Water Supply, Wells, Pumps & Tests

Water Supply, Wells, Pumps & Tests

Home Page & Article Index

- POST a QUESTION or COMMENT about installing, diagnosing, repairing, or replacing all of the components and controls for private well water systems.

This page provides an index to key articles about water supply systems installation, diagnosis, repair of wells, well pumps, water tanks.

These water, well, and water supply equipment articles answer inspection, diagnosis, and repair questions about the building water supply sources and equipment including water testing, water piping, water pumps, water wells, & water tanks.

Page top photo: orange brown water coming out of this bath tub faucet was traced to a combination of water having been unused or not run for several months while the home sat empty, combined with a whole house plumbed with rusted galvanized iron piping.

But take care: water color or odors (or test results) can point to a problem at your water source and may mean that the water unsafe to drink.

This water supply home page lists key articles on all building water supply topics including wells, water supply pumps, water tanks, water testing and water treatment equipment.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water Information Topics Organized Here

Here we describe installing or repairing systems for delivering water to buildings, such as well pumps, pump controls, water filters, water heaters, water pressure problems, water supply piping, water softeners, water tank types, leaks, problems, repairs, water quality, water quantity, water contaminants, water testing, water treatment equipment, all types of wells, well piping, well controls.

The article series outlined below starts by organizing problems into categories. Each of the water supply system categories listed below is a link that will provide a list of helpful troubleshooting & repair articles.

To find what you need quickly, if you don't want to scroll through this index you are welcome to use the page top or bottom SEARCH BOX to search InspectApedia for specific articles and information.

Article Series Contents

- WATER PUMPS, TANKS, TESTS, WELLS, REPAIRS

- WATER CONTAMINANTS & TESTS

- WATER PIPING, CONTROLS, DRAINS

- WATER PRESSURE - poor or no water pressure diagnosis & repair

- WATER PUMPS - types of water pumps, troubleshooting & repair

- WATER QUALITY - what's in the water

- WATER QUANTITY - how much water can we get

- WATER TANKS - for water systems

- WATER TREATMENT SYSTEMS - remove contaminants

- WATER WELLS - types, construction, testing, troubleshooting, repairing

Best bet for getting help with water related topics: use the search box found near the top or bottom of any InspectApedia article.

[Click to enlarge any image]

Water Tests, Water Contamination Limits, Drinking Water Testing Procedures

This page lists InspectApedia articles helpful in the diagnosis & testing of all types of drinking water contaminants, and in diagnosing & fixing water supply quantity and quality problems: wells, pumps, pipes, water tanks, water pressure, water flow.

This page lists InspectApedia articles helpful in the diagnosis & testing of all types of drinking water contaminants, and in diagnosing & fixing water supply quantity and quality problems: wells, pumps, pipes, water tanks, water pressure, water flow.

Reader Question: rusty water at the bath tub

4/29/2014 john popa said:

Rusty water is coming from hot water in bathtub that is never used. Also it's coming from another sink. All of this was found during a home inspection. We have found nothing.

Inspector suggested could be a issue with the hot water heating coil. We think it is from non-use. Should we clean out the pipes using an acid wash? Can you make some suggestions? [This Q&A originally appeared at CLOGGED PIPES / TANKLESS COIL DE-SCALE]

Reply:

John, Don't do anything yet. If the home has galvanized iron pipes and water sat in piping without flowing for some time, rusty water would be no surprise and should flush out with use. An acid wash has other risks including toxicity - not something to undertake lightly. And tankless coil tubing is copper, not likely to be a source of red rusty water.

I took the photo of reddish brown water running into a bath tub shown at the top of this page under just the same conditions as you describe. The home had galvanized iron pipes and had been unoccupied for many months. The ugly water flushed out and that was the end of the discoloration complaint.

As long as you are not seeing the same discoloration elsewhere, the unused pipe theory holds water.

Watch out: there may be other implications: galvanized pipes in an older home mean new piping is in your future. Galvanized iron pipes are often nearing end of life and may be partly clogged by rust and scale in both the water supply piping and water drain piping - leading to a costly but ultimately necessary expense.

- ARSENIC IN DRINKING WATER - health effects, exposure standards, how to remove arsenic from water

- CHEATING on WATER TESTS - testing water for real estate transactions - make sure your water test is valid

- CHOICES of WATER TESTS & FEES - a summary of types of water tests, degrees of comprehensive water testing, details of water test parameters

- CISTERNS, WATER STORAGE - for water storage outside or inside of buildings; rainwater storage; water tank types

- CLEARANCES for WELLS - distance between well & septic system and other water pollution sources, online table of well distances

- CONSERVATION MEASURES, WATER - home

- CROSS CONNECTIONS, PLUMBING - bacterial contamination of building piping - sources

- DRINKING WASTER TEST ADVICE - for home buyers, home owners, home inspectors

- DRINKING WATER CONTAMINANT LEVELS - maximum allowed

- DRINKING WATER CONTAMINATION - how to detect, test, correct, and prevent well water contamination - US EPA - groundwater

- FILTERS for DRINKING WATER PURIFICATION - for a discussion of portable and emergency water filters that are designed to purify drinking water, including portable ceramic water filters, silver ceramic filters, magnetic (bogus) water purifiers, paper and polypropylene water filters, etc.

- INTERPRET & ACT on WATER TEST RESULTS - what the results mean and what to do about them

- CORRECT UNSATISFACTORY WATER - what to do, when to do it, treatment alternatives, equipment, filters, etc.

- WATER TREATMENT METHODS - hardness, odors, sediment, etc: choices of systems, recommendations

- WELL CHLORINATION & SHOCKING - procedure for shocking a well to "correct" bacterial contamination (temporarily or maybe longer)

- LEAD CONTAMINATION - in drinking water: how to correct lead in drinking water

- LEAD POISONING SYMPTOMS - (extreme) Feb.. 2006 NY Times Article on Kosovo Roma Camps

- LEAD TEST RESULT VARIABILITY - caused by test methods and water supply lines/entry mains: advice re: testing with lead pipe & lead solder on plumbing

- ODORS in DRINKING WATER - causes of odors in water, health risks, treatment for odors

- TOTAL COLIFORM TEST - what is total coliform, why do we test for it, what do test results mean

- SEWAGE / SEPTIC CONTAMINATION - investigation, testing and remediation

Reader Question: well water contamination issues, questions, answers

(Sept 2, 2011) Frances Franconi said:

Our well came back with coliform and ecoli and disinfecting did not clear it up. We have had a lot of rain lately. We have had this well for some time. What could cause this issue?

(Nov 5, 2012) Sandra Sanders said:

We tried to shock our well with clorox bleach after finding out we had e coli in our well. I believe we used too much, it's been days and is still very strong. What can we do?

Reply: persistent bacteria problems are different from persistent bleach problems: here's dealing with each:

Persistent coliform and e coli in a well may be from

- surface runoff leaking into the well

- nearby septic system failure leaking in to the aquifer

- or sometimes inadequate well and plumbing cleaning/shocking

I'd look closely at the numbers on the bacteria test results as that can help diagnose the problem. If the starting count is high, shocking doesn't usually fix anything and we look for either a source of contaminants leaking into the well or we decide the aquifer is contaminated.

In any case a well water disinfection treatment system will be needed to assure potable water.

Watch out: where surface water leakage into a well brings bacteria it might bring chemicals or other contaminants along too.

Sandra: indeed improper well shocking procedure using solid bleach tablets or pool tablets, or improper installation of chlorine into the well can make it hard to flush out later. If you poured straight clorox down into the well you may have coated rusty well casing sides, piping, etc. with a too-strong bleach solution. Perhaps connecting a garden hose to an outside faucet and recycling water a bit to flush down the well casing sides and well piping followed by a flush-out will help.

