Celotex Fiberboard Identification

Celotex Fiberboard Identification

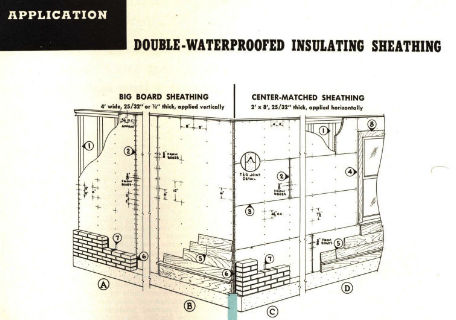

Celotex Wall & Roof Sheathing, Insulating Board Identification Key

- POST a QUESTION or COMMENT about fiberboard building sheathing: how to identify fiberboard products, fiberboard uses, fiberboard, Celotex, Homasote, Insulite & other brands, fiberboard ingredients, does fiberboard contain asbestos?

Celotex insulating sheathing identification guide:

Here we help identify and give information about the manufacture, ingredients & use of Celotex® insulating fiberboard building sheathing products used as exterior wall sheathing and as interior wall & ceiling surfaces.

In this article series we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products.

We also answer questions such as do Celotex or Homasote or other fiberboard and insulating board products contain asbestos? fiberboard water resistance, fiberboard recycling.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Identify Celotex® Insulating Board / Celotex Insulating Lumber, Fiberboard Products

Our photographs show Celotex® insulating board with an older Celotex fiberboard building sheathing board at above/left and a more recent Celotex insulating board product shown at the top of this page.

Our photographs show Celotex® insulating board with an older Celotex fiberboard building sheathing board at above/left and a more recent Celotex insulating board product shown at the top of this page.

Also see this closeup of an OLDER Celotex INSULATING SHEATHING BOARD [image file] product.

Components & Properties of Celotex Insulating Lumber

Celotex described their Celotex Insulating Lumber as an exterior sheathing product intended for use as a base beneath plaster or beneath a stucco building exterior as well as for roof insulation.

Celotex insulating lumber was sold in 7/16" thicknesses (and possibly other thicknesses), in 4 foot width boards at lengths from 8 ft. to 12 ft. and weighing about 60 pounds per square (100 sq.ft.).

Celotex Corporation produced the first fiberboard made from bagasse in 1920. (Jester 2014).

Celotex insulating lumber (today we call it insulating board or insulating sheathing) was sawed "like ordinary lumber" and nailed directly to the building framing to support stucco, brick veneer,m or other finishes.

Celotex Insulating Lumber was a cellulose fiber board made from bagasse or sugar cane fiber using a felting process, and produced in Celotex's New Orleans LA plant.

These fibers "each of which contains thousands of sealed air cells", were fabricated into "building lumber" using a patented press and bonding process.

Several patents listed in the mid 1920's addressed the production of insulating, structural, and sound-absorbing board products for walls, roofs, and ceilings produced by Celotex.

See CANEBOARD PANELS for details.

In wood frame construction Celotex insulating lumber was used as a structural sheathing to replace horizontal or diagonal 3/4" thick board sheathing while adding insulating and sound-deadening properties. The company described the insulating value of this new product as

In wood frame construction Celotex insulating lumber was used as a structural sheathing to replace horizontal or diagonal 3/4" thick board sheathing while adding insulating and sound-deadening properties. The company described the insulating value of this new product as

"... equal, as insulation, to 3 1/3 inches of solid wood, 12 inches of solid plaster, 12 inches of solid brick, or 24 inches of solid concrete".

We estimate, based on the wood comparison, that the R-value of this 7/16" thick board was about R-3. According to Celotex this insulating lumber product was waterproof, could be painted, and could be used itself as an exterior finish as well, though we have not seen any surviving examples of that application.

Celotex's insulating lumber was also advertised for use as an interior finish, left natural, stained, painted, or stenciled.

Celotex recommended its use also as a base for plaster walls or ceilings, for which some installation instructions can be read in the image just below. Thanks to reader [Anon by private email 21/14/15] for this image.

A number of these instructions suggest that over-wetting or prolonged wetting of these boards might lead to swelling, weakening, buckling, bulging, or other issues in the finished plaster job.

see FIBERBOARD PLASTER BASE SYSTEMS - instructions for applying plaster to Celotex boards - for details.

From our own field inspections, we believe that Celotex insulating lumber or similar products were indeed also often left exposed as an interior finish most commonly in summer camps, cottages, and in commercial or farm buildings.

