Diagnostic Guide for Weak or NO Water Pressure - Table 1 of 3

Diagnostic Guide for Weak or NO Water Pressure - Table 1 of 3

Troubleshoot water pumps, pressure switches, & other causes of water pressure & flow trouble

- POST a QUESTION or COMMENT about how best to diagnose the cause of poor building water pressure or lost water pressure

This WATER PRESSURE PROBLEM DIAGNOSIS TABLE series provides a table giving step by step checklist for diagnosing water pressure, water pump, and water well problems.

We give diagnostic and repair procedures for both municipal water supply problems and well water supply problems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Table of Diagnostic Steps for Poor Water Pressure from a Pump & Well System

Checklist of water pressure problem diagnosis and repair steps. Well pump problem diagnostic checklist. Well water problem diagnostic checklist.

Water pressure loss or poor water problem diagnostic checklist. How to diagnose loss of water pressure or loss of water in a building - both municipal water supply and private well systems are addressed.

Article Series Contents

- TABLE 1: PUMP WON'T RUN, WON'T STOP, or CYCLES - this table is just below

- TABLE 2: PUMP RUNS, WEAK or NO WATER PRESSURE - separate page

- TABLE 3: PUMP RUNS, NO WATER or INSUFFICIENT WATER - separate page

Keep in mind that if water is running elsewhere in the building (another shower, sink, dishwasher, clothes washer, garden hose, etc) then the water pressure you will observe at your location will usually be reduced.

Table 1: Pump Won't Start, Wont' Stop Running, or Cycles Rapidly |

||

|---|---|---|

Well Pump Will Not Start or Pump Will Not Run |

||

Well Pump Will Not Start or Pump Will Not Run Check the steps in this table or go to WATER PUMP WON'T START - home - for details. |

Check that electrical power is turned on and being delivered to the pump control switch and to the pump.

|

If a check (with power off) shows that you cannot turn the pump impeller assembly the impeller or pump motor itself is bound and needs repair or replacement. Other pump motors may fail to start if the motor has tripped a thermal overload switch (some may re-set automagically), or if the motor has a failed start/run capacitor. If turning on the motor trips the circuit breaker or blows the fuse there is a wiring short circuit or a short circuit in the pump motor or controls. Symptoms such as a humming motor means the pump has power but is not able to operate. Watch out: turn off the pump in these cases to avoid further damage, shock or fire. WATER PUMP ELECTRICAL SWITCHES - electrical power switches ELECTRIC MOTOR OVERLOAD RESET SWITCH - the diagnostic table ELECTRIC MOTOR DIAGNOSTIC GUIDE - how to test an electric motor |

Check the water pressure at the tank & by using an independent pressure gauge (in case the tank gauge is stuck)

|

WATER PUMP DIAGNOSTIC FAQs - helps sort out problems with well pumps & booster pumps The Form M4 (low pressure cut-out feature) is only available on the Square-D 9013FSG & 9013FYG pressure switches. Schneider Electric offers this additional detail about the low pressure cutoff feature included in these two pressure control switch models: The low pressure cutoff remains fixed at 10 psi below the low pressure cut-in for the pressure switch. Although it is not independently adjustable, it will follow the low pressure set point. However, the pressure switch will not be effective if the cut-in point is set below 10 psi. - Op. Cit.

|

|

Pressure switch does not turn on in response to drop in water pressure:

|

WATER PRESSURE CONTROL SWITCH ADJUSTMENTS - how to set the Differential & Range nuts to adjust the pressure control switch cut-in and cut-out pressures. If the pressure switch contacts are burned possible causes include:

Burned pressure switch contacts can be replaced in many pressure control switches. A replacement parts kit typically includes a new set of contacts and a new pressure sensing diaphragm actuator. |

|

...

Pump Will Not Shut Off |

||

Well Pump Keeps Running, Pump Will Not Shut Off Check the steps in this table or go to WATER PUMP WONT STOP RUNNING - home - for details. |

Common causes include:

Less common causes:

Watch out: turn off the pump to avoid damage. |

Watch out: a pump that does not turn off, it is actually delivering water, creates a dangerous over-pressure condition in the system. See more warnings just below. |

...

