Radiant Heat Floor Design & Installation Manuals

Radiant Heat Floor Design & Installation Manuals

Radiant ceiling, floor, wall guides

- POST a QUESTION or COMMENT On radiant floor heating problems

Radiant heating system design or installation manuals: free PDF downloads.

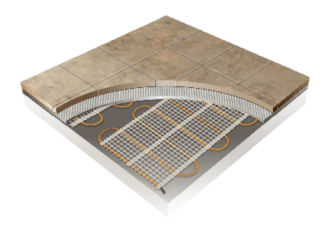

Page top sketch of an electric radiant heat floor installation layout is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company.

This article series explains how to avoid some fatal mistakes when installing radiant heat in a concrete floor slab by describing an incompetent radiant heat floor installation along with an explanation of why things went wrong and how to avoid these errors.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Radiant Heat Slab Installation Manuals, Research, Products, Guides

Photo of workers installing a radiant heated slab is courtesy of InspectApedia reader Connie.

Photo of workers installing a radiant heated slab is courtesy of InspectApedia reader Connie.

[Click to enlarge any image]

- Azel Technologies controls, temperature gauges & thermostats for radiant heating systems provides a wide range of radiant heat controls including at least the following:

Contact: Azel Technologies, Inc., P.O. BOX 53138 Thornhill ON L3T 7R9 Canada Tel: 905-223-5567 Email: info@azeltec.com Web: azeltec.com-

Excerpts from the company's Product Catalog (2023/12/12) azeltec.com/catalog.html#D-508F- i-Link SERIES ZONE CONTROLS (CIRCULATOR PUMP SWITCHING RELAYS ) FOR HYDRONIC / RADIANT FLOOR HEATING SYSTEMS INSTRUCTION MANUAL [PDF] SP-82/83/84/85/86 note that The company offers Models SP-81 to SP-86

Quoting: The i-Link series multi-zone circulator pump switching relays simplify wiring for hydronic heating ( radiant floor heating ) systems. With leading edge features and superior product design, i-Link makes installation quick and easy. - i-Link SERIES ZONE VALVE CONTROLS FOR HYDRONIC / RADIANT FLOOR HEATING SYSTEMS SZ-84/86DX MANUAL [PDF]

Excerpt:

The series multi-zone zone valve controller is operated by low voltage thermostats or any other low voltage controllers having an SPST switching action. The -Link controller provides intermediate switching to permit up to six zone valves and a boiler operating control in a multi-zone hydronic heating system.

- UNIVERSAL DIGITAL TEMPERATURE GAUGE: DS-60P -

Quoting: TDS-60 REPLACES TWO mechanical temperature gauges as it can centralize the readings in one spot and simultaneously display the accurate temperatures of supply and return piping on a hydronic heating system.

In addition, the solid state temperature sensor probe can be extended up to several hundred feets. The unit is designed to be powered by 24VAC input or by lithium battery. When 24VAC is supplied, the lithium battery enable the unit to work in case of power failure.

Its features also include Min/Max memory which shows the highest and lowest temperature after the last reset and instant Fahrenheit to Centigrade conversion. DS-60 is also ideal for any application (EG. Solar heating or Geothermal) that requires quick and accurate response to temperature change, an easy to read display and a wide temperature range. - D-508F DIGITAL NON-PROGRAMMABLE THERMOSTAT FOR HYDRONIC RADIANT FLOOR HEATING INSTRUCTION MANUAL [PDF] - retrieved 2023/12/12, original source: azeltec.com/images/D-508Finstruction.pdf

Quoting: D-508F digital non-programmable heat only thermostat is designed to control either ambient(air) temperature (A Mode) or floor temperature (F Mode) or a combination of ambient temperature with floor temperature limits(AF Mode).