According to one source the material was also used to construct insulated shipping boxes. [8] By 1925 Celotex had published "Celotex insulating Lumber Specifications and Details for Standard Building Board" and also offered "Your Home" a plan book of twenty-five ideal small homes.

A review of the patents and product description for Celotex insulating lumber products shows that asbestos was not among the product's ingredients.

Celotex Cemesto Board Structural Panels - 1/8" Asbestos Cement Board Laminate

Cemesto-Board,1 1/2 to 2-inch thick 4' x 8' or 12' panels comprised of asbestos-cement panels adhered to a vegetable-fibre core (Celotex sugar cane), first introduced by Celotex in 1937, is described in detail at

CELOTEX CemestO BOARD HOMES

Celotex Regular Insulation Sheathing Continues in Production as Blue Ridge™ Fiberboard & SturdyBrace® Sheathing

In 1955 there were at least fourteen different insulation fiberboards examined by the US FPL. Today Celotex continues as a major producer of the product. [15]

In 1955 there were at least fourteen different insulation fiberboards examined by the US FPL. Today Celotex continues as a major producer of the product. [15]

As of 2012 Celotex continued to produce a wide range of insulation products including PIR polyisocyanurate foam boards in various designs and for various applications. The company continues to produce Regular Insulation Sheathing as a 1/2-inch thick insulating board with an R-value of 1.2. Celotex Regular Insulation Sheathing is described in contemporary product literature as:

Produced from cellulosic interlaced fiber bond with natural binders. Manufactured from Sugar cane by-product called bagasse, recovered wood chips and consumer newsprint. Available in 4' width in standard lengths of 8' and 9'.

Designed for use as an insulating sheathing for frame walls under exterior finishes such as lap and panel sidings, stucco, masonry veneer and shake shingle products.[2]

Celotex Blue Ridge™ Fiberboard, also referred to in its product literature as SturdyBrace® is a wood fiber product that is described by the company as:

SturdyBrace® meets national codes for structural integrity. The insulating exterior wall sheathing is competitively priced. You may bid with confidence year round. SturdyBrace® improves the structural integrity of homes and light commercial buildings and eliminates the need for corner bracing.

SturdyBrace® meets codes for wind shear and seismic conditions. Check with code officials in your area.

Trapped moisture in exterior walls is caused by condensation and water leaks. This moisture can lead to mold growth and other water related problems. SturdyBrace® “breathes” permitting the moisture to escape into the outside air.

Mold experts recommend use of wall sheathing with a minimum ASTM permeability rating of 5. SturdyBrace® rates more than 20.0 perms while OSB and plywood have permeability ratings of 2 and less than one respectively.

SturdyBrace® is an earth-friendly fiberboard made of recovered wood fibers interlaced and bonded with asphaltic binders for strength.

It is easy to install and cuts with a knife, saving you time and money. SturdyBrace® is available coated on one or six sides. SturdyBrace® saves energy costs at a low cost per R-value. Our wall sheathing provides R-value of 1.3 per 1/2”, more than doubling the R-Values of OSB and gypsum sheathing.

*Building codes may require use of weather resistant barrier. [2]

Watch out:

Blue Ridge Fiberboard products must not be used in close proximity to chimneys, heater units, fireplaces, steam pipes or other surfaces which could provide long term exposure to excessive heat (maximum 212*F) without adequate thermal protection. [2] - guidespec

See CELOTEX HISTORY & PRODUCTS

Celotex Strong-Wall Fiberboard Sheathing

Photos of this 1960's Celotex Strong-Wall fiberboard insulating sheaathing is provided courtesy of InspectApedia.com reader Elton White.

Photos of this 1960's Celotex Strong-Wall fiberboard insulating sheaathing is provided courtesy of InspectApedia.com reader Elton White.

[Click to enlarge any image]

Comment: CeloteX Strong-Wall BOCA-12A - 1960s insulating sheathing

2021/02/01 Elton W White said:

I'm remolding a house in Baton Rouge, LA that was built in early 1960s. It has black 7/16" sheeting on exterior of framing under an exterior siding such as brick. It's nailed directly to the exterior studs and labeled as CeloteX Strong-Wall BOCA-12A.

I've read about CeloteX products on this site, but have found nothing directly addressing this product. Does anyone have additional info and would you like additional pictures beyond the attached.

