Radiant Heat Temperatures

Radiant Heat Temperatures

- POST a QUESTION or COMMENT about radiant heat system temperatures

Here we describe the proper operating temperatures for radiant heating systems, where and how to measure temperature, and typical temperatures for different types of radiant heating systems.

This article discusses the maximum, minimum, & recommended operating temperatures for radiant heated floor systems, including typical temperatures used in different types of radiant-heated floors: tile, wood, laminate, carpeting, etc.

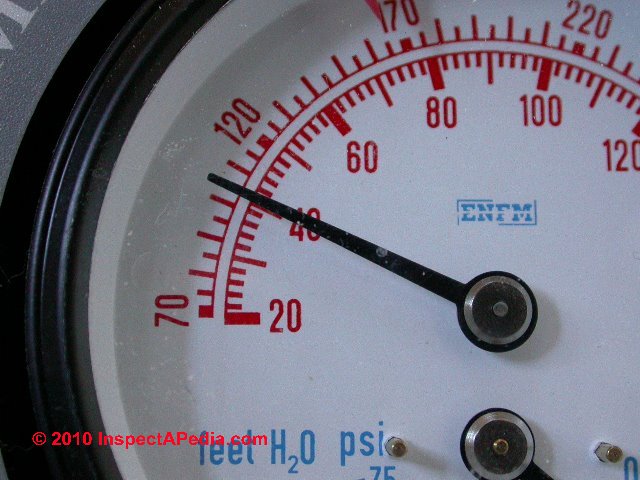

Our page top photo shows the output temperature of an electric boiler used to heat tubing in a radiant-heated tile floor set over concrete in a Minnesota home.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What are the Normal Operating Temperatures for Radiant Heat Systems?

This article describes actual radiant heat temperature settings and targets.

This article describes actual radiant heat temperature settings and targets.

We describe the normal or correct radiant heat setting temperatures and we explain what happens if the radiant heat temperatures are set too low or too high. And we discuss

- Radiant heat temperature settings at the boiler. Radiant heat temperature settings in the tubing.

- Maximum temperature for radiant-heated floor surfaces.

- Energy efficiencies of radiant floor heating. Heat loss rates into earth below radiant heated floor slabs.

- Operating temperature comparisons for types of radiant heating.

Photo: this Minnesota homeowner indicates the placement of radiant heat tubing in the slab of a new heated garage.

Article Contents

- RADIANT HEAT FLOOR TEMPERATURES (Typical)

- RADIANT HEAT FLOOR OXYGEN DIFFUSION

- RADIANT HEAT FLOOR TEMPERATURE CHECK

- RADIANT HEAT FLOOR IMPACT of CARPETING

- RADIANT HEAT CEILING TEMPERATURES

- RADIANT HEAT CEILING PANEL PRODUCTS

- RADIANT HEAT DRIVEWAY & WALKWAY DEICING SYSTEMS

- RADIANT HEAT CIRCULATOR FLOW RATES

- RADIANT HEAT SUPPLIERS & MANUALS

For help choosing, installing, and adjusting radiant heat temperature controls themselves, see this separate article:

- RADIANT HEAT TEMPERATURE CONTROLS & SAFETY DEVICES

Here we add details about different operating temperatures for radiant heating systems.

...

Typical Radiant Heat Floor System Operating Temperatures

Typical radiant floor systems operate at 85 - 125 °F water temperature entering the tubing, and put the floor surface temperature about 5 degrees above the room thermostat set temperature.

Typical radiant floor systems operate at 85 - 125 °F water temperature entering the tubing, and put the floor surface temperature about 5 degrees above the room thermostat set temperature.

Similarly other sources such as the Oregon state energy conservation department gives the typical operating temperature range for radiant heating systems at 85-140 °F (30-60C) though we agree that 140 deg. F. is a bit higher than suggested by other sources.

A radiant heat system manufacturer, Radiant Floor Company, opines that 120 to 135 deg F is "ideal" and most sources we have found discuss typical radiant heat operating temperatures in the 115-135 degree range.

Where PEX tubing is used for radiant-heat under-floor tubing, 125 to 130 °F is typical operating temperature used for water entering the tubing.

Most radiant floor heating systems we've examined run at around 115F water temperature entering the tubing of the radiant section, and you'll see by the temperature gauge at the top of this article that 115 °F was the factory default set temperature on the control of an electric radiant heat boiler we installed.

The control on that boiler's circuit board is shown just above.

But as we explain below, the optimum operating temperature for radiant heat floor systems will vary depending on the insulating or heat-conducting properties of the flooring material itself.

Photo above: adjustment dial for setting the radiant heat water temperature for a radiant heat floor system that turned out to be unusuable: the contractor omitted good insulation under the slab.

You can avoid that fiasco by a review of RADIANT HEAT MISTAKES.

Typical Temperatures at the Upper Surface of Radiant-Heated Floors

Our photo (above) shows our friend Steve and his dog explaining the radiant heat tubing layout in the new garage floor slab of a Minneapolis MN home. Radiant heat tubing was installed under the concrete floor to provide a heated garage.

The open corner garage door design permitted cars to turn into the garage from a narrow alley.

Unless you have a black crayon and an infrared thermometer it may be a bit more difficult to measure the finished-floor surface temperature (what your bare feet would feel when walking on the floor) than it is to just look at a temperature gauge on the hot water heating pipes or heating boiler themselves, but looking at the finished floor surface is one important temperature to note.

The finished floor surface temperature is what the building occupants feel when walking on the floor, affects the rate of heat radiating into the air above the floor, and if too high, can also become a safety concern.

According to CMHC (Canadian Mortgage and Housing Corporation) the finished floor temperature should never exceed 85 F (29 C).

Watch out: Note that for special installations such

as DRIVEWAY & WALK DE-ICING SYSTEMS installation the radiant heat system operating temperatures will be higher than used in an in-building heating system.

