Masonite™ & Other Hardboard Products, Brands

Masonite™ & Other Hardboard Products, Brands

History & Ingredients of Masonite™ Hardboard +

Artworks on Hardboard

- POST a QUESTION or COMMENT about Masonite & other Hardboard products.

What is Masonite™ and what are the history, composition, and properties of hardboard used in siding, furniture, and many other products?

We include of all of the Masonite™ patents by inventor William H. Mason and other related Masonite research. Also find here: a history of Masonite™ in Australia and a discussion of use of hardboard or Masonite™ like products in works of art.

Photo at page top: Antique S1S wet-process Masonite™ hardboard showing the back side of an early hardboard interior-use product labeled "Genuine 4 Masonite De Luxe QuartrBoard © InspectApedia.com.

This article series describes various kinds of building materials and give the history and dates of their first (and in some cases last) use in residential and light commercial construction.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Masonite™ & Other Hardboard Sheet, Siding & Building Materials

History & examples uses of of Masonite™ and other hardboard products - contributions invited.

History & examples uses of of Masonite™ and other hardboard products - contributions invited.

[Click to enlarge any image].

Our illustrations and citations here describe Masonite and similar hardboard and MDF products ranging from exterior hardboard siding, even roofing products, ( those didn't work out very well) to interior bathroom Masonite™ temprtile wallboard, to furniture, signs, baking equipment, even musical instruments, all made of Masonite hardboard.

Article Contents

- HARDBOARD MASONITE™ & OTHER BRANDS

- DEFINITION of HARDBOARD & MASONITE

- HISTORY of MASONITE HARDBOARD

- HISTORY of MASONITE HARDBOARD in AUSTRALIA

- HARDBOARD BATHROOM & KITCHEN PANELS - separate article, describes the 1950s Temprtile shown above.

Definition of Masonite™ & Hardboard

"Hardboard", of which Masonite™ is a familiar brand, is a high-density fiberboard (HDF) made from highly-compressed wood or other vegetable fibers bonded together in either a wet or a "dry" process to produce hard wood panels, brown in color, of varying thicknesses, depending on the end-product required.

Typical Masonite™ hardboard is sold in building supply stores in 1/8 to 1/4" thick sheets, solid or perforated, as well as in specialized forms. Hardboard or HDF, first patented in 1772 ( Katlan 1994) has been widely used world-wide since the 1930s in a stunning rang of applications including construction, furniture, shelving, signs, kitchen tools, parts in airplanes, trucks and cars, works of art, and even musical instruments.

Watch out: In some countries and texts the word masonite has been used generically for a wood or vegetable-fibre hardboard that may in fact have been manufactured by another company.

Currently hardboard, produced by Masonite or by other manufacturers, is distributed in a number of forms and dimensions, of which panels (sheets) and boards (lap-siding) are the most-common.

- S1S hardboard panels have one smooth side and a reverse that usually has a "window screen" pattern such as shown in our photo above. S1S hardboard or Masonite™ is produced by a wet process.

- S2s hardboard panels are smooth on both sides are are manufactured by a dry process.

- Tempered hardboard is manufactured with the addition of an oil polymerized by heat and pressure during production.

- Composite hardboard panels may combine a layer of polyester fabric or by kraft paper impregnated with melamine resin or polyester resin and a substrate of hardboard sold as a "low pressure laminate" product such as sometimes found in countertops and kitchen or bath paneling.

Masonite's low-pressure laminate is identified as MCP™. (Pell 1986)

Wood-fiber hardboard products were produced first in England in 1898 (from waste paper). Funded by two lumber companies, (Wisconsin & Laurel), Masonite™ produced commercially by the Mason Fiber Company beginning in 1924.

Masonite™ - a wood fiber hard-board material was patented and produced in North America by William H. Mason, as a means of producing a useful product made from wood sawdust and other wood waste produced by lumber mills.

Masonite™ - a wood fiber hard-board material was patented and produced in North America by William H. Mason, as a means of producing a useful product made from wood sawdust and other wood waste produced by lumber mills.

That Mason was a protégé of the prolific American inventor Thomas Alva Edison may explain Mason's own prolific patents involving the processing of wood waste, wood pulp, and the production of fiberboard and hardboard, many of which we cite below.

In 1928 the Mason Fiber Company was re-named the Masonite Corporation. According to fundinguinverse.com, Mason's wife's family owned sawmills in Laurel Mississippi - his first primary source of wood chips and sawdust to produce usable wood products.

The company's success grew to include sales world-wide as Masonite™ hardboard was used widely not only in construction but even in automobiles and airplanes as body and partition sections, furniture, and the wildly-popular pegboard hanging in our garage.

Faced with a declining market as newer wood board products such as OSB increased in popularity, and to forestall a corporate raider takeover by General Felt Industries in the 1980s Masonite sold a controlling interest in the company to USG (US Gypsum).

In 1988 Masonite was acquired by International Paper Corporation. Premdor, a door and door component manufacturer formed in 1979 merged with the Century Wood Door Company ten years later in 1989 and more-recently, in 2001 Premdor, Inc. obtained the Masonite business from International Paper, and began using the Masonite™ brand. In 2002 Premdor became the Masonite International Corporation whose contact information we give below.

American Hardboard Association Hardboard Identification Codes

The American Hardboard Association provides plant identification codes that you may find stamped on to the back of some hardboard products. The table below translates AHA Plant numbers to location and manufacturer to help identify a hardboard product.

AHA Hardboard Manufacturing Plant Codes |

||

| AHA Plant No. | Manufacturer | Location |

| AHA01 | Boise Cascade | International Falls, MN |

| AHA02 | Weyerhaeuser | Broken Bow, OK |

| AHA03 | Temple | Diboll, TX |

| AHA04 | Abitibi/ABTCO, LP | Roaring River, NC |

| AHA05 | Forestex | Forest Grove, OR |

| AHA06 | Masonite, IP or Champion, GP | Laurel, MS |

| AHA07 | Bowwater, US Plywood | Catawba, SC |

| AHA08 | Masonite, IP | Ukiah, CA |

| AHA09 | ||

| AHA010 | Weyerhaeuser | Klamath Falls, OR |

| AHA011 | MacMillan, Weyerhaeuser | Sturgeon Falls, ONT |

| AHA012 | Masonite, IP | Towanda, PA |

| AHA013 | ||

| AHA014-19 | ||

| AHA20 | Collins | Klamath Falls, OR |

| Masonite (Canada) | ||

| Masonite (Australia) | ||

Notes to the table above

Note that manufactured in other countries HDF and MDF of course appear under other product names, such as the VEB Ribnitz-Damgarten panel illustrated

at HARDBOARD & MASONITE USED in WORKS OF ART

AHA American Hardboard Association, 1210 West Northwest Highway, Palatine, IL 60067 USA

Telephone: 847-934-8800

E-mail: aha@hardboard.org

Website Excerpt:

Definition of Hardboard

Hardboard is a generic term for a panel manufactured primarily from inter-felted ligno-cellulosic fibers, consolidated under heat and pressure in a hot press of density of 31 pounds per cubic foot (a specific gravity of about 0.5: or about 0.50 grams per cubic centimeter density) or greater.

Other materials may be added during manufacture to improve certain properties such as stiffness, hardness, finishing properties, resistance to abrasion and moisture, as well as to increase strength, durability and utility.