Thanks Elton@katzwhite.com

Moderator reply:

Thank you so much for the Celotex Strong-Wall photo, Elton.

Your sheathing is brown,not black, but indeed some "black" or dark-coated fiberboard sheathing products uses an asphalt-base coating for water resistance, as well as a treatment called the Celotex Ferox Process to help resist termites & rot.

Your sheathing is brown,not black, but indeed some "black" or dark-coated fiberboard sheathing products uses an asphalt-base coating for water resistance, as well as a treatment called the Celotex Ferox Process to help resist termites & rot.

I've posted older photos of the Celotex product line, including sheathing products, here and at the companion

page CELOTEX HISTORY & PRODUCTS

but not the exact one in your photo so its a welcome addition that I'll include above along with what information I can add.

You may enjoy seeing this historical document describing Celotex products - these are 5 years or more earlier than the Strong-Wall shown in your photos.

Celotex "Strong Wall-board" was described as early as 1930 (Blondin 1930) but has not appeared widely in online resources.

- CELOTEX STRUCTURAL INSULATION AND OTHER BUILDING PRODUCTS [PDF] (1954) from Sweets 1955 Construction Guide.

Here is similar, HIGH RESOLUTION [PDF] copy of the same document.

Celotex products described in this older document include (this is not the whole list)

- Celotex Celo-Rok weatherproof (Core-Treated) sheathing

- Celotex Cemesto structural insulating panels - a laminate of cement-asbestos board over a cane fiber core - also see

- Celotex structural / insulating sheathing boards, asphalt coated and Ferox Process treated fibres resist termites & dry-rot

- Celotex sheathing backer board

- Celotex insulating interior finishes

Research on Celotex Strong-Wall Products

Research on Celotex Strong-Wall Products

- Armin, Elmendorf. FIBER PLANK [PDF] U.S. Patent 2,377,484, issued June 5, 1945. Filed by Celotec Corp.

Excerpt:

This invention relating to cement-fiber boards has as an object the provision of such a board block or other insulating mass having relative rigidity so that it may be used particularly in building construction in various manners, not only to insulate against the transmission of sound, heat and cold, but also as a supporting base for desired finishes as in wall construction.

The principal object of the invention hereof is the provision of a cement-fiber board as above which is a distinct improvement over such boards as they have been heretofore proposed in that such cement-fiber boards made in accordance with the inventions hereof are decidedly superior 'in strength and stiffness when compared with boards of this type as heretofore proposed, and in addition has other improved and distinguishing characteristics as compared with cementfiber boards heretofore proposed. - Joseph, Blondin. Aircraft supporting and controlling surface [PDF] U.S. Patent 1,775,386, issued September 9, 1930.

Excerpt:

This skeleton is encased in a covering 20 of light and strong wall-board, such as Celotex, which is glued and screwed, or otherwise fastened, throughout all zones or surfaces of contact, ...

- Hahn, Frank R. Building construction and building element [PDF] U.S. Patent 2,164,322, issued July 4, 1939.

Excerpt:

The next step is to apply an insulation material to the surface of the wall. This insulation material may be of any composition material such as Celotex, Insulite, or Beaver Board or the like. - Lathrop, Elbert C. "The Celotex and Cane-Sugar Industries1Bagasse or Sugar a By Product?." Industrial & Engineering Chemistry 22, no. 5 (1930): 449-460.

- Lindahl, Robert L. "Building construction." U.S. Patent 2,317,926, issued April 27, 1943.

- Munroe, Treadway B., and Elbert C. Lathrop. "Fiber storage and preservation." U.S. Patent 1,920,129, issued July 25, 1933. Assigned to Celotex Corp.

- Researching the product name "Strong-Wall" or StrongWall" is a bit confounded as there are also steel and other products sporting the Strong-Wall™ name, so having the photo you provided is helpful. For example Simpson Strong Tie describes their

Simpson SSWT - Steel Strong Wall for Timber Frame Racking Resistance [PDF] product series that combines steel components with Celotex GA3000 on the outside face. - Samuel, Krajci. "Unit for roofs and walls." U.S. Patent 2,400,357, issued May 14, 1946. Filed by Celotex Corp.

Working together makes us smarter. Thank you again for taking the time to post and contribute.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-02-01 by (mod)

Thank you so much for the Celotex Strong-Wall photo, Elton. I've included your photo and a bit of discussion in the article above on this page.

Working together makes us smarter. Thank you again for taking the time to post and contribute.

