Radiant Heat Floor Design & Installation Mistakes to Avoid

Radiant Heat Floor Design & Installation Mistakes to Avoid

Radiant floor slab disaster diagnosis & prevention

- POST a QUESTION or COMMENT On radiant floor heating problems

Radiant heating system design or installation mistakes that must be avoided.

This article explains how to avoid some fatal mistakes when installing radiant heat in a concrete floor slab by describing an incompetent radiant heat floor installation along with an explanation of why things went wrong and how to avoid these errors.

The workers in the photograph at page top, where our concrete slab was being poured, were not guilty of a thing. But the contractor who prepared the forms and under-slab insulation placed radiant heat floor tubing too deep in the slab and he omitted proper under-slab insulation.

The result: the owners ultimately had to abandon the entire radiant heated floor system.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Really Foul Up a Radiant Heat Concrete Floor Installation - Mistakes to Avoid, Diagnosing & Fixing Radiant Heat Slabs

Our contractor (Nightmare-works Construction), didn't want to insulate below the radiant-heat floor slab at all, insisting that "Once you get that dirt heated up below your floor your the earth will stay warm and your home will cost almost nothing to heat."

Our contractor (Nightmare-works Construction), didn't want to insulate below the radiant-heat floor slab at all, insisting that "Once you get that dirt heated up below your floor your the earth will stay warm and your home will cost almost nothing to heat."

He was dead wrong - a SNAFU that led to complete abandonment of the heating system he installed.

How to avoid some really bad mistakes when installing radiant heat in a concrete floor slab. How our contractor ruined the installation our radiant slab heating system, causing its abandonment.

How to place radiant heat tubing at the proper depth in a concrete slab. Building floor slab insulation design advice.

Article Contents

- HEAT LOSS RATE THROUGH SLAB on GRADE

- CODE SPECIFICATIONS for RADIANT HEAT SLABS

- CRITICAL DESIGN DETAILS for RADIANT HEAT FLOORS

- DIAGNOSE RADIANT HEAT FLOOR NOT WORKING

- GAPS in RADIANT HEATED WOOD FLOORS - separate article, gaps caused by running the radiant heat at too-high a temperature.

- RADIANT HEAT SLAB SPECIFICATIONS

- SUCCESSFUL RADIANT HEAT SLAB DESIGN SOURCES

- WHY A BAD RADIANT HEAT SLAB SYSTEM DOESN'T WORK

Original Research Identified Heat Loss Rates Through a Concrete Slab on Grade with Various Insulation Schemes

The nonsensical view that one can heat up the soil below an building slab on grade and that the soil would magically stay warm forever was put to the test experts when the author was five years old and the contractor was not even a gleam in his daddy's eye.

The nonsensical view that one can heat up the soil below an building slab on grade and that the soil would magically stay warm forever was put to the test experts when the author was five years old and the contractor was not even a gleam in his daddy's eye.

During February and March 1948, using a specially built, instrumented structure, Harlan Bareither and other experts and students at the University of Illinois Department of Mechanical Engineering conducted careful tests of various slab on grade floor and insulation designs to map heat loss, temperature, and moisture permeation characteristics of nine types of concrete slab subfloor constructions laid on the ground. [4]

Previously, the US National Bureau of Standards had already indicated that the heat loss of a concrete slab (floor) on grade (on the ground) is proportional to the perimeter of the building.

Bareither et als. referred to that work, but because the original testing was in warmer conditions (outside temperature had not been below 35°F. for more than three successive days), they recognized the need to test slab-on-grade floors in still colder conditions - in a climate where the ground is frozen during much of the heating season.

The 1948 heat loss research was important in part because it recognized that the rate of heat transfer from the heated building to the outside (earth and surrounding air) would be greater in proportion to the temperature difference between the heated space and the surrounding soils.

Photo: the radiant heat system that we had to abandon because of improper radiant heat tubing placement (too deep) and improper insulation below the slab (incomplete) includes the Thermolec B10-U electric boiler capable of providing 34,120 BTUH, circulator pumps, expansion tank, and radiant heat controls shown here as well as the entire tubing system. [Click to enlarge any image]

This research on floor slab heat loss rates confirmed that

- The rate of heat loss from a building varies by the temperature differences between the heated and un-heated space - the colder climate and frozen ground gave more rapid heat transfer, colder in-building floor temperatures, and thus provided an opportunity to test and measure different floor slab and foundation perimeter insulation schemes

- The best overall slab on grade performance "... was obtained by a floor construction in which a two-inch thickness of rigid waterproof insulation extended six inches down parallel to the exposed edge of the floor and [two feet *] back from the exposed edge ....

- The heat loss through the insulated floor was about 70% of that through the uninsulated floor

- * The heat loss through an uninsulated floor away from the building perimeter remains constant.

The authors accepted contemporary (1948) building practices that did not attempt to insulate under the entire floor and they pointed out that through the uninsulated center of the floor, the heat transfer rate from the building to the ground beneath, while slower than at the building perimeter, remained constant, forever - directly contradicting our contractor's theory that it was possible to "warm up the earth" and stop losing heat through the floor. [4]

Nightmare-Construction's Insulation Scheme & Radiant Tubing Location Details

One exception to the general order of priorities of where to insulate in buildings concerns homes built with slab-on-grade construction, particularly homes which have used radiant heat in the floor slab.

See details at HEAT LOSS PREVENTION PRIORITIES

The contractor (Nightmare-Works Construction) for a small cabin in the North combined being opinionated and a bully with dismal ignorance of how to construct a properly insulated radiant floor slab.

See details at SLAB LOG CABIN SIDING - cabin photos and other comments

Not only did the owners have to battle with the bully to put insulation under the entire slab (he thought that Mother Earth would be warming the home from "ground heat" (which is below 40 °F in winter there).

Owners also lost a battle to have the contractor install proper insulation around the slab perimeter with a frost wall before the floor was poured (he insisted on a floating slab with no inside-perimeter insulation plan).

Worst of all, the contractor also pushed the radiant heat tubing so deep into the concrete (ranging from 7" deep to more than 18" deep) that the entire radiant heat system was not usable at all. Running the radiant heat pushed heat faster into the ground than it did up into the building, even with foam insulation under the slab.

We had to abandon the (expensive) radiant floor system and install alternate heating.

The Results of Combined Incomplete Floor Slab Insulation near the Perimeter and "Too-Deep" Radiant Tubing Placement were an Abandoned Heating System

- Unable to heat the building:

Even running the radiant floor heating system full time at the highest boiler settings and control settings allowed we could never heat the building to comfortable temperatures during cold Minnesota winters. - Abandoned radiant floor heat system.

Ultimately we had to completely abandon the radiant heat floor installation, wasting the costs of the boiler, tubing, installation labor, wiring, etc. The building is currently heated by plug-in electric wall heaters, pending a more permanent re-design.

Details about this radiant floor slab heat failure and and research on its cause are provided below.

Also see SLAB INSULATION, RADIANT / PASSIVE SOLAR for a discussion of proper insulation below a heated floor slab.

