Water Pump Pressure Control Switch Diagnosis & Repair

Water Pump Pressure Control Switch Diagnosis & Repair

Pumptrol® & similar pressure control switch repair procedures & kits

- POST a QUESTION or COMMENT about diagnosing, repairing, or replacing a well pump pressure control switch

Pumptrol and similar water pressure control switch repair procedures.

Water pressure control switch repair: Pumptrol switch repair & repair kits.

This article describes how a water pump pressure control switch works and how to diagnose problems with the building water supply that seem to be traced to the pump control, switch, or to other underlying issues with a water pump, well, piping or other controls. We describe the diagnostic steps to take if a water pump won't turn on, won't turn off, or a switch that is burned, corroded or damaged.

We discuss: How to Repair a Water Pressure Control Switch that Sticks "ON" or "OFF" or is irregular, and how to Diagnose a Malfunctioning Water Pump Control Switch.

Pumptrol 20-40, 30-50, or 40-60 pressure switch operation. What are the controls, switches, valves found on water tanks and water pumps, what do they do, how are they repaired?

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water Pump Pressure Control Switch Repair Procedures

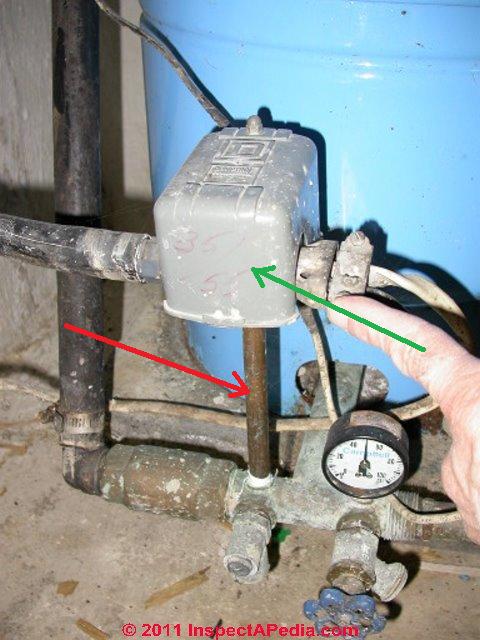

This article explains inspecting, cleaning, and possibly repairing a typical Water Pump Pressure Control Switch, normally found mounted on piping at the water pressure tank such as in this example [image] where you see a small gray-covered box with electrical wires coming in (power) and out (to pump) of it.

We describe troubleshooting several problems that can cause the control switch to fail to turn the pump ON when it should or that can cause the control to fail to turn the pump OFF when it should.

Following the procedure to test the operation of a pump control switch just below we provide links to individual diagnostic & repair articles that address particular pump operating problems such as a pump that won't turn on or won't turn off or that runs continuously.

How to Check a Well Pump Pressure Control Switch for Normal Operation

If the water supply is high in sediment

often sediment will clog the pressure sensing opening at the bottom of the pressure control. We've tried cleaning out this orifice but it's never proven to be a lasting repair.

If your pump pressure switch stops responding to changes in water pressure it probably needs to be replaced.

How to Diagnose and Repair a Water Pump Pressure Control Switch that Sticks "on" or "off" or is misbehaving

If we’ve traced a pump control problem to the water tank or water pump pressure switch itself with some certainty, we will often just replace the switch.

But beware, we once replaced a pump control switch when the problem was a clogged filter which was causing the pump to cycle on and off erratically. We felt pretty stupid.

How to Diagnose a Malfunctioning Water Pump Control Switch

We’ll need to do some water pump switch diagnosis – here are a few ideas that may help getting a recalcitrant pump control switch working again.

We’ll need to do some water pump switch diagnosis – here are a few ideas that may help getting a recalcitrant pump control switch working again.

Watch Out: Safety warning - Shock Hazards: To remove a pump control/pressure switch remember to turn off electrical power, and using a neon tester or VOM double check to make SURE that electrical power is off, and taped-off so that on one turns it on and causes you to get shocked.

Working around electricity and plumbing is particularly dangerous because of the increased chance of touching a live electrical wire while touching grounded plumbing piping. Turn off power.

See WATER PUMP ELECTRICAL SWITCHES.

A pump or water tank pressure control switch is designed and adjusted to turn the pump on at a "cut in" pressure, usually 20 psi or 30 psi, and to turn the water pump off at a "cut out" pressure, usually 40 psi or 50 psi.

When you buy this control it is usually set at the proper cut-in and cut-out pressures - check the box.

If your pump control is properly adjusted then it should be turning the pump on and off nicely at the pre-set pressures.

If the switch is behaving erratically or not coming on or not shutting off at all, there could be various explanations, some of which have nothing to do with the switch itself.

