Fiberboard Ceiling/Wall Panel Repair & Paint

Fiberboard Ceiling/Wall Panel Repair & Paint

Repair procedures for fiberboard ceiling & wall panels

- POST a QUESTION or COMMENT about fiberboard building sheathing repairs

Fiberboard insulating sheathing repair suggestions:

This article offers advice on procedures for reparing loose, warped, gouged or stained fiberboard ceiling and wall panels or tiles. We borrow from conservationists and we include some DIY homeowner procedure suggestions for non-historic buildings.

This article series describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as Homasote, Celotex, Insulite, and Masonite, Upsonboard, Nu-Wood and other insulating board sheathing products.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Repair or Painting Damaged Fiberboard Panels

Repairs to Loose or Warped Fiberboard Sheets

Repairs to Loose or Warped Fiberboard Sheets

Loose fiberboard can be re-attached using 4d finishing nails, though if your experience is like mine you'll need to drive longer nails, perhaps 6d on a 45 degree angle through the fiberboard into the stud or ceiling joist for the nail to hold the material in place.

Wilson and Snodgrass suggest that it may be possible to repair de-laminated soft fiberboard by injecting wheat paste between de-laminated layers, using a mixture of 1 tablespoon of wheat starch to 5 tablespoons of distilled water, microwaved 20-30 seconds until the mixture is stiff and translucent.

To make such a repair you may need to remove the panel or to form a press that can be applied to the damaged wall or ceiling surface.

Those authors describe removing a warped panel for repair so that it can be wet slightly, placed flat, and pressed while drying. I do not recommend this repair except for structures and panels of historic value, as in my experience, unless you're an experienced conservationist, trying to remove a 70 year old fiberboard panel from a wall or ceiling leads to ever worse damage to the panel.

Really? For other than historic preservation purposes, in my view it makes more sense to remove and replace damaged fiberboard panels with new ones of the same or similar texture and color. You won't find beveled Nu-Wood panels in new stock as the product has been out of production since about the 1970's or earlier.

If there is extensive damage throughout a non-historic structure, remove the panels entirely and replace them with drywall. That step brings your building closer to modern fire-code requirements, and it provides an opportunity to upgrade exposed wiring, plumbing, insulation and and to inspect the structure for hidden rot or insect damage.

You could instead leave the panels in place and cover them over with drywall: a step involving less mess. But you may find that the window and door trim and receptacles and switches in the room all need to be built-out, making this option expose its own achilles-heel.

Watch out: if you are working on a historic building you should not remove nor modify its materials before consulting with your local historic preservation authority.

Repairs to Dings & Gouges in Nu-Wood®, Homasote®, or other Fiberboard Wall or Ceiling Panels or Tiles

BJ's photograph of Nu-Wood like fiberboard wall paneling above provides more information about the identification of these panels. - B.J. by private email 2017/07/29

The gouge contributed by the movers exposes the characteristic brown soft wood fibers that we'd expect in a fiberboard panel.

The vertical V-groove in thephotograph above is a bit narrower than the panel butt-joint v-groove photo that we provide below. So measuring between the actual butt joints will give the true panel width, probably 48".

Repairs to a deep ding or gouge in fiberboard panels can take either approach.

DIY homeowner approach to interior fiberboard repair on walls and ceilings.

- Vacuum out or gently dust any very loose materials and dirt or debris from the gouge.

- Paint the area of damage with a latex or acrylic paint to seal and stabilise the loose fibers. Homasote recommends using latex-based paints and where glues are needed, the company recommends Titebond® #5262 or Elmers® Carpenters Glue

- Fill the gouge using a latex-based or white vinyl or phenolic non-shrinking caulk or, as recommended by some fiberboard manufacturers like Homasote, you can use a polyurethane sealant.

For deep gouges or wide areas of damaged fiberboard you probably need to use one of the putty-type products listed here and you may need more than one pass, after keeping the initial fill-patchbelow the final surface, to bring the repair out flush with the original surface.

To patch small holes and gouges in fiberboard such as Homasote or NuWood we have successfully used the patching compounds listed below.