An auxiliary remote sensor is provided to measure slab temperature in order to control the floor temperature(within maximum and minimum limits in AF Mode) in hydronic radiant floor heating system. It can also be used for sensing the outdoor temperature in A Mode. - DIGITAL PROGRAMMABLE THERMOSTAT FOR HEATING/COOLING & HYDRONIC RADIANT FLOOR HEATING -

Quoting: Azel Technologies introduces 500 series electronic programmable thermostat that utilizes the lastest digital technologies for residential and light commercial systems.

D-500 is designed for 24 Vac single-stage heating and cooling systems. D-502F is designed to control the floor temperature in Hydronic Radiant Floor Heating Systems.

The 500 series can accurately control the temperature within one degree. Reliable permanent memory retains the programmed settings in the event of a power failure. In addition, the large, easy to read LCD display with backlit makes the thermostat easy to operate and simple to program. - Azeltec, SOLAR DIFFERENTIAL CONTROL: DST-932, INSTALLATION & OPERATION MANUAL [PDF]

Quoting: The DST-932 differential temperature controller is designed for the Solar Heating Systems. The DST-932 switches on a pump in order to transfer heat from solar collector to a storage tank.

The controller reads the temperatures of the storage tank (T1) and of the collector (T2), when this differential temperature (T2-T1) is higher than a set value (dt), it will switch on the pump.

It is possible to limit the maximum temperature of the storage tank and also activate a freeze protection function. By switching to manual mode it allows the test of the heating system by turning the pump ON or OFF.

A universal sensor P-01 or P-02(higher temperature range) is supplied with the control. This solid state temperature sensor probe can be extended up to 500 feet.

- i-Link SERIES ZONE CONTROLS (CIRCULATOR PUMP SWITCHING RELAYS ) FOR HYDRONIC / RADIANT FLOOR HEATING SYSTEMS INSTRUCTION MANUAL [PDF] SP-82/83/84/85/86 note that The company offers Models SP-81 to SP-86

- CA, BUILDING HVAC REQUIREMENTS [PDF] California Department of Energy, retrieved 2023/05/31, original source: energy.ca.gov/sites/default/files/2021-03/2019_Chapter 4 - Building HVAC Requirements_ADA.pdf

See serction 4.7.2 Radiant Floor System for design requirements - John Siegenthaler, is a professional engineer specializing in radiant heat designs and heat transfer theory in buildings. Mr. Siegenthaler principal of Appropriate Design, a consulting engineering firm specializing in hydronic heating design.

He is the author of Modern Hydronic Heating and Radiant Precision (available from the Radiant Panel Association (www.radiantpanelassociation.org, 800-660-7187).

Siegenthaler explains in various articles that the rate at which a hydronic heating system can actually move "sensible heat" from the heating source (perhaps hot water in tubing in a radiant floor slab) into the occupied space (perhaps a room in a building over such a floor) can be calculated as q=(8.01 x D x c) x f x (deltaT). This formula is not as intimidating as it may seem.

Even though our contractor said all of this theory was nonsense, q= the rate of heat flow in Btu/hr, D= density of the fluid (lb/cubic foot), c = the specific heat of the fluid (Btu/lb/degrees F), f= the fluid flow rate in the tubing (gpm), delta T= the temperature change of the heating fluid in deg F, and 8.01 is a units conversion factor.

For a discussion of heat transfer or flow through soil or dirt,

see SOIL R-VALUES

- Holdrite, Tel: 1 (877) 700-4242 Web: https://www.holdrite.com/ - We could not find a physical address on the company's website.

Above: Holdrite's accessories for installing pex tubing include PEX tubing supports that clamp to the slab re-bar.

See these example

Holdrite PEX TUBING IN-SLAB SUPPORT INSTALLATION INSTRUCTIONS [PDF] Op. Cit.

The excerpt below pertains to the Holdrite 703-series in-slab "stub-up support" for PEX

In-slab stub-up supports keep PEX and conduit in place and can help prevent damage to stub-ups on the job site. The 703 Series prevents pipes movement while concrete is poured or and protects pipes while crews apply a smooth finish to the concrete slab.