Also, if you introduced bleach-disinfected water into a well water pressure tank or water heater tank you may need to drain those completely to speed the bleach flushout procedure.

Reader Question: water odor complaints - smells like oil

(Jan 15, 2012) Neater Poole said:

I had a well put down in Dec. and when my home was put in the water was truned on and it had a bad smell and you cann't drink it. It smelled like oil.

Reply:

Neater Poole, the oil contaminants in your well might be left from the drilling process and if so can be flushed out;

It is normal to TEST the water delivered by a new well, both a flow rate test and a rather broad spectrum of contamination tests to be sure the water is potable and the source is not contaminated.

Check to see if those tests were done when your well was drilled.

Watch out: hydrofracking and oil and gas well drilling operations in some areas have been related to oil and even gas odors in water wells nearby, though more often contamination issues seem to track to the disposal of drilling wastewater.

See ODORS IN WATER

Water Supply Piping, & Drain Piping

- PIPING in BUILDINGS, CLOGS, LEAKS, TYPES - topic home page

- DRAIN & SEWER PIPING - topic home page

- SUPPLY PIPING - topic home page

- PLUMBING SYSTEM INSPECT DIAGNOSE REPAIR - topic home page

- PLUMBING FIXTURES, KITCHEN, BATH - topic home page

- SEPTIC SYSTEM INSPECT DIAGNOSE REPAIR - topic home page

- TOILETS, INSPECT, INSTALL, REPAIR - topic home page

- WATER SHUTOFF VALVE LOCATION, USE - where to find and how to turn off the main water valve in buildings

Water Tanks: installation, adjustment, troubleshooting, repair of water storage tanks & water pressure tanks

- WATER TANK: USES, TROUBLESHOOTING - topic home page

- WATER HEATERS - topic home page - hot water tanks, sources of hot water in buildings, equipment installation, troubleshooting, repair

- HOT WATER PRESSURE EXPANSION RATE - how much does heating water cause pressure to increase in a water heater or in a hot water heating boiler?

- WATER PRESSURE TANKS - what they are for, how they work, what goes wrong, how to fix them

- WATER TANK BLADDERS & CAPTIVE AIR

- WATER TANK REPAIRS

- WATER TANK TYPES - what are the types of water pressure tanks, how are they tested, maintained, repaired

- WATER TANK AIR CHARGE - how to fix a water tank that has lost its air charge

- WATER TANKS - how to diagnose problems with water tanks, such as the need for air, how to add air, stop water pump short cycling to avoid damage - water storage water pressure tank safety.

- WATER TANK AIR INLET VALVE - how to add air to the water tank by the air valve

- WATER TANK TYPES: WATER, OIL, EXPANSION, ALL - what are the types of water pressure tanks, how are they tested, maintained, repaired

- WATER TANK REPAIRS - how to diagnose problems with water tanks, such as the need for air, how to add air, stop water pump short cycling to avoid damage, water storage, water pressure, tank safety

- WATER TANK SAFETY - water tank safety and water tank plastics and contaminants health warnings

Water Treatment Equipment: water disinfection, water filters, water purifiers, water softeners, water odor removal

- WATER TREATMENT EQUIPMENT CHOICES - topic home page

- DRINKING WATER - EMERGENCY PURIFICATION

- DRINKING WATER EMERGENCY SOURCES

- WATER FILTERS, HOME USE - filters for water

- ODORS IN WATER - how to diagnose and cure various smells or odors in the water supply

- REVERSE OSMOSIS WATER TREATMENT - impact on septic systems & impact on water quantity used

- WATER PURIFIERS - what types of equipment are used to remove which contaminants from drinking water?

- WATER SOFTENERS & CONDITIONERS - how to handle hard water, water high in mineral content, water softener maintenance, adjustment, and water softener effect on drinking water and on septic systems

Water Pumps, Pump Controls, Water Pressure, troubleshooting, repairs

- WATER PUMP REPAIR GUIDE - topic home page

- DIAGNOSTIC GUIDE TO WELL PUMP PROBLEMS - for water pumps, wells, motors

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- GRUNDFOS SCALA 2 PUMP GUIDE

- NO WATER PRESSURE - no water at all? Start here.

- WATER PUMP REPAIR GUIDE - guide to diagnosing & repairing well water pumps

- WATER PRESSURE LOSS DIAGNOSIS & REPAIR - weak water pressure diagnosis, repair

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE - table of causes & cures for bad water pressure

- WATER PUMP DIAGNOSTIC TABLE

- WATER PRESSURE MEASUREMENT - how to measure water pressure and flow

- WATER PUMPS, TANKS, DIAGNOSTICS

- WATER PUMP SHORT CYCLING - what to do if the water pump keeps turning on and off too rapidly

- WATER PUMP SHORT CYCLING DIAGNOSIS TABLE

- INTERMITTENT CYCLING WATER PUMPS - pump turns on for no apparent reason

- WATER PRESSURE REDUCER / REGULATOR - how to adjust the water pressure regulator on a municipal water supplied building

- WATER PUMP PRESSURE ADJUSTMENT - how to adjust the pump cut-on and cut-off pressure at the pressure control switch

- WELL WATER PRESSURE DIAGNOSIS - how to improve water pressure and flow in a building served by a private well and pump

- WELL PUMP PRIMING PROCEDURE - how do we re-prime the well pump?

- WATER PUMP LIFE EXPECTANCY

- WATER PUMP, ONE LINE JET - what is a one-line jet pump, used on shallow wells, how to inspect, diagnose, & repair

- PUMP, TWO LINE JET - what is a two line jet pump, how to inspect, diagnose, & repair

- PUMP, SUBMERSIBLE - what is a submersible well pump, how to inspect, diagnose, & repair

- WATER PUMP CAPACITIES TYPES RATES GPM

- SHAKE the WATER TANK - how to test the water tank as part of diagnosing loss of water or water pressure

- SUBMERSIBLE WELL PUMPS - what is a deep well submersible pump, how to inspect, diagnose, & repair

- WATER PRESSURE BOOSTING - how to install a system to increase water pressure at a building

Reader Question: The well pump runs, but we get air, not water

Two months ago I started having problems with our water well. The first thing to happen was the pressure switch caught fire, it was 25+ years old, I replaced it. Then I had the problem of the well pump kicking on and off every few seconds so I had to adjust the air in the air tank.

Everything was fine for a month, then last week we started getting air in the lines, at first it was just a little air but as time went on there was more and more air until there was more air than water coming out of the faucets.

Two days ago I turned on the faucet and just a trickle of water was coming out, I went outside, looked at the pressure gauge and it was at 20 pounds and the pump was still running.

I turned off the pump, checked for leaks in the house as well as all around the well housing to the home, no leaks. I left the pump off for a hour or so because I thought the water level maybe low, 20 inches of rain this month, didnt really think it would be low but I thought it maybe a possibility.

A hour later when I turned on the pump it still would only go up to 15-20lbs of pressure and the pump was still running.

When I turn off the pump I don't lose any pressure, it stays at 15-20lbs until I use water in the home. I looked again for leaks, didnt find any so I replaced the pressure switch, the pressure gauge, the wires from the breaker box to the pressure switch and the wires from the pressure switch to the other bigger switch.

I thought maybe the wires were bad and not allowing enough current to run the pump properly.

I filed all the points on the bigger switch box and cleaned all the connectors. I tried the pump again, still it will only go up to 15-20lbs of pressure and the pump will keep running.

The well is around 400 feet deep, I opened the top of the well housing and put my ear to it, I don't hear any water leaking back into the well and I can hear the pump running.

