Cad Cell Relay Switches on Oil Burners

Cad Cell Relay Switches on Oil Burners

Cad cell relay & sensor troubleshooting, installation, repair on oil burners

- POST a QUESTION or COMMENT about cad cell relay safety controls on oil burners & about sources of cadmium in homes

Cad cell relays on oil burners:

This article explains the operation, use, and reset button on Cad Cell Relay Controls.

We provide : a guide to inspecting and re-setting the cad cell relay safety device on oil burners. We describe how the cad cell relay and the cad cell sensor itself are tested.

We explain how the cad cell works to "see" the oil burner flame, what goes wrong in an oil burner that the cad cell "eye" can detect, and how cad cell sensors are tested using several methods including a VOM. We include cad cell trouble spots - particular oil burner installations or conditions that can make it hard for the cad cell to sense even a good flame.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Oil Burner Cad Cell Relay Controls

Flame sensing devices on oil-fired heating appliances: modern oil-fired heating furnaces, boilers, and water heaters use a Cadmium Cell

sensor, usually located inside the oil burner tube, to "see" the

presence of flame and thus to assure that the oil burner assembly stops pumping oil into the combustion chamber if flame ignition is

unsuccessful.

Flame sensing devices on oil-fired heating appliances: modern oil-fired heating furnaces, boilers, and water heaters use a Cadmium Cell

sensor, usually located inside the oil burner tube, to "see" the

presence of flame and thus to assure that the oil burner assembly stops pumping oil into the combustion chamber if flame ignition is

unsuccessful.

The cad cell itself, that is the little cell that "sees" the oil burner flame, is wired (often by a yellow wire) to the cad cell relay switch (see photo) which is usually a gray box with a red "reset" button located on top of or alongside the the oil burner assembly.

The cad cell causes the relay to switch the oil burner off when a flame is not established during oil-burner startup ("trial for ignition or TFI" in some manuals) or if oil burner flame is later lost at the

oil burner (or inside the furnace or boiler's combustion chamber).[2]

Our photograph shows a modern Honeywell(R) R8184G 4009 cad cell relay for use on (typical) intermittent ignition oil burner equipment.

This device is likely to be found on oil burners less tan 15 years old,

and on both hot air furnaces and hot water boiler heating systems provided that they are heated by an oil burner.

Just below is a photo of what the cad cell itself looks like. You cannot see this part unless the oil burner is disassembled.

The cadmium cell is simply a type of photo cell that is mounted in the oil burner tube, usually near the rear, where it can "see" the flame when the oil burner is operating properly.

If the oil burner flame is not present the cell passes that information on to the cad cell relay switch which will, after a delay of 15-20 seconds, shut down the oil burner.

You can see that if the glass surface of the cad cell sensor becomes coated with soot, it won't "see" the oil burner flame very well and it will, when dirty enough, shut down the oil burner.

How to Reset the Cad Cell Relay on an Oil Burner for Boilers & Furnaces

How to Reset the Oil Burner Cad Cell Relay:

The photograph shows an older Honeywell aquastat relay switch that may also make use of a cad-cell sensor. The gray box in the right in this illustration.

If the cad cell has told the relay that it can't see any flame, the cad cell relay switch will have turned off electrical power to the oil burner and the red button will have popped up.

If the red "reset" button on the cad cell relay is sticking up

and the oil burner has shut down, the homeowner is permitted to try ONCE to "reset" the system by pressing the red reset button.

Watch out: If the oil burner does NOT turn on and run normally and continuously (no smoke, no loud noises, etc.) for at least 5 or 10 minutes after resetting the relay or pressing the reset button,

DO NOT keep resetting the system since doing so can flood the combustion chamber with un-burned heating oil - a dangerous condition.

Where are all the heating system reset buttons?

If you are looking for the main reset button on heating equipment that looks like the gray box above, you'll want to

see: AQUASTAT CONTROL FUNCTIONS

and CAD CELL RELAY SWITCH (oil-fired hot water boilers, furnaces and some water heaters).

Your oil fired boiler or furnace might not have either an aquastat like the one just above or the separate cad cell relay control box shown earlier in this article.

Instead some older oil fired boilers, furnaces, and water heaters use a

separate STACK RELAY SWITCH and mounted on the flue vent connector piping.

Other heating system reset buttons may be found

at FLUE GAS SPILL SWITCH TRIPPING & RESET (gas fired equipment),

and also LOW WATER CUTOFF CONTROLS on steam heating systems.

At ELECTRIC MOTOR OVERLOAD RESET SWITCH we discuss the thermal overload switch and reset button that is found on many electric motors including those operating air conditioning fans, heating system oil burners, and furnace blowers and motors.

