Hemp / Jute Insulation

Hemp / Jute Insulation

Identify Flax, Hemp & Jute building insulation

- POST a QUESTION or COMMENT about how to identify different kinds of building insulation

This article describes flax, linen, hemp and jute building insulation products and includes a history of the use of jute and hemp as an insulating material.

Page top: a photo of jute insulation placed between rafters of a North American home built in the 1920s, courtesy of an InspectApedia reader.

This series of articles provides details about all types of building insulation, identifying each type of insulation.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Flax, Linen, Hemp & Jute Building Insulation

Question: realtor says this insulation is Balsam Wool

Question: realtor says this insulation is Balsam Wool

2021/07/27 Emily:

Hi, please see the image for what's insulating most of my 1923 brick house.

I was told by the realtor that this is balsam wool, but it's not really looking like a match to me as I research.

Your thoughts? Thank you!

[Click to enlarge any image]

Moderator reply: your photo shows Jute insulation installed between rafters

@Emily,

Thank you for an excellent photo and a helpful question.

That is Jute building insulation, described at

JUTE INSULATION inspectapedia.com/insulation/Insulation-Identification-Guide.php#Jute

which is also described in our insulation identification page at

inspectapedia.com/insulation/Insulation-Identification-Guide.php INSULATION IDENTIFICATION GUIDE

I'll add your photo in our Jute / Hemp insulation article.

Question: what is this brown fibrous insulation found behind plaster and lath?

What insulation did I find behind the plaster and lath. This was wet in some places. Was nailed on the studs about 5 inches apart

This Q&A were posted originally

at INSULATION INSPECTION & IMPROVEMENT

Moderator reply: woven or pressed vegetable fiber / fabric insulation vs mineral wool?

Jodeen

Can you please try again to see if you can get a photo that's not blurry?

I think that may be mineral wool or more-likely a plant-based insulating fabric such as jute or hemp or often a combination of the two, but I can't see it clearly.

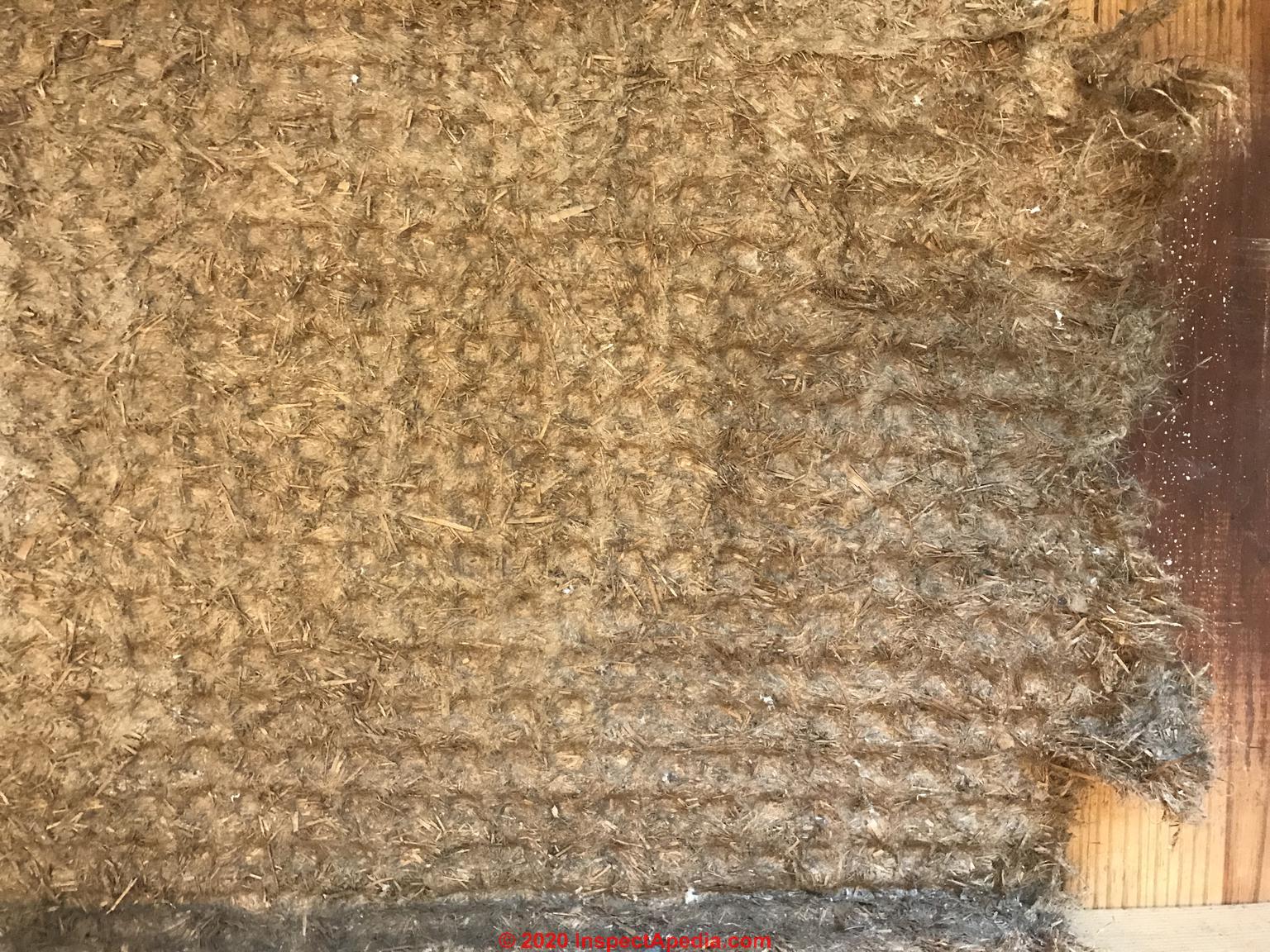

If it looks like brown cellulose-paper insulation, in a waffle pattern it's probably jute insulation.

ute insulating blankets were used in homes in North America beginning around 1900 and extending into the 1930s.

Also, was there a kraft or foil facing on the insulation? Any identifying labels?

In any event if the insulation is or has been wet it should probably be removed as water invites mold contamination.

Reader follow-up: jute insulation in a 1915 home

Better pictures of my brown fibrous waffle-pattern attic insulation stapled between wall studs.

It’s being removed but was curious what it was.

House was built in 1915.

Moderator reply:

Thank you for the question and photos of a thin jute- or wood-product (cellulose) insulating mat that I have not seen before.

Your under-floor insulating fabric appears to be a very thin jute-based pressed or woven insulating material applied under subflooring, nailed or stapled to the joist sides

In the U.S. attic and wall insulation made of flax panels appeared in 1910 under the brands Flaxlinium and Fibroleft. ( Bozsaky 2010)

Celotex fiberboard insulating panels had their debut in the U.S. in 1920 and are found separately in this article series.

Can you tell me the country and city of the building?

Usually where jute is used as a building insulation in more-recent construction, we see it in thicker forms like the product shown below.

Is it possible that someone re-purposed jute from another source and added it to your building?

