Sheeps Wool Insulation

Sheeps Wool Insulation

Properties, benefits, IAQ & environmental questions: wool & hemp insulation

- POST a QUESTION or COMMENT about identifying & troubleshooting building insulation & ventilation systems

Using sheeps wool as a building insulating material is described as a green building material using a renewable resource. Some research sources also cite features of sheeps wool insulation such as its ability to absorb water (it's hygroscopic) and its ability to absorb VOCs and formaldehyde.

Photo: ewe and lamb in New Zealand, photo by the author, 2014.

This article series discusses how to inspect, diagnose and correct problems in building insulation or ventilation systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Sheeps Wool & Hemp Building Insulation

Sheeps wool insulation used in buildings for acoustic or thermal insulation is made by combining sheeps wool (often wool waste from the wool industry) whose fibres are then bonded using 5-20% polyester adhesive to form the wool into insulating batts.

Sheeps wool insulation used in buildings for acoustic or thermal insulation is made by combining sheeps wool (often wool waste from the wool industry) whose fibres are then bonded using 5-20% polyester adhesive to form the wool into insulating batts.

As a thermal insulation sheeps wool is providfed in 16" or 24" wide batts or rolls of varying thicknesses. Sheeps wool insulation is also provided by some manufacturers (Havelock) as a blow-in insulation.

The R-value of sheeps wool insulation depends on its form and is given by Havelock as R 3.6/inch for loose fill / blown-in sheeps-wool and as R 4.3/inch for sheeps-wool batts.

The cost of sheep's wool insulation varies by country and vendor; in the U.S. R-13 sheep's wool insulation costs about 67 cents per square foot, a bit under half that of fiberglass insulation or cellulose and a bit less than cotton insulation.

Photo: sheep penned at the Travis Wetlands, in Burwood, outside Christchurch New Zealand, 2014. [Click to enlarge any image]

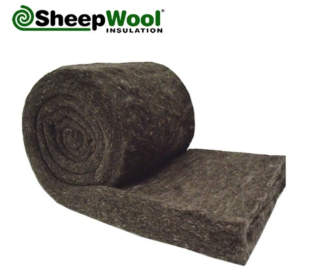

Sold in the U.K. as shown here, SheepWool® insulation is sold in a 50mm thickness, in lengths of 9m (rolled up) at 380mm wide, and is described by the UK Vendor cited below as follows:

Sheep Wool Insulation Optimal is a range of grey coloured sheep's wool insulation rolls offering high thermal and acoustic. Optimal rolls are suitable for use in floor and ceiling level applications and are available in a variety of convenient dimensions.

Sheep Wool Insulation Optimal is a range of grey coloured sheep's wool insulation rolls offering high thermal and acoustic. Optimal rolls are suitable for use in floor and ceiling level applications and are available in a variety of convenient dimensions.

Optimal Insulation rolls may also be used Vertically as well as horizontally due to their high density, so they can be used also in walls, and sloping ceilings.

Please note this product is 100% pure, natural sheeps wool insulation.

High Performance

Optimal is a highly effective insulation roll with a superior thermal performance over glass or mineral wool products. Optimal is made of pure new wool fibres, which hold their shape and thickness right throughout their lifetime.

Being produced from 100% pure wool fibres, Optimal is a fully breathable material that will maintain it's thermal efficiency even in the harshest climates.

Interestingly this natural wool insulation product contains no binders and is not moisture proofed in any way; the manufacturer describes the insulation as able to "breathe" and to regulate humidity. - Source: UK Insulation Superstore, retrieved 2019/01/04, original source: https://www.insulationsuperstore.co.uk/product/optimal-sheepwool-insulation-100pc-natural-50mm-x-380mm-1026m2-pack.html

Watch out: SheepWool insulation is fire-rated as Euro Classification E. According to the citation given below, a fire classification of "E" is defined as follows:

Combustible materials: highly contribution to a fire: Will resist only a small flame attack in the beginning of the fire.