Be sure that the tubing you select is rated for use at that operating temperature.

Our photo shows an abandoned driveway de-icing radiant heat system that has been abandoned. Only the manifold remains in place near the home's heating boiler.

Our photo shows an abandoned driveway de-icing radiant heat system that has been abandoned. Only the manifold remains in place near the home's heating boiler.

Watch out: if you saw 167.8 F at the boiler, that sounds too hot for normal circumstances on a radiant heating system. Running a radiant heat system hotter than necessary can have a range of harmful effects including:

- Shorter heating boiler life

- Shorter radiant heat tubing life

- Oxygen diffusion problems [discussed below]

- Uncomfortably hot or even dangerously hot floor surfaces

- Unnecessarily high heating system operation costs

See PEX PIPING INFORMATION for more details about temperature ratings of plastic tubing. It may be useful to ask why someone has set the temperature of this radiant heating system so high. It could be

- Simply a mistake

- A control not functioning properly

- An improperly installed or designed radiant heat system that is not delivering adequate heat into the occupied space

- A misunderstanding of the controls or a misread of the temperature at the wrong location. See "Where to Check the Temperature ..." at the end of this article.

Typical Radiant Heat Temperatures Under Ceramic Tile

Under ceramic tile a higher temperature might be allowed without risking floor damage (we don't have wood shrinkage for example) and/or might have been set by a homeowner who likes a really warm bathroom floor.

But since ceramic tile is a *better* heat conductor than wood flooring, if anything, one would expect the temperature setting for that floor to be lower, not higher than otherwise.

Radiant under ceramic tile or vinyl tile, lower end of the temp;

Typical Radiant Heat Temperatures Under Finished Wood Flooring

Under wood floors nailed right to the subfloor and tubing below, radiant heat temperatures are typically at the middle of our 85-135 °F. temperature range, or about 105-115 °F. Electric radiant heat systems may warm the floor to just 75 °F.

Under wood floors nailed right to the subfloor and tubing below, radiant heat temperatures are typically at the middle of our 85-135 °F. temperature range, or about 105-115 °F. Electric radiant heat systems may warm the floor to just 75 °F.

The radiant heated wood floor shown in our photo (left) was installed asd a retrofit in an older a New York home.

The finish flooring was 3/4" oak over plywood subflooring and was run too-hot, resulting in shrinkage gaps and floor damage. How did this happen?

Attempting to "drive out" tubing odors the installer pushed the floor temperature up a bit too high, taking the blame for gaps that appeared in the flooring as a result discussed at

at GAPS in RADIANT HEATED WOOD FLOORS - caused by running the radiant heat at too-high a temperature.

See also WOOD FLOOR RADIANT HEAT design.

Radiant Heat Temperatures Under Laminate Flooring

Under laminate type finish flooring, keep the temperature under 82 °F or risk floor damage (per http://www.shawfloors.com/)

Radiant Heat Floor Under Carpeting: R-Values & Operating Temperature

While carpeting isn't the most-effective walking surface over a radiant heat floor system, it can work provided you use thin carpet with minimal or no padding. The total R value of any or all materials to be laid over a radiant heat floor should be held to less than R-4 and ideally held to R 2.5 or less.

Under carpet over subfloor, radiant heat will need to operate at the higher end of its temperature range to overcome the insulating effect of the carpeting and carpet padding. Keep in mind that carpet padding or foam backing on carpeting can, by itself add an R-value from R-0.8 to R-2.

Watch out: some radiant heat product manufacturers will void your radiant heat warranty if you install carpeting of any type over their radiant heat system.

...

Oxygen Diffusion in Too-Hot Radiant Heated Floors

Radiant Floor Company, a radiant heating system manufacturer, raises another interesting point, indirectly:

at temperatures over 140 °F can cause an oxygen diffusion problem and require special "oxygen barrier" tubing in some cases (depending on the boiler design) - otherwise system life may be reduced or the boiler damaged.

...

Typical Temperatures for Radiant Heat Ceilings

Question: What should my my hot water temperature be so I don't crack my ceilings?

(Oct 15, 2018) Ronald Tabellione said:

I have radiant heat hot water system in my plaster ceilings. What should my my hot water temp be so I don't crack my ceilings.

I have 2 zone heat and a brand new furnace. House built in 50's

Reply: 150-170 degF in the ceiling or wall panels

Radiant heat ceilings generally run in the 150-170 degF. range - thus delivering more BTUs per square foot than radiant floor heating.

Radiant heated ceilings and possibly radiant heat wall panels can operate at significantly-higher temperatures than radiant heated floors, probably because we need to be able to walk on the floor without getting a hot-foot.

The wiring in some electrical radiant heat gypsum board (drywall) panels is rated for 250 degF but doubtless operates well below that.

Here are some details and information sources. I'm collecting more and will add that to this page.

Floor heat temperatures, in comparison with radiant heated ceiling panel temperatures

typical operating temperature range for radiant floor heating systems at 85-140 °F (30-60C) though we agree that 140 deg. f. is a bit higher than suggested by other sources.

The US DOE notes that

Radiant floor heating systems are significantly different from the radiant panels used in walls and ceilings. - www.energy.gov/energysaver/home-heating-systems/radiant-heating#307668-tab-0

Regrettably the DOE doesn't give any different temperature ranges for radiant panel heat in walls or ceilings.

...

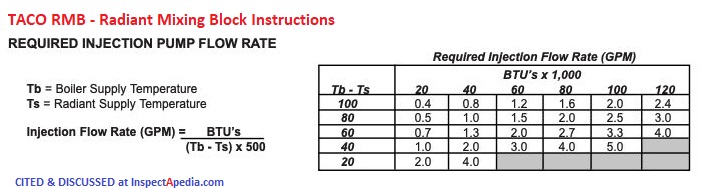

Minimum and Maximum Circulator Flow Fates for Tankless Water Heater Radiant Heat Systems

Reader question: A tankless water heater has a minimum and maximum circulator flow rate however I have not seen this addressed in any radiant heat open or closed designs. Why?

