Fiberboard Plaster Base Systems

Fiberboard Plaster Base Systems

Fiberboard & fiberboard-gypsum panels used as a base for plaster walls & ceilings

- POST a QUESTION or COMMENT about how to identify different types of interior wall & ceiling plaster installation methods&

Types of fiberboard or fiberboard-gypsum laminate used as a base for plaster walls & ceilings:

In this article series we describe and discuss the identification and history of older interior building surface materials such plaster, plaster board, split wood lath, accordion lath, sawn lath, and expanded metal lath, Beaverboard, and Drywall - materials that were used to form the (usually) non-structural surface of building interior ceilings and walls.

Synonyms for "plaster" include stucco, render, lime plaster, cement plaster, gypsum plaster, and plaster of paris. Lime plaster is also the principal ingredient in whitewash often used on building stone walls both indoors and outside and also sometimes applied to wood surfaces.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

History & Identification of Fiberboard & Fiberboard-Gypsum Plaster Base

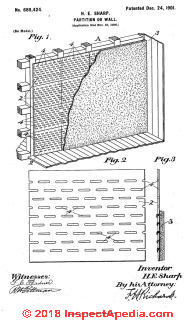

Harry E. Sharp (1901) patented the earliest forms of plaster-board we have found. To overcome shortcomings of wood-lath and metal lath Sharp proposed a panel made from "... made from the plastic compound or pulp consisting of a preferably fibrous material ..."

Within a decade or two Celotex, Insulite, Graylite, and other brands of fiberboard or cellulose-based sheathing were widely used both as exterior wall sheathing and as interior wall sheathing or as a base for plastering as we describe in this article. This fiberboard is a cellulose product, not asbestos.

Excerpted from a photo provided by a reader who was renovating a North American home built ca 1930, here we see fiberboard-gypsum panels used as a plaster base.

[Click to enlarge any image]

Fiberboard pre-laminated to gypsum was sold in sheets in several thicknesses for use as a plaster base.

Separately, fiberboard, including Celotex™ was also sold in raw fiberboard form for use as a plaster base, without pre-lamination of the fiberboard or pre-coating of it with gypsum.

These fiberboard sheets were lighter, easier to transport, and less fragile than the fiberboard-gypsum laminate product we show just above. Celotex provided detailed instructions for using their fiberboard as a plaster base. You can see those details just below on this page.

More about Celotex and other fiberboard products used as exterior and interior sheathing as an insulating board is

at FIBERBOARD SHEATHING IDENTIFICATION.

If you are worried about possible asbestos contamination in fiberboard sheathing or in fiberboard-gypsum laminate boards used as sheathing or as a plaster base,

see SHEATHING, FIBERBOARD ASBESTOS CONTENT

Using Celotex™ Fiberboard Sheets as a Plaster Base

Above is a page describing Celotex™ "Insulating Lumber" - used as exterior sheathing and similar products made by other manufacturers used bagasse, waste paper, and a variety of other organic products to which waxes and coatings were added for exterior use.

Above is a page describing Celotex™ "Insulating Lumber" - used as exterior sheathing and similar products made by other manufacturers used bagasse, waste paper, and a variety of other organic products to which waxes and coatings were added for exterior use.

This same product, but without water resistant coatings or waxes, was used indoors for wall and ceiling sheathing and also as a plaster base.

Insulite™, a cellulose-based (all wood fiber) insulating board or sheathing material that unlike Celotex, was made from wood pulp by-product or tailings fibers.

Both of those products are described in this article.

Both of those products were very widely used for roughly half a century as exterior and interior sheathing that provided insulation as well as a base for other finish surfaces. Fibreboard was produced both as an all-fiber product and as a board product to which plaster was laminated.

...

Details of the materials used to produce fiberboard or plaster-laminated fiberboard sheathing are given separately

at FIBERBOARD SHEATHING INGREDIENTS

[Click to enlarge any image]

Look closely at the photo below and you can see a first layer of fiberboard behind the plaster to which my pen is pointing.