Critical Design Details for a Radiant Heated Concrete Floor

Don't permit your contractor to make the (many) mistakes this one did. Insist that radiant heating in a poured concrete slab have these attributes:

- Insulate below the entire floor slab. Sketch at left courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Although the rate of heat loss through the floor slab is slower at the center of the floor than at the building perimeter (of an installation that is not insulated), in cold climates the heat loss through the floor will be continuous will be significantly greater at an uninsulated slab. - Insulate the slab perimeter, making sure that the insulation design does not rely on foam placed against the slab perimeter and extending above grade up to siding where it will invite termites or carpenter ants into the structure

- Place the radiant heat tubing at the industry-recommended depth down from the surface of the slab. Typically the maximum depth that tubing should be placed in a concrete floor slab is 2" down from the finished floor surface.

- Supervise: If you cannot be present at the job site at critical stages in construction, find someone knowledgeable who can inspect for you before the work continues

- If your contractor is an opinionated bully like ours who ridicules standards for good workmanship and proper radiant heat floor design, find someone else to do the work. Most contractors are conscientious and are glad to hear about good design.

Radiant Heat Floor Slab Installation Details vs Design Specifications

Radiant heat tubing in a concrete slab needs to be closer to the top of the slab than its bottom, normally in the top 2-inches of concrete. Placing tubing deeper in the slab means, simply-put, that more heat will transfer into the slab and ultimately into the soil below than will be transferred up to the top of the slab and into the occupied space.

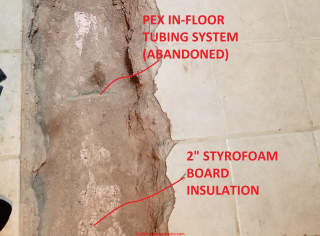

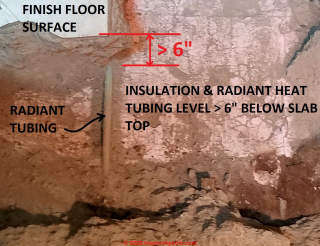

Our photos above and below show that the radiant heat system tubing for this improperly-installed system was placed right on top of the styrofoam insulation intended to be at the bottom of the concrete floor slab. This placed the tubing at varying depths but generally about 7-inches below the finished floor surface, with tubing at some locations near the slab perimeter placed 18-inches deep in the slab!

In fact the tubing was stapled directly to the surface of the styrofoam insulation.

Re-bar was laid atop the tubing and also at the bottom of the slab. (It should have been roughly mid-slab). Placing concrete atop radiant floor PEX tubing stapled to the foam-board insulation might work IF

- The insulation is adequate

- The concrete slab depth is not great

- The climate is not one of low temperature extremes

That was not the case for the home shown here.

After reviewing photographs taken during installation of the radiant heat floor slab described above, here's what we wrote to the owner and to the contractor:

I am doubtful that we can successfully and economically heat the cabin with radiant in floor heating as the current system is designed and installed, and it is unfortunately the case that the cost-to-cure is prohibitive as the slab would need to be completely replaced with one using proper insulation and tubing placement.

The bully contractor, who originally estimated the monthly heating cost for this small and otherwise well-insulated building, had

said the owners would face winter heating bills of about $30./month based on his prior experience.

Stunning heating bills arrived, exceeding

$400./month or more than ten times the estimated amount. That's when we began digging into the installation details of this project. Literally.

The floor slab and radiant heat tubing had been placed by the contractor while we were unable to attend the jobsite.

When the heating bills were excessive and when the heat, running 24-hours a day for weeks, was unable to raise the interior temperatures above 60 deg .F., the contractor offered to "correct" the problem by installing larger capacity circulator pumps.

The "option" of adding larger pumps for this radiant heat floor was not a proper solution for several reasons:

- Forcing a faster hot water flow

in the radiant tubing would only correct a boiler operating problem if the boiler internal temperature were running too high and causing a shutdown due to the thermal over temperature sensor - this is not what was happening (I measured input and output temperatures) - The boiler was already operating at spec

in that it was producing more than 20 degrees between the input line and output line - so the problem is not flow but rather the inability of the boiler to handle the heat loss through the slab due to the slab tubing placement and insulation design. - Installing a boiler of higher capacity

might permit delivery of more heat to the slab and raise the indoor temperatures and slab surface temp but at a higher heating cost - The current heating costs

if we turn on the radiant floor system run $300. to $440 a month which is 10 times what the contractor originally estimated - doubling these costs by adding a larger boiler or faster water flow is unreasonable. - We didn't have the option of taking advantage of reduced electrical rates

because the electrician sub-contracted by our builder did not install the electrical service to our specifications - leaving out a separate service and meter at the entry point.

The most economical fall back is to install electric baseboard heating or possibly hydronic heating using the existing electric boiler which was installed to pump heated water through the radiant tubing in the concrete floor.

Meanwhile we shut down this unfortunate radiant slab heat system, installed a few portable electric heaters, and given the tight, well-insulated construction, we found we can keep the little cabin comfortable for a fraction of the cost of heating the earth underneath our floor with the contractor's heating installation.

Details of errors visible in photographs taken during and after installation of the radiant floor:

In 2020, observing water leaking up through the slab in this location from below, the floor was opened to permit further investigation. Our photo above shows accumulating groundwater just below the slab insulation. A system to drain off water and prevent water entry of frost damage to the slab was needed.

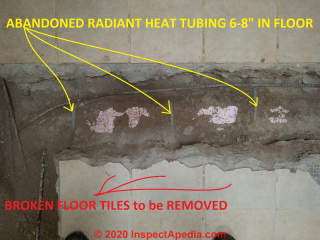

Our photos above and below were made possible by breaking into the floor slab with a jackhammer, removing concrete to expose the exact details of how and where the radiant heat tubing was installed in this floor - shown below.

Following this exposure of the tubing and convinced that the radiant heat system could never work properly we removed the boiler intended for use in providing radiant heat and filled in the damaged areas of the floor with new concrete and tile.

- Photographs of the slab and radiant tubing installation for the cabin show that the guidelines for radiant heat slab installations were not followed.

- Tubing is at a depth greater than 2" from the top of the slab, typically at the slab bottom at 6-7 inches down from the floor surface, and at some locations is considerably deeper than that, in some areas more than 18" deep in concrete.

- Insulation is incomplete around the slab perimeter and cannot be added outside due to 1. insect damage risk and 2. would not extend below and under the slab edges

- Insulation is incomplete within the slab where tubing installed at a lower level is stepped down from the upper slab level and heat transfer is permitted into the gravel fill below the main slab area.

- The installing contractor decided on his own to skip the frost footings specified for this slab, instead building a "floating slab" that was simply set atop the ground.

A floating slab can "work" but is more-vulnerable to frost heave, cracking, and damage than a slab supported by footings extending below the frost line.

That risk is exacerbated if the building and the floor slab cannot be kept sufficiently warm during freezing weather. Over the ensuing life of this floor slab cracks have appeared in several locations, fracturing the ceramic floor tile across wide areas and in some locations even chipping the surface of the floor tiles - shown below during a cosmetic repair effort.