For large holes or badly warped panels it's best to cut out or remove and replace the damaged area or the entire panel.

Watch out: these repairs work very well on fiberboard wall and ceiling surface repairs indoors but outdoors I have not found such surface patching durable over the longer term.

Fillers for Fiberboard Panels, Homasote, Nu-Wood Damage Spots

- Dash Patch for HOMASOTE PANEL REPAIR [PDF] shown just above, recommended & listed as a "joint filler" at the Homasote website at http://www.homasote.com/assets/files/installation/dash_patch.pdf - retrieved 2020/04/14

Dash Patch is a PorRok product: Por-rok products are licensed through Novex Systems Interntional and manufactured/ distributed by CGM, Inc

DASH PATCH is a gypsum based powder which, when mixed with water forms a plastic composition that can be troweled onto most surfaces to provide a smooth base for resilient or hard surfaces. DASH PATCH is designed to have rapid setting, high strength, adhesion and workability. DASH PATCH will not shrink or expand.

- Durham's "Rock Hard" Water Putty [shown above].

Durham's Water Putty is a light tan colored powder that is simply mixed with water to form a patching compound. Don't use more water than necessary to spread a paste that will adhere to the fiberboard;

You may need to either texture the surface as it's nearly dry or smooth the surrounding surface before painting.

- Sikaflex®-1c SL [recommended by Homasote as a "joint filler"] also listed as BASF Master seal.

Sika Sikaflex-1c SL is a single component, self-leveling, premium-grade polyurethane sealant with an accelerated curing capacity. Sikaflex 1cSL can be used in concrete joint 24 hours after the concrete is poured and also in damp concrete applications.

- SONOLASTIC® NP 1™ [recommended by Homasote as a "joint filler"] is also a polyurethane sealant.

Other patching products that may work acceptably on fiberboard walls and ceilings:

- Aquacoat® Clear Wood Grain Filler - not a filler but possibly for use as a sealant?

Aqua Coat Clear Grain Filler is a water-based, easy-to-apply gel designed for filling and leveling the pores of "open-grain" wood structures such as oak, mahogany, and ash. It reduces the number of sealers and top coats required to obtain a glass-like, high-build finish. - Bona Pacific Water Borne Fille, a trowelable fcompound for filling holes & gouges

- Timbermate® Waterbased Wood Filler

Timbermate Woodfiller is an Interior grade 4 in 1 woodputty, grainfiller, edgefiller and crackfiller. When thinned slightly with water can also be used as a sanding sealer. Timbermate does not shrink, sink, crack or fall out and has an indefinite shelf life.

The secret ingredient of Timbermate is tap water therefore containing no Acrylic, Latex or Solvents.

MDF:

Due to the finishing system used to manufacture MDF it is essential to seal the job with a water based non-acrylic product before applying top coats. Therefore TIMBERMATE meets your needs.

Do you Need to Match the Surface Texture of Surrounding Fiberboard?

If the original fiberboard panel surface was textured such as shown in some of the Nu-Wood illustrations and also the classic textured Homasote and other interior-use fiberboard wallboard panels, your patch will look too-smooth unless you texture the surface.

We want to avoid creating a too-smooth island of patch in the middle of a rough-textured panel.

Options for matching the original surface texture include the following:

- Use a scrap of existing fiberboard to press gently into the nearly-dry surface of the patched area to match the surrounding surface texture.

Some experimenting may be needed to sort out just how hard to press the texture-imprinting scrap and you may need to make a reverse-imprint block if the surface indentations rather than raised elements are so-reversed as to be noticeable. - Use a thin, flexible, flat-bladed drywall knife that is at least a four inches wider than the widest width of the opening that you need to tool.

When making a final pass over the patch surface to smooth your filling compound, hold the drywall blade lightly on the surface so that you allow it to travel up and down over the irregularities of the original surface near the repair-work.

That movement will permit the blade to move up and down or side to side, closely-matching the texture of the surrounding surface.

Above you can see my imperfect but satisfactory attempt to copy the rough texture of T111 plywood siding into what would otherwise have been smooth filler/sealant used at the corner of this building.

