Insulated & Self-Insulated Concrete Blocks

Insulated & Self-Insulated Concrete Blocks

Use EPS Styrofoam or other insulating material in concrete block construction

- POST a QUESTION or COMMENT about this article topic

This article describes the types of insulation methods used to insulate otherwise hollow concrete blocks or concrete masonry units CMUs to produce a higher R-value concrete block wall, floor, or roof.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Concrete Block Insulation Methods

Concrete block walls are most-often insulated by the addition of foam board placed on the outside of the wall in new construction, or on the inside of walls in an insulation retrofit job.

However some builders may construct a concrete block wall adding foam or loose fill foam beads in the hollow spaces afforded by the concrete blocks, or by using pre-fabricated concrete blocks that are sold with a foam insulation core.

Examples of these products are given below.

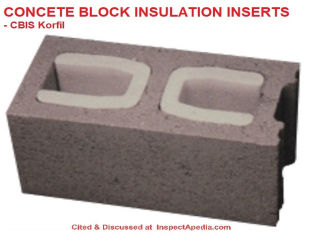

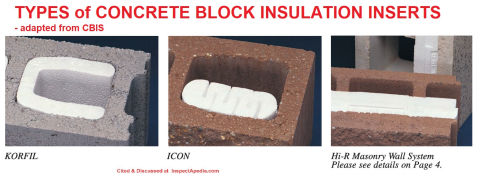

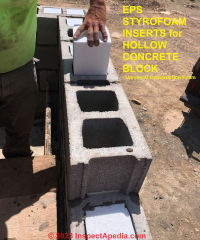

Below: concrete block foam core inserts: styrofoam inserts to add insulating value to concrete block walls are sold in a variety of forms, as you can see in the illustration that we adapted from CBIS Korfil, cited in detail below.

Notice that the "insert" approach to insulated concrete block wall construction leaves a hollow core center that can provide drainage.

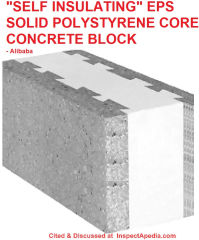

Other forms of self-insulating concrete block may be factory-made with a solid polystyrene core - shown just below (alibaba.com) or a hollow concete block wall or floor assembly may be insulated with pumped-in foam.

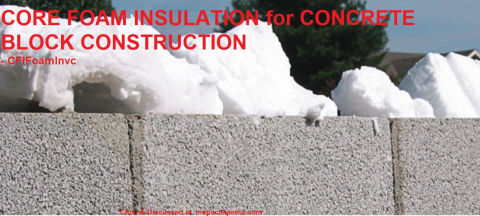

Below: foam insulation installed in a concete block wall, from CFIFoam, cited in detail below.

This foam is injected into the block wall during construction.

Watch out: in at least some installations, filling the core of a concrete block foundation wall with foam can raise concerns about trapped moisture and mold. These questions are addressed by CFIFoam's documents cited below.

- CFIFoam CORE FOAM MASONRY FOAM INSULATION SPECIFICATIONS (for new concrete block wall construction) [PDF] CFI Foam, Inc., Injection Foam Products Co., P.O. Box 10393, Knoxville, TN 37939 USA, Tel: 865.588.4465 Email: info@cfifoam.com - retrieved 2023/09/07, original source: Product-Info-Submittal.2Page.2021.pdf

- CFIFoam CORE FOAM MASONRY FOAM INSULATION WYTHE CAVITY FILL [PDF] CFI Foam, Inc., Injection Foam Products Co., - retrieved 2023/09/07, original source: cfifoam.com/wp-content/uploads/CoreFoamWytheCavityFillMasonryInsulation.pdf

Excerpt:

Completely filling the cavity of double wythe masonry walls with foam insulation runs counter to conventional wisdom among some architects. However, some foam insulation contractors have successfully installed foam in this manner with success since 1978. The information below is intended to answer questions asked by cautious architects:

This document addresses architect's concerns about drainage, moisture, mold, and formaldehyde with foam core masonry block construction.

Excerpts: For new construction, cfiFOAM, Inc. recommends damp-proofing the backup CMU for added protection in case the wall’s drainage capacity becomes temporarily overwhelmed.

Though the cured foam creates a barrier, barriers like dams sometimes become temporarily overwhelmed.

For new construction, installing cavity width strips of 4-lb/ft3 mineral fiber drainage board at the base of cavities fully protects weep holes and further assures adequate drainage.

Amino-plast foam e.g. CORE FOAM Masonry Foam Insulation is auto-toxic meaning that it inherently resists microbial attack and fungal growth. In fact demonstrations have shown amino-plast foam to kill most molds on contact. - CFIFoam CORE FOAM MASONRY FOAM INSULATION (for new concrete block wall construction) [PDF] CFI Foam, Inc., Injection Foam Products Co.,

Website excerpts:

Core Foam Masonry Foam Insulation® is a “dry” resin foam-in-place insulation product designed for the cores of concrete block walls....

Core Foam Masonry Foam® is a Class 1/Class A fire rated product and meets or exceeds all testing requirements of current standard building codes.

