Insulation Identification Photos

Insulation Identification Photos

Identify different building insulating materials

- POST a QUESTION or COMMENT about how to identify different kinds of building insulation

How to identify types of insulation used in buildings & their mechanical systems:

This series of articles provides details about all types of building insulation, identifying each type of insulation.

We illustrate and include photographs of insulation materials that would not be expected to contain asbestos as well as asbestos-containing materials.

This document assists building buyers, owners or inspectors who need to identify building insulation & those who need to recognize asbestos-containing materials (or probable-asbestos) in buildings by simple visual inspection.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

A Guide to Identifying Various Types of Insulation Materials Used in Buildings

On this page we provide a list of links to a comprehensive list of building insulating materials.

On this page we provide a list of links to a comprehensive list of building insulating materials.

Each of those links provide photographs, uses, & properties of that insulating material.

[Click to enlarge any image]

Which building insulation materials do or do not contain asbestos?

While an expert lab test using polarized light microscopy may be needed to identify the specific type of asbestos fiber, or to identify the presence of asbestos in air or dust samples, many asbestos-containing building products are obvious and easy to recognize.

But since there were not other look-alike products that were not asbestos, a visual identification of this material can be virtually a certainty in many cases.

ASBESTOS-FREE INSULATION MATERIALS contains our complete list. These non-asbestos insulations include cellulosic insulations such as loose-fill cellulose and balsam wool batts, cotton insulation, fiberglass insulation, mineral wool insulation, slag wool insulation, and rock wool insulation.

Index to Types of Building Insulation

- INSULATION IDENTIFICATION GUIDE

- PREHISTORIC & EARLY INSULATION MATERIALS

- AEROGEL INSULATION

- ASBESTOS FIREPROOFING SPRAY-On Coatings - separate article

- ASBESTOS INSULATION

- BALSAM WOOL INSULATION

- BRICK INFILL INSULATION

- BUBBLE / CLOSED-CELL FOAM SHEET INSULATION

- CARDBOARD CORRUGATED FIBERBOARD INSULATION - separate article

- CELLULOSE INSULATION - separate article describes paper-based insulating products

- CERAMIC INSULATION

- CONCRETE BLOCK INSULATION

- CONCRETE, LIGHTWEIGHT, INSULATED & ICF CONSTRUCTION

- COTTON INSULATION

- DUCT INSULATION

- EEL GRASS INSULATION

- FIBERBOARD

- FIBERGLASS

- FIRE BLOCK FOAM

- FOAM SPRAY INSULATION

- HEMP / JUTE INSULATION - separate article

- ICF Insulated Concrete Form Construction: see CONCRETE INSULATION

- ICYNENE FOAM NSULATION

- LATEX FOAM SPRAY INSULATION

- MINERAL WOOL INSULATION

- MOSS INSULATION

- PERLITE INSULATION

- POLYESTER FIBER INSULATION

- POLYPROPYLENE INSULATION

- POLYISOCYANURATE INSULATION

- POLYURETHANE FOAM SPRAY (SPF) INSULATION

- POLYSTYRENE INSULATION

- RADIANT BARRIERS - separate article

- REFLECTIVE INSULATION - separate article

- ROCK WOOL - see MINERAL WOOL INSULATION

- SEAWEED INSULATION

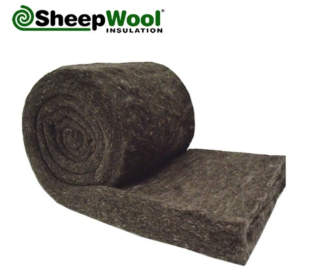

- SHEEP WOOL INSULATION photo.

Also see SHEEPS WOOL INSULATION - separate article - SHREDDED INSULATION PRODUCTS - large coarse fibres

- SOY-BASED FOAM SPRAY Building Insulation

- SPRAY INSULATION SYSTEMS - other, cork, EPS, wood fiber, etc.

- STARCH FOAM INSULATION

- STRAW BALE CONSTRUCTION - separate article

- STRAW INSULATION

- STRUCTURAL INSULATED PANELS (SIPs) - STRESS SKIN INSULATED PANELS - separate article

- STYROFOAM INSULATION

- TRIPOLYMER FOAM INSULATION

- UFFI INSULATION

- VERMICULITE INSULATION

- WOOD FIBRE INSULATING PANELS - separate article

Watch out: don't confuse the R-values per inch versus specific product R-values given for insulation products discussed in this article series. For example, Thermablok® Thermal Insulation is described as having an R-value of 10.3/Inch; the product thickness is 0.4 inches so it's effective R-value when used in a single thickness is R 4.12.

Quoting R-values as R per Inch is helpful for comparing the innate insulating values of various products but to find the actual product R-value you need to find its actual thickness.

See details at INSULATION R-VALUES & PROPERTIES - R-values & U Values of various materials

Also any insulation product's installation details can completely swamp it's R-values, in particular if the installation suffers significant air leakage.

See details at INSULATION AIR & HEAT LEAKS

Early & Prehistoric Building Insulating Materials

Prehistoric insulating materials included animal skins,fur, wool, and plant products such as reed, flax, and straw, while for greater warmth and protection from weather builders used natural shelters (caves), stone, and earth or soil.

Prehistoric insulating materials included animal skins,fur, wool, and plant products such as reed, flax, and straw, while for greater warmth and protection from weather builders used natural shelters (caves), stone, and earth or soil.

Photo: Straw bale house in San Miguel de Allende, Guanajuato, Mexico, photographed by the author.

Some sources describe earth as having excellent insulating materials but in our opinion the benefit is better described as having good thermal mass so that temperatures inside the structure changed slowly.

The houses in the Neolithic village of Skara Brae (Orkney Island, Scotland) are the oldest known – nearly 5.000 years old – earth-sheltered, green roofed dwellings in the world. (Bozsaky 2010)

Natural materials used for insulation included vegetable fibres (eelgrass, reeds, wheat straw (cf thatched roofs), and by the 1800s, reed panels that were decay resistant but needed to be coated with tar or similar materials to resist moisture.

Other building or home insulating materials that people have used include cork (Romans, 23-79 AD, wall panels, 1870), straw bales (U.S. Nebraska 1880s), compressed straw, and "wood wool (1842 von Pannewich) and wood waste-based insulation (1920s in Scandinavia) that should be considered early instances of "balsam wool" and "jute-flax" insulation described on this page. (Bozsaky 2010)

When insulating living space or buildings, insulating material can be faced with problems of suitability to the specific application, cost to produce and install, decay, insect and rodent attack, mold contamination, moisture, rot, compression, loss of insulating value and fire hazards.

As you will read in the descriptions of each insulating material, each has its strengths and its vulnerability.

Aerogel Insulation

Aerogel materials are made from silica or silicate materials and are properly-called silica-aerogels, a material first produced by Kistler in 1931.

- Thermablok, Inc.

6900 Interbay Blvd., Suite A

Tampa, FL 33616 USA

Tel:1.813.756.8354 / 813-980-1400

Web: www.thermablok.com

Email: sales@thermablok.com

Thermablok INSULATION DATA SHEET [PDF] Thermablok is an aerogel: 0.4 " (10mm) thickness, R 10.3/Inch

Excerpt: Thermablok is a flexible, nanoporous aerogel blanket insulation that reduces energy loss while conserving interior space in residential and commercial building applications.

Thermablok™ SAFETY DATA SHEET SDS [PDF] (2009) retrieved 2021/07/26 original source: https://www.thermablok.com/wp-content/uploads/Thermablok_msds_20090318.pdf

The company provides strip and blanket insulation products used in building construction & insulation.

Asbestos Insulation Found in Buildings

Above: a common form of asbestos insulation found in older buildings is an asbestos-based corrugated paper insulating wrap used on pipes.

See details about actual building insulation made of or contaminated with asbestos, discussed

at ASBESTOS BUILDING INSULATION.

Also see ASBESTOS FIREPROOFING SPRAY-On Coatings

Also see ASBESTOS PIPE INSULATION - asbestos used on heating or plumbing pipes.

Because asbestos was used in many other products found on or in buildings, also

see ASBESTOS INSULATION for a complete guide to all forms of asbestos insulation found in or on buildings.

Balsam Wool Insulation photo

"Balsam Wool" is a wood fiber product or "cellulose" insulation that was widely used in homes and in a variety of other applications in the U.S. from at least the 1930's.

See BALSAM WOOL BATT INSULATION for details.

Brick Infill in Building Walls as "Insulation"

Brick wall "insulation" or brick nogging may be found in wood framed buildings built up to about 1900. Usually these homes have exterior clapboards and interior plaster walls.

See BRICK or BLOCK WALL CAVITY INSULATION

Bubble Foil or Polyethylene Foam Flexible "Reflective Insulation"

Bubble insulation combines the properties of a radiant barrier with bubbled plastic (basically bubble wrap) to achieve both a limited R-value and a reflective barrier value.