Pump Keeps Cycling Off & On |

||

Well Pump Turns On and Off too Often - water pump short cycling or Pump turns on every time water is run Check the steps in this table or go to SHORT CYCLING WATER PUMP - home - for details |

Most common cause

Less common causes

|

Watch out: a clogged sensor port or tubing at the pressure switch can delay the response of the switch to rising water system pressure and can cause the pump to run after it should have turned off. |

Notes to the pump diagnostic tables just above and just below

- By "constant cycling" or "short cycling" pump on and off, we mean that the pump turns on - and then off - every few minutes or less.

See

SHORT CYCLING WATER PUMP for diagnostic steps in finding and fixing the trouble - By "intermittent cycling" we mean that the pump seems to run at odd times when you think no water is being run in the building it serves.

See

INTERMITTENT CYCLING WATER PUMPS for diagnostic procedures

- By pump running continuously - we mean that the pump simply never turns off.

Watch out: in that case if no water is being delivered the pump may be damaged or ruined: turn it off right away and then diagnose and fix the trouble.

See

WATER PUMP WONT STOP RUNNING for those diagnostic procedures

Pump Turns On for No Reason |

||

Well Pump Runs Intermittently for No Apparent Reason - no water running Check these causes or see INTERMITTENT CYCLING WATER PUMPS for details |

Most common cause:

|

Watch out: a clogged sensor port or tubing at the pressure switch can delay the response of the switch to rising water system pressure and can cause the pump to run after it should have turned off. The resulting high water pressure in the system risks leaks or even a dangerous burst pressure tank or piping - not just a leak but a source of injury. This sporadic or unexplained "on-cycles" of a pump is a different problem from a well or system that sometimes simply runs out of water. For that problem see WATER PRESSURE INTERMITTENT LOSS and see PLUMBING LEAK DETECTION METHODS |

...

Pump Motor Chatters |

||

| Pump Runs, shuts off immediately after start then runs again: Pump Chatter | Most common cause:

|

May occur when a new pump is installed especially if it's a higher horsepower than its predecessor. Install a water pressure surge protector at the pump outlet. Schneider / Square-D offer these parts in quantity (PN 1530S6G1) but buy just one from your plumbing supplier. |

Notes: Some of the well pump troubleshooting suggestions in this list can be found at the Betta-Flo Jet Pump Installation Manual from the National Pump Co.

These diagnostic suggestions include, expand, and adapt information from : "Preventive Maintenance and Troubleshooting Guidelines for Class 9013F and 9013G Pressure Switches" (2007), Original source: Schneider Electric USA 8001 Knightdale Boulevard Knightdale, NC 27545 USA 1-888-SquareD (1-888-778-2733) www.us.SquareD.com

To select the proper Square-D pressure control switch see to the Schneider Electric catalog Commercial Pressure Switches Types F and G Class 9013

(9013CT9701), Industrial Pressure Switches (9012CT9701), or Nautilus™ Electronic Pressure Sensors, XMLE, XMLF, XMLG (9014CT0201).

National Pump Company, "Betta Flo Jet Pump Installation Manual", National Pump Company, LLC., 7706 North 71st Ave. Glendale, AZ 85303 Tel: (800) 966-5240, offices in the U.S. in Arizona, California, Florida, Georgia, Mississippi, Texas; Email: info@natlpump.com, retrieved 1 April 2015, original source: http://www.nationalpumpcompany.com/pdf/betta_flo_iom_jet_pump.pdf

Tractor Supply Co., "CountryLine Cast Iron Jet Pumps Owners' Manual", Tractor Supply Co., 293 Wright Street, Delavan, WI 53115 Phone: 1-800-535-4950 Fax: 1-800-526-3757 Web Site: tractorsupply.com, retrieved 1 April 2015, original source: http://www.tractorsupply.com/ProdContentPDFs/1028145_Man1.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2024-05-06 by John J.