Masonite also has plants in Australia, Canada etc)

Hardboard Product Failures & Troubles to Avoid

While uses and applications for S1S, S2S and tempered hardboard range widely, the material does not have structural strength, and it does not tolerate exposure to water or the weather - in our opinion a key factor behind some exterior hardboard siding and roofing product failures beginning

at SIDING HARDBOARD IDENTIFICATION & CLAIMS and

at FIBER-WOOD & FIBERBOARD ROOFING

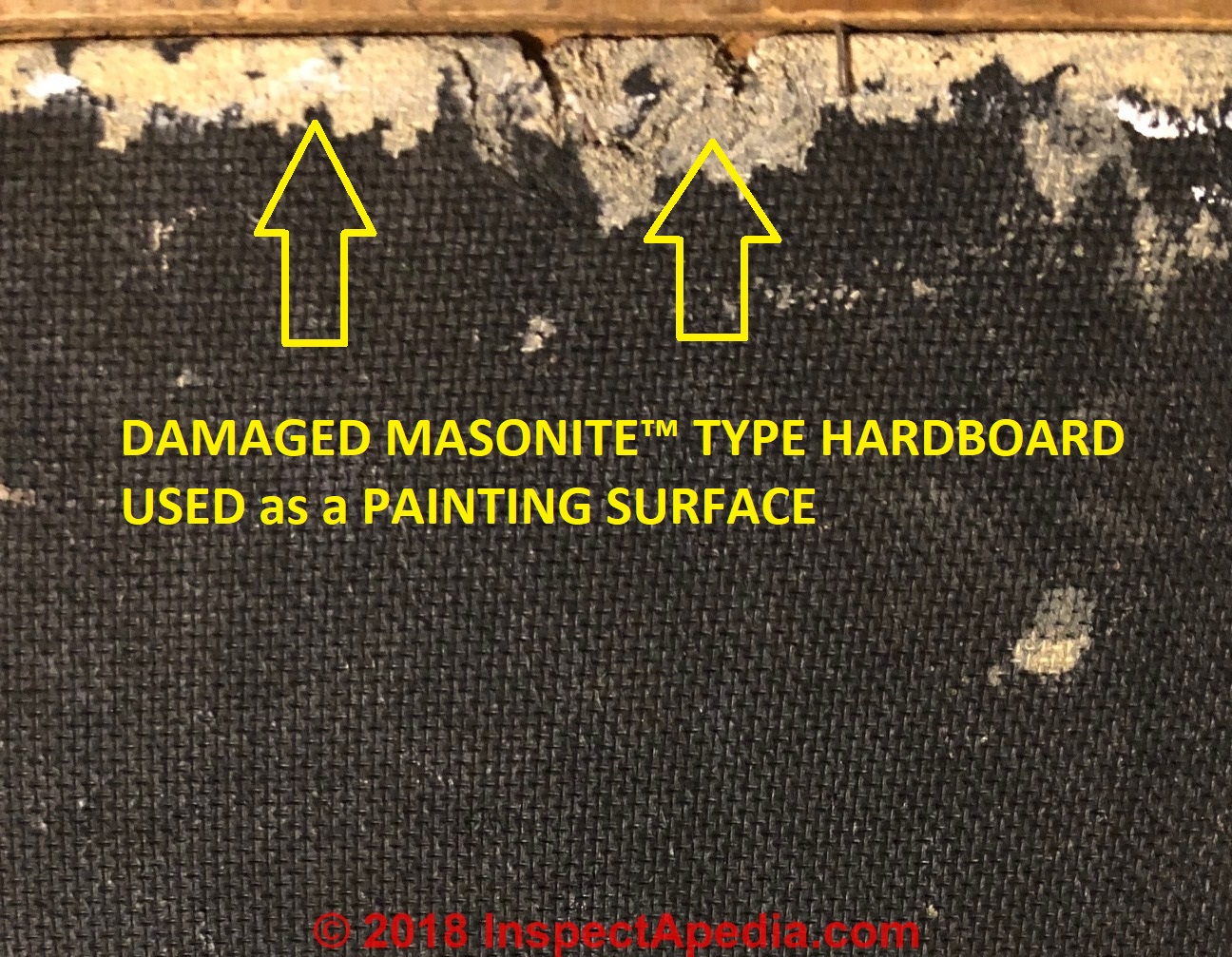

Above: Masonite™ fragments (wood fibres) isolated from a surface sample of an oil painting that was executed on a hardboard substrate.

At PAINT FAILURE, DIAGNOSIS, CURE, PREVENTION we explain why tempered hardboard may suffer brown bleed-through staining when painted if it is not properly sealed first.

Above: S1S Dry Process Masonite™ used as substrate for a painting whose owner was concerned that the product might contain asbestos (highly unlikely).

The hardboard shown above and the painting on its other side are discussed in detail

at HARDBOARD Masonite™-like INGREDIENTS

History of Masonite™ Hardboard & Ingredients of Masonite™-like Hardboard or Fiberboard

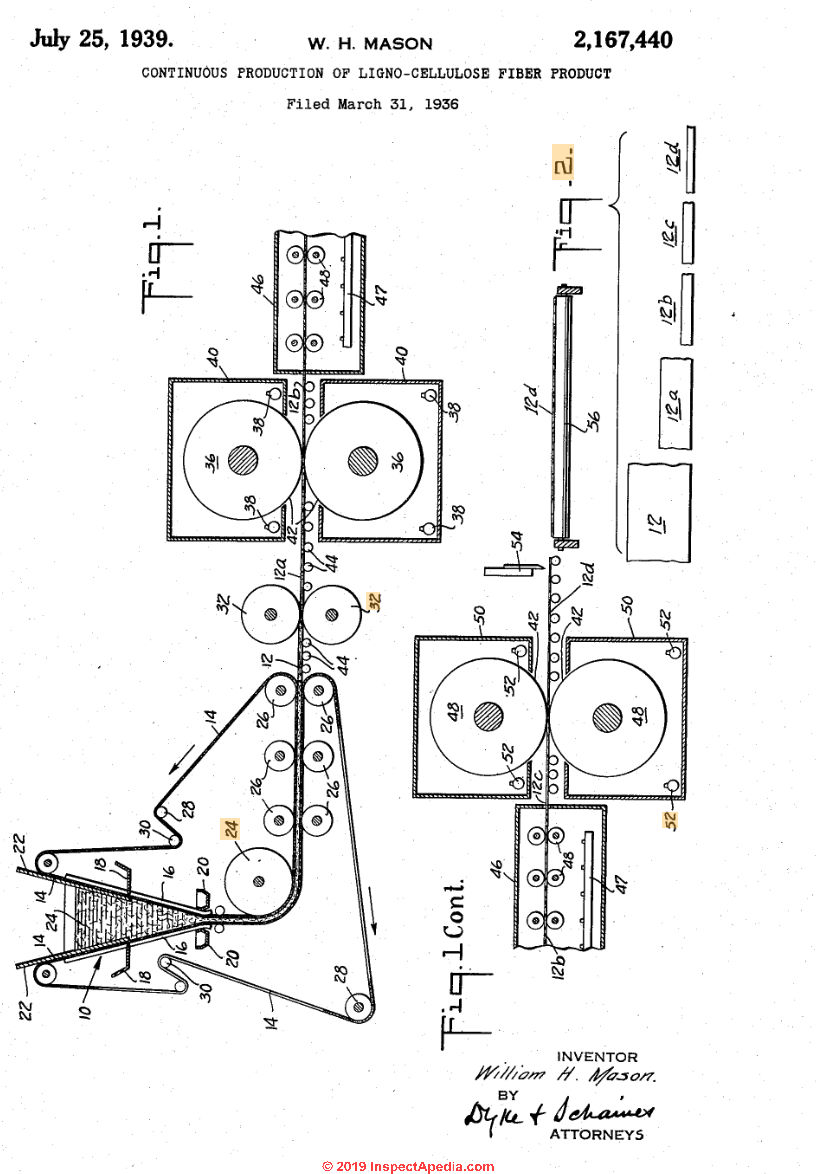

Illustration: Continuous production of ligno-celluose fiber product later trademarked Masonite™ from Mason's US Patent 2, 167,440 filed 1936 and cited below.