These insulating products are often used in metal buildings and in some RVs or similar vehicles in lieu of alternative insulation products like fiberglass that may trap and hold condensing moisture.

Similar to air bubbles trapped in plastic and faced with a reflective barrier, often polyethylene, are foil-faced closed-cell polyethylene foam insulation products.

Both provide a flexible insulating material but the thickness, density, and R-vales differ between these two approaches. Both products combine features of

- Air barrier & vapor barrier (usually combined)

- Reflective barrier - see details including more data on bubble insulation

at REFLECTIVE INSULATION and

- A thin insulating core of varying R-value by product

Producers of foil- or reflective-barrier-faced closed-cell polyethylene foam insulation products

- Prodex, Insulation4Less.com, 8801 Wallisville Rd. C., Houston TX 77029 USA, Web: https://www.insulation4less.com/

Prodex Difference R17, Reflective, reinforced foil-faced (both-sides) of 5 mm (0.2") closed-cell polyethylene foam center. The polyethylene center is coated on both sides with a polyethlene backer and then surfaced on both sides with a reflective, reinforced foil

Excerpt: Prodex Difference: R17/Inch, unaffected by humidity, prevents condensation, prevents 97% of radiant heat transfer, vapor barrier, core sealed on both sides with flang, elastic, seals around nails, closed-cell polyethylene foam center, rippled [foil] surface increases airflow [presumably reducing surface condensation - Ed.]

Producers of foil- or reflective-barrier-faced trapped air bubble type insulation products

- EcoFoil

202 Blue Creek Drive

Urbana, IA 52345 SA Tel:

(888) 349-3645

Email:

customerservice@ecofoil.com Web: https://www.ecofoil.com/

1/4" to 5/16" thick double bubble layers faced with an aluminum-polyethylene reflective barrier on both sides; also sold as a single-bubble layer insulation. The company's website does not quote an R-value. Typical R-value for double-bubble insulation is R 1.1 per layer or about R 4.4 / Inch.

Ecofoil describes the insulation product shown above:

This insulation is constructed of a double layer of polyethylene bubble insulation, bonded to two radiant barrier metalized sheets. The insulation not only works well to reflect radiant heat, but it also works as a vapor barrier, preventing condensation which can cause mold.

EcoFoil Double Bubble Foil Insulation is primarily used for pole barns, metal buildings, basement walls, crawl spaces, and storage units.Our insulation can be used for both new construction and existing buildings. - EcoFoil, https://www.ecofoil.com/products/double-bubble-foil-insulation-foil-both-sides-4-x-75-300-sq-ft

- RadiantGuard Reflective Foils & FIlms, RadiantGuard® INSTALLATION INSTRUCTIONS [PDF] RadiantGuard, Tel: (866) 528-8412, Web: https://www.radiantguard.com/ retrieved 2021/07/26 original source: radiantguard.com/pages/how-to-install-radiant-barrier

- See more product examples

at RADIANT BARRIERS - including installation instructions and more product sources

The "double bubble insulation" foil faced on both sides shown above is also discussed in a roofing repair question cited originally at ROOFING INSPECTION & REPAIR

Cellulose building insulation photo

Our photo above is of blown-in cellulose insulation.

See CELLULOSE LOOSE FILL INSULATION for details.

Ceramic Insulation

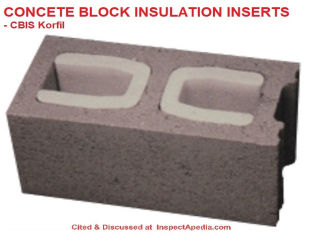

Concrete Block Insulation - EPS Styrofoam Inserts

Concrete block walls are most-often insulated by the addition of foam board placed on the outside of the wall in new construction, or on the inside of walls in an insulation retrofit job.

However some builders may construct a concrete block wall adding foam or loose fill foam beads in the hollow spaces afforded by the concrete blocks, or by using pre-fabricated concrete blocks that are sold with a foam insulation core. Examples of these products are given in detail

Other forms of insulated concrete block are blocks made of lightweight concrete.

See those "insulated concrete block" details

at CONCRETE INSULATION & ICF CONSTRUCTION [just below on this page]

Lightweight Concrete & ICF Insulated Concrete Form Construction

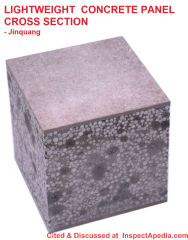

Both lightweight concrete block and panels may also be manufactured as lightweight cellular concrete shown below, without the concrete "skin" on the lightweigh concrete blocks shown above. (Illustration below adapted from Alibaba's oniste store, September 2023).

Above are examples cross-section of a lightweight panel distributed by Jinquang and building construction using those panels, cited in more detail below.

See details about lightweight concrete construction and also ICF construction at

CONCRETE INSULATION, LIGHT WEIGHT

Differences among Foam Core Insulated Concrete Block, Lightweight concrete block, and ICF Insulated Concrete Form Construction

Shown above: lightweight concrete in panel form.

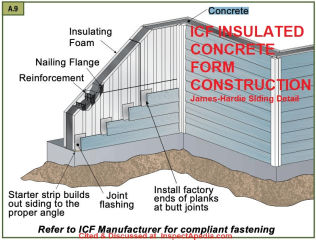

Below: ICF Insulated concrete form construction: concrete is placed between or inside of pre-fabricated insulating forms that are left in place to set the R-value for the wall (illustrated below).

Above, James Hardie provides a general example of how the company's siding products should be attached to ICF or Insulated Concrete Form constructed buildings. Cited below in this discussion.

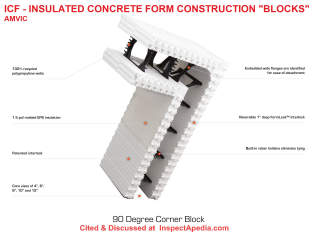

The ICF Block illustrated below, from AMVIC, is an EPS (expanded polystyrene) foam "block" with polhypropylene webs that is filled with concrete, to provide an insulated concrete wall.

This is an EPS (expanded polystyrene) foam "block" with polypropylene webs that, at the jobsite, is filled with concrete, to provide an insulated concrete wall.

ICF or Insulating Concrete Form construction is defined in the 2006 IRC

INSULATING CONCRETE FORM (ICF).

A concrete forming system using stay-in-place forms ofrigid foam plastic insulation, a hybrid of cement and foam insulation, a hybrid of cement and wood chips, or other insulating material for constructing cast-in-place concrete walls.

In that same model code, ICF design and construction are regulated in the model codes such as the International Residential Code or IRC (2006) in

IRC R404.4 Insulating concrete form foundation walls

You can see an example of this building code as adopted by the U.S. state of Maryland in

- MARYLAND & SAN ANTONIO TX & OTHER STATES 1 & 2 FAMILY BUILDING CODE (2012) [PDF] [51MB] Based on their adoption of the International Residential Code® For One- and Two- Family Dwellings, 2006, Retrieved 2016/09/17 original source: online ref for ICC_IRC (2006) law.resource.org/pub/us/code/ibr/icc.irc.2006.pdf (appendix E)

Also see discussions of the use of lightweight concrete found at

ENERGY SAVINGS RETROFIT OPTIONS includes ultra lightweight concrete insulation, insulating forms for concrete foundations

STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs)

- AMVIC R22 INSULATED CONCRETE FORMS (ICF) Product Data Sheet [PDF] AMVIC, 501 McNicoll Avenue Toronto, ON, CA, M2H 2E2 Tel: 1 (877) 470-9991 Web: amvicsystem.com -retrieved 2023-09-07, original source: amvicsystem.com/wp-content/uploads/2019/08/Amvic-ICF-R22-Product-Data-Sheet.pdf

- James Hardie FIBER CEMENT BEST PRACTICES, Appendix A, (2014) [PDF] available from James Hardie Corporation, 231 S. LaSalle St., Suite 2000

Chicago, Illinois 60604, USA, Website: https://www.jameshardie.com or in Canada: http://www.jameshardie.ca

[Photo examples of ICF construction and lightweight concrete construction are needed, please use the page top or bottom CONTACT link]

Cotton building insulation photo

Our photo above is of cotton batt building insulation.

See COTTON INSULATING BATTS for details.

Duct Insulation

See

Eel-grass Insulation

Our discussion of eelgrass insulation is now found at

Fiberboard building insulation photos

Fiberboard insulating sheathing board was used and continues in use as a structural wall sheathing board 15/32-inches thick (one board was 1/2") and with R-value of about 1.5.

Fiberboard insulating sheathing was and continues to be made of plant cellulose such as wood fibers, combined with a binder, a water-resistive coating or component (such as paraffin and/or asphalt), and other treatments.

