Standard Water Pump and Tank Pressure Control Settings

Standard Water Pump and Tank Pressure Control Settings

Factory Settings: pump-on & pump-off pressure settings

- POST a QUESTION or COMMENT about Setting the Water Pump Pressure Switch and Improving Water Pressure

Standard settings for a well pump pressure control switch:

This article describes how to adjust building water pressure by setting the water pump cut-in and cut-out pressure on the well water pump pressure control switch.

We also point to our article on how to adjust building municipal or community water pressure at a building. Contact Us by email if you are having trouble finding the information you need.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What are the Usual Water Pump and Tank Pressure Control Settings in PSI?

Most residential water systems using a water pressure tank and water pump use one of these two pressure operating ranges:

Low-pressure operating range pumps like low horsepower pumps and many jet pumps

- Cut in (start pumping) - 20 psi

- Cut out (stop pumping) - 40 psi

Higher-pressure water pumps, like submersible pumps, and higher horsepower 2-line jet pumps

- Cut in (start pumping) - 30 psi

- Cut out (stop pumping) - 50 psi

How to Restore Factory Settings to the Pump Pressure Control Switch

This procedure will guide you in restoring the original factory settings to a typical pressure control switch if you have changed one or both of its adjustment nuts and now need to restore the original settings.

This procedure will guide you in restoring the original factory settings to a typical pressure control switch if you have changed one or both of its adjustment nuts and now need to restore the original settings.

- Turn off electrical power to the pump & control - for safety to avoid fatal electrical shock

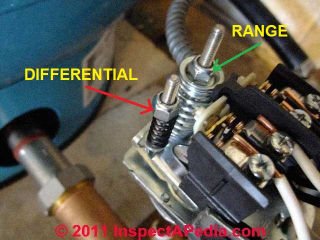

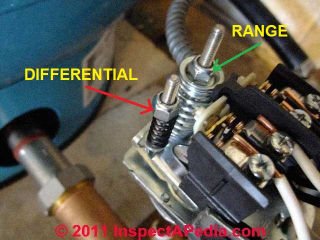

Watch out: there is live voltage at the terminals inside the pressure controls switch. Touching a live contact can shock you or kill you. Be sure to turn electrical power OFF before trying to adjust the pump pressure control switch. - Loosen the differential nut (the smaller adjuster nut) until there is no pressure on the spring you'll have set the switch to a difference (between CUT-IN and CUT-OUT) in pressure of about 15 psi.

Really? Well not necessarily. If the differential nut has never been adjusted off of the original factory settings, then leave it where it is. In fact some manufacturers point out that you don't usually need to change the range nut away from factory settings. But if you did, well now we'll find our way back. - Tighten the range nut (the larger, taller adjuster) so that there is considerable pressure on the spring - but the spring is not 100% closed or squashed down,

- Turn ON electrical power to the pump & start it by opening a nearby faucet if necessary.

If the pump does not start, run water at a nearby faucet until the pump turns on. - Watch the pressure increase on the tank pressure gauge; With pump running turn off the faucet, let the pump run pressure up to 40 PSI. .

- Turn OFF electrical power to the pump at 40 psi

Watch out: at 40 psi immediately turn the pump OFF. - Adjust the range nut to open the switch contact points: loosen the large nut (the taller adjuster) by turning it counterclockwise

until you see the pressure switch contact points just open up. (That's turning the pump OFF at the present pressure which we just stopped at 40 psi.) - Turn on electrical power to the pump - in order to watch its normal cycling

- Note the CUT-IN pressure: Run water to cause the pump to turn on - note the pressure at that point - that's you current the CUT-IN pressure.

If you're spot-on the CUT-IN pressure will be 20 psi.

- Note the CUT-OUT pressure: Turn the water off and let the pump run - up to the CUT-OUT pressure.

Watch the pump and tank pressure until the pump turns off. Note that higher pressure - that's your current CUT OUT pressure.

If you're spot-on the CUT-OUT pressure will be 40 psi.

Watch out: NEVER LET THE PUMP KEEP RUNNING so that it creates pressure in your water pressure tank above 70 psi or you risk a leak and worse, at higher pressures that exceed the water tank's limit, the tank can burst, injuring or killing anyone nearby. (This actually happened to a plumber in New Paltz, New York some years ago.) - Set the Differential:

IF you previously had adjusted the differential nut off of its original factory setting, and therefore IF at step 2 you loosened it further,

THEN you will need to adjust (tighten) the smaller differential-nut to increase the difference between CUT-IN and CUT-OUT until it's at about 20 psi of difference. - Re-Adjust the Range Nut if necessary: You may need to make small adjustments to the range nut if the CUT-OUT (larger nut) does not reach the standard top-end pressure.