- Source: The European Reaction to Fire classification system (Euro classes), Fire Safety explained, retrieved 2019/01/04 original source: ROCKWOOL Ltd /Rockpanel Customer Services/Sales Support Advisor Wern Tarw Pencoed Bridgend CF35 6NY Tel.: +44 (1656) 863 210 Fax: +44 (1656) 863 611 www.rockpanel.co.uk http://www.rockpanel.co.uk/technical-support/fs-xtra/euroclass/

Question: possible contamination of sheeps wool insulation?

2019/08/16 Art said:

Hi, i have done extensive work battling mold in my home and I'm at my last step and need your professional opinion. Half of my very low pitched roof had extensive black mold that was causing numerous health symptoms. I had the roof sheathing replaced.

I had the ventilation and insulation problems fixed a year before this year off and therefore all of that mold was dried. I also sanded down the raftets while they were exposed and encapsulated them in elmers glue and water mixture. I became very symptomatic after this tear off and feel the symptoms the strongest on the second floor. We have cleaned the house but we will clean it again with better detail.

My question is this; do you think that when the moldy sheathing was torn off and i sanded some of the rafters that some of that mold landed on my sheeps wool insulation on the Attic floor and is causing those symptoms?

Since that insulation was quite expensive it would hurt to run-over it but my and my family's health is priceless. Thank you for your help

This Q&A were posted originally

Reply: possible contamination of sheeps wool insulation by mold & VOCs

With the reclama that nobody who has an ounce of sense will pretend that he or she an inspect and diagnose a mold or IAQ problem or health worry by a brief e-text, yes it is entirely possible that insulation can become contaminated with mold or other irritants and allergens while still looking pretty clean.

Photo: a batt of sheeps wool insulation as shown by Wikipedia, August 2019.

See FIBERGLASS INSULATION MOLD for an example of mold found by microscopic examination of insulation that looked fine to the naked eye.

That same effect can occur on any fibrous material including sheeps wool insulation. In my OPINION sheeps wool insulation may also be vulnerable to other biological contaminants as, being organic, it's nice to eat (for some organisms).

Also sheeps wool can absorb VOCs and may thus serve as a reservoir. Some wool experts assert that the binding of at least some gases and chemicals to wool is permanent.

What's unclear to me is just what that means under changing conditions and also just what the total limitations are on absorption of environmental contaminants. Surely no material has an infinite absorption capacity and ultimately the material's ability to absorb contaminants and thus to isolate them must be limited.

Sheeps wool insulation is noted for its ability to both absorb and release moisture. Does that mean that while the wool is high in moisture content it invites mold growth? In my view more research is neeed, but at least some sources including sheeps wool insulation providers assert that the natural keratin in sheeps wool insulation resists mold growth and that the amino acids in sheeps wool bind and trap nitrous oxide, NOx,sulphur dioxide, SO2 and perhaps CH2O-formaldehyde.

Wool is also a good absorber of air pollutants (Beikircher 2014) but that might also mean that it can serve as a pollutant or contaminant reservoir in a building. Research on this question is ongoing.

Sheeps Wool Insulation Providers

Photo: lambs in Akaroa New Zealand, photo by the author, 2014.

Photo: lambs in Akaroa New Zealand, photo by the author, 2014.

- Black Mountain, wool, hemp, other insulating products. Website: https://www.blackmountaininsulation.com Tel: 01745 361911 Address: in the U.K., not provided

In the U.S. Tel: (231) 399-0700 Address not provided. - Coler Natural Insulation 1194 Scandia Drive Webster, NY 14580 USA, Tel: 585-626-0629, Website: https://www.coler.com/sheep-wool provides sheep wool insulation in batt and roll forms.

- Ecological Building Systems Limited,

Main Street,

Athboy,

Co. Meath,

Republic of Ireland

Telephone: +353 (0)46 9432104

distributes Thermafleece Cosywool sheeps wool insulation in 370mm wide rolls, 75% sheep wool, 15% recycled polyester, and 10% polyester binder. The thermal conductivity of this insulation is 0.039 W/mK or specific thermal capacity of 1800 J/(kg.k). - Grenian Ltd, 1 George Street Snow Hill Wolverhampton WV2 4DG Website: www.grenian.co.uk, Tel: 07703 472025 Email: matthew@grenian.co.uk provides sheep wool insulation, cork insulation, wood fibre insulating batts and other insulating materials.