See WATER PRESSURE CONTROL SWITCH ADJUSTMENTS

These other problems are discussed

at WATER PRESSURE LOSS DIAGNOSIS & REPAIR

and WATER TANK REPAIRS.

Alternatively you may want to see one of these water pressure or pump diagnostic procedures:

1. The water PUMP WON'T TURN OFF when it should - the pump just keeps running.

If water pressure is at or above the pressure switch CUT-OUT pressure and the pump won't turn OFF there could be several causes and fixes that we will describe.

Watch out: this is a dangerous condition. If the pump brings water pressure well above normal building water pressure levels, say over 70 psi, there is risk of a burst pipe or burst water tank that can cause a flood or injure someone. Turn off the pump.

See WATER PUMP WONT STOP RUNNING - there we list all of the things that can cause a pump to run continuously.

2. The water PUMP WON'T TURN ON when it should.

If water pressure falls below the pressure switch CUT-IN pressure and the pump won't turn ON there could be several causes and fixes that we will describe.

See WATER PUMP WON'T START - where we list all of the things that prevent a pump from turning on.

Some water pump control problems can cause both pump-start and pump-stop problems, as you'll see in the following

3. The water pump runs but there is WEAK WATER PRESSURE

See PUMP RUNS, WEAK or NO WATER PRESSURE for a diagnostic table

4. The water pump runs but there is NO WATER PRESSURE

See NO WATER PRESSURE for a diagnostic table

5. The water pump runs but the PUMP CYCLES ON & OFF RAPIDLY or INTERMITTENTLY

See WATER PUMP SHORT CYCLING for diagnosing a pump that turns on and off too rapidly

See WATER PUMP INTERMITTENT CYCLING for diagnosing a pump that runs at odd times and for no apparent reason

The pump pressure control switch, by being connected

to the actual water piping in the building, senses the water pressure and when necessary, turns the water pump on.

The water pump pressure control switch either turns on the water pump directly, or (particularly when a submersible water pump is in use), this switch may operate a physically separate (usually wall-mounted) heavier-duty pump relay which turns on the water pump itself.

See WATER PUMP RELAY SWITCH for more details of that control.

If the Water Pump Is Not Turning OFF

Watch out: If your well pump won't stop running, you should probably turn power to the pump off to avoid burning up the pump motor.

If the water pump will not turn OFF,

see WATER PUMP WONT STOP RUNNING for detailed diagnostic and repair procedures.

Water Pump Won't Start - If the Water Pump is Not Turning ON Try These Steps:

If your well pump won't start, see the diagnostic and repair advice

Try the Pressure Control Switch Re-Set or Manual or Bypass Lever - if your pressure switch has one

See details at CHECK RESET SWITCH / BYPASS LEVER (not present on all controls)

Check the pump pressure control switch for pressure sensor clogging or failed diaphragm

See these two procedures

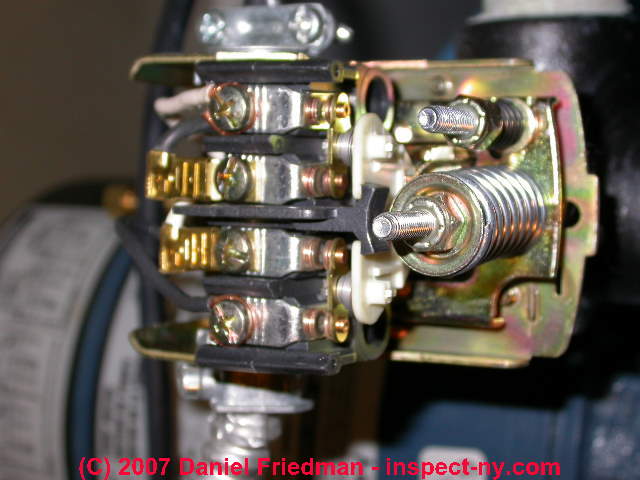

Check & Clean the Well Pump Switch Contacts

If the pump pressure control switch contacts are burned we can sometimes get it working again for a while by first, turning off electrical power as we described above,

and then using a file, carefully cleaning all touching-surfaces the switch contacts.

Details are at CHECK PRESSURE SWITCH RELAY CONTACTS

If after inspecting the pump pressure control switch or its mounting fittings you decide that you've repaired it or that you need to replace it, follow the instructions

at PUMP PRESSURE CONTROL REPLACE for reinstalling the control.

Watch out: do NOT try working on a pump control switch without first removing electrical power - you could be killed by electrical shock.

Replacement Parts & Repair Kits for Pumptrol® and Similar Water Pump Control Switches

This topic has moved to PRESSURE SWITCH REPAIR KIT - separate article

Guides & Manuals for Adjusting or Repairing the Water Pump Pressure Control Switch

This section has moved to WATER PUMP PRESSURE SWITCH MANUALS

Thank you to our readers for their generous comments

Jack Moore said:

Wow, thanks for writing! This is really helpful to someone who just inherited a house with one of these pumps. No one I know had ever had one before, so I was a little intimidated. But now I know a little more about how to find, adjust, and repair the well pump. Glad I found this!