Cycle though steps 7-10 above if necessary.

You can also adjust the range to operate in the 30/50 psi range instead of the 20/40 psi range to which we reset the control.

Watch out: even a perfectly-adjusted pump pressure switch won't work properly if the water pressure air charge was not set properly.

Details are

A table showing change in psi for turns of the adjustment nuts in the pressure control switch is

at WATER PRESSURE SWITCH NUT ADJUSTMENTS

Also see instructions for your specific pump control switch at

WATER PUMP PRESSURE SWITCH MANUALS

How High Can we Set the Water Pressure in My Building?

You can't just set the pump pressure as high as you want to. Here's what can go wrong with excessive pump pressure control settings:

- Exceeding well pump pressure capability: If you set the cut out (stop pumping) pressure higher than the water pump is capable of reaching, the pump will just keep running indefinitely until it burns up or blows a fuse or trips a circuit breaker or overheats.

- Causing a ruptured water tank internal bladder: we have had a number of reports of ruptured bladders in water tanks.

In normal use the bladder in most water tanks is not stressed at all - the internal water tank bladder simply moves up and down as water enters or leaves the tank - pressure on either side of the bladder (air on one side, water on the other side) remains the same.

If your water tank were a less common model in which air were inside the bladder rather than outside it, excessive air pressure could burst the bladder.

If you set the water pump pressure too high on one of these systems, you might cause the water bladder to rupture inside the tank. In an extreme case you might blow up the water tank itself. Most water tanks are not designed this way. - Blowing up a water pressure tank - serious safety hazard: if you set water pressure too high, even if the pump is capable of reaching that pressure it may be unsafe.

Watch out: Most water pressure tanks are designed to operate safely in the water pressure ranges we cited above.

If you had the bad luck (and stupidity) as to be using a water tank that has no pressure relief valve installed, it is possible to cause the tank to rupture or even explode, risking damage to the building or even serious injury or fatality if anyone is nearby. - Causing leaks at fixtures: even if your water tank were rated for high pressure, and even if your water pump is capable of high water pressure, if you run water pressure in a building over 70 or 80 psi you can expect to have recurrent leaks at plumbing fixtures: most water faucets and tub faucets are not designed for high pressure use.

- See details at MAXIMUM PRESSURE SWITCH SETTINGS

- Also see WATER TANK SAFETY

- Also see HOW MUCH AIR TO ADD - How Much Air is needed in the water pressure tank?

Reader Question: How can I increase the well pump cut-in pressure without setting the cut-out pressure too high?

We have a well and have been experiencing intermittent low water pressure.

I checked the pump and it cuts in at 25 PSI and cuts off at 65 PSI. But the diagram on the inside of the pump switch cover indicates that it should be cutting in at 40 PSI and out at 60 PSI. It has a maximum PSI of 80.

How do I get the well pump to cut in at 40 PSI instead of 25 PSI? I believe this would give us adequate water pressure at all times.

According to the information on your website adjusting the mainspring will change both the cut in and cut off pressures and adjusting the differential will adjust only the cut off pressure. Apparently, there is no way to adjust only the cut in pressure? Thanks for your help. - L.W.

Reply: Here is how to change the cut-in pressure without pushing the cut-out pressure too high

A competent onsite inspection by an expert usually finds additional clues that help accurately diagnose a water pressure or pump problem.

And your cause of inadequate water pressure might be due to more than just the static pressure capability of the pump. For example, the pump's maximum flow rate in gpm could be inadequate, or you could have a partly closed water valve or clogged water pipe.

Put another way, many homes that operate between 30 and 50 psi have very good water pressure and flow rate at the fixtures. So if you don't there may be another problem besides the pressure switch settings.

That said, here are some things to consider:

Most pump pressure controls are tricky to adjust in the way you mentioned, but you should be able to set the cut-in to a higher number and then adjust the cut-in - cut-out pressure differential to keep the cut-out pressure from being too high. That will cause your well pump to turn sooner when you start running water (and will cycle it more often, a factor in pump wear).

At PUMP PRESSURE CONTROL ADJUSTMENT we explain that the smaller nut on the pump control switch adjusts the differential or gap between cut in and cut out and the larger nut raises the cut-in pressure (as well as cut off).

In other words you can set the cut in pressure higher and then narrow the differential so that the cut-off pressure is not dangerously high or above what the pump can reach.

Watch out: don't run the water pressure control with too narrow a differential between the cut-in and cut-out or the pump may just sit there short-cycling until you burn up the motor. If your pump is staying on for less than 30 seconds (I prefer longer), you may be heading for trouble.

