Paperboard Products & their Contents

Paperboard Products & their Contents

Does Paperboard contain Asbestos?

- POST a QUESTION or COMMENT about paperboard products and their contents, does paperboard contain asbestos?

Paperboard products used in construction & buildings.

What are the contents of paperboard products and do paperboard products contain asbestos?

This article addresses the question of possible asbestos found in paperboard products, and specific concerns for artists and the art conservancy community.

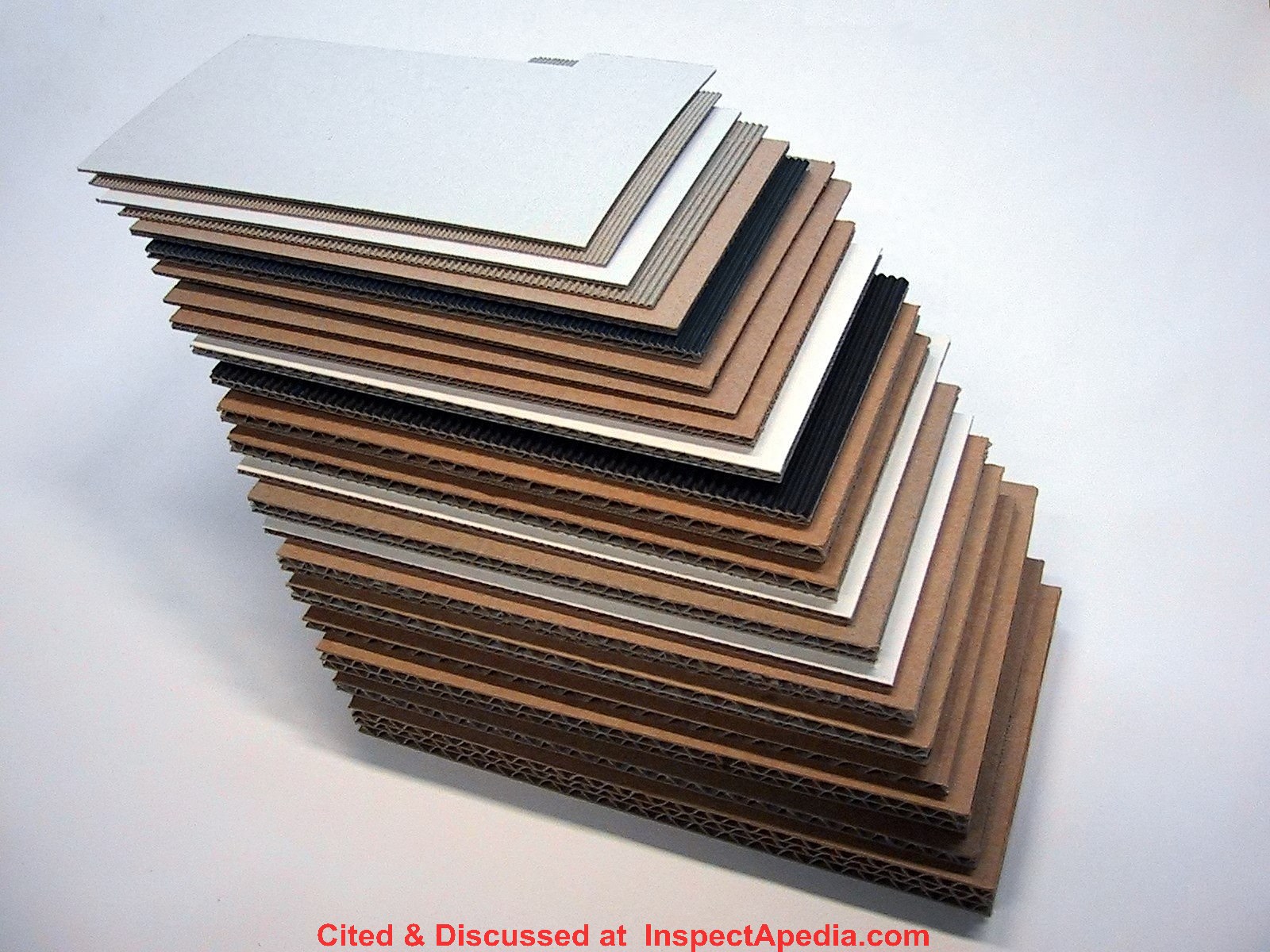

Page top photo: corrugated fiberboard samples made from paperboard (courtesy of By Chris 73 / Wikimedia Commons, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=2606705).

