Radiant Heated Floor Slab Tubing & Fluid Choices & Guidelines

Radiant Heated Floor Slab Tubing & Fluid Choices & Guidelines

+ Research on leaks & offgassing or VOCs from plastic tubing used for water

- POST a QUESTION or COMMENT about the different types of tubing & fluids used with radiant heating systems

Radiant heat tubing & heating fluid choices, advice:

This article discusses the suitability of various tubing materials for radiant heated concrete floor slabs, and choices of heat conducting fluids for radiant floors.

Our page top photograph shows polyethylene tubing being installed in a new concrete floor slab for radiant heat in a Two Harbors Minnesota building.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Radiant Floor Slab Tubing & Fluids: Choices, Features, Advice

Accompanying text is reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Accompanying text is reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Our page top photo shows polyethylene tubing emerging from a radiant-heated floor slab under construction in Two Harbors, MN in 2007.

Note the nice detail, use of a larger diameter tubing around the heating distribution plastic tubes, protecting the heating tubing from bending damage where it emerges from the slab.

"Radiant Slab Fluids"

The question-and-answer article about radiant slab fluids and radiant slab tubing, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

Questions about radiant slab floors:

What is your opinion about the relative suitability of various plastics (e.g. polybutylene, EPDM, etc.) for carrying heat transfer fluids in concrete radiant slab floors?

Which radiant floor slab tubings are acceptable for use with water, propylene glycol, Syltherm 444? -- C.R. MC, East Lansing, MI

Answers about radiant floor tubing and fluids:

Both copper tubing and plastic poly or PEX tubing are used in radiant heat systems.

Our photo (below) shows brass or copper connectors used at the transition from an electric boiler to in-slab radiant tubing. These fittings should have not been used in the concrete itself.

Plastic piping or tubing used for radiant heating systems varies in wall thickness, density, and chemical composition.

Consequently, each grade of plastic tubing that might be considered for radiant heated floors has its own temperature, pressure, and chemical compatibility limitations.

High-temperature polybutylene pipe is rated for 200 degF continuous use at 80 psi with water and/or glycols used as heat transfer fluids.

This makes polybutylene piping applicable to many radiant floor designs including the radiant floor design shown in the photograph at the top of this page.

The two radiant heat ubing sizes used most often in radiant heat floor designs are 7/8" Poly tubing or 1/2" PEX tubing.

Compared with traditional copper radiant heat tubing, use of these newer materials often reduces the number of connectors and thus the risk of leakage, and easy-radius bends in tubing also improve fluid flows thorugh the system.

Radiant Floor Tubing Choices: diameters, BTUs per foot, temperature & pressure ratings

When installing radiant floor heat tubing in a concrete slab in new construction there should not be an issue with tubing bending radius nor spacing constraints.

When installing radiant floor heat tubing in a concrete slab in new construction there should not be an issue with tubing bending radius nor spacing constraints.

However when installing radiant heat tubing beneath a wood-framed floor the spacing of the floor joists and other obstacles becomes a consideration when planning for tubing bends, turns, and routing.

Our photo illustrates the radiant floor heating zone manifold for a multi-zone system installed during reconstruction of a home in Tivoli, NY.

Copper piping feeds heating water to the zone manifold which in turn distributes heating fluid to four individual heating zones.

7/8-inch Polyethylene Tubing Radiant Floor Heat Tubing

Larger-diameter 7/8" Poly radiant floor tubing spaced 16" on center provides about 50 BTU's per linear foot (depending on heating fluid temperature and flow rate through the tubing.

Using this larger diameter radiant heat floor tubing will reduce the bending radius available for turns at the ends of tubing runs but it can usually be fit successfully in conventional wood-framed 16-inch on center floor joists.

1/2-inch PEX Radiant Floor Heat Tubing

Where there are radiant heat tubing bend radius concerns consider using 1/2" PEX that is capable of tighter bends.