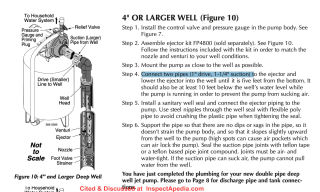

I have replaced a nonfunctioning submerged well pump in a shallow well with a jet pump system. I purchased a 100ft roll of 1-1/4" black well pipe for the 35ft deep well. For the convenience and cost I chose to purchase reducers and use the 1-1/4"" pipe for the return line instead of buying a 100ft roll of 1-1/2" (minimum available length). It works but can take three or four minutes to build to the 50lb cutoff pressure. Did I make a mistake on the choice of well return pipe size?

On 2024-05-06 y InspectApedia Publisher

@John J.,

In my opinion, yes, it's a mistake though not a disaster. When a 2-line jet pump is installed the smaller line down to the well is sending water through the injector whose job is to use that venturi and jet to draw up a larger volume of water back from the well than the quantity that was sent down.

When the returning "suction" line is the same as the pressure (down) line you're limiting the ability of the system to send back a larger volume or flow rate of water. You may be able to live with this just fine but your pump is working harder and the gpm delivery rate from the well is being a bit limited.

On the other hand, your injector is probably down at around 32 or 33 ft. So the total lift height is not too great - less work for the pump.

On the third hand, we don't know what pump brand and model you bought so we can't check its instructions.

Using a Flotex 2-line jet pump (convertible from 1-line) as an example - found at FLOTEC FP4200-FP4300 CONVERTIBLE DEEP WELL JET PUMP MANUAL [PDF] (2005)

You'll see that the manufacturer suggests a 1" drive line and a 1 1/4" suction line. That may not seem like a big difference, but it's significant.

As one of my best teachers ever, at IBM SRI, told us, when you don't have a number, make one up. Start with 1. 1 is a good number.

So using simple example - we can compare water flow rates through two different pipe diameters.

1" pipe, at an average pressure range of 20-100PSI and a simple application with just about 12 feet per second flow velocity you might see 37 - 1400 gph - note that's gallons per HOUR not per minute.

Now if we move up to a 1 1/4" ID pipe, with the other parameters the same as above, you might see 62 - 3750 gph.

So a 25% increase in pipe internal diameter - for our example case (which is arm-waving, it's not going to be an exact match for your set-up) roughly doubles the water flow rate or capacity.

IMO that's remarkable, and perhaps some of our fluid or plumbing engineer readers will comment on this point.

inspectapedia.com/plumbing/Flotec-FP4200-Pump-Manual.pdf

at WATER PUMP MANUALS

has installation instructions for some example jet pumps.

Watch out: I hasten to add, that having installed, fixed, and inspected a lot of well pump systems since the 1970s (now retired) I've too often seen that the owner or installer put down a more-powerful water pump hoping to get more water from the well only to discover that the well's flow rate was so weak that the new pump simply ran the well dry.

If we combine a questionable flow rate well with a pump protection device (there are several types) to keep us from burning up the pump by running it dry, for those low-flow well cases, the bottom line is that the pipe diameter didn't matter, and the pump capacity in gph didn't matter either, because ultimately it was the well's flow-rate that determined how much or how fast the pump system could deliver water from well to building.

When your well is only 35 ft deep, unless it has a fabulous flow rate, a more-powerful pump is simply going to pump out the well's static head (the volume of water in the well between tailpiece bottom inlet and water top) in a jiffy and then you'll be limited to the well's flow rate.

SO bottom line, don't rush out to dig up and put on a larger suction pipe. But do get your well's flow rate and consider that in the water delivery system design.Continuing...