On 2021-02-01 by Elton W White

I'm remolding a house in Baton Rouge, LA that was built in early 1960s. It has black 7/16" sheeting on exterior of framing under an exterior siding such as brick. It's nailed directly to the exterior studs and labeled as CeloteX Strong-Wall BOCA-12A. I've read about CeloteX products on this site, but have found nothing directly addressing this product. Does anyone have additional info and would you like additional pictures beyond the attached.

Thanks Elton@katzwhite.com

[Photos shown above on this page - Ed.]

On 2020-06-24 - by (mod) -

Yes you can but keep in mind that you may need to build out trim and receptacle wall plates Etc

On 2020-06-24 by Anonymous

Can you install sheet rock over this

On 2020-03-04 - by (mod) -

Peter

I would open the walls,

remove the wet or disintegrating fiberboard,

Let the remaining fiberboard trapped between siding and studs dry

Repair or replace wiring

Insulate with closed cell foam

On 2020-03-03 by Peter Spano

My question is this my house got flooded with 26,000 gallons of water from the inside out upstairs floor to the bottom for the insulation board got soaking wet almost through the whole house is just totally deteriorated 25 years old my Home

I need to replace that for the water came from the inside out is it verifiable that fiber board for 25 years old with the room to get water hit it from the upstairs down continuously for three days I cannot seem to dry it out and when it does dry out it turns to dust

On 2019-07-14 - by (mod) -

There are some cellulose or paper tape gray insulating board products. However it's also possible that if the board was put there as a fire barrier it contains asbestos. I'm sure you will understand that we can't accurately identify material by text alone. A photo would be helpful. Meanwhile treat the material as presumed to contain asbestos, or have a sample tested. The test cost is not significant. Typically around $40.

On 2019-07-14 by Chuck

I'm currently working on a condo in Phoenix AZ that was built in the early to mid 70's the second floor sub floor looks to be some kind of fiber board ,grey board or a soft board the sheets are 2'x 8'x 1/1/2'' T&G. I have never seen this before and need some help in trying to identify this product unfortunately i have no photo yet and any help will be greatly appreciated

Thank you!

Question: Celotex wallboard wetting before use in plastering

I know per your articles that Celotex interior fiberboard usually does not contain asbestos but the directions on the back of mine talk about spraying it the day before installing it. My question is what might that spray do to the product?

I'm enclosing a picture of my product label. I find no other product marking however and want to be assured that it is not something containing asbestos.

Any thoughts would be appreciated. - Anon. by private email 2015/12/14

Reply:

Thanks for the question and also for the image - it was one I've not seen and it contains helpful details.

In the article above in the Celotex section I've posted your image of the Celotex instruction label discussing wetting the wallboard before use in plastering

OPINION: The spray was intended to boost the adhesion of plaster when this board was used as a substitute for (earlier) wood lath. These products were somewhat water resistant, some including waxes specifically for that purpose.

Wetting wallboard 24 hours before installing it as a plaster base would have increased its moisture content a bit; I doubt it'd have become too soft to apply or the manufacturer wouldn't have advised spraying both sides.

In this context I wouldn't expect other problems (such as mold growth) from this step as the board was to be installed to studs or ceiling joists promptly.

...

Continue reading at CELOTEX HISTORY & PRODUCTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- HARDBOARD Masonite™-like INGREDIENTS

- SHEATHING, FIBERBOARD - home

- CANEBOARD PANELS

- CELOTEX ASBESTOS PRODUCTS

- CELOTEX CemestO BOARD HOMES

- CELOTEX DRYWALL ASBESTOS

- CELOTEX HISTORY & PRODUCTS

- CELOTEX: IDENTIFY Celotex® Insulating Board and Fiberboard Products

- CELOTEX INSULATING BOARD ASBESTOS CONTENT

- DEFINITION of FIBERBOARD SHEATHING

- FIBERBOARD CEILING & WALL COVERINGS

- FIBERBOARD MANUFACTURERS & BRAND NAMES

- FIBERBOARD SHEATHING IDENTIFICATION

- POLYISOCYANURATE FOAM BOARD - more about Celotex and Dow insulating sheathing

- SHEATHING FIBERBOARD CONSTRUCTION

- SHEATHING, EXTERIOR PRODUCT INDEX

Suggested citation for this web page

CELOTEX: IDENTIFY Celotex® INSULATING & FIBERBOARD PRODUCTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Jester, Thomas C., ed. Twentieth-century building materials: History and conservation. Getty Publications, 2014.