This article series describes asbestos content in building sheathing & other construction products including fiberboard, insulating board and sheathing board.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Is there Asbestos Content in Paperboard Products?

Heavy paperboard products, widely used across a range of applications, are occasionally found in building construction as wall or ceiling sheathing and in other locations.

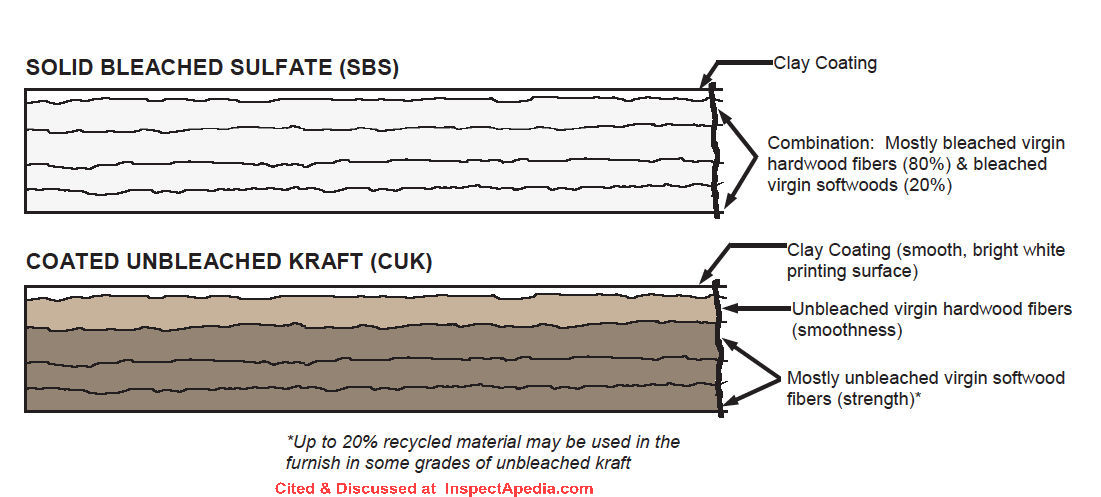

Paperboard is described, roughly, as one of four types:

- SBS - Solid Bleached Sulfate,

bright white, premium paperboard made from bleached virgin hardwood fibers and up to 20% virgin softwoods, with a clay-coated surface, usually thin, used in packaging and in medical products

[Click to enlarge any image] - CUK - coated, unbleached Kraft paper,

using unbleached virgin hardwood and mostly unbleached virgin softwood fibers for strength, with up to 20% recycled material - Coated recycled paperboard,

often with a top layer of white fibers and a clay coating, used in packaging - Non-bending "chipboard"

made from recycled newsprint and old corrugated box papers, used in the body of heavy duty shipping boxes, covered with printable paper surface - definition and image source: https://paperbox.org/4-types-of-paperboard/ 2022/04/03

Definition of paperboard

Paperboard products are paper-based materials that are thicker than just paper, and can be single ply or multi-ply. It is a useful product for many reasons such as its light weight, strength, and ability to be cut and formed.

The terminology used to describe paperboard is not always consistent, often depending on type of industry and location, with terms such as cardboard, kraft board, chipboard, boxboard, and others being used to refer to a paperboard product.

Paperboard can be made from new raw materials, such as fibers from various hardwoods or softwoods, or recycled paper. Products made from recycled materials are often less functional and the actual composition may be somewhat unclear leading to some added precautions when used for food packaging.

Variables among paperboard products include:

- source of materials used to make it

- the type of pulping process to extract the necessary fibers

- whether bleaching of some type is used to change the color

- how many ply is used for the product - anywhere from single ply to several layers

- a potential added coating to improve whiteness and surface appearance

History of Paperboard Carton Material

The first paperboard carton was produced in 1817 in England. Further refinement and uses developed throughout the 1800s and 1900s with ovenable paperboard arriving in 1974.

Thanks to Wikipedia (of which we are a supporter) for it's overview of paperboard products.

Along with the other cited resources, their information was helpful in writing this article.

Does This Layered Stiff Paperboard used in Artwork Contain Asbestos?

