Scala 2 Pump Guide

Scala 2 Pump Guide

Water pressure booster pump install, diagnose, repair

- POST a QUESTION or COMMENT about the Grundfos Scala 2 booster pump

This article describes the features and field performance of the Scala2 water pressure booster pump. We include links to free PDF downloads of Scala 2 installation, operation, and service manuals, and we provide company contact information for its manufacturer, Grundfos.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Grundfos Scala 2 Pump Installation, Field Experience, Troubleshooting, Repair

Grundfos describes the SCALA2 pump:

Grundfos describes the SCALA2 pump:

The SCALA2

is an integrated, self-priming, compact water booster pump. It is designed for perfect pressure inside the home. It's quiet, easy to install, and maintains consistent pressure in all taps at all times. - (Grundfos 2023)

This water pressure booster pump provides an easily adjusted output pressure that the pump will then maintain even when more water is being run in the building.

[Click to enlarge any image]

The pump and its controls are simple to operate but it's also sophisticated, providing a number of other adjustments and settings such as its ability to automatically lower the water pressure setpoint if it cannot reach the pressure level set by the user, and its ability to sense and respond to a building plumbing water leak.

Scala 2 Water Pump Factory Settings & Features

The Scala2 factory default settings will leave the pump working just fine for most situations, but the Scala from Grundfos also has some sophisticated control options that can be turned on by your installer.

- The Scala 2 pump can detect a water leak in the building

- It can re-program itself to the available water supply to protect against running dry

- The Scala can also be set to shut itself down in the event of long running (30 minutes of non-stop operation)

- The Scala pump can be set to detect regular cyclic running for fixed "on-cycles" that are characteristic of a plumbing leak (40 times can be set to trigger a shut-down)

More Scala pump features

Excerpting from Grundfos literature:

An important feature noted by the company that protects the pump is that its design includes "dry-running" protection. The SCALA2 is an advanced single-line jet-pump design that can pump from a depth of 8 metres (26 feet) of vertical lift.

SCALA2 is a fully integrated water booster pump providing perfect water pressure in all taps at all times – even with multiple taps and showers running at the same time. It packs pump, motor, tank, sensor, drive and non-return valve into one compact unit.

And with its intelligent pump control, SCALA2 automatically adjusts performance to both inlet pressure and water consumption in the home.

Thanks to a water-cooled motor, SCALA2 even offers one of the lowest noise levels of any booster on the market.

What is intelligent pump control?

SCALA2 features a built-in sensor, which constantly measures the discharge pressure.

If the pressure drops below the desired level, SCALA2 boosts its operation immediately to compensate for the loss of pressure.

We call it intelligent pump control and the result is perfect water pressure. - source: http://us.grundfos.com/products/find-product/SCALA2.html retrieved 2017/03/26

Normal Scala2 Pump Shaft Leakage: Shaft Seal Run-In

It is important to understand that, as Grundfos explains in the Scala manual, the main pump shaft is lubricated by the "pumped liquid" - in our case, water.

Excerpting from the service manual:

The shaft seal faces are lubricated by the pumped liquid. A slight leakage from the shaft seal of up to 10 ml per day or 8-10 drops per hour may occur.

When the pump is started for the first time, or when the shaft seal has been replaced, a certain run-in period is required before the leakage is reduced to an acceptable level.

The time required for this depends on the operating conditions, that is, every time the operating conditions change, a new run-in period will be started.

Under normal conditions, the leaking liquid will evaporate. As a result, no leakage will be detected.

The leakage is visible where the screws are mounted on the base plate.

If the unlikely event of internal leakage occurs, the liquid will be drained through the bottom of the pump. - Grundfos SCALA Installation and Operating Instructions cited below.

Install the pump in such a way that no undesirable collateral damage can arise.

Watch out: as you will read below at "Scala 2 Pump #2 Installed February 2019 - seized in 2023" we think that leaving the pump turned off for long periods of time when water has been (normally) leaking at the pump shaft may invite so much corrosion that the shaft and seal are actually damaged, requiring either a shaft seal replacement and pump rebuild job or in the worst case, pump replacement.

If you must leave the pump OFF for months at a time you may want to follow Grundfos' advice and remove the pump from service, draining it of all water, and storing it in a warm dry place.

Scala 2 Pump Failures / Replacements: Field Performance

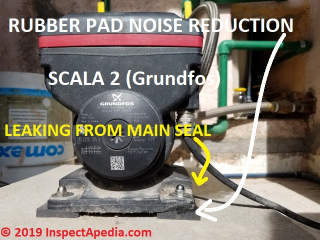

Scala 2 Pump #1 Installed: March 2017 - leaked in less than two years

We installed a Scala 2 at a home in March of 2017 and found its performance excellent until its main bearing began to leak significant volumes of water at the pump's main seal (photo above), and the pump became noisy.

This combination of increasing water use and increasing pump noise, combined with noticing that the leakage continued after several weeks, was enough that we considered it a pump failure, not just normal leakage requiring a new run-in period.