- Havelock Wool

204 Edison Way | Reno, NV 89502 USA, Email: sales@havelockwool.com Tel: +1 775 971 4870 Website: https://havelockwool.com

Website excerpts: Wool improves indoor air quality, wool manages moimsture, wool absorbs sound, wool resistrs compression. retrieved 2019/08/18 original source: https://havelockwool.com - International Wool Textile Organisation,

Rue de l'Industrie 4

1000 Brussels

BELGIUM

Phone: +32 2 505 40 10

Fax: +32 2 503 47 85

E-mail: info@iwto.org Website: https://www.iwto.org/sustainability

Website Excerpt:

IWTO is the recognized global authority for standards in the wool textile industry. Since 1930, IWTO has represented the interests of the global wool trade. Our membership encompasses the entire wool textile pipeline, from farm to retail. By facilitating research and development, wool textile education and knowledge sharing, IWTO ensures a sustainable future for wool. - NuVision Energy Unit 19P Flighways Business Park Dunkeswell EX14 4PB Company Reg: 6849811 Email: accounts@nuvisionenergy.co.uk Contact 01404 891693

- Oregon Insulation, Info@oregonshepherd.com

1-888-629-WOOL (9665)

1-503-556-3800 or 888-629-9665

Website excerpt:

Wool, with its unique fiber qualities is naturally fire resistant. Untreated wool fiber will not support open flame. Oregon Shepherd’s loose fill insulation is treated, just as most insulation products, with a chemical solution called Solubor with Sodium Borate, to make it even more fire resistant.

The difference is that our treatments are not petrochemicals; they are natural chemicals from the earth. Petrochemicals emit Volatile Organic Compounds (VOC’s); things like formaldehyde, benzene, and methane; which are not materials you would like to inhale on a daily basis.

Our chemical treatments do not emit VOC’s, neither in the production process, nor in your home.

EPA’s Office of Research and Development’s “Total Exposure Assessment Methodology (TEAM) Study” (Volumes I through IV, completed in 1985) found levels of about a dozen common organic pollutants to be 2 to 5 times higher inside homes than outside, regardless of whether the homes were located in rural or highly industrial areas.

TEAM studies indicated that while people are using products containing organic chemicals, they can expose themselves and others to very high pollutant levels and elevated concentrations can persist in the air long after the activity is completed. - Sheep Wool Insulation

Unit 1, Railway Business Park, Balleese Lower, Rathdrum, Co. Wicklow, Ireland Website: https://www.sheepwoolinsulation.com

100% pure SheepWool insulation with "full ionic protect" - ThermaFleece, U.K., provides sheep's wool and hemp insulation and other insulating products including insulation from recycled plastic bottles. Tel: 01768 486285 Email: enquiries@thermafleece.com Website: https://www.thermafleece.com

InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information for the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website. We very much welcome critique, questions, or content suggestions for our web articles.

Research on the health effects & considerations of natural insulation such as sheep's wool

- Beikircher, Wilfried, Philipp Zingerle, and Michael Flach. DEVELOPMENT OF MODULAR WOODEN BUILDINGS WITH FOCUS ON THE INDOOR ENVIRONMENTAL QUALITY [PDF] In WCTE 2014—World conference on timber engineering: renaissance of timber construction, WCTE 2014 proceedings. Quebec City. 2014. https://www.uibk.ac.at/holzbau/aktuelles/aktuelles-2014/wcte-abs038_development-of-modular-wooden-buildings.pdf

Abstract

During the last three decades there has been increasing concern within the scientific community about the effects of indoor air quality on health. Changes in building design devised to improve energy efficiency and has induced that modern homes and offices are frequently more airtight than older structures. Furthermore advances in construction technology have caused an extensive use of synthetic building materials.