Knowing your location and climate will be helpful.

The first attempts to produce flax panels for roof insulation were made in the USA and eventually around 1910 the first products (Flaxlinium, Fibroleft) were put on the market. (Bozsaky 2010)

A similarly-named product, Fibroloft, was produced by Courtauld and was a high-bulk hollow rayon fiber. Unlike its natural-fiber ancestors, rayon, of which Fibroloft was an example, is a a synthetic fiber, made from natural sources of regenerated cellulose, such as wood and related agricultural products. - "High oil prices windfall for producers of rayon", The Herald, Manchester Conn., 17 February 1961, p. 17.

I'm researching further for product names.

Definition & Uses of of Fibers: Flax, Hemp, Jute & Linen?

- Fibre-Flax or Flax (Linium usitatissimum). Common name: Linseed.

Flax is a flowering plant of the Linaceae family cultivated as a food and as a fibre crop in regions of temperate climate.

In New Zealand, "flax" plants are members of a different genus: Phormium.

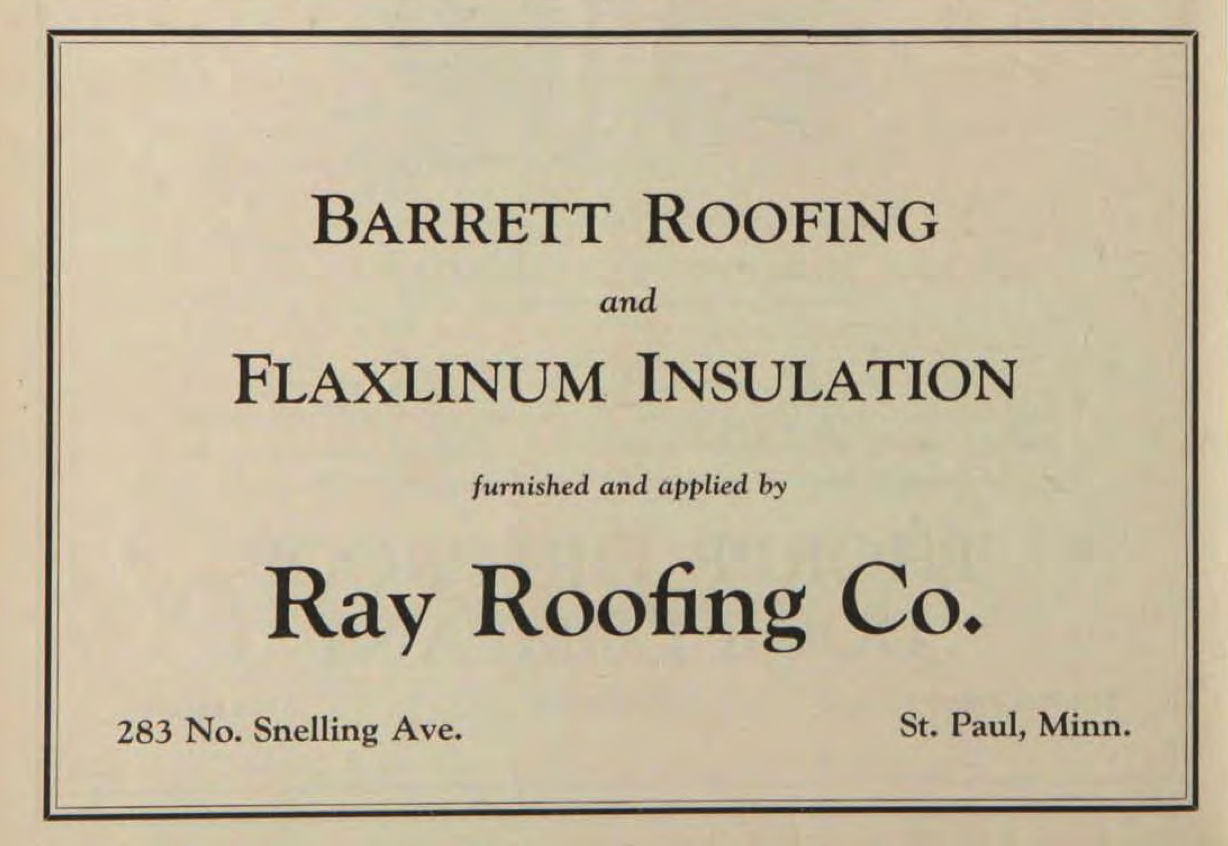

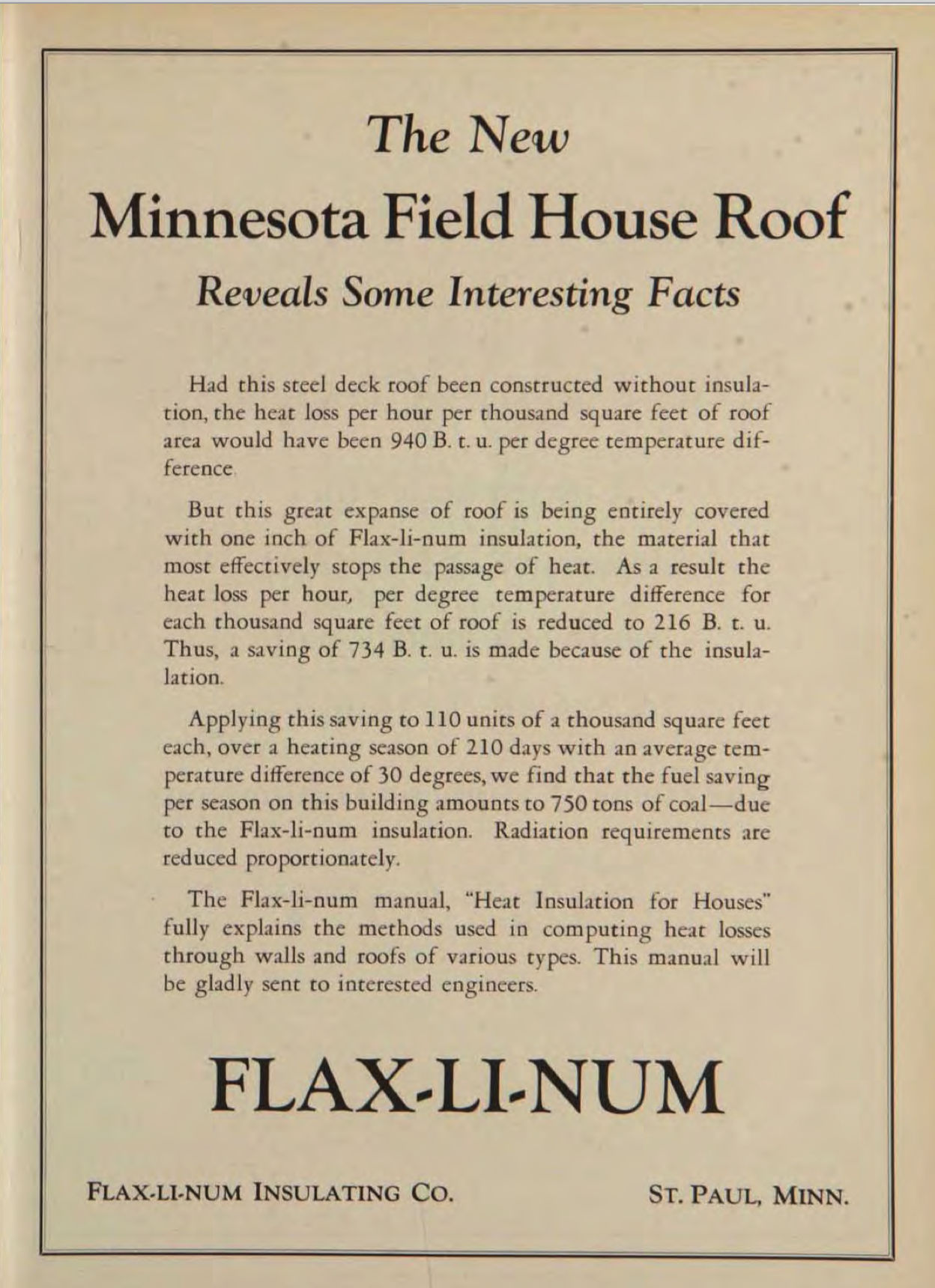

