single circulator pump. It has OLD strap-on limit controls, both on the hot side just above the boiler. One limit control is the high temperature shut-off for the burner, the other controls the circulation pump.

The boiler is currently set to 180, which seems right to me. My question is, what temperature should the circulation pump temperature sensor be set for?

Reply:

Jim, typically the high limit control is set 180 to 200. I like 200 as more efficient. A low limit on your boiler may be used with a tankless coil -

is one In Use on your system?

If so it may want to lock out the ccirculator to give priority to the coil at temps 120 or below.

(Dec 4, 2014) Jim said:

Thanks for the response. This is an old stand-alone oil fired heating system with a multi-section cast iron boiler with no tankless coils. I'm trying to get the best efficiency out of it, so I will test the actual temperature with an infrared thermometer and set the high limit to 200. With regard to the circulation pump, I'm trying to determine the correct temperature to start/stop the pump to obtain the best efficiency.

My instinct tells me that the pump should run whenever the water temp is heating the house (within reason...for example, when heating the house to 70, shut off the pump at 90-100), but that may not be the most efficient thing to do. What do you think?

Reply:

Jim

Watch out: one of the down sides of those old strap-on controls is an inaccuracy in sensing temperature - the control is depending on good thermal contact between the pipe surface and the device sensor.

I'm unclear on how the lower limit is being used on your system, but most likely it's just as you say - intended to operate the circulator and includes two ranges - a cut-in and a cut-out. Send me photos and brand, and part number and we can dig up the specs and instructions. Use the email at our CONTACT US link found at page bottom or top.

There is argument about circulating water temperature limits. IN some areas (including much of Canada) circulators run as long as the boiler is switched on, and the TT just turns the burner on and off. Benefits are more even heat distribution and reduced risk of freezing.

Question: System 2000 EK-2f : setting the White Rodgers Aquastat?

(Jan 7, 2015) Mike said:

I have a syste 2000 Ek-2 f I stupidly moved the seting on the white - Rodgers aqua stat. It has two permanent tabs and a screw with two gears which rotate. Can anyone tell me where to put these back to factory settings? I guess meaning first, the main dial should be pointed at the arrow at what temperature.

Then my next question would be the arrow with the screw on it needs to be set at what number? Help please.

Reply:

Mike if you are discussing a single-purpose limit control most likely the large dial is the upper limit and a smaller dial on the side of the unit is a DIFF setting. But I'm not sure - maybe if we saw a sharp photo of the control (use the email at our CONTACT link at page top or bottom) or if you tell me the aquastat model number we can be more specific.

There should be a label inside the aquastat cover that gives brand, model and maybe even setting information. With that data you or we can find the installation and operation manual for the control.

...

Continue reading at LIMIT SWITCH, BOILER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AQUASTAT CONTROLS - used on heating boilers & some water heaters

- AQUASTAT SELECTION GUIDE - complete list

- HONEYWELL L4006A,B,E, H HIGH LIMIT CONTROL MANUAL [PDF] (2005)

- HONEYWELL L4006A,B,C,E,G and L4007A CONTROLLERS MANUAL [PDF] (older units)

- HONEYWELL AQUASTAT L4080B,D & L8080A HONEYWELL MANUAL [PDF]

- HONEYWELL AQUASTAT L4080B,D,F,G & L8080A HONEYWELL MANUAL [PDF]

- FAN LIMIT SWITCH for limit controls on forced warm air heating systems.

- INDIRECT HOT WATER HEATER TEMPERATURE CONTROL

- LIMIT CONTROL, SINGLE

- LIMIT SWITCH, BOILER

- MANUALS & PARTS GUIDES - HVAC - home

- MANUALS for HEATING & A/C SYSTEM CONTROLS - home

- TANKLESS COIL HOT WATER HEATER TEMPERATURE CONTROL

- OIL HOT WATER HEATER TEMPERATURE CONTROL

Suggested citation for this web page

LIMIT CONTROL, SINGLE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [2] Thanks to Bottini Fuel service manager Ron Thomas for discussing aquastat functions, low limit controls, oil burner short cycling causes, and boiler maintenance, reliability, and service contracts 4/13/2010. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- We provide links just below to several aquastat installation, setting, and adjustment documents in response to reader requests and comments that people sometimes have difficulty finding this information. But readers looking for specific aquastat control information should always first try the control manufacturer.

- Armstrong 24-hour time and aquastat control accessory: provides on/off pump control according to preset operating times, designed only for use with specified Armstrong Astro series wet roto circulators installed in indoor hot water re circulation applications. Typical timer applications will cycle the pump at preset times, allowing the user to select operation of the circulating pump during high peak usage periods in order to decrease the delivery time to outlet fixtures and reduce wasted water, also available at www.honeywell.com

- [5] Honeywell Corporation, control installation guides for Honeywell aquastats and other heating and cooling controls: see http://customer.honeywell.com

- [6] Honeywell L4008E Aquastat high limit,manual reset, aquastat controller instructions

- Honeywell L4041A,C Pool Heater Aquastat Controller Instructions, also available at www.honeywell.com

- [8] Honeywell L4006, Manual Reset Strap-On Aquastat (high limit control, 100 to 240 °F) [we consider strap on controls less accurate and reliable than immersion type sensor controls; these were commonly found on older heating boilers including the GE series downfired boilers]

- [9] Honeywell L4026B Aquastat control instructions (contact Honeywell Corporation) Here is some basic description of the Honeywell L4026B control, also available at www.honeywell.com

- Honeywell L4029 Reset Limit Control, also available at www.honeywell.com

- Honeywell L4103A,B,C Combination Aquastat and High Limit Controller Instructions, also available at www.honeywell.com

- Honeywell L6006A Aquastat Controller installation instructions, also available at www.honeywell.com

- Honeywell L6006 and L6007 Aquastat Controllers, installation instructions for the trained service technician, these controls combine low or high limit and circulator control, with or without an immersion well depending on the control model A,B, C etc., also available at www.honeywell.com

- [14] Honeywell L6191 Dual aquastat immersion thermostat, also available at www.honeywell.com

- Honeywell L7224 Aquastat Controller, oil electronic controls allowing high limit, high limit differential, low limit, and separate low limit differential settings - set to the specifications of your oil heating equipment manufacturer - 69-1957-1 L7224 Series controls, also available at www.honeywell.com

- Honeywell L7224U Oil Electronic Aquastat Controller - 69-1720-2 series instructions. These newer aquastat controllers are often used to replace the older Honeywell L8124A series that was and remains widely used, also available at www.honeywell.com.

- Honeywell L8124A,B,C,E,G,LO,M Aquastat Relays immersion type controllers for forced hydronic heating systems that include domestic hot water service (such as a tankless coil), also available at www.honeywell.com

- Honeywell R8182D,H Combination Protectorelay™ Primary Control and Aquastat® Controller Installation Instructions combination protectorelay Primary Control installation and operations manual, also available at www.honeywell.com

- [19] Lochinvar High Efficiency Water Heaters, Boilers & Pool Heaters, Lochinvar, LLC World Headquarters, 300 Maddox Simpson Pkwy., Lebanon, TN 37090, Tel - Customer Service: 615-889-8900, contact Lochinvar Technical Service at 1-800-722-2101 web search 12/15/2012, original source: http://www.lochinvar.com/

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.