AOsmith has this note in their orders manual.

"The recirculation pump is to provide no less than 2 GPM (7.5 L/min) and no more than 4 GPM (15 L/min) through each activated unit in the system." - On 2021-01-25 by VU

-

This Q&A were posted originally

at CIRCULATOR PUMP REPAIR FAQs

Here are the recommended flow rates for radiant heat in-floor systems and how is the flow rate adjusted?

VU

VU

Thank you, that's a great question that I'd re-phrase as: What are the recommended flow rates for radiant heat in-floor systems and how is the flow rate adjusted?

I'm not an expert on the question but I can offer some comments and explanation, and I'll research further and improve this text.

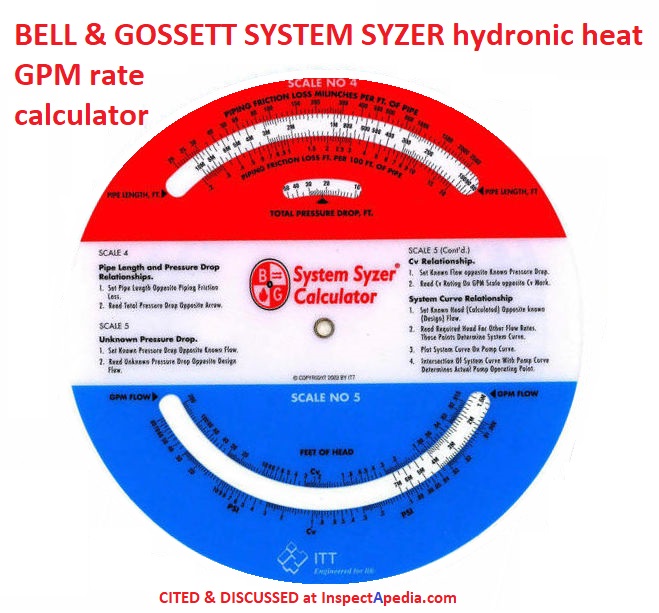

Illustration: Bell & Gossett's Sysetm Sizer calculator wheel, one of several tools the company provides free to HVAC installers and designers to permit calculating the required heating water flow rate for a building.

Watch out: Keep in mind that the actual flow rate in GPM that you need to heat a building's occupied space depends on the building properties including square feet, volume, heat loss rate and heating zone or climate.

So there will not be a single "one-flow-rate-fits-all" answer for hydronic heat flow rate needed.

The basic hydronic or hot water heat flow rate calcuation for buildings, widely discussed, is

GPM Required = Heat Load1 / 5002 x DeltaT2

where

- Heat Load

= the heat loss rateor heating load for the building expressed as BTUs/Hour - 500

= a constant representing the weight and volume of water at a standard temperature, expresses as

8.33 pounds per gallon x 60 minutes at 60°F

Note that more-accurately the water temperature must be adjusted from 60°F to the actual higher temperature used for building heating

- Delta t°F

is the difference in water temperature between water leaving the heating boiler and water returning to the boiler - typically designers use t°F = 20°F

- Source: Bell & Gossett Systm Syzer, available free at https://bellgossett.com/selection-sizing-cad-tools/system-syzer/ available as a computer program, an app, and historically as a round cardboard calculator wheel that you can order from your local B&G supplier.

In general, radiant heat floor flow rates are much less than those used other hydronic heating systems employing baseboards or radiators.

In general, radiant heat floor flow rates are much less than those used other hydronic heating systems employing baseboards or radiators.

- Hydronic heat flow rates in GPM:

typically have a capacity between 0 and over 50 GPM with a typical residential hydronic heat circulator (e.g. Taco 0015e3ECM) running between 0 1nd 16 GPM. - Radiant floor heat flow rates

in GPM: typically operate between 0.4 GPM and 5.0 GPM [see Taco's RMB table below] and the system maximum flow rate or GPM capacity will run between 0.4 and 15 GPM.

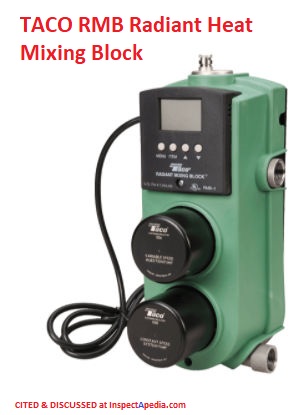

Illustration: the Taco Radiant Heat mixing block used to control flow rate and thus BTU outpout of radiant heat systems.

[Click to enlarge any image]

Water flow rates for Domestic Hot Water Production

Watch out: your question cites minimum and maximum flow rates for tankless water heaters. A tankless water heater is used to produce domestic hot water (for washing and bathign) and is absolutely not intended for use as a building space heater (hyrdonic heating to keep occupants warm).

Do not confuse hot water for domestic use with hot water for heating.

Tankless water heater flow rates are indeed specified by the manufacturer, such as your cited

no less than 2 GPM (7.5 L/min) and no more than 4 GPM (15 L/min)

because at too slow a speed the heater might overheat or might not even turn on its heating element (for safety), while at a too high-flow-rate the tankless water heater can not heat the pasiing water hot enough for domestic use (washing and bathing).

Watch out: also if you are using a tankless water heater as your heat source for a building radiant heating system, make sure that the manufacturer agrees that the tankless water heater you have selected is rated and acceptable for that level of usage.

Water Flow rates for Building Heating Systems

Hot water flow rate through any hydronic or radiant heating system will indeed affect the heat output: flowing faster delivers more BTUs per minute to a given length of radiant tubing or baseboard, but I suspect an accurate equation is far more complex than meets the eye.