We replaced the pump and air tank 5-6 years ago. We have lived here for 20 years and have had only a problem one time with low water levels and that was in the middle of summer with very little rain for months, its always had water.

I also checked the air tank, the rubber thing inside of it is busted or something, I'm getting water out of the air valve on top of the tank. I don't think the air tank has anything to do with the amount of pressure the pump pumps up to the home but it will have to be fixed.

There is no one close that has a pump puller in service, the closest is almost 100 miles away, and its going to take them almost two weeks to get here to check out the problem.

So if anyone has any ideas, suggestions, or anything that maybe able to help please post! It will be greatly appreciated! We have 5 children with no water, its getting kind of crazy! Thank you! - Woody

Reply: Some Water Loss Diagnostic Suggestions for This Case

Usually we start diagnosing a well pump and water problem by focusing first on the obvious, known problem, assuming that the chances of multiple problems happening at once are less likely.

But in fact multiple well pump, water tank, piping, and pump control switch problems can occur in a given interval and might even be related to a single root cause.

If you want to click right over to a diagnostic article

see AIR DISCHARGE at FAUCETS, FIXTURES

But based on what you've said so far, it sounds as if:

1. You need to replace the water pressure tank. A burst bladder in the tank can briefly send air out through faucets and will end up leaving the well pump short cycling on and off as the water tank air charge becomes lost.

A burst bladder in the water tank can also interfere with water entering the tank and it might even interfere with proper operation of the pressure control switch.

2. A short cycling well pump for any cause can burn-up the pump pressure control switch.

On occasion it can also damage the pump itself - which in your case is a submersible down in the well, costly and a lot of trouble to replace. So we ought to be as thorough as we can with the above-ground tests and fixes before pulling the pump out of the well.

3. Some causes of a well pump running on without shutting off include loss of water in the well, a damaged pump, a well piping leak, and a pressure control switch set to a cut-off value higher than the pump can reach.

First swap out that bad water pressure tank and give us a comment back here on what happened.

At WATER PUMP DIAGNOSTIC TABLE you will find a catalog of things to check, and in particular, take a look

at WATER PUMP WONT STOP RUNNING

See WATER PRESSURE LOSS DIAGNOSIS & REPAIR for our complete diagnostic series.

Or choose one of the water pressure diagnosis and repair starting points listed at the beginning of this section.Reader Question: my pump switch was broken, how do I get it going again? Loss of electrical power to the well pump?

Reader Amy asks: Concrete blocks from the well pit wall fell onto my pump and pressure control switch, smashing everything. I'm trying to get it working again. How do I fix-up and get the pump switch going?

(Apr 2, 2012) charity said:

Please the power supply for my pump isnt on. so i ran a cord from my meter box to the pump. it got wet when it stromed and shorted out and melting the breaker on the pump. i replaced it and hooked back up my cord. nothing. i have tested the cord its give the electrity. what is wrong and what do i need to do help.

C

Reply: your pump pressure control switch may need replacement

Amy, take a look at WATER PUMP PRESSURE CONTROL SWITCH to see details on how these switches work, are wired, and are repaired or replaced. If the blocks broke off the switch from its mount, you'll probably find it easier and more reliable to just replace the switch and its mounting tubing or hardware.

Charity, considering that you have already risked death by electrocution once by your pump wiring, I hope you'll leave it off and hire a licensed electrician. It's no joke that you could kill yourself or someone else.

Reader Question: water pressure loss diagnosis: the water pressure dropped throughout the whole house and the pipes are humming

What would cause a water pressure drop throughout whole house and after runs a little bit a loud humming sounds is produced through the pipes - anon reader

(Nov 30, 2011) mikebarber said:

I just replaced my old water tank with a new "pressurized" tank. Now, when I take a shower and the pump hits the low/pump on pressure of 40 psi, I loose pressure (almost to a trickle) in the shower and the water temperature fluctuates. I did not have this problem with the old tank. What could be causing this?

Reply: look for a well or pump problem; humming may be transmitted from an aboveground pump.

Anon reader - About a water pressure drop throughout the whole house and humming pipes: the observation that it's the whole house that's affected argues that the problem is with your well or pump. But with no other information a diagnostic guess would be just too speculative.

See WATER PRESSURE LOSS DIAGNOSIS & REPAIR

or WATER PRESSURE PROBLEM DIAGNOSIS TABLE to see our diagnostic guide for loss of water pressure in a home.

Mike, we saw this question on another InspectApedia page just recently. If I recall, the reply could only be a speculation that offered some things to check:

If you replaced the pressure tank but kept the old pressure control switch, debris stirred during the plumbing work may have clogged the pressure sensing switch mounting nipple (that small diameter pipe) or the bottom of the switch itself, causing it to fail to respond to the pressure drop.

Try tapping on the switch, and also watch the pressure gauge at the pressure tank. Or replace the switch and its mounting nipple.

The fluctuating water temperature might be related to changes in the water flow rate through your water heater, especially if you're using a tankless coil to make hot water.

Reader follow-up:

(Dec 1, 2011) mikebarber said:

Thanks Daniel: Yes I did ask the question on another page and couldn't figure out how to get back to it (I bookmarked this page).

The pressure control switch is mounted on the Sears Shallow Well Jet Pump (3/4 hp - 40 to 60 psi). There is no fitting on the tank since it is a pressure/bladder tank. There is a small black tube going from the pump body to the bottom of the pressure control switch/box. I did remove it from the pump at one point.

I have since drained the pump, tank and water lines via what looks like a car radiator drain cock on the bottom of the pump (hopefully clearing any debris or air from the PCS line). The pressure gauge is on the pump in the opening designated as the "priming port" in the pump manual.

This pressure gauge has always been there.

Recently I noticed that as the water runs and the pressure drops the gauge gets to 49 psi and stops, then suddenly drops to 40 psi and the pump turns on. It takes on average 4 mins and 15 secs for the pressure to return to 60 psi.

The tank manufacturer tells me that this is a 19 gal/ 45 gal equivalent with a 5.9 gal "draw down" which should be the same as my old steel 45 gal tank.

I have a gas fired "normal" water heater and I suspect the temperature change is as you suggest, just exacerbated because of the extremely low water pressure.

I will take the pressure switch hose and fittings off to make sure they aren't clogged (do you think the sudden pressure drop is a symptom of this?)

Water Wells, Cisterns, Springs: installation, troubleshooting, repairs & maintenance

- WELLS CISTERNS & SPRINGS - topic home page - types of sources of drinking water, what they look like, what goes wrong, what to do about it

- BASEMENT WELLS - as a water source, what to watch out for, how to inspect, test, make safe

- CISTERNS, WATER STORAGE - what are the types of cisterns, where are they found, when are they acceptable for drinking water storage or supply?

- CLEARANCE DISTANCE for WELLS - distance between well & septic system, other water pollution sources, roads, property borders, buildings, online table of well distances

- CLEARANCE DISTANCE for SEPTIC SYSTEMS - between septic system & wells, streams, trees, property boundaries, online tables of septic distances

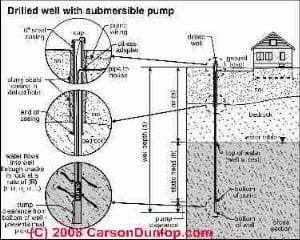

- DRILLED WELL STEEL CASING WELL - and also bored wells, how to inspect, diagnose, & repair well problems

- DRILLED WELL w/ SUBMERSIBLE PUMP - what is a submersible pump, how to inspect, diagnose, & repair

- DRIVEN POINT WELLS - what is a driven point well, what are its characteristics?