Watch out: setting the cut-out water pressure too high can cause the pump to never turn off or at high pressures you may find leaks at fixtures. And high water pressure that exceeds the rated water tank pressure can burst the tank - a very dangerous event. Also make sure your pressure tank has a relief valve installed.

Don't Forget to Check For Other Causes of Bad Water Pressure

Finally, I suspect that after you have increased the pump cut-in or cut-on pressure to a higher number, say 30 psi, if you will find that this does not fix your water pressure problem.

Finally, I suspect that after you have increased the pump cut-in or cut-on pressure to a higher number, say 30 psi, if you will find that this does not fix your water pressure problem.

The fact that your low water pressure is intermittent might in fact point to a problem with the well flow rate itself.

See details at WELL YIELD DEFINITION

Once the well pump turns on and presuming you are running water continuously, especially if more than one fixture is running, you may see that your pump runs continuously until you turn the water off.

If this is the case, it's not the starting water pressure setting that is at fault, it's the pump or piping or well that is limiting the water flow rate.

If I'm right that means that the water flow rate through the system, from well through pump and pipes, elbows, valves, etc. is just not enough, and further diagnosis is in order.

Our photo of copper supply piping (above left) was sent by reader Tom.C. who was tracking down a clog in the supply piping that meant poor water pressure from the point of the fitting you see above onwards through the plumbing fixtures served by that pipe.

Follow-up and Water Pressure Problem Solved:

Looks like I will call a plumber. I adjusted the mainspring to raise the cut-in/cut-out range but there was no change.

The water pump switch was faulty and had to be replaced. Also the line going into the water tank was clogged and had to be rodded out. Working fine now.

The homeowner attempted to adjust the pressure control switch for the water pump. When he turned the adjusting nut the water pump behavior and water pressure did not change. That observation led to calling a plumber who replaced the pressure control switch - which solved the water pressure problem.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-07-25 by (mod) - pump won't knock off

Brady: you would set the pressure control switch to cut off at a lower pressure, say 50 psi.

Those instructions are at: WATER PRESSURE CONTROL SWITCH ADJUSTMENTS

But you should also read the diagnostics at

On 2020-07-25 by Brady

How do you adjust pressure on well pump on 60 psi won’t knock off

On 2019-02-19 - by (mod) -

Kim

In the article index given just above on this page you will find a diagnostic procedure title something like pump won't stop running.

There you'll see usual causes for the condition that you described which is the pump unable to reach the cutoff pressure. When it's a new pump I don't suspect damage to the pump itself unless it was run dry, but I suspect a low water supply in the well, a leak, or low voltage.

On 2019-02-19 by Kim

I have installed a new two lined jet pump and a new bladder tank but the pump will not get a psi higher than 25, I can get water pressure in the first bathroom and washer, closest to the pump house and then no pressure anywhere else.. Help

On 2018-12-14 by cjstone

My 2-line jet pump fills tank, great pressure at second-floor bathroom, but will not switch off. Gauge reads about 52 psi when I shut pump off at electricity-supply switch. No drop in tank if water not used. A new pressure switch reacts the same, even after shut-off coil adjusted to extreme (counter-clockwise).

The hose from the switch to the pressure gauge box has also been replaced, presumably eliminating sediment blockage at both ends. It appears be 3/4 full of air. When manipulated, content broke up into separate bubbles and pockets of air and water. Should it be only water in the hose? Would it not take a much higher pressure to compress air to the point where it would sufficiently push the diaphragm in the switch?

On 2018-11-11 - by (mod) -

Adding air to the pressure tank will not make one iota of difference in having NO water pressure - e.g. due to pump not working.

If the "motor" is above ground, that IS your pump.

That will be either a one-line jet pump or a two line jet pump - both of which are described in this article series - check the ARTICLE INDEX to read about those pumps.

If you have no pump above ground, then your pump is in the well and it's a SUBMERSIBLE PUMP - also in that article index.

You wrote

The motor is warm and did seem to have like a trying to kick on hum to it but no production.

You could not have said that if your pump were down in the well - a submersible pump.

On 2018-11-11 by Charles

so if I pump air in from the valve to build the air pressure back up that wouldn't make a difference cause the motor is bad which draws up the water into the pressure tank? How do you know if it's the motor or the pump in the well under the water?

On 2018-11-10 - by (mod) -

Charles

With the pump OFF and all water pressure drained from the system the pressure tank would be pre-charged with air pressurized to 2 psi below the pressure control-switch CUT-IN pressure (e.g. 18 psi at a 20 psi cut-in setting).

Lack of an air charge in the tank will not itself explain loss of water pressure - it's the pump that obtains water and pressurizes the system.

However if the pressure tank was water-logged (had no or insufficient air precharge) the pump may have been short cycling on and off until the pump motor was burned-up or the control switch relay contacts burned-up.