The photograph tells a lot about this oil burner and heating system. The debris on top of the cad cell relay contacts (pointed to by our ruler) indicates that the system is running dirty and perhaps with a puff-back at startup or with backpressure in the combustion chamber.

Look closely at the mostly-covered gray cover of this Honeywell cad cell relay control. In the upper center of the photo you can just see a hole in the top of the cover. Marked by an orange arrow, this is where we should have seen a red cad cell relay button.

Watch out: sometimes the red plastic button on older heating equipment primary controls can break off - like the one we show at left. .

At RESET SWITCH, HEATER REPAIR we show how to reset the equipment safely if this happens to you.

How to Test the Oil Burner Cadmium Cell Relay Switch & Switch Sensor

Watch out: Honeywell's instructions for R4184D and R8184G,M,N,P Protectcorelay® series of oil burner controls advises [4]

- Only a trained, experienced service technician should perform the troubleshooting procedure.

- This control contains no field-replaceable parts. Do not attempt to take it apart. Replace the entire control if operation is not as described.

However this instruction pertains to the control itself. The cad cell relay sensor is a plug-in replaceable part that can be cleaned or field-replaced if appropriate.

Button & Switch Tests of The Cad Cell Relay

There are three possible heating system trouble or failure modes addressed by this control:

- Flame failure: oil burner is running and flame becomes weak, or goes out

- Ignition Failure: oil burner fails to start running, flame does not successfully ignite within an allowed time interval

- Electrical Power Failure: electrical power fails during burner operation

In the first two cases the device will shut down the oil burner and require manual pressing of the reset button to attempt a re-start.

In the third case the burner should re-start when electrical power is restored.

Function-Testing cad cell relays: is possible by simply pressing the red button down when the oil burner is operating. If the oil burner is operating normally and you press the cad cell relay reset button down it should turn off the oil burner. When you release the button the oil burner should re-start.

This oil burner safety test checks the interrupt circuit in the cad cell relay.

We recommend not trying this test unless the oil burner has been on for a few minutes or more (and has had time to warm up) so that we don't produce unnecessary sooting in the combustion chamber during stop and start of the burner.

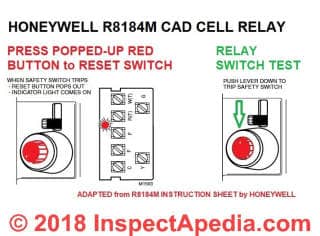

Using the Safety Switch "Test" Lever to Test the Primary Heating System Control

Using a Honeywell R8184G primary control as an example we illustrate the reset button (red arrow in our photo, below left) and the safety switch lever (black arrow, below left).

The red button is the "reset button" on this control.

On some equipment the round reset button is accompanied by a small thin lever or "switch" (the black arrow in our photo above left). On some older controls the safety switch lever is a thin silver metallic lever protruding through the control cover rather than the nice chubby black switch shown here.

If your control incorporates that little lever (which will also protrude out through the control cover) you can test the control by holding the lever down or in the opposite of its normal position (you may have to move it to one side instead of down depending on how the control is mounted).

Holding the switch lever out of its normal position for a short time will cause the safety switch to shut down the equipment and the reset button will pop out - sticking out further from the control cover. To re-start the burner, push the red reset button back in.

Resistance Testing the Cad Cell Sensor using a VOM or Digital VOM

Honeywell's description of their cad cell sensor used on their R4184D and R8184G,M,N,P Protectcorelay® series of oil burner controls describes it as follows:

All [Protectorelay series oil burner controls] models use the C554A Cadmium Sulfide (cad cell) Flame Detector to monitor the burner flame and shut down the system on ignition failure or on flame failure during the run cycle. [4]

Testing the Cad Cell Sensor Itself

Our photo of a cad cell relay being tested by our oil heating company service tech (Bottini Oil, Poughkeepsie, NY), shows how an expert can check on the cad cell function without disassembling the equipment.

- 0.5 Ohms to 600 Ohms: When the oil burner is firing, an ohmmeter reading of 1/2 ohm (close to zero) to a maximum of about 500 to 600 ohms (see note below) is normal.

Under 1600 ohms:

Beckett advises that a properly functioning cad cell control will measure under 1600 ohms but not zero resistance. - Above 1600 ohms:

check for a sooty cad cell sensor, a sensor that is misaligned and doesn't "see" the flame, or a bad oil burner flame itself (dirty or misadjusted oil burner). If the flame and alignment are good then replace the cad cell sensor. - Very high ohms: When the oil burner is not firing,

the reading across the cad cell terminals should be close to infinity, that is, high resistance. [1] That is, the cad cell is not seeing any flame.