The advertisement for Flaxinium Insulation shown here appeared in the Minnesota Alumni Weekly, February 11 1928, Vol. 27 No. 17 p. 5 - more on Flaxlinium is given below.

- Hemp (Cannabis sativa - var).

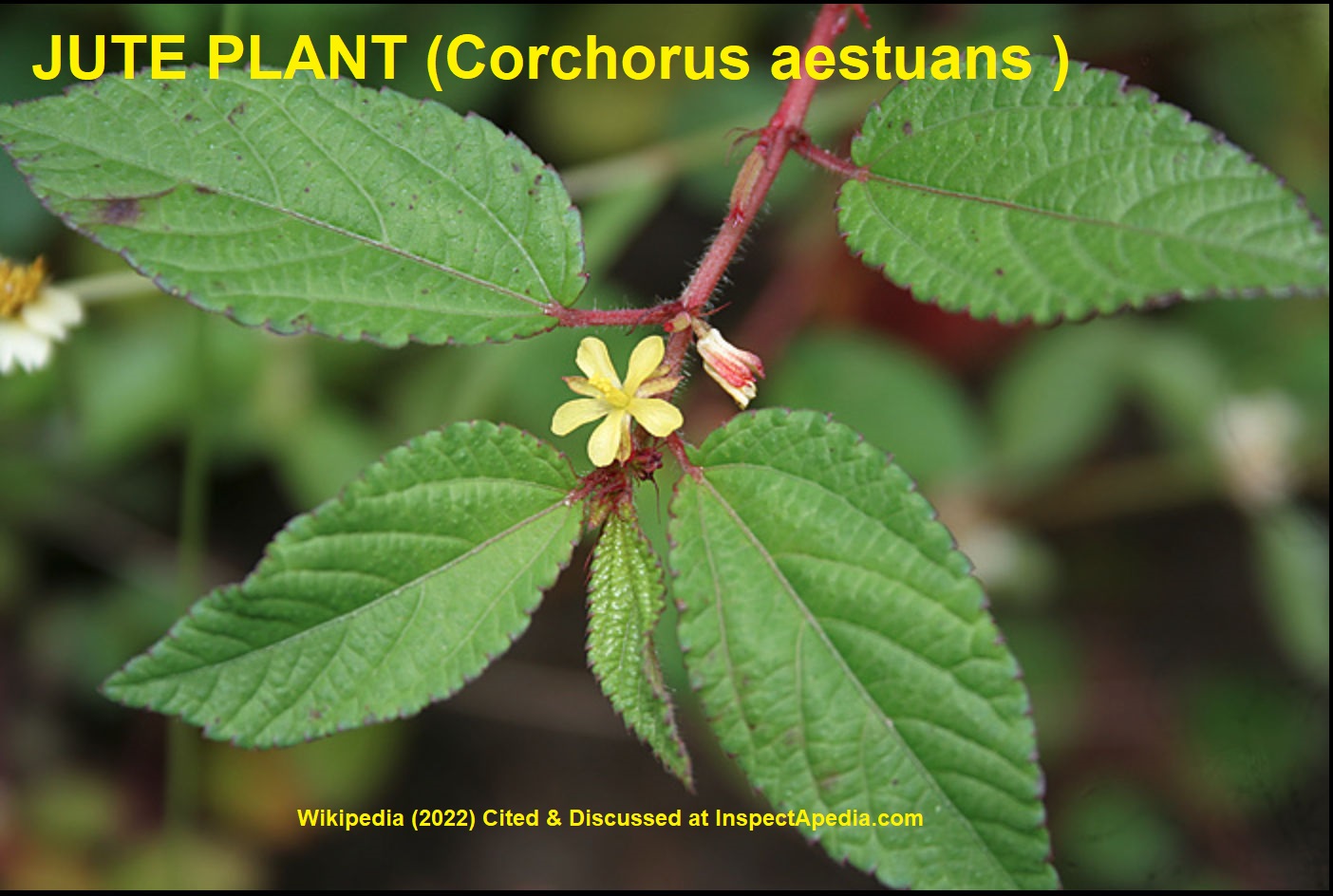

One of the fastest growing plants known, first spun into fibres for use as fabric 50,000 years ago, used to produce rope, textiles, clothing, and as an ingredient in foods and animal feeds as well as in a variety of more-refined products, even paint and biodegradable plastics, also used to produce insulation. - Jute (Corchorus olitorius)

The genus Corchorus was first described by Linnaeus in his great work Species Plantarum (1753).

Jute is produced from flowering plants in the genus Corchorus, in the mallow family Malvaceae. The primary source of the fiber is Corchorus olitorius, ... considered inferior to that derived from Corchorus capsularis.

"Jute" is the name of the plant or fiber used to make burlap, hessian or gunny cloth. - Wikipedia 2021/07/27 - Linen is simply a textile made from fibres of the flax plant.

Hence the name Flax-Li-Num as an early flax-based insulating product described below.