- DUG WELLS - hand dug well use, safety, sanitation, and digging procedure. Case study of providing sanitary water from a hand dug well

- HAND DUG WELLS - home

- HAND DUG WELL PROCEDURE - a case study of the process of digging a well and assuring that its water supply is sanitary

- FOOT VALVES - a leaky foot valve can lead to loss of well pump prime and loss of water pressure

- SHALLOW WELL 1-Line JET PUMP - what is a one line jet pump, how to inspect, diagnose, & repair

- SPRINGS for WATER SUPPLY - what are they, can they be sanitary and safe?

- WATER SOURCE ALTERNATIVES - other sources of water for watering lawns, gardens, orchards, or for purification as drinking water, besides wells and municipal water supply: comparing the effectiveness and costs of condensation, graywater systems, rainwater collection systems, cisterns, etc.

- WELL BORE ALIGNMENT PLUMBNESS STRAIGHTNESS - standards, test procedures, why well bore alignment is important

- WELL FLOW RATE - how do we find out well water quantity - well flow rates or draw down tests

- WELL FLOW TEST PROCEDURE - how can a homeowner or home buyer make a simple well water quantity test

- WELL PIPING LEAK DIAGNOSIS - a leak in the water piping anywhere between the well bottom and the building can wreak havoc

- WELL PITS - special warnings for properties where the well and well equipment, pump, tank, etc. are outside in a pit

- WELL, PUMP, TANK LIFE EXPECTANCY - how long should a typical well, water pump, or water tank last?

- WELL YIELD IMPROVEMENT - how to improve well water yield - steps to try before drilling a new well

Reader Question: water filter plugs up after shocking the well; sand and debris in the water supply

After shocking my well, i had to replace my whole house water filter about 6 to 8 times, because it would plug up with black sediment. Is this normal? - Tom

(Oct 23, 2012) Sheila said:

we are having issues with our well. Earlier in the season, we kept getting sand in our water.

Everyone kept saying "its the water table" because we were in a draught. But, we've been getting rains for the past month or so fairly regular and now we are getting mud in our water. A filter that should last about 6 months is barely making it for 2 weeks. Any ideas.

Reply:

Tom, no it's not normal for shocking the well itself to cause the water filter to clog up.

If by shocking the well you simply poured a bleach solution into the well casing, that alone wouldn't explain the debris clogging at your water filter, but if you followed our recommended procedure of washing down the casing sides with recycled chlorinated water then indeed you may have stirred up debris in the well.

After replacing the filter a couple of times this problem should stop.

If the clogging of your water filter continues then I suspect that something has happened either to the well casing (a crack or opening admitting dirt), the aquifer (changed, perhaps due to nearby drilling or blasting), or the well piping (a leak).

If the problem persists you'll need to install a higher capacity sediment filter system on your water supply.

See FILTERS, WATER.

Watch out: the conditions you describe would lead me to also have a bacteria test for well contamination.

Sandra

Shut off water, drain your pressure tank and hot water tank, run water to an outside faucet to clear the well, then refill tanks and flush piping.

Water Well Bore Alignment & Plumbness

This discussion moved to its own page

at WELL BORE ALIGNMENT PLUMBNESS STRAIGHTNESS - standards, test procedures, why well bore alignment is important

Water Pressure Diagnosis & Repair

- WATER PRESSURE LOSS DIAGNOSIS & REPAIR - topic home page

- WATER PRESSURE MEASUREMENT - how do we measure water pressure and water flow rate in a building?

- WATER PRESSURE LOSS DIAGNOSIS & REPAIR - how to diagnose and correct poor water pressure in any building

- MUNICIPAL WATER PRESSURE DIAGNOSIS - diagnose/fix bad municipal or city water pressure/flow

- WATER PRESSURE REDUCER / REGULATOR - how to adjust the water pressure regulator on a municipal water supplied building

- WATER PRESSURE REGULATOR BAD - how to diagnose & repair a defective water pressure regulator.

- WATER PRESSURE - diagnosis & repair

- WATER PUMP SHORT CYCLING - causes pressure surges

- WATER PRESSURE VARIATION CAUSES

- WATER PRESSURE TOO HIGH: DANGERS

- WATER QUANTITY - diagnosis & improvement

- WATER PUMPS, PUMP CONTROLS - installation, diagnosis & repair

- WATER SUPPLY PIPES & WATER DRAIN PIPES

- WATER TANKS - installation, diagnosis & repair

- WATER PUMP PRESSURE CONTROL - how to adjust the well pump pressure control switch to set pump cut-on and cut-off pressures

Well Water Quantity - how much water can we get? There's not enough water

- WELL FLOW RATE - topic home page

- WELL FLOW RATE - how much water is in the well, how much water do we have available, how to get more water from the well - well flow rates or draw down tests

- STATIC HEAD of WATER in the WELL - definition of static head, what it means, why you care

- WELL FLOW TEST PROCEDURE - how can a homeowner or home buyer make a simple well water quantity test

- WELL YIELD, SAFE LIMITS - defined by sum of static head plus flow rate & other measures

- WELL YIELD DEFINITION - how much water can we get out of the well over what time period at what flow rate

- WELL YIELD IMPROVEMENT - how to get more water from the well, how to improve well water yield - steps to try before drilling a new well

- WELL WATER PRESSURE DIAGNOSIS - how to troubleshoot bad water pressure

- WATER QUANTITY REQUIREMENTS - home & outdoor living water usage, typical amounts needed

Well Water Quality - what's in the water? Some water is not so good to drink

- WATER TESTS for CONTAMINANTS - topic home page

- ODORS IN WATER - if your well water smells bad, here is how to diagnose and fix the problem

- WATER SOFTENERS & CONDITIONERS - how to treat hard water to avoid pipe clogging and other water problems

- WATER TEST CHOICES & WATER TEST FEES

- WATER TESTING GUIDE

- WATER TEST INTERPRETATION

- WATER TREATMENT EQUIPMENT CHOICES - see detailed links at the ARTICLE INDEX

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-10-05 by InspectApedia (Editor) - new pump is rapidly short cycling

@David J,

Thank you for following-up; am I right that you increased the pipe diameters between pump and tank?

On 2022-10-05 by David J

@InspectApedia-911,

Hooray! It’s works as intended now. Thanks for your quick knowledge to guide us all.

On 2022-10-05 by InspectApedia-911 (mod)

@David J,

Thanks, do let us know what do you find as that will certainly help others who read this article.

On 2022-10-05 by David J

@InspectApedia-911,

I suspect the same and am taking steps to change it now.

I will let you know how that goes with an update.

On 2022-10-05 by InspectApedia-911 (mod)

@David J,

And just to be sure we've got this exactly right, the pre-charge is set when there's no pressure on the system. Otherwise you can get fooled about what the recharge actually is.

So if we are confident that the pre-charge is correct and that there is no valve or check valve that's blocking the flow between the pump and the pressure tank, and the pump is rapidly short cycling, I suspect that the pump output rate is getting ahead of what it can flow through the smaller diameter piping between the pump outlet and the pressure tank inlet.

On 2022-10-05 by David J

@InspectApedia-911,

Yes I pre-charge the tank to 28 psi because my switch is a 30/50 psi switch

On 2022-10-05 by InspectApedia-911 (mod)

@Anonymous,

What is the pressure tank pre-charge pressure, and did you set that with the tank empty?

On 2022-10-05 by David J

I changed out my well tank and pump. They were completely different in design, new versus old. The new system cycles when the pressure reaches 50. No leaks to speak of.

Also does my well pump need to be higher than a couple inches above the supply/suction line.

Switch is mounted on pump. Do I need to move it to the t valve since that is the new style?

At a loss as to why the pump cycles.