Repairs to this cracked ceramic tile floor are illustrated

Discussion of the Above Radiant Slab Heat Performance Case Study: Why the Radiant Heat Slab Didn't Work

James Darling, General Manager of Preferred Heating LLC, in Eagle River, WI commented on this article that the contractor's promise of heating the building for $20. a month was an unreasonable promise not to be relied on - one that could make the article above misleading.

We agreed that the description of the failure of this installation needed some clarification, and added the following information that should be considered:

Actual Heating Costs for the Building Described Above

Keep in mind that this was a small new structure (624 sq.ft.) whose construction details, methods, materials were unusually well documented as a project. So the insulation, air tightness, materials, heating details were known.

The building was super insulated, tiny, airtight, with double-glazing throughout, leading to an expected low heating cost. If the owner's actual heating bills for the structure had been even five times what was promised for this building that was occupied only part-time, the owners would have been happy. Heating bills weren't the arm-waving promise of $20 per month, they were not $200. per month. They were more.

In fact, the utility cost to heat this tiny cabin resulted in bills that more than doubled the corresponding costs of the nearby 1960's vintage two story large old, comparatively poorly-insulated house on the same property, exposed to the same conditions. And the exploding heating costs were observed when heating the building well before the coldest part of the heating season.

Heating Capability Limitations of an Improperly-Installed Radiant Floor Slab

The effects of putting the tubing deep into the slab created a problem of heat transfer losses to the ground, not just a matter of longer response time to warm the building. Even if money had been no object, the system simply could not heat the building to an acceptable temperature.

The problem with very deep radiant-heat tubing, combined with incomplete insulation, is that even with just 12 to 18" of concrete above the tubing, heat flowed enough into the ground below the building that

even with the thermostat set to maximum, and running heat continuously for a week solid, in moderately cold weather (in the 40's in Northern Minnesota where in winter it can drop to 20 deg F below zero)

we never ever could get the indoor temperature above 59 to 60 °F. And this was in a new, small, airtight one-story well-insulated building.

even if we had continuous solid foam insulation under the slab, say R-10 for simplicity, if we have enough inches of concrete above, even though the "R" of concrete is much lower than the insulation, it's the total heat resistance by the total inches that comes into play.

If we have enough thickness of concrete above the tubing (Where 1" to 2" tubing depth is the best design and 6" is considered a lot, in this building we are looking at 18" or more at least in many areas, maybe 24").

With radiant tubing at those depths, the concrete begins to offer not just a lag time in heating (Mr. Darling's point) but also an actual resistance to heat transfer until we begin losing at least some heat into the ground.

The contractor and others tried to improve the system's performance by changing the boiler settings from those set by the manufacturer on its integrated circuit control board, upping the circulator size and capacity, checking flow rate through the system, checking the thermostat controls.

What Caused the Failure of This Radiant Floor Heating System?

Our photo (left) shows where we found the radiant heat floor tubing when we later broke open a section of the floor slab. Radiant tubing was at the bottom of the slab, in this area more than seven inches down in the concrete, and set atop the foam sub-slab insulation.

Our PHOTO above on this page [Image file] shows that tubing was in some sections more than 18" deep, and adjacent to a large area where sub-slab insulation was simply omitted by the contractor.

We also measured floor temperatures in different areas of the building, mapping clearly where the radiant heat tubing dropped to the bottom of the footing-portion of the monolithic-slab footings!

That deep run, probably combined with the incomplete insulation at the level drop between slab bottom and the integrated footings, were almost certainly the prime cause of the failure of this system to heat the building.

As our reference document(s) below show by calculation and model, ultimately, the heat flow into the ground for tubing really too deep in the slab can be significant, even if there is insulation below all or part of the slab. In the structure described here, not only was some tubing 12 to 18" or even more below the slab top, the insulation below the slab was incomplete, inviting ready heat flow into surrounding soils.

Despite varying opinion by some radiant floor installers, consumers, and installers as well should be wary of ignoring the advice of the radiant heating design experts and heat transfer engineers about tubing depth in radiant floor slabs shown just below.

Worse than too-deep radiant floor heating tubing, in this case, because the contractor put NO insulation at the area of soil where he stepped the slab down to the depth of the monolithic integrated footings, we have heat transfer from some of the tubing through concrete right into the cold soil, not just through concrete up into the room through the ceramic tile floor.

In this egregious error, even worse than putting radiant heat tubing too deep in the slab, insulation was simply omitted where the floating-slab monolithic footings were poured. The R-value of concrete is roughly .08/inch (US DOE).

The builder located sections of the radiant tubing so that there was about 6" or less of concrete (in the 12" footing section") between the tubing and the cold soil, giving us a heat transmission path (tubing to soil) of R 0.24 or less.

This is a likely area of heat loss at all four sides of the building: where the slab dropped down to form footings.

See INSULATION R-VALUES & PROPERTIES

As an aside the ceramic tile on the finished floor slab was set in mastic - leaving some air spaces and mastic that is a poor conductor compared with tile set in concrete (optimal) - but we doubt that's nearly as important in the system failure in this case.

Proper radiant heat concrete slab design

Our photo (left) illustrates a successful radiant heat system installation in Minneapolis, MN - a climate similar to that where we had trouble with the Two Harbors system above.

- Industry Expert Modeling of Effects of Tubing Depth in Radiant Floor Slabs:

An excellent if somewhat techno article on the problems of putting tubing at the bottom of the slab is at http://findarticles.com/p/articles/mi_m0BPR/is_6_20/ai_102862289/pg_1 - The floor construction

in that case is a 4-in, concrete slab sitting on 1-in. (R-5) polystyrene insulation, and covered by 3/8-in, oak flooring. The embedded tubing circuit consists of 1/2-in. PEX tubing spaced 12-in, on center. Several versions of this basic model were developed to simulate tubing at different depths with the slab.

THIS IS NOT OUR SLAB- which is has tubing at 6" deep and along one side where the tubing is deeper, 10-12" or more. We have better insulation but much deeper placement.

Here is a quote from the last page of the article which reports an expert's study of the heat characteristics that change as tubing moves lower than 3/4" from the top of the slab:

QUOTING except for [bracketed comments]

"These results indicate that tube depth does have a nontrivial effect on the thermal performance of a heated floor slab. There is a performance penalty associated with leaving the tubing at the bottom of the slab vs. positioning it near mid-depth of the slab.

The analysis performed was also based on steady state conditions. It doesn't predict the consequences of the longer response times associated with deeper tubing. These could be significant in situations where a building is recovering from a setback condition, or when heat flow from the slab needs to be reduced quickly to accommodate internal heat gains.

Considering the tradeoffs, perhaps it is time we pay more attention to quality control procedures to ensure that performance is not compromised as concrete is poured over radiant tubing circuits.

When future archeologists dig up the ruins of our buildings several centuries from now, will they ponder why we put the heating tubing at the bottom of the slab? Might they wonder if we didn't know any better?