History & Properties of Jute Insulation: Jute, Hemp, Flax Fibres

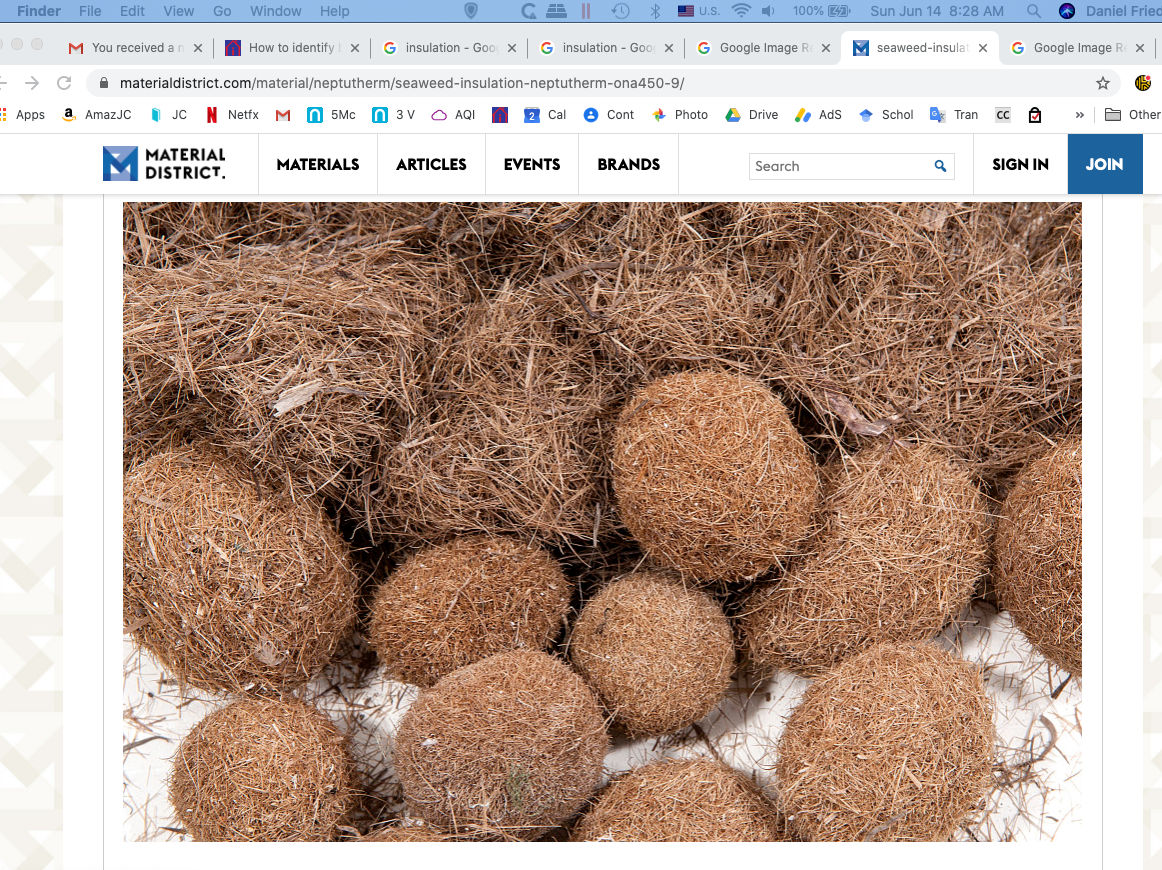

Photo: Contemporary insulating batts made of a combination of hemp and jute fibres, described just below as Combi Jute insulating mats made of jute and hemp or flax.

Photo: Contemporary insulating batts made of a combination of hemp and jute fibres, described just below as Combi Jute insulating mats made of jute and hemp or flax.

This product consists of flexible insulation matts made from durable robust hemp fibres and upcycled jute fibres from food bags. - (TDS 2021)

The jute-hemp-flax product in this photo is manufactured by HempFlax Building Solutions GmbH; Industriestraße 2; 86720 Nördlingen, Germany, is sold in mats that are 375mm x 1.2m x 40 mm (14.7" wide x 1.5" thick x 47.2" long) each.

Among the different fibre crops, jute is one of the oldest cultivated fibre crops in India. Jute is mostly cultivated in the eastern part of India, and stands highest production in the world, used popularly as technical textiles over the centuries.

Jute fibre is used for reinforcement of

rural mud house. ... , it is the cheapest fibre crop available

commercially in bulk quantities as of today. As far as the properties of jute fibre are

concerned, it has both good characters as well as unwanted properties.

Basically, this fibre is

a mesh like structure which provides good coverage, good tensile strength, provides

toughness and durability, less elongation at break, ensures dimensional stability, and natural

colour which is ethnic in nature.

Unlike any other fibres, the drawbacks of jute fibre crop are

high surface roughness and prickliness, low extension at break, and coarseness, which

restricts its use in textile garment. (Debnath 2016)

Jute-Hemp R-Value / Insulating Value: Its insulating value is expressed in Joules per Kilogram per Kelvin (J/kg-K) and for the Combi Jute product below is given as 2300 J/kg K - 0.5493456 BTUIT per pound degree F.

This is the amount of energy required to change one unit mass of this insulation product by one degree F.

If any of you engineer readers want to help us express this in an R-value for Jute that would be helpful; a direct translation doesn't appear easy.

Watch out: don't confuse the R-values per inch versus specific product R-values given for insulation products discussed in this article series. For example, Thermablok® Thermal Insulation is described as having an R-value of 10.3/Inch; the product thickness is 0.4 inches so it's effective R-value when used in a single thickness is R 4.12.

Quoting R-values as R per Inch is helpful for comparing the innate insulating values of various products but to find the actual product R-value you need to find its actual thickness.

Quoting R-values as R per Inch is helpful for comparing the innate insulating values of various products but to find the actual product R-value you need to find its actual thickness.

See details at INSULATION R-VALUES & PROPERTIES - R-values & U Values of various materials

Watch out: what some sources call "jute" is not made from jute or hemp fibres. For example in the automotive industry:

Jute is the most common OEM insulator. It’s lightweight, absorbs sound, and has a high R-value.

Our jute is made of recycled cotton fibers that are treated for mold and mildew resistance.

It all-natural (so no itching), class A fire rated, and is sandwiched between two aluminum foil barriers to make it a good radiant heat shield too. - Second Skin Auto & Home Insulation, retrieved 2021/07/27 original source: https://www.secondskinaudio.com/heat-insulation/foam-r-value-explained/

This company (Second Skin) offers Heat wave Thermal/Acoustic insulation: 3/8" thick aluminum foil-faced "jute" blanket material that reports an R-value of 3.91 / inch

(note that this is a foil-faced product made of recycled cotton, not jute fibers). This is an automotive product, not one intended for use in buildings.

[Click to enlarge any image]

Above: Minnesota Alumni Weekly, February 11 1928, Vol. 27 No. 17 on p. 5 described the use of Flax-Li-Num insulation in the new Minnesota Field House Roof. The Flax-Li-Num Insulating Company was located in St. Paul, Minnesota.

Excerpting from that issue, p. 5:

Huge Roof Heavily Insulated Against Loss of Heat

Interesting facts in connection with the roof of the new Field House are brought out in the statistics furnished by the Ray Roofing company.

Aside from the structural steel comprising the framework of the roof,

12 carloads of Barrett roofing, 80,000 metal screws,

12,000 feet of one-inch manila rope,

and 50 truck loads of FlaxLinum insulation were required to cover the roof which has 135,000 square feet of area.

This gives a glimpse of the enormous expanse of the roof and the material required to cover it to keep the heat in during the winter and out during the summer.

Research on Properties & History of Flax Jute Hemp Insulation

Photo: Corchorus aestuans (jute plant) in Hyderabad, India - Wikipedia 2022/06/10.