Core Foam Masonry Foam Insulation® is typically used in commercial and institutional building new construction such as retail box stores, schools, and churches. It is also used in residential new construction applications such as concrete-block stucco walls, foundations, and basement walls. - CFI Foam FOAM CORE INSULATED CONCRETE BLOCK FIRE SAFETY [PDF] CFI Foam, Inc., Injection Foam Products Co., retrieved 2023/09/07, original source: cfifoam.com/wp-content/uploads/Phony-Noncombustible-Claim.pdf

Excerpt:

While in service, aminoplast masonry foam insulation is “life-of-structure” protected by the concrete elements of insulated concrete masonry wall assemblies.

Even so, building codes require quantifying what, if any, combustible content is contributed by all of wall assembly components. Building codes reference a single appropriate test method for foam plastic insulating materials by which this important information must be quantified: NFPA 259 [ASTMD5865].

NAVLAP accredited 3rd party testing demonstrates that Core Foam Masonry Foam Insulation by cfiFOAM, Inc. contributes less combustible content to concrete masonry wall assemblies than all others brand of aminoplast masonry foam insulation sold for installation in the US.

Testing per ASTM D5865 demonstrates that the Potential Heat of Core Foam Masonry Foam Insulation is < 80 Btu/lb. or ≈ 21 Btu/ft2 in 8” CMU walls, and ≈ 32 Btu/ft2 in 12” CMU walls. - CRIS, Core-Fill 500 FOAM INSULATION APPLICATIONS [PDF] (2013) Tailored Chemical Products Inc., PO Box 4186

Hickory, NC 28603

USA, Tel: (800) 627-1687

- retrieved 2023/09/07, original source: core-fill500.com/application.htm

Excerpt - illustrated above

Block Insulation - Core-Fill 500™ can be used to insulate concrete block, either by side or "pressure fill" or by top fill application. It provides the highest R-Values among all integral insulations systems, including perlite, vermiculite or "inserts". 6", 8", 10" or 12" CMU are easily insulated in both running or stacked bond wall systems.

The pressure fill application, the most common installation method, requires small holes to be drilled directly into the bed joints of the masonry wall.

Pressure filling generates a complete fill of the masonry cores, head joints and bed joints as the foam moves up and down the vertical core and horizontally through the head joints of the wall system.

- CRIS, Korfil PRE-INSULATED MASONRY PRODUCT CATALOG [PDF] CBIS - [illustrated above] Concrete Block Insulating Systems

P.O. Box 1000

Freight House Road

West Brookfield, MA 01585-1000 USA - retrieved 2023/09/07 original source: s3.amazonaws.com/nmrcdn/optimized/991/assets/responsive/567000/567372/Brochure.pdf

Excerpt:

Both KORFIL and ICON Inserts are individually molded from EPS. They are designed to fit standard 2-core masonry units of 6, 8, 10 and 12-inch widths.

The Hi-R Wall System is a specially designed concrete masonry unit and individually molded EPS insulation insert.

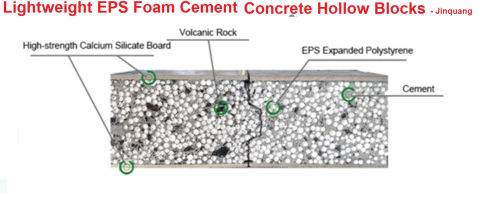

The assembly provides a wall system capable of achieving higher thermal R values than conventional masonry, with little effect on structural integrity - Jinquang Lightweight EPS FOAM CEMENT CONCRETE Hollow Blocks & Lightweight Insulating Concrete Panels - source: alibaba in 2023, produced by Golden Power Building Material Technology Co., Ltd. in Fujian, China and sold in the Phillipines and othe rlocations.

This is an "eps styrofoam sandwich board" using as raw material rock wool, cellulose fiber, quartz sand and portland cement.

Below is a cross-section view of these "hollow" concrete blocks made of lightweight cement from the same source.

- Universal, CMU Insulation Blocks, produced by Universal Construction Foam, Tel: 1-410-498-0000 Email: sales@universalfoam.com Web: universalconstructionfoam.com

Produces solid styrofoam (EPS) insulating blocks inserted into each block at the jobsite, during wall construction, are illustrated just below.

Website excerpt: The EPS blocks are inserted in the voids of the concrete block and provide a blended R-Value of R-13.53.

Other forms of insulated concrete block are blocks made of lightweight concrete.

See those "insulated concrete block" details

at CONCRETE INSULATION & ICF CONSTRUCTION

...

Continue reading at CONCRETE INSULATION & ICFs Insulated Concrete Form construction - what's the difference? , or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CONCRETE INSULATION & ICFs Insulated Concrete Form construction - what's the difference?

- CONCRETE INSULATION, LIGHT WEIGHT

- ENERGY SAVINGS RETROFIT OPTIONS - ultra lightweight concrete insulation, insulating forms for concrete foundations

- FOAM BOARD INSULATION TYPES

- HEAT LOSS in BUILDINGS - home

- INSULATION INSPECTION & IMPROVEMENT - home

- INSULATION LOCATION - WHERE TO PUT IT - home

- INSULATION R-VALUES & PROPERTIES

- STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs)

Suggested citation for this web page

CONCRETE BLOCK INSULATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.