The construction process and the production of building materials not only consume the most energy they also have a big impact on the Global Warming Potential. While these improvements have led to more comfortable buildings with lower running costs, they also provide indoor environments in which contaminants are readily produced and may build up to much higher concentrations than outside.

Because about 80-90% of our time is spent indoors, where we are exposed to chemical and biological contaminants and possibly carcinogens, the Indoor Environmental Quality plays an increasing role.

The aim of this study was to develop building components out of sustainable natural materials for modular building concepts with regard to the Indoor Environmental Quality such as the air quality and the indoor climate, the temperature and humidity. To guarantee high Indoor Air Quality a mechanical ventilation system is part of the construction. It has to ensure a controlled air change with a minimum of dissipation of energy.

Building parts were assembled to meet high energy efficiency Standards. For the construction parts wood, hemp, sheep wool and clay were used to meet the settled requirements. As a first result of this study two modular buildings were erected, in which the indoor air quality and the construction physics will be monitored in the next few years for generating valuable data. - BUCIŞCANU, Ingrid-Ioana and Melinda PRUNEANU “Gheorghe Asachi”, SHEEP WOOL - A PERFORMANT

AND SUSTAINABLE ALTERNATIVE

TO CONVENTIONAL BUILDING INSULATION [PDF] Technical University of Iaşi, Romania, retrieved 2019/08/18 original source: http://www.agir.ro/buletine/3010.pdf

Abstract:

Use of natural building materials and improvement of thermal efficiency are key elements of sustainability in the construction industry. In this context, sheep wool is being promoted as an environmentally friendly, effective and consumer-safe insulation material.

During last decades, great amounts of raw wool, mainly of low quality grades, were rejected by the textile industry and turned into a problematic waste. Production of sheep wool insulation contributes to the valorization of raw wool waste into value-added technical applications.

This paper aims to review the main wool fiber characteristics that are relevant to its use as insulator for sustainable building, and the manufacturing technologies for sheep wool insulation currently on the market. Keywords: raw wool, waste valorization, green building, energy efficiency, sustainability

Excerpt from this paper:

Condensation is one of the major challenges facing the building industry today. Excess moisture has a detrimental effect on the structure of a building and is also a root cause of mold, which can have adverse effects on the inhabitants’ health.

Apart from its thermal properties, wool’s main advantages as insulator come from its capacity to control condensation. Natural wool is hygroscopic: it can absorb over 35% of its own weight in moisture without significant changes to thermal performance, whereas the thermal performance of man-made mineral fiber insulation deteriorates when condensation is present.

OPINION: Watch out: absorbing moisture may also increase the risk of mold contamination in any insulating material, particularly organic material that may host some species of fungi. (Stefanowski 2017) (Dujardin 2018) - Editor. However the authors claim:

... unlike mineral insulation, wool is not a health hazard, as it is naturally non-toxic, non-allergenic, resistant to mold and odorless.

... the use of preservation and fire-retardant additives. One disadvantage of sheep wool is the danger of moth infestation, which makes the protective treatment mandatory. Chemicals commonly used for this purpose are organic halogen compounds.

Use of such additives with toxic effects on humans and environment is inconsistent with the requirements of “green” products, when it comes to house or commercial building. Currently, wool insulation is treated with about 4% non-toxic borax to prevent moth infestation, fungi growth, and to enhance its fire-retardant properties.

... potential allergenic, due to mold growths on its surface. Recently, tests on durability and susceptibility to mold growth of different bio-based insulating materials like hemp, wool and wood fiber, showed that despite its high hygroscopicity, wool exhibited the lowest growth intensity of common mold strains [11].

... pollution associated to cleaning and preparation processes. In order to be produced for effective insulation, wool has to be properly cleaned and treated. These operations involve the use of toxic chemicals and the release of highly-polluted wastewater.

However, cleaning and scouring, wellknown for their negative environmental impact, are key operations in all production processes applied in the wool textile industry if high quality products are desired. Till now, the contribution of wet processing to the environmental impact of wool-based insulation has not been estimated. - Carbon Smart Materials Palette: SHEEPS WOOL, retrieved 2019/08/18 original source: https://materialspalette.org/wool/ Excerpts:

Wool insulation is made from sheep’s wool fibers. Wool is an effective thermal and acoustic insulation and is available in both batt and blow-in forms. Wool inherently manages moisture, improves indoor air quality by absorbing harmful chemicals, is sound absorbing, and is naturally fire resistant.