Key features:

Available in single and double pipe runs for multiple slab depths Multi-run versatility for manifolds with interlocking feet IAPMO PS 42-2013 Material: Reinforced Polypropylene Fluid Temperature range: 32 F thru 200 F Temperature range: -10 °F to 120°F - HUD, PPFA, DESIGN GUIDE for RESIDENTIAL PEX WATER SUPPLY PLUMBING SYSTEMS [PDF] (2006) HUD, U.S. Department of Housing & Urban Development, Plastics Pipe Institute, Inc (PPI)

105 Decker Court

Suite 825

Irving, TX 75062

www.plasticpipe.org and Plastic Pipe and Fittings Association (PPFA)

800 Roosevelt Road, Bldg. C, Ste. 312

Glen Ellyn, IL 60137

www.ppfahome.org and Partnership for Advancing Technology in Housing

451 7th Street, SW

Washington, DC 20410

www.pathnet.org and NAHB Research Center, Inc.

400 Prince George’s Boulevard

Upper Marlboro, MD 20774

www.nahbrc.org retrieved 2019/09/20 original source: https://www.huduser.gov/portal/publications/pex_design_guide.pdf

Excerpts: Continuous-use temperature ratings as high as 200ºF (93ºC) are required as well as standardized chlorine resistance testing to ensure that the piping will withstand the most aggressive drinking water conditions.

Temperature and Pressure

PEX piping meets all requirements for pressure and temperature performance in residential applications.

Consensus standards published by the American Society for Testing and Materials (ASTM) International specify temperature and pressure-resistant capabilities of PEX pipe and all tubing used in residential applications bears the appropriate test marking.

In the event of a water heating system malfunction, PEX piping is designed to accommodate short-term conditions of 48 hours at 210ºF (99ºC) and 150 psi (1034 kPa) until repairs can be made.

The most commonly used safety relief valve (T&P) activates (opens) at either of these temperature or pressure conditions.

All PEX piping has been tested to withstand T&P activation for 30 days to ensure that safety requirements are met. As such, PEX systems DO NOT require the use of a special T&P valve.

ASTM F 876: Standard Specification for Cross-Linked Polyethylene (PEX) Tubing covers PEX piping that is outside diameter controlled, and pressure rated for water at three temperatures—160 psi @ 73.4ºF, 100 psi @ 180ºF, and 80 psi @ 200ºF.

Included are requirements and test methods for material, workmanship, dimensions, hydrostatic sustained pressure strength, burst pressure, oxidative (chlorine) resistance, and environmental stress cracking.

ASTM F 877: Standard Specification for Cross-Linked Polyethylene (PEX) Plastic Hot- and ColdWater Distribution Systems covers requirements and test methods for PEX hot- and cold-water distribution system components made in one standard dimension ratio, and intended for 100 psi water service, up to and including a maximum working temperature of 180ºF.

Components are comprised of piping and fittings. Requirements and test methods are included for hydrostatic sustained pressure strength, thermocycling resistance, fittings, and bend strength.

Also in this document see Figure 11.2 – Snow and Ice Melt Piping for a Driveway p. 92 - MacNevin, Lance, P.Eng., DESIGN AND INSTALLATION OF HYDRONIC SNOW AND ICE MELTING (SIM) SYSTEMS TO OPTIMIZE PERFORMANCE AND EFFICIENCY [PDF] Plastics Pipe Institute, Inc (PPI) 105 Decker Court Suite 825 Irving, TX 75062 www.plasticpipe.org retrieved 2019/09/20, original source: https://www.modernhydronicssummit.com/wp-content/uploads/sites/3/2017/09/MacNevin-Summit-2017.pdf

- Olesen, Bjarne W. RADIANT FLOOR HEATING IN THEORY AND PRACTICE [PDF] ASHRAE Journal July 2002 pp. 19-24. Retrieved 2019/09/27 original source: http://umh0717.edu.umh.es/wp-content/uploads/sites/482/2015/03/Radiant-floor-heating.pdf

Excerpt from "Conclusions"

Conclusions

The advantages of hydronic radiant floor heating include the efficient use of space and that cleaning is not required. Also, the system does not produce noise, cause drafts or use ducts. The system has uniform temperature distribution and is a low-temperature heating system.