Our photo is of a fiberboard building sheathing / insulating board product. See Sheathing Celotex Homasote & Other brownboards discussed

at SHEATHING, FIBERBOARD for details about insulating sheathing used on both the exterior (under siding) and interior of buildings.

See FIBERBOARD SHEATHING IDENTIFICATION where we include identification photos and historic details and insulating properties of all of the current and prior brands and tupes of fiberboard panels.

Example: CELOTEX CemestO BOARD HOMES

Fiberglass Insulation Product Photos

See FIBERGLASS INSULATION IDENTIFICATION & PROPERTIES - properties for a key to identifying fiberglass building insulation brands & products.

Fire Block Foam Insulation

Fire-block foam is a fire-resistant foam spray used to seal building floor, wall, or ceiling penetrations, especially in new construction or a spray-foam insulation retrofit job.

See FIRE-BLOCK FIRE RETARDANT FOAM SPRAY BUILDING INSULATION

Foam Spray Insulation Types

Please see this separate article that sorts out all of the various types of foam insulation

FOAM SPRAY INSULATION TYPES including both modern sprayed in place foam insulating products including SPF (Spray Polyurethane), or

ICYNENE FOAM SPRAY INSULATION) and older

sprayed UREA FORMALDEHYDE FOAM INSULATION, UFFI.

Also see FORMALDEHYDE HAZARDS

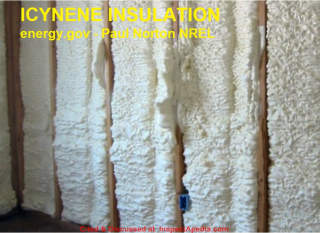

Icynene Foam Insulation photo

Our photograph shows icynene spray foam building insulation.

See ICYNENE FOAM SPRAY INSULATION

and also PHENOLIC FOAM INSULATION

and POLYISOCYANURATE FOAM and IAQ for details.

Hemp & Jute Building Insulation

Above, a photo of jute insulation placed between rafters of a North American home built in the 1920s, courtesy of an InspectApedia reader.

See details at HEMP / JUTE INSULATION

Mineral Wool Insulation Identification

Mineral wool is produced by melting rock and slag to produce a mineral fiber that may be aggregated and bound by a resin for use as building insulation.

Mineral wool, also called "rock wool" or slag wool or stone wool may be found in buildings as chopped loose-fill insulation, as longer twisted ropy loose fill insulation, or as insulating batts such as the Gold Bond Rock Wool insulating batt shown in our photograph.

See MINERAL WOOL - ROCK WOOL INSULATION - home

Below: While mineral wool insulation may be white, gray, black or even pink, it most-often looks like either the photos just below.

See all of the MINERAL WOOL APPEARANCE VARIATIONS in our separate photo guide to the different versions, colors, and textures of mineral wool, rock wool, or slag wool insulation.

Question: is this an asbestos insulation?

I stumbled upon your site while trying to find out what kind of insulation I have in my very old home.

I stumbled upon your site while trying to find out what kind of insulation I have in my very old home.

Here is a picture.

[Click to enlarge any image]

Of course my main worry is that it's asbestos. - Anonymous by private email 2018/06/02

Reply: mineral wool, or a mix w/ fiberglass

The photo is indistinct, but it looks like a mixture of fiberglass and rockwool or a mineral wool insulation product, this one rather ground-up.

It seems unlikely, certainly there would not be asbestos expected to be in fiberglass or mineral wool. But keep in mind I can't that your health and your money on a blurry photograph.

You can see more identification photos of those materials at our website.

Reader reply:

Well thanks again. I couldn't get too much of a close up but those chunks you see are very soft, like paper or cardboard. Here's another picture a little closer, the plastic bag may be dulling the image a bit.

But from what you said, there's doesn't seem to be a need for too much concern. I suppose I can send it out to a lab if I need to. Anyway, thanks for helping on a saturday.

Moderator reply:

"Paper insulation" would be cellulose insulation.

Moss Building Insulation

Moss has been used as building or shelter insulation [research in process - Ed.]

- Bakatovich, Aliaksandr, and Florindo Gaspar. "Composite material for thermal insulation based on moss raw material." Construction and Building Materials 228 (2019): 116699.

Abstract:

The demand for thermal insulation materials composed of sustainable raw materials remains a challenge.

The substances used in the manufacture of thermal insulation materials may also, under certain conditions, have a beneficial effect on the insulated surfaces, the environment, and the human or animal body, in particular by the ability to absorb moisture and biocidal properties.

Ecological insulation materials of vegetable raw materials are increasingly widespread. Most of the time, these materials are made from flax, hemp or wood fibres, agglomerated with a binder.

The objective of this work was to determine the possibility of using Sphagnum moss as a fibre in thermal insulation panels. To carry out this study, several compositions were developed for thermal insulation boards based on moss, rye straw and reed, using liquid glass as a binder.

The specimens were tested for thermal conductivity, and strength to compression and bending. Best results were achieved on panels of moss and straw with thermal conductivity of 0.044–0.046 W/(m.K) at a density of 156–190 kg/m3, without shrinking during drying and a compression strength between 0.20 and 0.21 MPa.

Electronic microscopy of rye straw and reed stems made it possible to examine the presence of outer and inner parts in the structure, which affect the thermal and strength characteristics.

With the use of natural raw materials from plants and agricultural production residues, an effective and ecologically safe rigid board insulation was obtained, which has biocidal properties and has no analogues in the market for the construction of thermal insulation materials.

Perlite Insulation

Our photograph shows perlite insulation.

Polyester Fiber Insulation

At least an an experimental level, thermal insulating panels made of polyester fiber have been produced from recycled post-consumer PET bottles. Details are in this studh:

- Intini,Francesca & Silvana Kühtz, Recycling in buildings: an LCA case study of a thermal insulation panel made of polyester fiber, recycled

from post-consumer PET bottles [PDF] The international journal of life cycle assessment 16 (2011): 306-315.

Excerpt from Conclusions:

In this paper, an eco-profile of a thermal insulation panel made of polyester fiber recycled from post-consumer PET bottles has been defined. The energy and environmental benefits associated with its use into residential buildings have been assessed with a life cycle approach.

The results show that the use of waste PET involves a significant reduction of the environmental impacts derived from the employment of virgin PET while maintaining high thermo-physic properties.

A reduction can be obtained with 100% recycled PET into the manufacturing process or with the use of low impact additives.

The percentage increase of recovered PET by separate collection in Italy would reduce the amount of purchased waste PET from foreign countries and conse- quently the amount of impacts derived from transports.

The virtuosity of the product is the use of thermobonding virgin PET in place of acrylic resin.

Polypropylene Insulation Identification

Question: what is this plastic faced insulation ?

We are starting to look into getting some new insulation and facing put in our shop. The current product is at least 15-20years old. We were going to just carefully wipe down the dirty putter facing and postpone this project for another year or two, but that job in itself quickly became a hassle.

As we are currently looking into which insulation and facing we will replace it with, we are trying to figure out what kind of insulation facing was originally put on that we have right now. The facing itself is exposed on the walls and ceiling besides the first 8’ of wall cover at the bottom.

Do you know of anyway to determine what type of facing we have? I attached a few pictures of it in case you might be able to help out with any guesses...

Thanks a lot for your help! - Anonymous by private email 2018/02/10

Reply:

The facing is a polypropylene product from Lamtec, to be specific, Metallized Polypropylene reinforced with Tri-directional Fiberglass/Polyester. See the attached sheet from Lamtec.

Unfortunately I can't read all of the details on your insulation labels nor can I see what's inside that plastic bag.

I'd send your photos directly to your insulation supplier to ask about the insulating material itself - I couldn't make much out in the photo.

Your supplier is still in business: Bay Insulation Supply, Website: http://www.bayinsulationsupply.com/

It's useful to know where the insulation was installed in the building: roof, walls, ducts, on equipment, etc.

Let me know what you're told and we can take it from there.

See

- LAMTEC WMP-10 POLYPROPYLENE / SCRIM / KRAFT INSULATION [PDF] (2010) LAMTEC CORPORATION 5010 River Road Mount Bethel, Pennsylvania 18343-5610 U.S.A. Phone: (570) 897-8200 Fax: (570) 897-6081 Web: www.lamtec.com

- INSULATION CHOICES & PROPERTIES where we discuss the Ultra-R™ R-50 insulating panel is a rigid polypropylene-encased vacuum insulation panel

Polyisocyanurate Foam Insulation Photo

See POLYISOCYANURATE FOAM BOARD

Polystyrene foam board insulation photo

Our photograph shows indoor use of polystyrene foam insulating board on the inside of a basement foundation wall - notice the absence of a suitable fire-resistant covering?