On 2022-04-01 by Reader (an art conservator)

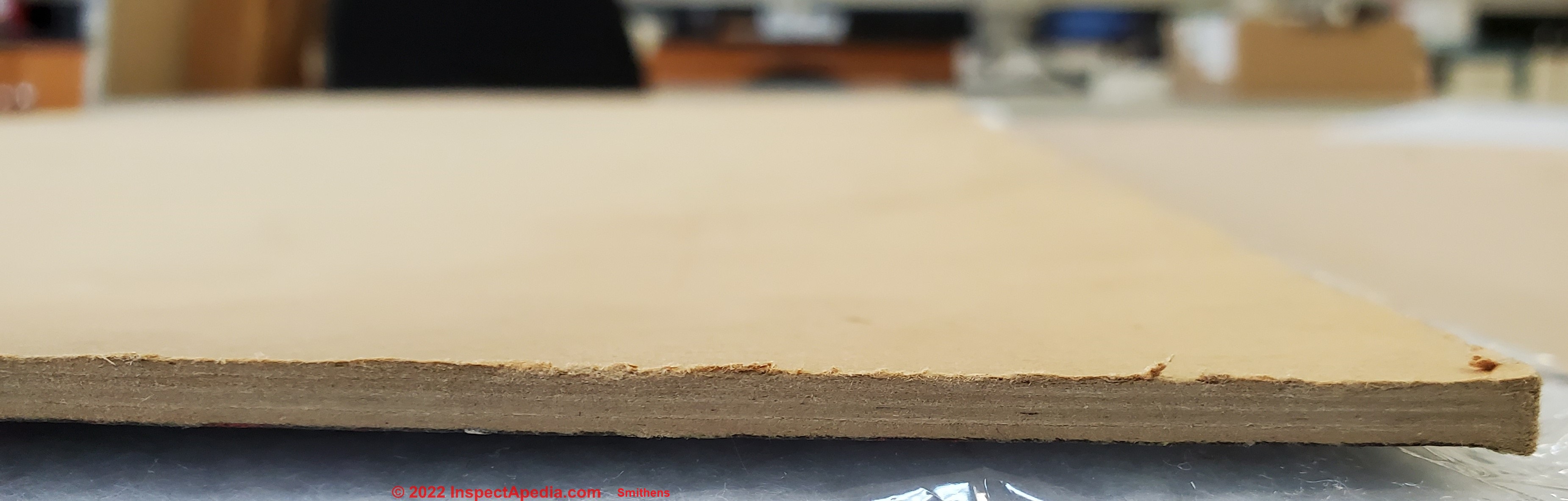

I have an odd question regarding the identification of an industrial board product. Someone has cut it down to use as a support for an artwork, likely from the mid-20th century.

I was hoping you might be able to identify the product and advise whether it might contain asbestos.

The board is 5 mm thick, comprised of four layers of pressed fibrous paper forming a stiff paper board support. The colour is even and grey along the outer edges and light brown on the reverse.

The light brown reverse is smooth. The front surface is coated with a matte, dark brown material which entirely covers the front surface of the board and appears to be commercially applied, as part of its original finish.

It has a dimpled texture. See photo below for a detail of the surface and the outer edge.

Thank you so much for considering this one. - Re-Posted from private email

Reply: need to identify the white board material adhered to paint spattered fiberboard

It was common to use fiberboard (soft or MDF material) as an art base though harder board products such as Masonite were far more widely used.

When those are a wood- or plant-based product (usually brown or tan fibres) it'd be unusual to find asbestos, though not impossible, as you can read on this page.

I'm unclear about what looks like a white board material adhered to the paint-spattered fiberboard and shown at the bottom of your photo - what is that and is that an asbestos concern?

Reader follow-up:

I had realised that fibreboards do not often contain asbestos (from your posts), but our FTIR-ATR spectra did show a clay-based mineral in the board which could be anthophyllite, but it could also be a talc or clay filler.

If the brand of board could be identified, it might give more information and provide information about whether it was safe to handle (and display).

The image I sent before was an oblique view of the paint-spattered board with the edge of the board (which is actually light brown - grey toned, rather than white) and a view of the surface. Ignore the spattered paint - that is artist applied, but the dark brown surface is part of the original board.

[Above] is a another view of the outer edge (and the back of the board).

- Art Conservator

Reply: need more information to answer asbestos question

That's a really interesting thick gray-white paperboard product and not one I've seen - with those multiple laminated layers. And it's whiter than those older wood or plant-based products.

We have researched and written about asbestos in talc - a reasonable concern in particular if the product is being sawn or demolished.

So let's fill in all we can find out about your specific board.