The company offers a main seal rebuild kit, not something that our local pump installer was willing to attempt.

Scala 2 Pump #2 Installed February 2019 - seized in 2023

Instead, the Scala that we first installed in 2017 was replaced (under its two-year warranty) in February of 2019.

Shown in our photo above is the new Scala 2 pressure pump after its installation in 2019 (the copyright notice is earlier than the original photo date).

You can see some orange rust stains on the concrete mounting block at the right side of the pump - left by leaks from the previous model.

During the COVID epidemic, this pump was left turned off for more than two years. It was returned to service in February 2023, shut down three months later, then returned to service in July 2023.

When the pump was turned on it would not run, and instead displayed an error light - pointed to by my pen in this excerpt from a Scala2 manual illustration.

The Scala2 IO manual provides a detailed guide to the diagnostic lights and symbols for this pump - in this case the indicator meant that either the pump shaft has been seized up or the pump is blocked by impurities.

This failure will not automatically reset - repair is required.

Starting Up the Scala 2 After a "Standstill" (Seized Pump Shaft)

Grundfos instructions provide a procedure for Starting up the product after standstill.

In sum, when the main pump shaft is seized it may be possible to free it up by using a thick bladed screwdriver to manually turn the shaft.

An end cover is removed (photo above) and a thick bladed screwdriver or similar tool might permit you to free up the seized Scala2 shaft (pointed-to in the photo below)

Watch out: the company warns that the pump must be disconnected from electrical power before attempting repair - else you could be shocked or killed.

When we removed the cap to expose the end of the pump's main shaft in an effort to free it, we could see indications of water leaks (below), making us not too optimistic about the condition of the pump.

But with considerable and careful effort, gentle tapping and wiggling of the shaft end, and a brief squirt of WD40 we were able to free up the shaft.

Returning power to the pump it ran immediately - but not well. We think this procedure may be quite successful if the shaft seizure is minor, perhaps due to a bit of oxidation on the bearing surfaces but where there has been leakage and corrosion and then the pump sits off for months, as you'll read below, this repair won't be enough.

Unlike the very quiet normal operation of the Scala2 pump, this one screamed so loudly that neighbors at the end of the block stepped outdoors into the hot July heat to see what disaster was underway.

You can listen for yourself to the recording - below, though in my [DF] opinion the recording doesn't do justice to the noise level of this failing Scala2 pump.

Choose the first file for a small, fast-loading audio file, or the second for a movie of the noisy pump.

- SCALA2 PUMP BEARING FAILURE NOISE [600K M4a file] - faster loading (sound only)

OR - SCALA 2 PUMP BEARING FAILURE NOISE [80 MB mp4 file] (movie) demonstrating the loud grinding whining sound we heard when the pump motor bearings were seized due to a combination of pump seal leak and inactivity.

We also found that the pump's shut-down behavior when building water use stopped had changed. Previously the pump would stop running just a few seconds after any water use in the building had ceased.

Now we heard the pump continue to run, sometimes pause, then run further, for a much longer interval after water use in the building was turned off.

Inspecting the failed, seized Scala2 pump more closely we saw leak stains at its bottom vent/drain, (below), a condition that may be normal, as we and Grundfos explain at

the SHAFT SEAL RUN-IN section above on this page.

When we removed the priming cap and check valve assembly from the old pump, we saw rust-colored stains at its O-ring (not shown), hinting that a leak there may explain why the pump was having trouble shutting down neatly after building water use was turned off.

Scala2 Pump #3 Installed July 2023 - quiet, lessons learned

Now out of warranty, we replaced the pump whose purchase price had, no surprise, increased substantially since its last replacement.

Grundfos warns that if the pump is to be left out of service, at least in a freezing climate and perhaps anywhere, it should be completely removed from service, drained of all water, and stored in a dry place.

Alternatively and our current plan, we will leave the pump in service and will report here how it lasts in normal, if rather light-duty, use in the coming years.

We still think this is a great product, quiet, smart, water-saving, highly functional, delivering plenty of water pressure and flow when demand requires. But the failure history has been a disappointment.

Grundfos Scala 2 Contact Information & Scala2 Pump Manuals

The Scala 2 water pressure boosting pump is in some discussions mis-named as Scala II ScalaII Scala-II

- Contacto: Grundfos Mexico, Blvd. TLC No. 15 Parque, Ind. Stiva-Aeropuerto, Apodaca, N.L. 66600, Web: mx.grundfos.com

- Contact: Grundfos North America, 2001 Butterfield Rd. Ste 1700, Downers Grove IL 60515, USA, Websites: www.grundfos.us www.grundfos.ca www.grundfos.mx

- Grundfos product selection guide - Scala 2 description - retrieved 2023/07/16, original source: https://product-selection.grundfos.com/products/scala/scala2?tab=models - excerpted at the top of this page.