I used a small 6-inch drywall knife, dragging it almost at right angles to the surface, holding the blade lightly. As the blade bobbled over the rough T-111 surface the parallel lines in the existing surface copied into the surface of the sealant to make that filler less obvious.

Restoration-conservationist approach to fiberboard repair

- Make a flour and water paste, mix up fibers from a scrap of extra fiberboard of the same or similar brand and model,

- fill the gouge with a patch of fiberboard material and paste or a cut and trimmed patch to fit,

- press until dry, polish the surface,

- paint to match surrounding surface.

Expertise, plenty of time and labor, and trouble mean this is probably not appropriate for a non-historic building.

Once the panel surface has been repaired you'll need to re-paint the panel, wall, or ceiling if you don't want to look at an obvious, white patch job that doesn't match its surroundings.

See FIBERBOARD PANEL PAINTING below.

Watch out: Because a few fiberboard products such as some Nu-wood (Conwed) ceiling tiles contained asbestos, see a discussion of possible asbestos at plants producing these cellulose-based ceiling tiles produced

Watch out: about fire safety.

I like these old fiberboard walls, but I am compelled to add the caution that for improved fire-resistance to meet modern codes you may ultimately decide to laminate a layer of drywall over them - something to discuss with your local building inspector.

While treatments were done to some products to improve fire resistance their fire rating, particularly after many decades of service and possible deterioration, might be in question.

How to Paint Fiberboard Panels

Re-painting existing, already-painted fiberboard panel or tile ceilings or walls requires using an interior paint that is compatible with the paint that's already on the surface.

If the existing fiberboard surface is stained from previous leaks, and assuming you were smart enough to fix the leaks before trying to paint, you may need to seal the stained area with a lacquer primer-sealer to prevent the stain from bleeding-through the new paint job.

This is particularly necessary on fiberboard panel paint jobs since solvents in some paints (as well as some water leaks) can dissolve tannins and other components in the panel to form a brown or black stain that may simply bleed through a new coating of a water-based latex or acrylic paint.

Watch out: using an incompatible paint on an already-painted surface can cause the new or old or both layers of paint to fail by peeling, bubbling, or falling right off of the surface. Details are

at INCOMPATIBLE PAINTS [separate web article at InspectApedia].

Painting previously-un-painted fiberboard panels, comes up when a fiberboard-covered interior room is being converted from storage to living space or "modernized" or when you're sick of looking at stained Beaverboard.

If you must paint previously un-coated fiberboard, the job may not be as easy as you think: a bleed-through problem may infect your paint job unless you first coat the fiberboard with a lacquer primer/sealer, just as I discussed above.

Above: a painted-over Nu-Wood ceiling discussed below in a Q&A

about NUWOOD ASBESTOS CONTENT

about NUWOOD ASBESTOS CONTENT

Watch out: as we warn throughout these articles, don't start slapping paint onto un-painted surfaces of a historic building before you've consulted your conservation authority.

Note: presently in the U.S. a separate company, Nu-Wood Synthetical Architectural Millwork, Syracuse, NY, produces polyurethane-based faux stone and brick panels and columns used indoors and outdoors. These products are not those described in the article above.

Watch out: if you're worried about asbestos in fiberboard panels or sheathing products,

see SHEATHING, FIBERBOARD ASBESTOS CONTENT

Fiberboard Conservation, Repair, Painting Research

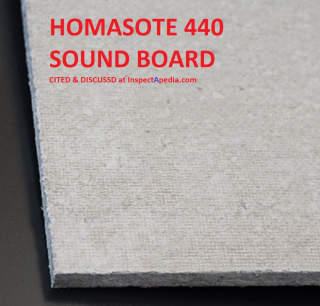

Photo: Homasote 440 Sound Board insulating board, a cellulose / paper product cited below.

Photo: Homasote 440 Sound Board insulating board, a cellulose / paper product cited below.