This installation probably violates local building codes. Foam insulating boards do not contain asbestos but can present a fire hazard because they give off dense smoke and possibly toxic fumes in a fire.

Other older building insulation materials such as corn cobs, newspaper, bricks, and simple reflective barriers using aluminum foil also would not be expected to contain asbestos.

Seaweed Insulation

Our discussion of seaweed and seagrass insulation is now found at

Sheep's Wool Insulation - 100% wool

Sold in the U.K. as shown here, SheepWool® insulation is sold in a 50mm thickness, in lengths of 9m (rolled up) at 380mm wide, and is described by the UK Vendor cited below as follows:

Sold in the U.K. as shown here, SheepWool® insulation is sold in a 50mm thickness, in lengths of 9m (rolled up) at 380mm wide, and is described by the UK Vendor cited below as follows:

Sheep Wool Insulation Optimal is a range of grey coloured sheep's wool insulation rolls offering high thermal and acoustic. Optimal rolls are suitable for use in floor and ceiling level applications and are available in a variety of convenient dimensions.

Details are at SHEEPS WOOL INSULATION

- Source: The European Reaction to Fire classification system (Euro classes), Fire Safety explained, retrieved 2019/01/04 original source: ROCKWOOL Ltd /Rockpanel Customer Services/Sales Support Advisor Wern Tarw Pencoed Bridgend CF35 6NY Tel.: +44 (1656) 863 210 Fax: +44 (1656) 863 611 www.rockpanel.co.uk http://www.rockpanel.co.uk/technical-support/fs-xtra/euroclass/

Starch Foam Insulation

Starch foam, originally produced for use in bio-degradable packaging and as an alternative to polystyrene foam insulating products, is described by Siverstein (2007):

Starch foam was made already in 1989 as biodegradable packaging, and is an alternative material to the traditional polystyrene foams. Starch is a polysaccharide made up of glucose units linked by glycoside linkages, and its length is generally between 500-2000 repeat units.

Starch is made up of amylose and amylopectin Amylose is more linear and gives the foam flexibility and keeps the density low, while amylopectin is highly branched and makes the product more foamable. Starch can be extracted from for example corn or potatoes.

Starch foams are produced by extrusion where the starch is melted and mixed with a blowing agent. The blowing agent for starch is often water or methanol, which is turned into steam when the system is heated and forms air bubbles within the starch matrix.

The extrusion process is a continuous, low-cost method that is easy to use. It is still hard to make the foam smooth and have a high number of closed cells. The use of thermoplastic polymer additives can help even out the surfaces, but can also decrease the degradability of the foam by incorporating slowly degrading or non-degradable polymers. - Siversten, 2007

Starch has been used as a binder in "super green" building products, including some insulation products or bio-fiber insulation products, possibly including cellulose or wood fibers, ("bico fibers") installed in North America beginning in about 1985, using starch extract from corn, beans or other sources. - Bomberg

- Siversten, Katrine, POLYMER FOAMS, [PDF] (2007),Massachusetts Institute of Technology, MIT, Open Courseware, retrieved, 2017/04/02, original source: https://ocw.mit.edu/courses/materials-science-and-engineering/3-063-polymer-physics-spring-2007/assignments/polymer_foams.pdf

Excerpt:

Biodegradable foams Biodegradable polymer foams are investigated not only because of the increasing waste and environmental problems for traditional polymer foams, but also because of the increasing price of petroleum products that are used in manufacturing the polymer foams.

Biodegradable foams are water soluble and sensitive to humidity, while traditional petroleum-based foams are more inert to water. Biodegradable foams are also limited in making foams that have microcellular structure, which means they will be hard to make into thin sheets.

However, they are important in reducing the amount of CO2 emission. There is also a wide range of different candidates of biomaterials that can be used for biodegradable foams, including ethylene vinyl alcohol, polyvinyl alcohol, polycaprolactone, polylactic acid and starch. - Bomberg, Mark and George Chrenka, "EE9-1 INNOVATIVE MATERIALS: BIO-FIBER BATTS AND BOARDS" , [PDF] National INstitute of Building Sciences, retrieved 2017/04/02, original source: https://c.ymcdn.com/sites/www.nibs.org/resource/resmgr/BEST/BEST2_030_EE9-1.pdf

Abstract:

A short review of historic development from macerated paper introduced in 1919 as a commercial insulation product in Canadian Prairies lead us to the 2009 American production of cellulose fiber batts and blankets and European flexible and rigid wood-fiber thermal insulation boards.

A short expansion from the current R/D activities bring us a new world of bio-fiber thermal insulations where different recycled and fresh fibers are mixed and bonded with advanced chemical technology to produce composites for several construction and industrial applications.

Shredded Insulation Products

Here we describe less-common shredded materials found in buildings as insulation, such as this woody or plastic-like insulating material provided by an InspectApedia reader.

Note that other more common shredded insulations are shown separately at

On 2021-05-01 by Rafal

what kind of isolation is this? looks like a shredded paper.

On 2021-05-03 by (mod) - tips for identifying shredded insulation

@Rafal,

@Rafal,

That's an insulation product that I have not seen although we did come across a shredded plastic material it looked similar.

Can you tell me the country and city where the building is located and the building age?

Shredded paper is a reasonable possibility or some other shredded plant or industrial waste material. Cardboard?

Look closely at some of the fragments for printing or for variation in color and try posting a sharp close up photo.

If you see actual printed letters and/or inks of various colours then it's probably shredded paper or newsprint.

But as I've not seen paper (cellulose) insulation quite like this, the jury is out for the moment.

See CELLULOSE LOOSE FILL INSULATION for examples of identifying that material.

On 2020-09-15 by Billy J. - shredded plastic "insulation"?

Found this behind lath and plaster. Any idea what it is? Thanks !

Found this behind lath and plaster. Any idea what it is? Thanks !

On 2020-09-15 - by (mod) -

coarse black fibrous insulation identificationBilly

Thank you for the photo and question;

Like the Poughkeepsie Police desk sergeant told our tenant Anna M. when she called to say she wanted the cops to tell the railroad engineers not to blow their horns at night, .... "Well that's one I've never encountered before".

That looks like plastic or other fibrous shards. What's the texture? It could be a wood or paper product. I'm researching further.

Reader follow-up:

Thanks for the reply! feels like plastic or maybe rubber. Just want to know if it’s safe to work around !

On 2020-09-15 - by (mod) - shredded plastic insulation - recycled polyurethane insulation?

It looks like shredded plastic to me, too, or maybe shredded housewrap or plastic refuse or polyurethane scraps;

Keep in mind that if this isn't a listed insulation it may not be fire-safe.

I'd take a pinch of it outside, put it in a saucer, and see if you can light it on fire. (Do not get burned, etc.) stay safe.

Let me know what you find.

Also is there any kraft facing or wrapping with any markings?

Watch out: using a DIY or re-purposed material for building insulation, if the material is not listed and approved for that purpose, may be a dangerous fire hazard.

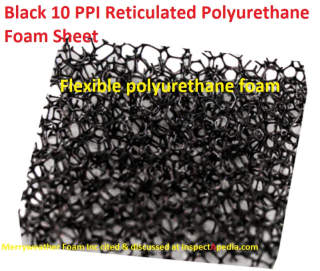

Above, suggested by another reader, we illustrate Merryweather Foam Inc.'s .75" x 38" x 46" Black 10 PPI Reticulated Polyurethane Foam Sheet that is used for a variety of purposes such as filters but that in my opinion is entirely unsuitable for building insulation: its openings are far too large to imprison air and thus won't have much insulating value.

On 2020-09-15 by Billy J.

ya we tried burning it and it did burn. Smelt like plastic but didn’t burn like it. Any worry about it being asbestos ?

ya we tried burning it and it did burn. Smelt like plastic but didn’t burn like it. Any worry about it being asbestos ?

On 2020-09-16 - by (mod) - properties of shredded-plastic-like building insulation

Billy

Post a photo of the burning test;

And consider that the real worry here isn't asbestos - if it's plastic it's not likely to sport much by way of asbestos - but that we don't know what the material is, we don't know that it's a listed, safe insulating material, and we don't know that in the event of a fire you may have a faster- or hotter- fire spread that results in more-extensive loss, damage, injury or worse, death.

I'd look further into the history of the building, when was this stuff added, what is it.

Spray Insulation Systems, Various

In addition to foam, cellulose chopped-fiberglass and mineral-wool insulation already described and linked-to on this page, there are quite a few other spray insulation products used in modern construction as we note here.

Above: illustration from AISLA Insulation System's catalog cited below shows the most-common insulating materials used in spray applications.

[Click to enlarge any image]

Below: an example of CoolMachines.com insulation spray equipment from the same catalog cited below.

Modern insulation, adhesive, and sealant spray applications cover a wide range of materials and applications including building insulation, noise and sound control, damp-proofing, and adhesives used in construction.