[Click to enlarge any image]

- Current Contact:

Masonite Corporation1600 Britannia Road East

Mississauga, Ontario L4W 1J2

Canada

Telephone: (905) 670-6500

Toll Free: 800-663-3667

Fax: (905) 670-6520 Website: www.masonite.com

Masonite [Doors], Tel: 1-800-663-3667 Email: helpline@masonitee.com Website: https://residential.masonite.com/ - AHA BASIC HARDBOARD PRODUCTS [PDF] AHA American Hardboard Association, 1210 West Northwest Highway, Palatine, IL 60067 USA

Telephone: 847-934-8800

E-mail: aha@hardboard.org

Excerpt:

General purpose construction panels consist of Standard, Tempered, Service, and Tempered Service grade hardboards, and they are covered by American National Standard, ANSI/AHA A135.4-1982. These construction panels have a variety of uses in the house, basement, garage, and out-building such as paneling, cabinets, ceilings, linings, dog houses, etc. - AHA, RECOMMENDED BASIC APPLICATIONS & PAINTING INSTRUCTIONS for HARDBOARD SIDING [PDF] Op. Cit.

- AHA, MAINTENANCE TIPS for HARDBOARD SIDING [PDF] Op. Cit.

- AHA TODAY'S HARDBOARD [Composition & Properties of Hardboard] [PDF] Op. Cit. includes a description of the hardbaord manufacturing process.

- Ampersand Art, "The Story of Hardboard" [PDF] Ampersand Art Supply, 1235 S Loop 4, Suite 400 Buda, TX 78610 USA Tel: (800) 822-1939 / (512) 322-0278 outside the US Website: https://ampersandart.com/ retrieved 2019/12/31 original source: https://ampersandart.com/the-story-of-hardbord.php

- ANSI A135.4–2004 (CPA 2004a) Basic hardboard physical properties for selected products

- ANSI /AHA A135.4-1995 BASIC HARDBOARD [PDF] retrieved 2019/12/29, source: AHA, cited above.

This standard defines hardboard, covers requirements and test methods for water absorption,thickness swelling, modulus of rupture, tensile strength, surface finish, dimensions, squareness, edge straightness, and moisture content of five classes of basic hardboard. - ANSI / AHA A135.5 - 1995 PREFINISHED HARDBOARD PANELING [PDF] retrieved 2019/12/29, source: AHA, cited above.

- ANSI / AHA 135.6 - 1998 HARDBOARD SIDING [PDF] retrieved 2019/12/29, source: AHA, cited above.

- Cai, Zhiyong; Ross, Robert J., Wood Handbook, Chapter 12: Mechanical Properties of Wood-Based Composite Materials, [PDF] General Technical Report FPL-GTR-190. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: 12-1 - 12-12. Chapter 12. (2010)

- Church, Jennifer & Daniel Friedman, EL LABERINTO DE FRIDA KAHLO - MUERTE, DOLOR, Y AMBIVALENCIA, Jennifer Church & Daniel Friedman, CIAM Press, 2008, 176 pages, ISBN 978-0-615-23125-9, Spanish, english translations of annotations and writings of Frida Kahlo, commentary, historical and analytical notes.

Also available at Amazon.com.

For educational use the Labyrinth of Frida Kahlo, Death, Pain, & Ambivalence, a richly-illustrated bi-lingual (Spanish / Englis) book describing Frida Kahlo's art and writing is also available directly from the authors for the cost of shipping & postage. CONTACT us by email. CONTACT us by email. - Cohen, Laurie P., "International Paper Plans to Buy USG's Masonite," Wall Street Journal, October 3, 1988, p. 1.

- Dobbs, David, A HARD LOOK at HARDBOARD SIDING [PDF], Journal of Light Construction, June 1990 - This article includes a useful list of "Hardboard Do's and Don'ts"

- FIBERBOARD ROOFING & FIBER-WOOD ROOFING for examples of uses of hardboard or fiberboard as an roof shingles

- Funding Universe, "History of Masonite International" [Web page], retrieved 2019/12/29, original source: http://www.fundinguniverse.com/company-histories/masonite-international-corporation-history/

- Gottsegen, Mark David. A manual of painting materials and techniques. Harper & Row, New York, 1987. ISBN 0-06-042421-4

- Gottsegen, Mark, PAINTING on PANEL: WORKING WITH MASONITE [PDF], Ampersand Art, retrieved 2019/12/31, original source: https://ampersandart.com/blog/2013/04/painting-on-panel-working-with-masonite/

Note:

For more detailed and technical (believe it or not) information on hardboard and Hardbord™, please refer to our website: ampersandart.com/tips/archivalinfo - HARDBOARD SIDING - examples of applications of hardboard or Masonite type products in construction

- HDF HIGH DENSITY FIBERBOARD Products defined

- JLC, HARDBOARD SIDING PULLED from FLORIDA MARKET [PDF] Journal of Light Construction, Eight Penny News, May 1994

Excerpt:

Masonite Division of International Paper, the nation’s leading producer of hardboard siding, announced in March that it was pulling its product out of Florida after Palm Beach County building officials banned the use of hardboard siding in new construction. Masonite and other hardboard siding is permitted in the county only for warranty and repair work.

Masonite’s problems in Florida began several years ago when occupants of HUD-financed homes in a Palm Beach County subdivi- sion named Victoria Woods complained of discoloration and rot affecting their siding.

Although the problems were due to faulty construction, not the materials, according to company executive Errol Savoie, Masonite wound up replacing most of the siding in the development. - Jones, Kevin D., "The Making of a Dinosaur," Mississippi Business Journal, July 1989, p. 14.

- Katlan, Alexander W. "Early wood-fiber panels: masonite, hardboard, and lower-density boards." Journal of the American Institute for Conservation 33, no. 3 (1994): 301-306. [Copy on File at InspectApedia.com as Early-Wood-Fiber-Panels-Masonite-Hardboard-and-Lower-Density-Boards.pdf ]

Abstract:

The author discusses the early use in the 19th and 20th centuries of lignocellulose fiberboards by artists.

Hardboards and “Masonite process” boards are defined and discussed, and patent dates are clarified, including the possibility that fiberboards were available to artists as early as 1861, judging by two British patents of that date, and the fact that wood-fiber boards were commercially manufactured in England by 1893.

The advantages and disadvantages of Masonite as an artist's painting support are discussed, as is a new Masonite-type hardboard that recently was introduced.