In a radiant floor heating system, the required operative temperature may be obtained at a lower indoor air temperature. This reduces ventilation heat loss compared to more convective heating systems. The transmission heat loss is more related to the operative temperature and is more or less the same for convective and radiant systems. - OPTCO, Basic Hydronic underfloor - thermal storage 8 to 14 hours of control [PDF] sketch, provided by OPTCO, is not a conventional radiant heating system design -

and you'll see that the designer places the tubing too deep for efficient radiant heat delivery to the occupied space. However this design is intended for heat storage, such as in a solar heat storage system. See PASSIVE SOLAR DESIGN METHOD for more information. - Pexuniverse INSTALLING PEX TUBING IN CONCRETE SLABS [PDF] PexUniverse.com

5811 Foster Ave

Brooklyn , NY 11234

USA, Tel: 800-818-3201 Email: sales@pexuniverse.com - retrieved 2022/01/18 original source: https://www.pexuniverse.com/installing-pex-tubing-concrete-slabs

Pexuniverse handles a broad "universe" of PEX tubing and related HVAC and plumbing brands. - Radiant Floor Co. Radiant Floor DESIGN & INSTALLATION MANUAL 11th Ed. (2007) Radiant Floor Company Barton, Vermont Fax: 1-802-525-3940 1- 866-WARM-TOES 1-866-927-6863 1-802-525-1132 www.radiantcompany.com retrieved 2019/09/20 original source: https://www.radiantcompany.com/wp-content/uploads/radiantcompanymanual.pdf

- The Radiant Panel Association: Radiant Panel Association - Radiant Professionals Alliance

8512 Oswego Road

Suite 180

Baldwinsville, New York

13027

Phone (315) 303-4735

Fax (315) 303-5559

http://www.radiantpanelassociation.org/

www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=1 offers design guidelines at http://www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=115 including these insulation R-value and coverage details:

Application#, Minimum R-Value, and Insulation Coverage

The following insulation alternatives are given for Slab on Grade construction:

Alternate #1 [(Ti-To)x0.125)=R-value, with coverage from perimeter to below frost line ["Ti-To" means we calculate the necessary R-value as (Ratio of indoor to outdoor temperature) x 0.125]

Alternate #2 R-value=5, with coverage 4' horizontal or vertical at perimeter

Alternate #3 R-value=5, with coverage under entire slab and slab edge [this is our preferred design for a cold northern climate]

The Radiant Panel Association offers education and publications in radiant heat design. See radiantpanelassociation.org

Here's their page on hydronic floors: http://www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=99 where you'll see some vague "source temperature required" graphs that give relative but not absolute temperatures. - Radiantec, INSTALLING PEX TUBING FOR CONCRETE SLAB UNDERFLOOR HEATING [PDF] Radiantec, Inc., PO Box 1111, Lyndonville, VT 05851 USA, Tel: 1 800-451-7593 Web: https://www.radiantec.com/ - retrieved 2022/01/18 original source:

https://www.radiantec.com/installation-manuals/installing-tubing-for-concrete-slab-underfloor-heating/

Radiantec offers a wide selection of design and installation manuals using PEX tubing in buildings. - Suntouch SPACE WARMING MANUAL D12 Series [PDF] (2007) Watts SunTouch, 4500 E. Progress Place, Springfield MO 65803 USA Tel: 888 4232-8932 Website: www.suntouch.com radiant heat flooring systems

- Takagi radiant heat systems: Takagi offers pre-assembled radiant heating system installation packages including for do-it-yourself'ers, and including systems that combine radiant heat flooring with domestic hot water production using a gas-fired tankless water heater. See takagi.com for more information. "The T-KJr model (gas inputs up to 140,000 BTU per hour) is the smallest unit in the Takagi line-up. The T-KJr is perfect for light residential (i.e. small apartment units) and radiant heating applications." Also see Tankless WATER HEATERS.

