Drilled Steel Casing Modern Drinking Water Wells, Types & Repairs

Drilled Steel Casing Modern Drinking Water Wells, Types & Repairs

- POST a QUESTION or COMMENT about steel casing drilled water wells at residential properties

Drilled wells:

This article describes the properties & construction of drilled wells that use a steel well casing, modern drinking water wells.

We discuss well problem diagnosis, testing, & repair procedures - advice about what to do when things go wrong with the well such as loss of water pressure, not enough water volume, contaminated wells, wells that have smelly water, wells that just run out of water or have a low recovery rate. We describe the parts of a water well and its piping and controls including the pitless adapter.

We explain how a well water recovery rate is measured or calculated. We explain the role of static head of water in a well and how to measure the static head.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Drilled Wells - guide to modern steel casing wells

Here we describe modern steel-casing drilled water wells, including how the well is constructed, sealed against contaminants, and how the well flow rate or water recovery rate is evaluated.

Here we describe modern steel-casing drilled water wells, including how the well is constructed, sealed against contaminants, and how the well flow rate or water recovery rate is evaluated.

The page top photo is of a modern well casing, in good condition, extended properly above ground.

The small-diameter pipe parallel to the six-inch steel well casing is an electrical conduit - so we know that for this particular water supply system a submersible water pump is used and it is installed in the well itself.

The electrical conduit carries electrical power to the water pump down in the well.

The blue and white plastic rope in the page top photo was probably used to raise and lower the well piping and pump from within the casing.

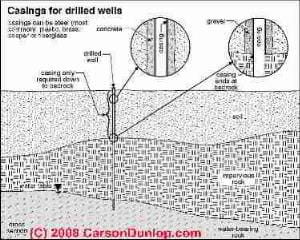

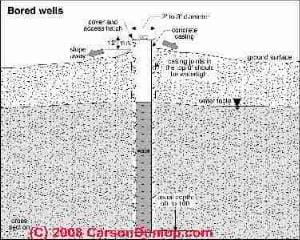

In Carson Dunlop's sketch at left we show the typical construction of a drilled water well in cross section.

You can see that the typical well casing diameter is 6" (4" in some areas), that the well depth can be considerable (50 50 ft. to 900 ft. or more), and that the steel well casing does not extend down into the bedrock.

As we show in In Carson Dunlop's sketch below, there are several types of well casings and more than one type of well casing sealant.

Drilled well casing types: Drilled well casings can also be constructed of plastic pipe, brass pipe, copper pipe, or fiberglass pipe.

Drilled well casing sealant with concrete or gravel and slurry: A concrete slurry or gravel and mud mixed grout is poured around the exterior of the well casing after it has been pushed into the drilled well opening.

This grout is necessary to prevent surface water from leaking into and contaminating the well water. The water that enters this well comes from cracks or fissures in water bearing rock shown at the bottom of the sketch.

Not shown in this sketch are the well details such as submersible well pump, well piping, pitless adapter, and piping between the well and the building it serves. We discuss the pitless adapter and these other parts below.

The photo shown just above is of an older drilled-well casing which has been placed with its casing cap at ground level - increasing the risk of well contamination from surface runoff.

All we can see is the well cap.

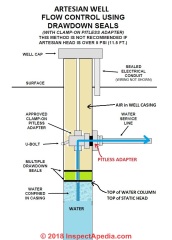

Pitless Adapters for Well Casings

The water pipe leaving this well to carry water to the building will be buried below ground, and in freezing climates, below the frost line.

A special fitting, the pitless adapter is used to seal the passage cut into the round well casing. Below we illustrate the use of a pitless adapter on a drilled artesian well.

Details are at PITLESS ADAPTER

Details about artesian wells are

at ARTESIAN WELLS, WELL SPOOLS

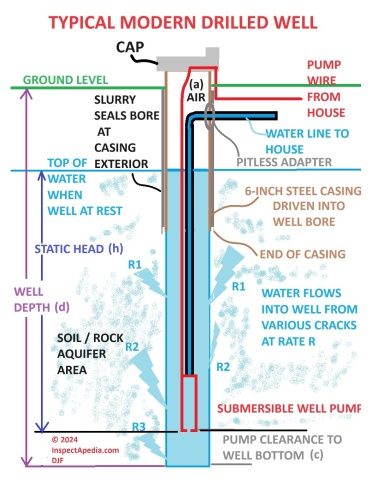

Below: here is a rough sketch of the parts of a well showing its various measurements of depth, water column, static head etc. [Click to enlarge any image]

Key to our sketch of the parts and features a drilled water well shown just above

d = well depth as drilled. More about measuring the depth of a well is

at DEPTH of a WELL, HOW TO MEASURE

a = air - the distance from the ground surface to the top of the water when the well is at rest and is fully "recovered" from recent use

c = clearance distance between the bottom of the well pump (or foot valve) and the very bottom of the drilled well. this distance is required to avoid having the pump pick up mud and debris from the well bottom.

h = static head: the volume of water available to the well pump when the well is at rest and is fully recovered.