If you see infinite resistance or an open circuit then most likely the cad cell eye is broken or a wire or connection is broken.

If the cad cell fails,

or more likely if a dirty oil burner flame soots up the face of the cad cell device, the soot blocks view of the flame and cad cell resistance will increase. (That's why at zero flame and when it's dark in the combustion chamber the cad cell will read infinite resistance.)

Significantly, Honeywell's Protectorelay installation and testing instructions do not include a recommendation for testing the resistance of the cad cell sensor. Instead the company recommends the test sequences described above, and note that if the cad cell is not responding to the flame, you should replace it [4] But before doing so

- Make sure that the cad cell you are testing is clean and all electrical connections good

- Make sure that the cad cell mounting bracket is properly located, un-bent, properly aimed, and clean.

- Some oil burner installations appear to depend in part on reflected light from the flame adding to the light signal perceived by the cad cell, so a very dirty oil burner assembly and burner tube may also interfere with proper operation.

Thanks to reader Tony for the following comment:

Hi, I love the work you guys do and think it can be a life saver when you may have exhausted all options. My comment is with regards to the section entitled "How to Test the Oil Burner Cadmium Cell Relay Switch", the sub titled, "Testing the Cad Cell Sensor Itself" section.

You mention that an ohm reading on the flame sensor terminals when the boiler is running should be .5 to .6 I took an ohm reading after having cleaned soot from an obstructed cad cell and got an ohm reading of 500 to 600.

I though my flame sensor was faulty. But then i opened the canopy containing the flame sensor and shined a 100 watt light (137 foot candles of illumination) bulb at the flame sensor with my friend taking the readings and compared the results to a specs chart on the flame sensor that charted foot candle power vs ohms and saw that 500 to 600 ohms was correct.

I realize i took the reading while the boiler was off but the wires from the cad cell to the terminal screws where connected and that may have given me a skewed reading but i just wanted to point out the difference between your recommended ohm results and what is observable to an average joe like me. - Ton6 2/11/2012

Other Cad Cell Sensor & Oil Burner Cad Cell Primary Control Troubles

Watch out: here are some other cad cell sensor troubles that can give odd readings, or that can cause the cad cell control to switch the heating system off on "reset"

- An oil burner that is adjusted with excessive combustion air

can sometimes produce a flame that is abnormally bright, giving abnormal cad cell readings, probably too low. - An oil burner that uses an oil nozzle that produces a very narrow flame,

combined with the high mount of the cad cell in the burner tube, can make it difficult for the cad cell to see the flame, even if the burner is operating properly.

Some oil heat service techs used to polish up internal components in the burner tube or even spray aluminum paint on surfaces to improve reflectance to help out the cad cell. In our OPINION those repairs are likely to be short-lived. - An oil burner whose squirrel cage fan is dirt-clogged

will eventually not get enough combustion air.

The result, at least for a while, is that the cad cell sees what was a narrow flame pattern before, even better as the weak flame curls up into view of the cad eye.

But of course weak oil burner flame is sooty flame which is likely to eventually soot up the cad cell eye so that it becomes blind. It will then shut the system down. Finally. - Modern oil burners in heaters with a small, short combustion chamber

use oil burner nozzles that produce a short flame. When the flame is burning well (without sooty curling up flame ends) it may be harder for the cad cell to see the fire.

Automated LED Readouts Give Cad Cell Relay Condition

On more advanced primary oil burner controls such as the Honeywell R7184 Series Primary Controls, the control unit itself is capable of monitoring the status of the cad cell relay. [2]

A series of LED flashes indicates the cad cell resistance in ohms (for this control) as follows:

| Honeywell Cad Cell Resistance (R7184 Series Primary Controls) | |

|---|---|

| R7184 Number of LED Flashes | Honeywell Cad Cell Resistance (ohms) |

| 1 | 0-400 |

| 2 | 400-800 |

| 3 | 800-1600 |

| 4 | > 1600 |

Notes to the Cad Cell Resistance Table

The control will work properly at any of the resistances indicated in the first three lines of the cad cell relay table above. In other words, the cad cell resistance should be below 1600 ohms for this control.

The utility of reading the number of flashes and thus inferring the cad cell resistance is that higher resistances can indicate trouble brewing and dirty oil burner operation or a poor sooty flame.

To observe the cad cell condition for this primary control, Honeywell instructs "While the [oil] burner is firing, and after the ignition has been turned off, press and release the reset button (hold 1/2 second or less) to check cad cell resistance.

