Fiberboard Identification

Fiberboard Identification

Building Wall & Roof Sheathing,

Insulating Board Identification Key

- POST a QUESTION or COMMENT about fiberboard building sheathing: how to identify fiberboard products, fiberboard uses, fiberboard, Celotex, Homasote, Insulite & other brands, fiberboard ingredients, does fiberboard contain asbestos?

Fiberboard insulating sheathing identification guide:

Here we help identify and give information about the manufacture, ingredients & use of various fiberboard insulating sheathing products.

We explain how to recognize/identify Celotex®, Homasote®, Masonite® Nu-Wood® and other insulating fiberboard building sheathing products used as exterior wall sheathing and as interior wall & ceiling surfaces.

This article describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as "black-board", Barrett R-Brace, Eastman PS-57-73, Celotex, Homasote, Insulite, and Masonite, Upsonboard, Nu-Wood and other insulating board sheathing products.

In this article series we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products.

We also answer questions such as do Celotex or Homasote or other fiberboard and insulating board products contain asbestos? fiberboard water resistance, fiberboard recycling.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Identify Fir-Tex™, Homasote®, Barrett®, Celotex®, Insulite, Nu-Wood, Upsonboard, & Fiberboard & Insulating Sheathing Board & Plasterboard

Low-density fiberboard panels and products trace their origin in the U.S. to Azel Storrs Lyman's 1858 patent for separating the fiber of wood and for the manufacture of paper and other purposes. (Jester 2014).

Low-density fiberboard panels and products trace their origin in the U.S. to Azel Storrs Lyman's 1858 patent for separating the fiber of wood and for the manufacture of paper and other purposes. (Jester 2014).

More significant for fiberboard products was W.E. Hale's patent for wallboard that described using fiberboard in construction (Hale 1870) and Cobb's patent for using a soft board made of straw in place of wood lath as a plaster base (Cobb 1871).

[Click to enlarge any image]

Jester explains that Cobb's straw fiber board was treated with cheap oil as a waterproofing agent, an idea that was elaborated by Homasote, Celotex, and the other big boy fiberboard producers of the 20th century.

The Agasote Millboard Co. (Trenton N.J.) was formed in 1909, and as Jester notes, by 1916 that company was producing the widely known Homasote brand fiberboard that probably has been a century-long thorn in the side of Celotex, Insulite, Nu-Wood, and Masonite.

By 1910 in the U.S., the manufacturer of fiberboard made these products available to builders and homeowners for use as a sheathing product that was used on wall exteriors, wall and ceiling interiors, and even as roof sheathing. In my personal experience, low-density fiberboard roof sheathing was a bad idea.

Article Series Contents

If you know the manufacturer name of your fiberboard, see the list below and click on the relevant link.

If you do not know the manufacturer, use your material sample or photos to review the below article to look for similar examples to help identify your fiberboard and its manufacturer.

- FIBERBOARD SHEATHING IDENTIFICATION

- CLASSES & TYPES of FIBERBOARD PRODUCTS

- EXTERIOR vs INTERIOR FIBERBOARD TYPES

- IDENTIFY ALLIED CHEMICAL / BARRETT R-Brace Insulating Board & Fiberboard

- IDENTIFY ARMSTRONG Fiberboard Sheathing

- IDENTIFY BEAVERBOARD / BUFFALO BOARD

- IDENTIFY CANEBOARD PANEL

- IDENTIFY Celotex® Insulating Board and Fiberboard Products

- IDENTIFY Dierks Fiberboard Sheathing

- IDENTIFY Donnacona Fiberboard acoustic & insulating panels

- IDENTIFY Eastman Sheathing Board

- IDENTIFY Fir-Tex Firtex Firetex Insulating board

- IDENTIFY Homasote® Brand Fiberboard

- IDENTIFY Insulite, or Graylite cellulose fiber board product useful for plasterboard

- IDENTIFY IKO Fiberboard & Other Insulating Sheathing

- IDENTIFY JOHNS-MANVILLE Fiberboard Sheathing (Strongboard)

- IDENTIFY Masonite™ and other hardboard Sheet and Siding Building Materials

- IDENTIFY National Gypsum Gold Bond® Brand Insulating Board

- IDENTIFY NU-WOOD PANELS

- IDENTIFY PINEX FIBERBOARD

- IDENTIFY RUSSIAN or ITALIAN FIBERBOARD

- IDENTIFY SHUMITE BOARD

- IDENTIFY SUNDEALA BOARD COMPOSITION & HISTORY

- IDENTIFY UPSON BOARD

- IDENTIFY US GYPSUM INSULATING SHEATHING

- IDENTIFY Weyerhaeuser IB INSULATING FIBERBOARD SHEATHING

- UNIDENTIFIED FIBERBOARD PRODUCTS

- WOOD FIBRE INSULATING PANELS

- FIBERBOARD PLASTER BASE SYSTEMS - using fiberboard or fiberboard-gypsum panels as a plaster base

- FIBERBOARD RESEARCH CITATIONS

- SHEATHING, FIBERBOARD ASBESTOS CONTENT - FlintKote, Stalwart, NuWood and other sheathing products.

How to Identify the Type of Fiberboard

Illustration: Barrett Board "Rigidwall" fiberboard used as an interior OR exterior wall nail base.

Illustration: Barrett Board "Rigidwall" fiberboard used as an interior OR exterior wall nail base.

Below we discuss several observations and measurements that help classify fiberboard products.

Be sure to also read

UNIDENTIFIED FIBERBOARD PRODUCTS

On 2021-11-08 by [pseudonyms] - density is the best factor for classifying fiberboard

John Marker / Bob Ruteledge said:

Perhaps, the best factor for classifying fiberboard is the density. This is internationally recognized. There is a rather simple difference between pressed and

not pressed sheets hut the range of qualities is wide and there is an overlapping.

Another point which should be taken into consideration is the fact that wood

fibers are blended occasionally with mineral fibers (such as asbestos), plastics

and with other chemical additives. Some half-hard fiberboard contain no less

than 20% of thermoplastic bonding agents.

[Poster's promotional link to an article by Kollman et als is deleted but cited in our reply below - Ed.

]

So does this mean that an old fiberboard ceiling or wall from 50s or 60s could have asbestos added in it?

This Q&A were posted originally at

FIBERBOARD CEILING & WALL COVERINGS by Bob Routeledge

and at

UNIDENTIFIED FIBERBOARD PRODUCTS by John Marker

On 2021-11-09 by (mod) - what is the right way to identify or classify fiberboard products?

John Marker and Bob Routeledge:

John Marker and Bob Routeledge:

Your posts under those names at two InspectApedia web pages were identical in content including a publication link. Unfortunately duplicate posts by various pseudonyms multiply the work for our moderators and do not reflect well on their author. Please post questions just once.

You cited Kollman et als (1975) whose work we include in the FIBERBOARD RESEARCH CITATIONS at the end of this article. Your reference to Kollmann's article does not address your question about the asbestos content in fiberboard products.

Note in that authors' own abstract (given at the end of this page) they use the phrase "ligno-cellulosic fibers " - that means plant-based fibers.

At FIBERBOARD DENSITY CLASSIFICATIONS you'll find details of the various densities of fiberboard products.

Really? But no typical building contractor nor homeowner is likely to know the actual measured density, such as in psf per cubic foot of material, for the fiberboard product they're considering.

In the Recommended Articles at the end of this page you will see a thorough exposition of the various types of fiberboard, such as HDF, MDF, LDF, and the properties of each;

You also seem to have tripped over a bit of confusion about identifying fiberboard sheathing products. There are at least four different fiberboard identification questions:

- What is the Type of fiberboard ?

There is the 1st question of type of fiber board such as HDF, MDF, and LDF three different densities or hardness has of otherwise a similar material. Your question suggests these as the right way to identify hardboard.

Older author (Kollman et als 1975) identified no less than seven different fiberboard product densities ranging from "non-compressed" up to extra-hard or "special densified" hardboard products. We describe those

at FIBERBOARD DENSITY CLASSIFICATIONS

But currently the three densities listed above are the most-widely-used.

See DEFINITIONS, ENGINEERED WOOD HDF LDF LVL MDF MDO OSB where we describe the differences between HDF, LDF, MDF, etc. and where we discuss product or fiberboard densities.

Also see SIDING HARDBOARD IDENTIFICATION & CLAIMS where we describe different hardboard brands, product failures, warranties

But by "identify hardboard" (or MDF or LDF) many readers are asking something else.

They want to identify the brand or product or they want to know the constituents of the product and they want to know if it contains asbestos.

- What is the Brand or manufacturer of fiberboard ?

Separate from the fiberboard type question is that of identifying the specific brand of fiber board.

At FIBERBOARD SHEATHING IDENTIFICATION (you are on this page) will find a complete list of fiberboard manufacturers, past and present, along with visual clues that can help identify specific brands. - What is the Asbestos content in fiberboard ?

Separate from the questions above is whether or not any fiberboard sheathing or siding, basically a plant product, contains asbestos: to which the answer is generally no with rare exceptions principally from cross-contamination.

At SHEATHING, FIBERBOARD ASBESTOS CONTENT you will find an answer to that question along with explanation and citation of expert sources.

Also see HARDBOARD Masonite™-like INGREDIENTS

- What is the intended use of the fiberboard product?

Fiberboard products intended for exterior sheathing differ in treatment and moisture resistance from those intended for interior cladding of ceilings or walls.

Fiberboard products intended for use as insulating exterior sheathing, or for interior wall coverings are generally MDF or LDF while fiberboard products intended for use as exterior siding or cladding - exposed to the weather - are HDF materials.

Fiberboard products sold for interior use as a plaster base were in MDF form.

Fiberboard products intended for uses where structural strength is required, such as for furniture, are generally HDF.

Fiberboard products intended primarily for insulation in board form will usually be LDF

The articles in this series address all of those questions.

Excerpt from Types of Fiberboard, (Kollman 1975)

There are various types of fiberboard1, and unfortunately the terminology is not yet internationally standardized. [Note that this was in 1975 - Ed.] Nevertheless, one fundamental definition generally is recognized (FAO, 1958/1959, p. 4):

"Fiberboard is a board generic term encompassing sheet materials of widely varying densities manufactured from refined or partially refined wood fibres or other vegetable fibres.

Bonding agents and other materials may be incorporated in the manufacture of the board to increase strength, resistance to moisture, fire or decay or to improve some other property."

In the technical sense the ISO-definition is more precise:

"Sheet material generally exceeding 1.5 mm in thickness, manufactured from

ligno-cellulosic fibers with the primary bond from the felting of the fibers and

their inherent adhesive properties. Bonding materials and/or additives may be

added".·

FAO, OEEC and ISO used formally various definitions but the differences

between them are without practical importance.

The classification of fiberboard into types is based on:

a) Type of raw material and method of fiber production;

b) Method of sheet formation;

c) Density of product (kg/m3 or g/cm3 or Ib./cu. ft.);

d) Kind and place of application.

Perhaps, the best factor for classifying fiberboard is the density. This is internationally recognized. There is a rather simple difference between pressed and

not pressed sheets hut the range of qualities is wide and there is an overlapping.