We need both temperature and time of contact to conduct heat out of hot water into and thus out of a radiating device.

And in-floor hydronic radiant heat systems are more-complex than a conventional baseboard or radiator heating system in that we also need to keep the floor temperature from rising anywhere near the surface temperature of a conventional radiator or baseboard, lest we burn the occupants' feet or damage the floor itself.

So radiant floor systems use a mixing system that recirculates the same hot water through the flooring loop, mixing in a bit of hotter water from the boiler under the control of one or more radiant loop thermostatic controllers monitoring the temperature of the return water.

That temperature control is in addition to the aquastat on the boiler itself.

So you can see that regulating flow rate rather than thermostatically-controlled hot water mixing much complicates the question of whether or not we should be concerned with varying the gpm rate of the circluator pump itself.

In fact the terms "GPM" and "Flow Rate" do not even appear in many circulator pump IO manuals.

See the various circulator pump manuals provided at

CIRCULATOR PUMP MANUALS

The simplest approach used by heating system installers or designers is to choose a circulator that, at a given temperature range, can deliver sufficient BTUh of heat to the heated area - which of course varies by area size and heat loss rates and the total amount of radiating equipment.

Taco offers products specifically designed for radiant heating systems such as the company's

TACO RMB RADIANT MIXING BLOCK INSTRUCTION MANUAL [PDF] (2015) TACO, INC., 1160 Cranston Street, Cranston, RI 02920 USA Tel: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8 Canada Tele: 905/564-9422. FAX: 905/564-9436.

Website:

http://www.taco-hvac.com

from which the table below is excerpted.

[Click to enlarge any image]

Specifications fodr the Taco RMB discussed here include:

Flow Range: 0-15.5 GPM

Head Range (ft): 0-15′

HP: 1/40, 1/25

Max. Fluid Temp.: 185°F (85°C)

Min. Fluid Temp.: 32°F (0°C)

Max. Working Pressure: 125 PSI

Connection Size: ¾” NPT

Additional Taco radiant heat system conrols are found

at TACO HVAC components & controls

I will review our documentation on radiant heat system installation and controls: there are indeed controls on radiant heat systems that will affect flow and temperature, but to date our focus, and that in the documents I've read and systems I've worked-on has been on getting the right temperature rather than the flow rate in gpm;

I will repeat the question and include a reply in the reader Q&A at

RADIANT HEAT TEMPERATURES

If I find enough different material on flow rates for radiant heat I'll spin that off into a new article. Thank you again for asking.

Most hyrdonic heat system circulator pumps do not have an adjustable flow rate, though a group of circulators have a variable speed control, such as the Taco brand - take a look at the conventional hydronic - hot water - heating system flow rates discussed at

CIRCULATORS VARIABLE SPEED

in a section titled

CIRCULATOR PUMP SPEED SELECTION & ADJUSTMENT

We welcome your further questions, comments, suggestions.

Reseach & Support for Heating Load Calculators and Hot Water Heat Flow Rate Calculations

- Bell & Gossett System Syzer Hydronic Heating System Flow Rate & BTU/H Calculators - https://bellgossett.com/selection-sizing-cad-tools/system-syzer/

See details and manuals

at BELL & GOSSETT B&G EQUIPMENT MANUALS & CONTACT - Carey, George How to Calcuate the Proper Flow Rate for any Hydronic Sysetm, Indoor Comfort, web article (2019) original source: https://www.indoorcomfortmarketing.com/how-to-calculate-the-proper-flow-rate-for-any-hydronic-system also available as archived copy at https://inspectapedia.com/heat/calculate-GPM-Flow-Rate-for-Hydronic-Heat-Carey.pdf

- TACO HVAC components & controls

...

Radiant heat ceiling product manufacturers

Note that some of these radiant heat ceiling or wall panels are entirely electric; other radiant heat panel systems use hot water from a boiler or from a solar heating system.

- Calorique Perfectly Warm Radiant Ceiling Heat, 2380 Cranberry Highway West Wareham, MA 02576 USA Tel: 800-922-9276 Email: info@calorique.com Website: https://www.calorique.com

- Enerjoy Radiant Heating Systems, SSHC, Inc.

P.O. Box 769

Old Saybrook,CT 06475

USA, Tel: 800-544-5182 or 860-399-5434

SSHC, Inc. 1244 Old Clinton Road Westbrook, CT 06498 Email: info@sshcinc.com

Enerjoy produces radiant heat modules - electrical panels that can be installed on a ceiling or possibly a wall. - Messana Radiant Cooling and Heating ceiling solutions Messana Radiant Cooling

4105 Soquel Dr, Suite B

Soquel, CA 95073

USA

Tel: (855) RAY MAGIC (729-6244) Email: info@radiantcooling.com Website: https://radiantcooling.com/

radiantcooling.com/messana-radiant-cooling-products/ray-magic-radiant-panel/

Products include an EPS radiant panel built into sections of drywall that can be installed on walls and ceilings. - Thermaray Therma-Ray Inc.

670 Wilsey Road, Unit 6

Fredericton, New Brunswick

Canada E3B 7K4 Tel: 866-457-4600 Website: thermaray.com/radiant-ceiling-electric-radiant-heating-system/

Thermaray produces electric radiant heating systems for floors, ceilings, and other applications such as driveway de-icing systems and snow melting.

I am collecting more operating temperature specifications for those radiant heat panels and will add that information, product specifications, etc. here.

...

Where to Check the Temperature of A Radiant Heated Floor System

Mixed Radiant & Hydronic Baseboard or Radiator Heating Systems

Watch out: often there are mixing and flow controls on the radiant system that limit the actual temperature in the radiant tubing, typically by only introducing new hot water into the loop when temperature requires it - otherwise recirculating most of the loop water without returning it to the boiler.

You will particularly see this if the boiler is serving a mixed-design system, including some heating baseboards and other radiant floor heated sections.