- K Arun Prasath and B Radha Krishnan, MECHANICAL PROPERTIES OF WOVEN FABRICBASALT/JUTE FIBRE REINFORCED POLYMER HYBRID COMPOSITES [PDF] Int. J. Mech. Eng. & Rob. Res. 2013, ISSN 2278 – 0149 www.ijmerr.com

Vol. 2, No. 4, October 2013 - retrieved 2022/06/10, original source: www.ijmerr.com/v2n4/ijmerr_v2n4_34.pdf

Abstract:

Composites are emerging as realistic alternatives to the metal alloys in many applications like automobiles, marine, aerospace applications, sports goods, etc.

Fiber composites offer many advantages such as low specific gravity, tensile strength and modulus, compressive strength and modulus, better fatigue strength, etc.

Due to the low specific gravity the strength weight ratio and modulus weight ratio of these composite materials are markedly superior to those of metallic materials. I

n this work it is concerned general purpose poly ester-based polymer composites are developed by reinforcement of basalt fabric and jute fabric into general purpose poly ester matrix by compression moulding technique.

This study describes the basalt fiber and jute fibre reinforced hybrid composites with poly ester resin with different stacking sequence.

Fabricated composite plates subjected to mechanical properties like Flexural strength, Impact strength test of the various specimens are calculated by using computer assisted Universal testing machine and Charpy Impact testing machine.

From the results it is found that pure basalt fibre combination maintains higher values in both flexural and tensile test. But for impact test basalt fibre is slightly lower than jute fibre reinforced composite.

Excerpt:

Jute Fiber, developed in the late 1940s, was the first modern composite and is still the most common. It makes up about 65% of all the composites produced today and is used for hulls, surfboards, sporting goods, swimming pool linings, building panels and car bodies.

Fiber reinforced resin composites that have high strength to weight and stiffness-to-weight ratios have become important in weight sensitive applications such as aircraft and space vehicles. This chapter dealt with the basic introduction about composites and the types of composites. It gives the introduction about the fiber reinforced composites. - Balador, Zahra, Morten Gjerde, Nigel Isaacs, and Marzieh Imani. THERMAL AND ACOUSTIC BUILDING INSULATIONS FROM AGRICULTURAL WASTES [PDF] Handbook of Ecomaterials; Torres Martínez, LM, Oxana Vasilievna, K., Boris Ildusovich, K., Eds (2018): 1-20.

- Bozsaky, David. THE HISTORICAL DEVELOPMENT OF THERMAL INSULATION MATERIALS [PDF] Periodica Polytechnica Architecture 41, no. 2 (2010): 49-56.

David BOZSAKY Department of Architecture and Building Construction Szechenyi Istvan University, Faculty of Engineering Sciences, GYOR, Hungary H-9026 GYOR, Egyetem ter 1. (D504), Tel.: +36(96)-503-454, Fax: +36(96)-613-595 e-mail: bozsaky@gmail.com

Abstract excerpts:

The history of thermal insulation materials is not as long as that of other materials, but the necessity of insulation is as old as building activity. Prehistoric people built shelters to protect themselves from the elements, originally using organic materials and later more durable substitutes. However people used not only materials that were found in nature, but discovered others which were suitable for insulating.

Processing organic materials produced the first insulated panels in the 19th century: meanwhile an increasing range of artificial materials were developed (rock wool, fibreglass, foam glass, hollow bricks, expanded perlite).

... Nowadays the most popular insulation materials are plastic foams and mineral wool with only a small amount of natural materials being produced.

Excerpt:

In 1920 the American Celotex Company introduced insulating panels made of bagasse (a waste by-product of sugar manufacturing).

It was used as thermal insulation in home construction and in the manufacture of refrigerated railroad cars. Owing to their flammability, later one or both of the sides were coated with asbestos cement.

- Bozsaky, David. NATURE-BASED THERMAL INSULATION MATERIALS FROM RENEWABLE RESOURCES—A STATE-OF-THE-ART [PDF] (2019) Rev. Slovak J. Civ. Eng 27 (2019): 52-59.

Excerpt: It should also be mentioned that efforts in some countries have been made to introduce special thermal insulation products made from kenaf fiber (also called Deccan hemp or Java jute), rice stalks, and pineapple leaves (Ardente et al., 2008; Asdrubali et al., 2015).

There have also been attempts to create thermal insulating products with sunflower stalk additives (Evon et al., 2015). - Bynum, R. T. (2001) Insulation Handbook, The McGraw-Hill Companies, New York (USA), 2001, ISBN 0-07-134872-7

- Combi Jute Insulating Mats, [photo just above] HEMP FLAX THERMO HEMP COMBI JUTE INSULATION Description [PDF] described by Ecological Building Systems in Great Britain, Ecological Building Systems UK Ltd Cardewlees Carlisle, Cumbria CA5 6LF United Kingdom Email: info@ecologicalbuildingsystems.com Tel: +44 (0)1228 711511 Web: https://www.ecologicalbuildingsystems.com/

- Combi Jute Hemp Flax Insulation TECHNICAL DATA SHEET - SPECIFICATIONS [PDF] (2012) Op. Cit. retrieved 2021/07/27

- Combi - THERMO HEMP COMBI JUTE DECLARATION of PERFORMANCE [PDF] (2020) Op. Cit. retrieved 2021/07/27

Excerpt: Fields of application: Cavity insulation of the internal and external walls in timber frame and comparable constructions (WH, WTR), Insulation of external walls between a support structure (WI), Insulation between the rafters and beams as well as in cavities corresponding construction, cavity insulation between sleepers in the floor and comparable substructure (DZ), Interior insulation of ceiling and roof, e.g. insulation under the supporting structure (e.g. rafters), suspended ceiling (DI) - Crini, Grégorio, Eric Lichtfouse, Gilles Chanet, and Nadia Morin-Crini. "Applications of hemp in textiles, paper industry, insulation and building materials, horticulture, animal nutrition, food and beverages, nutraceuticals, cosmetics and hygiene, medicine, agrochemistry, energy production and environment: A review." Environmental Chemistry Letters 18, no. 5 (2020): 1451-1476.

- 2. Czigany T (2006), “Special Manufacturing and Characteristics of Basalt Fiber Reinforced Hybrid Polypropylene Composites: Mechanical Properties and Acoustic Emission Study”, Department of Polymer Engineering, Faculty of Mechanical Engineering, Budapest University of Technology and Economics.

- Debnath, Sanjoy. THERMAL INSULATION BASED ON "JUTE" [PDF] (2016) In Insulation Materials in Context of Sustainability. IntechOpen, 2016.

Abstract:

Among the different natural fibres, jute is a less expensive fibre, annually renewable, and commercially available compared to other natural fibre crops. This jute is mostly cultivated in India and Bangladesh. More than a century, this fibre is well known as packaging (sacks), hessian, and carpet backing.

Since 1950s, the synthetic fibres slowly took the market share of conventional jute textiles due to their low cost and high production speed. As far as suitability of the insulating material is concerned, it has high potential of using as three types of insulation (thermal, sound, and electrical).