- Mason, William H. "Process and apparatus for disintegration of wood and the like." U.S. Patent 1,578,609, issued March 30, 1926.

- Mason, William H. HARD GRAINLESS FIBER PRODUCTS and PROCESS of MAKING SAME [PDF] U.S. Patent 1,663,505, issued March 20, 1928.

Note: The word "asbestos" does not appear at all in this original fiberboard, i.e. Masonite hardboard patent disclosure from William H. Mason, its inventor.

Excerpt: The raw material, such as wood in small pieces or chips, is first converted into fiber.

The fiber is preferably prepared by explosion from a gun through a constricted outlet- 'or outlets under high pressure, preferably steam pressure of about 275# to 1000# per sq. in., but the wood may-be ground or transformed into fiber in other Ways, so long as practically all the constituents are disintegrated into substantially fibrous state and the fibers are not unduly chopped or shortened.

Chemically digested fiber from which the lignins have been substantially removed is not adapted for the purposes of my invention, practically all, or at least the larger part of the natural lignins present in the wood or woody-material being necessary to be retained and incorporated in my product in order to obtain thorough cohesion throughout.- the fibrous body. - Mason, William H. "Process of making integral insulating board with hard welded surfaces." U.S. Patent 1,812,969, issued July 7, 1931.

- Mason, William H. "Process and apparatus for disintegration of fibrous material." U.S. Patent 1,824,221, issued September 22, 1931.

- Mason, William H. "Process of manufacturing insulating board." U.S. Patent 1,812,970, issued July 7, 1931.

- Mason, William H. "PROCESS for the MANUFACTURE of VEGETABLE FIBER PRODUCTS [PDF] U.S. Patent 1,844,861, issued February 9, 1932. Original Assignee, Masonite Corporation.

In explaining the manufacture of Masonite™ hardboard we read that indeed asbestos might be used as a component of the press used to form the hardboard, but asbestos was not an ingredient in the hardboard material itself.

Excerpts:

My invention relates to an improved process for the manufacture of vegetable fiber products of cellulose and lignin compacted or welded together under pressure-accompanied by heat,

and has for its object the treatment of the material in such a manner as to obtain a product of maximum rigidity and strength to resist flexure and other stresses, and to prevent or minimize any 10 tendency which it may have to stick to the surface of the press platens or other molding surface.

The invention is in the nature of an improvement upon the process disclosed and broadly claimed in U. S. Patent No. 1,663,505, granted March 20, 1928.

The raw material used is one which contains lignin and cellulose, for example, wood chips obtained from saw mill waste, although other materials may be used provided they contain lignin in sufficient quantity to bind or Weld the cellulose fibers together in compact relation when subjected to moisture, heat and pressure.

The raw material is first thoroughly disintegrated into fiber by any process in which at least the principal part of the l1gn1n 1s retained, as, for example, the process disclosed and claimed in U. S. Patent No. 1,578,609, granted March 30, 1926,

in accordance with which the fiber is obtained by subjecting the wood chips in a closed high pressure chamber to penetration by an elastic fluid such as steam at high pressure, and progressively discharging the same through a constricted outlet from said chamber while substantially maintaining the pressure in the pressure chamber, whereby the sudden expansion of the fluid is utilized for disintegrating the material.

It is possible to increase or prolong the time interval employed for the closing of the press while still avoiding the heating of the material above 212 F. before the application thereto of a pressure of 200 lbs. or more per square inch by providing the upper surfaces of the movable press platens with means for retarding the flow of heat therefrom,

for example a layer of asbestos may be applied directly to the platen surface, and a wire mesh screen above the asbestos. In addition to the provision of such means, the wet lap sheets may be placed upon steel surface plates outside of the press and conveyed thereby into the press, the surface plates resting upon the wire mesh screen and forming the pressing surface. - Mason, William H. "Acoustical board." U.S. Patent 1,875,074, issued August 30, 1932.

- Mason, William H. "Liquid separation." U.S. Patent 1,875,075, issued August 30, 1932.Mason, William H. "Cut-off machine." U.S. Patent 1,924,162, issued August 29, 1933.

- Mason, William H. "Screening and refining of fiber." U.S. Patent 1,970,330, issued August 14, 1934.

- Mason, William H. "Composite structural unit." U.S. Patent 1,995,264, issued March 19, 1935.

Excerpt:

My invention relates to composite units for structural purposes, as for example, parquetry and tile floor and wall construction, panelling, etc. The preferred material used in the manufacture of such units is fibrous board, preferably lignocellulose fiber board. - Mason, William H., and Charles H. Westphalen. "Pressure inversion process of making hard board products." U.S. Patent 2,046,750, issued July 7, 1936.

- Mason, William H., Robert M. Boehm, and Koonce Wilbur Euclid. "Molding composition and process of making same." U.S. Patent 2,080,078, issued May 11, 1937.

- Mason, William H. "Process of making ligno-cellulose fiber products." U.S. Patent 2,120,137, issued June 7, 1938.

Patent Excerpt:

My invention relates to vegetable fiber products that are highly hard, strong water-resistant and dense, and process of making same.

My new process comprises the drying of a sheet 5 or blank of ligno-cellulose fiber, which before drying is light and porous, to a state of practically complete freedom from moisture, followed by simultaneous application of high heat and high pressure to the previously dried sheet or blank.

The thorough preliminary drying may be accomplished in various ways, and in one or more steps or subdivisions. About the simplest mode of preparing the dried blank is to form the wet fiber into a sheet from a water bath, pass through squeeze rolls, and dry thoroughly in a hot air drier.

To obtain a final product of maximum density, it is desirable to prepare the dried blank so as to be itself of quite high density, and, when manufacturing fiat products such as boards or sheets,

such dense blanks may be formed as by drying the moist fiber sheet under heat and pressure in a multiple hot platen press or equivalent apparatus, having provision for escape of moisture during drying, such as a wire screen interposed between the fiber mass and a press platen. - Mason, William H. "Momentary-pressure process of making ligno-cellulose products." U.S. Patent 2,140,189, issued December 13, 1938.

- Mason, William H. "Burnishing of fiberboards." U.S. Patent 2,118,763, issued May 24, 1938.

- Mason, William H., CONTINUOUS PRODUCTION of LIGNO-CELLULOSE FIBER PRODUCT [PDF] U.S. Patent 2,167,440, issued July 25, 1939.

Excerpts:

My invention relates to the production of dense ligno-cellulose products. The present inv vention is in the nature of an improvement on my Patent 1,663,505 issued March 20, 1928. 6

One object 'of the' present-inventionis the provision of a process in which heated rolls can be made use of for applying heat-and pressure to a sheet of ligno-cellulose fiber, and good, dense, strong sheets or boards obtained by controlling 10 the condltlons for heat and pressure application so as to get thebenefits of densifying and bonding a body of ligno-cellulose fiber originally con taining a material percentage of water while drying the same, and also of further densifying 15 and bonding of the-body of ligno-cellulose fiber in the substantial absence of moisture.

A further object of the invention consists in the provision of a process whereby heat and pressure are applied to the ligno-cellulose fiber mate- 80 rial by passing a sheet thereofthrough rolls at increasingly high temperatures, and a drying step is performed on the fiber material between roll passes.