Wool is a keratin and therefore will not support the growth of mold. It is important to distinguish natural sheep’s wool from mineral wool or rock wool, which are actually made from rock, blast furnace slag, or other raw materials which are then melted and sun into fibers.

Wool fibers sequester atmospheric carbon. Carbon makes up 50% of the weight of wool (compared to 40% for cotton and 24% for cellulose). This carbon comes from the grasses and other plants that wool sheep eat. Most products available conform to Class A of the building code.

Products are readily available and increasingly being used in projects of all sizes across the US, Canada, the EU and Australasia. Statistics Carbon makes up 50% of the weight of wool, higher than cotton (40%) or wood pulp-derived cellulose (24%) 1 kg of clean wool equates to 1.8 kg of CO2 stored - Curling, S. F., C. Loxton, and G. A. Ormondroyd. "A rapid method for investigating the absorption of formaldehyde from air by wool." Journal of Materials Science 47, no. 7 (2012): 3248-3251.

- Dujardin, Nicolas, Vincent Feuillet, David Garon, Laurent Ibos, Mario Marchetti, Laurent Peiffer, Didier Pottier, Virginie Séguin, and Dominique Theile. "Impacts of environmental exposure on thermal and mycological characteristics of insulation wools." Environmental Impact Assessment Review 68 (2018): 66-80.

Abstract:

Fieldwork was conducted on 138 energy efficient buildings, to check if building site practices induced exposure to weather of thermal insulation. In nearly 80% of cases, insulation was exposed to weather due to insufficient protection.

Therefore insulating wools were exposed, divided into three parts (control, exposure under shelter, exposure to weather).

After the exposure period these samples were submitted to thermal conductivity measurements and infrared spectroscopy. A numerical study was carried out to evaluate the influence of weather conditions on thermal performance.

Identifications of molds were realized by direct cultures of each sample. Mycological analyses provided the most significant results, showing a significant effect of exposure condition, with possible consequences in human health (toxinogenic, allergenic or pathogenic species) and material properties (cellulolytic species). Infrared spectrometry also showed some changes in sensitivity to water.

These results show the interest to study in more detail the variations in the sensitivity, to moisture and mold, of insulation material throughout its ageing on site, and the interactions with the practices of the building process. - Jerman, Miloš, Irene Palomar, Václav Kočí, and Robert Černý. "Thermal and hygric properties of biomaterials suitable for interior thermal insulation systems in historical and traditional buildings." Building and Environment 154 (2019): 81-88.

Excerpts:

Properties of wood fiber board, flax fibers, hemp fibers, jute fibers, and sheep wool are analyzed.

Heat and moisture transport and storage parameters are determined.

All five biomaterials have low thermal conductivity and high moisture diffusivity.

Water vapor diffusion parameters and hygroscopic properties are suitable for the use on interior side.

Measured data can be applied for advanced hygrothermal- and energy-related assessments. - Latif, Eshrar, D. Chitral Wijeyesekera, Darryl Newport, and Simon Tucker. "Potential for research on hemp insulation in the UK construction sector." In Proceedings of Advances in Computing and Technology,(AC&T) The School of Computing and Technology 5th Annual Conference, University of East London, pp. 2010.

Abstract:

Hemp based thermal insulation has the potential to reduce CO2 emissions from buildings and to be 'carbon-negative' in its production and manufacture. Hemp has been in use to produce biobased natural fibre insulation in the UK in recent years.

With further development in hemp agronomy, production process and selection of raw materials in the production, hemp-based insulation materials are likely to become environmentally and functionally superior products to other insulation materials developed from petrochemical and mineral based sources.