Another point which should be taken into consideration is the fact that wood fibers are blended occasionally with mineral fibers (such as asbestos), plastics and with other chemical additives.

Some half-hard fiberboard contain no less than 20% of thermoplastic bonding agents.

The general term "fiberboard" is not only adopted for use in the publications

of FAO and ECE, but is generally understood in the literature and in the industry.

FAO (1958/1959) gives a survey on the nomenclature.

Fiberboard is manufactured from separated fibers or bundles of them. This is a fundamental difference between fiberboard and particleboard. Fiberboard is produced by interfelting of fibers in such a way as to produce a mat or sheet.

The properties of the mat depend on the characteristic natural bonding of fibers between themselves. Chemicals may be added during manufacture with the aim to improve the cohesion and the water resistance.

Typical of fiberboard is the wide range in densities between 0.02 and about 1.45 g/cm3 (approx 1.25 and 901b/ cu. ft.).

Asbestos in fiberboard?

"Lignocellulosic fiber is a scientific name that refers to natural fiber, because all plant fibers are constructed by few constituents (cellulose, hemicelluloses, and lignin). Most of plant fibers contain 50%–70% of cellulose ..." - sciencedirect.com 2021/11/07

Asbestos is a mineral, not a plant.

Asbestos is indeed uncommon in any fiberboard products but there are exceptions, as we describe at

SHEATHING, FIBERBOARD ASBESTOS CONTENT

You will want to read that article.

Exterior Fiberboard Sheathing vs. Interior Fiberboard Walls & Ceilings

Fiberboard manufacturers such as those listed in this article series produced cellulose-based fiberboard or "caneboard" from a variety of plant- or wood-fiber sources.

Fiberboard manufacturers such as those listed in this article series produced cellulose-based fiberboard or "caneboard" from a variety of plant- or wood-fiber sources.

These panels were used as an insulating sheathing on building exteriors (mostly walls, rarely roofs).

Fiberboard panels were even more-widely used inside buildings as ceiling and wall paneling that was sometimes left unpainted, sometimes painted, and sometimes used as a plaster-base.

Exterior Fiberboard Sheathing

Insulating board sheathing has been widely used on building exterior walls, under roofs, and against masonry foundations in finished basements.

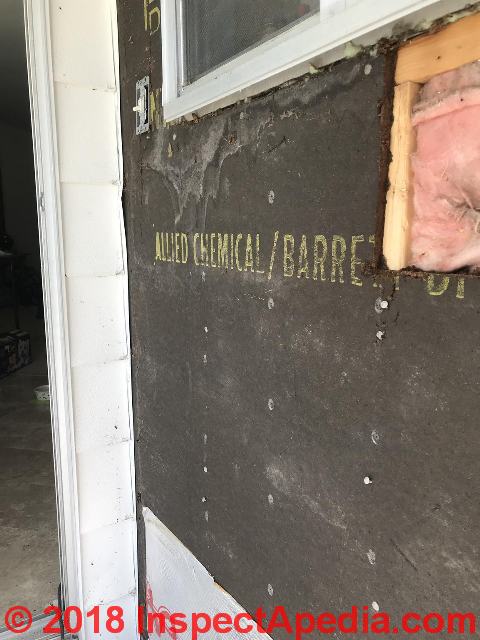

Exterior fiberboard, like the Allied Chemical / Barrett R-Brace sheathing shown here was usually treated to improve its water-resistance. If exterior-use fiberboard has a dark coating that's black or nearly-black it is usually an asphalt-based surface.

If the exterior-use fiberboard is tan or dark-brown in color it will probably also have a satin or slightly-shiny surface as it was treated with a water-repellent wax.

Both types of fiberboard or "caneboard" sheathing may be impregnated throughout with a water repellent and often also with borate or other insect repellents.

That's true across the fiberboard-producing companies. You can often further-identify the fiberboard sheathing by a specific manufacturer if the sheathing bears stampings or printed product or company names.

Interior Fiberboard Sheathing

Interior fiberboard sheathing like the light brown fiberboard we show just below might also have been coated or treated with water repellents and insect repellents, but more-often the manufacturer's interior-use fiberboard products did not require and were not treated.

As a result interior-use fiberboard is more-likely to be light tan or brown in color with a natural finish - unless it was painted or plastered-over.

Our fiberboard photo shows the wall-cavity side of an interior-use fiberboard paneling that was found in the U.S. in an older home in Vermont.

You can see the characteristic linear screen-link texture on the fiberboard's surface. There are no manufacturer's marks. This photo, provided by an reader by email in 2018, identifies interior-use insulating board for which we can rule-out some brands like gray caneboards but beyond that the manufacturer is uncertain.

Below is another fiberboard photo provided by the same reader.

Above we're looking at the interior of a fiberboard panel that has been split or torn during demolition. You can see the difference in surface texture - still without a certain identification of a specific manufacturer.

Below is a third fiberboard panel photo also provided by the same reader.

Above: the reader cut this fiberboard, perhaps with a sharp knife, and doubled it back over itself so that the wallboard sides that had been painted form a white line in the center of the image between the two board edges.

You can see the consistency of material in this insulating board. We can correctly state that this is a wood-based or wood-fiber based insulating board. Products made from post-consumer paper will be more gray in color throughout.

By color we can rule out Greylite, Homasote, and Upsonboard, but that's about our limit.

By color and texture this looks like but is not Beaverboard - Beaverboard bore identifying stampings or markings -

see details at IDENTIFY BEAVERBOARD FIBER PANELS & SHEATHING

I suspect this is an older Celotex insulating board product.

Allied Chemical / Barrett R-Brace Insulating Sheathing

See details about idenytifying AB fiberboard including additional photos, asbestos test results and more information now found

at IDENTIFY ALLIED CHEMICAL / BARRETT R-Brace Insulating Board & Fiberboard - separate article

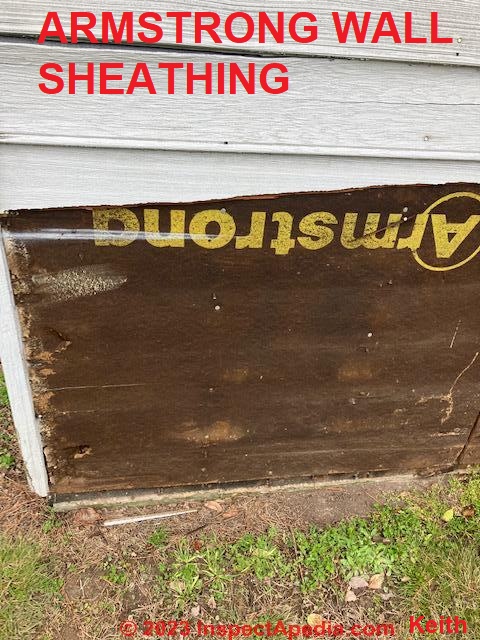

Identify Armstrong Fiberboard Sheathing

Photos above showing the Armstrong logo on what looks like brown fiberboard insulating wall sheathing and below in closer view, are provided courtesy of InspectApedia.com reader Keith who found this material on a shed built in 1969, whose photos are discussed further, below.

Armstrong provided insulating board and sheathing products including under the brands listed just below:

- Temlok sheathing

- Temlok roof deck

- Temlok shake-backer, shingle-backer

- Temlok insulation board

- Temlok plank

- Temlok tile

- Cushiontone

- Temlok lath

- M-67 Monowall

- Insulating wool

- Hardboards.

Armstrong's Temlok was sold in various sizes such as 2' x 8', 4' x 8', 4' x 9' and was sold as a lower-cost competitor for horizontal wood plank sheathing.

Asbestos in Armstrong Temlok Sheathing? No, but ...

The product description itself does not include mention of use of asbestos, and other sources describe Temlok as made from Southern Pine, but this board was used in combination with several asbestos containing products such as a backer for asbestos-cement shingle siding and as a substrate to which asbestos could be bonded for other uses.

Armstrong Fiberboard Information Sources

- ARMSTRONG BUILDING PRODUCTS CATALOG [PDF] (1955) Internet Archive, Retrieved 2023/02/25 original source: https://archive.org/details/Sweet1955armstrong40 - Sweets Building Catalog

Excerpts:

Armstrong Temlok® Sheathing is an asphalt-impregnated fiberboard coated on one side with a water-repellent Rain- Shield* finish. This finish keeps the exposed sheathing dry during construction yet permits the walls of the finished house to “breathe,” and allow harmful moisture to escape.

Additional protection against water absorption is provided by the asphalt impregnation of each individual fiber, keeping Temlok Sheathing dry and efficient.

Uses:

Wall sheathing over frame construction. Floor insulation of basementless houses—(a) underside of joists in crawl spaces; and (b) insulation between walls and concrete floors. Farm building insulation. Not recommended for roof sheathing unless furring strips are used.

BRACING STRENGTH.

Stronger than horizontal wood sheathing. Approximately equal bracing strength to more costly diagonal wood sheathing. Both V 2 " and 2 % 2 " thicknesses meet FHA requirements.

INSULATION VALUE.

When used as a replacement for wood sheathing, Temlok Sheathing reduces heat loss through walls by about 30% (for 2 % 2 " thickness) and by about 20% (for V 2 " thickness).

LOW LABOR COSTS.

Reduces labor by about 30%, as compared with horizontal wood sheathing labor costs; by about 50%, as compared with diagonal wood sheathing labor costs. Large, lightweight units of Temlok Sheathing go up fast, with minimum cutting and fitting necessary. - Kelley, Stephen J. Insulation board and method of making the same [PDF] U.S. Patent 2,213,249, issued September 3, 1940

Excerpt:

It has also been proposed to overcome the inherent defects of fiber boards by cementing to the faces of the boards, by means of-a sodium silicate cement, preformed sheets of asbestos fiber-hydraulic cement composition.

This laminated product possesses a relatively high degree of resistance to'deformation and structural strength but is expensive to produce and has a tendency to beso come loose upon contact with moisture, and permits expansion of the fiber board which it covers. There is no mechanical bond between the laminations.

It is an object of my invention to produce an 35 insulation board which is structurally strong and rigid and possesses a high insulating value, a low specific weight and presents a smooth surface for decoration.

It is a further object of my invention to provide an insulation board in which n the insulating core is so sheathed and confined that expansion thereof upon the absorption of moisture is restricted and the board is rendered fire resistant. - Shaw, Myron Berkley. A Descriptive Analysis of the Documentary Drama Television Program, the'armstrong Circle Theatre,'1955-1961. University of Michigan, 1962.

Excerpt:

... the production of Temlok fiberboard materials from southern pine.

Beaver Board & History of How Fiberboard Was & Is Manufactured

Beaver Board was marked on the back of each sheet with an ink-stamped trademark and brand.

Beaver Board was marked on the back of each sheet with an ink-stamped trademark and brand.

If a single fiberboard sheathing product wanted to go up against Homasote as claiming the most-generic use of its name to describe low-density fiberboard sheathing made from wood fibers, or plant fibers, it'd be Beaver Board.