To understand the volume of water in gallons in the static head of your 35 ft deep well please

see WELL DYNAMIC HEAD & STATIC HEAD DEFINITION

Also see WELL WATER VOLUME CALCULATION

On 2022-12-16 by Dave k

I've been dealing with this issue for 3 years I'm on a community well I have 60 lb of pressure at the farthest point from the inlet of the house the water pressure reads like I said 60 pounds when I turn on the washer it goes to 50 when I turn on the sink with the clothes washer it drops to 20 can't even run two sprinklers any answers would be greatly appreciated

On 2022-12-20 by InspectApedia (mod)

@Dave k,

I understand. Recapping:

I said earlier that small diameter water pipes reduce the flow rate through any water system. Increasing water piping diameter in even part of the system improves water flow anywhere downstream from that point.

Water "pressure" is NOT the same thing as "water flow rate" though people do, I acknowledge, use the words "water pressure" to describe how much or how fast water appears to come out of a tap when it's opened.

If no water is running in a building, water pressure will. measure exactly the same everywhere in the system unless you take a measurement on the downstream (outlet) side of a water pressure regulator or pressure reducing valve. In that case water pressure would indeed be lower on the outlet side of the pressure regulator than on the inlet side.

It is perfectly normal for measured "pressure" in a water piping system to fall immediately once a valve is opened anywhere in the system, and 50 is still pretty good.

Just how far the water pressure falls in the system depends on how fast water is flowing out into open air at, for example, a sink, or clothes washer, or sprinkler system.

The greater the quantity of water flowing out of the piping system the lower will be the (now dynamic) water pressure measured somewhere on the water piping system.

How you can increase the water flow rate in your home:

For a water supply system coming from a well, see

WELL WATER PRESSURE IMPROVEMENT

For community water system from a common source feeding multiple buildings or occupancies, or for municipal (city) water pressure, see

MUNICIPAL WATER PRESSURE IMPROVEMENTS

You’ll find additional, more-detailed articles at the end of each of those pages, such as using a water pressure booster pump or adjusting a water pressure regulator.

Take a look and let me know what questions you have after that.

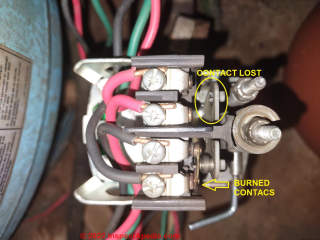

On 2022-12-06 by Rachel - lost contact part needs repair or replacement

Hi. My pump will not come on when I pull the metal lever up as it normally does. It has been cycling over and over again and then shutting off by itself every few days. I've taken the box cover off and can see a spring and small piece of metal has broken off. I'm not sure how to fix it myself or who to call for help. Can you help me? Thank you.

On 2022-12-06 by InspectApedia (Editor)

@Rachel,

It sounds as if a contact relay tip has broken off - the switch then can't turn on the pump. You will need help from an electrician or experienced plumber who can replace the pump pressure control switch.Looks like a contact part has been lost from the upper contact in your photo

I would not try to repair this switch, though there are re-build kits for water pump pressure controls. It's simpler and similar in cost to replace the switch.

See

WATER PUMP PRESSURE SWITCH INSTALL / REPLACE

On 2021-09-12 by joe

I replaced the pressure switch, and the pressure tank, but my well is still not kicking on. Is there something else that I can try before I have to pull the pump?

On 2021-09-13 by inspectapedia.com.moderator

@joe,

An experienced well pump installer and some electricians as well know some electrical tests that can be made of your well pump before actually pulling the pump.

For example measuring the current draw can sometimes indicate that a motor or impeller has seized.

On 2022-07-11 by Timothy Davey

Why my pump will mot shut off we have a whole new pump and pressure switch. Primded it and it still won't shut off

Contact me buy email if you could help I can't get any one to look at it.

On 2022-07-11 by InspectApedia (mod)

@Timothy Davey,

Take a look at the diagnostic steps we have at

WATER PUMP WON'T STOP RUNNING

If that still leaves you with questions, please let us know.Or

WATER PRESSURE TABLE 1: PUMP WON'T RUN, WON'T STOP, or CYCLES

Could point you to a series of diagnostic steps that you can try yourself. That's a good place to start.