- "Conwed Corporation, An Inventory of Its Records at the Minnesota Historical Society Manuscripts Collection", Minnesota Historical Society, retrieved 2015/12/04, original source: http://www2.mnhs.org/library/findaids/00477.xml

- HOMASOTE 440 SoundBarrier® INSTALLATION INSTRUCTIONS [PDF] Homasote, 932 Lower Ferry Road, West Trenton, New Jersey 08628 USA,

800-257-9491 609-883-3300 Fax: 609-883-3497 609-530-1584

Sales Extension 1500 Website: www.homasote.com Email: sales@homasote.com

Technical Support: Extension 1332 Email: techhelp@homasote.com

Excerpt: Homasote 440 SoundBarrier® is a special-density, structural board made from 100 percent environmental Homasote® cellulose fiber, a homogeneous composition manufactured with uniformly distributed protection against termites, rot and fungi and resistance to moisture. It also insulates, with twice the R-value of wood.

See also instructions for all Homasote products at http://www.homasote.com/installation - HOMASOTE 440 SoundBarrier® ARCHITECTURAL SPECIFICATIONS [PDF] includes installation recommendations but not much about repair, retrieved 2020/04/14

Excerpt:

Replace panels that cannot be repaired. - Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Oregon Caves NM: HISTORIC STRUCTURES REPORT (Part V), [PDF] U.S. National Park Service, discussing preservation of Nu-Wood panels, retrieved 2017/07/30, original source: https://www.nps.gov/parkhistory/online_books/orca-hsr/hsr5.htm

- SHEATHING, FIBERBOARD - Fiberboard insulating sheathing used on or in buildings

- Wilson, Richa, Kathleen Snodgrass, "Early 20th-Century Building Materials: Fiberboard and Plywood", [PDF] (2007) United States Department of Agriculture, Forest Service, Technology & Development Program, 073-2308-MTDC, retrieved 2017/07/29, original source: https://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/

This article makes helpful distinctions between fiberboard, low-density fiberboard, medium density fiberboard, and hardboard.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-10-20 by (mod)

@Jocelyn Berman,

That sounds reasonable.

On 2021-10-20 by Jocelyn Berman

Thanks for the response. The sill plate is only damaged in a few areas; 3' section length by one wall, and 8' section at a corner (4' on each side) near the a/c compressor. As a precaution, I am going to remove the 1st two bottom courses of cedar shakes and remove the fiberboard insulation to check the entire sill perimeter, just to make sure there are no other needed sill repairs, a week before we are ready to install the new siding. I already dug down 6" from the sillplate exposing the slab and using salvaged 2" thick paving stones and gravel from the old patio, around the house perimeter, leaving 4" of exposed slab, so there will no longer be soil build-up. Thanks again for the advice.

On 2021-10-13 by (mod)

@Jocelyn Berman,

I wish we could be more helpful and apologize, but most of your questions can't be answered usefully just based on a text note. For example "what kind of board is on the exterior?"

But in general, for the problems you describe, the best solution is to remove siding and rotted framing, supporting the building wall as necessary, then build up a masonry foundation to a foot above grade or more; then repair the framing, bringing it down to a pressure-treated sill plate atop the new foundation.

As you plan to re-side the whole building with vinyl it does not , in my OPINON, make economic sense to try to match the original fiberboard sheathing and cedar shingles or shakes; any temporary weatherproof enclosure would suffice.

On 2021-10-13 by Jocelyn Berman

I just bought a Hi-Ranch built in 1974 on a slab with cedar shakes and 1/2" rigid board under the shakes. The board is dark grayish/brownish and appears fine pieces or like sawdust, where has disintergrated and broken off into small pieces around 6-10" as my handyman broke off 6' length and 16" high, from the sill plate up about two shake courses due to soil build up over slab and moisture/seepage into the board and sill plate. No paper between the shakes and board, so moisture discoloring the board is evident where shakes are missing from walls and seepage from soil build up over slab. When re-grading the soil to remove soil over slab, we could see the moisture/seepage from the soil had rotted out some of the board and damaged the cedar shakes touching the soil. We started to remove 2 courses of shakes in the section we found sill rot, and removed the damaged board as well, and now need to decide; 1. what product to use to replace the board and seal the joint to the remainging board, so we can replace the cedar shakes temporarily. The inside of the house has paper covered batt insulation in the walls between the studs, between the attic joists, and foil batts in exterior wall in the bathroom. We plan to re-side the entire house, in vinyl siding. If it's too late to do in November, we will do it in the spring. My next questions are 2. besides what type of board is on the exterior, 3. is the board acting as a structural element attached to the studs, and should I leave it all; just replaceing 16" from the sill up around the perimeter, replacing the disintergrated board due to the soil encroachment. 4. Lastly, if the board is not a structural element, should it all be removed when we remove the shakes and just install foil insulation board covered by vinyl siding. Thanks for any advice.