Details about identifying true Beaverboard panels are

at BEAVERBOARD IDENTIFICATION.

However "beaverboard" as well as "celotex" are often used as a generic product name.

That's understandable, because Beaverboard and other low-density fiberboard sheathing or wallboard products were similar in being comprised of relatively-homogenous plant-fibers bonded together by the interlacing of the fibers and treated with a waterproofing agent.

While no doubt some ugly logs that wouldn't have made a nice stud or joist were ground into chips for processing, I think that most of these sheathing products were considered to take enormous advantage of sawmill waste in the form of wood chips, sawdust, and wood scrap, or for some manufacturers, in the form of other plant materials such as straw, sugar cane, or bagasse.

Where wood was the initial material the wood was chopped into chips, sized, ground to finer size, and smashed into individual wood cells using steam and rollers.

The combination of steam or water and pressure permitted the fibers to bond together into a sheet that was further pressed by hydraulic rams and rollers called platens (think of a huge typewriter platen or roller if you were born before 1980).

Randomly-crossed wood fibers make a strong product, a realization that appeared again later as MDF and HDF and similar products. To get the plant or wood fibers to adhere to one another beyond their mechanical arm linking, adhesives were used during the fiber consolidation process.

Jester names silicate of soda, flour paste, glues, dextrin, plaster of paris, waterglass and clay, rosin, turpentine, paraffin wax (see HOMASOTE® IDENTIFICATION), asphalt (giving a nice dark black color to the fiberboard panels and making them unattractive to termites and carpenter ants). (Jester 2014 pp 90-90).

Photo above: low density fiberboard is not, however absolutely insect-proof, as my photo shows. More about this particular insect damage is

at FIBERBOARD SHEATHING MOLD CONTAMINATION

Beaverboard, as other low density fiberboard products, was then trimmed, treated with a water repellent, and possibly colored, or for fancier products like Nuwood™ [web page] cut to bevels or tooled.

Caneboard sheathing

Caneboard was a fiberboard panel made from sugar cane.

Details are at IDENIFY CANEBOARD PANEL.

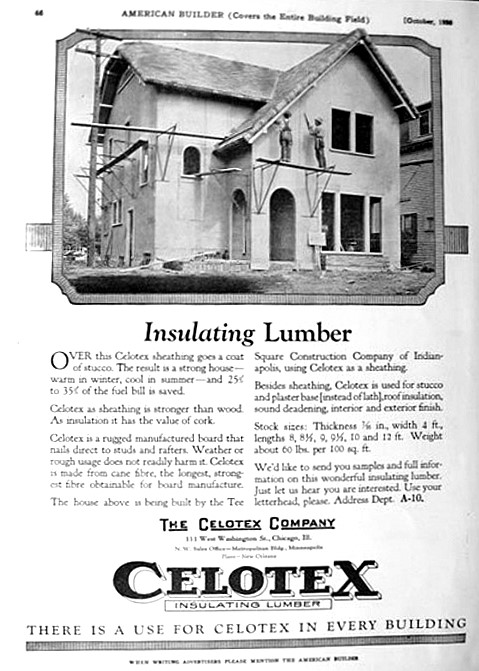

Celotex® Insulating Board and Fiberboard Products

Celotex produced its first insulating sheathing board from bagasse (sugar cane waste) in 1920.

Our photographs below show Celotex® insulating board with an older Celotex fiberboard building sheathing board at left and a more recent Celotex insulating board product shown at below-right.

Details for identifying Celotex at at

IDENTIFY Celotex® Insulating Board and Fiberboard Products

and at CELOTEX HISTORY & PRODUCTS

Identify Dierks Fiberboard Sheathing Products

On 2022-10-04 by InspectApedia (Editor) (mod) - History of Dierks Forestry, Lumber Products, & 1960's wall sheathing

@Kinga J,

@Kinga J,

Dierks was a, among other trade names, an Arkansas lumber company (Arkansas-based Dierks Forests, Inc.—which amassed holdings of 1.75 million acres of timberland—was one of the largest family-owned landholding entities in the United States until its sale to Weyerhaeuser Company in 1969.- source: https://encyclopediaofarkansas.net/entries/dierks-forests-inc-8188/

After over 75 years in the lumber business, Dierks Forest, Inc., was purchased by Weyerhaeuser for $317 million in 1969. - source: https://www.arkansasheritage.com/arkansas-register/dierks-lumber-company-building

So it's most-likely that your Dierk's intermediate wall sheathing (between framing and exterior siding) was produced by that company during that era.

That Dierk's produced lumber and other building products including insulating sheathing board.

And we found Dierk's - an Iowa lumber company (dating from the 1880's).

And we found Dierk's - an Oklahoma lumber company :

CHOCTAW LUMBER COMPANY.

The Choctaw Lumber Company appeared in McCurtain County in 1906. The company's founders, brothers Hans and Herman Dierks, had been profitably engaged in retail lumber businesses in Iowa, Nebraska, and North Dakota from 1880 to 1895.

The retail business named Dierks Brothers continued until it expanded in 1895 to become Dierks Lumber and Coal Company, headquartered in Lincoln, Nebraska. Joined in management by brothers Peter and Henry, they continued to expand the Nebraska operations.

In 1897 the company moved its headquarters to Kansas City, Missouri, and was incorporated in 1898. - source: https://www.okhistory.org/publications/enc/entry.php?entry=CH050

Insulating sheathing would have been, and is labeled in your photo, a Dierk's product. The photo isn't quite sharp (a close-up would help) but it looks like fiberboard such as discussed above on this page.

The possibility of asbestos content of these basically plant-based products, is discussed at

FIBERBOARD SHEATHING ASBESTOS CONTENT

https://inspectapedia.com/structure/Fiberboard-Sheathing-Asbestos.php

**Please** tell us the location of your building and we can comment further.

On 2022-10-04 by Kinga J - what kind of fiberboard is this, marked Dierks

What kind 9sbfiberboard is it ? Does it contain asbestos. House is dated 1960

[Photo above showing Dierks ... Intermediate ... tan fiberboard exterior wall insulating sheathing board. ]

Also see DIERKS LUMBER COMPANY HISTORY [PDF] Arkansas Heritage - retrieved 2022/10/04, Source: arkansasheritage.com/arkansas-register/dierks-lumber-company-building

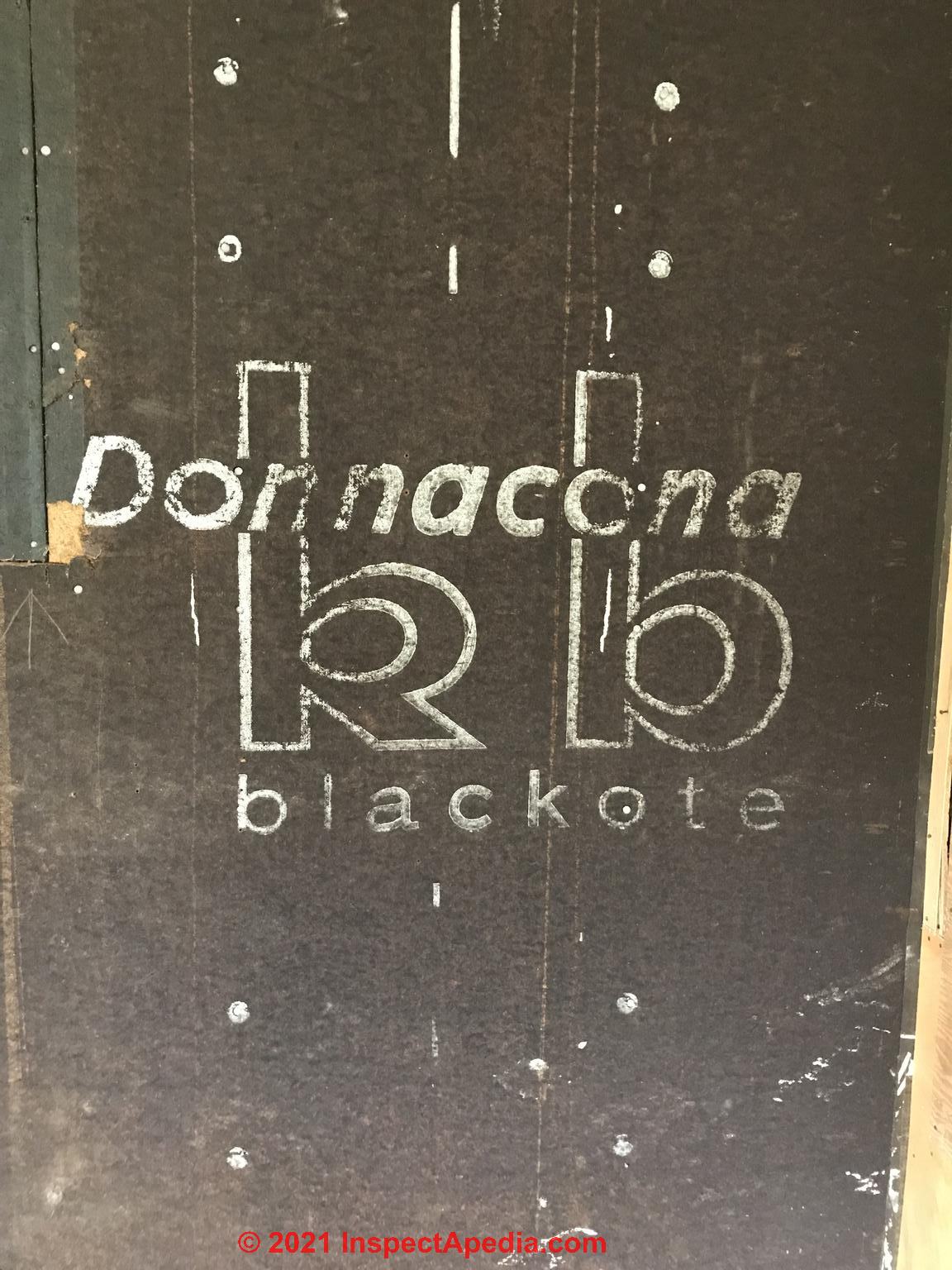

Identify Donnacona Board Sheathing & Acoustic Panels

Donnaconnaboard may be light coloured or greyish or it can be a dark brown, almost black asphalt-like coated board.

See details and more identification photos, history, tests for Donnacona board now found

at IDENTIFY Donnacona Fiberboard acoustic & insulating panels - separate article

Photo of Donnacona blackote Fiberboard from a British Columbia home built in 1965, provided courtesy of InspectApedia reader John Vere.

Identify Eastman Sheathing Board

Eastman insulating sheathing, apparently cellulose-based fiber insulating board stamped with code PS 57-73 - [citations and research in process]

- English, Brent, John A. Youngquist, and Andrzej M. Krzysik. LIGNOCELLULOSIC COMPOSITES [PDF] Cellulosic polymers, blends and composites. New York: Hanser (1994): 115-139.