Would they conclude that some builders of the time were just too lazy to bother lifting the tubing? Thinking back to how ancient Romans used lead piping for water supplies, perhaps those archeologists will conclude that even after centuries of experience, we still had a hard time doing this pipe thing right.

[FIGURE 4 OMITTED], [FIGURE 5 OMITTED]

Table of heating water temperatures needed with radiant tubing at different depths in the concrete slab

| Table of Insulation Material Properties | ||

| Average water temperatures needed for heat output of 15 and 30 Btuh/sq ft. | ||

| Upward Heat Flux Requirement (Btuh/[ft.sup.2]) | Tubing Depth 2" Below Slab Surface, Average Water Temp. Required °F. | Tubing Depth at Bottom of 4" Slab, Average Water Temp. Required °F. |

| 15 Btuh | 95 °F | 102 °F |

| 30 Btuh | 120 °F | 134 °F (1) |

Notes to the table above

(1) regarding the "134 °F" in the bottom right of the above table:

This is moving down just 2" deeper. We estimate maybe 168 degrees water temperature would be needed at 4" down and

well over 200 deg heating water would be needed in tubing 6" down.

In the slab in our construction project, the critical

tubing, leaving the heating boiler, was placed more than 12" deep in poured concrete.

Heating energy costs will increase consistent with the increase in heating water operating temperature requirements.

Below see our list of RADIANT HEAT DESIGN & INSTALLATION MANUALS

2006 IECC: effectiveness of foundation perimeter insulation and insulation recommendations for radiant-heated floor slab designs

Reader Question from Wenell: I would like to know what the persons that wrote and researched this article thinks about what Montana has on research.

On their web page MONTANA SLAB EDGE INSULATION ANALYSIS FOR 2006 IECC ADOPTION [PDF] There seem to be so many theories on this.

One thing we have found that if the soil conditions are quite damp, there definitely needs to have some type of insulation under the slab.

Another theory I have read is that the heat as it goes down, which it will, some is that it radiates horizontally, which makes insulating the edge quite well. - Wendell Schubloom

Reply: thorough under-slab and perimeter insulation and proper tubing depth are critical for radiant heat floor slab designs

Wendell, there is not actually any contradiction between the Montana (DOE) research you cite above and radiant heat floor slab insulation requirements.

Wendell, there is not actually any contradiction between the Montana (DOE) research you cite above and radiant heat floor slab insulation requirements.

The study you cite does not focus on radiant slab heating designs but or a more narrow question about the benefits of foundation/floor slab perimeter insulation.

The DOE photo (below left) shows a typical Montana construction practice that gives a thermal break between a concrete floor slab (not yet poured) and the exterior foundation wall.

I've read quite a lot of supporting research on slab and slab perimeter insulation for radiant heat flooring, and I have some direct experience with installing radiant heat and more with inspecting radiant heat flooring problems.

Quoting from the conclusions of the Montana DOE-sponsored study you cite, [2] [photo at left showing interior foundation insulation before the slab is poured, U.S. DOE, op cit.]

This study shows that insulating slab edges with R-10 insulation to 4-ft depth along the slab edge saves about 3% annual energy and reduces annual fuel cost by between 1 and 2%. The energy savings vary slightly depending on the insulation configuration and building type.

Although the current installation practice in Montana does not extend the interior footing insulation to the top of the slab, based on empirical data, this study concludes that irrespective of the insulation installation configuration, Montana buildings will save energy by insulating the slab edge with R-10 insulation to a depth of 4 ft.

The payback period could vary from 4 years for small retail commercial buildings to 12 years in small office buildings.

This study, using eQUEST, Version 3.0 simulation modeling, compared full versus partial slab perimeter insulation schemes and found that there was useful energy cost savings even with partial insulation.

The study data includes comparison with fully-insulated slabs too, but most important for our discussion, it does not address radiant-in-floor-slab heating designs that, without full insulation, can find an easier heat flow into the ground than into the building - not what we want to see nor pay for in heating bills. Quoting:

The local practice of insulating the slab footing on the interior allows heat loss along the slab perimeter and thus does not achieve the full savings that could be achieved with full edge insulation configurations, but the savings are still significant.

The risk in misinterpreting the Montana study conclusions above would be to apply them generally to radiant heat floor designs and that to improperly infer that complete under-radiant-heat-floor-slab insulation is not needed in cold climates.

That study makes a general conclusion for all Montana buildings and by no means does the conclusion adequately address radiant in-slab heating system designs.

The fallacious concept held by the contractor in our horror story was that "once you heat up the earth below your building it will start "giving back" heat to the building and you'll be just fine. His theory was nonsense, as both expert advice and actual field experience proved.

The earth in a cold climate like Montana or Minnesota, is for practical and design purposes, an infinite heat sink. A radiant floor slab heating system will, if improperly designed, keep pumping heat into the ground as long as the heat is turned on.

Forever.

We saw this in astronomical heating bills and a cold building interior in the Minnesota home discussed above. Heat always flows, and continues to flow from a warmer material into a cooler material.

Heated the soil beneath a building where insulation was incomplete, inadequate, or omitted, will never reach some magic perimeter after which it stops sending heat into the surrounding soil any more than an ice cube placed into the sea will stop melting because it's "cooled down" the water around itself.

As the principal author of this material I relied largely on the concrete industry and the radiant flooring industry's radiant floor slab design specifications and advice [1] as they, above all, have a huge vested interest in their installations being successful.

There is no doubt that in virtually every radiant-heat-floor-slab design we need continuous insulation under the slab and at slab perimeter, though the appropriate insulation amount might vary depending on the local climate.

The folks who seem to disagree have been people like the bully contractor who himself admitted he had never read instructions, attended a class, nor asked for expert advice.

As is often the case with small contractors in remote areas and without expertise, he was "winging it". Don't try mentioning "thermodynamics" or "heat flow theory" to a bully.

Just how bad an uninsulated, under-insulated, or incompletely insulated floor slab will perform with radiant in-slab floor heating depends on some additional variables: climate, soil moisture (read thermal conductivity as you suggest), and critically, the depth of tubing in the slab. In ALL cases we want the insulation in place.

But in the horrible installation we describe in these articles, the contractor not only provided incomplete and no perimeter slab insulation, he also buried the tubing so deep in the concrete that heat moved much more down into the cold earth than upwards into the occupied space.

There was so much heat loss that we could not get the room temperature up even in cold but not bitter cold weather, and even though the same contractor had done a great job insulating the upper portions of the structure's roof and walls. (He was a framer/carpenter, and should not have attempted radiant slab installation nor tile work.) That's why we had to abandon the whole radiant floor installation.

If the floor slab had been very well insulated, the installation still would not have performed well because of the excessive tubing depth in the slab ( over 12" down in some sections ).

I appreciate the Montana reference and have added it to this article below at references [2].

Comment: Butler Cat radiant floors in the Dakotas, steel buildings, radiant floor heat.