- Grundfos Domestic Water Pressure Boosting Pumps, Grundfos CME Plus, BMQE system, and MQ series pumps are designed for pressure boosting systems, Grundfos Pumps Corporation 2001 Butterfield Road, Suite 1700, Downers Grove, IL 60515, Website: https://us.grundfos.com

Grundfos Indianapolis – Peerless Brand: 1-800-879-0182

Grundfos Chicago – Yeomans, Morris, Chicago Brands & Grundfos Wastewater Products: 1-800-921-7867

Grundfos Kansas City – Grundfos Brand: 1-888-237-1960 - Grundfos Australia, Grundfos Pumps Pty. Ltd Mail: P. O. Box 2040, Regency Park, South Australia 5942 Delivery: 515 South Road, Regency Park, South Australia 5010 Website: http://au.grundfos.com/

Choose the correct installation and operating, adjustment and repair manual for your Scala2 pump depending on when your pump was manufactured. Check the dates given below.

- Grundfos SCALA2 INSTALLATION & OPERATION MANUAL 2023 [PDF] (2023) Grundfos, retrieved 2023/07/16 - this is the latest Scala2 pump manual

- GRUNDFOS SCALA2 PUMP SERVICE MANUAL [PDF] (2016) Scala pump service and repair instructions

- Grundfos SCALA2 INSTALLATION & OPERATION MANUAL 2017-06 [PDF]

- GRUNDFOS SCALA2 OPERATING INSTRUCTIONS pictorial guide 2017-05 [PDF]

- GRUNDFOS SCALA2 INSTALLATION & OPERATION MANUAL 2016-05 [PDF]

- GRUNDFOS SCALA2 INSTALLATION & OPERATION MANUAL 2015-06 [PDF]

- SCALA2 INFORMACION BASICO [PDF] bomba de aumento de presion, no usa tanque external

- GRUNDFOS SCALA2 DATA SHEET (English) 2016-02 [PDF]

- GRUNDFOS SCALA2 DATA SHEET [PDF] retrieved 2017/03/26, original source: us.grundfos.com/content/dam/GPU/Literature/SCALA2/SCALA2-DATASHEET.pdf

- SCALA2 DATOS [PDF]

- SCALA2 GUIA RAPIDA [PDF]

- SCALA2 GUIA de INSTALACION y OPERACION [PDF]

- SCALA2 CATALOGO de JUEGOS de SERVICIO [PDF]

Examples of mechanical system installations for which the Scala2 was installed / used

- STEAM BATH / SHOWER GENERATOR INSTALLATION - installation of a Mr. Steam generator required softened water with adequate supply pressure

- TANKLESS WATER HEATER WHISTLE - installation of a Bosch Compact MiniMAXX in tankless water heater required adequate water supply pressure

- WATER SOFTENER RESIN REPLACEMENT - installation of a Pentair Fleck water softener required adequate water pressure

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-11-14 by InspectApedia Com Moderator - Rubber Mount Reduces Normal Operating Noise from a Water Pressure Booster Pump

How to reduce transmission of pump noise into the building

How to reduce transmission of pump noise into the building

In our photo you'll see the Scala-2 water pressure pump that we installed at a home in Guanajuato.

The pump was installed on a rooftop that can itself act as an enormous speaker diaphragm to transmit even modest or normal pump noises into the building.

We used sections of thick rubber padding between the pump feet and the concrete block that was itself then cemented to the roof surface to eliminate any noise due to vibration between the concrete block and the roof surface.

The result was a reduction in pump noise by about 90%.

Watch out: in addition to using a pump noise transmission reducing mount, be sure that the pump is not running dry, and that it's not damaged. Worn bearings for example or abnormal voltages or even debris in a pump impeller can cause the pump to make abnormally loud noises.

And if your water pump really is running literally continuously, that's not normal and you need to find the cause such as a leak in piping, water left turned on, or an improperly-adjusted pump control.

BE SURE to see WATER PUMP NOISE DIAGNOSIS since water pump noises can be causes by a variety of problems each requiring a different cure.

Details about the Scala 2 pump and its performance, repairs, manuals are above on this page.

On 2021-11-14 by Anonymous: continuous noise of a water pressure booster, if it is an automatic one

How to ease the continuous noise of a water pressure booster, if it is an automatic one

How to stop the continuous noise

...

Continue reading at WATER PRESSURE BOOSTER PUMPS, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- VARIABLE FREQUENCY / VARIABLE SPEED DRIVE WELL PUMPS (VFDs)

- WATER PRESSURE TOO LOW

- WATER PUMP CONTROLS & SWITCHES

- WATER PUMP & TANK I&O & REPAIR MANUALS

- WATER PUMP LIFE EXPECTANCY

- WATER PUMP NOISE DIAGNOSIS - failed impeller, pump bearings bearings, air or water leaks, other defects.

- WATER PUMP REPAIR GUIDE - home

- WATER PUMP SHORT CYCLING

- WATER PUMP TYPES

- WATER PUMPS, TANKS, TESTS, WELLS, REPAIRS - home

- WATER PRESSURE BOOSTER PUMPS

Suggested citation for this web page

GRUNDFOS SCALA 2 PUMP GUIDE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.