On 2021-09-02 by (mod)

Re-posting without improper link

so according to this it says fiberboard ceiling boards and panels contained asbestos

Moderator reply:

Rose that's a law firm looking for litigation business, not an authoritative information source on asbestos use in building products.

In general, fiberboard is a plant product: made from cane or bagasse or wood fibers - those are not asbestos.

There were some reports of cross-contamination of some fiberboard products made by companies at the same time and same location as where those same manufacturers produced or used asbestos in other products.

Use the on page search-box to find ASBESTOS in FIBERBOARD and you'll find

SHEATHING, FIBERBOARD ASBESTOS CONTENT https://inspectapedia.com/structure/Fiberboard-Sheathing-Asbestos.php

that actually cites supporting scholarly reserch

On 2021-08-23 by (mod)

@samie,

You posted this question and we replied at

https://inspectapedia.com/interiors/Fiberboard-Ceilings-Walls.php

On 2021-08-22 by samie

would asbestos be in a 1950s mobile home ceiling.the ceiling is not tiles,it is a panel or board material

On 2021-06-04 by (mod)

@Greg,

Using a ceiling tile like the one in your photo, provided the tile itself is new enough that you're not worried about fooling with asbestos material, is a clever move if you don't have scraps of fiberboard panel to repair the damage in your earlier photo.

Use a very sharp box knife ("drywall knife" like the fancy Stanley Box Cutter shown below) and a steel straight edge to cut out the damaged area;

Work carefully, don't get trash in your eyes and don't cut off a finger. Getting blood all over the ceiling is a mess (speaking from experience).

I make my existing-ceiling cuts on a 45 degree angle with the larger-dimension "up" towards the ceiling.

I trim my replacement piece of fiberboard (or ceiling tile) to be just about 1/8" smaller in length and width, and of course cut its bevel the opposite to that in the ceiling opening.

By angling the replacement square up into the ceiling and if necessary pulling it down with a couple of coarse-threaded sheet metal screws, I glue the replacement in place using a paintable acyrlic sealant.

When the repair is flush I leave it alone for the sealant to cure.

As your original ceiling was smooth, you may want to use some drywall compound to skim-coat the area of repair before re-painting the ceiling.

Let me know how this works for you.

Below: Stanley box cutter knife useful for cutting LDF and MDF fiberboard panels

On 2021-06-04 by Greg Cunningham

The ceiling is board and batten, and is fixed, I was just going to use the ceiling tile as additional material to fill in the hole (image attached).

With the hardware stores closed in Canada, it's hard to know what to get.

On 2021-06-04 by Greg Cunningham

Hey Daniel,

I have a cottage which has a hole in the ceiling caused by a water leak and stepping through by mistake from the attic. It seems like the fiberboard is cardboard, is there risk to using a water based filler as it would just be absorbed by cardboard and not bond?

I found another ceiling tile, and was going to cut a hole the same size as the (ceiling 6" hold saw"), put sticky tape in the attic to hold it in place, then caulk around and finally fill in. What do you think?

On 2020-09-13 by (mod)

Any building supplier,

But first take a look at the fiber board repair suggestions above on this page. Are you sure that won't work for you?

On 2020-09-12 by Diana Berne

Our home is just about to close escrow but we need to fix a huge concave hole in the fiberboard. Where do I find this material?