Where there are radiant heat tubing bend radius concerns consider using 1/2" PEX that is capable of tighter bends.

However 1/2-inch PEXC tubing generates about 25 BTU's per foot, so to obtain the desired radiant floor heat capacity you should space the tubing runs closer than with larger tubing - thus you will increase the total linear feet of tubing used and the project installation cost increases a bit for this material.

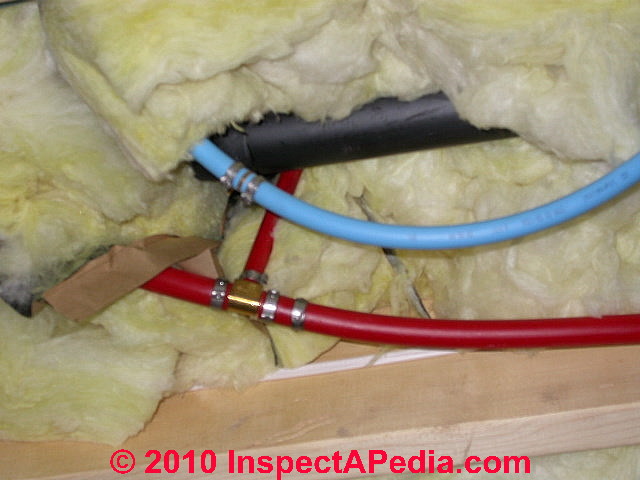

Photo above: Just because you see PEX tubing when inspecting under a floor, don't assume it's a radiant heat installation.

The photo above shows red (hot) and blue (cold) PEX tubing used in a water supply installation.

The routing, connectors, and presence of both blue and red PEX tubing make clear that this is not part of a radiant heat system.

Radiant Heat Tubing Spacing Recommendations

Typical: spacing: 8" / 200 mm on center

Higher heat-loss spaces: 6" / 150mm

For radiant heat applications operating at higher temperatures or pressures (such as snow melt installations) 1/2-inch PEX tubing may withstand these conditions better than larger-diameter poly tubing but in all installations you should be sure to compare the temperature rating for your tubing with the intended use and operating system temperatures and pressures.

Watch out: in some wood-framed floor radiant heat installations where radiant heat tubing odors were a complaint, in new installations the installer may recommend running the system continuously at higher than normal temperatures for several days in a hope to "cook out" odors.

But operating the system at temperatures above those for which the tubing is rated may cause damage or leaks.

EPDM Tubing Used for Radiant Heat Installations

EPDM tubing, the type used in SolaRoll™, will handle up to 300 degF. for water and glycols.

Neither EPDM tubing nor polybutylene tubing is recommended for use with silicone oils or hydrocarbons [so watch out when choosing the antifreeze product to be used in radiant heat floor systems when this tubing is selected].

Our photo (left) illustrantes Entran 3 radiant heat tubing.

A less-successful predecessor, Entran-II tubing failures and leaks are discussed separately

High density polyethylene tubing, not the type commonly found in retail building outlets, can also handle water temperatures typical of radiant heat floor systems, but with glycols and silicone oils, temperature limitations apply.

For a given radiant floor heating application, it would be wise to consult with the manufacturer of the specific tubing material and its connectors before making your purchase. Some manufacturers do not recommend the use of brass fittings embedded in concrete.

If possible, buried tubing joints should be avoided altogether.

Radiant Heat Tubing Research

- J. Boucher, "Radiant Subfloor Panels," Journal of Light Construction, (18:7), pp. 75-81, April 2000.