- Wood Conversion Company, "NU-WOOD INTERIORS FOR EVERY WALL AND CEILING", [PDF] Wood Conversion Company, St. Paul Minnesota, (u1936), retrieved 2015/12/04, original source: https://archive.org/stream/ Nu-woodInteriorsForEveryWallAndCeiling/ Nu-woodInteriorsForEveryWallAndCeiling_djvu.txt,

- Wilson, Richa, Kathleen Snodgrass, "Early 20th-Century Building Materials: Fiberboard and Plywood", [PDF] (2007) United States Department of Agriculture, Forest Service, Technology & Development Program, 073-2308-MTDC, retrieved 2017/07/29, original source: https://www.fs.fed.us/t-d/pubs/htmlpubs/htm07732308/

- [1] Homasote® Company, 932 Lower Ferry Road, West Trenton, NJ 08628-0240 Tel: 800-257-9491 Ext 1332, or from outside the U.S. call 609-883-3300. Website: http://www.homasote.com/ , Email: Sales@homasote.com.

- Thanks to Homasote CEO Warren Flicker for technical review and comment on this article.

- [2] Celotex Corporation, PO Box 31602, Tampa FL 33631, with offices in Atlanta, Chicago, Cincinnati, Dallas, Oakland and Philadelphia, and plants in six U.S. States is headquartered in Tampa, FL. Celotex is a national manufacturer of residential and commercial building materials. Website: www.celotex.com Tel: 800-CELOTEX

"Insulation Selector Guide", Celotex Corporation, web search 6/29/12, original source: http://www.silvercote.com/PDF/ThermaxInsulSelectorGuide.pdf, [copy on file as CelotexThermaxInsulSelectorGuide.pdf ]

"Celotex Blue Ridge Fiberboard", SturdyBrace®, produced by Blue Ridge Fiberboard Inc., 250 Celotex Dr., Danville VA 24541, product literature, web search 6/29/2012, original source: blueridgefiberboard.com/pages/sturdybrace.php, [Copy on file as Celotex_BlueRidge_SturdyBrace.pdf].

MSDS: original source: blueridgefiberboard.com/pages/sturdybrace/pdfs/SturdyBrace-msds-br.pdf

"Guide Specifications: SturdyBrace® Structural Fiberboard Wall Sheathing", 6/29/12, original source: blueridgefiberboard.com/pages/sturdybrace.php [Copy on file as SturdyBrace-guidespecs.pdf] - [3] Douglas Leen, Petersburg AK 99833, contributed the photograph of insulating board scraps from roof insulation removed from a building. Dr. Leen provides such a wide range of services, collectables, and historical information about the Northwest that a succinct description is difficult: flying dentist goes anywhere, antique forestry posters, historic campers, the tugboat Katahdin, in Alaska, Washington, and Wyoming. Mr. Leen can be contacted at mail@dougleen.com or at 907-518-0335

- [4] Georgia Pacific: information about DensGlas gypsum board building sheathing can be found at the company's website at gp.com/build/product.aspx?pid=4674

- [5] "Roof Shingle Tear-Off Procedure for Homasote Products", PDF document, Homasote Co., 932 Lower Ferry Road, West Trenton, New Jersey 08628-024, U.S.A. 800-257-9491 website: at www.homasote.com

- [6] Thermafiber, Inc., (now a division of Owens Corning®) at Thermafiber, Inc., 3711 Mill Street, Wabash, IN 46992, Tel: 888-834-2371 (U.S. & Canada) - 260-563-2111 Website: www.thermafiber.com or Thermafiber technical services at 888-834-2371 (U.S. & Canada) ; Phone: 260-569-0801, Fax: 260-563-8979 or Email: technicalservice@owenscorning.com

- [7] Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

- [8] Pittsburgh Press, "Yesterday - in costly homes alone, Today even the simplest home can have this hidden comfort", The Pittsburgh Press, 19 April 1925, classified ads section. Web search 6/22/12, [Copy on file as Celotex_Ad_023_PP.jpg and more]

- [9] pending research

- [10]

Patents pertaining to building insulation & insulating board, Celotex & Insulating Board type products

- "Sound absorbing board for walls and ceilings", Patent No. 1,554,180, issued to W.S. Trader, September 15,1925, first disclosed a wallboard constructed from "Celotex", a felted mass of strong bagasse fibers, so compacted as to be capable of use as an artificial lumber in that it can be sawed and nailed, and has sufficient strength in many cases to be substituted for lumber. That same patent mentions "Insulite", a building board made from wood pulp tailings and which likewise has a porous fibrous body portion and which is possessed of considerable strength so that the same can be nailed, etc. Celotex was preferred as an insulating material because its internal cells produce a sound-deadening insulating effect.