That's because we want the hotter temperatures in the baseboards (hotter is more efficient heat transfer), and cooler temps in the radiant flooring.

So: was this a mixed design system with some baseboards and some radiant? and were there mixing controls on the radiant loop section ?

Question: how can I boost the temperature of our radiant-heated floors?

I have radiant heat floor throughout my house and I have some questions about boosting its output. I’d love to enlist the serves of someone from your team who can answer questions about heat exchangers, optimal temperatrures, max temperatures, etc.

The sooner the better as we are feeling chilly at the moment. - Anonymous by private email 2017/12/11

Reply: (Mod) said: take care not to over-boost radiant heat floor temperatures

I may be able to answer specific questions or I may have a few suggestions but you will be best served by an on-site expert who can look at your equipment, controls, house and its design and points of heat loss.

I may be able to answer specific questions or I may have a few suggestions but you will be best served by an on-site expert who can look at your equipment, controls, house and its design and points of heat loss.

Watch out: In general, if you boost temperature too high with a radiant heat floor you can find the floors too hot to walk on comfortably; and of course adding rugs to make walking comfortable block the heat output.

- I would take care to keep your radiant heat temperatures in the heating loop under 135°F (57°C).

- The finished floor temperature should never exceed 85°F (29°C).

That is typically managed by adjusting the temperature controls at the mixing valve that maintains the floor temperature by mixing in return loop water with outgoing water from the circulator/boiler.

Too much heat can also damage floors if they're wood, and too much heat may exceed the rating of the radiant tubing that was used, leading to a tubing failure - costly leaks.

My photo shows gaps that developed in a wood floor installed over radiant heat tubing after the radiant heat was driven to temperatures above those recommended by the radiant floor heat system manufacturer.

Start by finding the operating temperature of your system as it is.

Consider also looking over the home to reduce its heat loss, particularly if there are drafts.

I cannot assist on a for-pay consulting basis. We do not sell anything. In order to absolutely assure our readers that we write and report without bias we do not sell any products nor do we have any business or financial relationships that could create such conflicts of interest.

For reducing your home's heat loss these articles might be useful

...

Carpeting Impact on Radiant Heat Floor Systems

Question: does it cost more to operate radiant heat flooring covered by carpeting than by tile?

On carpet - while carpet may impact the performance of radiant heat, does it impact the efficiency? As in, am I spending more money trying to heat the carpeted areas of the house vs the tile?

I guess a bad carpet installed could insulate the floors so much that all the heat gets bled off into the uninsulated parts, but Id think even if I removed all the carpet in favor of LVP for example, Id still be using more gas due to other heat loss issues.

Can carpet cost more to heat? - Anonymous by private email 2019 09 27

Reply: yes

OPINION: Wall to wall carpeting, especially thick or heavy carpeting acts as insulation to slow heat transfer from the tubing and warmed slab up into the occupied space.

The result is that for the radiant heating system to satisfy the thermostat it has to stay on longer. It's a bit over-simplifying but a heat source that has to run longer to satisfy the room thermostat - all other factors being held constant - increases energy consumption and thus heating cost.

One would infer that during that "stays on longer" only if there were ZERO heat / energy losses through pathways that do not transfer heat into the occupied space would there be close to zero additional heating cost. So yeah we're heating something else besides the occupied space.

Even in a theoretically zero-entropy "perfect" heating system with zero heat losses through other pathways than into the occupied space, and thus zero additional heating energy cost (electricity or gas or oil or whatever), nevertheless simply running the circulator would add a little energy cost. And of course that ideal case doesn't exist in the real world.

"The capacity of a floor system depends on the heat exchange between the floor surface and the space (convective and radiant heat exchange coefficient), the heat conduction between the floor surface and the tubes (floor surface material, type of concrete, type of floor system, slab thickness, spacing between tubes) and the heat transport by water (water flow rate, temperature difference between supply and return). (Olesen 2002) Olesen is an ASHRAE fellow.

- Olesen, Bjarne W. RADIANT FLOOR HEATING IN THEORY AND PRACTICE [PDF] ASHRAE Journal July 2002 pp. 19-24. Retrieved 2019/09/27 original source: Universitas Miguel Hernandez, Instalaciones de Climatizacion, offering a masters degree in heating and electrical systems and energy efficiencyt, retrieved 219/09/27 original souirce: http://umh0717.edu.umh.es/wp-content/uploads/sites/482/2015/03/Radiant-floor-heating.pdf

Here is a key remark from that article

For maximum capacity, it is important to avoid floor coverings with a high thermal resistance such as heavy wall-to-wall carpets.

This increases the required water temperature and then also the back losses to ground or unheated space.

Also, higher water temperature reduces the efficiency of the heat generator (condensing boiler, heat pump).

Really? Well other energy losses can dominate heating cost. Very basic things the air leakage rates will dominate the heating load even in a well-insulated home. We've published some studies on this, for example see

and

...

Driveway & Walkway De-Icing Systems Installation

What are the basic design parameters, tubing sizes, operating temperatures and controls used in snow and ice melt systems (SIMs) for driveways, walks, and parking lots? Here we discuss these parameters and include links to detailed SIM design guides from experts in the field.

Question: can I mix 1/2" and 3/4" tubing on the same PEX radiant heat circuit

2019/09/19 Bill said:

I have a radiant floor heating system for two rooms with 1/2" PEX that works fine. When I put it in, I used a manifold with an extra space in case I wanted to add a circuit.

We are going to re pour front steps and sidewalk to the driveway and I thought that that would be a good use of my additional circuit. But I have read that any outdoor application should use 3/4" PEX instead of 1/2".

Can I mix have two circuits with 1/2" PEX and one with 3/4"? Can I just use 1/2" for the outdoor steps and sidewalk and expect it to keep the snow off? (I live in SE Michigan.)