We are in the steel building business so we have a lot of in floor heat done. with the experienced heating people we use, have had no problems.

But the question I have is- in North and South Dakota there is a Cat dealer by the name of ButlerCat.

They have built huge shops and I found out this spring what they do for floor hear.

They place the foam down and put the PEX directly to this and then place 4 to 6" of sand on top before pouring the floor. I ask why and was told if the have any floor problems they can remove any thing need to. They done this on I think four bldg's

What are your thought's

Reply:

Wendell it's a fair question, and I welcome the discussion. But I suspect this may be a case of intelligent people who think things up on their own, make up an explanation that sounds reasonable, but may not know the whole story.

The deeper you put radiant heating tubing in the slab the worse the heating system will perform in delivering heat to the interior. Furthermore, the thermal conductivity of sand is much below that of tubing directly in contact with the concrete slab itself.

The expert sources I found on this want tubing in the concrete and very close to the slab top surface, an inch or two at most down is best.

I agree that if there is enough insulation under the slab and it's well done and complete, in the design (foam, tubing, sand, concrete) you describe you will eventually probably warm the slab upper surface, but consider that there are heat flow rates through insulation too, it's not "heat proof".

With 6" of sand and say nominally 6" of concrete, your tubing is 12" down - way too deep, and furthermore, the first 6" of material (sand) between the tubing and the occupied space, does not quite the same level of thermal conductivity as tubing in contact with solid concrete.

The sources I cite at references below point out that there is heat flow resistance through concrete and sand as well.

So while it may not be intuitively obvious, and while it's true that the thermal conductivity of concrete and even sand (which is not as good as concrete) is greater than insulation, if we have enough sand or concrete above the tubing, and little-enough insulation below the tubing, heat flow down through the insulation can still be significant.

Think of it as "heat flow resistance" through various materials. You can have a more conductive material above the tubing, but if you have a lot of it, the total heat flow resistance can still be significant.

Finally, the supposition that "if they have floor problems they can remove anything they need to" sounds highly suspect to me - it's not thought out. In any case you'd have to chop entirely through the floor slab to get to the tubing below, and meanwhile you are paying in higher heating bills than necessary over the life of the building.

How to Troubleshoot a Radiant Heat Floor That's Not Working

The following un-edited discussions, a continuation of RADIANT HEAT MISTAKES, illustrates efforts to track down the reason that a radiant-heat slab system is not heating adequately.

Also see RADIANT HEAT DESIGN FAQs - questions & answers about installing & troubleshooting radiant heating systems

Tips for Investigating a Radiant Heat Floor Slab Design for SNAFUs

- Check the heat source & controls first:

something as simple as improperly adjusted mixing valves, temperature settings, or a poorly-maintained gas or oil fired boiler can be enough to explain unnecessarily high heating costs - Check occupant behaviours:

watch out for occupants who like to sleep with the thermostat set to 80F and their windows open. - Check radiant heat slab plans & photos:

If there were house plans, or better yet, photos of the home during slab construction those would be invaluable. That was how I found out how Nightmare Construction had fouled up the radiant slab I wrote about. - Thermal scanning?

Check the climate: Where is your home - province or state and city? What's its heating zone? Except in quite cold weather, there may not be enough indoor / outdoor temperature difference to benefit from thermal imaging until colder weather arrives.

In cold weather thermal scanning of the floor can show radiant tubing routing, locations, leaks, temperature variations. Measuring actual floor temperatures may give additional data to compare with the floor's design specifications. - No view under slabs:

For radiant heat installed over a framed wood floor there should be access below to inspect the tubing installation and other construction details. But that's not likely to be the case for a radiant-heated floor slab. - Test hole through the slab?

For people buying a home with a radiant-heated slab, I'm doubtful a seller is going to let you cut a hole anywhere indoors. I wouldn't;

The last thing a home seller needs is some fool to bore a hole that cuts a heat tubing or pipe line, or to cut a hole and then bail on the purchase and leave the seller with a holed and stigmatized house for sale. - Excavate the slab from outside?

A seller MIGHT let you excavate under the slab from outside to see what you find - maybe at a corner least likely to suffer from water or runoff when the fill is restored.

Dig down to follow the edge of the slab into the soil then dig out a bit below that to see what you find - and send me those photos if that's allowed. You might promise to restore the soil and even put down sod afterwards.

Watch out: No single hole or inspection point or even four or five of them is going to guarantee that the entire slab was properly insulated.

In the case study starting at RADIANT HEAT MISTAKES some portions of the slab or insulated but the installer left whole sections just exposed to the dirt. We would never have found which sections of insulation were omitted if we haven't had the photos. Similarly his second and fatal radiant heat installation mistake was putting the tubing at the bottom of the slab.

We couldn't see those details without destructive chopping up of the concrete or finding photos taken during construction.

My point is that drilling one inspection hole in a radiant heated floor to examine the insulation scheme and tubing depth, even if you could avoid cutting tubing, wouldn't assure you that there wasn't a problem elsewhere under the floor.

- Look also for clues that the present heating system was inadequate:

did prior occupants put aux heaters of any sort in any location? Compare the home's heating bills with comparable structures in the same area.

For a really bad radiant installation with tubing too deep (common) or incomplete insulation (somewhat common) I abandon the system - painful as that is, as it makes no sense to just pump heat and dollars into the ground all winter.

For a case that can't be fixed above the slab (like air leaks) I'd install an alternative that's least disruptive, such as wall mounted split-system heat pump.

Radiant Heat Slab Installation Manuals, Research, Products, Guides

Now moved to RADIANT HEAT DESIGN & INSTALLATION MANUALS

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-08-09 by Lance

Looking to buy an older home that has radiant heat in a poured slab over the basement and powered by a new boiler system. I am concerned about finding a pre-purchase inspector that can adequately evaluate the system. Any suggestions on locating a competent inspector to examine the system? Thanks

On 2022-08-09 by InspectApedia (mod) - what to look for when inspecting a radiant heat floor system

@Lance,

You can start with our

HOME INSPECTORS DIRECTORY

Let us know if you have additional questions.And ask the inspector if he or she is familiar with radiant heated slab systems and listen to how that person will evaluate the system operation.

There are some advantages if you can do the inspection when the weather is cold.

For example the inspector might use thermal scanning to check the floor areas.

On 2021-05-13 by Anonymous

I’m under contract on a 3000sf home in Manistee Michigan that was built in 1992 and I’m looking for someone qualified to inspect the radiant heat system. My inspection period starts on next Monday May 17, 2021 and ends 14 day later.

Do you know of a resource of qualified contractors or inspectors that I could utilize? In lieu of a list of qualified contractors, might you have a list of questions I can use to screen the contractor myself?

Also, I understand that early on when radiant slab systems were being install that poor tubing was used in some instances. Is this the case and how can I identify this tubing?

On 2021-05-13 by danjoefriedman (mod) - points to consider in a competent onsite radiant heat system inspection

A competent onsite inspection by an expert usually finds additional clues that would permit a more accurate, complete, and authoritative answer than we can give by email alone, as we haven't a shred of information about your radiant heat design, location, climate, building etc. You will find additional depth and detail in articles at our website.