A further object of the inventionconsists in B the provision of a process of hot-roll manufacture of dense ligno-cellulose products in which drying is avoided until the material is subjected to a first hot roll pass. - Mason, William H., Robert M. Boehm, and George G. Simpson. "Process for making hardboard." U.S. Patent 2,317,394, issued April 27, 1943.

- MASONITE ANNOUNCES INTENTION to PHASE OUT HARDBOARD SIDING [PDF] (2001) press release.

Excerpt:

Chicago, Illinois, March 6, 2001, Masonite Corporation announced today its decision to phase out production of all hardboard siding proucts. This will result in the closure of the Ukiah, Calif. mill, and the shutdown of two siding production lines at the Laural, Miss. mill. The other products manufactured atthe Laurel Mill will not be impacted.

The company will phase out production of all siding products including Colorlok®, Woodsman® Lap and Panel, SuperSide®, and HiddenRidge® siding, and Modulux®industrial board. Other Masonite industrialfiberboard products will continue to be available from the companyh's Lisbon Falls, Maine, mill.

... Althogh Masonite is phasing out production of hardboard siding products, International Paper will continue to make these products available to qualified claimants for repair and replacement purposes under the terms of a 1998 legal settlement.

- Mccorkle, James B. "Process of producing primed hardboard." U.S. Patent 2,654,296, issued October 6, 1953.

- Moore, John Hebron. "William H. Mason, Southern Industrialist." The Journal of Southern History 27, no. 2 (1961): 169-183.

- Pell, Ed, GUIDE to PLASTIC LAMINATES [PDF], The New England Builder / Journal of Light Construction, November 1986

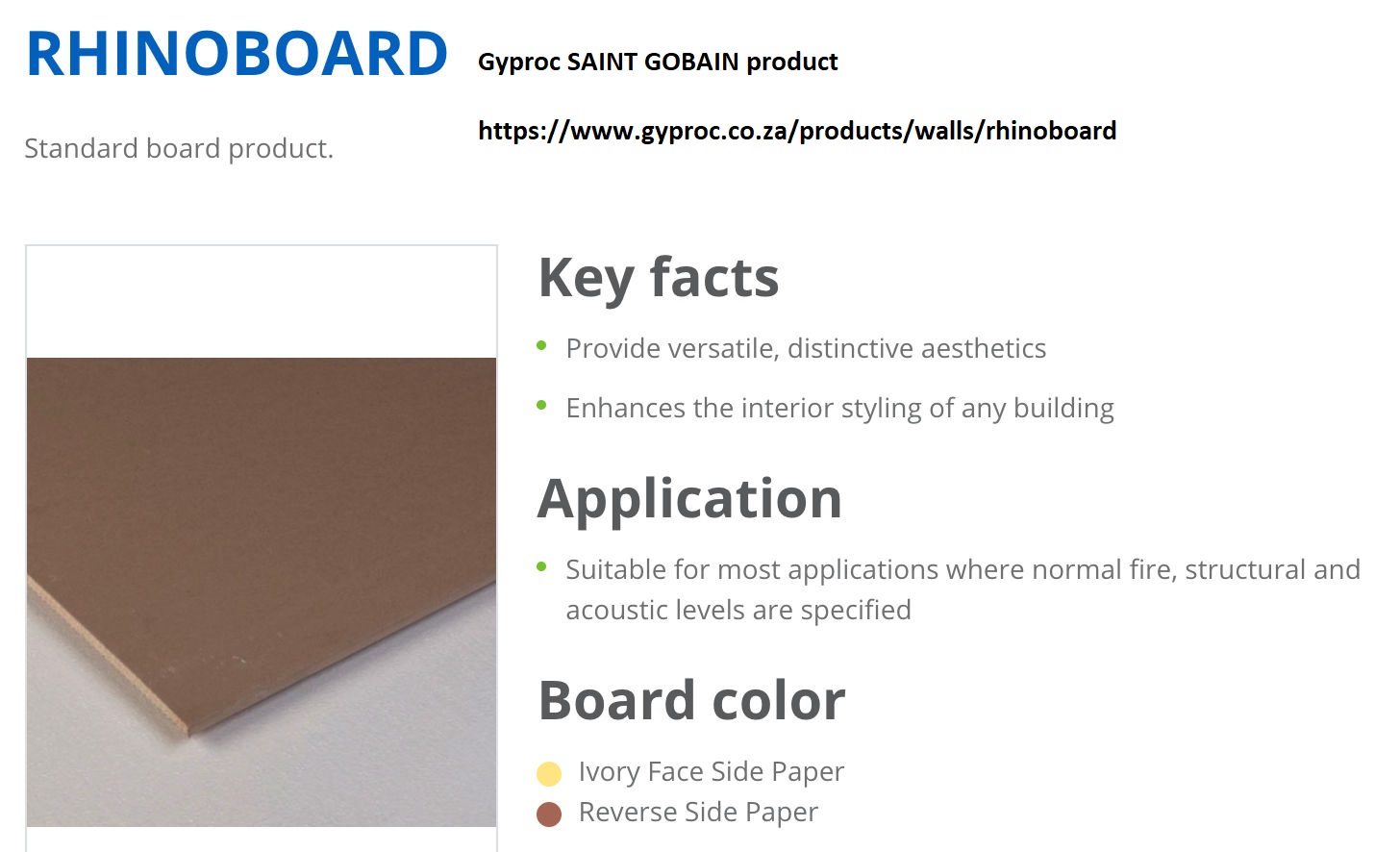

- RhinoBoard, various products & sources with this name at least previously may have included hardboard with a Rhinocerous stamp imprinted on the board's back surface - [citations needed]

Current versions are available from several sources including Custom Building Products (Pacific Island Floors), Seal Beach CA 90740 USA Tel: 800-272-8766 Website: www.custombuildingproducts.com

How Our Backerboard Products Stack Up Rhinoboard™ and Wonderboard® [PDF] retrieved 2019/12/31 original source http://www.pacificislandfloors.com/Product_Info/CB/StackUp.pdf,

Designed for countertops and interior flooring subfloor;

RhinoBoard Product Data [PDF] Gyproc Saint-Gobain

Excerpt:

RhinoBoard is a plasterboard and consists of an aerated or foamed gypsum core encased in, and firmly bonded to, special paper liners.

Modern Rhinoboard Plasterboard, 9mm [PDF] Saint Gobain: 2019/12/31 https://www.specifile.co.za/wp-content/uploads/2017/06/saint-gobain-gyproc-rhinoboard-2017-03-pdf.pdf and at https://www.gyproc.co.za/products/walls/rhinoboard

Excerpts:

Gyproc RhinoBoard 9.0mm consists of an aerated gypsum core encased in, and firmly bonded to, strong paper liners.

Gyproc RhinoBoard 9.0mm is plasterboard that is suitable for ceilings and bulkheads in residential and commercial buildings.

Waste from gypsum plasterboard products is normally classified as ‘non-hazardous’, inert and is fully recyclable. - Runeberg, Ulrik, STAINING AND MICROBIOLOGICAL INFESTATION OF ACRYLIC PAINTINGS ON HARDBOARD [PDF] (2008),Conservator (Dipl. Rest./M.A.), Restaurierungszentrum der Landeshauptstadt Düsseldorf, Germany, Email: Rune-Ulrik@gmx.de

Previously Museo de Arte Contemporáneo de Puerto Rico, San Juan Presented, April 2007 conference in Richmond Virginia, sponsored by the AIC (American Institute for Conservation), this paper discusses the staining and microbial infestation of acrylic paintings on hardboard. - private correspondence, ER <->DF 2020/01/05 - 2006/09/12.