- Portland Cement Association: www.concretethinker.com/Papers.aspx?DocId=8 indicates that

- tubing for radiant heat in a concrete slab is installed UP TO two inches below the surface of the slab

- the slab is insulated from the ground at all sides to direct heat upwards to the living space [this is our preferred design for a cold northern climate] - Radiant Panel Association, P.O. Box 717, 1433 West 29th Street, Loveland, CO 80539

Phone: (970) 613-0100 or (800) 660-7187, Email: Email: info@rpa-info.com, Website: rpa-info.com

www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=1 offers design guidelines at http://www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=115 including these insulation R-value and coverage details:

Application#, Minimum R-Value, and Insulation Coverage

The following insulation alternatives are given for Slab on Grade construction:

Alternate #1 [(Ti-To)x0.125)=R-value, with coverage from perimeter to below frost line ["Ti-To" means we calculate the necessary R-value as (Ratio of indoor to outdoor temperature) x 0.125]

Alternate #2 R-value=5, with coverage 4' horizontal or vertical at perimeter

Alternate #3 R-value=5, with coverage under entire slab and slab edge [this is our preferred design for a cold northern climate]

The Radiant Panel Association offers education and publications in radiant heat design. See radiantpanelassociation.org - R. Groff, "Mixing Forced-Air and Boiler Heat," Fine Home Building, (No. 85) pp. 86-87, January 1994.

- Heatway Corporation, "Radiant Heat Installation", Heatway Corporation, 3131 W. Chestnut Expwy, Springfield MO 65802, Tel: 417-864-8161

- Hydronic Radiant Heating Division,

The Hydronics Institute,

P.O. Box 218,.

Berkeley Heights, NJ 07922

Phone: (908) 464-8200 - Dan Holohan, Hydronic Radiant Heating: A Practical Guide for the Nonengineer Installer, 1998. Dan Holohan Associates, Inc., 63 North Oakdale Avenue, Bethpage, NY, 11714; Phone: (800) 853-8882; $20.00.

- J. Siegenthaler, Modern Hydronic Heating, Delmar Publishers. 1995. Available from Delmar/Thomson Learning, Order Fulfillment, P.O. Box 6904, Florence, KY 41022; Tel: 800-347-7707. ISBN: 0-8273-6595-0.

- J. Siegenthaler, "Hydronic Radiant Heat for Wood-Framed Floors,"The Journal of Light Construction, (11:11) pp. 34-37, August 1993.

- J. Siegenthaler, "Radiant Slab Techniques,"The Journal of Light Construction, (10:11) pp. 21-24, August 1992.

- J. Siegenthaler, "Radiant Slab on a Tight Budget," The Journal of Light Construction, (13:10) pp. 47-50, July 1995

- Olsen, B. & Lidelt, D., Existing Knowledge on Possibilities and Limitations of Radiant Floor Cooling- #4014, , 1996. Part of the January 25-29, 1997 ASHRAE Winter Meeting Technical Program. American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), 1791 Tullie Circle NE, Atlanta, GA 30329; Phone: (800) 527-4723; website: www.ashrae.org

- J. Truini, "Adding Radiant-Floor Heating," Home Mechanix, (91:792) pp. 56-61, Feb 1995.

- N. Nisson, "Can Radiant Floor Cooling Succeed Despite Design Limitation?"Energy Design Update, (17:5) pp. 5-8, May 1997.

- "Canadian Study Details the Impact of Carpets on Radiant Floor Heating," Energy Design Update, (18:11) pp. 12-13, November 1998.

- B. Kaercher, Jr. , "Electric-Radiant Floors,"Fine Home Building, (No. 75) pp. 68-72, June/July 1992.

- Heatway, Goodyear Square Off in Court Over Radiant System Failures," Energy Design Update, (18:10) pp. 2-4, October 1998.

- Ohio Jury Says Goodyear’s Entran 2 Hosing Was Not Defective," Energy Design Update, (20:4) pp. 5-7, April 2000.

- C. Wardell,"Radiant Floor Systems,"Custom Builder, (10:6) pp. 26-30, Sept/Oct 1995..

- Takagi radiant heat systems: Takagi offers pre-assembled radiant heating system installation packages including for do-it-yourself'ers, and including systems that combine radiant heat flooring with domestic hot water production using a gas-fired tankless water heater.