This paper looks at the research works on the present and future housing scenario in the UK, reductions in embodied energy of insulation materials, techniques for increasing thermal performance and ways in which the environmental impact can be lessened. - Mansour, E., C. Loxton, R. M. Elias, and G. A. Ormondroyd. "Assessment of health implications related to processing and use of natural wool insulation products." Environment international 73 (2014): 402-412.

Abstract: This paper discusses possible health implications related to dust particles released during the manufacture of sheep's wool-based non-woven insulation material. Such insulation may replace traditional synthetic insulation products used in roofs, wall cavities, etc. A review of the literature concerning organic dusts in general and sheep's wool fiber summarizes dust exposure patterns, toxicological pathways and the hazards imposed by inhalation and explosion risk.

This paper highlights a need for more research in order to refrain from overgeneralizing potential pulmonary and carcinogenic risks across the industries. Variables existing between industries such as the use of different wool types, processes, and additives are shown to have varying health effects. Within the final section of the paper, the health issues raised are compared with those that have been extensively documented for the rock and glass wool industries. - Mansour, Elie, Simon F. Curling, and Graham A. Ormondroyd. ABSORPTION OF FORMALDEHYDE BY DIFFERENT WOOL TYPES [PDF] In International Panel Products Symposium, Llandudno, UK. 2015. http://e.bangor.ac.uk/5642/1/33692.pdf

Summary:

This document summarises the quantitative analysis of the absorption of formaldehyde gas by different wool types. Formaldehyde, along with other VOCs, is of increasing concern due to its role as an accumulating indoor air contaminant.

Building upon previous data, different wool types were subjected to cycles of exposure to formaldehyde gas whilst the weight gain was measured.

The nature, condition and possibly the level of pigmentation of the wool all seem to effect the maximum quantity of formaldehyde absorbed. - Mansour, Elie, Simon Curling, Antoine Stéphan, and Graham Ormondroyd. ABSORPTION OF VOLATILE ORGANIC COMPOUNDS BY DIFFERENT WOOL TYPES [PDF] Green Materials 4, no. 1 (2016): 1-7.

Abstract: This paper summarises the quantitative analysis of the absorption of volatile organic compounds (VOCs), namely gaseous formaldehyde, toluene, limonene and dodecane, by different wool types. VOCs are of increasing concern due to their role as accumulating indoor air contaminants, and this paper demonstrates the potential of wool as a sustainable and natural solution to this problem.

Building on previous data, different wool types were tested by way of two different methods to assess their absorption ability with regard to these VOCs. For formaldehyde analysis, the samples were subjected to cycles of exposure to excess formaldehyde gas while the weight gain was measured. For the other VOCs, a modified microchamber was used to flow the gases through the samples, followed by trapping and quantification of the non-absorbed VOCs using Tenax TA tubes.

The data presented indicate that wool is able to absorb a range of VOCs in differing amounts. The data also show that the amount and the type of VOCs absorbed by wool were dependent on the sheep breed and the processing of the wool. - retrieved 2019/08/18 original source www.researchgate.net/profile/Elie_Mansour/publication/295079483_Absorption_of_Volatile_Organic_Compounds_by_Different_Wool_Types/links/56e6828a08ae68afa11380f5.pdf - Maskell, Daniel, Carla Florbela da Silva, Keith Mower, Rana Cheta, Andy Dengel, Richard Ball, Martin Ansell, Pete Walker, and Andrew Shea. "Properties of bio-based insulation materials and their potential impact on indoor air quality." (2015).

Abstract:

Significantly decreasing energy consumption in buildings requires more air-tight construction combined with much higher insulation levels. A potential unintended consequence of this approach has been deterioration in the indoor air quality, resulting from significantly reduced ventilation rates and the accumulation of airborne pollutants, and this has proven to be a bottleneck to successful implementation of legislation.

The use of natural bio-based insulation materials has increased in recent years, largely driven by concerns over the embodied energy and whole-life environmental impact of insulation materials. This has led to their increased use, typically within breathable wall constructions. A breathable wall construction allows the insulation material to directly contribute to the indoor air quality.