(Also see PAINT FALURE, DIAGNOSIS, CURE, PREVENTION) The following quotation is from the paper's abstract:

"Hardboard served as a common and popular support for many modern paintings that were carried out from the mid - 1920’s, and still is used occasionally in contemporary art. Many artists rejected hardboard as an inferior industrial construction material of low aesthetical value, whereas others considered the processed and compressed wood fiber boards to be a stable, light and economic alternative to solid wood panels and other rigid supports.

"From the conservator’s critical point of view, the many disadvantages of this type of support include: high acidity, hygroscope characteristics, tendency of ‘off-gassing’, (>tendency of) warping, occasional flaking of painting material in the case of tempered hardboard.

The deterioration of paintings on hardboard depends on a number of factors including: the quality of the hardboard, prevailing storage conditions, and the preparation of the support by the artist. While there are many paintings on hardboard that are in very good condition, this paper will focus on those paintings that are heavily deteriorated and damaged.

"A very characteristic damage found on porous painting layers such as acrylic colour on hardboard, is the formation of stains. Generally, those stains are described without any differentiation as ‘fox-spots’.

The examination of various paintings concerned led to the conclusion, that there exist different kinds of stains that need to be discriminated against each other, to ensure an appropriate conservation and restoration treatment.

"This paper aims to characterize and differentiate the stains, and will provide preventive and practical treatment proposals for the conservation and restoration of affected paintings. Questions such as ‘What are the stains composed of?’ and ‘Which may be the causes?’ will be addressed.

Stains may consist of a variety of contents, such as: Ligneous residues, fungal infestation, bacterial activity, a combination of microbial and support induced discolouration [SID], a ‘symbiotic relation’ of ‘SID’ and fungal infestation, or the blooming of ingredients from the original painting materials. A range of microscopic analysis of the actual microbiological infestation of selected samples will be provided.

The paintings that were examined, sampled and treated, are part of the Puerto Rican heritage, and were all kept in excessive humid tropical conditions, before they entered the Conservation Department of the Museum of Contemporary Art in Puerto Rico.

"Conservation treatment options of stained paintings on hardboard will be discussed. A high level of acidity (caused from SID and/or micro-organisms) may require measures of reduction, disinfection and neutralization.

Treatment methods that reduce the ligneous stains and residues of micro-organisms, and neutralize affected areas in painting layers include stain removal through the application of soaking compresses (poultices), and de-acidification through alkaline material.

"Other aspects of deterioration, that do not have to do directly with the formation of stains, but also are typical for hardboard as painting support, will be mentioned briefly." - U.R. - Stark, Nicole M.; Cai, Zhiyong; Carll, Charlie G., Wood Handbook, Chapter 11: Wood-Based Composite Materials-Panel Products- Glued-Laminated Timber, Structural Composite Lumber, and Wood-Nonwood Composite Materials, [PDF] General Technical Report FPL-GTR-190. (2010) Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: 11-1 - 11-28. Chapter 11.

Excerpt:

The term composite is being used in this chapter to describe any wood material adhesively bonded together. Wood-based composites encompass a range of products, from fiberboard to laminated beams. - Williams, Gary, Fact Sheet: Masonite Hardboard Siding [PDF], A Sure-Look Home Inspections 3025 Mill Stream Court, Matthews, NC 28104 Tel: 704-488-4469 Fax: 704-882-8879 asurelook@yahoo.com www.asurelook.com Copy on file as Masonite+Siding+Fact+Sheet.pd

History of Masonite™ & Hardboard Production in Australia

While there are other producers of hardboard today, such as EvoWood™ (shown below ) and TrimTech flooring underlayment, the first Australian hardboard product manufactured in-country was by Masonite Corporation (Australia) that opened in 1938 at Raymond Terrace, New South Wales, Australia.

While there are other producers of hardboard today, such as EvoWood™ (shown below ) and TrimTech flooring underlayment, the first Australian hardboard product manufactured in-country was by Masonite Corporation (Australia) that opened in 1938 at Raymond Terrace, New South Wales, Australia.

A recent manufacturer of Masonite™ in Australia, Australian Hardboards, closed in 2011. It appears that the term "Masonite" is currently used by a number of hardboard manufacturers in Australia, as reflected in our citations below.

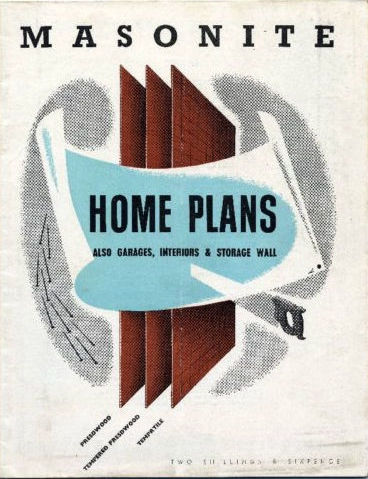

Illustration: A Masonite Home Plans book from the 1950s, provided by Moash University cited below.

[Click to enlarge any image]

Masonite (Australia) was reorganized and renamed Masonite Holdings, Ltd. Australia in 1955. Masonite (Australia) was the country's first "true hardboard" fabrication plant. ASTHC gives 1937 as first production of hardboard in Australia, using bagasse as the primary ingredient.

Masonite Australia was formed beginningin 1937 by Masonite U.S.A. who at inception retained a 29% ownership in the Australian company. Land clearing at the Raymond Terrace site began in 1938 but actual hardboard production in Australia didn't begin until the following year, 1939. (Henry 1988).

Masonite Australia epanded with a dry-process hardboard factory at Pyrmont in 1948, expanding again in 1952. Masonite Australia was not the only hardboard manufacturer in Australia.

C.S.R. constructed a hardboard factory at Pyrmont in 1948.

Another hardboard production facility, the Bernie Board & Timber, Pty Ltc., opened a hardboard production faciility in 1951 in Bernie, Tasmania, and later at Ipswich, Greenland in 1956. (Henry 1988).

Masonite and C.S.R. were merged in 1959. More details are in (Henry 1988).

Other hardboard products available in Australia include Evowood hardboard cited below.

- Australia National Library, Masonite Corporation (Australia). (1938-1955), retrieved 2020/01/19 original source: https://trove.nla.gov.au/people/598868?c=people

- Australian Timbers, Evowood™ (shown above) Hardboard,

273 Magill Road

Trinity Gardens SA 5068 Australia, Tel

(08) 8332 2666

or 141-145 Bedford Street

Gillman SA 5013 Tel: (08) 8332 2666 Website: https://www.australiantimbers.com.au/product/hardboard/

Website Excerpt:

Evowood Original Hardboard boasts a much higher tensile strength, structural strength and internal bond than other substitutes on the markets(MDF & HDF). - Falson, Sarah, "Australian Hardboards closes its doors after 50 years", Manufacturers' Monthly, retrieved 2020/01/19 original source: https://www.manmonthly.com.au/news/australian-hardboards-closes-its-doors-after-50-years/

Excerpt: Manufacturing company Australian Hardboards has closed its doors, with more than 140 employees now out of work, reportedly due to the high Australian dollar and competition from cheap imports.