This Q&A were posted originally

Reply: yes but watch out for some snafus: Design Parameters for Snow or Ice Melt Systems (SIMs) under Driveways & Walks

Bill

Depending on the heating load for your snow and ice melt system for your walk and driveway, you can use 1/2" PEX tubing. Here is a quote from the Radiant Floor Company who have provided an installation and design manual that we cite in detail below:

The 1/2” ID PEX is also a polyethylene tubing with a very high temperature and pressure rating (180 degrees at 100 psi). It emits about half the heat of the 7/8” PEX, but its bending diameter is tighter.

Using 1/2” PEX for small zones, tight crawl spaces, or snow melt applications makes sense. It has a bending diameter of 15” and should be spaced 8” to 12” on center. - Radiant Floor Company 2007

In a similar but not identical opinion, the Plastics Pipe Institute (cited below), in discussing outdoor de-icing systems notes that Pex Tube size for driveway and walk de-icing and snow-melt systems is typically 3/4 NTS but adds that 1/2 inch and 5/8 inch tubing is sometimes used.

What PEX tubing size you can use on a de-icing system or snowmelt system will be adequate depends on several factors

- the size of the area to be de-iced

- the drive or slab temperature when snow-fall begins and of courses the rate, density and depth of snow or ice on the surface;

- the outdoor temperature range anticipated. Wind velocity and sky temperature and teen outdoor humidity levels are also factors considered when computing the Snow and Ice Melt (SIM) system design loads.

- the design of the outdoor de-icing system (watch out: insulation and tubing placement are absolutely critical)

- the BTUH capacity of the heating boiler that's producing the hot water, and of course the circulator(s) and water flow rates possible

- other simultaneous loads on the system

- the type, placement, and quality of insulation under the drive or walkway

- the proper placement of the PEX or other heating tubing within the concrete or other paved drive or walkway surface - its proximity to surface versus bottom of the slab - detailed

at RADIANT HEAT MISTAKES

I'd start by making sure that the boiler providing hot water to the current and future systems has the needed capacity.

Then, yeah, you MIGHT be fine with 1/2" tubing.

Starting with our article RADIANT HEAT TEMPERATURES you'll see that outdoor or driveway or walkway de-icing systems need higher temperatures than indoor radiant heat flooring. Some details worth noting when choosing tubing for a de-icing or snowmelt system:

- You may need to re-size the hydronic boiler expansion tank when adding radiant heat loops for any purpose as the water volume is also going to increase

- Typically a Snow and Ice Melt System (SIM system) operates at two different temperatures:

an "idle" temperature of 28°F (-2°C) when melt operation isn't needed but the system is in "stand-by" mode,

a melting temperature of 38°F (4°C) when the system is at work; both of these temperatures must be adjustable for variation in local conditions. - PE-RT is a type of polyethylene tubing that has Raised Temperature-Resistance (CSSA B137.18)

- Your ice or snowmelt system will need to warm the melt-area by applying 051 BTU/lb (Op. Cit.). MacNevin, writing for the PPI, notes also that

That does NOT mean the same boiler can't serve both, but you'll need temperature regulation devices that provide the proper temperature for indoor versus outdoor PEX radiant heat tubing loops.

See the Radiant Heat Guides suggested just below. You will read that experts ( MacNevin 2016) discuss an array of additional controls such as drive or walk surface moisture monitors and other instrumentation that can improve both the efficiency and effectiveness of SIM (snow and ice melt) systems.

Night Time Setback Recommendations for Radiant Heat Slab Systems

Moved to RADIANT HEAT TEMPERATURE NIGHT SETBACK

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

What is "normal" and what is "too hot" for radiant heat water circulating in the piping?

I just inspected a complex combine forced air (hydronic) heating system combined with a several circulating radiant floor heating components.

My question is what is normal and what is “too hot” for the water circulating through the piping distribution under ceramic tile floors installed over wood framed floor systems.

When I took the Watts® Regulator course they emphasized that temperatures should not exceed 130 degrees.

During my inspection the water leaving the boiler was 167.8 degrees (going into the heating distribution system for hydronic radiant, hydronic forced and also potable (yeah, I know that part is a problem!). - Ron Wells (ASHI#515) Wells Inspection Services, Inc.

Reply: It depends ..

The high temperature effects of too-hot radiant heat under wood flooring, and the effect on finished wood flooring are cited

and more radiant heat design specs are

On 2020-12-14 1 by Richard Malik - radiant heat floor in pole barn

I have a pole barn with in floor heat. I did not install it (it was there when I purchased home)

This year it seemed like the boiler was running about 2 time as long as it has in the previous years and it has been somewhat warm (lows in upper 20 and highs in upper 30) the heated space is 40 x60 on one zone and 12 x 18 on another.

I had a repair man come check it and he said that the secondary pump was not running and that it was installed backwards ( pushing water in wrong direction) He replaced pump installed it correctly and he said see how that works. well it runs longer now that before he came and temps are the same.

the boiler is set to kick out about 166 degrees when heating the larger area it does not get above 120 degrees, until just before or just after it shuts down.

When heating the smaller area it goes up to the set point shuts off until the water cools enough and starts back up like it should

. I had him come back and he cleaned the boiler thinking maybe it was plugged and that did nothing The boiler is approx. 5 years old. I have a lazzer temp gauge and the water takes a very long time to heat up going into the loops

There are 8 loops not sure how long they are temps never get above 110 degrees goin into the floor with temps coming out about 95 at the highest.

Most of the time the floor is about 56 degrees risenig to about 60 degrees. temp is set on t-stat to 60 degrees. the boiler used to run about a hour or so with temps in this range when he first started it was running about 2 hours and after he changed the pump now it is running 3 hours. with the temps starting to go down It will be very costly to run. any ideas what might be wrong?

On 2020-12-15 - by (mod) - look for radiant heat floor tubing leak

Richard

Have you or your service tech found any indication that there's a leak in the floor tubing system?