...

...

Continue reading at WATER PUMP PRESSURE SWITCH INSTALL / REPLACE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see WATER PUMP PRESSURE SWITCH REPAIR FAQs - pump control switch diagnostic & repair questions & answers posted originally at the end of this article.

Or see these

Recommended Articles

- WATER PRESSURE REGULATOR ADJUSTMENT

- WATER PUMP INTERMITTENT CYCLING - pump turns on for no apparent reason

- WATER PRESSURE REGULATOR ADJUSTMENT - municipal water pressure control

- WATER PRESSURE CONTROL SWITCH ADJUSTMENTS - home for water pump pressure control switch

- WATER PUMP PRESSURE SWITCH DIFFERENTIAL NUT ADJUSTMENT

- WATER PUMP PRESSURE SWITCH RANGE NUT ADJUSTMENT

- WATER PUMP PRESSURE SWITCH SAFETY

- WATER PUMP PUMP PRESSURE SWITCH STANDARD (PSI) SETTINGS

- WATER PUMP PRESSURE SWITCH MAXIMUM PRESSURE SETTING

- WATER PUMP PRESSURE SWITCH SETTINGS TOO HIGH

- WATER PUMP PRESSURE SWITCH INSTALL / REPLACE

- WATER PUMP PRESSURE SWITCH INSTALLATION MANUALS

- WATER PUMP PRESSURE SWITCH HUMMING SOUND

- WATER PUMP PRESSURE SWITCH LEAKS

- WATER PUMP PRESSURE SWITCH LOCATION

- WATER PUMP PRESSURE SWITCH NOISES

- WATER PUMP PRESSURE SWITCH REPAIRS

- WATER PUMP PRESSURE SWITCH SAFETY

- WATER PUMP SHORT CYCLING - home

- WATER PRESSURE TABLE 1: PUMP WON'T RUN, WON'T STOP, or CYCLES

- WATER PRESSURE TABLE 2: PUMP RUNS, WEAK or NO WATER PRESSURE

- WATER PRESSURE TABLE 3: PUMP RUNS, NO WATER or INSUFFICIENT WATER

- WATER PUMP SHORT CYCLING - pump turns on and off to rapidly

- WATER PUMP WON'T START - no water pressure

- WATER PUMP WONT STOP RUNNING - pump just keeps running

- WATER TANK AIR PRESSURE ADJUSTMENT

Suggested citation for this web page

WATER PUMP PRESSURE SWITCH REPAIRS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to reader Bob Hartman-Berrier for discussing the diagnosis of a pressure switch that would not turn the pump on, traced to a switch tubing fit problem. June 2010.

- Square D Company, Schneider Electric - North American Operating Division, 1415 S. Roselle Road, Palatine, IL 60067, Tel: 847-397-2600, Fax: 847-925-7500

- Square D Pressure Control Switch Catalog

- Square D 9013 series pressure control switches provide these special water pressure control switch features: narrow pressure differential controls, higher horsepower pump control switches, manual on/off switches, automatic low water pressure cut-off, pulsation plugs, and other features.

- Narrow Differential Pressure Switches Schneider Electric provides narrow differential switches including 6-20 PSIG differential switches. Choose from the 9013FSG42/49 or higher HP 9013FYG42/49. Also available is the 9013FRG with reverse action. The 9013FRG pressure switch is non-adjustable differential with 6-14 PSIG cut-in and 1-11 PSIG cut-out ranges.

- Higher HP Pressure Switches Need a larger HP motor for longer runs in deep wells? Then look to the 9013FYG or 9013GHG pressure switches. These switches directly control all types of pumps up to 5 HP and can be used in the control circuit of a magnetic starter for even larger pumps.

- Manual On/Off Switch The 9013 series of pressure switches offer an optional on/off switch. This allows you to manually turn on and off your pump system for extended periods of time.

- Automatic Low Pressure/Water Cut-off If system pressure is lost for any reason, a low water condition for example, the automatic lower pressure/water cutoff feature will open the contacts, turning off the pump.

- Pulsation Plug Pulsation plugs are available to control pressure due to increased start up pressure generated by high speed jet pump motors or by valves prone to a surge in pressure.

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- When Technology Fails, Matthew Stein, Chelsea Green Publisher, 2008,493 pages. ISBN-10: 1933392452 ISBN-13: 978-1933392455, "... how to find and sterilize water in the face of utility failure, as well as practical information for dealing with water-quality issues even when the public tap water is still flowing". Mr. Stein's website is www.whentechfails.com/

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.