The LED will flash 1 to 4 times depending on the cad cell resistance. For proper operation, it is important that the cad cell resistance is below 1600 ohms.

Source

- Honeywell R7184 Series Primary Controls, Technicians Quick Reference Guide, Honeywell International, Inc., 1985 Douglas Drive North, Golden Valley MN 55422 customer.honeywell.com and in Canada: Honeywell Limited-Honeywell Limited, 35 Dynamic Drive, Toronto Ontario M1V 42

Beckett Primary Control Cad Cell Relay Geni-Sys 7575 Burner Control Status Lights

| Beckett GeniSys 7575 LED Status Light Decoding Table | ||

|---|---|---|

| Light Color | Light On Continuously | Light Flashing |

| Red | Restricted (Hard) Lockout | Soft Lockout |

| Green | Flame Sensed during normal operation (Could be stray light during standby) |

Recycle |

| Yellow | Control is in Pump Prime mode |

N/A |

Notes to the Table Above

Source

- BECKETT GeniSys® 120V Model 7575 ADVANCED BURNER CONTROL MANUAL [PDF], Beckett Corporation, USA: P.O. Box 1289 Elyria, OH 44036

USA

Or

Canada: R.W. Beckett Canada, Ltd. Unit #3, 430 Laird Road Guelph, Ontario N1G 3X7 www.beckettcorp.com retrieved 2017/12/31, original source: https://www.beckettcorp.com/wordpress/wp-content/uploads/2016/03/61910-7575-GeniSys-120v-Control-Manual.pdf

Beckett GeniSys Model 7575 Control Cad Cell Resistance Testing

Excerpting from the manual just above:

Beckett Cad Cell Resistance Measurement

The Beckett 7575 control cad cell resistance can be selected and read on the GeniSys Contractor Tool, part 52082U.

If the contractor tool is not available, the cad cell leads can be unplugged from the control and the resistance measured with a meter in the conventional way. Conduct these tests with flame present.

Beckett GeniSys Model l7575 Cad Cell Resistance in Flame Detection |

|

| Flame Detection Range | Ohms with flame present |

| Normal | >0 - 1600 ohms |

| Limited | 1600 ohms to lockout |

| Defective control or dirty, mis-aligned sensor | > 1600 ohms |

| Open circuit, broken wire, loose connector | Infinite resistance |

3 Cad Cell VOM test Ohmeter readings

- Less than 1600 ohms but not zero. Cad cell operating properly.

- Above 1600 ohms but not infinite. Defective or dirty cad cell, misaligned sighting of flame, or improper flame adjustment. Clean cad cell and check for proper sighting of flame. Check for proper flame adjustment. If cell is defective then replace.

- Infinite resistance. Open circuit. Check for broken cell, holder, or wire. Loose cad cell in holder. If defective, replace necessary parts.

...

How to Service or Replace the Cad Cell Relay on an Oil Burner

Above we showed you the face of a cad cell and explained that it can become soiled and blocked by oil burner soot, particularly if the oil burner is itself running "dirty" or improperly.

Replacing the Cad Cell Sensor Itself

Try cleaning the sensor first.

Cleaning or replacing an oil burner cad cell is pretty easy, but this is a job for the service technician since it's necessary to turn off power to the oil burner and partly disassemble the oil burner to access the cad cell sensor.

Often by removing a lock screw or two, the voltage transformer (the black box atop[ the oil burner in this photo) is simply hinged back and one can see the yellow wire entering the oil burner tube and leading to the cad cell sensor.

The cad cell relay sensor will be mounted in a little bracket and positioned where it can "see" the flame when the oil burner is operating.

If the oil burner has not been operating properly, say has been producing too much smoke and soot, even after it has been adjusted it may be necessary to inspect and clean soot from the cad cell sensor so that it has a non-sooty clear view of the flame.

Or the technician, if s/he has any doubt about the sensor, will simply replace it. It's a simple plug-in

part (two pins on the sensor plug into a receptacle that is secured by a bracket inside of the oil burner tube).

Or the technician, if s/he has any doubt about the sensor, will simply replace it. It's a simple plug-in

part (two pins on the sensor plug into a receptacle that is secured by a bracket inside of the oil burner tube).

To order a new cad cell for most Honeywell Protectorelay controls order Honeywell part no. 130367 Cad Cell.

Replacing the Entire Primary Control With a Honeywell R7274U

Currently (2017) Honeywell recommends replacing an older primary controller for an oil burner using the Honeywell R7274U shown here.