On 2022-04-17 by Frikkie

It sounds if the motor is single phasing. Could the impeller be stuck inside? I turned the motor fan with a screw driver, it turns very difficult, then I started it again, primed it again and the motor still sounds if it is single phasing.

On 2022-04-18 by Inspectapedia Com Moderator - motor difficult to turn may indicate failed bearing

@Frikkie,

If the motor is difficult to turn that sounds like a failed bearing.

For other readers,

"Single phasing simply means that one of the line connections of a motor is not connected, resulting in the motor running on a single phase. A single-phase condition subjects the motor to an excessive voltage imbalance, often meaning high currents and motor heating.Induction motors designed to run from a single phase use a start or run capacitor to assure that the motor starts and runs in the correct direction. 3-phase motors rely on the phase sequence of the power supply to assure they start and determine their rotation, so with only two lines connected, it is uncertain if a motor will start and what direction it will rotate if it does." - thanks to HEVVY'S BLOG at Hevvy Pumps https://hevvypumps.com/ 2022-04-18

Single phasing can also be caused by a blown fuse or tripped circuit breaker on one of the pump's phase wires.

But when the motor is difficult to turn, I'm back to suspecting a bad bearing OR, as you suspect, a jammed impeller. That can happen if an impeller blade or part breaks off or if there is a very high mineral content in the water that might cause a chunk of solidified mineral deposit to cause an impeller jam.

On 2022-01-21 by No Water TP

I have been reading the information that you post on your website.

So we replaced our well pump last December because we had no water and that was what we were told was the problem.

It was good for about 9 months and now have lost water a few times again.

We have great water pressure throughout the house and than all of a sudden out of no where we have no water at all.

My husband shuts of the well pump and waits while and than the water fills back up in the well. He turns the pump back on and the water is ok again.

We have had professionals come in and they say we may need a new well or they suggested putting a water holding tank in our basement.

To me it does not seem possible for our well to be dry.

We do have a water softener system with reverse osmosis because we have hard water.

Any advice would be appreciate. We are still waiting to hear back from a well compliant that my husband called. But in the meantime I am trying is figure out what is going on?

On 2022-01-21 by Inspectapedia Com Moderator - possible signs that well is running out of water

@No Water TP,

The diagnostic steps in the table at WATER PRESSURE PROBLEM DIAGNOSIS TABLE - above on this page for NO WATER PRESSURE - are much more complete and thorough than I can write here making up that advice again off-the-cuff.

But it sure sounds as if you well is running out of water.

On 2021-09-11 by Matin

I hv a pressure pump. The motor doesnt turn. Bit if I open it, Plug it and turn The Small Wheel made of Brazelle inside with my hand The motor starts to turn for few seconds and it stop again. Wht cn it be The problem

On 2021-09-11 by inspectapedia.com.moderator

@Matin,

If the impeller itself isn't binding it's probably the motor

see

ELECTRIC MOTOR DIAGNOSTIC GUIDE https://inspectapedia.com/electric/Electric_Motor_Diagnosis.php

On 2021-08-25 by Rick - pump stops working, starts to hum, throws a breaker

I have a cabin that has a 2000 gallon water tank with minimal gravity flow.to the house. My 4-year-old 1/2 hp pump stopped working hums and then throws a breaker. So after reading your troubleshooting I replaced the breaker, then replaced the switch. Then out of frustration replaced the motor with another manufacture of the same size 1/2 hp.

Still, the same problem hums and then switches off. I even tried bypassing that circuit and ran to a different one and the same problem. I checked the air pressure in the bladder and it's perfect at 27lbs. Water does trickle out of the kitchen faucet as it normally does with water shut off and of course, I primed it.

I am at a loss of what else it could be any help would be appreciated ...... thank you

On 2021-08-25 by inspectapedia.com.moderator

@Rick,

A humming water pump that blows a breaker suggests that the pump motor is drawing high current - which happens when a motor is seized.