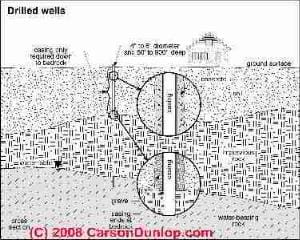

Bored Water Wells

A bored water well is a lot like a 'drilled well' and the use of this term is confusing to some.

The differences between a bored well and a drilled well are these:

- Unlike a drilled well described above, the bored well is prepared using different equipment which is not capable of boring to as great a depth.

- As Carson Dunlop's sketch shows, the bored well is often lined with interlocking sections of concrete piping rather than a continuous steel casing.

- A bored well is likely to be found in areas of high water table, and where the water supply is obtained from water bearing soil or sand rather than bedrock.

The usual depth of a bored well is 50' to 100' - not as deep as a drilled water well.

Definition of & Formula for Determining Water Well Recovery Rate

We provide an introduction to well recovery rate just below. Details of "how much water is in the well" are discussed

The well recovery rate is the rate at which water flows into the well opening from surrounding rock (or soil or other water source).

The well recovery rate is a complex number comprised of the water flow rate and water flow duration from various rock fissures and openings into the well casing or well opening.

Because water flowing into the well from a particular rock crack or fissure often flows at a varying rate, typically falling to a lower rate or even stopping after time, the total well recovery rate involves a summation equation adding up the individual rock fissure flow rates and considering the length of time that each flow rate can be expected to occur.

The length of time that each flow rate at each fissure may occur varies from just a few minutes to more than 24-hours.

Flows that continue at a given rate for 24-hours or more are considered "indefinite" for practical purposes because the usage level (taking water out) at a residential property is typically measured on a 24-hour use cycle.

R = total recovery rate

r = individual rock fissure well flow rate for individual flow rate times (for example rock fissure #1 may involve one or more flow rates depending on how its flow rate varies.

We add all of these r's for each rock fissure together to get the total flow from that fissure over 24-hours)

n = the total number of rock fissures feeding the well at all depths of the well opening

R0 = SUM [r1 - rn]

To include the variation in flow rate over time at each rock fissure that feeds a water well, we write an integral equation something like this:

R = [INTEGRAL 0 to X] SUM [r1 - rn] where the interval 0-X represent the varying flow rates over time.

Definition of Total Water Available from a Water Well over a Given Time Period

The total volume of water available from a water well is the sum of the static head plus the recovery rate for the time period, typically 24-hours.

Volume of Water over 24-hours = Static Head (h) + Recovery Rate (R)

Details of "how much water is in the well" are discussed

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2016-04-11 by Anonymous - how long can I run water on a 280 foot well with 3 gallon/minute flow?

how long can I run water on a 280 foot well with 3 gallon/minute flow?

On 2016-04-11 - by (mod) -

Don't know, Anon. The trouble is that a 280 foot deep hole might have just 10 feet of water in the hole when the well is at rest, or it might have 280 feet. So we dont' know the static head or reserve of water. That volume, particularly in a deep well with a big static head, is a significant component in the total draw down rate.

Skipping over that show-stopper, how long you can run water also depends on

- the flow rate into the well - which is not a fixed number, as flow rates vary over time and are actually multiple little flow rates from different rock fissures at different depths of the well (in many cases, not all cases)

- flow rates, properly measured, are over a 24 hour period.

- and on a low-flow rate well (3gpm is rather modest), if an installer includes a large water storage tank to allow the stored water volume to get ahead of daily use volume by drawing water slowly from the well over time, then the length of time you can run water will be set by that water storage volume too: add that volume to the static head volume.

So if your well was measured over 24 hours, you can draw water for 24 hours, PROVIDED the flow rate of all the water you're taking out of the well is 3 gpm or less.

Search InspectApedia for WELL FLOW RATE and for WELL STATIC HEAD to read details.

On 2012-09-13 by mountjeez - Instead of 190’, they drilled to 300’ and now have sulfur smell and bad tasting water.

Our well was drilled in the late 1940's and has a steel casing. Upon the last replacement of a submersible pump (2005), I was told that the casing at the top of the well head was very thin and I may be looking at drilling a new well in the near future...that was 7 years ago.

The well casing and cap is only about 1" above ground level which is dirt, and not concrete, but at least it is located in a cement block 4’X6” well pit where there is no run-off water from the outside and the dirt floor is always dry.

The well, if I recall correctly is about 190’ deep.