See takagi.com for more information. "The T-KJr model (gas inputs up to 140,000 BTU per hour) is the smallest unit in the Takagi line-up. The T-KJr is perfect for light residential (i.e. small apartment units) and radiant heating applications." Also see Tankless Water Heaters. - US DOE, RADIANT HEATING SYSTEMS, U.S. Department of Energy

- [3] PB (polybutylene with mechanical fittings) Piping leaks: especially in mobile homes and in the U.S. South, for example trailers and double-wides throughout Florida that were piped with this material - per M Cramer.

See "Polybutylene Piping: Time Bomb?" Daniel Friedman, Journal of Light Construction, August 1996 [Technical Q&A] . - [5] Polybutylene Plumbing (plastic pipes): gray plastic water supply piping cracked, leaked, and resulted in a class action and settlement.

- [7] PB Technology Center (information about PB Pipes) Tel: 800-338-7732, also see the 1990 PB Pipe recommendations published by the Polybutylene Product Line Committee of the Plastic Pipe and Fittings Association.

- Polybutylene Plumbing Failures: Spencer Class settlement, Web: spencerclass.com, 10% of replacement cost/damages, only for acetal (plastic)fittings

- [12] Zurn Manufacturing, Web: zurn.com , Zurn Pex, Inc., Highway 11 East, Commerce, TX 75428, Tel: (903) 886-2580

provides information about installing and using PEX piping including Type b PEX through their website. Quoting from the company's website

Zurn was founded in 1900 in Erie, PA. It originally manufactured a patented backwater valve, and it now manufactures and distributes one of the largest plumbing products packages in the world! Zurn includes: the Specification Drainage Operation, AquaFlush flush valves, AquaSense sensor-operated plumbing products, AquaSpec commercial faucets, Wilkins, Zurn Light Commercial, Flo-Thru, the Chemical Drainage Systems, Zurn PEX Plumbing Systems and Zurn Radiant Heat. - [13] Zurn PEX PLUMBING DESIGN AND APPLICATION GUIDE [PDF] - web search 2023/04/06 & 12/23/2010, original source zurn.com/operations/pexrh/pdfs/installation/PEXDesApplGuide.pdf

- [14] Zurn Pex Plumbing

Products Liability Litigation, United States Court of Appeals

FOR THE EIGHTH CIRCUIT, No. 10-2267, Filed 6 July 2011, Quoting:

Minnesota homeowners brought this action1 against Zurn Pex, Inc. and Zurn Industries, Inc (Zurn) alleging that brass fittings used in the company's cross linked polyethylene (PEX) plumbing systems are inherently defective.

In pretrial motions the homeowners sought class certification for their consumer protection, warranty, and negligence claims, and Zurn moved to strike the testimony of two of the homeowners’ experts.

After denying Zurn's motion to strike the expert testimony, the district court2 granted the homeowner requests for class certification for their warranty and negligence claims, but denied it for their consumer protection claims. Zurn appeals from the district court's certification order.

We affirm. - Web search 4/12/12, original source: www.ca8.uscourts.gov/opndir/11/07/102267P.pdf - [18] Chemax, "Cross-Linked Polyethylene Tubing and Water Contamination", retrieved 2/17/2013, original source: http://www.chemaxx.com/polytube1.htm [copy on file as [Water Contamination chemical investigation.pdf]

- [19] Ingun Skjevrak, Anne Due, Karl Olav Gjerstad, Hallgeir Herikstad "Volatile organic components migrating from plastic pipes (HDPE, PEX and PVC) into drinking water", Water Research Volume 37, Issue 8, April 2003, Pages 1912–1920

Abstract:

High-density polyethylene pipes (HDPE), crossbonded polyethylene pipes (PEX) and polyvinyl chloride (PVC) pipes for drinking water were tested with respect to migration of volatile organic components (VOC) to water.

The odour of water in contact with plastic pipes was assessed according to the quantitative threshold odour number (TON) concept. A major migrating component from HDPE pipes was 2,4-di-tert-butyl-phenol (2,4-DTBP) which is a known degradation product from antioxidants such as Irgafos 168®.