And have you done a thermal scan to see if all of the tubing is eating correctly and that that also doesn't suggest that there's a leak?

Beyond those basic checks I think we're looking at temperature sensor control problem

On 2020-12-06 by (mod) - Takagi T-H3M-P heater is variable from 15k to 120k BTU

Excellent, so you can set it as you suggested. Thank you for the added detail.

On 2020-12-06 by Craig

The Takagi T-H3M-P heater is variable from 15k to 120k BTU output and can push up to 6.6 gallons per minute.

@Craig, 2.2 is max I could get system with everything wide open, so much for the 8 gallons, and with short runs did not expect that much drop in volume.

On 2020-12-05 - by (mod) -

Craig

I'm talking beyond my expertise here but IMO just pushing the water flow rate alone may not be sufficient; we also need to know that the heat source is capable of pushing energy or heat into the increased flowing water, in essence into an increased effective volume per minute.

On 2020-12-05 by Craig

Charts say I need 40k BTU to heat my house and that 10k BTU / 1 gallon/min is required so 4 gallons per minute.

Currently I am only pushing around 2 gallons, think I should find a way to bump that up to 4, pump is capable of 8 per documentation.

On 2020-12-05 - by (mod) -

Craig,

Thank you for the helpful description and comments. That will be useful for other readers.

On 2020-12-05 by Craig - Takagi water heater

FYI, the temp of the gauge at top of page is 105F, not the 115F referenced in article..

My Takagi water heater will pass water through system and not heat the water when incoming temps are within 15 degrees of outgoing temps.

I used your 115F temp recommendation and have mixture of slab and under floor and so far this heating season it is working well.

Temps have not fallen below 10F outside yet, and propane usage is low compared to previous system, old space heater.

I did not prepare and have thermostat in slab so using ambient air to regulate system, set at 70, area over slab is 73 and over wood floor 67. Small home 650 square feet, 100 year old cabin with addition that ran PEX into slab and tub/fin under old cabin.

Slab temp is 79 when running, feels chilly in room even with high R and new windows, wasn't sure if should bump up temp on water heater or thermostat to break that feeling. I did not use a mixing valve in my setup as the water heater passes return water within 15 degrees of set temp.

...

Forgot to add, it appears it is running at least 50% of the time in the evenings throughout the night until the sun comes up.

The Sensi thermostat will send me monthly usage reports, last month, with a week of warm weather injected into our fall isn't typical, but it claims 543 hours of use.

Not sure how valid it is as it has 80 heating and 463 fan only when there is no fan.. But will use to compare to the next month of typical temps of the season.

My bedroom is next to utility closet so I can hear the heater kick in, the damper clicks, and just faint sound of actual heating unit, pumps are silent.

Addition with a 16x16 slab has 2 - 150 foot runs, and the 16x26 100 year old cabin has roughly 200 feet of PEX with heat spreaders under its floor.

Wrapped whole place in styrofoam and sided after new windows, old having R80 attic, blown walls, addition R19 walls and R38 ceiling, before the R10 styro and new argon windows, so shouldn't be shedding too much heat.

Tossed up ACX plywood on ceiling old cabin as it had those old fiber panel tiles, and new is all BCX. Having an energy audit next month to see if I missed anything.

Just thought odd it running so often.

Set manifolds so each zone pushing about 0.6 gallons per minute with Takagi reporting 1.9 gallons per minute in total.

New to all of this and just went off information I could absorb in 6 months of scouring internet for tips on system. I can monitor incoming and outgoing temps and water flow, think just need couple tips on dialing this in, thanks.

On 2020-10-15 - by (mod) - typical operating temperature range for radiant heating systems ranges from 85 °F to 140 °F (30-60C)

Donna:

Thank you for a helpful question.

The typical operating temperature range for radiant heating systems ranges from 85 °F to 140 °F (30-60C)

So if an item would be harmed by exposure to those temperatures you'd want to place it elsewhere than directly on the radiant-heated floor.

On 2020-10-15 by Donna

Can I put items on top of a radiant heat register/surface?

I have a sound machine on it that is plugged into the wall as well as a picture and a large feather

Comment: suggestions for radiant heat temperatures in Maine

Radiant Man (Guest):

While doing some research, I happened on this very helpful set of articles. We live in Maine so winters are cold.

I am running a new and very efficient, cold start, oil-fired boiler driving two hot water baseboard zones (which are generally not turned on because our new heat pumps are very effective, but the baseboard will get used on days that get very cold), a 50 gallon hot water tank through a heat exchange plate (this cycles only when we use significant hot water), and one radiant heat zone.

The radiant heated zone is a single room of about 200 square feet with a tile floor over concrete in which the piping is installed.

The feed from the boiler to the radiant heat goes through a mixing valve and the temperature there is about 100. The wall-mounted, somewhat old thermostat is set at 69. The floor temperature is 71 + or - .5 degrees.

The boiler seems to cycle very frequently and often very short cycles. From what I have rea d, this isn't good for either energy efficiency or the life of the boiler.

I am wondering what suggestions you might have for this situation: turn up the water temperature for the radiant zone; use some other source for the radiant zone; figure out if a new thermostat or one that can allow temperatures in the room to fluctuate by say 4 degrees to lower cycles.

Any thoughts appreciated.

raymond.hepper@gmail.com

Moderator reply:

at AQUASTAT TROUBLESHOOTING inspectapedia.com/heat/Aqua...

we discuss oil burner short-cycling and offer some diagnostic suggestions. Take a look there and let me know if that helps.

On 2019-12-28 - by (mod) - tradeoffs in dropping radiant heat temperature: heater also used for domestic hot water

Jenn:

Generally it's true that dropping the heat temperature saves fuel or energy overall, though there are some trade-offs:

1. the system efficiency may be lower at lower operating temperatures (as heat transfer rate is less efficient)

2. If your tankless water heater is also making domestic hot water for washing and bathing you may find that the bath-water isn't sufficiently hot.