In the last year or so, the toilet tanks slowly (over several months’ time) accumulates a dark, almost black cloudiness and stains the toilet bowl which needs to be cleaned every 5-6 days. It's not particulate matter or solid sediment...more like cloudy water as if someone put a drop or two of black dye in it.

I have a whole-house filter installed. When I put in a new white filter, within 2 weeks it is black and I change it. It does not however have any reduced water pressure indicating it is clogging, nor is it slimy...just discolored. I don't know if this is happening partly as a result of the drought, deterioration of the casing, iron bacteria, a combination, or something else entirely.

A well-drilling company has quoted me $6,000 to drill a new well, but if the problem is not with the casing and is instead from natural causes I don't want to have to drill for a new well. So my problem is two-fold. Will the casing last for a while, and what is causing the cloudiness in the toilet tanks.

The water in this well has always been great tasting and has never gone dry in the time since we have lived here (late 1950). We’re having the water tested this week and will see how the results come back and whether or not we can determine what the problem is...i.e. what’s causing the discoloration.

As I said, in a drinking glass there is no discoloration nor bad taste and no loss of pressure when the filter gets black...just staining the toilet tanks and bowls after several months following a good cleaning. Also, in a drinking glass, nothing (at least nothing that I can see) settles to the bottom. It is crystal clear.

The well driller says they can drill within 10’ of the old well, but in all probability won’t hit the same aquifer because they don’t know how deep the old steel casing is and they would put a new pvc casing probably to 100’. I’m really concerned because our neighbor (about ¼ mile away) had an old well very similar to ours (drilled in the 40’s-same depth), had the pump go out and stick in the casing so it could not be retrieved and had to drill a new well 20’ from his old well.

Instead of 190’, they drilled to 300’ and now have sulfur smell and bad tasting water.

I’m afraid the same thing will happen to us if we drill a new well. Is there anything we can do to stand a better chance of hitting the same aquifer that we’re currently on if we have to drill a new well?

Is there any way to check the old casing to see if it is, in fact deteriorating? What a mess!!

Any suggestions will be greatly appreciated.

Thanks, Wayne

On 2012-09-16 by (mod)

Mountjeez

Before thinking about a solution to black cloudy dirty water, we would best know first what's in the water and where it's coming from. For example, if the problem is a change in the aquifer feeding the well, one can't bet that a new well nearby will hit better water.

Let us know what your water test finds.Yes a well casing can be inspected using a well camera lowered down into the well bore.

On 2012-06-28 by Gary - How to Get More Water From a Well

I had a well that produced 80gal/min., but someone dropped a cherrybomb down the pipe and blew up the casing. My pump guy chased the hole but got his bit stuck. We moved over 10 feet, drilled another well, and came up dry. Is there a way of fracking the rock to gain access to water we obviously narrowly missed?

On 2012-06-29 - by (mod) -

Gary, maybe. In the article links near the end of this page, click on "How to Get More Water From a Well" for some suggestions. The success of hydrofracking depends on several variables including the rock properties and water proximity, but if your old well was a good one, there may be water near enough that hydroing the new well will work.

WATCH OUT: the nitwit who cracked the steel casing in your old well has made for a very expensive problem. Not only are you stuck for drilling a new well, the old well needs to be filled and sealed, probably completely. Don't just leave it capped.

The concern is that the fractured casing can let surface water runoff and contaminants leak INTO the well where they leak into and contaminate the water aquifer, spoiling it for your new well as well as anyone else tapping that aquifer.

Keep us posted. What you learn will help other readers.

...

Continue reading at WELL CASING LEAK REPAIRS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRILLED WELLS, STEEL CASINGS

- PITLESS ADAPTERS - Definition & use of a pitless adapter at water wells

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE

- WELL BORE ALIGNMENT PLUMBNESS STRAIGHTNESS - standards, test procedures, why well bore alignment is important

- WELL CAPS & COVERS for well casing cap sealing & venting requirements

- WELL CASING DIAMETER CHOICE - the effects of larger diameter well casings on the static head in a well

- WELL CASING LEAK REPAIRS

- WELL CLEARANCE DISTANCES how far should the well be from the septic, road, property borders, buildings

- WELL FLOW RATE how do we find out well water quantity - well flow rates or draw down tests

- WELL FLOW TEST PROCEDURE how can a homeowner or home buyer make a simple well water quantity test

- WELL PIPING LEAK DIAGNOSIS - a leak in the water piping anywhere between the well bottom and the building can wreak havoc

- WELL PITS - special warnings for properties where the well and well equipment, pump, tank, etc. are outside in a pit

- WELL YIELD IMPROVEMENT how to improve well water yield - steps to try before drilling a new well

Suggested citation for this web page

DRILLED WELLS, STEEL CASINGS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS & SPRINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about steel casing drilled water wells at residential properties.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.