I also have a smaller diameter hose for the water out from pump to tank. That is the supply line is 1 1/4” and the pressure line to the tank is 1" until it gets to the check valve then it is 1 1/4”. Is this a problem?

I also had to go to 3/4” 6 inches before th check valve. Maybe that’s the problem?

On 2022-03-16 by Inspectapedia Com Moderator - sand/shallow point well won't prime

@Kami D,

Rather than trying to give a complete answer here, please first take a look at

REPEATED LOSS OF WELL PRIME

where we provide common causes of lost well prime and step by step diagnosis and repair.

Start there and let us know if you have additional questions.

On 2022-03-16 by Kami D

I have a cottage where there is a sand/shallow point well installed. I try to prime the pump, but nothing happens. Where should I start with trying to get to the main issue here? Ive had plumbers look at it- they get it working after a lot of priming and then eventually stops producing any water.

On 2021-12-09 by Inspectapedia Com Moderator - low water yield may be due to pressure control switch that is clogged

@Karl Saidla,

Because you say that your well delivers plenty of water once it's gotten going, I suspect that that initial problem may not be a well flow rate but rather a pressure control switch that is clogged and not responding to the initial drop in water pressure.

Try replacing the switch and also clearing or replacing the tubing or pipe that conducts water pressure to the switch sensor port.

On 2021-12-09 by Karl Saidla

I have a double jet pump for a well that appears to be low yield. If our bathtub faucet is fully open, the water trickles to nothing after about 1 minute. After a break of a minute or two, water returns, and we can proceed normally for all other uses (dishwasher, shower, toilets, other faucet etc.).

We have never lost water in any permanent way - it just stops momentarily when we use water too quickly. It has been this way for the entire 13 years that we have been living in the house.

Recognizing that the "proper solutions" would probably include getting a holding tank or drilling a new well, are there adjustments we could make (to either our pump system or faucets that would reduce the severity of the problem?

I am wondering, for example, if we could slightly restrict the flow of water out of our pressure tank so that water is used a bit slower, or potentially decrease the differential of the cut in/cut off settings so that the pump starts running a bit sooner.

Right now, the pump cuts in at about 26 PSI, and cuts out at about 36 PSI. Assuming no faucets are on, it takes about 8 minutes from when the pump cuts in for it to reach 36 and cut out.

On 2021-11-17 by Inspectapedia Com Moderator - no water going into pressure tank

@Trudy Drover,

Old pressure switch may be debris clogged

No water enters pressure may be a closed valve or a stuck bladder

On 2021-11-17 by Trudy Drover

Water well troubles. Pulled the lines from the well, changed out foot valve, galvanized fittings, which had a leak, installed the well cap back on. Got a new well pump, now getting water to the faucet's/toilets, but no water going into pressure tank.

Having to turn switch from the pump on and off in order to get water and turn off water. The psi remains at 30 when pump switch is turned off. Looking for solutions to what the problem could be now? Thank you in advance.

On 2020-08-14 by (mod) - fix a leaky air valve at the water pressure tank

Bill:

Bill:

Look closely at the point of leakage; most likely you can remove, apply teflon paste, and reconnect a new fitting.

When it's a leak at the air valve or Schrader valve, look closely: is the leak at the threaded base of the valve? If so you may be able to tighten the valve or to remove it, apply teflon tape, and re-install it to stop the leak.

If the Schrader valve is leaking at its stem or core, a **temporary** emergency repair is to simply install and tighten a valve stem cap over the open end of the valve. This is a standard tire valve thread so any auto supplier has these caps as do the tires on your car. (In an emergency, I've borrowed the valve cap off of the car's spare tire.)

For a proper repair, it's possible to replace the Schrader valve stem core - again a standard automobile tire valve part, though on some water systems that use a snifter valve, the schrader valve stem core on that device uses a much weaker spring than an automobile tire valve core.

Exact details of how to repair a leaky water tank air valve are

at WATER TANK AIR VALVE REPAIRS

On 2020-08-11 by Bill

Hi hope you can help me. I have a pressure tank leaking from the bottom fitting as well as water coming out of the schrodier valve at the switch. The boost pump is attached top the wet side of the tank. Does the tank need replacing and can I just reattach the boost pump?

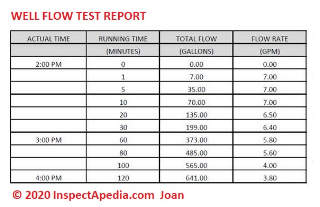

On 2020-08-10 - by (mod) - flow rate testing

Well flow test report interpretation Joan:

Joan:

"Flow rate" is defined in articles I'll cite below; basically it is not a useful number until you obtain it over a 24 hour period.

Otherwise you're simply exhausting the well - it's like claiming your car can get 80 mpg because you measured the fuel consumption rate after you drove a mile and turned off the engine.

5 GPM is a flow rate that is required for functional flow in the building; your well cannot sustain 5 gpm for more than one hour.

So if sometimes your flow rate is less, then you're depending on water storage to make up the difference; that is, for a low flow or limited flow rate well, a common step is to add a large water storage capacity, allowing the storage to recover at the lower flow rate overnight or during other periods of disuse.

Watch out: A well flow test is often run over a 24-hour period.

Your well flow rate fell from 7 gpm to under 4 gpm after two hours after drawing 600 gallons - about the typical daily water use for three people.

It's not that you couldn't live with this well, because you could, but you're starting off with a rather modest water supply.

You should be concerned, and you should budget for well flow improvement costs or water storage costs.

To understand this topic and thus to equip yourself to discuss it, I recommend reading these two brief articles:

WELL FLOW RATE - how do we find out well water quantity - well flow rates or draw down tests

WELL FLOW TEST PROCEDURE - how can a homeowner or home buyer make a simple well water quantity test

On 2020-08-10 by Joan

I’m not sure if you are able to help with this question but I’m really hoping so.

We just received the results of a well flow test on a house we are in the middle of purchasing.

The GPMs started out at 7 but began to drop after 20 minutes. By the end of the two hours test the GPMs had dropped to 3.8. The total flow was 641 which is just over the state requirement if I’m not mistaken and I know the GPM should be at 5 but I’m not sure if that is 5 during the duration of the test or as an average? I’m hoping you can give me some insight on whether I should be concerned.

During the home inspection of the home the inspector tried to fill up the bathtub and it took over an hour and I’m really wondering if the well could be the reason for this. The home is a full three bath house at 3000 square feet.

I've attached the results for you to view

Thank you for your time.

On 2020-08-08 by Moderator - Leathers and well bores

90 ft deep wells with a 2in board don't use leathers. Leather was used as a washer on hand pumps that used to be able to pump from a depth of about 20 to 25 feet.

And metal well piping doesn't rot. Wood rots.

So what do you report having been told sounds to me like someone who either doesn't know much about wells or is speaking very carelessly.

In order to try to restore a 90 ft deep 2 in weII service I would start by finding out what's in the well. That means hiring a more professional well service company who has a well inspection camera. Using the camera, you can find out the condition of the wellbore and whether it is collapsed or damaged and you can also find the depth of the water.

If the well bore used to be in good condition and there's a reasonable volume of water in the bore the next step would be to temporarily try pumping out the well to see if it has a usable flow rate or recovery rate. If it does then you'll probably install a two-line jet pump to provide water from your well.

On 2020-08-08 by John

I have just purchased an old brick school house. It has a 2 inch well that we believe is 90+ ft deep. I tried to run the pump and the elcetric motor ran for over 10 minutes without any luck bringing water up. Everything seems to be in working order.