If a motor hums and doesn't run it's jammed and needs repair or replacement. Leave it OFF to avoid further overheating or a fire.

On 2018-11-10 by Charles

This is the guy with the issue not a commenter. lol

he no water diagnostic I reviewed earlier and none of the items on the check list were an issue. No frozen lines, no shut offs activated, the well still has water, and the pipes from the well aren't clogged from debris.

There's just no water running. The pressure tank has no psi which I believe the motor pressurizes?

The motor is warm and did seem to have like a trying to kick on hum to it but no production. I check the power regulator where they says the 4 contacts sometimes have carbon build up from arching but no.

They are very clean like brand new. I'm going out to get a bicycle pump to put in some air pressure into the tank and see if that changes anything. I figure if you can pump a bicycle tire up to 20lsi I should be able to pump up the pressure tank the same way.

At-least when I took out what air there was in the pressure tank no water came out indicating a broken bladder.

On 2018-11-10 - by (mod) -

Charles

Regrettably, bleeding out the 10 psi charge in your pressure tank is not going to help with a case of running out of water UNLESS the tank air pre-charge pressure were higher than the pump control switch cut-in pressure. Typical cut-in pressures are 20 psi or higher.

If the pump motor hums but doesn't run the pump motor needs repair or replacement; it could be a bad starting capacitor or the motor could be seized. A seized or damaged motor or impeller can in turn also occur from debris in the water (impeller) or running the pump "dry".

I suggest the diagnostic steps at NO WATER PRESSURE https://inspectapedia.com/water/No_Water_Pressure.php

On 2018-11-10 by Charles Sardina

I have a well with water of course and 2 days ago the water stopped running. SO I went to the breaker box and all the powers were turned on. I went to the tank and it said 10lbs. So I decided to bleed out the rest of the tank to see if it would restart the pump. Nothing. Then I tapped on the motor and the gauge to check for debris and got nothing. The gauge didn't move and It still showed 3lbs.

X amount of minutes later I heared a small hum increase from the motor but no pressure increase in tak pressure and no water. What's wrong here?

On 2018-09-02 - by (mod) -

Watch out: very high pressure can blow a tank or pipe and injure or kill someone nearby.

Turn off the pump, drain down pressure below the pressure tank's rated maximum or below 70 psi.

Then re-set the pressure control switch CUT OUT - typically 40 psi on , 60 psi off maximum.

On 2018-09-01 by John Roberts

Started up my water pump. For 4 months. Just got it running but rhe pressures way too high 90psi how high should my pressure l tank be and should i adjust the pressure nut before i restart it again

...

Continue reading at WATER PRESSURE CONTROL SWITCH ADJUSTMENTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see PUMP PRESSURE SWITCH STANDARD (PSI) SETTING FAQs - questions & answers posted originally at this page.

Or see these

Recommended Articles

- WATER PUMP PRESSURE CONTROL SWITCH

- CHATTERING RELAY CONTROL SWITCHES

- MAXIMUM PRESSURE SWITCH SETTINGS

- PUMP PRESSURE SWITCH STANDARD (PSI) SETTINGS

- WATER PRESSURE CONTROL SWITCH ADJUSTMENTS

- WATER PUMP PRESSURE CONTROL SWITCH CHATTER

- WATER PUMP PRESSURE SWITCH NOISES

- WATER PUMP PRESSURE SWITCH REPAIRS

- WATER PUMP PRESSURE SWITCH REPAIR KIT

- WATER PUMP PRESSURE SWITCH INSTALL / REPLACE

- WATER PUMP PRESSURE SWITCH LOCATION

- WATER PUMP PRESSURE SWITCH MANUALS

- WATER PUMP SHORT CYCLING - home

- WATER PUMP PRESSURE SWITCH SAFETY

Suggested citation for this web page

PUMP PRESSURE SWITCH STANDARD (PSI) SETTINGS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thank you to Jason Gapco at Education Solutions for careful editing and text suggestions, 12/2008

- Thank you to Steven Prior, a reader, for questions leading to our clarification of the function of the large and small pump pressure control switch springs, and for his photograph of the pump switch springs, 3/23/2009

- Thanks to reader Rise for pointing out that turning a nut clockwise means "to the right" or to the "more tight" position in the convention of how most threaded devices work. Nov 2009.

- Thanks to reader Don Travis for discussing water pump adjustment details - July 2010

- Pumptrol™ Pressure Switch Adjustment, Square D, Schneider Electric Corporation, 8001 Knightdale Blvd., Knightdale< NC 27545 1-888-778-2733 - Square D Technical Library, web search 07/24/2010 original source: http://ecatalog.squared.com/techlib/docdetail.cfm?oid=09008926800a93be

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.