In addition, a range of esters, aldehydes, ketones, aromatic hydrocarbons and terpenoids were identified as migration products from HDPE pipes. Water in contact with HDPE pipes was assessed with respect to TON, and values ⩾4 were determined for five out of seven brands of HDPE pipes.

The total amount of VOC released to water during three successive test periods were fairly constant for the HDPE pipes. Corresponding migration tests carried out for PEX pipes showed that VOC migrated in significant amounts into the test water, and TON ⩾5 of the test water were observed in all tests. Several of the migrated VOC were not identified.

Oxygenates predominated the identified VOC in the test water from PEX pipes. Migration tests of PVC pipes revealed few volatile migrants in the test samples and no significant odour of the test water. - [20] Andrew J. Whelton, Ph.D., M.ASCE; Andrea M. Dietrich, Ph.D., Aff.ASCE; and Daniel L. Gallagher, Ph.D., P.E., M.ASCE, ”Contaminant Diffusion, Solubility, and Material Property Differences between HDPE and PEX Potable Water Pipes.” J. Environ. Eng., 136(2), 227–237.

doi: 10.1061/(ASCE)EE.1943-7870.0000147

Abstract:

the objectives of this work were to identify differences between the composition, bulk properties, contaminant diffusivity and solubility for new high-density polyethylene (HDPE) pipe and crosslinked polyethylene (PEX) pipe, as well as determine which contaminant and polymer properties are useful for predicting contaminant fate in water pipe.

Variations in PE pipe density (0.9371–0.9547 g/cm3) , crystallinity (69–72%), crosslinking (60 and 76%), and oxidative induction time (33 to >295 min .) were detected. While numerically these differences seem minor, results show that slight material differences have a notable effect on contaminant diffusivity and solubility. Nonpolar contaminant diffusivity and solubility were best predicted by bulk density.

Polar contaminants were more soluble and diffused faster through PEX than HDPE pipes because PEX pipes contained a greater amount of oxygen. For all materials, dipole moment and Log Kow were good predictors of contaminant fate and molecular volume was only useful for predicting diffusivity and solubility values for haloalkane and nonpolar aromatic contaminants. - [22] Andrew J. Whelton, Andrea M. Dietrich, and Daniel L. Gallagher. (2011) Impact of Chlorinated Water Exposure on Contaminant Transport and Surface and Bulk Properties of High-Density Polyethylene and Cross-Linked Polyethylene Potable Water Pipes. Journal of Environmental Engineering 137:7, 559-568

Online publication date: 1-Jul-2011.

Abstract:

The aim of this work was to determine if the aging of polyethylene (HDPE, PEX-A and PEX-B) water pipes by exposure to chlorinated water altered polar and nonpolar contaminant diffusivity and solubility by analyzing new, laboratory-aged, and exhumed water-distribution system polyethylene (PE) pipes.

After 141 days of aging in pH 6.5 water with 45 mg/L free chlorine, the surface chemistry and bulk properties of PEX-A pipe were unaffected. Carbonyl bonds (σ=1,713 cm−1) were detected on the surfaces of HDPE and PEX-B pipe, and these oxygenated surfaces became more hydrophilic, resulting in statistically significant increases in diffusion rates.

All 10 contaminant and four pipe material combinations had diffusivity increases on average of 50% for polar contaminants and 5% for nonpolar contaminants. Contaminant solubility was slightly increased for aged PEX-A and slightly decreased for PEX-B pipes.

Toluene and trichloromethane diffusivity and solubility values for 7- to 25-year-old buried water utility pipes were similar to values for new and laboratory-aged HDPE-based materials.