- ThermoTile RADIANT FLOOR HEATING MAT INSTALLATION MANUAL [PDF] from ThermoSoft, Corporate Headquarters 701 Corporate Woods Pkwy Vernon Hills, IL 60061 Tel: 847-279-3800 Fax: 847-279-8845 www.thermosoftinternational.com info@thermosoft.com Tel: 855.819.3015 Email: info@thermosoft.com Website: https://www.thermosoft.com/docs/tt_install_guide.pdf This company has offices in Canada, Chile, the U.S., Germany, Russia, the UK, Slovakia, and Japan.

- Uponor RADIANT HEAT RODUCT CATALOG [PDF] (2022) - Uponor GmbH P.O. Box 1641 97433 Hassfurt Germany T +49-(0)9521 690 0 F +49-(0)9521 690 750 E international@uponor.com Web: uponor.com

- U.S. DOE "Radiant Heating Systems"

- U.S. DOE ABSORPTION HEAT PUMPS & COOLERS [PDF] ,

- U.S. DOE SOLAR AIR HEATING [PDF] U.S. DOE also referred to as "Ventilation Preheating" in which solar systems use air for absorbing and transferring solar energy or heat to a building

- U.S. DOE SOLAR LIQUID HEATING [PDF] U.S. DOE, systems using liquid (typically water) in flat plate solar collectors to collect solar energy in the form of heat for transfer into a building for space heating or hot water heating. The term "solar liquid" is used for accuracy, rather than "solar water" because the water may contain an antifreeze or other chemicals.

- US DOE page on Radiant heating : web search 10/11/2010, original source: http://www.energysavers.gov/your_home

/space_heating_cooling/index.cfm/mytopic=12590 is, unfortunately short on details. - US DOE SOLAR WATER HEATING SYSTEM MAINTENANCE & REPAIR [PDF] , U.S. DOE

- US DOE SOLAR WATER HEATING SYSTEM FREEZE PROTECTION [PDF] , U.S. DOE,using antifreeze mixture in solar water heaters (or other freeze-resistant heat transfer fluids), as well as piping to permit draining the solar collector and piping system.

- US DOE "Scaling and Corrosion in Solar Water Heating Systems", U.S. DOE

www.energysavers.gov/your_home/water_heating/index.cfm/mytopic=12850 is the base U.S. DOE website for these articles - US DOE ACTIVE SOLAR HEATING SYSTEMS [PDF] , U.S. Department of Energy, including

- WARMBOARD APPROVED RADIANT HEAT TUBING LIST [PDF] Warmboard, retrieved 2023/06/06, original source: warmboard.com/wp-content/uploads/2022/03/ApprovedTubingList.pdf

- WARMBOARD-R PANEL INSTALLATION GUIDE [PDF] Warmboard, retrieved 2023/06/06, original source: warmboard.com/wp-content/uploads/2022/03/InstallGuide_Warmboard-R.pdf

- WARMBOARD-S PANEL INSTALLATION GUIDE [PDF] Warmboard, retrieved 2023/06/06, original source: warmboard.com/wp-content/uploads/2022/03/InstallGuide_Warmboard-S.pdf

- WARMBOARD TUBING & MANIFOLDS INSTALLATION GUIDE [PDF] Warmboard, retrieved 2023/06/06, original source: warmboard.com/wp-content/uploads/2022/03/InstallGuide_TM.pdf

- WattsRadiant, RADIANT PEX® INSTALLATION MANUAL [PDF] (2017) Watts Radiant, USA: Tel: (800) 276-2419 WattsRadiant.com Canada: Tel: (905) 332-4090 Web: Watts.ca Latin America: Tel: (52) 81-1001-8600 • Fax: (52) 81-8000-7091 WattsRadiant.com - retrieved 2019/09/20 original source: media.wattswater.com/IOM-WR-PAP-PEX-PEXAL-PERT.pdf

Reader Q&A

On 2022-07-04 by InspectApedia-911 (mod) - properly-constructed concrete slab can carry considerable weight

@Zack,

Fair question but as you put it, not possible to answer. A normal, properly-constructed concrete slab can carry considerable weight but "heavy machines" is undefined. For sure there are industrial installations where an engineered slab to carry much greater weight could be required.