Here we illustrate examples of contemporary insulation spray equipment and provide manufacturer catalog and contact information.

- AISLA SPRAY-INSULATION PRODUCT CATALOG - Sp. [PDF] Aislantes y Systemas Alternativos, SL, Pol. Ind. Valle del Cinca Calle D No 21, 22300 Barbastro (Huesca) Tel: 974-269-813 Email: info@aislasistem.com Website: www.aislasistem.com Catalog of spray insulation products & insulation spraying equipment,

Contact: Oscar Zamora, Departamento Técnico, Mvl: +34 691 129 778, Telf: +34 974 26 98 13 Email: tecnico@aislasistem.com Website: www.aislasistem.com

Also contact:

CoolMachines, www.coolmachines.com Tel: 419-232-4871 - GIC General Insulation Company, WEATHERIZATION PRODUCT CATALOG [PDF] Website: https://www.generalinsulation.com/

- Flokser Tekstil San. ve Tic. A.S.

Hadımkoy Mah. Urguplu Cad. No:7 34555 Arnavutkoy Istanbul Turkey

+90 212 866 49 00

kimya@flokser.com.tr

Produces closed cell polyurethane foam and other products. Excerpt from website:

Polyurethane systems used for heat, water and sound insulation purposes in roof, front, reverse ceiling and floors of buildings and in B1-B2 incombustibility class according to DIN 4102 standard. - Graco SPRAY FOAM EQUIPMENT CATALOG [PDF] (2017) Graco, Tel: 866-361-5959 Website: www.graco.com

- Johns Manville SPF SPRAY POLYURETHANE FOAM INSULATION Brochure [PDF] (2019) JOHNS MANVILLE CORPORATE OFFICES

P. O. Box 5108

Denver, CO 80217-5108

USA (offices world wide)

Phone: 303.978.2000 Tel: 800-654-3103 Website: www.JM.com retrieved 2020/02/07 original source: https://www.jm.com/content/dam/jm/global/en/building-insulation/Files/BI%20Toolbox/BID254_Spray_Foam_Brochure.pdf

Excerpt:

Johns Manville is proud to manufacture a family of high-performance, high-yield spray polyurethane foam (SPF) insulation solutions that create more comfortable and energy efficient homes. - Lapolla Spray Foam Insulation, 15402 Vantage Parkway E., Suite 322

Houston, TX 77032 USA

Phone: 713-273-2016 or (281) 219-4100

Fax: (281) 219-4106

Email: info@lapolla.com

Website: https://lapolla.com/spray-foam-insulation/

Produces FOAM-LOK™ closed cell foam, open celled foam, water based fireproof foam, primers, roof and wall coatings & other products, tools, services. See technical data sheets at https://lapolla.com/spray-foam-insulation/technical-data-sheets/ - Owens Corning Corporation Website: https://www.owenscorning.com/insulation/commercial

- TRAMACO GmbH Lise-Meitner-Allee 8 25436 Tornesch Deutschland

- USI SPRAY FOAM INSULATION CATALOG [PDF] USI Headquarters 445 Minnesota Street, Suite 2500 St. Paul, MN 55101 info@USIinc.com Website: https://www.usiinc.com/ Tel: 888-875-0016

- Vitcas Refractory Spray Insulation, 204-208 Broomhill Road, Brislington Bristol, BS4 5RG United Kingdom Tel. +44 (0)117 911 7895 Website: https://www.vitcas.com/

Straw Insulation

Uses of straw as a building insulation material [research in process, contributions welcome - Ed.]

- See also: STRAW BALE CONSTRUCTION - separate article

- Yu, Tao, Yizhe Ren, Zhensheng Guo, Xiao Chen, Jinxiang Chen, and Elsafi Mohamed Adam Elbashiry. "Progress of research into cotton straw and corn straw cement-based building materials in China." Advances in Cement Research 30, no. 3 (2018): 93-102.

Abstract:

This paper reviews the development of cotton straw and corn straw cement-based materials in China. With the use of unmodified straw fibres, the compressive strength of the cement-based material decreases with an increase in corn and cotton straw content, but the rate of decrease is considerably lower than that of wheat and rice straw, mainly because of differences in the strength of the straw.

The incorporation of fly ash, urea formaldehyde resin and other materials can effectively improve the mechanical and thermal insulation properties of mixed-type building materials.

Three methods of modification are proposed – alkali treatment, grafting treatment and direct addition of a modifier. A multiple linear regression equation between mechanical properties and the content of the main components of the cotton straw cement-based materials is obtained, which provides a theoretical basis to predict and design cement-based block materials.

Finally, to address the problems of the mix type (difficult stirring, slow hardening, and energy demands and environmental pollution during the modification process), the concept of a composite-type bionic straw cement-based building material is introduced, which provides direction towards the development of new bionic light straw materials.

Structural Insulated Panels (SIP's)

See details at STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs) - Structural Insulated Panels

Also see CONCRETE INSULATION & ICFs Insulated Concrete Form construction

Styrofoam board insulation photo

Our photograph shows indoor use of pink styrofoam insulating board on a basement ceiling.

As with the next example just below, this installation violates fire safety & fire codes - in an occupied or occupy-able space it should be covered with a fire-resistant drywall or other acceptable barrier.

See also

Tripolymer Foam Insulation Properties

Tripolymer foam building insulation may be used as building insulation as an alternative to more-widely-used icynene foam. Tripolymer foam, unlike icynene insulation, is a water-soluble foam insulation.

According to the U.S. Department of Energy,

Tripolymer foam—a water-soluble foam—is injected into wall cavities. It has excellent resistance to fire and air intrusion. - U.S. DOE, ret. 2017

Tripolymer foam, because it is water-based during application, has the following properties:

- Water-based, water soluble during application, plastic material

- Does not expand during application, solidifies in 30 seconds

- Considered non-toxic

- R-value: R-5.1 / Inch

- Density: 0.8 - 1.3 lbs./cu.ft.

- Perm-Rating: 15.5-16.9 per inch

- Used in both new & retrofit insulation jobs

- Does not settle nor compress after installation

- Cold setting compound

- Does not contain fiberglass, does not contain CFCs, urea formaldehyde as a solvent nor vehicle

Tripolymer foam, a product that was manufactured by C.P. Chemical Company, a New York Corporation, and marketed under the name Tripolymer4 105, was installed by injection into the building wall or (enclosed) ceiling cavities. In1986 C.P. Chemical was involved in litigation against the U.S. Consumer Product Safety Commission (CPSC) concerning this insulating material. C.P. Chemical's complaint against the CPSC was dismissed by the court.

Excerpts from the court decision cited below:

The suit arose from the Commission's ban on the use of formaldehyde-emitting foam insulation, 47 Fed.Reg. 57,488 (1982).

The Fifth Circuit ruled, in Gulf South Insulation v. U.S. Consumer Product Safety Commission, 701 F.2d 1137, 1148-50 (5th Cir. 1983), that the ban was improper because it was promulgated under the procedures of the CPSA, 15 U.S.C. §§ 2057, 2058, 2079(d), rather than under the appropriate procedures of the Federal Hazardous Substances Act, 15 U.S.C. §§ 1261-1276.

C.P. Chemical alleged that the Commission erroneously included within the ban its insulation product, Tripolymer 105, which emits no formaldehyde gas.

The district court held that the FTCA waiver of sovereign immunity does not extend to the agency conduct forming the basis for this tort action against the United States and the Commission.

The court also held that the CPSA provides no predicate for this action. For the reasons stated below, we affirm.

C.P. Chemical Company is a family-owned New York corporation that manufactured "Tripolymer 105," a foam insulation product that was mixed on the job site and pumped between a structure's walls. Tripolymer 105, a phenal-urea based product, competed with a similar product--urea-formaldehyde foam insulation ("UFFI").

However, unlike Tripolymer 105, UFFI was found to emit detectable levels of formaldehyde gas.

...

C.P. Chemical Company, along with other foam insulation manufacturers, sought judicial review of the UFFI ban pursuant to 15 U.S.C. § 2060. On April 7, 1983, the Fifth Circuit held that the Commission's rule was not supported by substantial evidence and therefore vacated the ban. Gulf South Insulation v. U.S. Consumer Product Safety Commission, 701 F.2d 1137 (5th Cir. 1983).

While expressly declining to address C.P. Chemical's claim that it should have been exempted from the ban because its product was safer than UFFI, 701 F.2d at 1140, the court also held that the Commission had followed the wrong rulemaking procedures when it promulgated the rule under the informal procedures of the Consumer Product Safety Act, 15 U.S.C. §§ 2058, 2079(d).