Thanks

On 2020-07-20 by Tony

In 1970 I was a carpenter apprentice and learning names of the tools we used

In the case of what we call a utility knife today was called a Cellotex knife

The explanation given by the old carpenters was that the knife was developed to cut Cellotex

50 years later I still call it a Cellotex knife

On 2019-02-02 by (mod)

Ned

Our best advice for patching a crack or ding in a Beaverboard ceiling panel, better organized and more complete than if I make it up off the cuff here, is in the text of the article above on this page.

Clean, seal, paint.

On 2019-02-02 by Anonymous

@Ned adams,

On 2018-02-28 by Ned adams

How to patch crack in beaver board ceiling circa 1948

...

Continue reading at FIBERBOARD SHEATHING IDENTIFICATION - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- HARDBOARD Masonite™-like INGREDIENTS

- IDENTIFY NU-WOOD PANELS

- SHEATHING, FIBERBOARD

- CANEBOARD PANELS

- CARDBOARD CORRUGATED FIBERBOARD

- CELOTEX HISTORY & PRODUCTS

- DEFINITION of FIBERBOARD SHEATHING

- HISTORY of FIBERBOARD INSULATING SHEATHING

- HOMASOTE HISTORY & PRODUCTS

- SYNONYMS for FIBERBOARD SHEATHING

- FIBERBOARD CEILING & WALL COVERINGS

- FIBERBOARD MANUFACTURERS & BRAND NAMES

- FIBERBOARD PANEL REPAIR

- FIBERBOARD PLASTER BASE SYSTEMS

- FIBERBOARD ROOF SHEATHING

- FIBERBOARD SHEATHED WALL BRACING

- FIBERBOARD SHEATHING ASBESTOS CONTENT

- FIBERBOARD SHEATHING INGREDIENTS

- FIBERBOARD SHEATHING FIRE RATINGS

- FIBERBOARD SHEATHING IDENTIFICATION

- FIBERBOARD SHEATHING MOLD CONTAMINATION

- FIBERBOARD SHEATHING MSDS

- FIBERBOARD ROOFING & FIBER-WOOD ROOFING

- FIBERBOARD SHEATHING INSECT DAMAGE

- FIBERBOARD SHEATHING MOLD CONTAMINATION

- FIBERBOARD PROTECT from WATER

- FIBERBOARD SOUND INSULATION

- HARDBOARD MASONITE™ & OTHER BRANDS

- HARDBOARD MASONITE™ & OTHER BRANDS

- HARDBOARD Masonite™-like INGREDIENTS

- SHEATHING, FIBERBOARD ASBESTOS CONTENT

- SHEATHING FIBERBOARD CONSTRUCTION

- SIDING HARDBOARD IDENTIFICATION & CLAIMS

- SUNDEALA BOARD COMPOSITION & HISTORY

- SHEATHING, EXTERIOR PRODUCT INDEX

Suggested citation for this web page

FIBERBOARD PANEL REPAIR at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Wood Conversion Company, "NU-WOOD INTERIORS FOR EVERY WALL AND CEILING", [PDF] Wood Conversion Company, St. Paul Minnesota, (u1936), retrieved 2015/12/04, original source: https://archive.org/stream/ Nu-woodInteriorsForEveryWallAndCeiling/ Nu-woodInteriorsForEveryWallAndCeiling_djvu.txt,

- Wilson, Richa, Kathleen Snodgrass, "Early 20th-Century Building Materials: Fiberboard and Plywood", [PDF] (2007) United States Department of Agriculture, Forest Service, Technology & Development Program, 073-2308-MTDC, retrieved 2017/07/29, original source: https://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/

- [1] Homasote® Company, 932 Lower Ferry Road, West Trenton, NJ 08628-0240 Tel: 800-257-9491 Ext 1332, or from outside the U.S. call 609-883-3300. Website: http://www.homasote.com/ , Email: Sales@homasote.com.