We can speculate about the history of the interior wall finish layers in this building looking at the photo below, moving from left to right:

- Masonry wall

- Wood structure to which interior fiberboard was nailed, in this case probably a window frame - Generally insulating fiberboard was nailed to the wall studs and plastered over.

- Fiberboard insulating sheathing used as a plaster base

- Plaster base coat

- Plaster skim coats -t he plastered surface was skim coated, twice in this case, later probably painted, and possibly even wall-paper-covered later in its life.

- Gypsum board - "drywall" Still later, typicallly to cover cracked, damaged plastger, a layer of drywall was installed over the original surface.

Celotex recommended use of their interior fiberboard sheets for use as a base for plaster walls or ceilings, for which installation instructions can be read in the image just below.

I've also excerpted them in more-legible text just below. Thanks to reader [Anon by private email 21/14/15] for this image.

The Celotex instructions for use of this fiberboard as a plaster lath base include some interesting details for Celotex applied as a plaster base. These plastering instructions were provided by the Celotex Company in Chicago and were affixed to Celotex fiberboards from the New Orleans Plant [and perhaps others].

Quoting Celotex in italics, we include additional explanation or speculation in the [bracketed comments]

- Spray Celotex Sheets on both sides with water and stack in pile the day before using.

[Note: soaking a cellulose based building material and leaving it stacked in sheets longer than the interval recommended by Celotex could cause a mold problem. That may be one of the reasons the company underlined "day before using".] - Space studs and joists 16 inches center to center

- Apply Celotex lengthwise on studs or joists.

- Put 2" x 4" headers at all cross joints.

- Leave 3/16" space between Celotex boards.

- Use large headed galvanized roofing nails, 1 1/2" long, spaced 4 inches apart.

- Drive nail head slightly below surface of the boards.

- Nail along the middle studs first, then around the edges.

- Use a little care and make a good job.

Below: a photo of cellulose or wood-based fiberboard that was not covered by plaster. You may still find this material in building interiors, often in an otherwise un-finished attic.

The fiberboard sheathing in the photo below was nailed to enclose the under-side of the overhanging portion of a raised ranch home in New York, constructed ca 1960.

[Instructions] To the Plasterer [for plastering over Celotex fiberboard sheets]

- Use gypsum plaster, 1/1/2 to 2 hours set gives best results.

- DO NOT USE LIME PLASTER

- Make the first plaster coat not less than 3/8" thick: allow brown coat to dry before applying finish coat.

- Fill all joints with plaster all the way back to stud or joist.

- VENTILATE ROOMS THOROUGHLY in Winter and Summer

[A number of these instructions suggest that over-wetting or prolonged wetting of these boards might lead to swelling, weakening, buckling, bulging, or other issues in the finished plaster job.]

From our own field inspections, we believe that Celotex insulating lumber or similar products were indeed also often left exposed as an interior finish most commonly in summer camps, cottages, and in commercial or farm buildings.

According to one source the material was also used to construct insulated shipping boxes. [8] By 1925 Celotex had published "Celotex insulating Lumber Specifications and Details for Standard Building Board" and also offered "Your Home" a plan book of twenty-five ideal small homes.

A review of the patents and product description for Celotex insulating lumber products shows that asbestos was not among the product's ingredients.

Cross-Section Photos of Plaster Lamainated to Insulating Fiberboard Interior Wall Sheathing

Below is a reader-contributed photo showing original fiberboard or "brownboard" interior wall sheathing used as a "lath" base for a rough-coat (white) and finish coat of plaster.

Our photo below shows a round cross section test plug we cut from a finished interior wall in an older home. Oldest materials are on the right side of the plug. From left to right we see

- Modern drywall (at leftmost side in the photo)

- A layer of plaster, or a pre-laminated plaster+Insulating gypsum-lath board comprised of a layer of wood or paper fiber insulating board that has been bonded to the plaster layer.

More about these surfaces is at FIBERBOARD SHEATHING.