The agency should have proceeded under the Federal Hazardous Substances Act, 15 U.S.C. §§ 1261-1276, which requires a formal hearing wherein rules of evidence are applied and the right to confront and cross-examine witnesses is recognized, 701 F.2d at 1149-50, see 15 U.S.C. § 1262(a) (2).

C.P. Chemical Company, along with other foam insulation manufacturers, sought judicial review of the UFFI ban pursuant to 15 U.S.C. § 2060. On April 7, 1983, the Fifth Circuit held that the Commission's rule was not supported by substantial evidence and therefore vacated the ban. Gulf South Insulation v. U.S. Consumer Product Safety Commission, 701 F.2d 1137 (5th Cir. 1983).

While expressly declining to address C.P. Chemical's claim that it should have been exempted from the ban because its product was safer than UFFI, 701 F.2d at 1140, the court also held that the Commission had followed the wrong rulemaking procedures when it promulgated the rule under the informal procedures of the Consumer Product Safety Act, 15 U.S.C. §§ 2058, 2079(d).

The agency should have proceeded under the Federal Hazardous Substances Act, 15 U.S.C. §§ 1261-1276, which requires a formal hearing wherein rules of evidence are applied and the right to confront and cross-examine witnesses is recognized, 701 F.2d at 1149-50, see 15 U.S.C. § 1262(a) (2).

...

CONCLUSION

For the reasons stated above, we hold that the district court correctly dismissed the complaint for lack of subject matter jurisdiction and for failure to state a claim. The judgment of the district court is affirmed.

References for Tripolymer foam insulation properties

- C.P. CHEMICAL COMPANY, INC., PLAINTIFF-APPELLANT, V. UNITED STATES OF AMERICA AND U.S. CONSUMER PRODUCT SAFETY COMMISSION, [PDF] Defendants-appellees, 810 F.2d 34 (2d Cir. 1987) Annotate this Case U.S. Court of Appeals for the Second Circuit - 810 F.2d 34 (2d Cir. 1987) Argued Oct. 31, 1986. Decided Jan. 26, 1987

- "Tripolymer 105", C.P. Chemical Company, White Plains NY, USA

- TYPES of INSULATION [PDF], U.S. Department of Energy, (undated) retrieved 2017/04/02, original source: https://energy.gov/energysaver/types-insulation

UFFI Urea Formaldehyde Foam Insulation photo

Our photograph above shows UFFI building insulation.

See UREA FORMALDEHYDE FOAM INSULATION, UFFI

Also see URETHANE FOAM INSULATION

Vermiculite insulation photo

Our photograph shows Vermiculite building insulation.

See VERMICULITE INSULATION for details.

Wood & Wood Fiber Based Insulation

Contemporary wood fibre panels are sold in a variety of textures and for a wide range of uses including as a nail base in roofing and siding, as structural insulated panels or SIPS, as insulating sheathing (fiberboard), and as acoustical panels for interior use.

Contemporary wood fibre panels are sold in a variety of textures and for a wide range of uses including as a nail base in roofing and siding, as structural insulated panels or SIPS, as insulating sheathing (fiberboard), and as acoustical panels for interior use.

Photo of wood fiber insulating panels is provided courtesy of InspectApedia.com reader Robin.

For contemporary wood fibre panels used both as insulation and as an acoustic or sound insulating panel, see details

at WOOD FIBRE INSULATING PANELS

See also BALSAM WOOL BATT INSULATION - older, traditional batts, paper enclosed shredded wood insulation -

See also SHEATHING, FIBERBOARD - home - fiberboard panels used as nail base and insulating sheathing indoors and on building exteriors

Below: an example of 1940s balsam wool insulation used inside of a refrigerator.

...

Insulation Identification Research

- US DOE, TYPES of INSULATION [PDF] (2023) U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy

Forrestal Building

1000 Independence Avenue, SW

Washington, DC 20585 USA - retrieved 2023-09-07, original source: https://www.energy.gov/energysaver/types-insulation

Note this commenet from energy.gov's website:

We are unable to provide technical assistance for specific home energy projects or troubleshoot home efficiency or equipment issues. Please contact a local contractor who can evaluate your needs. resnet.us/directory/search RES

NET or the bpihomeowner.org Building Performance Institute can help find an energy auditor or professional near you.

- US DOE, TYPES of INSULATION [PDF] (2020) U.S. Department of Energy - illustrated above, icynene plastic insulation blown into walls of home near Denver Colorado. - Paul Norton NREL

- US DOE, TYPES of INSULATION [PDF] (2017) U.S. Department of Energy - illustrated above, a contractor is installing blown-in cellulose insulation into a building wall - CIMA

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2024-01-12 by Pete

What kind of insulation do you think this is? Found in a wall behind a wooden panel in a Chicago suburb basement. The house was built in the early 1960s. Could it contain asbestos? It seems that the small paper has some kinda black substance on it.

On 2024-01-12 by InspectApedia Publisher

@ Pete, Please see your question, photos and our response on the other page you posted at

MICRO-AIRE® FS FIBERGLASS HVAC DUCTS

inspectapedia.com/Fiberglass/Johns-Manville-Micro-Aire-Ductwork.php

On 2023-12-16 by Vanessa Susan Bowler

I would appreciate any info or feedback on this, in the attic of a house we were hoping to purchase. Many thanks.

On 2023-12-16 by InspectApedia Publisher

@Vanessa Susan Bowler,

I'm not sure what you're asking,

- whether it's identifying insulation or

- the fact that there are areas with no insulation

- the condition of the plaster left ceiling that I think I see in areas of that photo

- the history of leaks in the attic and possible leak stains in a few areas

- the presence of a fiberboard panel

- the dimensions, spacing, and condition of the roof framing

- the extent of or absence of attic ventilation and the presence of moisture.

Every one of those, plus other things that an on-site inspector should see that I can't in your photo would be worth understanding.

Since you're posting on our insulation identification page I'm guessing that that was your primary question.

I see some areas with no insulation at all.

I also see what looks like possibly mineral wool or rock wool but the photo is a bit blurry so I can't be certain.

It's a bit hard to see insulation and just one small area of an attic of an older home. Normally if you were going to go to the trouble to add insulation you would do the whole attic not just one small area.

But then I don't know what the rest of the attic looks like.

If you look through the insulation examples that we give here you will see how to distinguishmineral wool from UFFI foam or other insulating materials.

Please also take a look through that since you've actually been on the site and have had a closer look than I can obtain from the photo.

Or if you have other photos that give a sharp closer view that would be helpful

On 2023-12-16 by Vanessa Susan Bowler

@InspectApedia Publisher, Thank you and apologies for only the one photo - it's the only one I've got. I guess I wanted to know what the white powdery insulation stuff visible might be.

On 2023-12-16 by InspectApedia Publisher - what is the white powdery insulation stuff in my attic

@Vanessa Susan Bowler,

Okay, that added detail is helpful.

If there's a crumbly insulation in that area that is powdery or easily is crumpled to powder it's probably UFFI.

You can read about that insulation in this article series

Surely you have had a professional home inspection if you're buying a home and in that case the inspector should have come in it to you on the insulation visible in the attic.

Can you tell me what that report contained and with the inspector said?

What's odd in my experience is to find UFFI only in a small area of an attic. Normally one wouldn't go to the trouble of blowing in foam insulation without doing the whole building or at least the whole attic and walls

On 2023-12-16 by Vanessa

@InspectApedia Publisher, Thanks very much for coming back to me - appreciated. We had a full survey of course and the surveyor has said it's a white powdery substance which could possibly contain asbestos.

Like you I find it strange that the rest of the loft wouldn't also have this white stuff in too. I can just make out some of the more recognisable pink roll insulation under a board to the left.

I'm wondering whether the white stuff could be mould. Anyway, we will have it tested once the vendor agrees to that.

On 2023-12-16 by InspectApedia Publisher - crumbly insulation may be UFFI

@Vanessa,

I'd be stunned to find mold that thick in an attic;

But if it's a material that crumbles easily take a look at UREA FORMALDEHYDE FOAM INSULATION, UFFI

Back in our lab where I could look at your photo on a large display, this close-up suggests UFFI, perhaps partly removed.

Do let us know what you find as that will be most helpful to other readers finding similar-looking insulation in old buildings.

Where is this building and what is its age?

On 2023-12-16 by Vanessa

@InspectApedia Publisher. Thanks again - most useful information. I will update when I've received more information from testing (not sure when that will be yet). The house is roughly 1950 and is in West Sussex here in the UK.

On 2023-12-16 by InspectApedia Publisher

@Vanessa,

Thanks for that added detail.

Our understanding is that unlike in the U.S., UFFI was never "banned" in the U.K. so it might well appear in homes of various ages.

Still, seeing it in just fragmentary remains in a home is unusual.