The electronic primary controller model Honeywell R7284U 15-second universal cad cell relay microprocessor oil burner control will replace most older Honeywell (and some other) primary controllers used on oil burners including the widely-used

- Honeywell R4184D series

- Honeywell R4184D1027

- Honeywell R8184G4025/U

- Honeywell R7184U1020/U

This article series answers most questions about central heating system troubleshooting, inspection, diagnosis, and repairs. We describe how to inspect, troubleshoot and repair heating and air conditioning systems to inform home owners, buyers, and home inspectors of common heating system defects.

The articles at this website describe the basic components of a home heating system, how to find the rated heating capacity of an heating system by examining various data tags and components, how to recognize common heating system operating or safety defects, and how to save money on home heating costs.

Contact us to suggest text changes and additions and, if you wish, to receive online listing and credit for that contribution.

Oil Burner Primary / Safety Control Manuals

Beckett Oil Burner Control Manuals & Beckett Cad Cell Primary Control Instructions

Beckett's GeniSys "advanced burner control" primary control for oil burners is sold in a range of model sizes including

- Contact: Beckett Corporation,

USA: P.O. Box 1289 Elyria, OH 44036

Canada: R.W. Beckett Canada, Ltd. Unit #3, 430 Laird Road Guelph, Ontario N1G 3X7 www.beckettcorp.com - Beckett GeniSys 12V Model 7556

- Beckett GeniSys Model 7505B with 15-second pre-purge, a replacement alternative for the Honeywell R7184B Primary Control

- Beckett GeniSys BK7505P1515U replacement Cad Cell Relay

- Beckett GeniSys 7575A0000 - 15-second lockout, no valve-on delay and no motor-off delay

- Beckett GeniSys 7575P1515 - 15 second lockout, 15 second valve on delay time, no motor off delay

- Beckett GeniSys 7575P054M - 15 second lockout time, 5 second valve-on delay time, 4 minute motor-off delay time. -

The company notes that Valve-on delay and motor-off delay timings on all models are programmable with Beckett Contractor Tool. Other factory set timings are available. Contact Beckett for alternate timings.

- Beckett Genisyus 5705 OIL BURNER CONTROL MANUAL [PDF] (2021) R.W. Beckett Corporation, 1-800-645-2876

Canada: R.W. Beckett Canada Ltd, 1-800-665-6972 Web: www.beckettcorp.com

Excerpt:

The Beckett GeniSys® Advanced Burner Control is a 120 Vac primary safety control for residential and light commercial oil burners used in boiler, furnace, and water heater applications having firing rates less than 20 GPH.

The GeniSys is used with a suitable cad cell flame sensor to control the oil burner motor, igniter, and optional solenoid valve. It has 24 Vac thermostat terminals (if applicable) compatible with both mechanical and many power stealing thermostats. It can also provide interrupted or intermittent duty ignition. - BECKETT CAD CELL DIAGNOSTIC PROCEDURE [PDF] R.W. Beckett Corporation 38251 Center Ridge Rd, North Ridgeville, OH 44039 USA, Tel: US: (800) 645-2876 Tel: Canada: (800) 665-6972 retrieved 2019/01/09 original source: https://www.beckettcorp

[Click to enlarge any image]

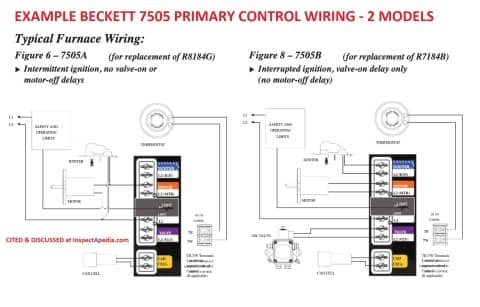

Above: Excerpted from the Beckett 7505A Manual given below, typical heater wiring when installing the Beckett 7505A replacement primary control for the Honeywell R8184G (Intermittent ignition, no valve-on or motor-off delays (left in the schematic)

or the Beckett 7505B replacement for the Honeywell R7184B primary control with interrupted ignition, valve-on delay only (no motor-off delay) shown at above right.

Watch out: the sketch above is simply an example and it may not be the correct wiring for your Beckett GeniSys control for your boiler or furnace. All of the wiring diagrams are given in the Beckett GeniSys manual PDF file given below.

Watch out: Consult the product manual and burner instructions for your specific oil burner and heating systems. Often the manufacturer warns that these controls must be installed by a trained, qualified HVAC service technician. Making a mistake risks a building fire or injury.