This present chapter gives emphasis on the basic methods of measuring jute based thermal insulation materials in different application areas. Apart from its evaluation methods, special attention has been made on the important factors affecting the thermal insulation behaviours of the jute-based textile materials.

Focusing the needs of the industry, present chapter also covers the future aspects regarding the insulation application from jute-based materials.

- Ecological Building Systems, HEMP FLAX THERMO HEMP COMBI JUTE INSULATION [PDF]Ecological Building Systems UK Ltd

Cardewlees

Carlisle, Cumbria

CA5 6LF

United Kingdom Tel: +44 (0)1228 711511 Email info@ecologicalbuildingsystems.com, illustrated just above, retrieved 2022/06/06 original source: https://www.ecologicalbuildingsystems.com/product/thermo-hemp-combi-jute

Website excerpt:

Thermo Hemp Combi Jute is a natural flexible insulation material made from a mixture of upcycled natural jute fibres and carbon negative hemp. Manufactured using discarded cocoa and coffee bean bags, processed using 100% renewable energy, and hemp which is renowned for its ecological credentials, Thermo Hemp Combi Jute uses the best properties of each material to create a unique high-performance insulation product. - Evon, P., Vinet, J., Rigal, M., Labonne, L., Vandenbossche, V., Rigal, L. NEW INSULATION FIBERBOARDS FROM SUNFLOWER CAKE WITH IMPROVED THERMAL AND MECHANICAL PROPERTIES [PDF] (2015) Journal of Agricultural Studies, 3(2), pp. 194-211, 2015, DOI: 10.5296/jas.v3i2.7738

- Kymäläinen, Hanna-Riitta, and Anna-Maija Sjöberg. "Flax and hemp fibres as raw materials for thermal insulations." Building and environment 43, no. 7 (2008): 1261-1269.

Abstract:

Bast fibres of, for example, flax and hemp are used as raw materials of thermal insulations. However, they have only a minor share in the market.

The aim of this paper was to evaluate the suitability of bast fibres of flax and hemp for thermal insulations. The functions and requirements of the bast fibrous insulations and their combustion resistance are discussed.

Thermal conductivity and the effects of several parameters on thermal performance are reviewed. The potential and costs of the raw material and quality and ecological aspects are also discussed. Finally, needs for future research is proposed. - Nor, A. F. M., M. T. H. Sultan, A. Hamdan, A. M. R. Azmi, and K. Jayakrisna. "Hybrid composites based on kenaf, jute, fiberglass woven fabrics: tensile and impact properties." Materials Today: Proceedings 5, no. 5 (2018): 11198-11207.

Abstract excerpt:

Abstract

Recently, environment and sustainability issues have arisen which resulting in remarkable achievements for green technology in the field of material production. Pertaining to this research, food tray table that are used in in-flight galley service is currently facing an environmental issue in regard of the use of non-degradable resources as the main element in food tray table production.

Hence, this research is attempting an effort to propose a newly developed material, which has the element of natural fiber in hybrid composites consist of jute (J), kenaf (K) and fiberglass (FG) for food tray table with less sustainability issues.

This paper presents the results of an experimental study on the mechanical properties consist of tensile and low-velocity impact properties on hybrid composites.

The aim of this research is to investigate the dynamic response of the hybrid composites under low velocity impact energy, as well as to analyze the experimental data for damage characterization from the tensile and impact testing. - Paul, N., and Mukul Mukhopadhyay. "Thermal Insulation Values of Jute Fabrics and of Its Blends with Other Fibres." (1977).

see inspectapedia.com/insulation/Thermal-Insulation-Values-of-Jute-Paul.pdf

Abstract excerpt:

Among the different natural fibres, jute is a less expensive fibre, annually renewable, and commercially available compared to other natural fibre crops. This jute is mostly cultivated in India and Bangladesh.

More than a century, this fibre is well known as packaging (sacks), hessian, and carpet backing. Since 1950s, the synthetic fibres slowly took the market share of conventional jute textiles due to their low cost and high production speed.

Really? Note the duplicate text in these two abstracts.

- Debnath, Sanjoy. "Thermal Insulation Material Based on “Jute”." Insulation Materials in Context of Sustainability (2016): 45.

Abstract:

Among the different natural fibres, jute is a less expensive fibre, annually renewable, and commercially available compared to other natural fibre crops. This jute is mostly cultivated in India and Bangladesh. More than a century, this fibre is well known as packaging (sacks), hessian, and carpet backing.

Since 1950s, the synthetic fibres slowly took the market share of conventional jute textiles due to their low cost and high production speed.

As far as suitability of the insulating material is concerned, it has high potential of using as three types of insulation (thermal, sound, and electrical). This present chapter gives emphasis on the basic methods of measuring jute based thermal insulation materials in different application areas.

Apart from its evaluation methods, special attention has been made on the important factors affecting the thermal insulation behaviours of the jute-based textile materials. Focusing the needs of the industry, present chapter also covers the future aspects regarding the insulation application from jute-based materials. - Second Skin, Heat Wave "JUTE" (Recycled Cotton) AUTOMOTIVE INSULATION [PDF] Second Skin Auto & Home Insulation, Second Skin Audio, 13825 W Business Center Drive, STE B, Green Oaks, IL 60045 USA Tel: 1-800-679-8511

- Strandberg-de Bruijn, P. B., Kristin Balksten, and Anna Donarelli. SUSTAINABLE INSULATION OF HISTORICAL WOODEN AND STONE BUILDINGS WITH LIME-HEMP [PDF] Academic Journal of Civil Engineering 35, no. 2 (2017): 651-655.

ABSTRACT

In this multidisciplinary project lime-hemp is studied as a thermal insulating material for the renovation of historic timber and brick buildings*). Focus is on buildings in the historic city of Visby on the Swedish island of Gotland in the Baltic sea.

Many historic buildings in Visby have over the past decades been thermally insulated with materials such as mineral wools and polystyrene. Due to this, damage caused by moisture and microbial growth has increased. As a consequence, cultural and historical values have been damaged.

Lime-hemp is a sustainable building material that consists of hemp shiv and building limes. It works differently than conventional insulating materials; in addition to good thermal insulation properties, it also has good thermal mass and moisture buffering capacity.

This project will study the durability of the lime-hemp, especially microbial growth and moisture problems, and opportunities for renovation of historic buildings, while creating a good indoor climate and preserving historical values. Labstudies as well as full-scale studies are conducted.

The aim of the project is to sustainably improve energy efficiency while preserving historical values, without durability problems. *) The project started in September 2016 and results are not expected until earliest autumn 2017. The article will therefore give an outline of the project and some preliminary findings.

Jute Hemp Insulation Look-Alikes

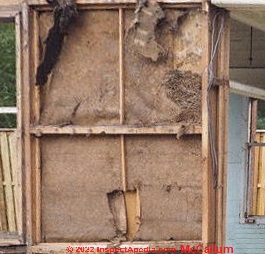

Some other natural fibre insulation products include balsam wool, seaweed, and other fiberboard products.

SEAWEED INSULATION is shown just above.