When you read our UFFI articles you'll see that while there was an early concern about formaldehyde offgassing, a problem that was detected particularly if the UFFI was improperly mixed during installation, that offgassing occurred in the early life of the material and by now that's long gone and not a worry.Still you might come across a home where someone was anxious and removed some or all of the material (needlessly in our opinion).

On 2023-12-19 by Vanessa Susan Bowler

@InspectApedia-911, well, the vendor got the sample tested yesterday by a specialist and I was very relieved to hear that it did not contain asbestos! Still no idea what it actually is, but that's what we needed to know so, all good.

On 2023-12-19 by InspectApedia DF (mod) - test results show no asbestos

@Vanessa Susan Bowler,

Good news about the negative asbestos test results. It would be helpful for us and other readers to know what else the test results said as that may help identify a similar insulation in the future, even if not asbestos.

Is it possible to get a copy of the test results from the vendor? If so, you could send us a copy of it via email which can be found at our Contact page (link at bottom of this page).

Thanks again for the discussion and the added information.If you take a look at the articles we recommended about UFFI you will see how easy it is to identify that insulation. Compare that with what you found in your attic.

On 2024-01-03 by Vanessa Susan Bowler

@InspectApedia DF, Hello again - the test result sheet gives no useful information unfortunately, other than that the material has been tested and is not asbestos. Sorry not to be able to help more.

On 2024-01-03 by InspectApedia Publisher

@Vanessa Susan Bowler,

I would like to have seen that report. We could keep it private if you want to send it to me by email. Certainly in my forensic work I would have told you what the material was or I would have admitted that I couldn't identify it. I agree that that's a separate issue from detecting or not detecting asbestos in the material.

A careful look in your attic might reveal that there was UFFI insulation and that most of it was removed and for some reason this bit was missed. That's the only explanation I can think of if UFFI is what's there.

No one would spray just a small area with foam insulation.

But if the attic had been insulated with UFFI and people panicked about it earlier in his life they might have removed it. Even though it was later found to have been an unnecessary step.

Or it could have been removed for other reasons such as access to building surfaces for repair or wiring etc.

On 2023-11-30 by EH

Can you help ID this? Found in the ceiling of a basement finished in MD in the 1950s as our contractor started demo to redo it. Didnt see it until after two days of demo and I’m worried we’ve busted open a bunch of asbestos.

On 2023-11-30 by InspectApedia Publisher

@EH,

That looks like mineral wool or rock wool insulation.

On 2023-08-08 by Davey

Hi, I tore a hole in some paper when replacing my bathroom fan.

Canadian Gypsum Company used asbestos. Is that grey material asbestos? Hole is blocked up for now.

On 2023-08-09 by InspectApedia Publisher (mod) - Canadian Gypsum Kraft paper faced Fiberglass Wall Insulation

@Davey,

I can't see too much in that little tear but it sure looks like fiberglass insulation to me..

Am I right that the imprint on the craft paper facing vet insulation is

Canadian Gypsum Company RED ?

If you can post a closer and sharper image that would be helpful.

On 2023-08-09 by Davey - decided to vacate the house and get the room and materials tested and have the attic inspected

@InspectApedia Publisher,

Hi, I decided to vacate the house and get the room and materials tested and have the attic inspected, I feel quite stupid for trying to do this job in an old house. Yes it says Canadian Gypsum Company RED.

On 2023-08-09 by InspectApedia Publisher (mod) - small tear in fiberglass insulation kraft facing = not dangerous

@Davey,

With all due respect, that sounds extreme considering that you have what looks like a tiny tear in a craft facing on what's most likely fiberglass insulation.Certainly if you're concerned, just tape over that torn kraft facing with a bit of foil tape.

Perhaps there's a hazard concern here that I have missed or misunderstood from your post.I urge you to read

OTHER PEOPLE's MONEY - watch out or you may spend a lot more than is appropriate

and

HAZARD vs RISK - what's the difference

On 2023-07-23 by Bill

Type of insulation? See partial bag in background

On 2023-07-24 by InspectApedia Publisher (mod) - light colored loose fill attic insulation: mineral wool?

@Bill,

Photo isn't fully sharp but that could be mineral wool - compare with the mineral wool given in links above on this page.

If you can post more-complete photos (one per comment) of any insulation kraft facing or packaging labeling that would be a great contribution and would allow us to research and comment further on what you've got.

On 2023-07-14 by Adam green

Anyone know what type of insulation this might be?

On 2023-07-15 by InspectApedia Publisher (mod) - photo of scraps of mineral wool or fiberglass insulation

@Adam green,

Mineral wool or white fiberglass.

On 2023-07-14 by Adam

Went rummaging thru an apartment complex attic, built in 1970. Does this look like asbestos?

On 2023-07-14 by InspectApedia Publisher (mod)

@Adam,

We will appreciate that follow-up.

Also see

MINERAL WOOL https://inspectapedia.com/insulation/Insulation-Identification-Guide.php#Mineral_Wool

photos and description and history

On 2023-07-14 by Adam

@InspectApedia DF, what a relief... will be testing it and will report test results. Thanks so much!

On 2023-07-14 by InspectApedia DF (mod) - 1970s mineral wool or fiberglass insulation

@Adam,

It looks like mineral wool insulation with some fiberglass bits as well.

On 2023-06-18 by Jeff

Are you able to tell us what this loose ceiling insulation is.

It looks like shredded wood.

The house was built in 1950's in Melbourne, Australia

On 2023-06-18 by InspectApedia Publisher (mod) - seaweed-like insulation in 1950's in Melbourne, Australia home

@Jeff,

See SEAWEED INSULATION https://inspectapedia.com/insulation/Insulation-Identification-Guide.php#Seaweed

or a similar plant based insulating fibre.

and also tell me the country and city of location of the building and the building age.

On 2023-06-05 by Dan

What kind of insulation is this?On 2023-06-05 by InspectApedia DF (mod) - photo of chopped fiberglass insulation

@Dan,

That looks like chopped fiberglass insulation.

On 2023-05-16 by Anonymous

What type of insulation is this

On 2023-05-17 by InspectApedia Publisher (mod) - example of foam insulation in an attic floor

@Anonymous,

That looks like foam insulation.

On 2023-04-28 by InspectApedia Publisher - mineral or slag wool insulation

@Eric L,

It looks like mineral wool, or slag wool, commonly used in most countries in the 1960s.

But there are some less-common lookalikes, even using wool, so do take a look through the insulation identification photos above on this page and let me know if you have a different idea.

On 2023-04-27 by Eric L

Hello. This is an attic insulation sample we took from a house we acquired built in 1962. Thoughts on the type ?

On 2023-04-25 by John Anderson

Blown-in insulation in the attic space of our home. This white/grey material that has a texture like flower with small granulars (1-2mm diameter) in it was found in my attic space underneath a layer of cellulose.

Just wondering if anyone has any experience with this material. From the previous owner, this insulation was installed between 1960 and 1970.

On 2023-04-25 by InspectApedia Editor

@John Anderson,

The photo isn't too clear but that looks like cellulose insulation - look very closely at samples to see if you can find tiny bits of newsprint - that would confirm my guess, and also look at example photos found at this guide

CELLULOSE INSULATION

https://inspectapedia.com/insulation/Cellulose_Insulation.php

Let me know what you think

On 2023-04-27 by John Anderson

@InspectApedia Editor , there are no bits of paper or anything like that. There is a layer of cellulose on top of this different material (not pictured). It is whiteish/grey and quite dusty with little grains that can be crushed between my fingers.

The cellulose material is much more coarse in texture and the particle size is larger. This material is more like flower with little grains.

On 2023-04-27 by InspectApedia Editor

@John Anderson,

Try posting a sharper close-up photo and I can say more.

And try looking through the ID photos and suggestions for various types of insulation above on this page.

Your first photo looks as if it could be MINERAL WOOL if it's not cellulose; Some early foams could be crushed to powder (UFFI) but don't look like what I see in your photo.

On 2023-04-27 by John Anderson

@InspectApedia Editor , here is a detailed image. Some of the material has clumped together when I removed it.

On 2023-04-27 by InspectApedia Publisher - insulating products mixing perlite and pumice

@John Anderson,

This is so exciting - maybe you've come up with an insulation that I've not seen personally.

There were some insulating products made mixing perlite and pumice.

I understand we think this insulation was installed in the 1960s.

Where is this building and when was it built?

Your photos appear to combine a gray fibrous material with small white pellets of varying size, and by your description (can crush to powder), those white fragments are not styrofoam nor do we think this is gypsum board or drywall debris contamination - as you'd be likely to find that uniformly distributed throughout building insulation.

I'm researching the topic a bit more and will add some citations.

Save one or two cubic inches of this insulation (no more) in a clean small-sized freezer-type ziplok bag that you can mail to me for forensic lab examination. Our email is in the page top or bottom CONTACT link - thence I can give you an address. I'm doing a bit of travel so am not always in the lab - we can discuss mailing.I'd like to look at this insulation under the microscope. (No costs are involved for you but postage, and of course I can't promise a thing about an unknown material.)