- BECKETT GeniSys® 120V Model 7575 ADVANCED BURNER CONTROL MANUAL [PDF], Beckett Corporation, op. cit. retrieved 2017/12/31, original source: https://www.beckettcorp.com/wordpress/wp-content/uploads/2016/03/61910-7575-GeniSys-120v-Control-Manual.pdf

- BECKETT GeniSys™ Model 7505 ADVANCED BURNER CONTROL MANUAL [PDF]

Excerpt: The Beckett GeniSysTM Advanced Burner Control is a 120 Vac primary safety control for residential and light commercial oil burners used in boiler, furnace, and water heater applications having firing rates less than 20 GPH.

The GeniSys is used with a suitable cad cell flame sensor to control the oil burner motor, igniter, and optional solenoid valve. It has 24 Vac thermostat terminals (if applicable) compatible with both mechanical and many power stealing thermostats. It can also provide interrupted or intermittent duty ignition. - BECKETT GeniSys® 120V Model 7575 ADVANCED BURNER CONTROL MANUAL [PDF], Beckett Corporation, op. cit. retrieved 2017/12/31, original source: https://www.beckettcorp.com/wordpress/wp-content/uploads/2016/03/61910-7575-GeniSys-120v-Control-Manual.pdf

- See our complete list of Beckett oil burner manuals found under "Beckett" in

OIL BURNER MANUALS - BECKETT

Carlin Oil Burner Primary Control Manuals

- CARLIN 60200 OIL PRIMARY CONTROL CAD CELL RELAY INSTRUCTIONS [PDF] (2015) Carlin Combustion Technology, Inc., 126 Bailey Road, North Haven, CT 06473 USA

Phone: (203) 680-9401

Email: info@carlincombustion.com retrieved 2018/08/23 original source: https://carlincombustion.com/wp-content/uploads/MN60200G-022415-final-1.pdf

Watch out: the company warns that these Carlin controls must be installed and serviced only by a qualified service technician. It is important that the installation of the oil burner, piping and fittings, safety devices, controls, electrical wiring and equipment be done in accordance with national and/or local regulations of the authorities having jurisdiction over such installation. - CARLIN Model 70200 UNIVERSAL OIL PRIMARY CONTROL INSTALLATION & OPERATING INSTRUCTIONS [PDF] (2017) Carlin Combustion Technology, Inc., op. cit., retrieved 2019/08/23 original source: https://carlincombustion.com/wp-content/uploads/70200-IOM.pdf

- Carlin PROMAXX 70200 UNIVERSAL REPLACEMENT for ALL PRIMARY CONTROLS [PDF] data sheet, , retrieved 2019/08/23 original source: http://orders.sidharvey.com/IMAGES/specs/70200s.pdf

- Carlin Oil Burner Manuals -

see OIL BURNER MANUALS - CARLIN - Carlin Gas Burner Manuals -

see MANUALS & PARTS GUIDES - HVAC - Carlin

Honeywell R4194 D Primary Control Manuals

- HONEYWELL R4194D R8184G,N PROTECTORELAY OIL BURNER CONTROLS MANUAL [PDF] (1991) Honeywell International Inc., Honeywell Tradeline brand.

Honeywell Inc., 1885 Douglas Drive North, Minneapolis MN 55422 USA Tel: 612 542-7500

Honeywell Inc., 740 Ellesmere Road, Scarborough Ontario M1P 2V9 Canada, international sales, world wide.

Honeywell R7284 Electronic Primary Control for Oil Burners

- HONEYWELL R7284B,P,U,G ELECTRONIC OIL PRIMARY ENVIRACOM™ ENABLED MANUAL [PDF] Honeywell International Inc. 1985 Douglas Drive North Golden Valley, MN 55422 customer.honeywell.com

- HONEYWELL R7284U Product Overview [PDF]

- HONEYWELL R7284U TRAINING MANUAL [Power Point] https://customer.honeywell.com/Documents/R7284U1004UniversalOilPrimaryTrainingModule.ppt

Honeywell R7795 Primary Control Manual

- HONEYWELL R7795A,B,C,D Flame Safeguard Primary Controls MANUAL [PDF]

Excerpt: The R7795 Flame Safeguard Primary Control provides flameout protection plus automatic control of commercial and industrial gas and oil burners. Models provide intermittent pilot or interrupted pilot with delayed main valve.

Honeywell R8184 Cad Cell Relay Controls

To RESET the Honeywell R8184 M cad cell relay switch press the popped-up red button. If the button has NOT popped-up then the switch has not tripped.

To TEST the Honeywell R8184 M cad cell relay switch, push the small lever in the direction shown in our sketch - adapted from Honeywell's instructions given above in PDF form.

- HONEYWELL R4194D R8184G / N PROTECTORELAY OIL BURNER CONTROLS MANUAL [PDF] (1991) Honeywell International Inc., Honeywell Tradeline brand.