Volatile Organic Compounds (VOCs) having boiling points within the range 60-280 °C contribute to the indoor air contamination in buildings, and at certain concentrations can contribute to building-related illnesses. This paper presents some findings from the early stages of a phased experimental study to explore use of bio-based insulation materials, including hemp-lime and sheep’s wool, to reduce VOCs from the room atmosphere.

There are many different volatile organic compounds and this study will consider the Total Volatile Organic Compound (TVOC) emissions expressed as toluene, as well as the formaldehyde emissions separately.

Insulation specimens with nominal dimensions 200 x 60 x 50 mm were prepared and placed in horizontally mounted cylindrical chambers. Air maintained at 23 °C (±2 °C) and 50 % (±5 %) RH was fed in coaxially to one end of the cylinder.

The exhaust air was sampled for VOCs and for formaldehyde following 3 and 28 day of exposure. The results of this paper will help inform the design of holistic indoor environments that consider more than just the hygrothermal properties of insulation materials. - Strandberg-de Bruijn, P. B., Kristin Balksten, and Anna Donarelli. SUSTAINABLE INSULATION OF HISTORICAL WOODEN AND STONE BUILDINGS WITH LIME-HEMP [PDF] Academic Journal of Civil Engineering 35, no. 2 (2017): 651-655.

ABSTRACT

In this multidisciplinary project lime-hemp is studied as a thermal insulating material for the renovation of historic timber and brick buildings*). Focus is on buildings in the historic city of Visby on the Swedish island of Gotland in the Baltic sea.

Many historic buildings in Visby have over the past decades been thermally insulated with materials such as mineral wools and polystyrene. Due to this, damage caused by moisture and microbial growth has increased. As a consequence, cultural and historical values have been damaged.

Lime-hemp is a sustainable building material that consists of hemp shiv and building limes. It works differently than conventional insulating materials; in addition to good thermal insulation properties, it also has good thermal mass and moisture buffering capacity.

This project will study the durability of the lime-hemp, especially microbial growth and moisture problems, and opportunities for renovation of historic buildings, while creating a good indoor climate and preserving historical values. Labstudies as well as full-scale studies are conducted. The aim of the project is to sustainably improve energy efficiency while preserving historical values, without durability problems. *) The project started in September 2016 and results are not expected until earliest autumn 2017. The article will therefore give an outline of the project and some preliminary findings. - Stefanowski, B. K., S. F. Curling, and G. A. Ormondroyd. "A rapid screening method to determine the susceptibility of bio-based construction and insulation products to mould growth." International Biodeterioration & Biodegradation 116 (2017): 124-132.

Abstract

Mathematical models have been developed to evaluate materials' durability and susceptibility to biodeterioration by moulds, however models are material and mould species specific. Ultimately the best way to determine a materials’ susceptibility is to expose the material to microorganisms.

This study attempted to develop a quick, reliable screening method to evaluate a number of different materials for their susceptibility to moulds at optimal and limiting conditions. This test method was based on modified versions of ASTM 4445-91 and BSEN 846.

The water absorption coefficient and Dynamic Vapour Sorption tests were also conducted to determine any correlation between the materials hygric properties and mould growth. The materials used to validate the novel screening method were: MDF, laminated MDF, Chipboard, Laminated chipboard, Wool, Hemp, Wood fibre insulation and pine.

It was found chipboard was the most susceptible to mould growth and wool the least when in direct and indirect contact with agar.

Primary colonisers (A. niger) easily colonised the materials, regardless of the environmental conditions, whereas secondary (A. alternate) and tertiary (T, virens) colonisers were absent on materials under limiting conditions. - Walker, I. K., and H. M. Williamson. "The spontaneous ignition of wool. I. The causes of spontaneous fires in New Zealand wool." Journal of Applied Chemistry 7, no. 8 (1957): 468-480.

Abstract:

An investigation was made of the causes of heating and spontaneous ignition of baled wool in the New Zealand wool trade. It is shown that temperatures high enough to cause combustion could not be promoted solely by exothermic wetting, bacterial rotting, or by friction during ‘dumping’.