On 2022-07-02 by Zack

In a commercial building with heavy machines and 6” slab with radiant heat, would insulating under it compromise the concrete .

On 2021-11-23 by Inspectapedia Com Moderator - an accurate radiant heat floor design is important

@warren gilmore,

The radiant heat floor design that would be right for your house should be informed by an on-site meeting expert I don't know something about how the home is constructed including his insulation, windows, sun exposure, heat loss rate at cetera.

Generally people want the garage heat to be on a separate Zone and therefore a separate loop from other radiant heat sections and in the living area is generally the installer may run the tubing closer together in areas where a cold floor would be least welcome such as in a bathroom.

You mentioned vapor barrier but of critical importance are the quantity and workmanship of insulation installed below your slab. If that's not done correctly you could end up with a system as bad as the one we described on this page.

On 2021-11-22 by warren gilmore

I am pouring a slab floor garage and living space one floor 50ftx 60 ft. 30ft garage 30ft living space what would you do for the garage area for radiant heat and for the living space? would you use the same patern for both spaces? and be 2" from the top of finnish slab.and what kinda of vaper bearier would you use for the ground?

cover under the radiant heat tubing?.this home is in western washington the N.w.. Thank you

On 2021-11-01 by inspectapedia.com.moderator

@Roger Shields,

Certainly there are some small radiant heat system boiler is made entirely of stainless steel. But I'm not sure that would solve the oxygen problem.

On 2021-11-01 by Roger Shields

Is it possible to obtain pumps, boilers and other fittings and equipment that do not contain iron so non oxygen barrier pex can be used? Are non iron equipment more expensive

On 2021-07-11 by inspectapedia.com.moderator - where should radiant tubing be laid

@Anonymous,

We don't know the construction, dimensions, layout of your home - details one would need to make a technically-confident reply to your question,

but in general bathrooms are places where people most like a warm floor as that's where we're barefoot and standing on tile, not warmer wood or other surfaces.

Depending on the layout of your bathroom, I'd at least like to have radiant heat under the walking-on part of the floor and might omit it under a vanity and certainly not close to the sides of a toilet;

so if it were my bath I'd include radiant heat the wider most-walked-on area of the floor.

On 2021-07-10 by Anonymous

I'm putting in slab hydronic radiant floor in new construction basement. My contractor did not run tubing in my bathroom saying that there's enough tubing in the rest of the flooring that the bathroom floor will only be about 1 degree less than the rest of the flooring. Should I have him run the tube in the bathroom?

On 2020-12-29 - by (mod) - radiant heat boiler on-time in cold weather

When weather is colder, John, you would expect to see the boiler on for a longer interval;

Affecting the boiler cycle rate are a number of factors; to decide if it's behaving normally we ought to review those:

- outdoor temperature

- age and type of building - some idea of rate of heat loss

- presence of mixing valves and manifolds that recycle radiant heat floor water and keep it from reaching a too-high temperature

- setting of temperature for the floor loops

- settings on the boiler's aquastat itself: HI LO DIFF

- presence or absence of a domestic hot water tankless coil on the boiler

- boiler fuel: oil/gas

- temperatures seen on the boiler gauge (and pressure)

Generally a longer "ON" cycle is more-efficient; it takes about 5 minutes for a boiler to get up to full operating temperature.

On 2020-12-29 by John H - is it better to run the boiler for longer intervals?