The Ipswich-based company, west of Brisbane, was operating in the city for 52 years before it was forced to close down.

Australian Hardboards manufactured masonite and chipboard from its Ipswich facility. - Intalay Masonite Underlay, distributed only by Kevmor, retrieved 2020/01/19 original source: https://kevmor.com.au/underlay/3658-intalay-masonite-underlay.html

Website Excerpt:

Intalay Masonite Underlay is a high quality, highly durable underlay product designed to be used over strip timber, particleboard, plywood and concrete floors to provide a flat, uniform, indent resistant base for sheet floor coverings.

Intalay Masonite Underlay is Australian made and manufactured using an ISO 9001 certified process and complies with AS/NZS 1859.4:2004 – Reconstituted wood based panels – Specifications – Wet processed fibreboard.

- MASONITE™ MSDS [PDF] Australian Hardboards Limited, 51 Ashburn Road Bundamba Qld 4304 Australia Tel: 1300 366 681 retrieved 2020/01/19 original source: https://www.forest1.com/images/stories/products/Masonite%20Standard/specs/Australian_Hardboards_Masonite_MSDS.pdf

Excerpt: This product in its intact state is not classified as hazardous, but the dust from this product is classified as hazardous according to the criteria of the National Occupational Health and Safety Commission [NOHSC:1008(2004) and www.ascc.gov.au/applications/hsis. - TECHNOLOGY in AUSTRALIA 1788-1988: FIBREBOARDS [PDF]

Australian Science and Technology Heritage Centre, (ASTHC) Old Arts Building

The University of Melbourne

Vic 3010

Australia

Phone: +61 3 8344 3304 retrieved 2020/01/19 original source: http://www.austehc.unimelb.edu.au/tia/242.html

A nice little history of Masonite in Australia is given by Technology in Australia: Chapter 4 p. 242:

Excerpt:

The first true hardboard plant in Australia was started by the Masonite Corporation (Australia) Ltd. at Raymond Terrace in NSW in 1938 and used chips from local eucalypts de-fibred by steaming at high pressure for a short period and then exploding through a narrow orifice (the Mason 'gun').

The product was formed by draining a water suspension of the fibres, after disc refining, through an endless wire mesh and then pressing and drying, to give a density in the approximate range 900-1100 kg/m3.

A detailed history of hardboard and Masonite in Australia is found in:

- Henry, Margaret & Dorothy Harrison, THE MASONITE FACTORY, Raymond Terrace [PDF] (1988), Australian Regional History, class notes, University of Newcastle, Australia, retrieved 2020/01/19 original source: https://uoncc.files.wordpress.com/2015/11/a7463-ii_bowtell-b.pdf

- Monash University, "Masonite Corporation (Australia) repositor of the Masonite Home Plans book shown above, retrieved 2020/01/19 original source: http://www.monash.edu/library/collections/exhibitions/home/virtual/photos/photo14.html

Excerpt: Masonite is a scientifically manufactured board, made entirely of exploded wood fibres of Australian timbers hitherto thought valueless. It is grainless, knotless, has no protruding fibres, slivers or other defects found in timber.

Although it is best known now as a material for indoor fittings, the company initially tried to promote it for exterior use as well. As a rival for fibrolite sheeting they marketed a special line, “Masonite Tempered Presdwood”.

Despite their claim that this was more moisture resistant than timber it did not prove so in practice. Problems with water notwithstanding, demand for Masonite was strong, for interior finishing and especially for cupboards and cheap furniture. "

Illustration: modern Masonite™ nominal 4 mm actually 3.2 x 2440 x 1220 mm hardboard distributed by Plyco in Victoria, Australia.

- Plyco, 14-20 Abbott St Fairfield, VIC, 3078 info@plyco.com.au (03) 9499 4997 distributor of Masonite hardboard in Australia, Website: https://plyco.com.au/products/masonite?variant=36869270544 - illustrated earlier on this page.

- Trimtec Hardboard Flooring Underlay Data Sheet [PDF] Trimtec, Australian Hardboard,Tel: 1-800-040-080 also available from Australian Timbers cited above.

- Also see other Australian wood fiber board products such as Adamo, Donnaconna board and ForestOne

at FIBERBOARD SHEATHING IDENTIFICATION

History of the Australian Masonite™ Cupcake boards, CocaCola signs & the Wobbleboard

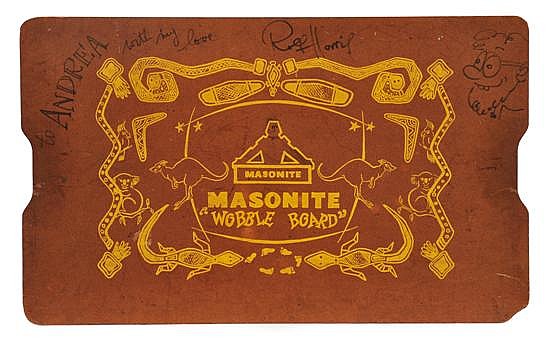

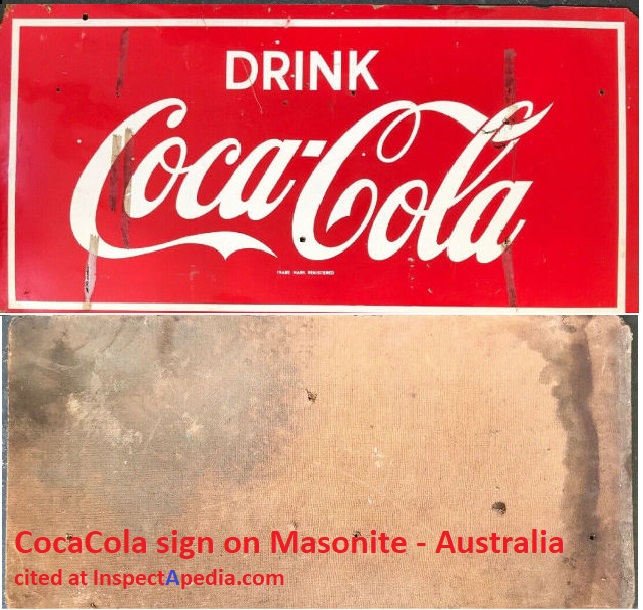

That Masonite™ has found a stunning range of uses from CocaCola® signs made of Masonite to cupcake boards to musical instruments is demonstrated by the Wobbleboard, image courtesy of InspectApedia.com reader Marc Joshmar (2020/01) and the Loyal Cupcake Boards shown below.

This wobbleboard made of Masonite™ was sold in Australia in the 1960s and early 1970s as a musical device.

The creation of the original Australian Wobbleboard is attributed to painter-musician Rolf Harris who, after experimenting with a Swedish-made hardboard, used a 2' x 3' x 1/10" thick segment of Masonite™ hardboard, doubtless produced by Masonite Corporation (Australia), to produce a "whoop whoop" sound made famous in his recordings of "Tie Me Kangaroo Down Sport" and other songs.