Honeywell Inc., 1885 Douglas Drive North, Minneapolis MN 55422 USA Tel: 612 542-7500

Honeywell Inc., 740 Ellesmere Road, Scarborough Ontario M1P 2V9 Canada, international sales, world wide. - HONEYWELL R8184 M PROTECTORELAY OIL BURNER CONTROL MANUAL [PDF]

Excerpt: APPLICATION

The R8184M Protectorelay control provides automatic, nonrecycling control of combination oil burner heating and cooling systems when used with a C554A Cadmium Sulfide (cad cell) Flame Detector and low voltage thermostat. It includes a 40 VA transformer to power a cooling contactor and fan relay during the cooling operation.

...

The R8184M is set at the factory and requires no adjustment or periodic maintenance. The R8184M contains no field-serviceable parts. Do not disassemble the R8184M. Replace the entire control if operation is not as described.

Honeywell RA890F commercial Protectorelay control

- HONEYWELL RA890F / G Flame Safeguard Primary Control Manual [PDF]

Excerpt: The [Honeywell] RA890F Protectorelay™ is a non programming, amplifying relay that provides solid state electronic flame safeguard protection for industrial and commercial gas, oil, or combination gas-oil burners.

ICM Primary Control / Cad Cell Relay

- ICM INTERMITTENT IGNITION Series Oil Primary Control using the C554A Cad Cell to monitor flame [PDF] ICM1501, ICM1502, ICM1503, ICM Controls, 7313 William Barry Blvd., North Syracuse, NY 13212 (Toll Free) 800-365-5525 (Phone) 315-233-5266 (Fax) 315-233-5276 www.icmcontrols.com

Retrieved 2019/01/09 original source:

https://api.ferguson.com/dar-step-service/Query?USE_TYPE=INSTALLATION&PRODUCT_ID=4858209

Other Controls & Switches & Manuals

- MANUALS & PARTS GUIDES - HVAC - home - Master Index to All Brand Names & HVAC manuals, wiring diagrams, installation and repair guides

- OIL BURNER MANUALS

- BOILER CONTROLS & SWITCHES - controls used on all brands of heating boilers and

- FURNACE CONTROLS & SWITCHES - controls used on all brands of heating furnaces

- Also see "Oil Burner Manuals & Guides for Boilers, Furnaces, Water Heaters" found in OIL BURNERS

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-01-20 by (mod) - how to recognize a cad cell relay vs a stack relay

Caniz

Typically the burner will run for less than 30 seconds before a flame is established; else the primary control will shut the burner down.

You can identify the cad cell relay by following wires from the primary control into the burner gun and onwards to the sensor eye - if it's a cad cell relay; follow the wire, usuallt yellow, into the burner tube and find the cad cell like my photo above.

You can identify a stack relay switch by finding the stack relay on the flue vent connector or "stackpipe" - see the article below and my photo above of a stack relay switch.

On 2021-01-20 by Caniz

Hi, How many seconds I must hear the burning (fooooohh,) sound after the first motor turn(oil pumping) on sound in a normal burner operation.

Also how I can know If the burner operates with a cad cell sensor or a stack relay switch.

On 2021-01-09 by (mod) - furnace motor just hums, won't start

Sounds like a failing motor or a bad start capacitor on the motor (if the motor uses one).

See CAUSES of HARD STARTING ELECTRIC MOTORS

See CAPACITORS for HARD STARTING MOTORS

On 2021-01-09 by William dimmer

Furnace motor won't run cd-back just hums

On 2019-08-23 by (mod) - basic Cad Cell checks when you can't get the burner to run

Gus

I aways check common problems to check before replacing the cad cell primary control:

1. a dirty cad cell sensor eye

2. bad cad cell sensor eye - easy, it's a trivial plug-in replacement - cheap and quick to try

3. bad cad cell wiring connection

4. oil burner improperly adjusted, producing too much soot - dirtying up the cad cell eye

5. causes of sooty oil burner operation or weak flame such as improper electrode adjustment, or such as an air leak in oil piping or at the oil filter

On 2020-12-01 by Gus

Hi I just finished my HVAC schooling now I do my own jobs on the side when I can and today I ran into a problem I can’t fix I replaced a Honeywell r7284 oil primary control and a cad eye and I’m still getting a hard lockout call service and it also shows tt closed and limit closed I really need some help so I can get this heat back on for these people

On 2020-03-28 - by (mod) -

Yes,

They were already in wide use when i worked on heatng systems in the 1980s

On 2020-03-27 by Keith

Thanks dan another questionoil burner in my hunting camp prolly at least 35 yrs old are cad relays for older applications pretty much the same

On 2020-03-20 - by (mod) -

Keith

Yes, indirectly, a bad oil burner motor can lead to cad cell relay tripping; in particular, if the oil burner motor is defective or having trouble starting, stopping, or running at proper speed, that in turn may result in a smoky or intermittent oil burner flame that soots up the cad cell relay sensor and leads to a system shut down.