Because chlorinated water exposure alters how polar contaminants interact with aged PE pipes, results of this work should be considered in future health risk assessments, water quality modeling, pipe performance, and service-life considerations. - [25] Website: GreenBuildingAdvisor.com, "PEX vs Copper", retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ community/forum/green-products-and-materials/ 16256/pex-vs-copper [copy on file as PEX vs Copper _ GreenBuildingAdvisor.pdf]

- [26] Website: GreenBuildingAdvisor.com," How Safe is PEX tubing?", retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ blogs/dept/qa-spotlight /how-safe-pex-tubing [copy on file as How Safe is PEX tubing_GreenBuildingAdvisor.pdf]

- [27] Lauren Hunter, "California’s PEX Battle Continues", Remodeling Magazine, June 2010, Website: Builderonline.com, "x", retrieved 2/18/2013, original souirce: http://www.builderonline.com/legislation/californias-pex-battle-continues.aspx [copy on file as California’s PEX Battle Continues - Plumbing, Legal Issues, Legislation - Builder Magazine.pd]

- [28] Contractor Magazine, "California approves PEX for plumbing — again- Contractor Magazine.pdf", retrieved 2/18/2013, original source: http://contractormag.com/news/ california-pex-plumbing-1234 [copy on file as California approves PEX for plumbing — again- Contractor Magazine.pdf]

- [25] Website: GreenBuildingAdvisor.com, "PEX vs Copper", retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ community/forum/green-products-and-materials/ 16256/pex-vs-copper [copy on file as PEX vs Copper _ GreenBuildingAdvisor.pdf]

- [26] Website: GreenBuildingAdvisor.com," How Safe is PEX tubing?", retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ blogs/dept/qa-spotlight /how-safe-pex-tubing [copy on file as How Safe is PEX tubing_GreenBuildingAdvisor.pdf]

- [27] Lauren Hunter, "California’s PEX Battle Continues", Remodeling Magazine, June 2010, Website: Builderonline.com, "x", retrieved 2/18/2013, original souirce: http://www.builderonline.com/legislation/californias-pex-battle-continues.aspx [copy on file as California’s PEX Battle Continues - Plumbing, Legal Issues, Legislation - Builder Magazine.pd]

- [28] Contractor Magazine, "California approves PEX for plumbing — again- Contractor Magazine.pdf", retrieved 2/18/2013, original source: http://contractormag.com/news/ california-pex-plumbing-1234 [copy on file as California approves PEX for plumbing — again- Contractor Magazine.pdf]

Original article

Here we include solar energy, solar heating, solar hot water, and related building energy efficiency improvement articles reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Portions of this article were published originally in Solar Age Magazine. A link to the original article in PDF form is immediately below

- TUBING CHOICES & HEATING FLUIDS for CONCRETE FLOOR SLABS - PDF form, use your browser's back button to return to this page

Solar Age Magazine Articles on Renewable Energy, Energy Savings, Construction Practices

...

Continue reading at RADIANT SLAB TUBING LEAKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CIPP PIPE LINING REPAIRS

- PEX PIPING INFORMATION

- PLASTIC PIPING ABS CPVC PB PEX PPR PVC

- PLASTIC PIPE LEAK CAUSES

- RADIANT HEAT - home

- RADIANT HEAT TEMPERATURES

- RADIANT SLAB TUBING LEAKS

- WOOD FLOOR RADIANT HEAT

Suggested citation for this web page

RADIANT SLAB TUBING & FLUID CHOICES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to RADIANT HEAT

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Solar Age Magazine was the official publication of the American Solar Energy Society. The contemporary solar energy magazine associated with the Society is Solar Today. "Established in 1954, the nonprofit American Solar Energy Society (ASES) is the nation's leading association of solar professionals & advocates. Our mission is to inspire an era of energy innovation and speed the transition to a sustainable energy economy. We advance education, research and policy. Leading for more than 50 years. ASES leads national efforts to increase the use of solar energy, energy efficiency and other sustainable technologies in the U.S. We publish the award-winning SOLAR TODAY magazine, organize and present the ASES National Solar Conference and lead the ASES National Solar Tour – the largest grassroots solar event in the world."

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.