On occasion we can get a motor going by replacing a the motor start/run capacitor.

details are at

ELECTRIC MOTOR DIAGNOSTIC GUIDE

and at

CAPACITORS for HARD STARTING MOTORSOn 2021-08-25 by Rick

@inspectapedia.com.moderator,

Yes, I thought it may be the motor so I replaced it with a new one from a different manufacturer and it's making the same humming noise . Then I bypassed the original line and hooked up a temporary line from a different circuit and still just humming?On 2021-08-25 by inspectapedia.com.moderator

@Rick,

New pump motor, still the pump hums?

hmmm thinking ... is it possible that the impeller is jammed?On 2021-08-27 by Rick

@inspectapedia.com.moderator, I took the cover off and turned it by hand but still didn't start .

On 2021-08-27 by inspectapedia.com.moderator - test motor apart form all pump connections and controls

@Rick,

A good test would be to see if the motor runs when it is on a test bench - completely apart from the water pump connection, controls, etc.

if the motor works on the bench but not on the pump then we figure a bad impeller bearing or improper wiring or installation at the pump; an electrician would check voltage delivered at the pump and would check current draw.

More detailed suggestions are at ELECTRIC MOTOR DIAGNOSTIC GUIDE I mentioned earlier.

Do take care; if you are not familiar with proper, safe electrical wiring, you could be shocked or killed.

On 2021-07-20 by Trevor

Why is my 10 bar pump pushing only 2 bar

On 2021-07-21 by inspectapedia.com.moderator

@Trevor,

take a look at the diagnostic steps and repairs at

WATER PUMP WON'T STOP RUNNING

On 2020-11-28 by Neal Rosenberg

Pressure system for small ranch does not start pump. The motor hums like when it starts the pump. If it hums too long it will blow the fuse to the pressure switch. 15 amp delay fuse. The axle between the motor and the pump turns easily.

The switch is clean and was replaced last year. The switch was rated for 40 to 60 lbs, I raised it when I installed it to 50 to 70 to make the system effective on our lawns. Water from the neighborhood system is awailable at 30 lbs to my pressure pump. So, what part is failing.

On 2020-11-28 - by (mod) -

You might see if there is a start capacitor that can be replaced

On 2020-10-01 by David Daski

The former pump and its now replacement both often cycle but don't build up pressure. I suspect a leak in the piping from the well. What I don't understand is that this is happening even though the well is artesian with a definite positive pressure. Should this not be forcing the air out of the system? Also, could I fix the issue by installing a submersible pump?

On 2020-10-02 - by (mod) - even artesian well needs proper pump priming

David

If a new water pump runs but doesn't deliver pressure, provided we didn't run it dry at time of installation (this can destroy some impeller assemblies), then the problem is probably elsewhere, such as low water in the well or air leaks in the piping or simply failure to properly prime the pump.

In an artesian well installation, you might still need to open appropriate bleeder fittings at and ahead of the pump to remove air from the system before running the pump. Else if you let the pump run too long - minutes or longer - while "dry" you can so damage the impeller that later even when the pump is primed with water it can't develop pressure.

On 2020-09-22 by Angel

Water pump works after filling the tank the cage drops to zero and does not want to pump more water

On 2020-09-22 - by (mod) - check for debris or low water supply from well

I suspect either the pressure control switch is debris clogged and doesn't respond to the pressure drop OR the well flow rate has fallen so much that you have to wait for the well to recover. If the pump runs but no water is delivered the well may be out.

On 2020-05-13 by Roy mattox

Lost water pressure

On 2020-05-13 - by (mod) - lost water pressure solutions

Roy

Thanks for asking,

I have divided pump and water pressure problems in to categories to try to help you and other readers home in on the most likely causes of trouble.

If you have no water pressure and

Table 1: Pump Won't Start, Wont' Stop Running, or Cycles Rapidly

describes what's happening, see Table 1 on this page.

If you have no water pressure and the pump is running continuously,

See "Pump Will Not Shut Off " table headed in green on this page.