On 2020-03-20 by Keith

Can a bad motor trip the cad cell relay

On 2019-08-29 - by (mod) -

Allen thanks for the follow-up; that may help other readers. Do keep us posted.

On 2019-08-29 by Allen

Thank you for your prompt reply. After having to restart the boiler every 3 days or so for the past 3 weeks it has been working fine for an entire week now. There seems to be no rhyme or reason as to why it was shutting down.

The label on the control says that the 1/2 second flashes are for lockout and the 2 second flashes are for recycle. If it shuts down again I'll try cleaning the eye of the cad cell and see if that helps. Thank you for your help and I'll let you know what happens or if I need your help again. Thanks in advance.

On 2019-08-23 - by (mod) -

Allen

Some common problems to check before replacing the control:

1. a dirty cad cell sensor eye

2. bad cad cell sensor eye - easy, it's a trivial plug-in replacement

3. bad cad cell wiring connection

4. oil burner improperly adjusted, producing too much soot

5. causes of the item above, such as an air leak in oil piping or at the oil filter

The cad cell can be simply wiped off but most techs prefer to kill off possibilities 1 & 2 by just plugging in a new cad cell sensor.

Look on your primary control or cad sell sensor (usually a black or gray box atop the oil bureer) and confirm that the yellow (usually) wires from the cad cell sensor eye are connected thereto.

Now attach a photo of the control and its labeling - we need to know the brand and model to make sense of the cad cell sensor warning LEDS or blink codes.

On 2019-08-23 by Allen

About 3 weeks ago my oil fired water boiler shut down. It's a Weil-McLain, WTGO-4 I think. I changed the basket filter, the pump strainer, and the nozzle and it ran OK for about a week. Now when it shuts down I reset it and it runs for 3 days or so, sometimes more, sometimes less

. It usually starts back up no problem but the other day I read the label on the, I think it's the relay, and it tells how the light can flash for either 1/2 second or 2 second intervals.

When I reset it, it was flashing 1/2 second intervals, it ignited and ran for about 15 seconds and then shut off and the light was now flashing 2 second intervals.

About 15 seconds later it came back on without resetting it and fired up and ran fine, again for about 2-3 days. Does this sound like a bad or dirty cad cell? If so what do I use to clean the cad cell?

...

Continue reading at STACK RELAY SWITCH or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CAD CELL PROTECT O RELAY FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- BOILER CONTROLS & SWITCHES

- RESET SWITCH, CAD CELL RELAY

- RESET SWITCH, HEATER REPAIR - how to fix a cad cell relay that has lost its red reset button

- RESET SWITCH, ELECTRIC MOTOR

- STACK RELAY SWITCH

- FURNACE CONTROLS & SWITCHES

- WATER HEATERS OIL FIRED

Suggested citation for this web page

RESET SWITCH, CAD CELL RELAY at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Thanks to reader S.M. for careful editing and noting that the ohmmeter reading on a cad cell test with the burner is NOT firing should be close to infinity.

- [2] Honeywell R7184 Series Primary Controls, Technicians Quick Reference Guide, Honeywell International, Inc., 1985 Douglas Drive North, Golden Valley MN 55422 customer.honeywell.com and in Canada: Honeywell Limited-Honeywell Limited, 35 Dynamic Drive, Toronto Ontario M1V 429

- [3] Thanks to Bottini Fuel service. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- [4] "R4184D; R8184G,M,N,P Protectorelay ® Oil Primary Controls", Honeywell Corporation, Automation and Control Solutions, Honeywell International Inc. 1985 Douglas Drive North, Golden Valley, Minnesota 55422, Web search 12/14/2012, [copy on file as Honeywell_R4184D_Cad_Cell.pdf]

- Carson Dunlop, Associates, Toronto, have provided us with (and we recommend) Carson Dunlop Weldon & Associates'Technical Reference Guide to manufacturer's model and serial number information for heating and cooling equipment

Special Offer: Carson Dunlop Associates offers InspectAPedia readers in the U.S.A. a 5% discount on any number of copies of the Technical Reference Guide purchased as a single order. Just enter INSPECTATRG in the order payment page "Promo/Redemption" space. - Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.