- Thickness: 5mm

- Number of plies:

- Date: ca 1950

- Used by:

- Found at:

- Condition:

- Artist and her history:

- In short, anything that we might use as a clue to try to track down the board's manufacturer, age, source, brand, ingredients.

And I'd sure like to see that Fourier-transform infrared spectroscopy report. Were the layers of material analyzed individually?

I appreciate the concerns that a conservator may face across the remarkable range of products and materials used by artists - my own research started with hazardous materials in glazing compounds and with the purported use of blood in artwork. (Kahlo)

Our comments on asbestos in talc are at

ASBESTOS in TALCUM POWDER

are at https://inspectapedia.com/Microscopy/Asbestos-in-Talc.php

and, spurious addition,

BLOOD in ART WORKS, TESTING FOR

and less spurious, hazards in glazing compounds has been widely considered including

- Rossol, Monona, "Arts and Crafts, an Industrial Hygiene Challenge", The Synergist, May 2012, pp. 34-37American Industrial Hygiene Association.

Arts & Crafts materials, hazards & toxicity: general classes include clays, dyes, glazes, solvents, minerals, pigments, photochemicals. Rossol lists hazardous materials commonly found in arts & crafts workshops, pottery studios, art workshops & art schools form an extensive list.[3]

Some examples include: ultra fine particles, even in nanoparticle size ranges, of inorganic compounds (antimony, cadmium, copper, chromium, cobalt, lead, manganese, mercury, titanium, zinc) used in paints, inks, and other colored materials; glazes and enamels, including ceramic glazes containing other metals such as nickel, and rare earths, selenium, vanadium; stained glass workshops offering exposure to arsenic and even uranium, along with soldering fluxes or solders containing barium, boron, lead, lithium, potassium, sodium; dyes including textile dyes (more than 2000);

- BUILDING ENVIRONMENTAL HAZARDS includes one of our lab photos of glaze fragments

Reader follow-up: possible asbestos in white paperboard used as art backer?

I had realised that fibreboards do not often contain asbestos (from your posts), but our FTIR-ATR spectra did show a clay-based mineral in the board which could be anthophyllite, but it could also be a talc or clay filler.

If the brand of board could be identified, it might give more information and provide information about whether it was safe to handle (and display).

The image I sent before was an oblique view of the paint-spattered board with the edge of the board (which is actually light brown - grey toned, rather than white) and a view of the surface.

Ignore the spattered paint - that is artist applied, but the dark brown surface is part of the original board. Here is a another view of the outer edge (and the back of the board).

On 2022-04-01 by Art Conservator

Reply: more-white board products (often more properly described as "paperboard") do raise the asbestos question

Thinking a bit more, still preliminary, about this question and adding a speculative remark about your FLIR results.

First: what problem are we addressing here?

- health and safety hazards for conservationists working on this item?

- shedding hazards and steps to avoid that?

- academic interest, history of material and its identity

We know that clay was a very common ingredient in coatings on some papers, particularly where used in artworks, posterboards, etc.,

Your 5mm paperboard is mostly white gray and has what look like quite a few plies. I'm doubtful that it's feasible to cut off a sample sufficient for microscopic examination as this is an artwork;

How did you collect your FLIR sample? Micro-punch or what?

Do you think this board is made to include laminated plies that include pre-coated papers in its construction? You'd expect that to be clay.

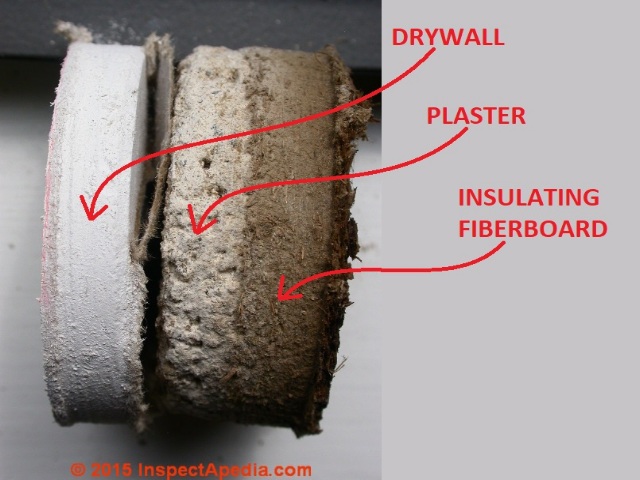

Examples of more brown or tan fiberboard products used in construction as insulating board, sheathing, or plaster backer and some of my photos are

at PLASTER TYPES & METHODS in BUILDINGS such as this test plug that I cut from an old house wall:

This fiberboard was being used not as an art backer or substrate but as a base for wall plaster.