On 2023-04-27 by InspectApedia Publisher - Loose fill Perlite pumice building insulation

@John Anderson,

Worth a look

Loose fill Perlite pumice building insulation

Glenn, Sucetti. "Light weight water resistant aggregate and method of making the same." U.S. Patent 2,824,022, issued February 18, 1958.

Mogg, D.W. et al, Manufaccture of a Lightweight Insulating Prooduct [PDF} U.S. Patent 3,344,217, Sept. 26, 1967

Copy at

https://inspectapedia.com/insulation/Mogg-Patent-US3344217.pdf

Excerpt:

This invention relates to a novel method of producing a lightweight thermal insulating product and to a process for blending the product components together. More specifically, this invention relates to the production of a lightweight building product composed of expanded perlite or other lightweight inorganic aggregate, fibers and (preferably) a nonfibrous binder.Generally, the blending together of the components of a light weight insulating mix containing fibers and ex panded perlite is carried out in one of two ways; either by a dry mixing operation or by the forming of a slurry. In the dry mixing process, the components are blended together by mechanical means such as stirring, tumbling or agitation.

A mixture of nonuniform composition, char acterized by fibrous agglomerates formed during or be fore the blending, usually results.In addition, much of the friable perlite or other lightweight aggregate is often crushed and its structure destroyed by the mixing. The resultant product whether loose-fill insulation or a formed shaped product, is nonuniform and generally of an infe rior quality.

and later

Ostertog, Robert J., and Anthony J. Page. "Insulating product and dry process for its manufacture." U.S. Patent 3,888,962, issued June 10, 1975.

and earlier, perhaps a precedent

Thomas, Harold Karren, Insulating Pipe Covering Composition [PDF] U.S. Patent No. 2,600,812, Application October 23, 1950, SN 191,723

Copy at

https://inspectapedia.com/insulation/Thomas-Patent-US2600812.pdf

One of the objects of the invention is to pro vide an insulating composition in which granu lar sintered and expanded perlite is the principal ingredient, and in which an inorganic binder is used to supplement the natural tendency of cer tain perlite granules to cake when compressed;

On 2023-04-27 by John Anderson

@InspectApedia Publisher, this is located in Nova Scotia Canada. The house was built in the 30’s.

Thanks for the help on this!

On 2023-04-28 by InspectApedia Editor - Nova Scotia has a long history of creative uses of material as building insulation

@John Anderson,

Thanks for that added information.

Nova Scotia has a long history of creative uses of material as building insulation. Early settlers used locally-available natural materials, even grasses (particularly sea grass), and tree bark, and later, wood shavings, or simpler, some folks simply crumpled up newspapers and stuffed them into attic floors and into wall cavities - not that your insulation looks like those materials.

Chopped newsprint "cellulose" insulation began to see wide use in North America in the 1950s, but I don't rule out that someone combined another paper source - not newsprint - and mixed it with perlite or similar insulating materials.

I'm researching further.

Of interest to our other Nova Scotia readers

Wyllie-Echeverria, Sandy, and Paul Alan Cox. "The seagrass (Zostera marina [Zosteraceae]) industry of Nova Scotia (1907-1960)." Economic Botany (1999): 419-426.

and our article on use of perlite in insulating applications is at

PERLITE INSULATION

And below you can see how thrilled I was to be on the road in Nova Scotia in 1974.

On 2023-04-01 by Amy VH

Hi, wondering if you can help me identify what kind of insulation this might be under the floor of the attic in my 1908 house. It looks like white cotton (underneath the dirt). Thank you!

On 2023-04-01 by InspectApedia Editor - mineral wool insulation

@Amy VH,

That looks like mineral wool insulation. See our article at

ROCK WOOL, MINERAL WOOL BUILDING INSULATION IDENTIFICATION

https://inspectapedia.com/insulation/Rock_Wool_Insulation.php

On 2023-02-19 by Cli

Hi there,

Could you advise on what insulation this is? Located on internal north facing walls of an 1950s house.

Kind regards

On 2023-02-19 by InspectApedia Editor - paper-backed closed-cell polyethylene foam insulation product

@Cli,

It's difficult to say from one photo but that looks as if it 'might' be a paper-backed closed-cell polyethylene foam insulation product.Continuing, zoom in on the photo. I think we might be looking at a thin layer of polystyrene white insulation

...

Continue reading at FOAM SPRAY INSULATION TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see INSULATION IDENTIFICATION GUIDE FAQs - questions & answers posted originally on this page

Or see these

Recommended Articles

- CARBON NANOTUBE MATERIALS

- FIBER & HAIR IDENTIFICATION

- INSULATION AIR & HEAT LEAKS

- INSULATION CHOICES & PROPERTIES

- INSULATION IDENTIFICATION GUIDE

- INSULATION INSPECTION & IMPROVEMENT

- INSULATION LOCATION - WHERE TO PUT IT

- INSULATION R-VALUES & PROPERTIES

- PIPE INSULATION CHOICES, MATERIALS, TYPES

Suggested citation for this web page

INSULATION IDENTIFICATION GUIDE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] 3/07: thanks to Gary Randolph, Ounce of Prevention Home Inspection, LLC Buffalo, NY, for attentive reading and editing suggestions. Mr. Randolph can be reached in Buffalo, NY, at (716) 636-3865 or email: gary@ouncehome.com

- [2] 06/07: thanks for photographs of transite asbestos heating ducts, courtesy of Thomas Hauswirth, Managing Member of Beacon Fine Home Inspections, LLC and (in 2007) Vice President, Connecticut Association of Home Inspectors Ph. 860-526-3355 Fax 860-526-2942 beaconinspections@sbcglobal.net

- AISLA SPRAY-INSULATION PRODUCT CATALOG - Sp. [PDF] Aislantes y Systemas ALternativos, SL, Pol. Ind. Valle del Cinca Calle D No 21, 22300 Barbastro (Huesca) Tel: 974-269-813 Email: info@aislasistem.com Website: www.aislasistem.com Catalog of spray insulation products & insulation spraying equipment,

Also contact:

CoolMachines, www.coolmachines.com Tel: 419-232-4871 - ASHRAE resource on dew point and wall condensation - see the ASHRAE Fundamentals Handbook, available in many libraries.

- 2005 ASHRAE Handbook : Fundamentals: Inch-Pound Edition (2005 ASHRAE HANDBOOK : Fundamentals : I-P Edition) (Hardcover), Thomas H. Kuehn (Contributor), R. J. Couvillion (Contributor), John W. Coleman (Contributor), Narasipur Suryanarayana (Contributor), Zahid Ayub (Contributor), Robert Parsons (Author), ISBN-10: 1931862702 or ISBN-13: 978-1931862707

- 2004 ASHRAE Handbook : Heating, Ventilating, and Air-Conditioning: Systems and Equipment : Inch-Pound Edition (2004 ASHRAE Handbook : HVAC Systems and Equipment : I-P Edition) (Hardcover)

by American Society of Heating, ISBN-10: 1931862478 or ISBN-13: 978-1931862479

"2004 ASHRAE Handbook - HVAC Systems and Equipment The 2004 ASHRAE Handbook - HVAC Systems and Equipment discusses various common systems and the equipment (components or assemblies) that comprise them, and describes features and differences. This information helps system designers and operators in selecting and using equipment. Major sections include Air-Conditioning and Heating Systems (chapters on system analysis and selection, air distribution, in-room terminal systems, centralized and decentralized systems, heat pumps, panel heating and cooling, cogeneration and engine-driven systems, heat recovery, steam and hydronic systems, district systems, small forced-air systems, infrared radiant heating, and water heating); Air-Handling Equipment (chapters on duct construction, air distribution, fans, coils, evaporative air-coolers, humidifiers, mechanical and desiccant dehumidification, air cleaners, industrial gas cleaning and air pollution control); Heating Equipment (chapters on automatic fuel-burning equipment, boilers, furnaces, in-space heaters, chimneys and flue vent systems, unit heaters, makeup air units, radiators, and solar equipment); General Components (chapters on compressors, condensers, cooling towers, liquid coolers, liquid-chilling systems, centrifugal pumps, motors and drives, pipes and fittings, valves, heat exchangers, and energy recovery equipment); and Unitary Equipment (chapters on air conditioners and heat pumps, room air conditioners and packaged terminal equipment, and a new chapter on mechanical dehumidifiers and heat pipes)." - 1996 Ashrae Handbook Heating, Ventilating, and Air-Conditioning Systems and Equipment: Inch-Pound Edition (Hardcover), ISBN-10: 1883413346 or ISBN-13: 978-1883413347 ,