Excerpt (p. 125):

The PP was Fortilene 1602 from Solvay Polymers, Inc.* (Deer Park, TX). The HDPE was recycled from milk bottles. The wood flour was western pine [-40, +80 mesh (-420, + 177 µm)] from American Woodfiber Co (Schofield, WI), Cellulose fiber was Solka-FIoc BW-40 from James River Corp. (Hackensack, NJ). The old newsprint (ONP) was hammermilled to 15-mm flakes.

The coupling agent was E-43 powder, a maleated PP, obtained from Eastman Chemical products., Inc. (Kingsport, TN). - Moore, John Hebron. "William H. Mason, Southern Industrialist." The Journal of Southern History 27, no. 2 (1961): 169-183.

Excerpt:

With this objective in mind, he compressed some wet insulating board in a press equipped with … big Eastman-Gardiner Lumber Company to join with them in financing the fiber board plant … Charles Green, president of Eastman-Gardiner, was the first president of the Mason Fibre - NEW SHEATHING DOUBLES INSULATION VALUES OF CONVENTIONAL MATERIALS IN HOMES AND BUILDINGS [PDF] Journal of Cellular Plastics. 1975;11(4):168-178. doi:10.1177/0021955X7501100402

- Current: Eastman is a specialty materials company founded in 1920. The company has offices world-wide. Website: https://www.eastman.com/ Tel: Corporate Headquarters 800-327-8626

Identify Fir-Tex, FirTex, Fire-Tex Fiberboard - Kaiser Gypsum

Fir-Tex, in some literature FirTex or Fire-Tex or FireTex was a fiberboard product, made principally of wood pulp and was produced by the Fir-Tex Insulating Board Co., an Oregon corporation operating at St. Helens, Oregon, engaged in the manufacturer of insulating wall board from at least the mid 1930s.

Fir-Tex, in some literature FirTex or Fire-Tex or FireTex was a fiberboard product, made principally of wood pulp and was produced by the Fir-Tex Insulating Board Co., an Oregon corporation operating at St. Helens, Oregon, engaged in the manufacturer of insulating wall board from at least the mid 1930s.

Note that asbestos, Asbestos, plaster of Paris, clay, turpentine, paraffin wax, or other materials were added to some mixes to improve fire resistance and produce other desirable qualities such as stiffness, hardness, smooth surfaces, increased strength, or durability. (Wilson 2007)

The trademark was associated with / registered by Kaiser Gypsum Co. - 1958-06-10.

The trademark category description includes

Composition wood fiberboard, insulating sheathing, roofdeck materials, insulating tile, building board, utility board, insulating plank, and acoustical tile

International Class

017 - Rubber, gutta-percha, gum, asbestos, mica and goods made from these materials and not included in other classes; plastics in extruded form for use in manufacture; packing, stopping and insulating materials; flexible pipes, not of metal.

019 - Building materials (non-metallic); non-metallic rigid pipes for building; asphalt, pitch and bitumen; non-metallic transportable buildings; monuments, not of metal.

- Rubber, gutta-percha, gum, asbestos, mica and goods made from these materials and not included in other classes; plastics in extruded form for use in manufacture; packing, stopping and insulating materials; flexible pipes, not of metal.

Building materials (non-metallic); non-metallic rigid pipes for building; asphalt, pitch and bitumen; non-metallic transportable buildings; monuments, not of metal.

- Fir-Tex Insulating Board Co., 69 N.L.R.B. 1086 (N.L.R.B-BD 1946)

- Fir-Tex SUPER INSULATING BOARD [PDF] (1938), included in the Sweets Catalog of building products for that year.

- Fir-Tex INSULATING BOARDS [PDF] (1945) (Product Catalog) Fir-Tex Insulating Board Co., Offices: Porter Building, Portland, Oregon, Factory: St.Helens, Oregon.

- Gould, Carol S., Kimberly L. Konrad, Kathleen Catalono MIlley, Rebecca Gallagher, "FIBERBOARD Dates of Production 1858 to the present, Common Trade Names" [American Wallboard, Beaver Board, Cornell BOard, C-X Boards, Feltex, Fir-Tex, Homasote, Insulite, J-M Board, Maftex, Masonite (presdwood Quartrboard, Tempered Presdwood), Nu-Wood, Upson Board), Chapter 12 in Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Rhiger, Hans. THE FIBER BOARD INDUSTRY [PDF] (1937). BSc Thesis, Oregon State Agricultural College (June 1937)

- Wilson, Richa, Kathleen Snodgrass, EARLY 20TH-CENTURY BUILDING MATERIALS: FIBERBOARD AND PLYWOOD [PDF] (2007) United States Department of Agriculture, Forest Service, Technology & Development Program, 073-2308-MTDC, retrieved 2017/07/29, original source: https://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/

Excerpt:

The Washington Office’s Improvement Handbook (1937) and Principles of Architectural Planning for Forest Service Administrative Improvements (1938) noted that certain fiberboards were acceptable for use as insulation and on interior walls and ceilings. These included Masonite, NuWood, Du-X, and Fir-tex.

...

Early trade names for insulation board included Insulate, Fir-tex, and Nu-Wood–all of which were made from wood pulp.

Identify Homasote® Brand Boards & Panels

Homasote® wallboard and panels used for building sheathing are a cellulose-based product made from re-cycled paper to produce an internally homogeneous (non-layered) gray or gray-tan panel. .

Homasote® wallboard and panels used for building sheathing are a cellulose-based product made from re-cycled paper to produce an internally homogeneous (non-layered) gray or gray-tan panel. .

Homasote® Identification: check color & texture & cross section

Despite widespread use of the word Homasote® to describe brown fibrous and soft board panels, actually Homasote is gray or in my OPINION gray-tan in color, as it's produced from post-consumer paper.

However once installed the product may have been painted or covered-over so an inspector cannot assume that she will always find the gray color without some digging into the structure.

The Homasote picture shown here is from a discontinued product previously sold at Lowes stores.

According to Homasote®,

[Homasote brand fiberboard products in] cross section would not show layers of fiber since our products, unlike other fiberboards, are not layered.

With aging our products normally have a yellowish brown tint otherwise they are gray.

In all cases, unsanded Homasote Products all have very visible patterns on the face and back side surfaces. As far as I can tell, none of the samples shown below [at UNIDENTIFIED FIBERBOARD PRODUCTS] have our mold patterns.

Each fiber is coated with a wax emulsion thus making the panel weather resistant.

Homasote® company history, current product list, product composition details, more identificatin photographs & contact information are

at HOMASOTE HISTORY & PRODUCTS

Is it OK to re-side a home with Homasote building sheathing on its walls?

My home was built in the early 1940s and it was re-sided around 1994 (possibly a bit later but that's all the info we have). There are what we thought was sheetrock on the outside, but someone suggested it may be Homasote boards from when the house was originally built.

Two questions, if they are these boards from 50 years ago (at the time the house was re-sided), was that ok to do based on housing codes? Could they contain asbestos? Thanks. - K 12/2/2011

Reply: Yes

I've not found any building code issue constraining the procedure of re-siding a home because of the type of exterior sheathing used on the structure. The asbestos question is addressed in earlier FAQs addressed above. Wood or plant fibers are not asbestos materials.

Watch out: fiberboard sheathing should be protected from water that penetrates some building siding systems (such as aluminum or vinyl siding) by installing a water or moisture barrier - housewrap.

Identify Graylite - Insulite, Cellulose FiberBoard Insulating Board & Plaster Base

Insulite and Graylite were a cellulose-based (all wood fiber) insulating board or sheathing material that, unlike Celotex, was made from wood pulp byproduct or sawmill tailings fibers.

See details and identification photos, history, research, lab tests and more information about Graylite and Insulite now found

at IDENTIFY Insulite, or Graylite cellulose fiber board product useful for plasterboard - separate article

Additional information about Graylite and Insulite is found in

FIBERBOARD PLASTER BASE SYSTEMS

Identify IKO Fiberboard Sheathing Products

Photos: IKO fiberboard insulating sheathing on a 1980 home on Vancouver Island.

IKO produces and has produced a range of building insulating sheathing products of various materials, including fiberboard insulating sheathing stamped with a gray-white IKO logo as shown in photos here, courtesy of InspectApedia reader David in 2023.

See identification photos, guides, research, history of Iko fiberboared sheathing now found

at IDENTIFY IKO Fiberboard & Other Insulating Sheathing - separate article

Johns Manville Fiberboard Sheathing Identification

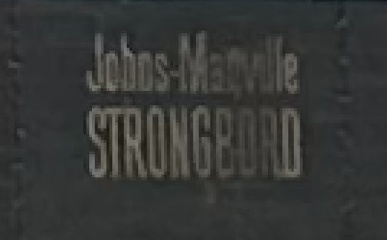

Above: Johns Manville's product name and imprint on an older U.S. home.

This "blackboard" sheathing product, widely-used in the U.S. at least by the 1960s, was typically installed as 1/2-inch thick 4' x 8' fiberboard panels that served as both a nail base for siding and insulating sheathing.

The photo below of Johns-Manville Strongboard fiberboard insulating sheathing was provided courtesy of InspectApedia.com reader Ann.

Debris from Johns Manville Strongboard: should I be worried about asbestos?

I had my siding redone and underneath there is this blackboard pictured "Johns Manville Strongboard".

It was left alone and wrapped with Hardie wrap then the new cement fiberboard on top, but a lot of nails and other pieces attached were disturbed and my lawn was left with a ton of tiny debris all over. The house is from the early 60's so this could be original. - On 2023-07-31 by Ann

Should I be worried about asbestos here or does this type of board not contain that? The siding that was removed was vinyl with the plastic underneath FYI so no ACM there if that is helpful.

Thank you in advance!

On 2023-08-01 by InspectApedia Publisher (mod)

@Ann,

Generally, fiberboard sheathing is a plant-based product - not asbestos, but I'd still want that debris cleaned-up.

In the company's 1949 sheathing product catalog their insulating sheathing was describd as made from "clean pine fibers". - source: Johns-Manville ASBESTOS FLEXBOARD INSULATING BOARD PRODUCTS [PDF] (1949) Catalog

We are researching further for any documents that give specifics about the ingredients in 1960s Johns-Manville blackboard sheathing and will add that here.

A more complete answer to your question is atSHEATHING, FIBERBOARD ASBESTOS CONTENT

And you will also want to read

SHEATHING, FIBERBOARD ASBESTOS CONTENT where we include a section

on BLACKBOARD ASBESTOS CONTENT

Once looking at those two articles, don't hesitate to ask any follow-up questions needed.For completeness, you can see a complete list of the Johns-Manville products known to contain asbestos, by scrolling down to that company name in our article:

ASBESTOS PRODUCING COMPANIES & TRUSTS

Thanks

DF

Masonite™ and other hardboard Sheet and Siding Building Materials

Our photo (left) shows the back side of an early hardboard interior-use product labeled "Genuine4 Masonite Quartrboard".

At HARDBOARD MASONITE™ & OTHER BRANDS we include a table translating mill codes to hardboard manufacturer for all brands of hardboard siding.