If you are unsure about identifying fiberboard sheathing products

see FIBERBOARD SHEATHING IDENTIFICATION

Graylite - Insulite, Wood-Pulp FiberBoard Plaster Base

Insulite was a cellulose-based (all wood fiber) insulating board or sheathing material that, unlike Celotex, was made from wood pulp byproduct or tailings fibers.

Insulite was a cellulose-based (all wood fiber) insulating board or sheathing material that, unlike Celotex, was made from wood pulp byproduct or tailings fibers.

Insulite was patented by Carl G. Muench who founded the Ontario Paper Company, and who started manufacturing Insulite, billed as "the first rigid insulating board", in International Falls, Minnesota in 1915. (Jester 2014)

We cite some of Muench's early patents below. His 1916 patent 1,187.476 describes equipment to produce fiberboard panels, filed 13 August 1914 and granted June 13 1916, referred to the construction of a felting machine to use basically left-over tailings or scrap from pulp mills, saw mills, and the like.

[Click to enlarge any image]

The Insulite board was treated to "... resist moisture, vermin and rodents" and also was sold as a "sound deadener"[10] and in some applications the product was installed in the air space between gypsum board partitions to improve sound isolation between building areas.

Insulite was described as having stronger structural properties than Celotex, the latter being superior for insulation and sound insulation while Insulite offered greater strength for other applications. Insulite was

... composed of large sliver-like particles often 1/16" to 1/32" in width and say one half an inch long. These sliver like fibers give great porosity to the mass but they render the binding together of the particles more difficult. [10]

Insulite as a plaster board contained rabbeted grooves or "joints" in its surface to which plaster or other material could be applied. Insulite's name for this product was Lok-Joint Lath. (The same engineers later developed "Bildrite Sheathing" that was used to replace horizontal wood bracing in wood frame construction.) The product cost was as low as 5 cents per sq.ft.

In "Insulite Co. vs. Reserve Supply Co", a 1932 lawsuit, relevant patents and ingredients are described, including a composition of plaster of paris, cement, or other like substance, combined with hair, wood fiber, sawdust, wool, wood shavings, excelsior, straw, or similar substances. (Asbestos was not cited in the product description. )[11]

Treadway B. Munroe, from Forest Glen, Maryland, was a prolific inventor who patented a variety of cellulosic board products assigned to companies including Dahlberg (St. Paul MN and Celotex, Chicago IL).

One of his early patents U.S. No. 1,333,628, described a plaster-board of fibrous material intended to provide a less costly base for plaster walls and ceilings.

This was the earliest citation of "Insulite" that we could find. It improved on the original "insulite" construction by including additional long fibers for strength combined with more short fibers to serve as filler for the mass, developing a board that was light weight, had adequate strength, and included entrained air for improved insulation.

This was the earliest citation of "Insulite" that we could find. It improved on the original "insulite" construction by including additional long fibers for strength combined with more short fibers to serve as filler for the mass, developing a board that was light weight, had adequate strength, and included entrained air for improved insulation.

This invention, instead of impregnating the insulating board with a waterproofing compound, simply coated its surface. The result was a product [intended and claimed to be] well suited for use as plasterboard.

Sound absorbing board for walls and ceilings", Patent No. 1,554,180, issued to W.S. Trader, September 15,1925, first disclosed a wallboard constructed from "Celotex", a felted mass of strong bagasse fibers, so compacted as to be capable of use as an artificial lumber in that it can be sawed and nailed, and has sufficient strength in many cases to be substituted for lumber.

That same patent mentions "Insulite", a building board made from wood pulp tailings and which likewise has a porous fibrous body portion and which is possessed of considerable strength so that the same can be nailed, etc.

Celotex was preferred as an insulating material because its internal cells produce a sound-deadening insulating effect.

Graylite interior-use insulating board produced by Insulite™ is described on p. 7 in Peck (1942) as follows:

The insulating board made from wood fibers, produced by a cold-grinding process, felted into a rigid board. The fibers were chemically treated and intimately mixed with finely divided asphalt before felting to increase the strength, water resistance, and resistance to rot and termites.

One surface of the boards had the appearance of closely woven fabric, designated "linen texture." There were two thicknesses, 1 in. and 1 1/3 in. The Insulate Co., "Graylite".