In my opinion the more-white board products (often more properly described as "paperboard") do raise the asbestos question BUT research shows that in producing paper, it was indeed possible to produce very-white pulp from trees.

- Georgia Tech RBI, "Defining Moments 1950s", (web article) Renewable Bioproducts Institute

500 10th Street NW

Atlanta, GA 30332-0620 - retrieved 2022/04/03 original source: https://rbi.gatech.edu/defining-moments-1950s

Excerpt:

The development and commercial use of chlorine dioxide made it possible to produce very white pulp from trees such as the southern pine. The availability of chlorine dioxide therefore was instrumental in establishing the Southeastern United States as a dominant pulping area.

So we might expect deliberate use of asbestos in a paperboard product chiefly where fire-resistance was needed and not in other paperboard products, but arguing with self: our experience with asphalt-asbestos and vinyl-asbestos floor tiles & sheet flooring demonstrates that asbestos may show up in both fibrous form ("long fibers") for reinforcement, or (often missed by labs and tests) as asbestos shorts (very short particles, sometimes in my lab I see down to the 1u range) used as filler material (in floor tiles).

This exchange helps me see where I need to clarify our own terms. A shift from "cardboard" to "paperboard" might help in researching this question.

References on Paperboard Products and their Contents

- Paine, Frank A., ed. The packaging user’s handbook. Springer Science & Business Media, 1990.

in the chapter Paperboard by

F. A. Paine B.Sc., C.Chem., F.R.S.C., F.I.F.S.T., F.Inst.Pkg., F.I.D. at https://link.springer.com/chapter/10.1007/978-1-4613-1483-7_4?noAccess=true

Abstract

Paperboard is one of the major raw materials used in packaging. It is the generic term covering folding boxboards, chipboards, straw boards, etc. for primary packages and corrugated and solid fibreboards for transit packaging.

‘Cardboard’ is often erroneously used as a generic term for these materials but should be reserved to describe boards used for making cards of all kinds.

There are many applications for paperboard, from simple cartons to more complex board structures for liquid packaging. It can be converted into fibre drums for bulk chemicals and combined with other materials to make containers for the transport and protection of heavy machine tools and delicate instruments.

Generally, in addition to its containment and protective qualities, paperboard has at least one surface suitable for printing.

I would buy the chapter but Springer wants about $270. U.S. for JUST the 17-page chapter - absurd to the point of insulting.

Excerpting:

Terminology for Paperboard Products

The line of demarcation between paper and paperboard is rather loose. ISO define paper with a grammage above 250 g/m2 as paperboard, or simply as board. However, in some parts of the world the dividing line is placed at 300g/m2.

There are many anomalies: e.g. blotting papers are often heavier than300 g/m2 and fluting medium and some liner boards used for corrugated are less than 250 g/m2.

Structure and general properties

Typical paperboards consist mainly of cellulose fibres of which the most common source is mechanical and chemical pulps derived chiefly from wood. Material recovered from used papers and boards (secondary fibres) are also widely used in the cheaper grades of material. Straw and esparto grass are also used for some boards.

The structure of typical boards can vary from a single homogeneous layer or two to eight plies, each of which may or may not have the same fibre composition depending on the strength,stiffness, optical, bending or other properties required for the finished board.

Typical structures for white lined folding box boards for cartons are shown in Figures 4.1--4.3. The top ply in a typical board is of bleached chemical wood pulp which will give the necessary surface strength and printability.

An underline of a lower grade (essentially white pulp) will prevent show through of the grey/brown colour of the middle plies of secondary fibre.

The back may be similar to the middles but where extra strength or printability is required, a better grade of chemical/mechanical pulp mixed in the appropriate ratio, should be used.

It is very important that all the plies are well bonded and this is dependent on achieving the right degree of mechanical entanglement and hydrogen bonding in the board making process.

Some definitions of Paperboard Components

Backs: The ply that forms the under surface of the sheet .Caliper (thickness): Also called substance, usually measured either in mils(thousandths of an inch) or microns (millionths of a metre (JLm)) (1 mil =25.4 JLm).

Furnish: The fibre composition of a paper or board sheet, usually given in percentages.

Grammage: The mass per unit area of the board in g/m2.

Liner: The ply that forms the top surface of the sheet, usually a good quality printable layer.