That said, I have these comments:

First, sorry, no I don't have a referral;

You should of course ask the contractor what is their experience with installing and fixing radiant heat systems.

Or read our articles on radiant heat failures and listen for some of that same mistaken thinking.

In particular take a look at

RADIANT HEAT CONTROLS

RADIANT HEAT DEFECTS LIST

RADIANT HEAT INSTALLATION

RADIANT HEAT MISTAKES

RADIANT HEAT TEMPERATURES

RADIANT SLAB FLOORING CHOICES

Live links for all of those articles are found at the Recommended Articles list at the end of the article above.

Often all you really need to do is ask even the most simple questions like: what are the important inspection points on a radiant heat floor system? Listen for: tubing routing, spacing, location, depth in slab, insulation below slab, slab perimeter insulation, controls, heat source, balancing, zone control.

The manufacturer of your tubing and heater and controls will, of course, have installation specifications that are worth your attention.

About your question about defective radiant heat tubing products,

See our discussion of "Plumb-Pex defective component installations in North America" included in PEX PIPING INFORMATION https://inspectapedia.com/plumbing/PEX_Piping.php

On 2021-02-07 by Steve

my floor heat boiler runs lots and cycles on the high limit switch of the boiler .. 120 f max .then it cuts out and until it goes to110 fro cut back in ... If water temperature in is 15 degrees lower then water temp out And it cycles in the high limit switch of the boiler until the thermostat settings are met .. is this ok ? System is 50 years old but boiler is brand new

On 2021-02-07 - by (mod) -

Steve

If the boiler is cycling frequently it may be that a balancing or mixing valve in the radiant floor heat system is not set correctly. Ask your heating service tech to take a look and let me know what you are told.On 2021-02-07 by Steve

To add .. this is a open system.. not under pressure ..

When I use a temp gun to check the pad it’s running at about 23- 25 degrees C (73 -77f)

Thermostat is set at 17C ..

Should my pad be running hotter if water going through it is 110-120 as the boiler says it is ..

Is water going to fast that transfer is not effective?or is it ok the way it is ?

Had a hard time meeting thermostat needs in cold weather like -25 and lower etc

On 2021-02-07 - by (mod) -

Pumping faster, with some subtle technical exceptions, puts more BTUs per minute into the floor;

Check the temperatures entering the floor loop and then returning out of it; you might see that there is a bigger drop than anticipated, hinting at heat loss into the ground at a rate not anticipated.

On 2020-05-22 by DJW

I installed thermal bluestone on top on 4" of concrete which has radiant heating tubing throughout. The large patio is under a covered porch.

The problem seems to be that there is moisture coming up to the surface of the thermal bluestone causing staining. Is it possible that the radiant heating tubes give off moisture/ condinsation which causes the bluestone to absorb the moisture.

Another patio was constructed in the same manor but is in full sun around a pool. There is no staining and the thermal bluestone looks beautiful. Any advice or thoughts?

Builder claims its my fault because I used bad concrete. I blame builder that his installed tubing is holding moisture and being "sucked upwards" through the bluestone. Any thoughts?

On 2020-05-22 - by (mod) - Builder claims its my fault because I used bad concrete.

DJW

The radiant tubing would only be expected to actually "give off" moisture if it has a leak - something you can track using infra red or a thermal scanner.We also sometimes find water coming up through a slab from inadequate site or slab drainage at time of installation or later if roof or surface runoff are not directed away from the building.

The tubing materials themselves, either copper or PEX or something similar, do not absorb, hold, nor give off moisture.

How old are the concrete slab and the bluestone installation?

How long after initial installation was the radiant tubing turned on and heated?

I ask because there could certainly have been high moisture in the concrete itself, now being driven out by heat from the tubing,

or

there could be water coming up through the slab from water below it.

On 2020-03-27 by Janine

If I turn the heating in the floor off could the frost get into the concrete and heave it up

On 2020-03-27 - by (mod) - If I turn the heating in the floor off could the frost get into the concrete and heave it up

Possibly, Yes, Janine, depending on

- the amount of water in soil below the slab

- the outdoor temperature

- the duration that heat is left off

- the slab construction details: reinforcement, drainage, insulation, thickness, soil conditions below the slab

(Oct 16, 2015) Sue said: The floor heats unevenly.

The floor heats unevenly. Some spots are cold even though other spots are toasty warm. This just started last winter. Can the pipes plug up?

Reply:

Yes individual circuits or loops can clog, particularly if they were run as separate loops off of a main. If there is a leak in radiant heat floor tubing the boiler may automatically take on make-up water through a water feeder valve so you may not recognize the leak, particularly if the leaking heating tubing leaks down into soils rather than up into the occupied space.

But a thermal scan of the floor can often find where leaks are occurring by noticing the spread of heat pattern.

Reader Question: radiant heat floor does not heat adequately - 2-year battle to fix radiant heating floor system that doesn't keep up in cold weather

2015/11/06 Melissa said:

I have a in floor heating system that we have been battling with for 2 years. The only time that it will heat up the floor is when the outside temp is warmer outside. The system cannot keep up heating when it is cold outside. Is it possible that insulation was missed.

The plumber cannot figure out the problem and is close to washing his hands of it.

Reply:

Yes, Melissa, certainly there could be missing or inadequate insulation. Have you done a thermal scan of the floor?

2015/11/07 Melissa said: what will thermal imaging show on a radiant heat floor?

We have not done thermal imaging, but what exactly would that show, or should we be looking for if we are able to do it?

Additional information. Let's say we set the thermostat at 24 deg celcius. The thermostat will activate the pump and will send hot water into the floor. The pipe at the tank is almost too hot to touch. The tubes coming out of the floor are noticeably cooler. The temperature does not climb in the basement and therefore the thermostat never stops asking for heat. I have a few theories;

1) Improper insulation. The energy is lost before it has a chance to heat the slab and when the system loses too much energy the time it takes the tank to reheat the coil all is lost and the system starts from square one again, and this constantly repeats itself, and the system essentially continuously chases it's tail.

2) Pump is unable to circulate the hot water quick enough through the system, and is actually the reason why the system isn't able to stay ahead.

Our plumber wants to more the thermostat because he feels that the fish tank that is about 4 feet away may be pushing heat into the thermostat, confusing it. As well 4 feet below the thermostat is out fresh air vent, so the plumber feels that it may also be confusing the thermostat.

Thoughts?

Reply:

If you turn on and run up the heat the image will show hot and cold spots that might tell us that the layout was insufficient, the loops mis-run, that there's been a leak, or that there are sections that look uninsulated; a thermography scan of the building exterior can give similar information around the floor perimeter.

In the article above I document what happens in a cold climate if the insulation is incomplete or the tubing too deep in the slab.

Certainly you can test the plumber's idea by simply insulating the thermostat from the fish and from any warm air drafts but I doubt that's needed. It'd be appropriate IF the thermostat was turning OFF the heat - thus thinking that you're warm enough.