Also compare your jute or hemp insulation with balsam wool and with fiberboard insulation products.

Above: an example of 1940s balsam wool insulation used inside of a refrigerator. You may note it looks much like hemp-jute insulation.

Possible Jute / Fibrous Insulation in Scotland

Comment: Insulation & Materials at Gordon Cottage Hospital, Gordon, Berwickshire, Scotland

I'm in Scottish Borders, and a small building belonging to a cottage fever hospital, built around 1910, is being demolished

The building is of timber frame with corrugated iron cladding and dry lining of various types internally.

Within the wall structure and, I suspect not original, there is a layer of thin fibre board of some description in the cavity. A very basic and nominal insulation installed at time unknown but probably early in the life of the building

It looks somewhere around slightly under 1/2” 9- 12 mm thk of beige brown fibres, that have lost binder integrity; it just crumbles to the touch now, though is suspended in the cavity with support at 400 - 500 mm c/c at a guess.

The wood frames are in good state of preservation and everything from a about 6” or 150mm above wall plate is tight and dry.

Age and possibly heat variation have done for the fibre board

Photos given here show, in broad terms, the building and its structure along with the location of the fibrous board material.

The building previously was part of Gordon Cottage Hospital, Gordon, Berwickshire, Scotland.

The oldest buildings on the site were of wood and corrugated iron, probably constructed by Speirs & Co. of Glasgow.

Later two brick built ward blocks were added. These were subsequently converted into geriatric wards before the hospital finally closed. (- historic-hospitals.com)

The photographs are of one of the original building now being taken down.

The board material crumbles to fibrous component of 5 - 15mm length . Looks like wood fibre and possibly even horse hair.

Thats only as the fibres are of varied thickness and colour.

I doubt there is enough integrity in the board structure to have a stamping still extant but I will check.

WM, R.A., Scotland - 2022/09/26 by private email

Moderator reply: historical notes on the development of insulation in the U.K.

By its placement - in a wall cavity between corrugated metal siding and what looks like plywood or gypsum-board, that material looks more like an insulating batt or blanket than a more-dense fiberboard.

There were insulating products that used animal hair or perhaps hair combined with plant fibres such as jute or whatever was inexpensive and available to the insulation producer.

At INSULATION IDENTIFICATION GUIDE we cite the production of wool insulation in the UK and here on our Hemp Insulation page we'll preserve what information you can provide about this brown fibrous insulating material used in Scotland.

Notes: The brown fibrous insulation in this Godron Cottage hospital building was, we think, added after the building's original construction.

The pictures above show the fibrous nature of this insulation quite well . Now its very friable and just falls apart when moved . The piece I photographed is from the edge of the roll or sheet or whatever . I could find no markings on any remnants on site .

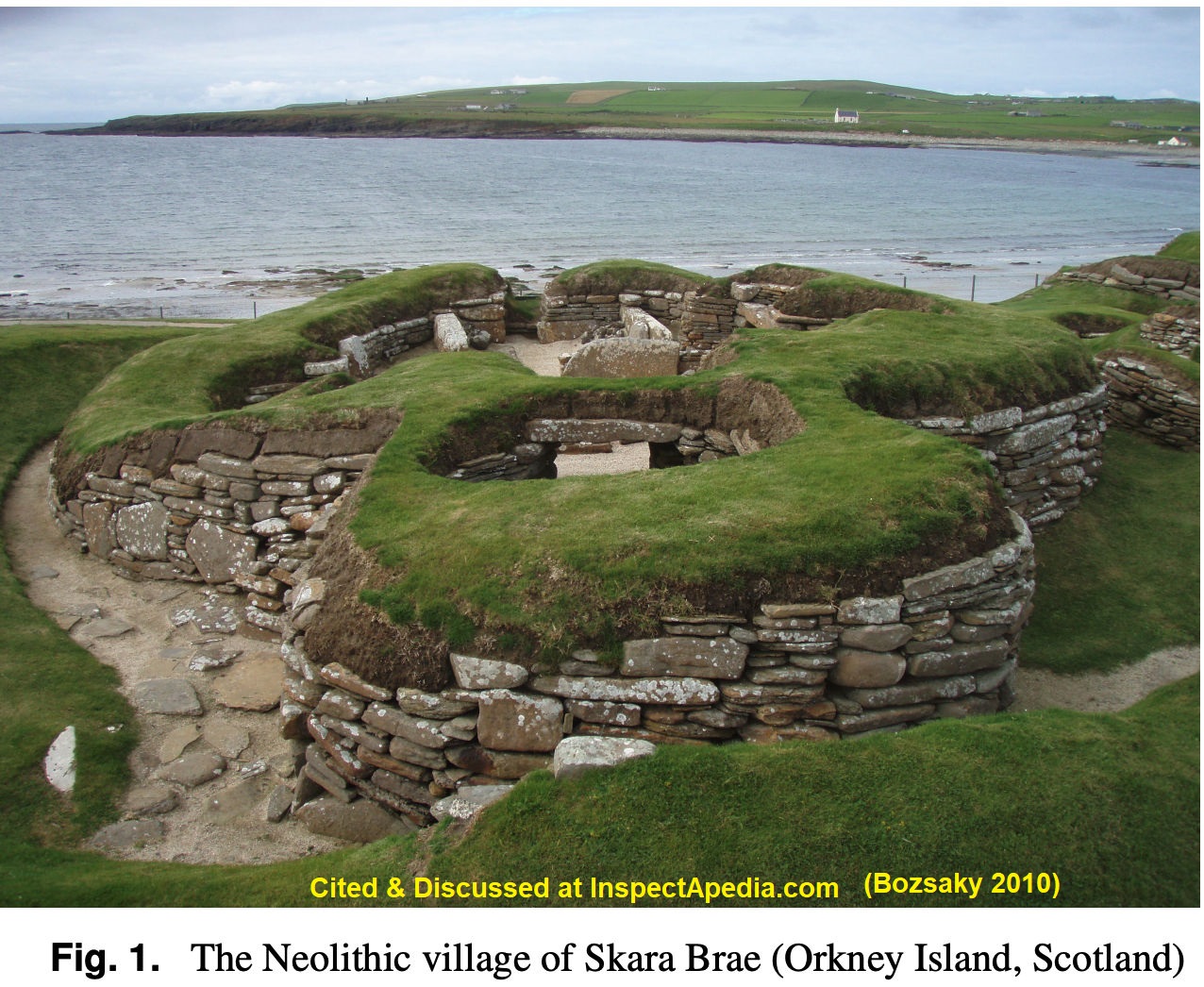

The earliest insulating materials used in the UK in prehistoric times were animal skins, fur, and wool, dating from about 2.5 million years ago to around 7000 BC. Between that era and about 1870 AD people were less nomadic and insulated their homes with earth, wood, bricks, straw, eelgrass, and reed.

The first uses of flax, cork, wood wool (plant fibres like that shown above - Ed.) and flax plates or cellulose insulation began around 1870 and continued to about 1950 when the first "artificial" insulation materials were produced (asbestos, mineral wool or rock wool, fiberglass and other materials. (Bozsaky 2010).