Other Insulite Product Names

We found references to Insulite mastic as early as 1913. By 1940 we find the additional sheathing product names associated with Insulite, a Minneapolis MN company.

- Bildrite Sheathing (exterior building sheathing)

- Fiberite (interior finish) - Not to be confused with contemporary Fiberite Corporation - appearing as several products and names including composite manhole covers (2018) and not to be confused with contemporary Nudo Products' FiberLite® FRP (fiberglass-reinforced plastic) panels (2018).

- Graylite (interior finish)

- Graylite Lok-Joint Lath

- Insulite (see below)

- Insulite Lok-Joint Lath

- Ins-Lite Lok-Joint Lath

- Satincote

- Smoothcote

Reader Question: is it ok to plaster over "beaver board" ?

Can I plaster over beaver board ? - Richard

Reply:

Richard, as our photo shows, people have indeed installed plaster over wood-fiber insulating boards, such as in the concrete building in our photo.

In my review of the bases on which plaster was installed I have confirmed that soft wood fiber board was widely used as a plaster lath system.

In addition to fiberboard as a plaster base, proposed as early as 1900 in the U.S., people also used wood lath, metal lath, and gypsum board lath, and also fiberboard to which gypsum or plaster was laminated to provide a plaster base coat.

These systems are described at FIBERBOARD PLASTER BASE SYSTEMS.

I'd be concerned that the beaverboard may not in all circumstances form a good base for plaster finished walls or ceilings installed in a wood-framed structure for these reasons

- If beaverboard was installed over widely-spaced or under-sized framing in an older, "light-weight" structure, that beaverboard is likely to be too flexible- leading to plaster cracking

- If your beaverboard has already been painted, or if it's a wax-coated product you may also have bond strength problems; normally the plaster base coat depends on mechanical adhesion.

- For some types of fiberboard (you may be using the term "beaver board" loosely, you may find severe bleed-through and brown staining of the finish plaster surface, though that's more likely if your "beaverboard" is an exterior product that was coated with asphalt or waxes.

- If the fiberboard is not flat then your job will be horrible.

- See the Celotex plastering instructions given above in this article

Watch out: DO NOT USE LIME PLASTER when plastering over Celotex™ or similar products.

I'd consider installing a laminate of drywall over the beaverboard instead. If you want a plaster finish install a base of gypsum board ("Rock lath"), or expanded metal lath to make a most-durable job.

See FIBERBOARD SHEATHING IDENTIFICATION to get help identifying just what product you have installed.

There you will find descriptions allowing you to IDENTIFY BEAVERBOARD / BUFFALO BOARD as well as other products.

Also see

Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

Research & Patents: Composition & History of Fiber-based Plasterboard, Insulite, Graylite, Fiberlite

Illustration: Method of Making Wall Panels, Ellis' 1940 patent of a fiberboard production machine assigned to the Insulte Company U.S. Patent 2,208,511 cited below.

Illustration: Method of Making Wall Panels, Ellis' 1940 patent of a fiberboard production machine assigned to the Insulte Company U.S. Patent 2,208,511 cited below.

- BEAVERBOARD IDENTIFICATION

- Ellis, George H. "Apparatus for and process of making synthetic products." U.S. Patent 2,030,625, issued February 11, 1936. Excerpts from this patent claim are given below:

This invention relates generally to an apparatus for and process of making synthetic products which are hard, stifi, board like and particularly to board like bodies which have high tensile strength, which are highly non-water absorbent and which have a small coeflicient of expansion in the presence of moisture.

Another object of the invention is in making of composition boards or sheets adapted for use in construction of buildings and for various other purposes.

A further object of the invention is to provide an improved process of forming composition boards or sheets from fibrous pulp stock which consists in subjecting the fibrous pulp stock to elements to form a web, subjecting the web to pressure to remove surplus fluid, applying heat and pressure to compact and unite the fibrous web, severing the web transversely and subjecting the severed portions to cooling.