Melissa said:

We are hoping that the problem isn't the lack of insulation. Is there any other problems that we could try to troubleshoot? We have switched out the thermostat already. The new one behaves the same way as the first one. The pump is definitely pumping, and we have a pressure gauge on the system showing roughly 18 psi at return.Reply:

I've suggested tubing too deep in slab and also tubing that runs through a too-cold section without proper insulation; you need to check the output and return temps at the boiler.

Melissa said:

Thank you so much for your replies. Unfortunately I think in the end we may discover that this system will never work. It has been a long drawn out battle to try and get the plumber to come, and the plumbers next solution was to shut the system off and pretend it was never there with no refund of our money.

We will bring in a different plumber and also look into the thermal imaging that you suggested. Thanks again!

Reply:

I would not abandon the radiant heat system before we have a clear list of everything that has been investigated - so that we can compare that with other ideas that need to be checked. It would be a shame to give up on an installed radiant heat system as "unrepairable" only to discover years later that a tiny switch on a circuit board was not set to the proper temperature range.

2015/11/07 Melissa said:

I completely agree. I am hoping that the new plumber will be able to troubleshoot and try and figure out possible causes of why the system won't heat the slab. It seems like people who take a look at our system are completely baffled as to why it won't work.

When we first got the system it only worked for a few short months in the winter, but it did work at one time.

I am just worried that the the plumber that I am bringing in won't be able to figure anything out for us, in which we will be left with a very expensive system that just won't work. Anyway the plumber is coming in a few days so we shall see.

Reply:

Melissa:

As I often discover in longer discussions with clients or readers, more clues emerge. The fact that your radiant floor heat worked properly at one time suggests that (barring something odd like a rising water table) the concerns of a innate design or installation errors such as tubing too deep or insulation left out are pretty much squashed.

So it sounds more like a control problem or even a tubing damage or leak or obstruction.

Before bringing in a plumber let's do some detective work: get a detailed thermographic scan of the floor and of the perimeter of the bottom of the building in cold weather with the heat on.

Send me the results.

See THERMAL IMAGING, THERMOGRAPHY for an introduction to thermography and what to expect.

On 2015-01-14 by Joyce

I found your article very interesting and educational especially since I am considering in-floor heating and trying to find out all pertinent information to do a good installation. I live in an area where the temps can drop to -40C, (-40F).

My plan was to put in the proper footing with maybe a one foot outside wall and then construct the walls up from there, thereby leaving room inside the short wall to install the Pex system. I need the home to be easy access with no stairs.

Would a double layer of R10 under the Concrete slab and then the installation of the new Pex Uponor "Fast Trak" tubing system, which in itself has insulation.

Do you think this new system will work well enough to give me the warm floors I want in an extremely cold climate?

I will be heating with a boiler system with a separate hot water tank for household use.

On 2015-01-15 - by (mod) - radiant heat floor workmanship is important

Joyce

Indeed I like radiant heat floors provided the workmanship gives a successful job.

It's not just the quantity of insulation - R20 might be fine - under the slab. It's watching out for other mistakes that cause the system to work poorly.

- be sure there is a thermal break at slab edges between indoors and outdoors

- be sure the tubing is high enough in the slab

- be sure the insulation is continuous under the slab

On 2015-01-03 by Susan - boiler setup for radiant heat

This boiler can handle three different setups with very different needs -- it does a prepurge and a postpurge when changing from one to the other. All loops share a small boiler circulator that moves water through the boiler loop, but each other setup has it's own in-line pumps. The "purge" appears to get the water in the boiler loop to an appropriate temp before switching from one demand to the other.

Our boiler is set with the DHW as priority 1, it has a target supply heat of 170, and the radiant heat as priority 2, target supply heat of 120; priority 3 is empty right now. There is a separate cutoff in the feed line to the radiant heat loops (past the common boiler loop) that will shut the whole thing down if it hits 140 -- that's the overtemp protection.

This system is *smart*! It even has built in defaults for radiant heat slab VS radiant heat ceiling (as well as almost any kind of HWH you might want). As the contractor and his crew learned about it, they taught us, since we had to play a bit with the supply target range to find the sweet spot that didn't overheat floors.

It took a long time, but boy do we have a nice setup now. The old unit was leading edge in 1952, the new unit is leading edge now.

Weil-Mclain Ultra 230 Condensing. They added some optional sensors, but the capability for the sensors is built into the base unit.

On 2015-01-03 - by (mod) -

Thanks for the helpful feedback, Susan.

The notion that a condensing boiler is also moderating temperature to a radiant heat floor system is useful to learn about but a bit uncertain at least for cases in which a heating boiler is being used both for radiant heat flooring and other applications such as heating conventional radiators or baseboard (those want to be at a higher temperature than radiant floor tubing) or heating a tankless coil for domestic hot water.

Kudos to you and your contractor.

On 2015-01-03 by Susan

Finally! The mixing valve was removed completely (Weil-Mclain says this is a condensing boiler and it does all the modulation, the mixing valve is not needed and was actually inhibiting flow); the pipes have been straightened out and several 1" lines are now 1.5"; and there's a proper overtemp cutoff in place on the floor loops.

The existing loops really do seem to be fine -- a sample of water was drawn for a repeat test of concentration for the X100 anti-corrosion agent, and the water was clean and clear.

And we can now run both pumps at once with flow of 5-7 GPM. The house is *evenly* warm now.

I think we're finally done! Just in time, 5-10 degree temps in the forecast.

Thank you for your time, Dan. Sites like this can help a *lot* - we were educated enough to understand what was going on, ask reasonable questions and help with the debugging process, and had a contractor who would work *with* us. As a partnership we got this resolved better and faster.

...

Continue reading at RADIANT HEAT TEMPERATURES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see RADIANT HEAT MISTAKES FAQs - questions, comments, arguments posted originally at this page.

Or see these

Recommended Articles

- CARPETING IMPACT on RADIANT HEAT FLOOR

- CERAMIC TILE DAMAGE REPAIR

- FLOOR TILE INSTALL on CONCRETE

- GAPS in RADIANT HEATED WOOD FLOORS - caused by running the radiant heat at too-high a temperature.

- DRIVEWAY & WALK DE-ICING SYSTEMS

- PEX PIPING INFORMATION

- PORTABLE ELECTRIC HEATER FAILURES - what happens when you rely on portable electric heaters for main heat source?