Cavity wall insulation, replacing tapestries hung on walls as an earlier form of "insulation" in the UK became more-widely-used beginning in the 1970s and has been compulsory for all new UK buildings since the 1990s.

More about corrugated roof/wall buildings is

and

at STEEL & IRON BUILDING SIDING where we add more observations about this building.

Insulation History & Resources in / for Scotland

- Bozsaky, Dávid. THE HISTORICAL DEVELOPMENT OF THERMAL INSULATION MATERIALS [PDF] (2010) Periodica Polytechnica Architecture 41(2), pp. 49–56. https://doi.org/10.3311/pp.ar.2010-2.02

Abstract excerpts:

The history of thermal insulation materials is not as long as that of other materials, but the necessity of insulation is as old as building activity.

Prehistoric people built shelters to protect themselves from the elements, originally using organic materials and later more durable substitutes.

However people used not only materials that were found in nature, but discovered others which were suitable for insulating.

Processing organic materials produced the first insulated panels in the 19th century: meanwhile an increasing range of artificial materials were developed (rock wool, fibreglass, foam glass, hollow bricks, expanded perlite). The appearance of plastic foams caused a huge revolution.

Although plastic production was well-known in the 19th century, the first plastic foam was not produced until 1941. ...

Excerpt:

The houses in the Neolithic village of Skara Brae (Orkney Island, Scotland) are the oldest known – nearly 5.000 years old – earth-sheltered, green roofed dwellings in the world (Fig. 1) above - Ed. .

- Castele, Daniel S., and Amanda L. Webb. "Insulating the Walls of Historic Buildings." APT Bulletin: The Journal of Preservation Technology 50, no. 1 (2019): 37-44.

- Harper Macleod, LLOP The History of Asbestos in Scotland and the evolution of asbestos law: https://www.harpermacleod.co.uk/insights/the-history-of-asbestos-in-scotland/

- Historic Environment: Scotland, Arainnechd Eachdraidheil, Alba: Insulate Your Property: Advice given at https://www.historicenvironment.scot/advice-and-support/your-property/saving-energy-in-traditional-buildings/insulate-your-property/

- Scottish Borders Councill Tel: 01835 824000 or see https://www.scotborders.gov.uk/info/20016/have_your_say/607/contact_us

Don't Confuse Jute Insulation with Asbestos Nor Other Materials

An inspectApedia reader asked us:

We live in the UK in a block of flats. The building of the house was completed in 1997/98 before asbestos was completely banned in the UK in 1999.

I was wondering if any of the insulation used on the flues could include any asbestos? I am attaching 3 pictures.

Thank you! On 2022-06-06 by Andrew

Reply by InspectApedia-911 (mod) - Properties of Jute Pipe Insulation in the UK - mixed with other fibres?

@Andrew,

@Andrew,

With a dissemblance that nowhere nearly matches the level of ducking and weaving in U.S. politics today, I note that I'm inspecting your insulation through the pinhole of a few photos - nowhere nearly as accurate as on-site or from a sample in our forensic laboratory.

But to me from your photos the material does not look like fiberglass or mineral wool.

PLEASE take a look at our insulation identification discussion, description, and photos found in the INSULATION IDENTIFICATION GUIDE - home - given in the list of Recommended Articles on this page.

There you can make additional visual comparisons.

Fiberglass and mineral wool don't look like plant fibres in colour, translucency, nor smoothness of the fibres.

--

I can't say what someone might possibly do or not about mixing insulation products but we don't normally find Jute mixed with asbestos nor fiberglass in simple jute insulating wraps for pipes.

Doing so flies in the face of the reasons given for the production of that insulation in the first place.

BUT a more fact-based answer can be found by a judicious search of patent disclosures and technical articles.

In fact at least for some advanced materials, Jute fibres are indeed mixed with other types of fibres including fiberglass and basalt fibres.

Those are not, of course, asbestos products, nor would you be likely to find them in simple jute or hemp insulating pipe wraps used on plumbing.

For example see

- K Arun Prasath and B Radha Krishnan, MECHANICAL PROPERTIES OF WOVEN FABRICBASALT/JUTE FIBRE REINFORCED POLYMERHYBRID COMPOSITES [PDF] Int. J. Mech. Eng. & Rob. Res. 2013, ISSN 2278 – 0149 www.ijmerr.com Vol. 2, No. 4, October 2013 - LIVE LINK to this PDF is given above on this page in the list of references.

About your insulation worry: I would not lose a nanosecond's of sleep worrying about an environmental hazard from a bit of jute insulation that fell into a ceiling cavity.

But I would ask and investigate why it fell off: is there a moisture problem or rodent problem that raises other concerns? Is there a freeze risk concern? Is there an energy cost concern?

Followup by Andrew

@InspectApedia-911,

Thank you very much for your answer – It’s really helpful! It seems as some kind of fibre indeed.

Thank you very much for your answer – It’s really helpful! It seems as some kind of fibre indeed.

If you don’t mind I would have a few more questions:

1. Based on the pictures do you think we can exclude mineral wool/rock wool and/or fibreglass, too?

2. Could the insulation on the pictures be some kind of a fibre combined with mineral wool or fibreglass?

3. It seems fibre-particles of the insulation came off and there are under the pipes – do you think it is problematic if these particles fall down from the concealed ceiling into our apartment (through the inspection hatches)?

(I have sent 3 pictures previously but I am not sure you have received the 3rd one so I attach only that one again)

Thank you again!

Andrew

[Photos shown above and below - Ed.]

Answer by InspectApedia-911 (mod) - wood fibre-like insulation on pipes does not resemble asbestos

@Andrew,

That's not asbestos insulation - it looks like jute (hemp-flax insulation) or a similar fibre.

Illustrated below are batts of hemp flax thermo-hemp insulation as distributed in the UK by https://www.ecologicalbuildingsystems.com/ described by the vendor as "Manufactured using discarded cocoa and coffee bean bags."

See details and compare your insulation with

HEMP / JUTE INSULATION https://inspectapedia.com/insulation/Jute-Insulation.php

and let me know what you think.

This Q&A discussion were posted originally

Closure by Andrew

@InspectApedia-911, Thank you for your thorough answer! Much appreciated for taking the time - it is really helpful.

...

Continue reading at HESSIAN or JUTE PIPE INSULATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BALSAM WOOL BATT INSULATION - older, traditional batts, paper enclosed shredded wood insulation -

- HEMP / JUTE INSULATION

- FIBER & HAIR IDENTIFICATION

- INSULATION CHOICES & PROPERTIES

- INSULATION IDENTIFICATION GUIDE - home

- INSULATION INSPECTION & IMPROVEMENT

- INSULATION R-VALUES & PROPERTIES

- SEAWEED INSULATION is shown just above.

- SHEATHING, FIBERBOARD - home - fiberboard panels used as nailbase and insulating sheathing

- SHEEPS WOOL INSULATION

- WOOD FIBRE INSULATING PANELS

Suggested citation for this web page

HEMP / JUTE INSULATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.