A further object is to provide an apparatus of the class described including heated pressing rolls which receive the fibrous web and compact it into a hard, stiff,, water resistant body.

A further object of the invention is the production of synthetic bodies which are evenly colored and of a uniform thickness. A further object of the invention is the continuous production of a sheet of the type described in any desired length, width and thickness.

The invention relates to the production of hard, stiff bodies by first forming from fibrous pulp stock a continuous web or sheet, squeezing the surplus moisture from the web or sheet, passing the web through a drier to dry the web, passing the web through heated rolls to compact and unite the web into a homogeneous body, trimming or severing thesheet longitudinally, severing the web into any desired length, and passing the severed portions through cooling apparatus from which the finished product is removed.

The invention also relates to the production of an endless sheet from fibrous pulp stock, passing the fibrous sheets through squeezing rolls to remove surplus moisture, passing the wet sheet through rolls to dry, compact and unite the fibrous sheet into a hard, stiff, water resistant body, severing the body into any desired length and width, passing the severed portions through humldlfying and cooling means to complete the operation.

The invention also relates to making fibrous products which will not be attacked by insects,fungi and the like.

In carrying out the process'water proofing material may be added to the fibrous pulp so that the finished products will have greater water resistant qualities. The water proofing material may be either vegetable or mineral oils. The water resistant material is preferably mixed with the fibrous pulp stock but it may be added to the 5 sheet after it is formed and so far as this process is concerned it is not material at what time the water resistant material is added. - Ellis, George H. "Method of making dense wall panels." U.S. Patent 2,208,511, issued July 16, 1940. - assigned to Insulite Co. [Illustration shown just above]

- Muench, Eduard. "Reddish-brown azo dye." U.S. Patent 737,445, issued August 25, 1903. [included as a possible family member for Carl G. Muench, for research purposes]

Excerpt:

EDUARD MUNCH, doctor of philosophy and chemist, a subject of the Grand Duke of Baden, residing at Ludwigshafen-on-the-Rhine, in the Kingdom of Bavaria, Empire of Germany, have invented new and useful Improvements in Azo Ooloring-Matters, of which the following is a specification. - Muench, Carl G. "Felting-Macine." U.S. Patent Application 1914856614A filed August 13, 1914. - this is probably the same as the 1916 patent cited below.

- Muench, Carl G. "Thermo non-conductor." U.S. Patent 1,153,512, issued September 14, 1915.

- Muench, Carl G. "FELTING-MACHINE" [PDF of patent disclosure text & images] U.S. Patent 1,187,476, issued June 13, 1916.

Excerpt:

The object of my invention is the production of a machine which is particularly adapated for felting the tailings, screenings or other products received from a pulp mill whereby said material is formed into a strip,sheet or plate of any thickness suitable for insulating structures from heat and cold and protecting against the transmission of sound.

A further object is the production of a machie which will economically manufacture a product out of said material of even texture and of sifficient strength to enable its use for general structural purposes. - Muench, Carl G. "Fiber plaster-board and process of making the same." U.S. Patent 1,337,254, issued April 20, 1920.

Except:

... certain new and useful Improvements in Fiber Plaster-Board and Processes of Making the Same - Muench, Carl G. "Indented fiber board." U.S. Patent 1,417,552, issued May 30, 1922.

- Muench, Carl G. "Apparatus and method of manufacturing board." U.S. Patent 2,518,806, issued August 15, 1950.

- Peck, Mahlon F., W. Gail Hoback and Vincent B. Phelan, BUILDING MATERIALS and STRUCTURES Report BMS90, - Structural Properties of "PHC" Prefabricated Wood-Frame Constructions for Walls, Floors, and Roofs, Sponsored by the PHC Housing Corporation, U.S. Department of Commerce, National Bureau of Standards, (1942) (original price 15 cents)

Illustration: Sharp's 1901 patent for a partition or wall using wood pulp based fibrous plaster board.

Illustration: Sharp's 1901 patent for a partition or wall using wood pulp based fibrous plaster board.