If your pump runs and you have very weak water pressure that then falls off or maybe even stops,

see WATER PRESSURE TABLE 2: PUMP RUNS, WEAK or NO WATER PRESSURE

If you have no water pressure and the pump runs but no water is being delivered, see the diagnostics at

WATER PRESSURE TABLE 3: PUMP RUNS, NO WATER or INSUFFICIENT WATER

On 2020-01-27 by Cor

my booster water pump suddenly can not get the pressure used to stop at 4 bar .the motor keeps on running but the pressure do not go higher than 2 bar

On 2020-01-27 - by (mod) - continuously running water pump diagnostics

Cor,

When a water pump runs continuously we have diagnostics at

WATER PUMP WON'T STOP RUNNING

And at

WATER PRESSURE TABLE 3: PUMP RUNS, NO WATER or INSUFFICIENT WATER

Please take a look at the diagnostic and repair suggestions there and don't hesitate to ask follow-up questions work to report back what you found.

On 2019-11-30 by Anonymous

Changed out my pressure switch and tank it’s not building up pressure

On 2019-11-30 - by (mod) -

Anon

Let's start with a diagnostics at

WATER PUMP WON'T STOP RUNNING

When you've been through those easy checks, we'll have a better idea of what's going on with your pump and well. Let me know what you find and will continue from there.

On 2019-07-11 by Marty

I replaced switch for well and well pump pumps up to spiket at casing but nothing to house

On 2019-07-15 - by (mod) -

Marty I don't quite understand the situation; but if the pump runs and no water is delivered, usually that means that either the pump impeller is damaged or there's no water in the well (or a big leak in well piping)

On 2019-06-21 by Randy

My pressure tank usually stops at 40psi but after draining it will reach only 27psi and the pump won't stop until it will become hot. Water is not a problem. The connections are good. What seems to be the problem?

On 2019-06-21 - by (mod) -

The diagnostics for the case you describe, Randy, are at WATER PUMP WON'T STOP RUNNING

Let's start there - post an update on what you find.

On 2019-01-23 by Anji Gardner

Pressure gauge will only pump up to 40 then you can hear gurgling . I have replaced new pump, gauge , and points switch and it still doesn’t work.?

On 2019-01-24 - by (mod) - gurgling may be from a number of things

My guess is that if you're hearing a gurgling sound near the end of the pump cycle and before you reach the cut-off pressure your water supply in the well is low or you have a poor well flow rate.

There could also be a leak in well piping below the water level that gets exposed as the water level in the well bore gets bumped down. That could be putting air into your system.

...

Continue reading at WATER PRESSURE TABLE 2: PUMP RUNS, WEAK or NO WATER PRESSURE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see WATER PRESSURE PROBLEM DIAGNOSIS TABLE FAQs Q&A about diagnosing lost or bad water pressure, posted originally at this article

Or see these

Recommended Articles

- NO WATER PRESSURE

- WATER PRESSURE MEASUREMENT

- WATER PRESSURE TABLE 1: PUMP WON'T RUN, WON'T STOP, or CYCLES

- WATER PRESSURE TABLE 2: PUMP RUNS, WEAK or NO WATER PRESSURE

- WATER PRESSURE TABLE 3: PUMP RUNS, NO WATER or INSUFFICIENT WATER

- WATER PRESSURE REDUCER / REGULATOR

- WATER PRESSURE STOPS, RETURNS

- WATER PRESSURE TOO HIGH: DANGERS

- WATER PRESSURE TOO LOW

- WATER PRESSURE VARIATION CAUSES

- WELL WATER PRESSURE IMPROVEMENT

Suggested citation for this web page

WATER PRESSURE TABLE 1: PUMP WON'T RUN, WON'T STOP, or CYCLES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about how best to diagnose the cause of poor building water pressure or lost water pressure.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Thanks to Jeneral Sewer Service - George - 845-297-2285, a New York Hudson Valley drain and sewer cleaning and de-clogging expert for technical details and consulting on drain clog diagnosis and repair, including proper use of the Kinetic Water Ram for drain clearing - 3/14/2009

- Thanks to our reader, Carole Cimitile, 2/17/2009, for reminding us that small problems like faucet o-rings, clogged faucet strainers and similar local plumbing fixture defects can have a big impact on hot water flow, cold water flow, or both hot and cold water flow and pressure problems.