Direct reaction with oxygen at temperatures below 60° can cause temperature rises up to the ignition point in some samples of pie wool. Results of analyses of representative pie wools are presented. It is concluded that the majority of (and perhaps all) spontaneous fires in raw wool are caused by pie wool. Adequate scouring of the pie wool removes the combustion hazard. - Zoccola, M., Montarsolo, A., Mossotti, R., Patrucco, A. and Tonin, C., 2015. Green hydrolysis as an emerging technology to turn wool waste into organic nitrogen fertilizer. Waste and biomass valorization, 6(5), pp.891-897.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: are these pipes insulated with asbestos?

1950s London house but had work done in 1990s. Are these pipes covered in asbestos? - Danielheyman123 2022/04/07

1950s London house but had work done in 1990s. Are these pipes covered in asbestos? - Danielheyman123 2022/04/07

This Q&A were posted originally

Moderator reply: wool or recycled fabric pipe lagging wrap used in the UK to insulate pipes

@Danielheyman123,

That's not a pipe insulation that I can identify with certainty.

It looks most like a pipe wrap made of recycled materials, perhaps fabrics, but possibly also some cellulose - used as a pipe lagging insulation. Typically those are made of wool or a mix of recycled wool and/or other fabric fibres.

In your photo (above) we can plainly see the edges of the wrap so we know it's a wrap-around pipe insulation, not a sleeve nor spray-on.

Recycled pipe wrap insulating fabric mix can, from a distance also look like insulation made from cellulose (wood or paper fragments) but it's not likely to be of cellulose.

See if you can get a very sharp close-up photo (you can post one photo per comment but as many comments as you need).

Look for evidence of use of chopped chopped fabric and also (unlikely) look for newsprint - tiny bit of paper with letters on them.

In the UK you may find that pipe insulation advertised as "cellulose or recycled rag or fabric pipe lagging" or as felt insulation, usually made of recycled cloth, sometimes specifically wool.

We direct you to our page on

SHEEPS WOOL INSULATION - you are on this page

Shown below are two examples of currently-available felt pipe lagging described as "Felt Insulation Hose (left in image) or as Pipe Lagging Wrap - natural wool (at right)" currently sold by online vendors.

More about cellulose insulation used as a loose-fill in walls and ceilings is at

CELLULOSE LOOSE FILL INSULATION

...

Continue reading at INSULATION INSPECTION & IMPROVEMENT - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BALSAM WOOL BATT INSULATION - older, traditional batts, paper enclosed shredded wood insulation -

- HEMP / JUTE INSULATION

- INSULATION IDENTIFICATION GUIDE

- INSULATION INSPECTION & IMPROVEMENT - topic home

- INSULATION R-VALUES & PROPERTIES

- MINERAL WOOL - ROCK WOOL INSULATION - properties; what is mineral wool or "rock wool" insulation. Is it the same as slag wool?Definition of mineral wool, slag wool, stone wool, rock wool and mineral fibre insulation products, insulation properties, R-values, IAQ hazards. Is there asbestos in mineral wool?

- ROCK WOOL INSULATION

- SHEEPS WOOL INSULATION

Suggested citation for this web page

SHEEPS WOOL INSULATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Insulate & Weatherize (Taunton's Build Like a Pro), [link to purchase this document] Bruce Harley. Review quoted:

An engineer who trains builders in energy-efficient construction, Harley offers a wealth of information that will allow readers to improve their home's efficiency, saving both money and natural resources. After an introductory section that explains the underlying principles of heat transfer, insulation, and air quality, Harley demonstrates basics such as weather-stripping and moves forward through advanced projects including insulation and major upgrades. Short "Pro Tips" as well as sections labeled "Trade Secrets," "What Can Go Wrong," and "In Detail" provide a great deal of helpful information. Increasing energy efficiency is one of the easiest ways for homeowners to save money - Super-Insulated Retrofit Book: A Homeowner's Guide to Energy-Efficient Renovation, [link to purchase this document] Robert Argue

- The super-insulated retrofit book: A homeowner's guide to energy-efficient renovation [link to purchase this document] (Sun builders series), Brian Marshall

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.