- Sharp, Harry E. "Partition or wall." U.S. Patent 689,424, issued December 24, 1901. This early plasterboard patent describes fiberboard and its useful properties. Sharp applied for this patent on November 10 1900.

This invention relates to improvements in partitions or walls, and more particularly to the composition and structure of the plasterboard, the principalobject being to provide a plaster-board in which the plastering-material will closely adhere and which will yield and adjust itself thereto and which is also durable and free from oxidation.

...It has heretofore been the practice to apply the plaster to boards formed of wood or iron, which while more or less dense and resistive of the moisture of fresh plasterare subject to quite rapid oxidation and also to expansion and contraction. Iron, for example, adheres but weakly to the plaster over its surface, while it is so affected by changes of tem-. perature that the dried plaster is liable to crack and scale off.

It is also found in practice to so rapidly rust that in a comparatively short time much will be eaten away, leaving the plaster without proper support.

Wood presents but little more adhesiveness than iron, and, moreover, swells from the moisture absorbed from the plaster and from the atmosphere, and then upon drying shrinks and is liable to detach the plaster coat. Wood also in time decays. Then both wood and iron have enough rigidity to be unable to yield or accommodate themselves to the plas ter in a satisfactory manner.

...To overcome these objections, I provide in the wall A a plaster-board 2, formed in sections and se cured to the furring in the usual manner, made from the plastic compound or pulp consisting of a preferably fibrous material which is capable of becoming at least slightly softened by the moisture of the freshly-applied plaster of any suitable composition, (shown at 3.)

This causes a certain disintegration of the surface of the board and a roughening thereof, the fibrous or other resulting projections closely interlocking over the contacting surface with the grains of plaster.

The same time some of the gelatinous size which may be used in making the boards is released and adheres to the plaster. This results in a strong adhesion over the entire surface.

This plaster board or sheet may be made of any suitable paper board, stock, or pulp and in some cases may be composed of a mixture of paper-board and strawboard, the fibers of the stock being bound together by some suitable adhesive material or sizing, the whole being compressed into the form of a board or sheet.

These composition boards are not subject to appreciable expansion, nor do they oxidize. - Shaw, John K. "Wood-fiber board." U.S. Patent 1,534,088, issued April 21, 1925.

- "INSULITE: STRUCTURAL INSULATION PRODUCTS ; THE ORIGINAL WOOD-FIBER INSULATING BOARD", [PDF] Sweets Catalog, product description and installation instructions.

- Weaver: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

- Whittemore, Herbert L., and Ambrose H. Stang, BUILDING MATERIALS and STRUCTURES Report BMS31 [PDF]

Structural Properties of "Insulite" Wall and "Insulite" Partition Constructions, Sponsored by the Insultie Co. (1939) - Also see additional historical research citations at FIBERBOARD SHEATHING

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-02-11 by Jeremy - Fiberboard used as a plaster base

My walls are made of this fiberboard material and a porous material?

I also have other walls with miscellaneous material.

On 2022-02-12 by Inspectapedia Com Moderator

@Jeremy,

Looks quite common: fiberboard used as a base for a plaster wall or ceiling system.

...

Continue reading at PLASTER TYPES & METHODS in BUILDINGS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- FIBERBOARD SHEATHING IDENTIFICATION

- HARDBOARD & MASONITE USED in WORKS OF ART

- IDENTIFY INSULITE, or GRAYLITE BOARD PRODUCTS

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTER ASBESTOS CONTENT

- PLASTER DUST EXPOSURE HEALTH HAZARDS

- PLASTER INGREDIENTS, MIX, PROPERTIES

- PLASTER, LOOSE FALL HAZARDS

- PLASTER REPAIR METHODS

- PLASTER TYPE IDENTIFICATION

- PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS

Suggested citation for this web page

FIBERBOARD PLASTER BASE SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, [purchase at Amazon.com] Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- Plastering Skills [purchase at Amazon.com] F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- Worsham, Gibson. "Exterior Plaster Restoration at the Lord Morton House, Lexington, Kentucky." Association for Preservation Technology Bulletin. Vol. XIII, No. 4 (1981), pp. 2733

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.