My local well man says it could be the leathers are too worn or the pipe is rotted through as the well is from 1900. I was hoping to revive this well. Any ideas? Can a sandpoint be lowered into this pipe and solve the problem? I only need 4-5 gal / minute

On 2020-07-29 by Moderator - When water requirements far exceed well capability to deliver water

When you see 10,000 gallons of water storage at a site then you know the on-site water requirements far exceeded the ability of the wells on the site to deliver water. Strategy in such a case is to use wells that have a poor weak or slow recovery rate to refill water tanks slowly, typically over a 24-hour period, or at night when not much water is in use.

I can't second-guess your well company who was on site, but from what you have described it seems to me that what was missing was a very common system that uses a type of pump protection switch or device that will turn off a water pump to prevent it from pumping air or running dry. It's running dry that destroys a water pump.

So you can tell your manager that you did exactly the correct thing by immediately turning off the pumps when you saw that there was trouble.

You can add my explanation that unfortunately by the time that could be discovered it may have been too late in that the pumps were already damaged,

and you can add that the original installer shortchanged you by not providing protection for the pumps or at the very least testing the well to establish their flow rate to prove that the system that was being installed would work correctly.

I can't really know, but I suspect that the fact that calls weren't returned means that the original installers knew perfectly well that they hadn't done the correct job.

Once you establish that you have functional well you should at least be sure that from protection devices are part of your new installation.

On 2020-07-29 by Sue

I work at a facility with 11 buildings on the grounds all of which, will eventually need running water. The buildings are 50+ years old and have not been used in 15-20 years. We are remodeling 1 building at a time and at this time only need to use water in 1 of them.

We have 2 wells only one of which was working and 4 10,000 gallon holding tanks. We recently replaced all the underground pipes running from the well to the buildings.

It's been 1 problem after another. Brand new underground pipes were bursting for no apparent reason And leaks around the pressure pumps, specifically from one of the boosters.

We just installed 4 new pumps and everything was working well for 2 days, and then all of a sudden, there was no water pressure. I walked around the property, looking for evidence of another leak from the underground pipes and could not find any. I turned the swith on the pump off anyway and called the owner.

He called & notified the pump company and said they would be out in morning. They never showed up the next day but instead sent an electrician out to install a flow switch so that when water got too low in one tank, it would automatically switch to another.

Unfortunately, the damage was already done and now my boss has to pay another $20,000 because all 4 new pumps need to be replaced again. My boss is understandably very angry, but thinks I did something to cause this.

All I did was turn the pump off when I noticed there was no pressure. I've never turned it on and know better than to mess with things I know next to nothing about. I dont know if someone from the pump company put this in his head or if he just thinks because I was the only one on the grounds at the time, that I must have caused it.

Apparently, the cause of the low pressure was due to the water level in the holding tank getting too low. The holding tank has tiny holes in the top 1/3 of the tank so it water shoots straight out the holes when the tank is filled over 2/3 from top.

I believe the pump company knew this problem would eventually happen because they knew there was nothing installed to protect the pumps, should the well run dry and that we should not be held liable, after all, they're the professionals. I believe they are reaming my boss because they believe they have found a money tree.

Apparently this whole ordeal has cost him $120,000. I dont know if he is exaggerating the cost to me or if this is typical or if he is just dealing with an unethical company, and I dont know enough about wells & pressure pumps and holding tanks to offer my opinion but I feel so strongly that something just isn't right, I'd really appreciate some expert advice.

On 2020-07-29 by Moderator

You will want to check with the pump manufacturers about the properties of the specific pump brand and model that you are selecting or planning to install.

Many pumps can tolerate running continuously for long intervals.

Rapid short cycling on and off is what damages a pump and / or the pump pressure control switch.

You should also consider including a pump protection switch to be sure that your long-running pump doesn't run dry and suffer damage from that condition.

On 2020-07-18 by Jeffy

Hi- I've lived here for 10 years. I am on my 3rd 1.5hp pump, and 2nd 119 gal bladder tank.

Concerned with these higher expenses, I asked the well company what is the best scenario for maximizing well components life while irrigating my yard etc. They recommended getting the well's flow rate output matched to the irrigation output, so that the pump runs continuously without cycling.

I have done this, and the water pressure runs steady at 48psi on each 25 minute irrigation cycle. The pressure switch is at 40/60psi. Is pump cycling more wearing than continuous running?

Does it depend on the water temperature the pump is submersed in? How long the pump runs continuously?Any scenarios better than what I am doing is greatly appreciated!

On 2020-07-11 - by (mod) - how to test for water hardness

Cheryl

Thanks for asking about water hardness testing.

Please take a look at WATER HARDNESS: HOW TO MEASURE

where we tested and demonstrated several different types of water hardness tests. The easiest, a simple test strip, properly used, will be fine for your purposes.

On 2020-07-11 by Cheryl D

What is the best water hardness kit to buy that will give me a close correct setting for my water softener

On 2020-07-05 - by (mod) -

Ahmed

Please find your question and our detailed reply now at

at WELL BORE ALIGNMENT PLUMBNESS STRAIGHTNESS - standards, test procedures, why well bore alignment is important

Thank you for asking a most helpful question. Let me know if you need more information

On 2020-07-05 by Husnain Ahmed

What is deep well deviation limit from vertical/plumbline .any material for deviation measurement please share

Please I want to know the various standards defined by international groundwater agencies for deep well casing deviation (plumpness limit) from plumbline for 300 ft depth.

...

Continue reading at WATER TESTS for CONTAMINANTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see WATER SUPPLY SYSTEM FAQs - questions and answers posted originally at this web page

Or see these

Recommended Articles

- AIR DISCHARGE at FAUCETS, FIXTURES

- CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS

- FOOT VALVES

- WATER CONSERVATION MEASURES - home

- WATER METERS, RESIDENTIAL

- WATER PRESSURE LOSS DIAGNOSIS & REPAIR - home

- WATER PUMPS, TANKS, TESTS, WELLS, REPAIRS - home

- WATER PUMP REPAIR GUIDE - home

- WATER QUALITY TESTS, CONTAMINANTS, TREATMENT

- WATER SUPPLY & DRAIN PIPING - home

- WATER TANK: USES, TROUBLESHOOTING - home

- WATER TESTS for CONTAMINANTS - home

- WATER TREATMENT EQUIPMENT CHOICES - home

- WELLS CISTERNS & SPRINGS - home

Suggested citation for this web page

WATER PUMPS, TANKS, TESTS, WELLS, REPAIRS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Drinking Water from Household Wells - PDF, U.S. EPA, Original source last retrieved 2/13/2013, original source: http://www.epa.gov/privatewells/pdfs/household_wells.pdf

- [2] Salzman, James, Drinking Water: A History, Overlook (2012), ISBN-10: 1590207203, ISBN-13: 978-1590207208, Quoting product description:

In Drinking Water, Duke University professor and environmental policy expert James Salzman shows how drinking water highlights the most pressing issues of our time--from globalization and social justice to terrorism and climate change--and how humans have been wrestling with these problems for centuries.

From the aqueducts of Rome to the revolutionary sewer system in nineteenth-century London to today’s state-of-the-art desalination plants, safety and scarcity of water have always been one of society’s most important functions. - [3] Soll, David, Empire of Water: An Environmental and Political History of the New York City Water Supply, Cornell University Press, (2013), ISBN-10: 0801449901, ISBN-13: 978-0801449901, Quoting: product review

"Empire of Water chronicles the fascinating story of New York City's water supply, which comes mostly from reservoirs in the Catskills and, remarkably, is unfiltered.

That's because the city has spent billions of dollars and decades of effort working with residents, businesses, and governments in the Catskills to protect the reservoirs from pollution caused by runoff from roads, farms, and dairies. This meticulously researched and persuasively reasoned history explores the change in New York City’s attitude toward water, from indifference to profligate water waste and environmental pollution to stalwart champion of water conservation and protection.