History, more photos, & dates along with a description of the ingredients in Masonite™ hardboard products are given

at HARDBOARD Masonite™-like INGREDIENTS

More about hardboard sheet products used on building interiors is found

at DRYWALL, FIBERBOARD, PLASTER INTERIORS

Identify National Gypsum's Gold Bond® Cellulose-based Insulating Board

Shown here in photos provided by a reader are a portion of the Gold Bond logo used by National Gypsum on "black" or "brown" board insulating board or IB.

The second photo plainly shows brown cellulose-like fibers that would be expected to be a wood or plant product based material.

National Gypsum produced a very wide range of building products, a number of which contained asbestos, principally in products based on gypsum board or plaster board, or cement or asbestos cement board and coatings.

At ASBESTOS PRODUCING COMPANIES & TRUSTS where you will find National Gypsum in that alphabetic list, we discuss a number of Gold Bond™ products, all produced by National Gypsum, that did indeed contain asbestos.

Nu-Wood Fiberboard Wall & Ceiling Covering Product Identification

Nu-Wood ® fiberboard panels, also referred to as NuWood or Nu Wood paneling or ceiling tiles were a low-density fiberboard panels used on walls & ceilings & as a plaster lath support. They were produced by the Wood Conversion Company in St. Paul, Minnesota who also produced Balsam Wool.

The parent Wood Conversion Company was incorporated in 1921 in Delaware by eleven stockholding companies, including the Weyerhaeuser firms. The Wood Conversion Company headquarters was located in Cloquet, Minnesota.

According to the company's product literature, some Nu-Wood fiberboard was thus plastered over while other installations were left with the original factory color coating.

Keep in mind that a 1940's home that used Nu-Wood wall or ceiling panels may well have been painted-over, plastered over, or later even laminated-over with a layer of more modern drywall.

[Click to enlarge any image]

Our details about the identifying details for Nu-Wood fiberboard panels are now found

at IDENTIFY NU-WOOD PANELS - a separate article.

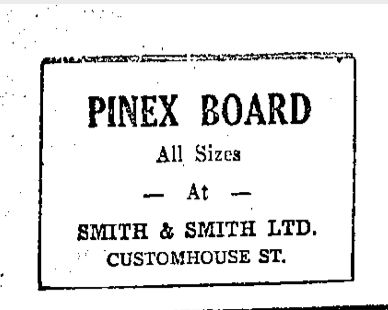

Pinex Fiberboard - Insulating Board "Softboard"

This advertisement for PINEX BOARD appeared in the Gisborne Herald on November 2, 1943.

Pinex is a specific brand of soft wood-fibre based insulating board that, in New Zealand, is often used as a generic name" for low-density softboard or fibreboard.

Pinex and equivalents was widely used as an insulating sheathing in New Zealand between 1941 and 1960, and appears also as finished ceilings, sometimes coated with plaster or covered by wallpaper or occasionally painted.

See details at

IDENTIFY PINEX FIBERBOARD - separate article

Photo of Russian or Italian Fiberboard Sheathing / Insulating Board

What are these wall insulating panels?

What are these wall insulating panels?

Hi there, fantastic trove of information you’ve got here! Any ideas as to what these panels are? They were used as insulation in the walls. - 2020/01/25 Mark

Reply:

Thanks for the compliment Mark, we work hard on this so I'm really grateful when you find our information useful.

About your panels, from the surface appearance first and the edge appearance second, those look like fiberboard insulating panels.

See SHEATHING, FIBERBOARD - home - for photo examples of fiberboard, or

you could go right to FIBERBOARD SHEATHING IDENTIFICATION [readers are now on this page]

or scroll through the examples of other types of insulation given

at INSULATION IDENTIFICATION GUIDE

There are also densely-packed mineral-fibre MINERAL WOOL insulation products that may have appeared as board-type insulating panels but I don't think those would have that brown wood-fibre-like surface that I see in your photo.

Can you tell me following?

1. the country and city where these are located

2. the type and age of building where they were found

3. exactly how they were applied or located? I mean, I'd expect these to be nailed to studs on the interior or exterior surface of a wall. If you found them in some other position that'd be interesting.

Reader follow-up:

The house is in northern Italy and is for the most part a prefabricated wooden house imported from Russia in the 70s.

These panels have been used in various locations around the house such as in between the studs as insulation, over roof space floorboards as insulation and as recently discovered as an extra layer to double up the battens for the external siding (thus increasing the air gap). Will try to get some more photos if that helps.

We have removed almost all of it, where possible, but the fact that the most worn and weather beaten panels break up easily, leaving dust behind, has left me wondering as to its makeup and its potential to be a health hazard!

Many thanks. Mark

Moderator reply:

Thanks Mark, clearly that is not at all likely to be a US-made fiberboard product.

Yes a sharp photo of the material edge and another of the surface would be great as would be any stamps or labels on the material.

From your description it sounds as if someone got a supply of fiberboard and cut it to insert between studs in an effort to improve the wall's R-value.

Generally this is a wood product, made from various species of vegetable matter depending on the country and area of origin, often pine board sawdust but given that the home originated in Russia the wood species could of course be different if the panels were made there - or in Italy or in another nearby country.

It doesn't usually contain asbestos (with a few uncommon exceptions).

In my opinion the smaller particles in just about any building dust are at the very least, respiratory irritants, possibly allergenic, and potentially harmful. It's always smart to wear a dust mask/respirator and to clean up the dust.

Some companies impregnated the panels with waxes, asphalt or other stabilizers to improve moisture resistance but any of them can become soft and crumbly with wetting, moisture, age. Which is why you won't see this material used in homes in Venice.

Reader follow-up:

2020/01/26 Additional photos of this wood-based or cellulose- fiberboard are posted for identification.

Mark said:

Follow up photos to the one posted higher up the page ... trying to identify these panels that are possibly Italian /European or Russian in origin. Many thanks.Moderator reply:

Certainly that looks like a wood fiber "fiberboard" Mark;

While in a few cases careful forensic microscopy or even spectroscopy can identify specific fibres used by specific fiberboard manufacturers (such as bagasse or sugar cane) in general you'd need to look for other means to know who made the product.

Those include a research of the building's age, site of construction, construction history, bills of materials, and of course any manufacturer's stamps or tags found on the product.

History of Shumite fiberboard (?) insulating board? Shu Mite? Shamite?

I am looking at blueprints for a sound stage from 1936, and I see a layer of 1/2" Shumite specified between roof rafters (and wall studs) and the 2" mineral wool they used for sound insulation. I can't find anything on Google called "Shumite," is this a material you are familiar with?

Insulite and plaster board are also specified on these drawings, so it should not be the same material. In some places Insulite is specified to replace Shumite. I turn to you because I learned what Insulite was from your website!

Anything helps. Thank you! - Anonymous by private email 2020/10/15

Moderator reply:

Thanks for the interesting question on Shumite, Anon. I, too, have not yet found a reference to that 1930s product that I infer, from your note, was, from the context of use, probably a type of sound-insulating board.

It's possible that Shumite was named for an individual, as the name Shumite does appear both in biblical text (2 Kings 4:12 et als; Shunammite was a native inhabitant of Shunem north of Mt. Gilboa in ancient Palestine) and in modern times a Shumite was listed among U.S. civil war prisoners.

If you can post or email me a photo of the document so that we can be sure of its spelling and any distinctive identification data that would help my research.

Sundeala Board

Sundeala board is a rigid or semi-rigid cellulose product made from recycled paper, produced first in 1898 by the Impermeable Millboard Company Ltd, in the U.K., and who continue to the present as the Sundeala company.

See details at SUNDEALA BOARD COMPOSITION & HISTORY

How to Identify Upson Board

Upson board embossed its marking into the board itself, and a "Blue Center" runs through every piece of the board.

Examine a cross section of the board for this characteristic blue material.

US Gypsum Insulating Sheathing

Details on identifying and finding properties of US Gypsum's sheathing products are now found

at IDENTIFY US GYPSUM INSULATING SHEATHING

USG's products included USG Insulation Formboard - a wood fiber product, and Pyrofill, a gypsum concrete product that included wood chips, shavings, fibers. Asbestos was used in some other products or in their installation support, for example in USG's roofing sheathing systems.

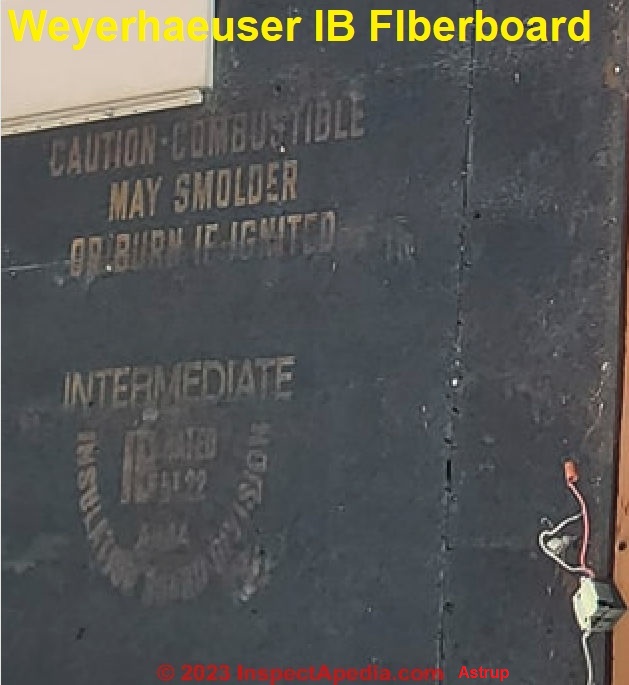

Identify Weyerhaeuser IB FIberboard or Insulating Board Products

Collected from several sources, as Weyerhaeuser manufactured and sold fiberboard or insulating board products under several product names and brands, we provide photos and examples below.

Note: the company's name is occasionally mis-spelled by people as We ye rhauser

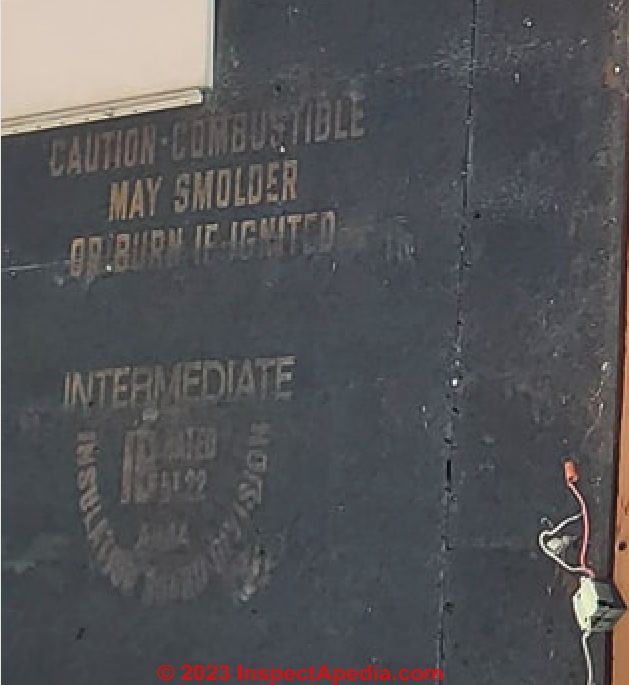

Any pointers to this exterior wall sheet - On 2023-07-10 by Bo Astrup - what can you tell me about this exterior wall sheathing

On 2023-07-10 by InspectApedia Publisher (mod)

@Bo Astrup,

Thats a Weyerhaeuser Intermediate Insulating Board "IB-Rated 5122" that is combustible - which is why it was not intended to be left exposed. It's intended to be covered with siding or if indoors, with drywall / gypsum board.