In 2014 Harris plummeted far from grace as a convicted and jailed paedophile and groper, as cited below. (BBC 2019)

- BBC, "Rolf Harris primary school incident to be investigated", 6 February 2019, retrieved 2020/01/19 original source: https://www.bbc.com/news/uk-england-berkshire-47141888?intlink_from_url=https://www.bbc.com/news/topics/cl1k9v2l3lyt/rolf-harris&link_location=live-reporting-story

- BBC: Donnison, Jon, "Rolf Harris conviction: Australia reacts to star's fall" BBC News, Sydney, 1 July 2014, retrieved 2020/01/19 original source: https://www.bbc.com/news/uk-28102609

- CocaCola® Sign on Masonite, above, showing the Masonite sign's front and back, located in Sa Australia, and for sale on eBay in 2020

- Loyal™ Cupcake Board: 8" Silver Round Masonite Cupcake Board, 5mm, and other baking boards made of Masonite/MDF, Loyal Bakeware, P O Box 5693 Brendale Qld 4500 Australia 07 3881 3950 Info@loyalbakeware.com retrieved 2020/01/19 original source: https://www.loyalbakeware.com/index.php?route=product/product&path=71_396&product_id=2731

- Hall, Laina (Curator), ... WOBBLEBOARD [PDF] Australian Journeys, retrieved 2020/01/19 origial source: https://web.archive.org/web/20150905231346/http://www.nma.gov.au/__data/assets/pdf_file/0012/5430/FriendsMar09-Rolf-Harris.pdf

- Web Archive, retrieved 2020/01/19 original source: https://web.archive.org/web/20100828083116/http://www.rolfharrisentertainer.com/faq.htm#11

preserving an Original website: Friends of Rob Harris, now offline [OPINION: As a convicted pedophile and molester it's likely that Mr. Harris has few remaining friends - Ed.]

Excerpt:

... My first wobble board was made out of a material called, at the time, Swedish Hardboard. The original one was a tenth of an inch thick, (roughly three mil), and was three feet long and two feet wide. I have since discovered that they can be much smaller than this and still bounce effectively and make that wonderful 'wop wop' sound.

A wobble board is similar to a pendulum insofar as the time of each swing of a pendulum depends on the length of the pendulum string. A longer string gives you a slower swing. With a wobble board, a longer board has a slower bounce, while a shorter board gives you a faster bouncing time. The wobble board I am now using is made of three mil tempered hardboard, and measures 16 inches by 31 inches in length. ...

You need very thin hardboard, because anything thicker than about three mil is just too thick to bounce properly. - Wikipedia, "Wobbleboard", retrieved 2020/01/19 original source: https://en.wikipedia.org/wiki/Wobble_board

Artworks Using & Paintings On Masonite™ Hardboard HDF & MDF

This topic has moved to

HARDBOARD & MASONITE USED in WORKS OF ART - Use of HDF & MDF in the E.U., Germany, Australia, & other

...

Continue reading at HARDBOARD Masonite™-like INGREDIENTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FIBER & HAIR IDENTIFICATION

- FIBER CEMENT & FIBERBOARD ROOFING

- FIBERBOARD PLASTER BASE SYSTEMS

- FIBERBOARD SHEATHING

- FIBERBOARD SHEATHING IDENTIFICATION

- FIBERBOARD SHEATHING INGREDIENTS

- FORENSIC LAB MICROSCOPE TECHNIQUES

- HARDBOARD MASONITE™ & OTHER BRANDS

- HARDBOARD Masonite™-like INGREDIENTS

- HARDBOARD & MASONITE USED in WORKS OF ART

- HISTORY of the USE of WOOD & OTHER WALL PANELING in North America.

- MASONITE & HARDBOARD CEILING & WALL COVERINGS

- MASONITE WOODRUF FIBERBOARD ROOFING

- MDF Medium-Density Fiberboard DEFINITION & CHARACTERISTICS

- SIDING HARDBOARD IDENTIFICATION & CLAIMS

- SHEATHING, OSB

- SUNDEALA BOARD COMPOSITION & HISTORY

- WOOD FLOOR AGE TYPES HISTORY

Suggested citation for this web page

HARDBOARD MASONITE™ & OTHER BRANDS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING AGE

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [4] American Plywood Association, APA, "Portland Manufacturing Company, No. 1, a series of monographs on the history of plywood manufacturing",Plywood Pioneers Association, 31 March, 1967, apawood.org 253-620-7400 APAWood.org

- [7] Georgia Pacific: information about DensGlas gypsum board building sheathing can be found at the company's website at gp.com/build/product.aspx?pid=4674

- [8] Homasote Co., 932 Lower Ferry Road, West Trenton, New Jersey 08628-024, U.S.A. 800-257-9491 homasote.com

- [9] "Hurricane Damage to Residential Structures: Risk and Mitigation", Jon K. Ayscue,

The Johns Hopkins University, Baltimore, Maryland, published by the Natural Hazards Research and Applications Information Center, Institute of Behavioral Science, University of Colorado, November 1996. Abstract:

"Property damage and loss from hurricanes have increased with population growth in coastal areas, and climatic factors point to more frequent and intense hurricanes in the future. This paper describes potential hurricane hazards from wind and water. Damage to residential structures from three recent intense hurricanes - Hugo, Andrew, and Iniki - shows that wind is responsible for greater property loss than water. The current state-of-the-art building technology is sufficient to reduce damage from hurricanes when properly applied, and this paper discusses those building techniques that can mitigate hurricane damage and recommends measures for mitigating future hurricane damage to homes." - online at www.colorado.edu/hazards/publications/wp/wp94/wp94.html - [10] "Evaluating OSB for Coastal Roofs," Paul Fisette, Coastal Contractor, Winter 2005, online at coastalcontractor.net/pdf/2005/0501/0501eval.pdf . Fisette cites: "Jose Mitrani, a civil engineer and professor at Florida. International University in Miami, was ... Florida’s official damage assessment team. ... After Hurricane Andrew, Florida code advisers ruled OSB sheathing inferior to plywood

- [15] Larry Olson, A-Quality Home & Building Inspections, LLC., Spokane WA 99224, Tel: 877-715-4520. private email, 6/5/2012 . Mr. Olson can be reached also by email to: lomo5202@gmail.com

- [16] OSB: "Evaluating OSB for Coastal Roofs," Paul Fisette, Coastal Contractor, Winter 2005, online at coastalcontractor.net/pdf/2005/0501/0501eval.pdf . Fisette cites: "Jose Mitrani, a civil engineer and professor at Florida. International University in Miami, was ... Florida’s official damage assessment team. ... After Hurricane Andrew, Florida code advisers ruled OSB sheathing inferior to plywood."

- [17] OSB: Timberco TECO is located at 2902 Terra Court, Sun Praire, WI 53590 USA, 608-837-2790. TECO provides a reference library of .PDF files that can be downloaded by consumers, homeowners, builders, and architects. The association refers to industry standards for oriented strand board OSB products

- "DOC PS 2, Performance Standard for Wood-Based Structural-Use Panels. Certified to CSA 0325, Construction Sheathing, or CSA 0437, OSB and Waferboard, OSB is accepted in the National Building Code of Canada, certified to EN 300, Oriented Strand Boards and recognized for structural use in Europe and certified to meet the JAS standard for structural panels in Japan."

A professional reference designed to assist surveyors, engineers, architects and contractors in diagnosing existing problems and avoiding them in new buildings. Fully revised and updated, this edition, in new clearer format, covers developments in building defects, and problems such as sick building syndrome. Well liked for its mixture of theory and practice the new edition will complement Hinks and Cook's student textbook on defects at the practitioner level.

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.