- "Method and apparatus for drying moving material", Treadway B. Munroe et als, assigned to Dahlberg & Co., U.S. Patent No. 1,598,980, 7 September 1926, described a method and apparatus for drying sheets of artificial heat insulating lumber, known on the market as Celotex, improving the original process.

- "Reenforced composition board", Treadway B. Munroe et als, U.S. Patent No. 1,578,344, 30 March 1926

- "Insulating Structural Board", U.S. Patent 2,159,300, Armen H. Tashjian et als, assigned to William B. Miller, Lakewood OH, 23 May 1939, describes insulating structural boards of laminated construction for use as roof or floor slabs, and refers to "Standard insulating fiber boards, such as "Celotex", "Masonite", "Insulite", etc. that had excellent insulating properties but have relatively slight structural strength in flexure or bending under load, hence are not and cannot be used as structural slabs for load sustaining purposes, as roof or floor slabs, for example. [Adding structural strength ran into the problem of reducing the insulating value of the product.]

- "Sound-absorbing chamber", Treadway B. Munroe et als, U.S. Patent No. 1,705,778, 19 March 1929 (using Celotex to construct a sound deadening chamber.

- "Method of and apparatus for drying moving material", U.S. Patent 2,376,612, Carl G. Muench, New Orleans, assigned to Celotex Corporation, described a method and apparatus for drying sheets of artificial heat insulating lumber, preferably formed by the felting of bagasse fiber along with other materials necessary to make a satisfactory structural fiber board. 22 May 1945

- "Sound-absorbing board for walls and ceilings," U.S. Patent 1,554,180, Sept. 15, 1925, Wilber S. Trader, assignor to Dahlberg & Company, Chicago IL. described an interior-use sound insulating product.

- [11] "Insulite Co. v. Reserve Supply Co.," 60F.2d 433 (1932), Circuit Court of Appeals, Eighth Circuit, July 26, 1932. Web Search t/23/12. Quoting:

Rabbeted joints in material to which plaster or other material is applied are found in the Jones patent, No. 886,813. In this patent the composition is made up of plaster of paris, cement, or other like substance, combined with hair, wood fiber, sawdust, wool, wood shavings, excelsior, straw, or similar substances. The length of the lath covers three joists instead of four. The boards are arranged in staggered relation to each other and the joints are shiplapped. The specification states that after the boards or blocks are placed in position they may be covered with wallpaper or other similar material, which, of course, would include plaster.- "Machine for perforating Insulite Boards", U.S. Patent No. 1,306,283, Patented 10 June 1919, John K. Shaw, inventor from Minneapolis MN, describes improvements for machines for perforating Insulite Boards.

- "Before you Build write for this mailing piece and a sample of Insulite", [advertisement], The Literary Digest, 13 September 1940.

- [13] "Separating the Fiber of Wood", A.S. Lyman, U.S. Patent No. 21,077, 3 August 1858

- [14] Standards pertaining to fiberboard insulating sheathing:

- ASTM C 208-95 (2001) – Standard Specification for Cellulosic Fiber Insulating Board. Type IV Grade 2 (Structural Wall Sheathing).

- ASTM C 846-94 (2003) – Application of Cellulosic Fiber Insulating Board for Wall Sheathing.

- ASTM D 1554 - Definitions of terms Relating to Wood Based Fiber and Particle Panel Materials.

- ASTM E-72 (1997)- Standard Method for Conducting Strength Tests of Panels for Building Construction.

- ANSI /AHA - A194.1, Cellulosic Fiberboard.

- U.S. Department of Commerce: PS57-73, Cellulosic Fiber Insulating Board

- A.F.A. (2003): Fiberboard Sheathing test results

- [15] "Properties of insulating fiberboard sheathing", Forest Products Laboratory (U.S.) Luxford, R. F. (Ronald Floyd), 1889 (1960), original report 1955, citation:hdl.handle.net/1957/2489, web search 6/29/12, original source: http://ir.library.oregonstate.edu/xmlui/handle/1957/2489

- R-Value of Wood, U.S. Department of Energy

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.