I notice as an aside some loose electrical wires - if those are carrying live voltage that's a more-immediate safety hazard.

If you're asking about asbestos, that's explained over at SHEATHING, FIBERBOARD ASBESTOS CONTENT https://inspectapedia.com/structure/Fiberboard-Sheathing-Asbestos.php

Thank you for the photos and question - we will copy the images and our reply into the article above to help other readers.

Please tell us the building location and its age and use. And let me know if you have other questions.

Thanks

DF

Below: Dierks fiberboard by Weyerhaeuser

See IDENTIFY Dierks Fiberboard Sheathing

Below:

Also see IDENTIFY NU-WOOD PANELS

History & Patents for Weyerhaeuser- Older Insulating Board IB Products

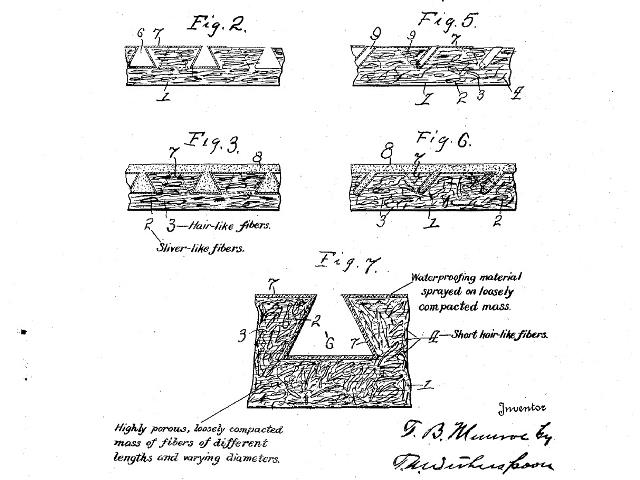

Above: an illustration from Frederick, Weyerhaeuser, and John S. Busch 1936 Patent 2,030,668, issued February 11, 1936. for wood-fiber insulating board. Cited below.

[Click to enlarge any image]

- Bryant, Benjamin S. "Compressible mat of whole wood fibers and uncured resin as overlay for wood product and process of making same." U.S. Patent 3,308,013, issued March 7, 1967. Application filed by Weyerhaeuser Co.

Claim: A process of making an overlaid woody product, comrising; screen forming a porous compressible mat consisting essentially of whole wood fibers from an aqueous, fiber slurry to a thickness of from 0.1 to 0.5 inch thick and a specific gravity f from 0.15 to 0.30; said fibers having an uncured synthetic resin solids precipitated uniformly thereon in an amount of at least about 5% based on the dry fiber weight;

adjusting the moisture content of said porous mat to between about 12% and 200% based on the dry fiber weight; disposing said mat in face to face relation to an unconsolidated substrate of adhesive bearing woody members; consolidating said substrate and mat heat and pressure to cure the resin and adhesive content and provid said cured mat with a specific gravity of between about 0.7 and 0.95, thereby filling any voids in the surface of said substrate. - Chase, Harry A. "Process of treating composite boards with borate chemicals produced thereby and product." U.S. Patent 3,438,847, issued April 15, 1969. 6 Application filed by Weyerhaeuser Co

- Heritage, Clark C. "Thermal insulation." U.S. Patent 2,264,976, issued December 2, 1941.

- Carl, Marx, and Elton R. Darling. Wall board, sheathing lumber and the like. [PDF] U.S. Patent 1,828,029, issued October 20, 1931.

Excerpt: The present invention relates to an im proved method of treating wall board and sheathing lumber of the type prepared from redwood bark and the like, particularly as set forth in the co-pending application of Elton R. Darling, Serial NO. 372,224, filed June 19, 1929. - Carl, Marx, and Elton R. Darling. "Wall board, sheathing lumber and the like." U.S. Patent 1,828,029, issued October 20, 1931.

- Darling, Elton R. "Production of sheathing boards from redwood bark." U.S. Patent 1,828,028, issued October 20, 1931.

- Darling, Elton R. "Manufacture of sheathing lumber from redwood bark." U.S. Patent 1,797,901, issued March 24, 1931.

- Heritage, Clark C. Dry-wall construction U.S. Patent 2,541,762, issued February 13, 1951. Application filed by Wood Conversion Co

Excerpt: The present invention relates generally to ther mal insulation and resistors to the flow of Water vapor, and in particular to thermally insulated and water-vapor-resistant space-enclosing or Sep arating structures. - Mason, William H. "Heat treatment production of vegetable fiber products." U.S. Patent 2,220,047, issued October 29, 1940.

Note: Hence "Masonite" - Ed. - Mason, William H. Process of making ligno-cellulose fiber products [PDF] U.S. Patent 2,120,137, issued June 7, 1938.

Excerpt: My invention relates to vegetable fiber products that are highly hard, strong water-resistant and dense, and process of making same. My new process comprises the drying of a sheet or blank of ligno-cellulose fiber, which before dry ing is light and porous, to a state of practically Complete freedom from moisture, followed by simultaneous application of high heat and high preSSure to the previously dried sheet or blank. - Nevin, James V. Sawdust wood fiber board and method of making same [PDF] U.S. Patent 1,899,768, issued February 28, 1933. Assigned to Wood Conversion Co.

Excerpt: The invention relates to a slab, board, block or other article formed from sawdust, or wood fiber, or shredded bark, or any vegetable fibrous material or combination of such materials mixed with and impregnated with a binding material, and passed into a forming mold.

This molded material has a high tensile and breaking strength, is readily penetrated with nails, screws and the like, and may be worked with ordinary carpenter tools in the same manner as natural wood. - Respess, Roland B. "Continuous process of reducing or reforming wood or other fibrous material." U.S. Patent 1,897,620, issued February 14, 1933.

Note: this process was a step in the fundamental science of producing insulating board panels from wood scraps, sawdust or other similar sources. - Ed. - Roberts, James R., and Ernest H. Collins. "Method of preventing excessive springback of dry felted fiber mats." U.S. Patent 2,925,360, issued February 16, 1960. Application filed by Weyerhaeuser Co

Excerpt: This invention relates to the manufacture of felted mats from individualized ultimate wood fibers, and has particular reference to a method of preventing excessive "spring-back” of such mats after cold pressing and improvement of the handling properties of Such cold pressed mats in the further processing of the mats to con solidate them into densified wood fiber structures. - Suchsland, Otto & George E. Woodson, FIBERBOARD MANUFACTURING PRACTICES in the UNITED STATES [PDF] (1986) USDA USFS

Excerpts: The term fiberboard applies to a category of sheet products that is part of the larger family of wood composition boards (fig. 1). These wood composition boards are distinct from solid wood in that they are composed of wooden elements of varying sizes held together by an adhesive bond.

...

Early fiberboard was all made by wet processes, essentially extensions of paper technology. Dry process fiberboards are more recent developments, and in some cases, at least, extended directly from particle board technology.

Fiberboards are also classified by density. Insulation board (thickness, 3/8 to 3/4 in; density, 10 to 31 Ib/ft^ represents the lowest density class. It is made only by the wet process.

Medium-density fiberboards (MDF) are made either wet or dry in a density range (about 40 to 50 Ib/ft^ similar to that of particle board. MDF-wet (thickness range: 1/4 to 1/2 in) is generally used as siding material.

MDF-dry (thickness, 3/8 to 1 in) competes with particle board as industrial core material (furniture). High-density fiberboard (about 55 to 70 Ib/ft^ is called hardboard.

Although there are significant differences between hardboard-wet and hardboard-dry, they compete in the same markets. Hardboard thickness ranges from 1/10 to 5/16 in. - Weyerhaeuser, Frederick, and John S. Busch. MEANS for INSULATING WALLS [PDF] U.S. Patent 2,030,668, issued February 11, 1936.

Excerpts: Still another object is the provision of an in sulation unit, such as a blanket, tile, board, or other form, flexible or rigid, which is more porous on one side than on the other side, which latter may be practically impervious to air and/or moisture.

...

Fig. 5 is a perspective view of a piece of insullating fiber board having an impervious face of asphalt.

...

Where an insulating porous fiber board as in Fig. 5, is used in a wall, or as a wall, one side of the board 60 may have a layer, such as as phalt 6f thereon, which is less pervious to moisutre than the board. - Whittemore, Herbert L., and Ambrose H. Stang. Structural Properties of Wood-frame Wall and Partition Constructions with" Celotex" Insulating Boards Sponsored by the Celotex Corporation. US Department of Commerce, National Bureau of Standards, 1940.

Un-Labeled Fiberboard Products

I photographed this insulating board under the overhanging floor portion of a raised ranch in Dutchess County New York. This is a brown insulating fiberboard product that is not Homasote™. What is it?

Often we can, however, use the color and texture to at least rule out some fiberboard products and thus to narrow the possible identification down to a short list.

See UNIDENTIFIED FIBERBOARD PRODUCTS for help in identifying fiberboard or insulating board products that look like this and that do not bear an identifying mark or stamp.

Above: wood fibre-reinforced cement board panels describe by the Architonic, a UK source of building products who insists on keeping the actual product manufacturer and identity a secret, Architonic ID: 1184351, prompting us to decline to cite the Archi tonic website directly.

See details at WOOD FIBRE INSULATING PANELS - large coarse fibres

Plant-Fibre Based Board Products & Fiberboard History Research

- American Lumberman, NEW DEVELOPMENT IN WALLBOARD [Image], American Lumberman, February 4 1922, p. 97 [PDF] from Google Books.

- APT Bulletin 28, No. 2-3. 1997. Articles on Homasote, Masonite, Beaver Board, and Upson Board. (Available for purchase, Jstor)

- BEAVERBOARD [Web Article]

- DOMTAR CEILING TILES - [Web Article] Domtar purchased the UPson Company in 1984.

- [3] Douglas Leen, Petersburg AK 99833, USA, Website: http://www.dougleen.com - contributed the photograph of insulating board scraps from roof insulation removed from a building. Dr. Leen provides such a wide range of services, collectables, and historical information about the Northwest that a succinct description is difficult: flying dentist goes anywhere, antique forestry posters, historic campers, the tugboat Katahdin, in Alaska, Washington, and Wyoming. Mr. Leen can be contacted at mail@dougleen.com or at 907-518-0335

- Drury, Architects', Builders' &c Reference Book (1950), p 226.