Typically a radiant heat flooring system includes a return-loop mixing valve that maintains floor temperature at an appropriate level while allowing the actual water heater to supply hotter water.

On 2019-12-18 by Jenn

Ps, we just have a concrete slab with infloor heating.

My partner and I had heard that keeping the temperature for our in floor heating to the tankless water heater set to 108 degrees was more cost saving than at 120 degrees. Is this true?

For our other tankless water heater that only heats water for the house, we have it set to 120 degrees.

On 2014-09-29 0 by b barry - what is the ideal water tempeathure setting for in floor heating ?

what is the ideal water tempeathure setting for in floor heating

On 2013-03-10 - by (mod) - How do we control the temperature of the radiant heated floor ?

Mark,

Stop by your heating supply house and ask them to show you the SEVERAL controls you will need for a properly working radiant heat floor system. Typically we control temperature using a thermostatically controlled mixing valve, flow rates, as well as a thermostat.

On 2013-03-10 by Mark

Out builder installed a pex system in our basement concrete floor and attached to its own water heater. Unfortunately our builder took off with all our money and we are forced to finish the house on our own.

How do we control the temperature of the floor as we have gotten two different answers. The plumber suggested simply putting a timer on the water heater and electrician has suggested a thermostat that gages the floor temp. Help!

On 2013-03-09 by Katie

What should a propane hot water heater be set at for radiant floor heating under concrete? I am going through way to much propane just to heat an 800 sq ft basement. Any suggestions on how to keep cost down?

On 2013-01-27 by Kathy

what are suggested ranges for ceramic heated floor during the winter

On 2012-12-18 - by (mod) -

Anon, the Honeywell TH115 series 7-day programmable thermostat is just that - a themostat in which you can program automatic temperature setbacks. Dropping the temperature when you can will save money - just keep temperatures high enough to avoid freeze damage risk.

On 2012-12-17 by Anonymous

is there a setting for the "LO" and "High" on the TH115 Honeywell thermostat that will save energy and cost

On 2012-01-20 by Richard

Thanks for the explanation on typical heat temperature [above on this page - Ed.]

...

Continue reading RADIANT HEAT CONTROLS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see RADIANT HEAT TEMPERATURE FAQs - questions & answers about radiant heat temperatures in walls, floors, ceilings, posted originally at this page.

Or see these

Radiant Heating System Articles

- HEAT LOSS in BUILDINGS - home

- HEAT LOSS INDICATORS

- HEAT LOSS PREVENTION PRIORITIES

- PEX PIPING INFORMATION

- RADIANT HEAT - home

- CARPETING IMPACT on RADIANT HEAT FLOOR

- DRIVEWAY & WALK DE-ICING SYSTEMS

- GAPS in RADIANT HEATED WOOD FLOORS - caused by running the radiant heat at too-high a temperature

- RADIANT HEAT AIR BOUND

- RADIANT HEAT CONTROLS

- RADIANT HEAT DEFECTS LIST

- RADIANT HEAT DESIGN & INSTALLATION MANUALS

- RADIANT HEAT INSTALLATION

- RADIANT HEAT MISTAKES

- RADIANT HEAT TEMPERATURES

- RADIANT HEAT TEMPERATURE CONTROL / MIXING VALVES

- RADIANT HEAT TEMPERATURE NIGHT SETBACK

- RADIANT SLAB FLOORING CHOICES

- RADIANT SLAB TROUBLESHOOTING

- RADIANT SLAB TUBING & FLUID CHOICES

- RADIANT SLAB TUBING LEAKS

- SLAB INSULATION, RADIANT / PASSIVE SOLAR

- THIN FILM RADIANT HEATING SYSTEMS for Ceilings & Floors

- WOOD FLOOR RADIANT HEAT

- WOOD FLOOR RADIANT HEAT DAMAGE

- THERMOSTAT SETBACK ADVICE

Suggested citation for this web page

RADIANT HEAT TEMPERATURES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to RADIANT HEAT

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Comments & Questions are Welcome Here

If you posted comments here and no longer see what you wrote, please check for your comment in the Reader Q&A found above on this page.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Calorique Radiant Heating Floor & Ceiling Systems, Calorique LLC, 2380 Cranberry Highway, West Wareham, MA 02576 USA, Tel: 800 922-9276, produces thin film radiant heating panel systems used for interior building heating (ceilings or floors), snow melting, de-icing, drum and tank heaitng, agricultural uses, pet heating systems, and consumer end products. The company provides radiant floor heating systems in several designs including specifically for use below laminate flooring, carpeting, and tile floors. - Thanks to reader Jim O'Dowd for suggesting this resource.

- FloorHeat 3130 Sovereign Drive, Lansing, MI 48911, 888-265-5455, Email: info@FloorHeatCompany.com) radiant floor heating panels,

- Heatshield Panels, 27354 Valley Center Road, Valley Center, California 92082 USA, 800-750-3978

- Nuheat Industries, 3105 - 6900 Graybar Road, Richmond, BC Canada V6W 0A5, electric radiant heat systems for use under tile, stone, and laminate flooring, Web: nuheat.com Tel: 800-778-WARM (9276) Email: info@nuheat.com

- ASHRAE 25 Heating, Refrigeration, and Air Conditioning engineering standards

- ASHRAE 90.1-2004 User's Manual, instructions for the design of commercial and high-end residential buildings "to ensure their compliance with ANSI/ASHRAE/HESNA Standard 90.1-2004 including the application of principles of effective energy conserving design..."

- CarbonicHeat radiant heat flooring products, Web: carbonicheat.com Tel: 866.786.1806 Email: sales@carbonicheat.com, [no mailing address]

- Entran radiant heat:

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.