The best histories shed light on the past as they illuminate the present. Empire of Water is in this category. By protecting the ecosystem services provided by a pristine watershed in northern New York, the city avoided having to spend $8 billion to build a treatment plant.

As we confront water shortages in the United States and across the world, Empire of Water teaches that business as usual—looking for new oases and relying on massive engineering solutions—no longer makes sense. We must acknowledge nature’s limits and work within them to secure a sustainable future for coming generations."—Robert Glennon, Regents’ Professor and Morris K. Udall Professor of Law and Public Policy, University of Arizona, author of Unquenchable: America's Water Crisis and What To Do About It - [4] Mithen, Steven, Thirst: Water and Power in the Ancient World, Harvard University Press (2012), ASIN: B00EDZ5OHC. Quoting product review at Amazon:

Water is an endangered resource, imperiled by population growth, mega-urbanization, and climate change. Scientists project that by 2050, freshwater shortages will affect 75 percent of the global population.

Steven Mithen puts our current crisis in historical context by exploring 10,000 years of humankind’s management of water. Thirst offers cautionary tales of civilizations defeated by the challenges of water control, as well as inspirational stories about how technological ingenuity has sustained communities in hostile environments.

...

Mithen blends archaeology, current science, and ancient literature to give us a rich new picture of how our ancestors lived. Since the Neolithic Revolution, people have recognized water as a commodity and source of economic power and have manipulated its flow.

History abounds with examples of ambitious water management projects and hydraulic engineering—from the Sumerians, whose mastery of canal building and irrigation led to their status as the first civilization, to the Nabataeans, who created a watery paradise in the desert city of Petra, to the Khmer, who built a massive inland sea at Angkor, visible from space.

As we search for modern solutions to today’s water crises, from the American Southwest to China, Mithen also looks for lessons in the past. He suggests that we follow one of the most unheeded pieces of advice to come down from ancient times. In the words of Li Bing, whose waterworks have irrigated the Sichuan Basin since 256 bc, “Work with nature, not against it.” - [5] Pabich, Wendy J., Taking on Water: How One Water Expert Challenged Her Inner Hypocrite, Reduced Her Water Footprint (Without Sacrificing a Toasty Shower), and Found Nirvana, Sasquatch Books (2012), ASIN: B00EB0JTB6, Quoting Amazon product review:

When Wendy Pabich received a monthly water bill for 30,000 gallons (for a household of two people and one dog), she was chagrined. After all, she is an expert on sustainable water use. So she set out to make a change.

Taking on Water is the story of the author's personal quest to extract and implement, from a dizzying soup of data and analysis, day-to-day solutions to reduce water use in her life. She sets out to examine the water footprint of the products she consumes, process her own wastewater onsite, revamp the water and energy systems in her home, and make appropriate choices in order to swim the swim.

Part memoir, part investigation, part solution manual, the book is filled with ruminations on philosophy, science, facts, figures, and personal behavioral insights; metrics, both serious and humorous, to track progress; and guidelines for the general public for making small (or perhaps monumental) but important changes in their own lives. - 1-Bromo-3-chloro-5,5-dimethylhydantoin (C5H6BrClN2O2) is produced world-wide and is also used in cleaners and bathroom disinfectants and deodorizers. Here is an example MSDS for this product, provided by Leisure Time

- "Bacteria in Drinking Water" - "Chlorine," Karen Mancl, water quality specialist, Agricultural Engineering, Ohio State University Extension. Mancl explains factors affecting the effectiveness of chlorine in water as a means to destroy bacteria and other microorganisms. OSU reports as follows:

- Chlorine kills bacteria, including disease-causing organisms and the nuisance organism, iron bacteria. However, low levels of chlorine, normally used to disinfect water, are not an effective treatment for giardia cysts. A chlorine level of over 10 mg/1 must be maintained for at least 30 minutes to kill giardia cysts. -- http://ohioline.osu.edu/b795/index.html is the front page of this bulletin

- "Chemicals and Our Health", Nicholas D. Kristof, New York Times, 16 July 2009, p. 27. This outstanding editorial calls for improvements in public health policy to address phthalates and other environmental contaminants from common chemicals and products in everyday use. - DJ Friedman

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- Endocrine Disruptor Exchange, Dr. theo Colborn (also see Our Stolen Future).

From that website: The Endocrine Disruption Exchange, Inc. is the only organization that focuses primarily on the human health and environmental problems caused by low-dose and/or ambient exposure to chemicals that interfere with development and function, called endocrine disruptors. ...

TEDX's work focuses on the endocrine system, which is the exquisitely balanced system of glands and hormones that regulates such vital functions as body growth, response to stress, sexual development and behavior, production and utilization of insulin, rate of metabolism, intelligence and behavior.

Hormones are chemicals such as insulin, thyroxin, estrogen, and testosterone that interact with specific target cells. The interactions occur through a number of mechanisms, the easiest of which to conceptualize is through a lock and key arrangement. - Giardia exposure limits for drinking water: see www.mass.gov/dep/water/drinking/standards/giardia.htm is the current regulatory exposure limit (your minimum target for sterilization)

- Health Effects of Chemical Contaminants in Drinking Water, US Environmental Protection Agency,

- Hydrogen peroxide: Wikipedia on history of use of hydrogen peroxide: Information on Hydrogen peroxide as a sterilant is in Wikipedia at en.wikipedia.org/wiki/Sterilization_(microbiology) HO2 has been used for a long time, including by vaporization for sterilizing freeze dryers.

- Hydrogen Peroxide warning: US FDA Warning about drinking hydrogen peroxide: www.truthorfiction.com/rumors/h/hydrogen-peroxide.htm This article cites a 2003 entry in Journal of Food and Science on using Hy.Perox to sterilize vegetables, referring to E.coli - NOT to Giardia.

- Iodine: "Do Iodine Water Purification Tablets Provide an Effective Barrier against Cryptosporidium parvum?", Starke, Jeffrey A., Bowman, Dwight D., Labare, Michael, Fogarty, Elizabeth A., and others, Military Medicine, 25 October 2001 [possibly a later version of this article appeared in 2005 -DF] http://www.amsus.org/military medicine/milmed.htm

- National Primary Drinking Water Regulations - The complete regulations regarding these contaminants available from the Code of Federal Regulations Website -(United States)

- Ohio State University article on the concentration of chlorine necessary to act as an effective disinfectant, and the effects of the water's pH and temperature: See http://ohioline.osu.edu/b795/b795_7.html for details.

- Our Stolen Future: Are We Threatening Our Fertility, Intelligence, and Survival?--A Scientific Detective Story, Theo Colborn, Dianne Dumanoski, John Peter Meyers. Plume-Penguin Publishing, 1997, ISBN 0-452-27414-1., ISBN13: 9780452274143. This book is a seminal work on endocrine disruptors (chemical contaminants having impact at extremely low levels in the environment).

Recommended by Daniel Friedman, this book is a critical update to the landmark Silent Spring by Rachel Carson and discusses the effects of minute trace amounts of chemical contaminants in the environment.

The text "Identifies the various ways in which chemical pollutants in the environment are disrupting human reproductive patterns and causing such problems as birth defects, sexual abnormalities, and reproductive failure. Reprint. Tour. NYT."

Amazon.com Review: By O T (Ontario, BC) - 'Our Stolen Future' is a great introduction to one of the most important scientific discoveries in our time. Having recently completed a thesis project at university on Endocrine Disruptors, I have reviewed hundreds of papers on the subject.

This book is a good clear overview of the scientific literature on EDs. The authors are experts - Theo Colborn is largely responsible for creating the field by bringing together diverse researchers so they could see the big picture of their work.