- Farley, Dougles, and Ann Mrie Linnabery, "The Upson Company" in Niagara County History,Douglas Farley, Director Ann Marie Linnabery Erie Canal Discover Center 24 Church St. Lockport NY 14094 716.439.0431 CanalDiscovery@aol.com www.NiagaraHistory.org retrieved 2021/07/06 original source: http://www.niagara2008.com/history85.html

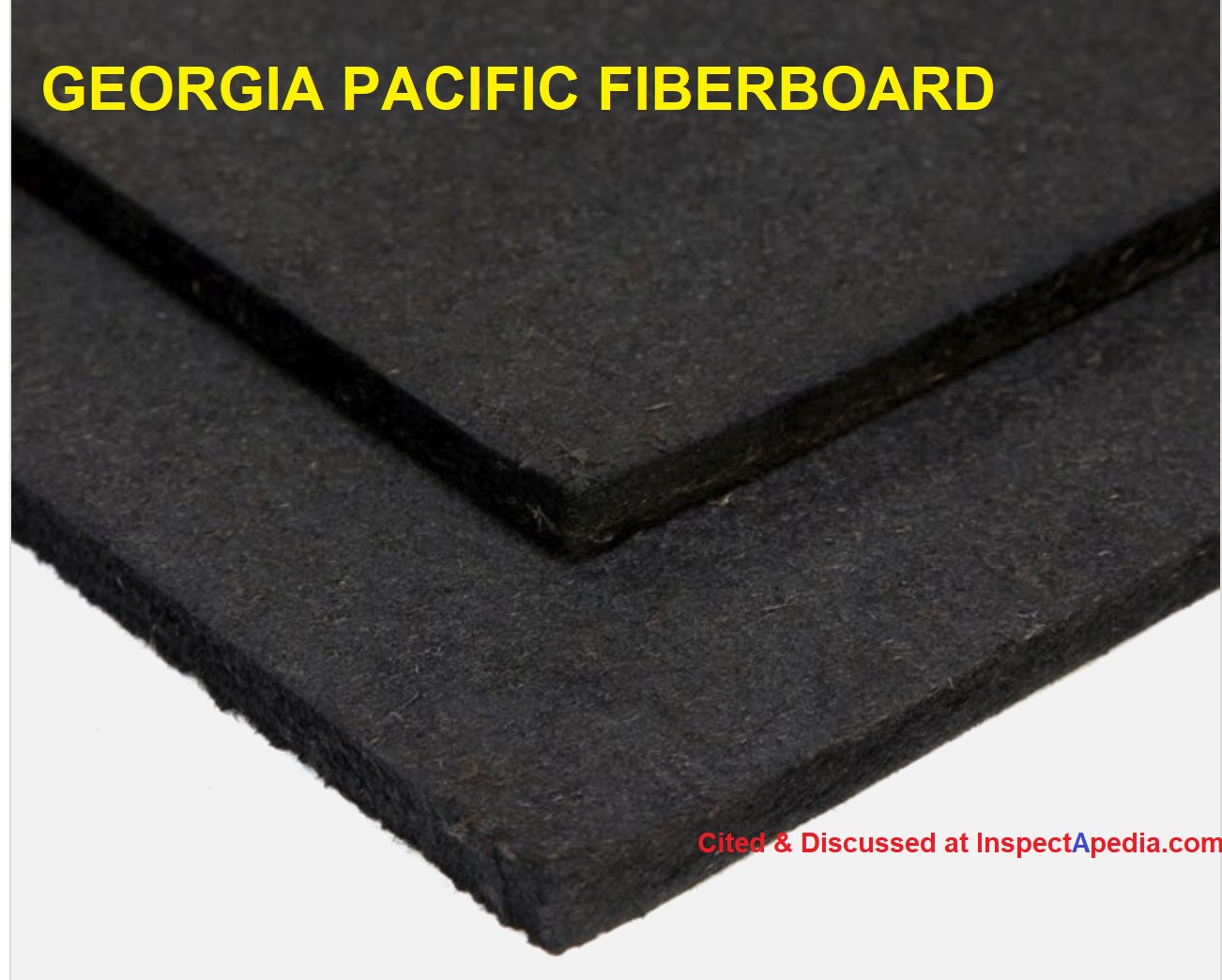

Above: Georgia-Pacific R- 1.31, 0.5-in x 4-ft x 8-ft Unfaced Cellulose Board Insulation with Sound Barrier - previously sold at Lowes building supply stores (not in 2022 - Ed.) [Shown above from a 2020 Lowes ad] Lowes description of this product was a bit confusing, "R- 1.31, 0.5-in x 4-ft x 8-ft Unfaced Cellulose Foam Board Insulation with Sound Barrier" - note that it's a plant-fibre or wood-fiber product, not foam board - Ed.

- [4] Georgia Pacific: information about DensGlas gypsum board building sheathing can be found at the company's website at gp.com/build/product.aspx?pid=4674

- Guedes, Pedro, The Macmillan Encyclopedia of Architecture and Technological Change (London 1979), p 276.

- Hartley, Tom, "Second Time Around, Recycling company creates paper line for industries", Buffalo Business First, 20 April 1998, retrieved 2021/07/06 original source: https://www.bizjournals.com/buffalo/stories/1998/04/20/smallb1.html

Reports on the Niagara Fiberboard company converting recycled paper into laminated paperboard products. - HUD, EXTERIOR WALLS REHAB GUIDE [PDF] (1999) PATH

Suite B 133

451 Seventh Street SW.

Washington, DC 20410

202-708-4250 (fax)

e-mail: pathnet@pathnet.org

website: www.pathnet.org, Prepared by:

Steven Winter Associates, Inc.

Building Systems Consultants

Norwalk, CT USA

- retrieved 2023/01./2, original source: https://www.huduser.gov/Publications/pdf/walls.pdf

Excerpt pl 29:

Fiberboard sheathing has a 40-year track record in the construction industry, and is in wide use through- out the country.

Known under a variety of names, such as “blackboard,” “grayboard,” and “buffalo board,” the material is made from recycled newspaper, wood fiber, and other cellulose products, held together with a binder.

It is available in regular density, which requires additional corner bracing, and high density with sufficient racking strength to be used without additional bracing (unless required by local code officials).

ADVANTAGES: Historically less expensive than most other sheathing material. Has higher R-value (approx. 2.4/inch) than OSB, gypsum sheathing, and paper board sheathing. Is vapor-permeable. Can be used as a substrate for a variety of finish materials including stucco and wood.

DISADVANTAGES: Has a lower R-value than insulated sheathings. Cannot be used as a nail base for alu minum and vinyl clapboard siding (siding must be nailed to studs or furring strips). Becoming less cost- competitive with OSB in some areas. - Jolly, Bridget 'Solomit in Australia and its European Context' (PhD submission, University of Adelaide, 1998), p 198.

- Kinniburgh, Dictionary, p 132. This is probably the same as the material referred to as 'asbestos-wood' in Percy Thomas, Modern Building Practice (4 vols, London, no date [c 1935]), III, p 498. Also cf p. 69.

- Kollmann F.F.P., Kuenzi E.W., Stamm A.J. (1975) Fiberboard. In: Principles of Wood Science and Technology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-87931-9_6

Abstract

There are various types of fiberboard1, and unfortunately the terminology is not yet internationally standardized. Neverthelesss, one fundamental definition generally is recognized (FAO, 1958/1959, p. 4): “Fiberboard is a board generic term encompassing sheet materials of widely varying densities manufactured from refined or partially refined wood fibres or other vegetable fibres.

Bonding agents and other materials may be incorporated in the manufacture of the board to increase strength, resistance to moisture, fire or decay or to improve some other property.” In the technical sense the ISO-definition is more precise:

“Sheet material generally exceeding 1.5 mm in thickness, manufactured from ligno-cellulosic fibers with the primary bond from the felting of the fibers and their inherent adhesive properties. Bonding materials and/or additives may be added”. - Lewis, Miles, AM, FAHA, FRSA, BArch(Hons), BA, PhD, 5.11 BUILDING BOARDS (Australia) [PDF] Dr. Lewis is Architectural historian; emeritus professor in the Faculty of Architecture, Building & Planning at the University of Melbourne, retrieved 2021/-7/07, original source: https://www.mileslewis.net/australian-building/pdf/05-timber-frame/5.11%20bldg%20boards.pdf Plywood, building boards, wood fibre boards in Australia, Masonite, Caneboard, Cane boards, Solomit

This helpful technical document describes a variety of building board products including some names less-familiar currently (2021) including

Excerpts:

Four early wood fibre boards marketed in Australia can be named,

Ten Test [available in Australia by 1913],

Beaver Board [available in Australia by 1914],

Upson Board [imported from the U.S.] and '

Amiwud [available in Australia by 1912].

Other fiberboard products besides those listed below are cited in the Lewis document, including

Fiberlic (American),

Cornell Board,

Treetex (Britain),

Pinex (New Zealand 1940s),

Donnacona (Canada),

Heraklith, Woodtex (Australia),

Fibrerock,

Magnelite,

Ankarboard (Sweden),

Sundeala (Britain),

Weyroc, Plimberite,

S.K board,

Genesco wallboard,

Okal, and of course

Masonite and

Marlite, also

Epiclad, and

bagasse fibre board anticipating

Celotex (bagasse & sugar cane waste, U.S.).

Adamo

Only one board, 'Adamo' [pronounced Adamo] seems to have been made in Australia from Australian wood pulp, and it was sold in all states by William Adams & Co Limited. It was claimed to be light, tough, rigid and white ant resistant, and was stocked in widths of 1 ft 6 in to four feet [0.45 to 1.2 m] and lengths of up to twelve feet [3.6 m].109 It seems to have been short-lived.

Alderite

found in the lining of the, former Viticultural Research Station at Narara, New South Wales, built in about 1915

Amiwud

'Amiwud' [that is, 'Am I wood?'] 70 was a compressed wood pulp board intended as a finished surface for wall panelling and ceilings. It came in 'golden oak', 'weathered oak', 'jenisero', 'mahogany' and plain, in sheets of up to 10 ft 6 in by 2 ft 8 in by 3/16 thick [3.23 m x 0.82 m x 4.8 mm], and was finished with 'battens' or cover straps at the joints.71

The makers were the Paraffine Paint Co of San Francisco and Chicago, better known for their 'Malthoid' roofing, and they insisted that it was 'a mechanical reproduction (not an imitation) of the beautiful artistic Oak and other hardwood grains'. A local product, though probably a short-lived one, was a pulp wallboard made in the 1920s by the Australiuan Paper and Pulp Company Ltd under their APPCO brand. (Marshall 1923)

Insulite

Subsequent developments in America included a rigid fibre board patented by Carl G Meunch73 and made from the ground wood tailings of a paper mill by the Minnesota & Ontario Paper Co at International Falls, with a pilot plant established in 1914 and marketed from 1915 or 1916 as 'Insulite', and the material seems to have been manufactured in Britain as well as the United States.

'Cornell', a compressed wood fibre board with an 'oatmeal' finish, was made by the Cornell Wood Products Co of Chicago at least by 1922.76

Amongst the subsequent United States products in this category was 'Sterling Wallboard' made by a mill in western New York State in sizes up to four feet by twelve [1.2 x 3.6 m], 3/16 inch [5 mm] thick, and sized on both sides.77

By the 1930s the United States Gypsum Co alone marketed 'Weatherwood Hardboard', of wood fibre; 'Fiber Wallboard', similar but less dense; 'Weatherwood Insulating Board' of felted wood fibre;

Weatherwood Insulating Tile Board, Weatherwood Insulating Plank, and other products.