- Thanks to Homasote CEO Warren Flicker for technical review and comment on this article.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- [2] Celotex Corporation, PO Box 31602, Tampa FL 33631, with offices in Atlanta, Chicago, Cincinnati, Dallas, Oakland and Philadelphia, and plants in six U.S. States is headquartered in Tampa, FL. Celotex is a national manufacturer of residential and commercial building materials. Website: www.celotex.com Tel: 800-CELOTEX

"Insulation Selector Guide", Celotex Corporation, web search 6/29/12, original source: http://www.silvercote.com/PDF/ThermaxInsulSelectorGuide.pdf, [copy on file as CelotexThermaxInsulSelectorGuide.pdf ]

"Celotex Blue Ridge Fiberboard", SturdyBrace®, produced by Blue Ridge Fiberboard Inc., 250 Celotex Dr., Danville VA 24541, product literature, web search 6/29/2012, original source: blueridgefiberboard.com/pages/sturdybrace.php, [Copy on file as Celotex_BlueRidge_SturdyBrace.pdf].

MSDS: original source: blueridgefiberboard.com/pages/sturdybrace/pdfs/SturdyBrace-msds-br.pdf

"Guide Specifications: SturdyBrace® Structural Fiberboard Wall Sheathing", 6/29/12, original source: blueridgefiberboard.com/pages/sturdybrace.php [Copy on file as SturdyBrace-guidespecs.pdf] - [3] Douglas Leen, Petersburg AK 99833, contributed the photograph of insulating board scraps from roof insulation removed from a building. Dr. Leen provides such a wide range of services, collectables, and historical information about the Northwest that a succinct description is difficult: flying dentist goes anywhere, antique forestry posters, historic campers, the tugboat Katahdin, in Alaska, Washington, and Wyoming. Mr. Leen can be contacted at mail@dougleen.com or at 907-518-0335

- [4] Georgia Pacific: information about DensGlas gypsum board building sheathing can be found at the company's website at gp.com/build/product.aspx?pid=4674

- [5] "Roof Shingle Tear-Off Procedure for Homasote Products", PDF document, Homasote Co., 932 Lower Ferry Road, West Trenton, New Jersey 08628-024, U.S.A. 800-257-9491 website: at www.homasote.com

- [6] Thermafiber, Inc., (now a division of Owens Corning®) at Thermafiber, Inc., 3711 Mill Street, Wabash, IN 46992, Tel: 888-834-2371 (U.S. & Canada) - 260-563-2111 Website: www.thermafiber.com or Thermafiber technical services at 888-834-2371 (U.S. & Canada) ; Phone: 260-569-0801, Fax: 260-563-8979 or Email: technicalservice@owenscorning.com

- [7] Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

- [8] Pittsburgh Press, "Yesterday - in costly homes alone, Today even the simplest home can have this hidden comfort", The Pittsburgh Press, 19 April 1925, classified ads section. Web search 6/22/12, [Copy on file as Celotex_Ad_023_PP.jpg and more]

- [9] pending research

- [10]

Patents pertaining to building insulation & insulating board, Celotex & Insulating Board type products

- "Sound absorbing board for walls and ceilings", Patent No. 1,554,180, issued to W.S. Trader, September 15,1925, first disclosed a wallboard constructed from "Celotex", a felted mass of strong bagasse fibers, so compacted as to be capable of use as an artificial lumber in that it can be sawed and nailed, and has sufficient strength in many cases to be substituted for lumber. That same patent mentions "Insulite", a building board made from wood pulp tailings and which likewise has a porous fibrous body portion and which is possessed of considerable strength so that the same can be nailed, etc. Celotex was preferred as an insulating material because its internal cells produce a sound-deadening insulating effect.

- "Method and apparatus for drying moving material", Treadway B. Munroe et als, assigned to Dahlberg & Co., U.S. Patent No. 1,598,980, 7 September 1926, described a method and apparatus for drying sheets of artificial heat insulating lumber, known on the market as Celotex, improving the original process.

- "Reenforced composition board", Treadway B. Munroe et als, U.S. Patent No. 1,578,344, 30 March 1926

- "Insulating Structural Board", U.S. Patent 2,159,300, Armen H. Tashjian et als, assigned to William B. Miller, Lakewood OH, 23 May 1939, describes insulating structural boards of laminated construction for use as roof or floor slabs, and refers to "Standard insulating fiber boards, such as "Celotex", "Masonite", "Insulite", etc. that had excellent insulating properties but have relatively slight structural strength in flexure or bending under load, hence are not and cannot be used as structural slabs for load sustaining purposes, as roof or floor slabs, for example. [Adding structural strength ran into the problem of reducing the insulating value of the product.]