Many of the principle investigators are interviewed and quoted at length on the way chemicals participate in and interfere with delicate hormonal systems in animals (including humans). The major accomplishment of the book is to make an easy-to-follow story out of complex research.

Many resources are available to help you assess the reliability of this story, and the best thing to do if you have any doubts is read review articles in scientific journals (which are easier to understand than technical papers). The Physicians for Social Responsibility (PSR) have a guidebook for health-care professionals on Endocrine Disruptors, and the US EPA has many reports on the matter. Beware of people or websites who try to 'debunk' this book (or the science behind it) by simply declaring it false, flawed or disproven. There is far too much supporting research for so simple a refutation.

OPINION: Significant and discussed in this book is the observation that at certain critical points in the development of animals, presumably including humans, exposure to extremely low levels of endocrine disruptor chemicals (EDC's) BPA - Bisphenol-A or BPA, Diethylstilbestrol - DES, dioxins, PCBs, and chemicals used in the production of certain cleansers, dyes, flame retardants, plastics, pesticides, white papers ) perhaps just a few molecules, or in the parts per trillion, is sufficient to cause disruption of the animal's development, including proper sex differentiation, or the lack of it that produced androgynous ducks unable to reproduce under such conditions.

A endocrine disruptor is a synthetic chemical compound that mimics natural hormones when it is taken into the body of a human or other animal. It "disrupts" the endocrine system by turning on or off normal chemical signals that in turn can affect normal hormone levels, bodily functions, and significantly, the development of embryos. Further, unlike naturally occurring hormones ingested, for example from plants (phytoestrogens), synthetically-generated hormones accumulate in the body and can have a half-life of decades or longer.

One significance of this finding includes the observation that an important medical effect that occurs with exposure to chemicals in extremely low concentrations means that experiments to test for correlations between chemical exposure and subsequent serious medical problems will be deeply flawed if, for example, the experimental design does not include testing for the presence of the chemical at extremely low levels.

A related concern is that even if harmful effects from exposure to extremely low concentrations of an endocrine disruptor are occurring, teasing out and proving that relationship can be also extremely difficult. - Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- [20] SCALE FORMATION in WATER HEATERS and METHODS of PREVENTION free download as [PDF] Krappe,

Justus Maximilian, Engineering experiment station. Gas engineering bulletin; no. 6; Research series; no. 74; On cover: Engineering bulletin, Purdue university. Vol. xxiv, no. 3a. June, 1940 (Layfayette Indiana) commonly referred to in some references as "Purdue University Bulletin No. 74" - thanks to researcher Robyn Goldstein for the full citation. LCCN: 40028844 & OCLC: 1038544 - Water analysis, water softening, hot-water supply. 27pages.

You can also obtain this document through your local library. (full copy file at InspectAPedia 3/31/2010) Purdue B074 can be hard to locate online.

Also Bradford White Corporation (a manufacturer of water heaters) previously published

SCALE FORMATION in WATER HEATERS - EXCERPTS [PDF] from that document made available by Purdue University. - Silent Spring, Rachael Carson, Mariner Books; Anv edition (October 22, 2002), ISBN-13: 978-061824906.

Amazon.com Review: Silent Spring, released in 1962, offered the first shattering look at widespread ecological degradation and touched off an environmental awareness that still exists.

Rachel Carson's book focused on the poisons from insecticides, weed killers, and other common products as well as the use of sprays in agriculture, a practice that led to dangerous chemicals to the food source. Carson argued that those chemicals were more dangerous than radiation and that for the first time in history, humans were exposed to chemicals that stayed in their systems from birth to death. Presented with thorough documentation, the book opened more than a few eyes about the dangers of the modern world and stands today as a landmark work. - UNESCO: World Water Assessment Programme [ copy on file as /water/Water_Assessment_UNESCO_129556e.pdf ] - , Executive Summary, UNESCO Publishing, Secretariat: C/O UNESCO/Division of Water Sciences, 1 Rue Miollis, F-75732 Paris Cedex 15, Tel: +33.1.45.68.39.28, Email: wwap@unesco.org, websearch 09/10/2010 original source: http://unesdoc.unesco.org/images/0012/001295/129556e.pdf - Quoting:

This report is organized in six main sections: a background, an evaluation of the world’s water resources, an examination of the needs for, the uses of and the demands on water (‘Challenges to Life and Well-Being’), a scrutiny of water management (‘Management Challenges’), seven representative case studies highlighting different water scenarios, and conclusions and annexes. - US EPA: list of drinking water contaminants: see http://www.epa.gov/safewater/contaminants/index.html

- UV light: This patent application for UV light sterilization www.patentstorm.us/patents/6565803.html Lists good references on water purification for Giardia et als

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- Handbook of Disinfectants and Antiseptics, Joseph M. Ascenzi (Editor), CRC, 1995, ISBN-10: 0824795245 ISBN-13: 978-0824795245 "The evaluation of chemical germicides predates the golden age of microbiology..." -

This well-focused, up-to-date reference details the current medical uses of antiseptics and disinfectants -- particularly in the control of hospital-acquired infections -- presenting methods for evaluating products to obtain regulatory approval and examining chemical, physical, and microbiological properties as well as the toxicology of the most widely used commercial chemicals. - Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- Principles and Practice of Disinfection, Preservation and Sterilization (Hardcover)

by A. D. Russell (Editor), W. B. Hugo (Editor), G. A. J. Ayliffe (Editor), Blackwell Science, 2004. ISBN-10: 1405101997, ISBN-13: 978-1405101998.

"This superb book is the best of its kind available and one that will undoubtedly be useful, if not essential, to workers in a variety of industries. Thirty-one distinguished specialists deal comprehensively with the subject matter indicated by the title ...

The book is produced with care, is very readable with useful selected references at the end of each chapter and an excellent index. It is an essential source book for everyone interested in this field. For pharmacy undergraduates, it will complement the excellent text on pharmaceutical microbiology by two of the present editors."

The Pharmaceutical Journal: "This is an excellent book. It deals comprehensively and authoritatively with its subject with contributions from 31 distinguished specialists. There is a great deal to interest all those involved in hospital infection ... This book is exceptionally well laid out.

There are well chosen references for each chapter and an excellent index. It is highly recommended." The Journal of Hospital Infection.: "The editors and authors must be congratulated for this excellent treatise on nonantibiotic antimicrobial measures in hospitals and industry ...

The publication is highly recommended to hospital and research personnel, especially to clinical microbiologists, infection-control and environmental-safety specialists, pharmacists, and dieticians."

New England Journal of Medicine: City Hospital, Birmingham, UK. Covers the many methods of the elimination or prevention of microbial growth. Provides an historical overview, descriptions of the types of antimicrobial agents, factors affecting efficacy, evaluation methods, and types of resistance. Features sterilization methods, and more. Previous edition: c1999. DNLM: Sterilization--methods. - U.S. Army Field Manual 21-10, Field Hygiene and Sanitation, 1988, web search 07/02/2010, original source: http://www.enlisted.info/field-manuals/fm-21-10-field-hygiene-and-sanitation.shtml

The purpose of this manual is to assist individual soldiers, unit commanders, leaders and field sanitation teams in preventing disease and environmental injuries.

The manual provides information on preventive medicine measures (PMM) to the individual soldier as well as essential information for the unit commander, unit leaders, and the unit field sanitation team on applying unit level PMM. - When Technology Fails, Matthew Stein, Chelsea Green Publisher, 2008,493 pages. ISBN-10: 1933392452 ISBN-13: 978-1933392455, "... how to find and sterilize water in the face of utility failure, as well as practical information for dealing with water-quality issues

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.