By 1950 'Maftex' board, made from fibres of liquorice root, was being exported from the United States to Britain, though it has not been reported in Australia. (Drury 1950)

Centulith, Heraklith, & Sackett Board

Mineral bonded wood wool slabs are said to have been first produced in Austria in 1914, using Portland cement or other hydraulic binders. (Guedes 1979)

However this seems inconsistent with the fact that the combination of wood fibre with cement was patented in the United States in 1904, (OBaylor 1904) and that in 1914 a building board of this sort using 'lime cement', was apparently available in Australia (allegedly called 'Sackett Board', which is puzzling, as this was generally known as a plaster board).

It was supposed to serve as a basis for plaster in lieu of laths. (Mayes 1914) The Austrian material was called 'Heraklith', Jolly 1998) and used a magnesite cement. It was later manufactured by W F Schlesinger & Co Ltd of London, Kinniburgh c 1935) and later still in Australia, as will appear below. An English type which does not seem to have reached Australia is 'Centulith'. (Kinniburgh)

Solomit

A form of strawboard had been pioneered in the nineteenth century when B Nicholl of Piccadilly developed a 'fireproof slab' which he showed at the Paris Exposition of 1867.

A 'framework' of wire about 1/8 inch [3 mm] in diameter contained a mass of straw or other fibrous material 'woven by the aid of a powerful machine', saturated with a fireproofing solution and subjected to great pressure.

The faces were finished in cement, normally imitating the appearance of stucco on the outside, and providing a plain surface on the inside for decorating.

- [13] Lyman, A.S., "Separating the Fiber of Wood", A.S. Lyman, U.S. Patent No. 21,077, 3 August 1858

- Marshall, V.C., The 'Herald' Ideal Homes Exhibition, Wirth's Park, Melbourne [catalogue] ([Herald, Melbourne] 1923), p 116.

- O Baylor, Elwood, of Adrian, Michigan, was granted US patent 751,712 on 9 February 1904 for a 'building block' consisting of a combination of concrete and a woody fibrous substance. Concrete, I, 1 (March 1904), p 25.

- Mayes, Price Book (1914), p 28; advertisement p 51.

- [8] Pittsburgh Press, "Yesterday - in costly homes alone, Today even the simplest home can have this hidden comfort", The Pittsburgh Press, 19 April 1925, classified ads section. Web search 6/22/12, [Copy on file as Celotex_Ad_023_PP.jpg and more]

- Plackett, D. V., J. M. McLAUGHLAN, and Rj Burton. FIBRE-BASED COMPOSITES IN NEW ZEALAND: PAST DEVELOPMENTS AND FUTURE OPPORTUNITIES [PDF] New Zealand Journal of Forestry Science 21, no. 2 (1991): 246-255. Retrieved 2021/07/08 original source: https://www.scionresearch.com/__data/assets/pdf_file/0010/59869/NZJFS212_31991PLACKETT246-255.pdf

Abstract:

Composite wood products based on Pinus radiata D. Don fibre have been made in New Zealand since the 1940s when a wet-process fibreboard plant was established in Auckland. Medium-density fibreboard (MDF) production began in New Zealand in 1976 and the total capacity of the New Zealand MDF industry is now 465,000 m3 per annum or about 6% of worldwide capacity.

In 1987 production began of a totally new type of board in which MDF surface layers are combined with a strandboard core in a steam-pressing operation.

Two areas of research in progress at the New Zealand Forest Research Institute (FRI) are aimed at adding value to composites such as MDF.

Firstly, research on dimensional stabilisation of MDF focuses on in-line chemical treatments of fibre.

Secondly, the vapour boron treatment developed jointly by FRI and Imperial College of the University of London has the potential to improve the fungal, insect, and fire resistance properties of fibre-based composites.

- [6] Thermafiber, Inc., (now a division of Owens Corning®) at Thermafiber, Inc., 3711 Mill Street, Wabash, IN 46992, Tel: 888-834-2371 (U.S. & Canada) - 260-563-2111 Website: www.thermafiber.com or Thermafiber technical services at 888-834-2371 (U.S. & Canada) ; Phone: 260-569-0801, Fax: 260-563-8979 or Email: technicalservice@owenscorning.com

- [15] US FPL, PROPERIES of INSULATING FIBERBOARD SHEATHING [PDF] Forest Products Laboratory (U.S.) Luxford, R. F. (Ronald Floyd), 1889 (1960), original report 1955, citation:hdl.handle.net/1957/2489, web search 6/29/12, original source: http://ir.library.oregonstate.edu/xmlui/handle/1957/2489

- Wilson, Richa, Kathleen Snodgrass, EARLY 20TH-CENTURY BUILDING MATERIALS: FIBERBOARD AND PLYWOOD [PDF] (2007) United States Department of Agriculture, Forest Service, Technology & Development Program, 073-2308-MTDC, retrieved 2017/07/29, original source: https://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/

This article makes helpful distinctions between fiberboard, low-density fiberboard, medium density fiberboard, and hardboard.

Excerpts:

Fiberboard is a generic name for construction panels made of wood or vegetable fibers. Some are homogenous materials, while others are laminated sheets with fiber cores and surfaces of ground wood.

The earliest fiberboard panels were made with fibers from an array of materials including jute, straw, sugar cane stalks, flax, hemp, grass, newspaper, and peanut shells. They were manufactured under names such as Fir-tex, Homasote, Masonite, Beaver Board, Feltex, Nu-Wood, and Upson Board - [7] Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR. https://www.jstor.org/publisher/aptech

- Also see additional page bottomReferences or Citations

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-09-10 by Camilla Watson - can I cover my fiberboard ceiling panels with paper or paint?

Hi, I have a 1957 California Ranch house with vaulted exposed beam ceilings- I do not know what product I'm working with, as far as the underside of the original roof deck or roof sheathing material that forms my ceilings.

It is now quite dingy/dirty and needs covering. Can I paint this material? Or can I paper over it? I'm looking to cover it with something very lightweight, as I don't believe the beams can handle much extra weight (such as dry wall) without saggingSee photo. I also posted in ceilings area.

I took a closer photo of the ceiling (I believe it is the underside of the original roof deck), in an area that has been damaged so you can see the orange/brownish color of the interior of the fiberboard.

Again it is a 1957 ranch house, you can see part of the exposed (painted) wood beam as well- the white paper coating of the fiberboard has gotten quite shabby over the years,

I want to either paint it, or possibly cover with paintable wall paper so it just looks clean and white, but I am unsure if the fiberboard can take paint, or even press and stick adhesive of a textured ceiling paper product without breaking down, delaminating etc.

On 2023-09-11 by InspectApedia Publisher

@Camilla Watson,

I think your follow-up photo here shows an insulating fiberboard product underneath what may be a plywood roof sheathing.

You'll see that the answer we gave you on the other page where you posted will still be appropriate.

I think you posted the same questions and we have already replied at

https://inspectapedia.com/interiors/Ceiling_Finish_Choices.php

Please take a look there and don't hesitate to post any follow-up questions or comments.

On 2023-08-30 by Nikkismirl - identify this stamp on chipboard subfloor in a Minnesota home - asbestos white stuff?

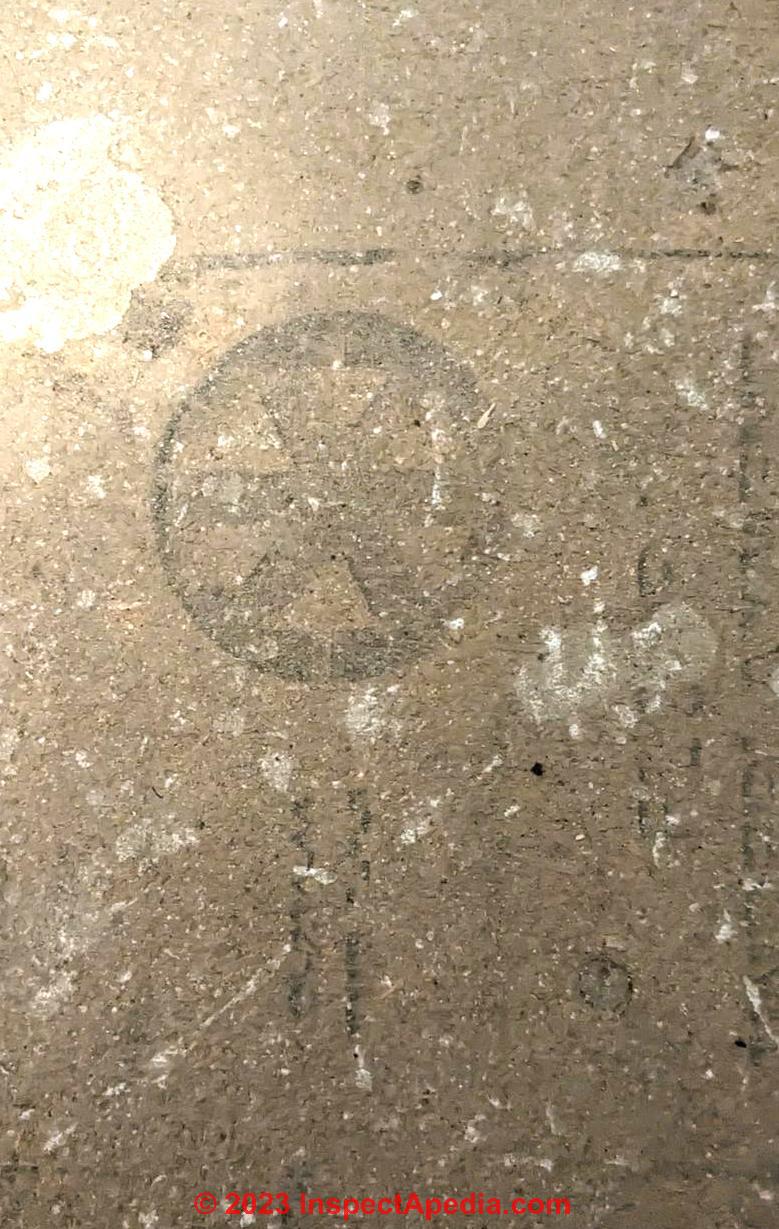

Hello. We just tore up some carpet and carpet padding in a 1936 home in Minnesota. The carpet and carpet padding was laid down sometime in the early 2000s, but under the carpet padding is a chipboard/fiberboard material that has the logo stamped on it as shown in the image.

I am concerned that the chipboard was installed prior to 1986 and may contain asbestos. I am also going to include additional photos. The chipboard is heavily stained and has some white patches on it.

I am wondering if the white patches are blue or adhesive that also may contain asbestos.

And now we have pulled up some more of the carpet and carpet padding and found a thick layer of white plaster like material on the fiberboard/chipboard. Any thoughts on what this could be?

We got a sample to take to a lab for asbestos testing, but I would be so grateful for any additional input.