- RADIANT HEAT - home

- RADIANT HEAT AIR BOUND

- RADIANT HEAT CONTROLS

- RADIANT HEAT DEFECTS LIST

- RADIANT HEAT DESIGN & INSTALLATION MANUALS

- RADIANT HEAT INSTALLATION

- RADIANT HEAT MISTAKES

- RADIANT HEAT TEMPERATURES

- RADIANT HEAT TEMPERATURE CONTROL / MIXING VALVES

- RADIANT HEAT TEMPERATURE NIGHT SETBACK

- RADIANT SLAB FLOORING CHOICES

- RADIANT SLAB TROUBLESHOOTING

- RADIANT SLAB TUBING & FLUID CHOICES

- RADIANT SLAB TUBING LEAKS

- SLAB INSULATION, RADIANT / PASSIVE SOLAR

- SOIL R-VALUES

- THERMAL IMAGING, THERMOGRAPHY

- THERMAL MASS in BUILDINGS

- WOOD FLOOR RADIANT HEAT

- WOOD FLOOR RADIANT HEAT DAMAGE

Suggested citation for this web page

RADIANT HEAT MISTAKES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to RADIANT HEAT

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - The Radiant Panel Association: Radiant Panel Association - Radiant Professionals Alliance

8512 Oswego Road

Suite 180

Baldwinsville, New York

13027

Phone (315) 303-4735

Fax (315) 303-5559

http://www.radiantpanelassociation.org/

www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=1 offers design guidelines at http://www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=115 including these insulation R-value and coverage details:

Application#, Minimum R-Value, and Insulation Coverage

The following insulation alternatives are given for Slab on Grade construction:

Alternate #1 [(Ti-To)x0.125)=R-value, with coverage from perimeter to below frost line ["Ti-To" means we calculate the necessary R-value as (Ratio of indoor to outdoor temperature) x 0.125]

Alternate #2 R-value=5, with coverage 4' horizontal or vertical at perimeter

Alternate #3 R-value=5, with coverage under entire slab and slab edge [this is our preferred design for a cold northern climate]

The Radiant Panel Association offers education and publications in radiant heat design. See radiantpanelassociation.org

Here's their page on hydronic floors: http://www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=99 where you'll see some vague "source temperature required" graphs that give relative but not absolute temperatures. - Takagi radiant heat systems: Takagi offers pre-assembled radiant heating system installation packages including for do-it-yourself'ers, and including systems that combine radiant heat flooring with domestic hot water production using a gas-fired tankless water heater. See takagi.com for more information. "The T-KJr model (gas inputs up to 140,000 BTU per hour) is the smallest unit in the Takagi line-up. The T-KJr is perfect for light residential (i.e. small apartment units) and radiant heating applications." Also see Tankless Water Heaters.

- "Basic Hydronic underfloor - thermal storage 8 to 14 hours of control", this sketch, provided by OPTCO, is not a conventional radiant heating system design - and you'll see that the designer places the tubing too deep for efficient radiant heat delivery to the occupied space. However this design is intended for heat storage, such as in a solar heat storage system. See PASSIVE SOLAR DESIGN METHOD for more information.

- The US DOE page on Radiant heating : web search 10/11/2010, original source: http://www.energysavers.gov/your_home

/space_heating_cooling/index.cfm/mytopic=12590 is, unfortunately short on details. - SOLAR WATER HEATING SYSTEM MAINTENANCE & REPAIR [PDF] , U.S. DOE

- SOLAR WATER HEATING SYSTEM FREEZE PROTECTION [PDF] , U.S. DOE,using antifreeze mixture in solar water heaters (or other freeze-resistant heat transfer fluids), as well as piping to permit draining the solar collector and piping system.

- US DOE, SCALING AND CORROSION IN SOLAR WATER HEATING SYSTEMS, U.S. Department of Energy.

- US DOE, ACTIVE SOLAR HEATING SYSTEMS [PDF], U.S. Department of Energy

- US DOE, RADIANT HEATING SYSTEMS, U.S. Department of Energy

- ABSORPTION HEAT PUMPS & COOLERS [PDF] , U.S. DOE

- SOLAR AIR HEATING [PDF] U.S. DOE also referred to as "Ventilation Preheating" in which solar systems use air for absorbing and transferring solar energy or heat to a building

- SOLAR LIQUID HEATING [PDF] U.S. DOE, systems using liquid (typically water) in flat plate solar collectors to collect solar energy in the form of heat for transfer into a building for space heating or hot water heating. The term "solar liquid" is used for accuracy, rather than "solar water" because the water may contain an antifreeze or other chemicals.

- Azel Technologies controls, temperature gauges & thermostats for radiant heating systems

- i-Link SERIES ZONE CONTROLS (CIRCULATOR PUMP SWITCHING RELAYS ) FOR HYDRONIC / RADIANT FLOOR HEATING SYSTEMS - Quoting: The i-Link series multi-zone circulator pump switching relays simplify wiring for hydronic heating ( radiant floor heating ) systems. With leading edge features and superior product design, i-Link makes installation quick and easy.

- i-Link SERIES ZONE VALVE CONTROLS FOR HYDRONIC / RADIANT FLOOR HEATING SYSTEMS

- UNIVERSAL DIGITAL TEMPERATURE GAUGE: DS-60P - Quoting: The i-Link series Zone Valve Controls simplify the field wiring and yet control up to six zone valves in a multi-zone hydronic radiant heating system. The contractor friendly Printed Circuit Board eliminates the problem caused by incorrect wiring and saves hours of installation time. There would be no more “messy” look of conventional zone valve installations.

- DIGITAL NON-PROGRAMMABLE THERMOSTAT FOR HYDRONIC RADIANT FLOOR HEATING - Quyoting: D-508F digital non-programmable heat only thermostat is designed to control either ambient(air) temperature (A Mode) or floor temperature (F Mode) or a combination of ambient temperature with floor temperature limits(AF Mode). An auxiliary remote sensor is provided to measure slab temperature in order to control the floor temperature(within maximum and minimum limits in AF Mode) in hydronic radiant floor heating system. It can also be used for sensing the outdoor temperature in A Mode.

- DIGITAL PROGRAMMABLE THERMOSTAT FOR HEATING/COOLING & HYDRONIC RADIANT FLOOR HEATING - Quoting: Azel Technologies introduces 500 series electronic programmable thermostat that utilizes the lastest digital technologies for residential and light commercial systems. D-500 is designed for 24 Vac single-stage heating and cooling systems. D-502F is designed to control the floor temperature in Hydronic Radiant Floor Heating Systems. The 500 series can accurately control the temperature within one degree. Reliable permanent memory retains the programmed settings in the event of a power failure. In addition, the large, easy to read LCD display with backlit makes the thermostat easy to operate and simple to program.

- Azeltec, SOLAR DIFFERENTIAL CONTROL: DST-932, P.O. BOX 53138 Thornhill ON L3T 7R9 Canada Tel: 905-223-5567 Email: info@azeltec.com Web: azeltec.com- Quoting: The DST-932 differential temperature controller is designed for the Solar Heating Systems. The DST-932 switches on a pump in order to transfer heat from solar collector to a storage tank. The controller reads the temperatures of the storage tank (T1) and of the collector (T2), when this differential temperature (T2-T1) is higher than a set value (dt), it will switch on the pump. It is possible to limit the maximum temperature of the storage tank and also activate a freeze protection function. By switching to manual mode it allows the test of the heating system by turning the pump ON or OFF. A universal sensor P-01 or P-02(higher temperature range) is supplied with the control. This solid state temperature sensor probe can be extended up to 500 feet.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.