Thank you very much for the swift reply! I'm sorry but I'm utterly ignorant in this area so for clarification I have to ask - is it acceptable to have the boiler cycle on/off every 12 minutes or so as it currently does or is it not the best way to operate the system?

Would it be better to have it run continuously for longer periods of time? Or does it matter and either way is fine? Thank you again for your help and patience. :-)

On 2020-12-28 - by (mod) - boiler may run nearly continuously in very coldest weather

John

That sounds perfectly reasonable to me. You may find that on the coldest days of the year your heater is running almost continuously but on other days it should be running at a much smaller percentage of the time just as you described.

On 2020-12-28 by John H - boiler cycles on-off every 2-12 minutes

I bought a home with hydronic floor heat (it was built in 1999). It's a one-story on a slab and has no basement. The system is one zone and serves the entire house (~1400 square feet) and the insulated 4-car garage. There is only one thermostat for it that I currently use as an off-on switch.

I've never before had a hydronic system and don't really know whether I'm operating it in the best way, and am hoping you can provide insight. I currently have it set up to provide 80 degree water to the floor piping and run it 24 hours per day, 7 days a week starting in mid-October through April.

The boiler cycles, burning for about 2 minutes and is off for about 12 minutes - so the total burn time per day for the boiler is 4-5 hours. Is this a "good" operating scheme or would it be better to run the boiler constantly for two 2.5 hour intervals during the day, and increasing the water temperature water so the boiler is operating continuously?

Operating it as I do does keep the floors comfortably warm through the winter and the ancillary heat (electric forced air) only operates infrequently - usually when the outside temperature is at or below 0 degrees F.

Thank you for any help you can offer.

On 2020-09-28 by Linda

thank you for your rapid response. I'll contact an experienced radiant heat floor installer and pursue having the slab checked for insulation.

On 2020-09-26 by mod) - how to add a radiant heating system on top of an existing concrete slab floor

Linda

There are certainly radiant floor heat systems that can work perfectly well on top of a slab, covered by new flooring; the exact process and choices will depend on what kind of finish flooring is in mind and on the need for furring strips and a new layer of subfloor over the slab.

Those include hydronic radiant heat floor systems - tubing set atop the existing floor, over which a new floor is placed, perhaps using furring strips, subflooring, finish flooring, and electrical radiant heating systems that can be installed similarly.

Thin film radiant heat systems, other electric radiant heat floor systems as well as hydronic or hot water radiant heat flooring systems are described on this page and at the

RECOMMENDED READING links at the end of this article.

Shown here is ThermoSoft's electric radiant heating mat, sold in 15 square-foot sections and that is used under ceramic or stone tile finish flooring.

Start by asking for guidance from an **experienced** radiant heat floor installer in your area.

She may want to investigate under the slab to see what sort of insulation is there and if necessary she may want to add insulation before adding the radiant heat system.

Here are examples of electric radiant heat flooring systems

- ThermoSoft, Corporate Headquarters 701 Corporate Woods Pkwy Vernon Hills, IL 60061 Tel: 847-279-3800 Fax: 847-279-8845 www.thermosoftinternational.com info@thermosoft.com Tel: 855.819.3015 Email: info@thermosoft.com Website: https://www.thermosoft.com/docs/tt_install_guide.pdf This company has offices in Canada, Chile, the U.S., Germany, Russia, the UK, Slovakia, and Japan.

- Nuheat radiant floor heating cable

- WarmWire Radiant Floor Heating Cable Website: https://www.warmyourfloor.com

- Watts SunTouch, 4500 E. Progress Place, Springfield MO 65803 USA Tel: 888 4232-8932 Website: www.suntouch.com radiant heat flooring systems

On 2020-09-26 by Linda

I read your fascinating article on installing radiant heat systems when pouring slab foundations;

however, I'm in the process of purchasing a house with an existing slab foundation, built in 1974, and no history of whether insulation or vapor barriers were installed at the time.

I'd like advice on how to add a radiant heating system on top of the floor, with the intention of replacing the flooring currently in place.