- Thanks to reader EK Woodard, Boise State University, Boise ID, for assistance in diagnosing poor water pressure following an electrical power loss. 3/14/2010

- Betta-Flo JET PUMP INSTALLATION MANUAL [PDF], National Pump Co., LLC., includes helpful well pump troubleshooting tips as well as basic jet pump installation details. Web search 07/24/2010, original source: http://www.nationalpumpcompany.com/Documents/OIM/Betta%20Flo%20IOM%20Jet%20Pump.pdf

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- Handbook of Disinfectants and Antiseptics, Joseph M. Ascenzi (Editor), CRC, 1995, ISBN-10: 0824795245 ISBN-13: 978-0824795245 "The evaluation of chemical germicides predates the golden age of microbiology..." -

This well-focused, up-to-date reference details the current medical uses of antiseptics and disinfectants -- particularly in the control of hospital-acquired infections -- presenting methods for evaluating products to obtain regulatory approval and examining chemical, physical, and microbiological properties as well as the toxicology of the most widely used commercial chemicals. - Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- Principles and Practice of Disinfection, Preservation and Sterilization (Hardcover)

by A. D. Russell (Editor), W. B. Hugo (Editor), G. A. J. Ayliffe (Editor), Blackwell Science, 2004. ISBN-10: 1405101997, ISBN-13: 978-1405101998.

"This superb book is the best of its kind available and one that will undoubtedly be useful, if not essential, to workers in a variety of industries. Thirty-one distinguished specialists deal comprehensively with the subject matter indicated by the title ... The book is produced with care, is very readable with useful selected references at the end of each chapter and an excellent index. It is an essential source book for everyone interested in this field. For pharmacy undergraduates, it will complement the excellent text on pharmaceutical microbiology by two of the present editors."

The Pharmaceutical Journal: "This is an excellent book. It deals comprehensively and authoritatively with its subject with contributions from 31 distinguished specialists. There is a great deal to interest all those involved in hospital infection ... This book is exceptionally well laid out. There are well chosen references for each chapter and an excellent index. It is highly recommended." The Journal of Hospital Infection.: "The editors and authors must be congratulated for this excellent treatise on nonantibiotic antimicrobial measures in hospitals and industry ... The publication is highly recommended to hospital and research personnel, especially to clinical microbiologists, infection-control and environmental-safety specialists, pharmacists, and dieticians."

New England Journal of Medicine: City Hospital, Birmingham, UK. Covers the many methods of the elimination or prevention of microbial growth. Provides an historical overview, descriptions of the types of antimicrobial agents, factors affecting efficacy, evaluation methods, and types of resistance. Features sterilization methods, and more. Previous edition: c1999. DNLM: Sterilization--methods. - U.S. Army Field Manual 21-10, Field Hygiene and Sanitation, 1988, web search 07/02/2010, original source: http://www.enlisted.info/field-manuals/fm-21-10-field-hygiene-and-sanitation.shtml

The purpose of this manual is to assist individual soldiers, unit commanders, leaders and field sanitation teams in preventing disease and environmental injuries. The manual provides information on preventive medicine measures (PMM) to the individual soldier as well as essential information for the unit commander, unit leaders, and the unit field sanitation team on applying unit level PMM. - When Technology Fails, Matthew Stein, Chelsea Green Publisher, 2008,493 pages. ISBN-10: 1933392452 ISBN-13: 978-1933392455, "... how to find and sterilize water in the face of utility failure, as well as practical information for dealing with water-quality issues even when the public tap water is still flowing". Mr. Stein's website is www.whentechfails.com/

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.