- "Sound-absorbing chamber", Treadway B. Munroe et als, U.S. Patent No. 1,705,778, 19 March 1929 (using Celotex to construct a sound deadening chamber.

- "Method of and apparatus for drying moving material", U.S. Patent 2,376,612, Carl G. Muench, New Orleans, assigned to Celotex Corporation, described a method and apparatus for drying sheets of artificial heat insulating lumber, preferably formed by the felting of bagasse fiber along with other materials necessary to make a satisfactory structural fiber board. 22 May 1945

- "Sound-absorbing board for walls and ceilings," U.S. Patent 1,554,180, Sept. 15, 1925, Wilber S. Trader, assignor to Dahlberg & Company, Chicago IL. described an interior-use sound insulating product.

- [11] "Insulite Co. v. Reserve Supply Co.," 60F.2d 433 (1932), Circuit Court of Appeals, Eighth Circuit, July 26, 1932. Web Search t/23/12. Quoting:

Rabbeted joints in material to which plaster or other material is applied are found in the Jones patent, No. 886,813. In this patent the composition is made up of plaster of paris, cement, or other like substance, combined with hair, wood fiber, sawdust, wool, wood shavings, excelsior, straw, or similar substances. The length of the lath covers three joists instead of four. The boards are arranged in staggered relation to each other and the joints are shiplapped. The specification states that after the boards or blocks are placed in position they may be covered with wallpaper or other similar material, which, of course, would include plaster.- "Machine for perforating Insulite Boards", U.S. Patent No. 1,306,283, Patented 10 June 1919, John K. Shaw, inventor from Minneapolis MN, describes improvements for machines for perforating Insulite Boards.

- "Before you Build write for this mailing piece and a sample of Insulite", [advertisement], The Literary Digest, 13 September 1940.

- [13] "Separating the Fiber of Wood", A.S. Lyman, U.S. Patent No. 21,077, 3 August 1858

- [14] Standards pertaining to fiberboard insulating sheathing:

- ASTM C 208-95 (2001) – Standard Specification for Cellulosic Fiber Insulating Board. Type IV Grade 2 (Structural Wall Sheathing).

- ASTM C 846-94 (2003) – Application of Cellulosic Fiber Insulating Board for Wall Sheathing.

- ASTM D 1554 - Definitions of terms Relating to Wood Based Fiber and Particle Panel Materials.

- ASTM E-72 (1997)- Standard Method for Conducting Strength Tests of Panels for Building Construction.

- ANSI /AHA - A194.1, Cellulosic Fiberboard.

- U.S. Department of Commerce: PS57-73, Cellulosic Fiber Insulating Board

- A.F.A. (2003): Fiberboard Sheathing test results

- [15] "Properties of insulating fiberboard sheathing", Forest Products Laboratory (U.S.) Luxford, R. F. (Ronald Floyd), 1889 (1960), original report 1955, citation:hdl.handle.net/1957/2489, web search 6/29/12, original source: http://ir.library.oregonstate.edu/xmlui/handle/1957/2489

- BASEMENT MOISTURE CONTROL [PDF] U.S. Department of Energy

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- Defects and Deterioration in Buildings: A Practical Guide to the Science and Technology of Material Failure, Barry Richardson, Spon Press; 2d Ed (2001), ISBN-10: 041925210X, ISBN-13: 978-0419252108. Quoting:

A professional reference designed to assist surveyors, engineers, architects and contractors in diagnosing existing problems and avoiding them in new buildings. Fully revised and updated, this edition, in new clearer format, covers developments in building defects, and problems such as sick building syndrome. Well liked for its mixture of theory and practice the new edition will complement Hinks and Cook's student textbook on defects at the practitioner level. - Historic Preservation Technology: A Primer, Robert A. Young, Wiley (March 21, 2008) ISBN-10: 0471788368 ISBN-13: 978-0471788362

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.