On 2020-05-14 by Connie

Thank you for your help. As for the framing in shed it is block walls and trailer frame for rafters, very little wood. Have a great day

On 2020-05-13 - by (mod) -

Insulation will help wherever you put it; outside, be sure you don't provide a path for carpenter ants or termites up into wood framing.

On 2020-05-12 by Connie

We talked about trenching around the outside and insulating the wall down to footer. Inside is a little harder to insulate because of constant welding, grinding etc. Do you think placing insulated foam on outside wall would help? Hubby did lots of research on the in floor heat based on size of area for how many lines needed.

On 2020-05-12 - by (mod) - Mini Broiler could not keep up with heating the floor

Good news is that it looks like the tubing may be high in the slab.

Good news is that it looks like the tubing may be high in the slab.

I cant assess whether or not the amount if tubing is sufficient.

But the glaring need for insulation on the block walls, a large source of heat loss.

On 2020-05-12 by Connie

We have a block building with poured walls that we placed in floor heating. There is no insulation on the walls.

There is insulation on the floor, think either 2 or 3 inches thick with three lines of pex fastened down in a pattern per specifications read.

Think concrete is about 3 to 4 inches thick, based on pictures taken and have on computer. Purchased a Mini Broiler and in floor thermostat. Hooked everything up and after a few issues like broken line needing fixed the heat was turned on.

Mini Broiler could not keep up with heating the floor so purchased a regular water heater and also a timer. Thermostat set at 68 degrees and the timer set to kick on every hour for 15 minutes.

Our electric bill for the building runs on average $400 during the winter. I told hubby he needs to figure out a more cost effective way of heating the building. Either figure out why the in floor heating is not efficient or perhaps not hooked up properly or that the building needs to be insulated etc.

He is so busy working a full time job as well as the part time job in shed so I am trying to be proactive before fall arrives again with no answers to our problem.

Everything was done quickly and not fully experimented with like bigger water heater and no timer. Any advice will be much appreciated.

On 2020-03-05 by Anonymous - you would not bother to run radiant heat under cabinets

Michael

Normally you would not bother to run radiant heat under cabinets and IMO even more important, not under a refrigerator, but if it does run there it's not a catastrophe.

Arguing: in very cold climates putting heat under a kitchen base cabinet were plumbing enters and drains exit might help prevent a freeze problem.

Counter-arguing: under a refrigerator a warm floor might cause the fridge to have to work harder to get rid of its heat, thus increasing its operating costs.

On 2020-03-05 by Michael Peters

Do you install radiant heat pex under refrigerator and kitchen cabinets?

...

Continue reading at RADIANT HEAT MISTAKES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FLOOR TILE INSTALL on CONCRETE

- GAPS in RADIANT HEATED WOOD FLOORS - caused by running the radiant heat at too-high a temperature.

- DRIVEWAY & WALK DE-ICING SYSTEMS

- PEX PIPING INFORMATION

- PORTABLE ELECTRIC HEATER FAILURES - what happens when you rely on portable electric heaters for main heat source?

- RADIANT HEAT - home

- RADIANT HEAT AIR BOUND

- RADIANT HEAT CONTROLS

- RADIANT HEAT DEFECTS LIST

- RADIANT HEAT DESIGN & INSTALLATION MANUALS

- RADIANT HEAT INSTALLATION

- RADIANT HEAT MISTAKES

- RADIANT HEAT TEMPERATURES

- RADIANT HEAT TEMPERATURE CONTROL / MIXING VALVES

- RADIANT HEAT TEMPERATURE NIGHT SETBACK

- RADIANT SLAB FLOORING CHOICES

- RADIANT SLAB TROUBLESHOOTING

- RADIANT SLAB TUBING & FLUID CHOICES

- WOOD FLOOR RADIANT HEAT

Suggested citation for this web page

RADIANT HEAT DESIGN & INSTALLATION MANUALS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to RADIANT HEAT

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.