Machine direction (MD) and cross direction (CD): Sometimes called grain and cross grain. The MD is the direction along the sheet as it emerges from the board-making machine and the CD is at right angles to the MD.

Middles: Plies in the middle of the board, frequently of secondary fibres or mechanical pulps.

Ply: One of several layers of fibre that make up a multi-ply board.

Sheet size: The width of a sheet is given first. This is the dimension measure din the CD, e.g. 500x750 mm means 500 mm in the CD and 750 mm in the MD.

Underliner: A ply of lower quality than the top surface between the liner and the middles. usually to prevent the grey/brown colour of the middles showing through the top liner.

- Emblem, Anne, ed. Packaging technology: Fundamentals, materials and processes. Elsevier, 2012.Chapter 10, A Riley, 10 - Paper and paperboard packaging

Abstract:

Paper and paperboard are made from cellulose fibres, extracted from trees, combined together with additives to make a continuous matted web.

This chapter covers the raw materials, processes and on- and off-line treatments used to manufacture fibrous substrates (paper and paperboard) used for the conversion into packaging components.

These components include wrapping materials, bags, sacks, cartons, tubs, lids, moulded fibre packaging, and backing cards for various plastic, paper and paperboard combinations. This chapter will also discuss the different substrates, conversion methods and decorating methods - Korhonen, Kari, T. Liukkonen, W. Ahrens, G. Astrakianakis, P. Boffetta, A. Burdorf, D. Heederik et al. "Occupational exposure to chemical agents in the paper industry." International archives of occupational and environmental health 77, no. 7 (2004): 451-460.

includes concern for asbestos in the paperboard industry - American Society for Testing Materials. Committee D-6 on Paper and Paper Products. Paper and paperboard: characteristics, nomenclature, and significance of tests. No. 60. ASTM International, 1951.

- Ryan, Dave. "Advice on Asbestos in the Home." EPA J. 12 (1986): 21. - not citing asbestos

...

Continue reading at FIBERBOARD SHEATHING ASBESTOS CONTENT or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS CEILING TILE IDENTIFICATION - home

- ASBESTOS in DRYWALL & in joint compound

- ASBESTOS IN FIBERBOARD BUILDING SHEATHING - asbestos content of fiberboard sheathing products i

- ASBESTOS TESTING LAB LIST

- FIBERBOARD SHEATHING - home - wood or cellulose based insulating board products

- FIBERBOARD SHEATHING IDENTIFICATION - recognize/identify Celotex®, Homasote®, Masonite® Nu-Wood® and other insulating fiberboard building sheathing products used as exterior wall sheathing and as interior wall & ceiling surfaces at InspectApedia.com

- HARDBOARD MASONITE™ & OTHER BRANDS

- HARDBOARD & MASONITE USED in WORKS OF ART

- HARDBOARD Masonite™-like INGREDIENTS

- IDENTIFY NU-WOOD PANELS - separate article

- SHEATHING, GYPSUM BOARD - some may contain asbestos

Suggested citation for this web page

PAPERBOARD PRODUCTS CONTENTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Homasote® Company, 932 Lower Ferry Road, West Trenton, NJ 08628-0240 Tel: 800-257-9491 Ext 1332, or from outside the U.S. call 609-883-3300. Website: http://www.homasote.com/ , Email:Sales@homasote.com

- [2]Celotex Corporation, PO Box 31602, Tampa FL 33631, with offices in Atlanta, Chicago, Cincinnati, Dallas, Oakland and Philadelphia, and plants in six U.S. States is headquartered in Tampa, FL. Celotex is a national manufacturer of residential and commercial building materials. Website: www.celotex.com Tel: 800-CELOTEX

"Guide Specifications: SturdyBrace® Structural Fiberboard Wall Sheathing", 6/29/12, original source: blueridgefiberboard.com/pages/sturdybrace.php [Copy on file as SturdyBrace-guidespecs.pdf] - [4] Georgia Pacific: information about DensGlas gypsum board building sheathing can be found at the company's website at gp.com/build/product.aspx?pid=4674

- [7] Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR. jstor.org/publisher/aptech

- [11] "Insulite Co. v. Reserve Supply Co.," 60F.2d 433 (1932), Circuit Court of Appeals, Eighth Circuit, July 26, 1932. Web Search t/23/12.

- [13] "Separating the Fiber of Wood", A.S. Lyman, U.S. Patent No. 21,077, 3 August 1858

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.